Automatic stamping equipment for chain safety production

A technology for safe production and stamping equipment, applied in metal processing equipment, perforating tools, manufacturing tools, etc., can solve the problems of inability to automatically feed materials, low punching efficiency, etc., to reduce time, improve work efficiency, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] An automatic stamping equipment for chain safety production, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 7 As shown, it includes an underframe 1, a working plate 2, a punching mechanism 3 and a feeding mechanism 4. The top of the underframe 1 is provided with a working plate 2, the middle part of the working plate 2 is provided with a punching mechanism 3, and the right part of the working plate 2 is provided with a punching mechanism 3. There is a feeding mechanism 4.

[0076] When people are making chains, they cannot quickly punch steel plates. The present invention helps people complete the production of chains at a faster speed. In the hole mechanism 3, start the punch mechanism 3, and the punch mechanism 3 punches the steel plate. During the process, the left part of the steel plate is pulled and pulled to the left to make the discharge mechanism 4 discharge until all the steel coils are punched. Just close the punching mechanism 3, and re...

Embodiment 2

[0078] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 , Figure 6 and Figure 9 As shown, the punching mechanism 3 includes a positioning frame 31, a motor 32, a special-shaped cam 33, a connecting frame 34, a pressure hole plate 35, a first return spring 36 and a worktable 37, and the middle part of the upper side of the working plate 2 is provided with a positioning frame 31 A motor 32 is installed in the middle part of the lower side of the working plate 2, and the output shafts on the front and rear sides of the motor 32 are provided with a special-shaped cam 33, and the top of the positioning frame 31 is slidably provided with a connecting frame 34, and the connecting frame 34 cooperates with the special-shaped cam 33 to connect The top of the frame 34 is provided with a pressure orifice plate 35, the upper part of the connection frame 34 is wound with four first return springs 36, the first return springs 36 are connected with the positioning fram...

