Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68results about How to "Accurate rotation positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

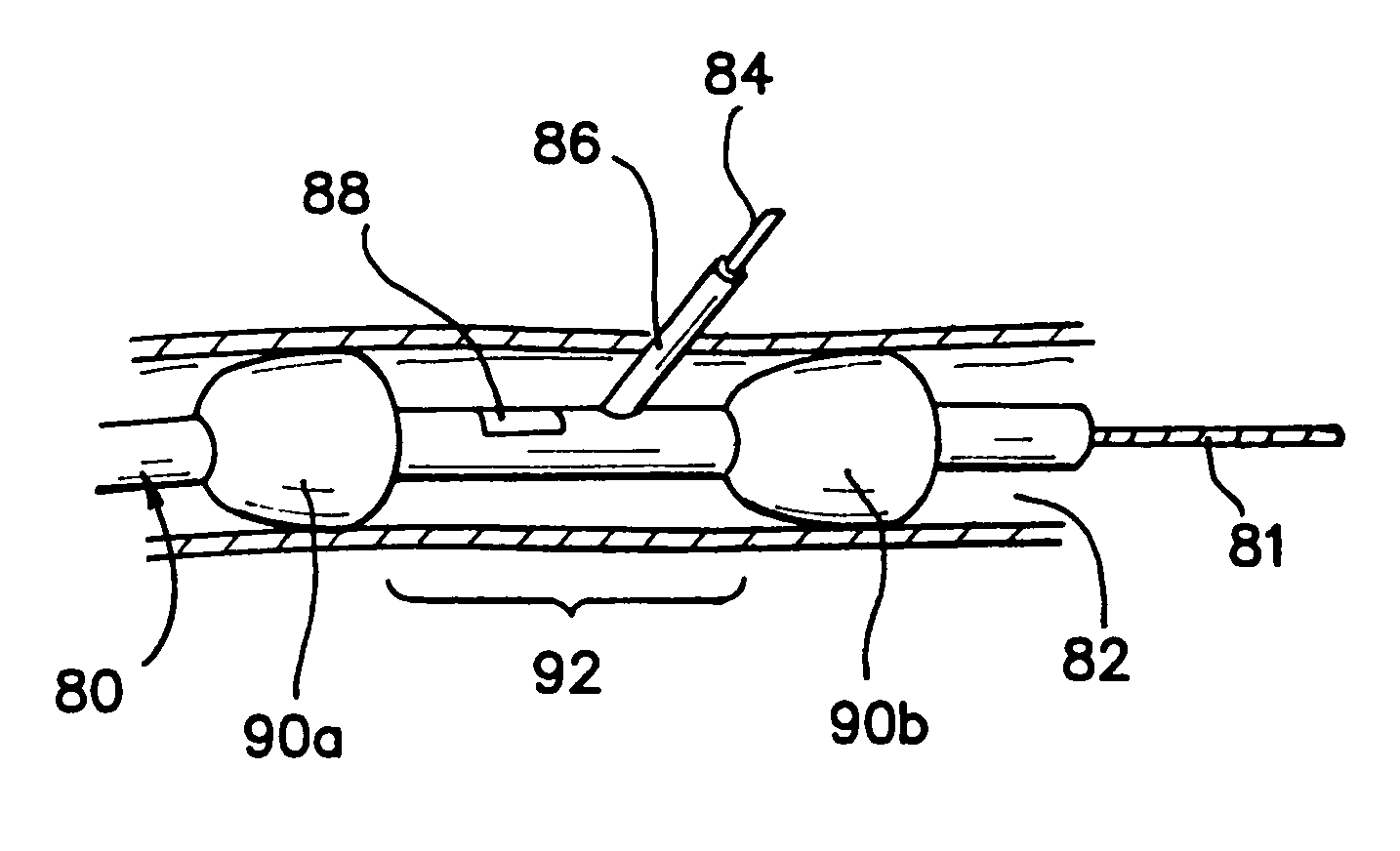

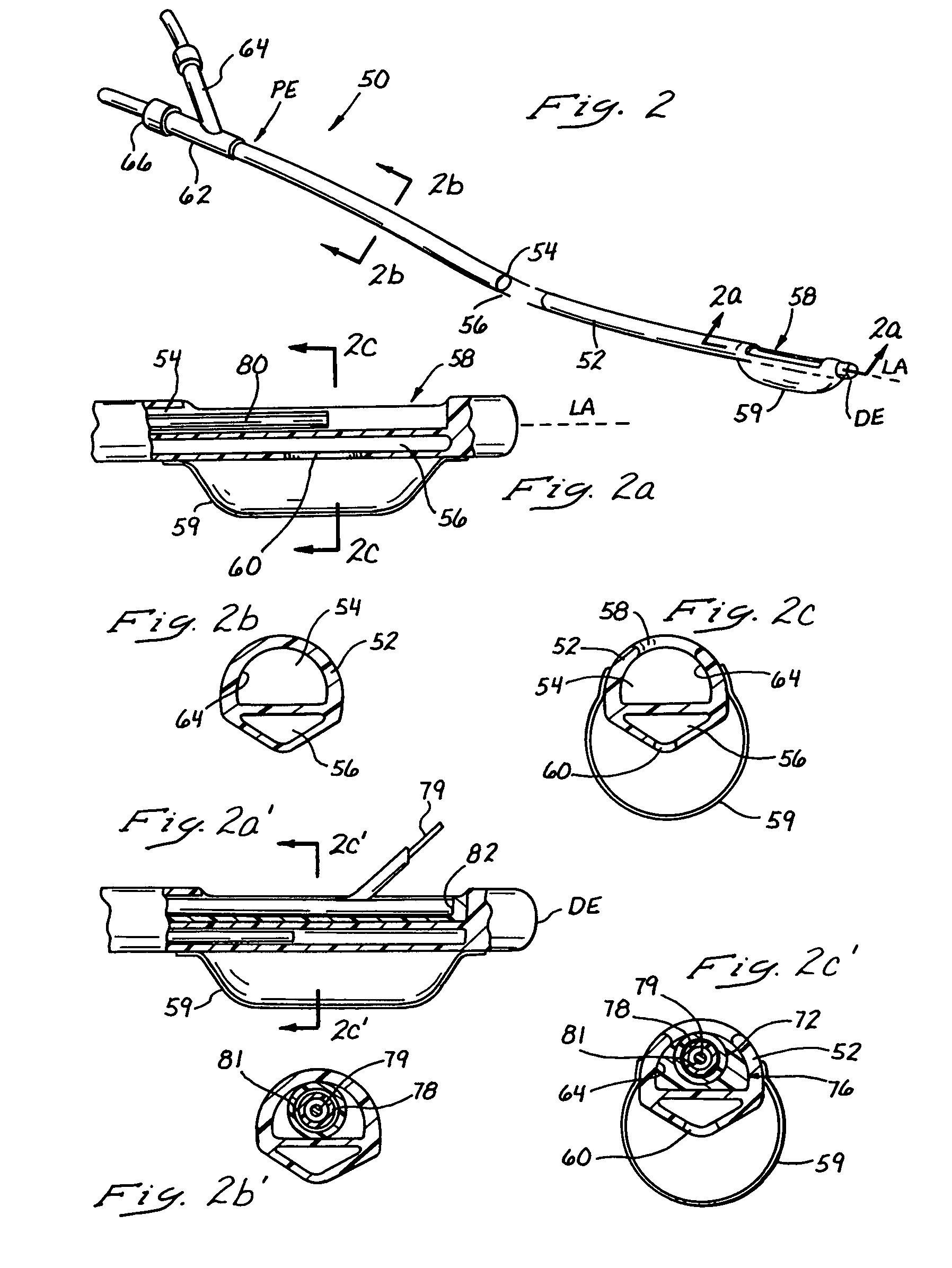

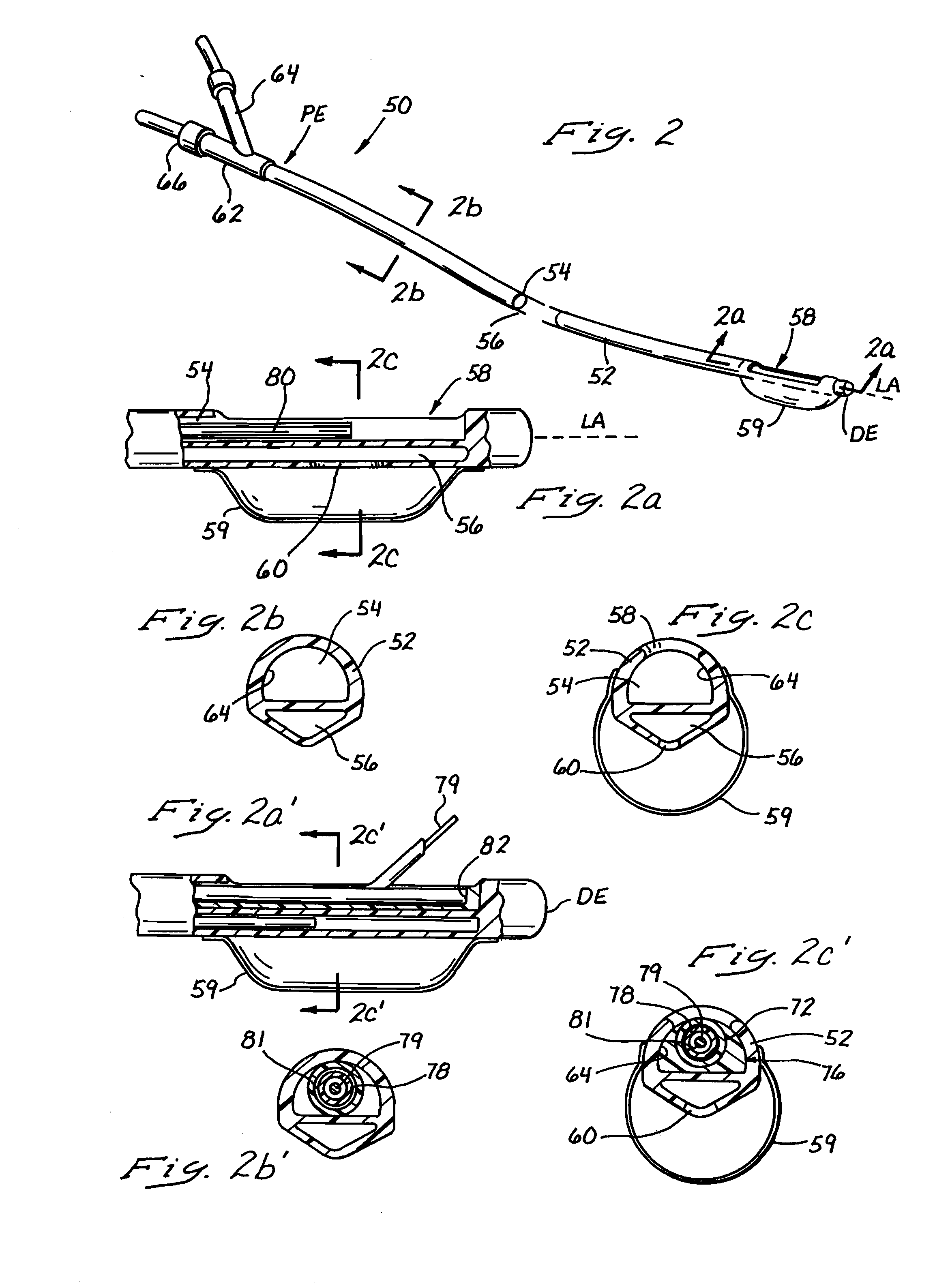

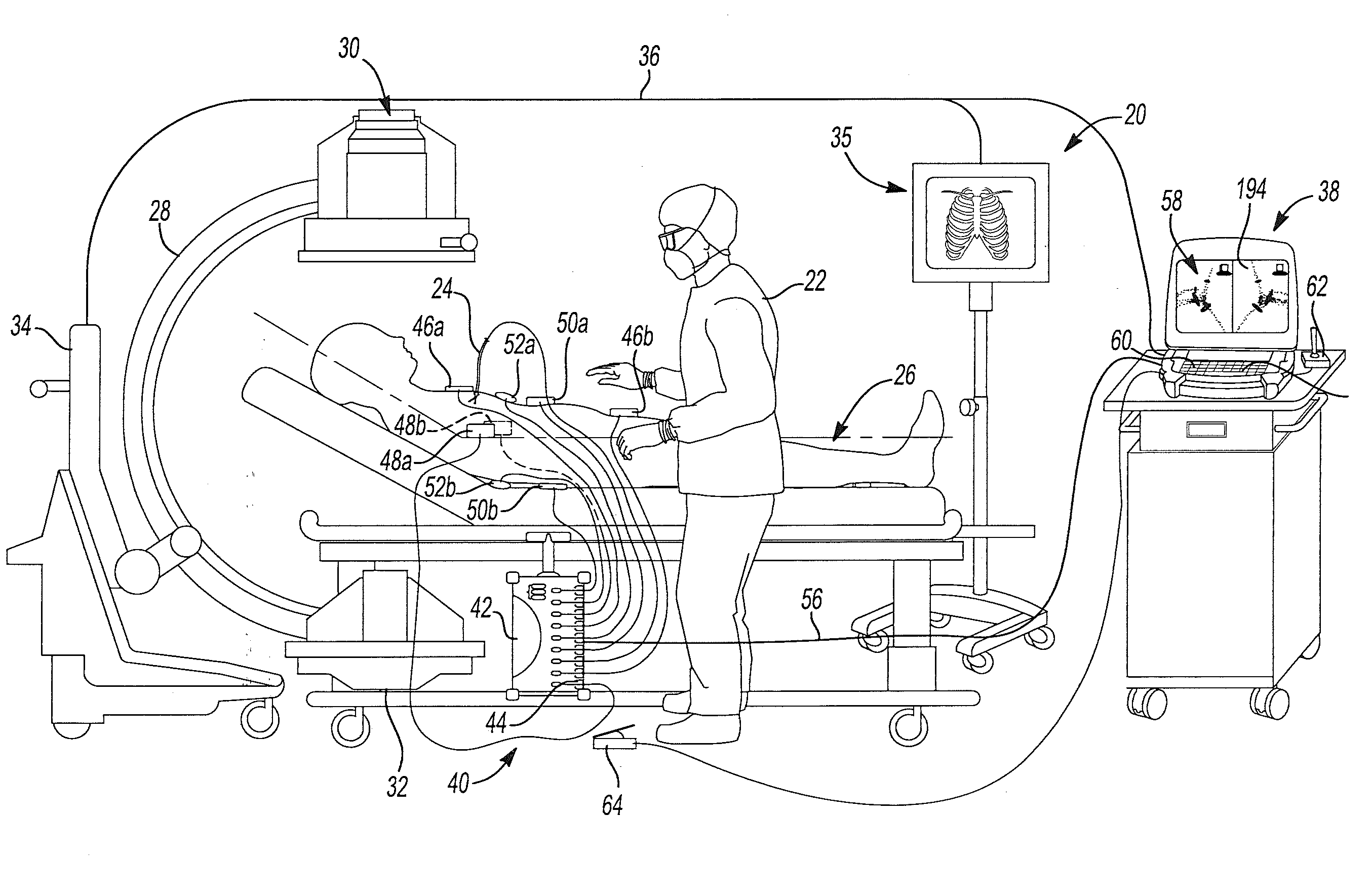

Stabilized tissue penetrating catheters

InactiveUS7729738B2Accurate and reliable positioningAccurately penetratedUltrasonic/sonic/infrasonic diagnosticsOrganic active ingredientsCoronary Revascularization ProcedureCoronary revascularization

A tissue penetrating catheter that is usable to advance a tissue penetrator from within a blood vessel, through the wall of the blood vessel to a target location. The catheter includes at least one stabilizing device thereon for stabilizing catheter prior to advancing the tissue penetrator. The tissue penetrator may extend through a lumen in the body of the catheter and project transversely through an exit port. The stabilizing device may be located closely adjacent to the exit port, or may surround the exit port. The stabilizing device may be one or more balloons, or other mechanical structure that is expandable into contact with the inner luminal wall of the blood vessel. Desirably, the exit port is forced into contact with the blood vessel wall to shorten the distance that the tissue penetrator projects from the catheter body to the target location. The catheter is particular useful for forming blood flow tracts between blood vessels, in particular in coronary revascularization procedures. Methods of utilizing such a catheter to bypass an arterial obstruction is also disclosed.

