Automatic turnover camera

A technology of automatic flipping and camera, applied in image communication, equipment, television, etc., can solve the problems of increasing product cost, not being able to realize self-portraits, and shooting effects that cannot satisfy people, and achieve the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

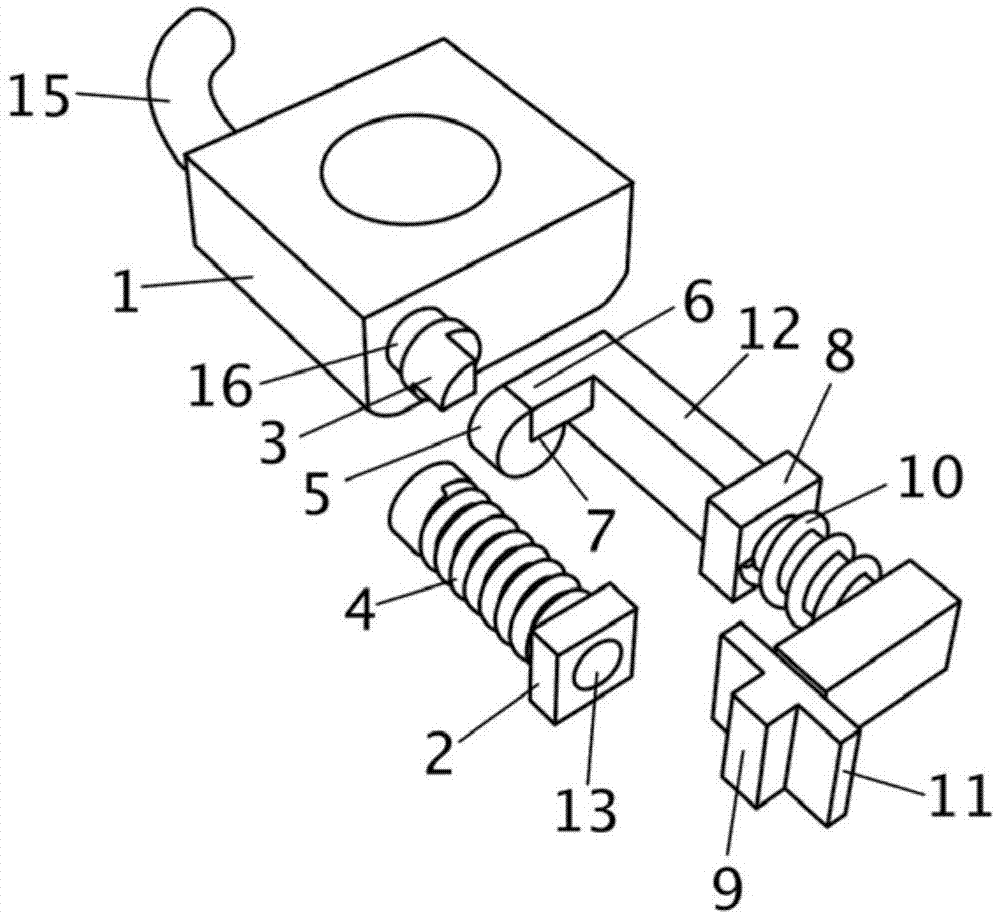

[0031] The automatic flip camera provided in this embodiment is as follows: figure 1 , Figure 6 to Figure 8 as shown in:

[0032] One side of the camera body 1 is connected to the first mounting end 2, the first mounting end 2 is provided with a through hole and fixedly connected with the mobile terminal device, the first mounting end 2 is provided with a connecting column 13, and one end of the connecting column 13 passes through the through hole Rotately connected with the first installation end 2, the other end of the connecting column 13 is fixedly connected with the limit block 5, the connecting piece 3, the rotating column 16, and the camera body 1 in sequence. The limit block 5 is provided with a limit groove 7, and the connecting column 13 is sleeved with a torsion spring 4, one end of the torsion spring 4 is fixed on the first installation end 2, and the other end is fixed on the connecting column 13. When the camera body 1 is not locked by the locking module, the...

