Full-automatic fixed-length cable taking machine system

A fully automatic, cable machine technology, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as working distance limitations, troubles for producers, adverse productivity, etc., to reduce uncertainties and improve operational safety. , stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described in detail below with reference to the drawings.

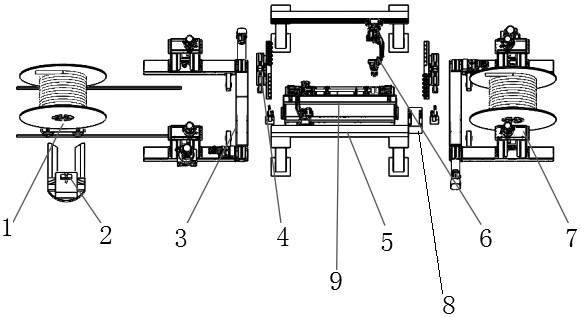

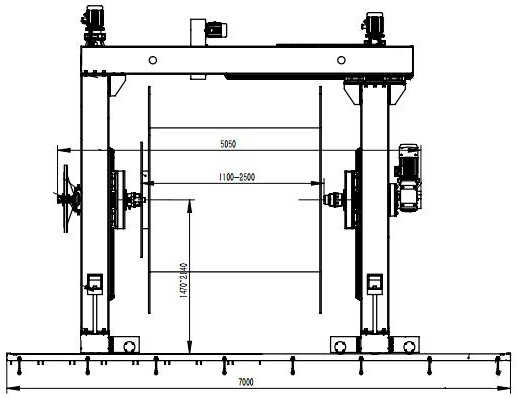

[0025] A fully automatic fixed length cable system, reference figure 1 , Including the tray train 1, the wiring gantry 3, the cutting device 8, the wireless gate 7, the cable 5, the cable 6, cable fixture 4; 1 Through the AGV Cart 2 Implement the automatic transfer of the cable disk, the line dragon gate 3 and the tailor gantry 7 for cable automatic looping line, cable mechanical arm 5, unpacking robot arm 6 and cable fixing device 4 pair The cable is automatically positioned and grabbed, and the truncation device 8 intercepts and samples the cable automatically, and the above components are uniformly controlled by the fixed length cable control system.

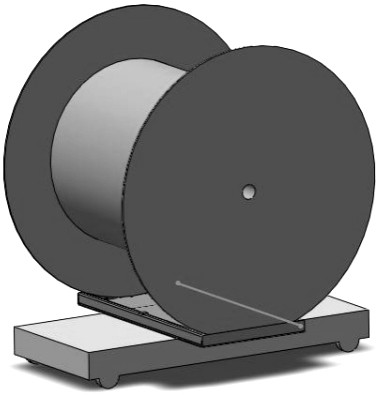

[0026] The pad trolley 1 is a track structure, including the AGV cell 2, a pad placement table, and a strip, where the strip is placed on the AGV cells 2, and the AGV cells are moved on the set track...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com