Owner:MEDTRONIC VASCULAR INC

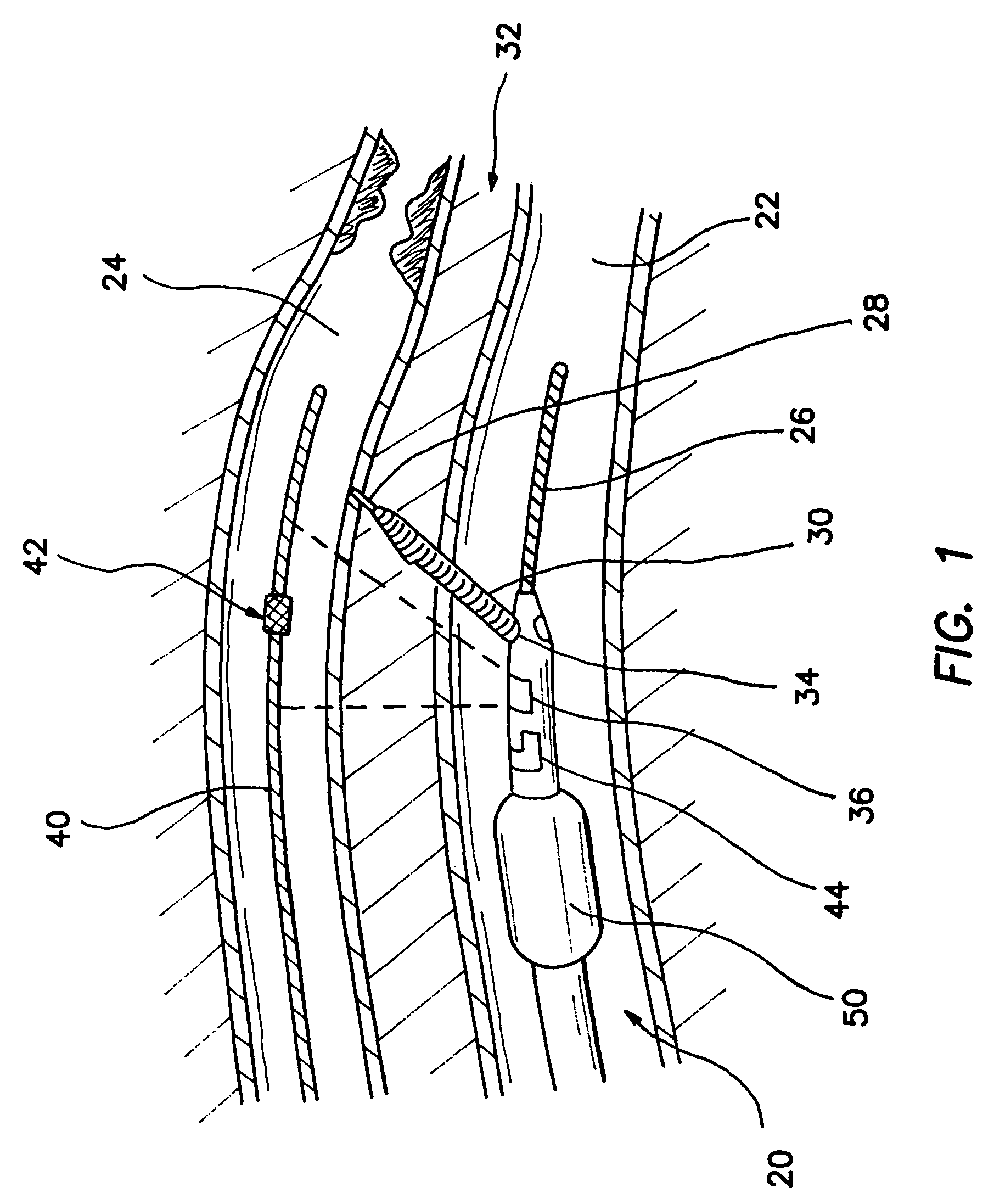

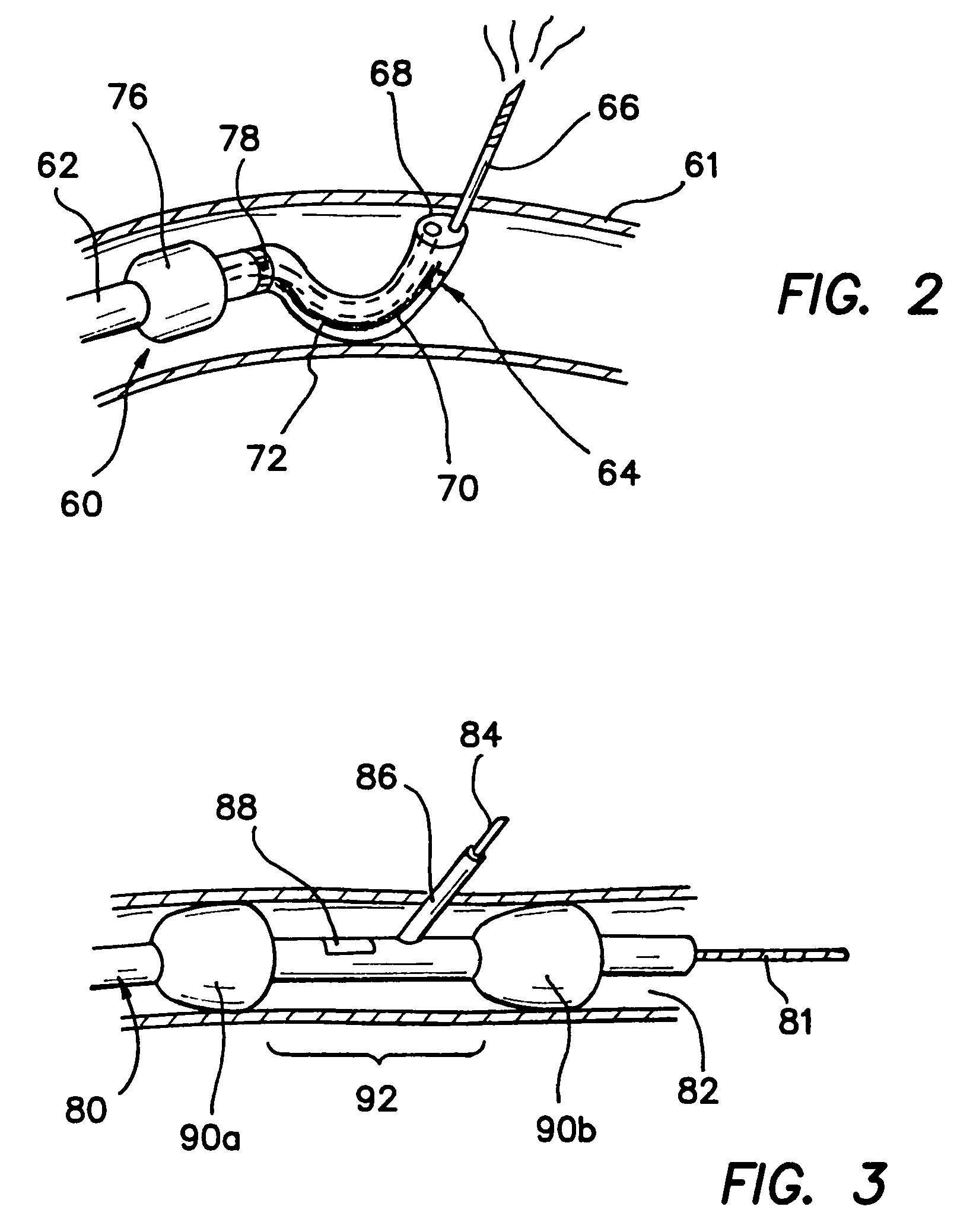

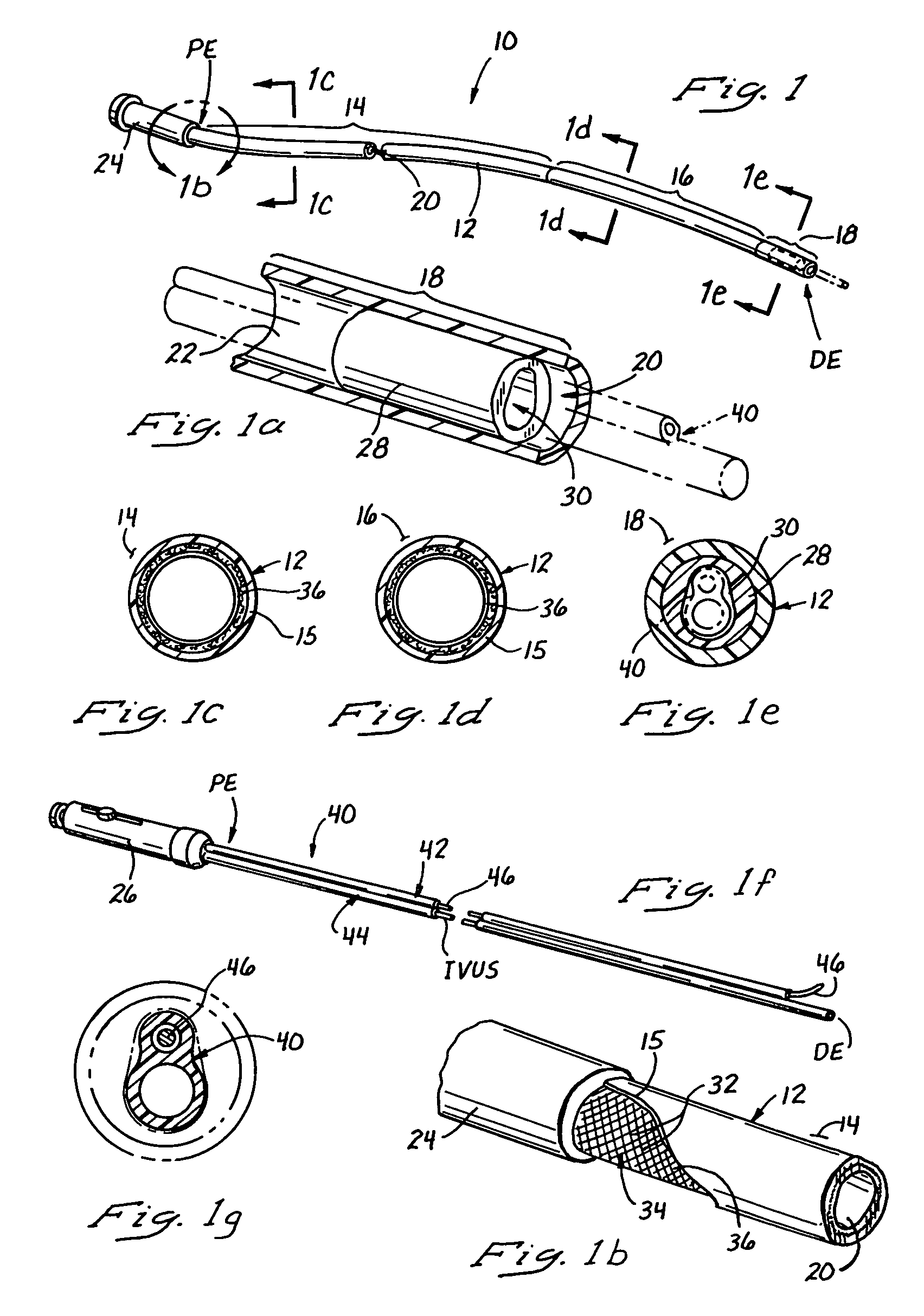

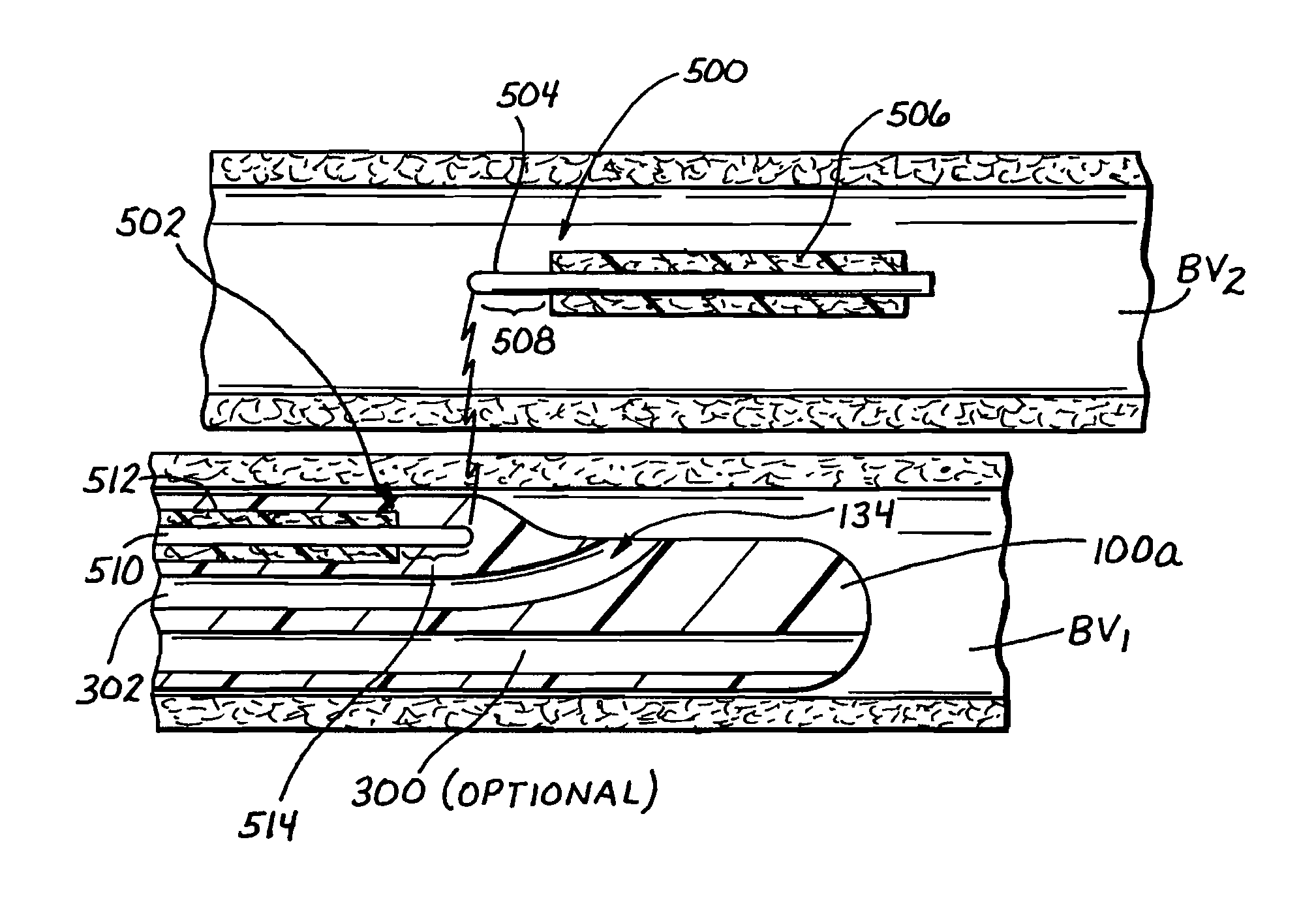

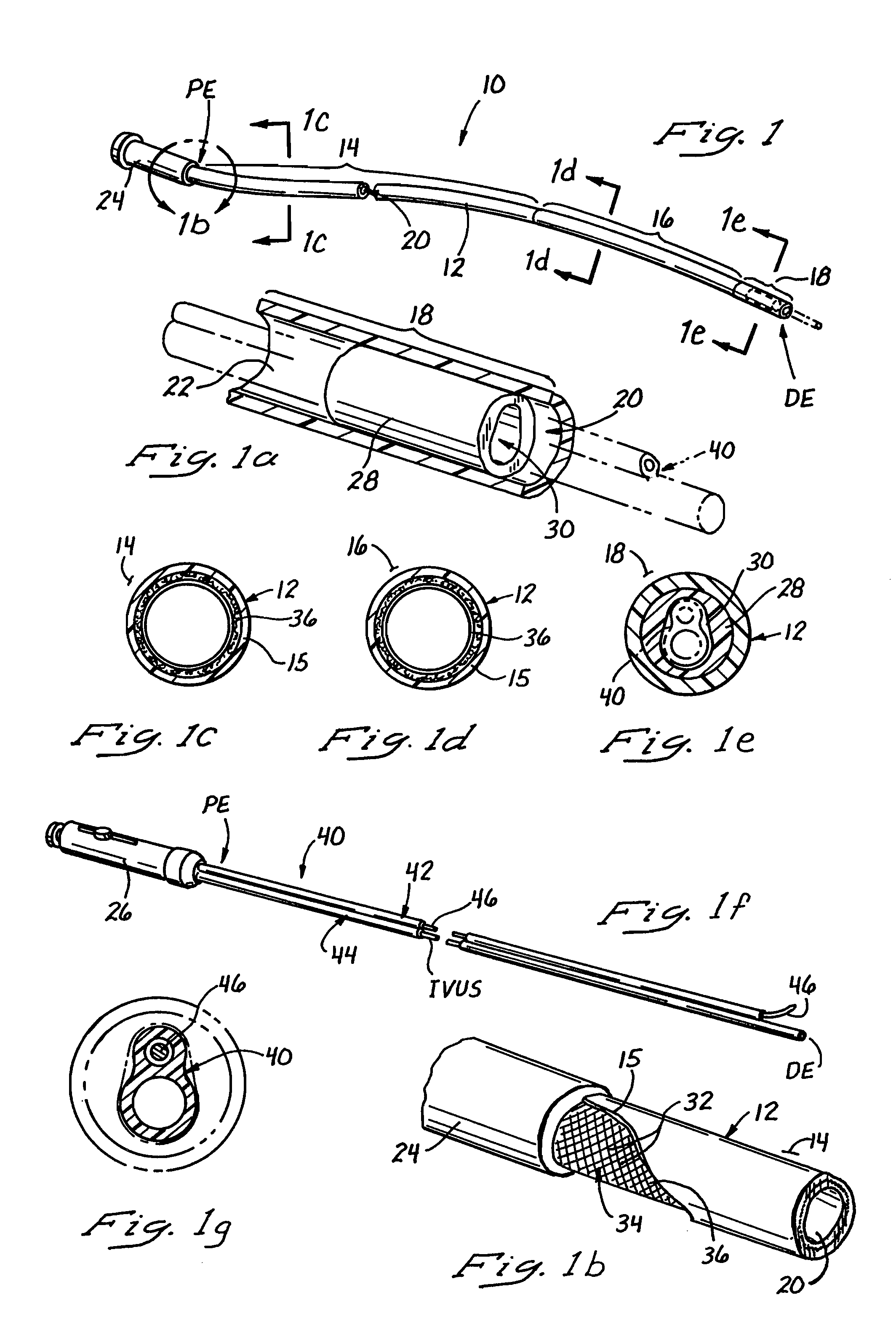

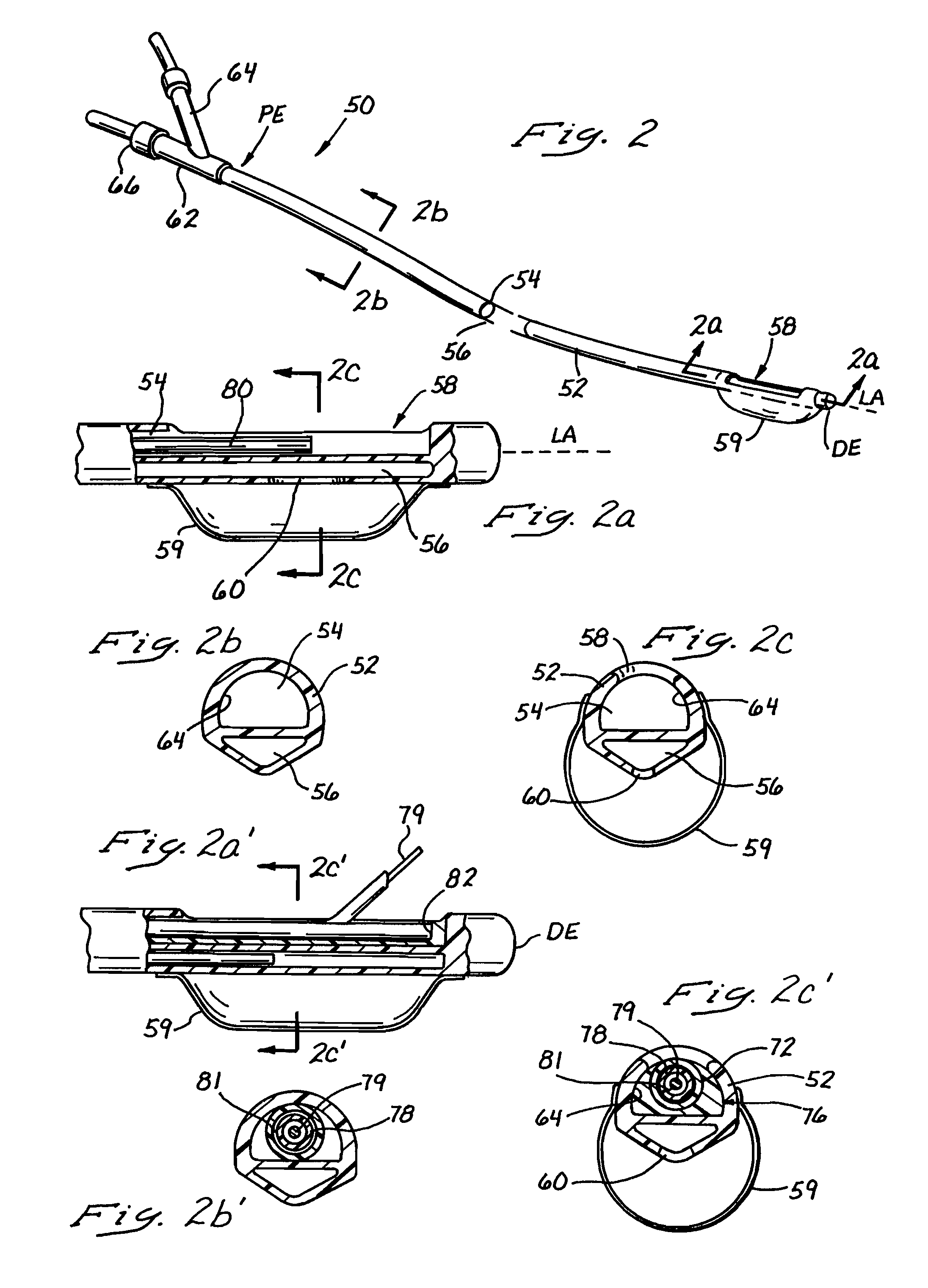

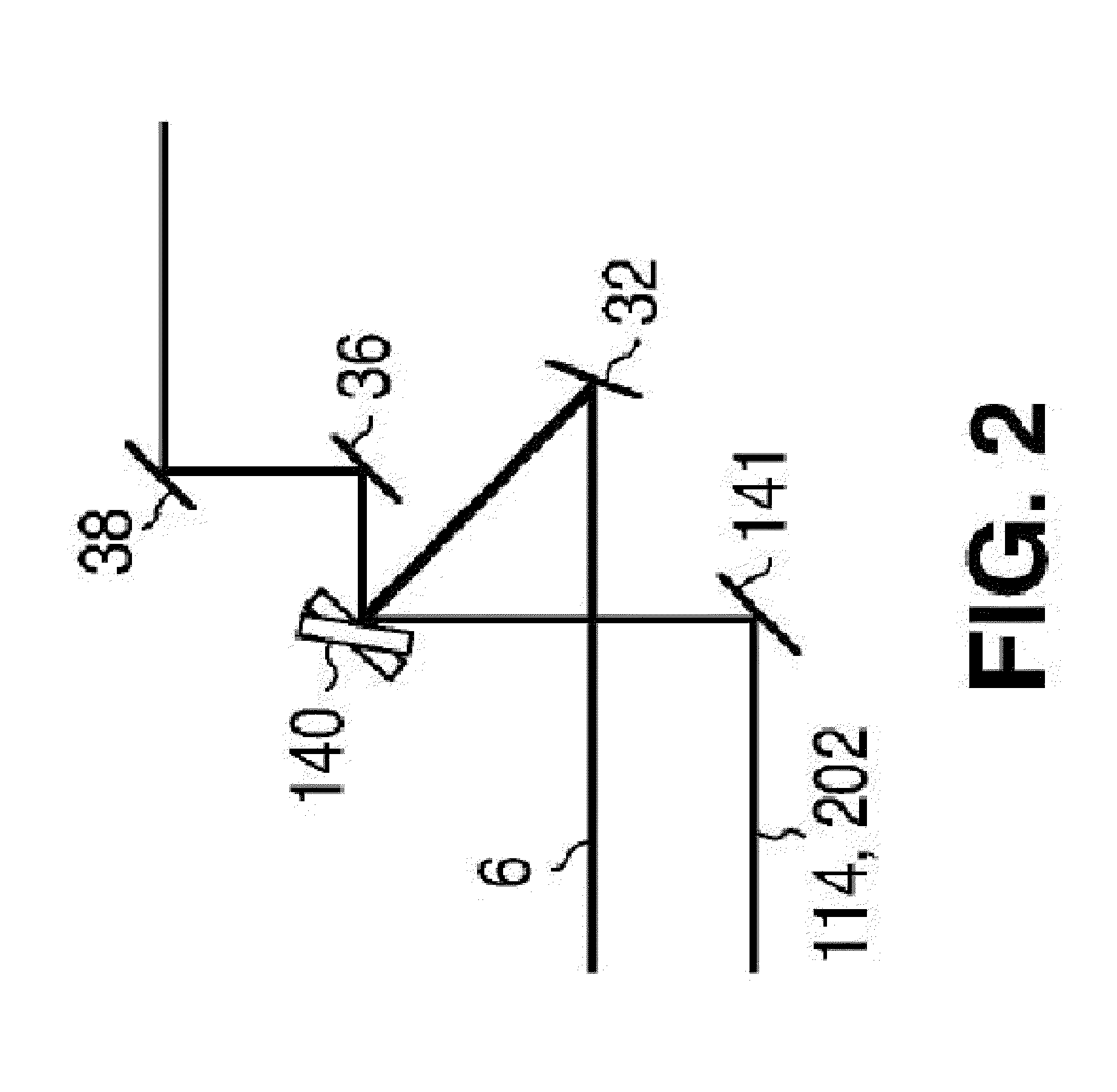

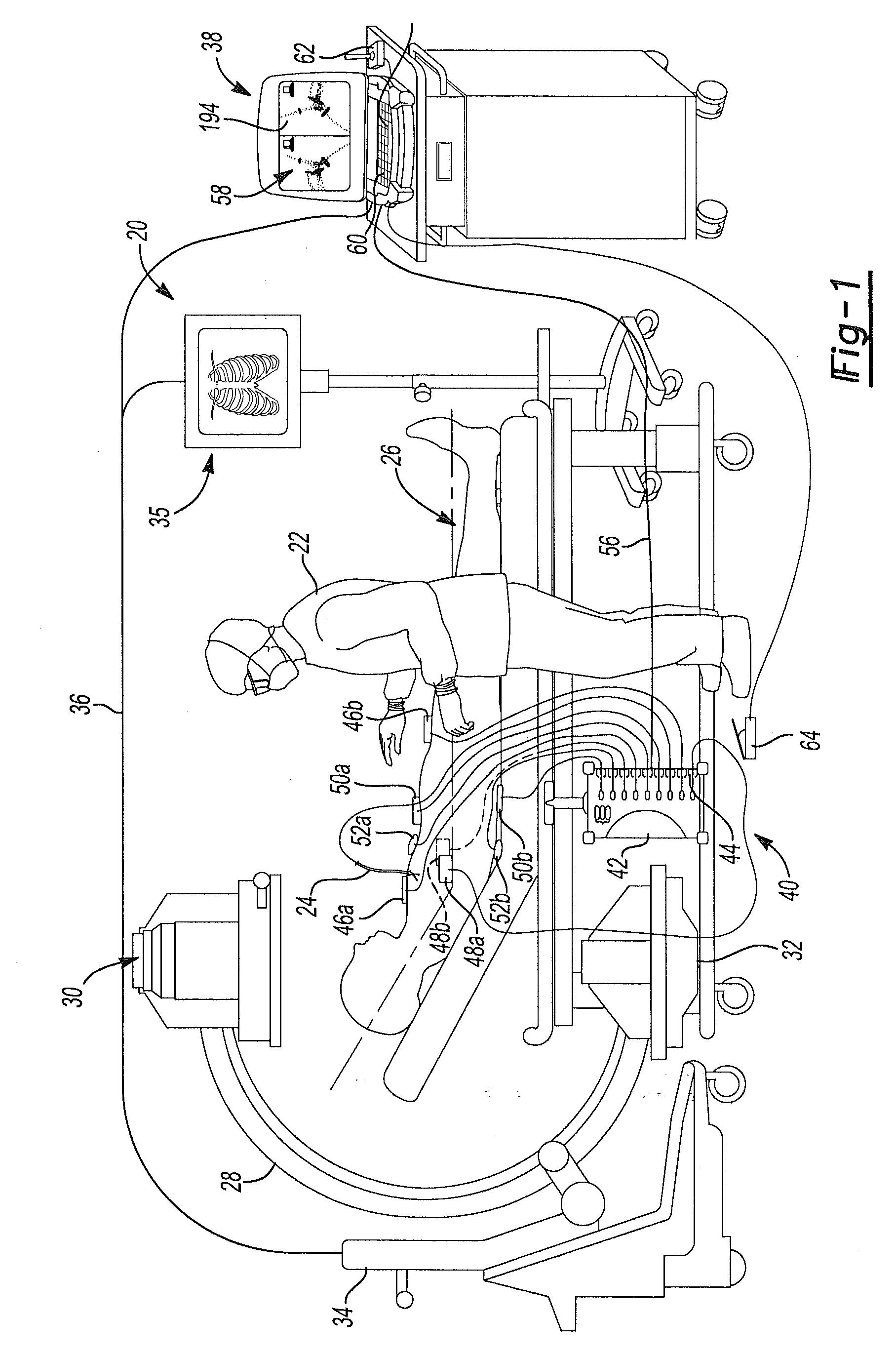

Catheters and related devices for forming passageways between blood vessels or other anatomical structures

