Iron sheet rolling groove winding drum machine

A reeling machine and groove-pressing technology, applied in the direction of heat exchange equipment, etc., can solve problems such as uneven manual force, waste of time, and reduced work efficiency, and achieve the effects of saving labor, ensuring overall quality, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

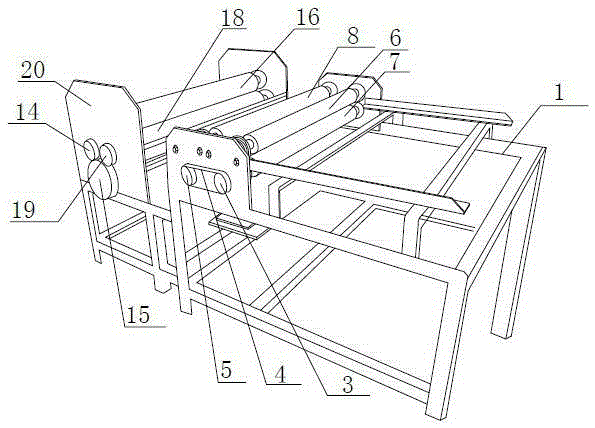

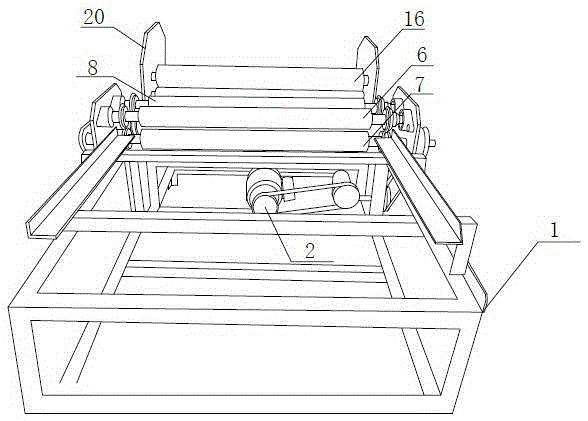

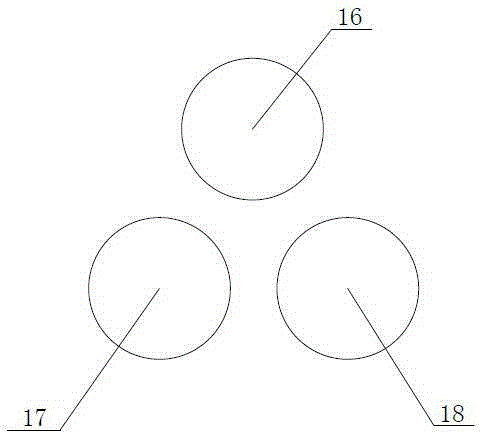

[0018] An iron sheet grooving reel machine, characterized in that it includes a frame 1, a plate feeding mechanism, a grooving mechanism, a reel mechanism and a mechanical transmission mechanism, and the plate feeding mechanism includes an active plate feeding roller 7 and a passive plate feeding pressure roller 7. Roller 6; described groove mechanism comprises pressure groove upper pressure roller 8 and pressure groove lower pressure roller 9, and the both sides of pressure groove upper pressure roller 8 are respectively provided with a pressure groove upper pressure roller 10, and pressure groove lower pressure roller 9 Both sides are respectively provided with a pressure groove lower pressure wheel 11, the pressure groove upper pressure wheel 10 is a convex mode wheel, and the described pressure groove lower pressure wheel 11 is an annular groove wheel, and the convex mode wheel and the annular groove wheel match; The reel mechanism includes the reel upper pressure roller 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com