Embodiment 3

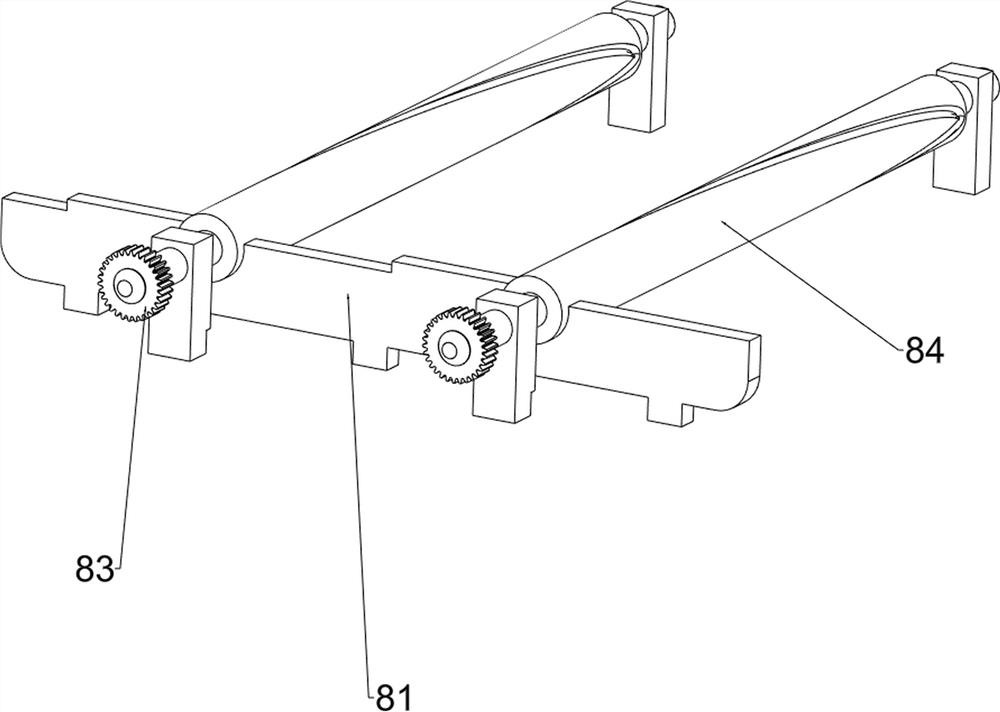

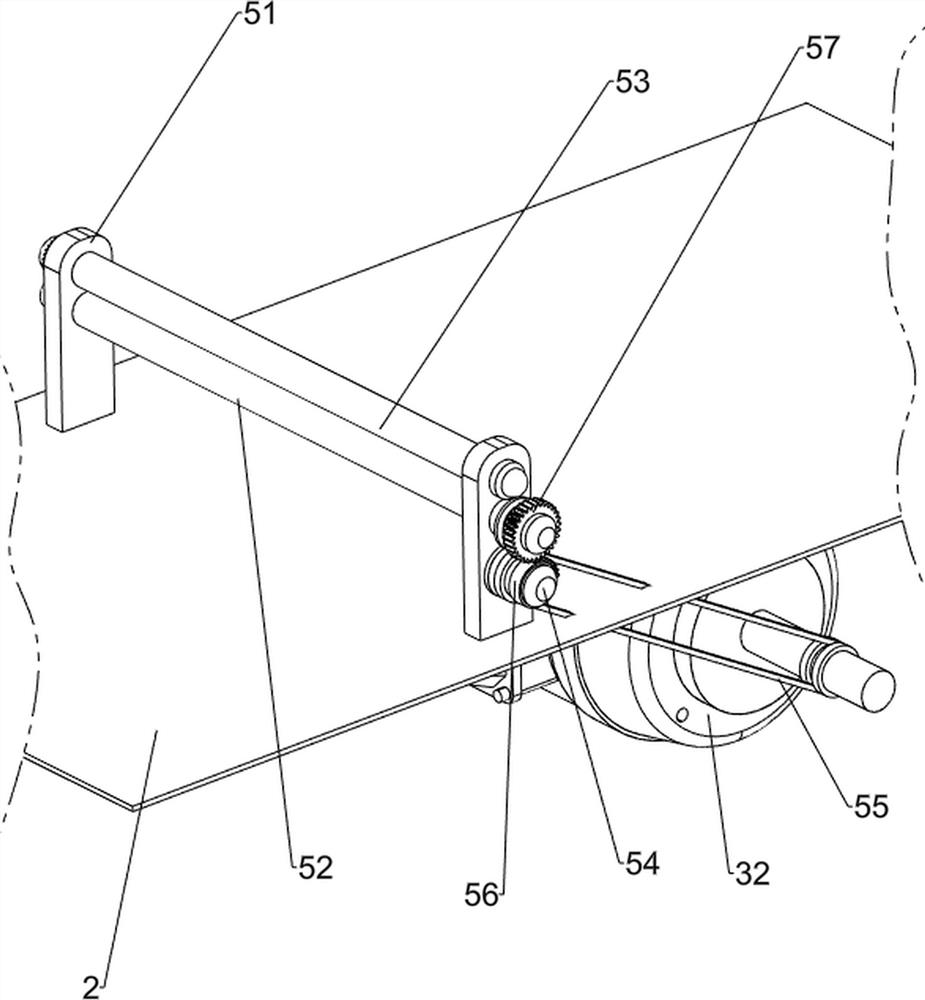

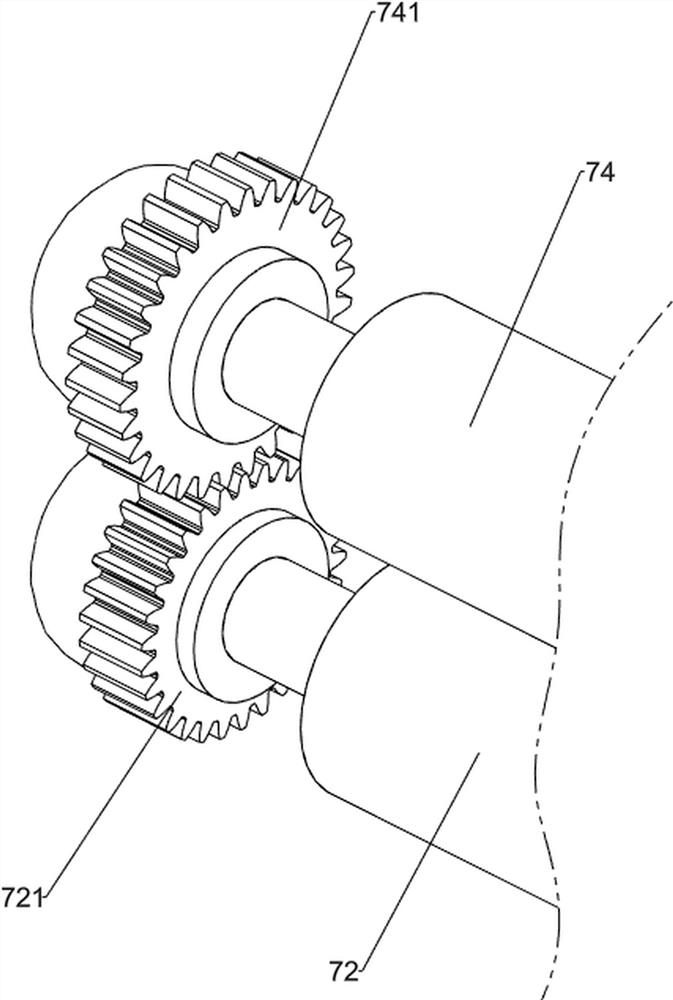

[0083] On the basis of Example 2, such as figure 1 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, a main pulling mechanism 5 is also included. The middle part of the working plate 2 is provided with a main pulling mechanism 5. The main pulling mechanism 5 is connected with the punching mechanism 3. The main pulling mechanism 5 includes a second column 51, a first roller 52, The first master gear 521, the second roller 53, the first slave gear 531, the transmission shaft 54, the first pulley assembly 55, the half gear 56 and the first full gear 57, and two second columns 51 are arranged in the middle of the working plate 2 , the inner side of the middle part of the second column 51 is provided with the first roller 52, the front part of the first roller 52 is provided with the first main gear 521, and the inner side of the second column 51 is provided with the second roller 53, the second The front part of the roller 53 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com