Embodiment 2

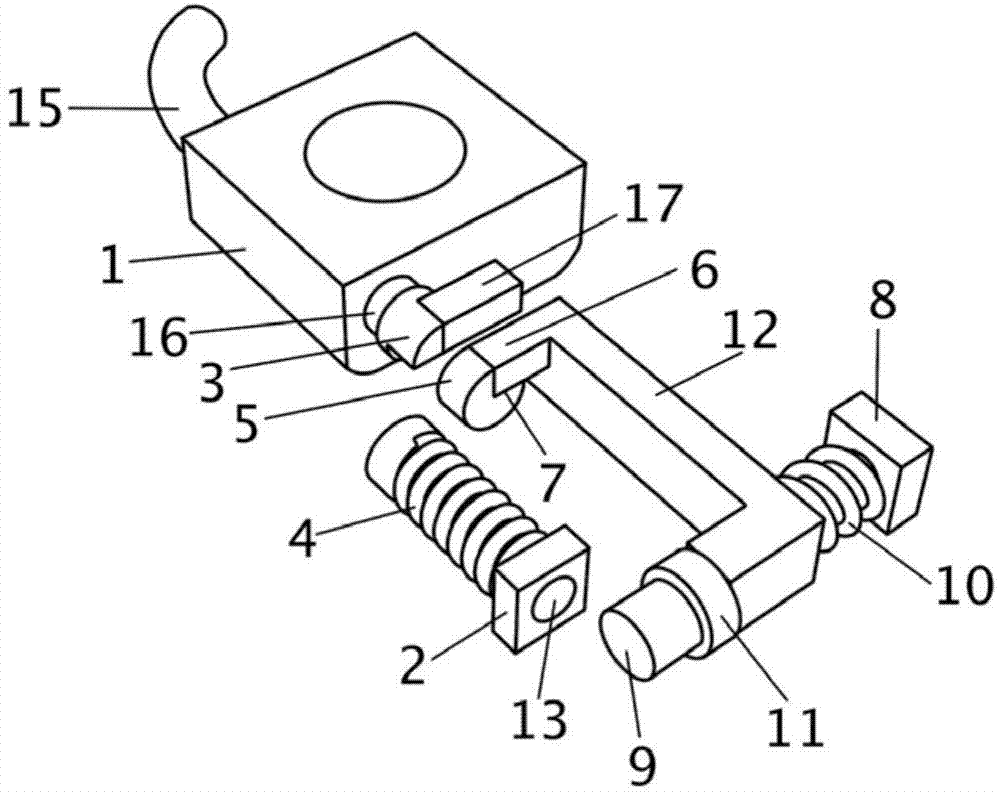

[0043] The automatic flip camera provided in this embodiment is as follows: figure 2 as shown in:

[0044] The structure of the automatic flip camera in this embodiment is similar to that of Embodiment 1, the only difference is that the movement direction of the limit post 6 of the locking module is perpendicular to the flip axis of the camera body 1, and the spring 10 connects the connecting rod 12 with the second Mounting end 8, the operating block 9 of this embodiment is a button type, and a brake block 17 is set in the mobile terminal device. The brake block 17 is rectangular, and its shape is similar to the limit post 6. When the camera body 1 is not overturned, A vertical end surface of the brake block 17 is aligned with the vertical surface of the connector 3 , and its bottom surface is at the same level as the bottom surface of the connector 3 .

[0045] By pressing the operation block 9, the limit column 6 can be driven out of the limit groove 7 via the connecting r...

Embodiment 3

[0049] The automatic flip camera provided in this embodiment is as follows: image 3 as shown in:

[0050] The structure of the automatic flip camera in this embodiment is similar to that of Embodiment 1, the difference is that the connecting column 13 is fixedly connected with the camera body 1 with respect to the rotating column 16 on the other side of the fixed connecting piece 3 and the limit block 5, and The rotating column 16 and the connecting column 13 fixedly connected to the connecting column 13 are provided with lines, and the two ends of the line are respectively connected to the main line of the camera and the flexible line 15 connected to a terminal equipment. Connect with the connecting column 13 in the same manner as in Embodiment 1; the integral structure of the limiting column 6 and the connecting rod 12 is L-shaped, and similarly, the second installation end 8 is directly sleeved on the connecting rod 12, close to the operating block 9 position, a spring 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com