InactiveUS7648517B2Precise rotation controlPrecise positioningUltrasonic/sonic/infrasonic diagnosticsCannulasAnatomical structuresDistal portion

The inventions described in this patent application include i) a torqueable introducer sheath which is useable in conjunction with a transvascular passageway forming catheter to effect precise rotational control of the catheter; ii) an anchorable guide catheter which is useable in conjunction with an intravascular imaging catheter and a transvascular passageway-forming catheter to effect precise positioning and aiming of the passageway-forming catheter; iii) a passageway forming catheter having a torqueable proximal portion to facilitate precise rotational positioning of the distal portion of the catheter; iv) a deflectable-tipped passageway forming catheter, v) various markers and other apparatus useable in conjunction with any of the passageway-forming catheters to facilitate precise positioning and aiming of the catheter, and vi) an apparatus which may be formed within a catheter to prevent a member, apparatus of flow of material from being inadvertently advanced through a lumen of the catheter.

Owner:MEDTRONIC VASCULAR INC

Catheters and related devices for forming passageways between blood vessels or other anatomical structures

InactiveUS8753366B2Precise rotation controlPrecise positioningUltrasonic/sonic/infrasonic diagnosticsCannulasAnatomical structuresDistal portion

The inventions described in this patent application include i) a torqueable introducer sheath which is useable in conjunction with a transvascular passageway forming catheter to effect precise rotational control of the catheter; ii) an anchorable guide catheter which is useable in conjunction with an intravascular imaging catheter and a transvascular passageway-forming catheter to effect precise positioning and aiming of the passageway-forming catheter; iii) a passageway forming catheter having a torqueable proximal portion to facilitate precise rotational positioning of the distal portion of the catheter; iv) a deflectable-tipped passageway forming catheter, v) various markers and other apparatus useable in conjunction with any of the passageway-forming catheters to facilitate precise positioning and aiming of the catheter, and vi) an apparatus which may be formed within a catheter to prevent a member, apparatus of flow of material from being inadvertently advanced through a lumen of the catheter.

Owner:MEDTRONIC VASCULAR INC

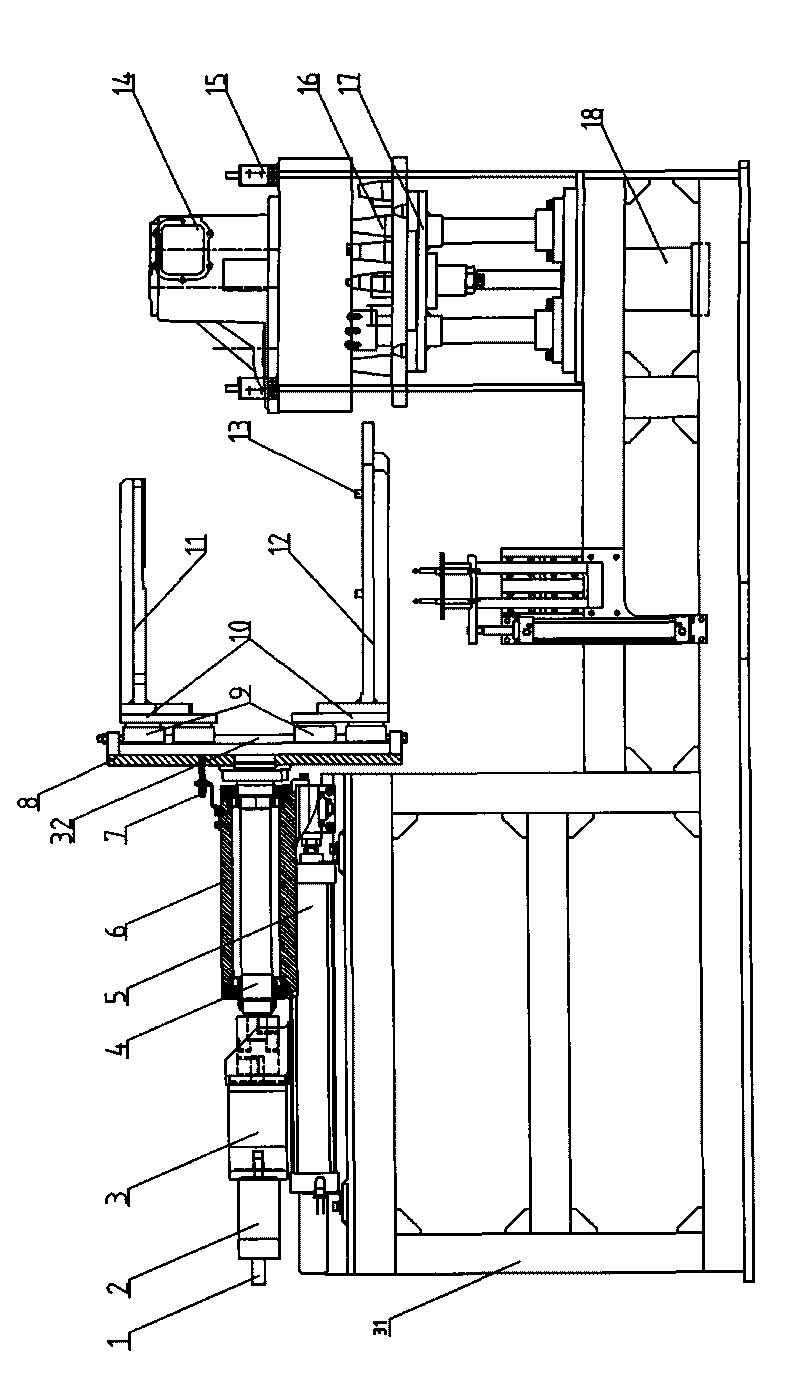

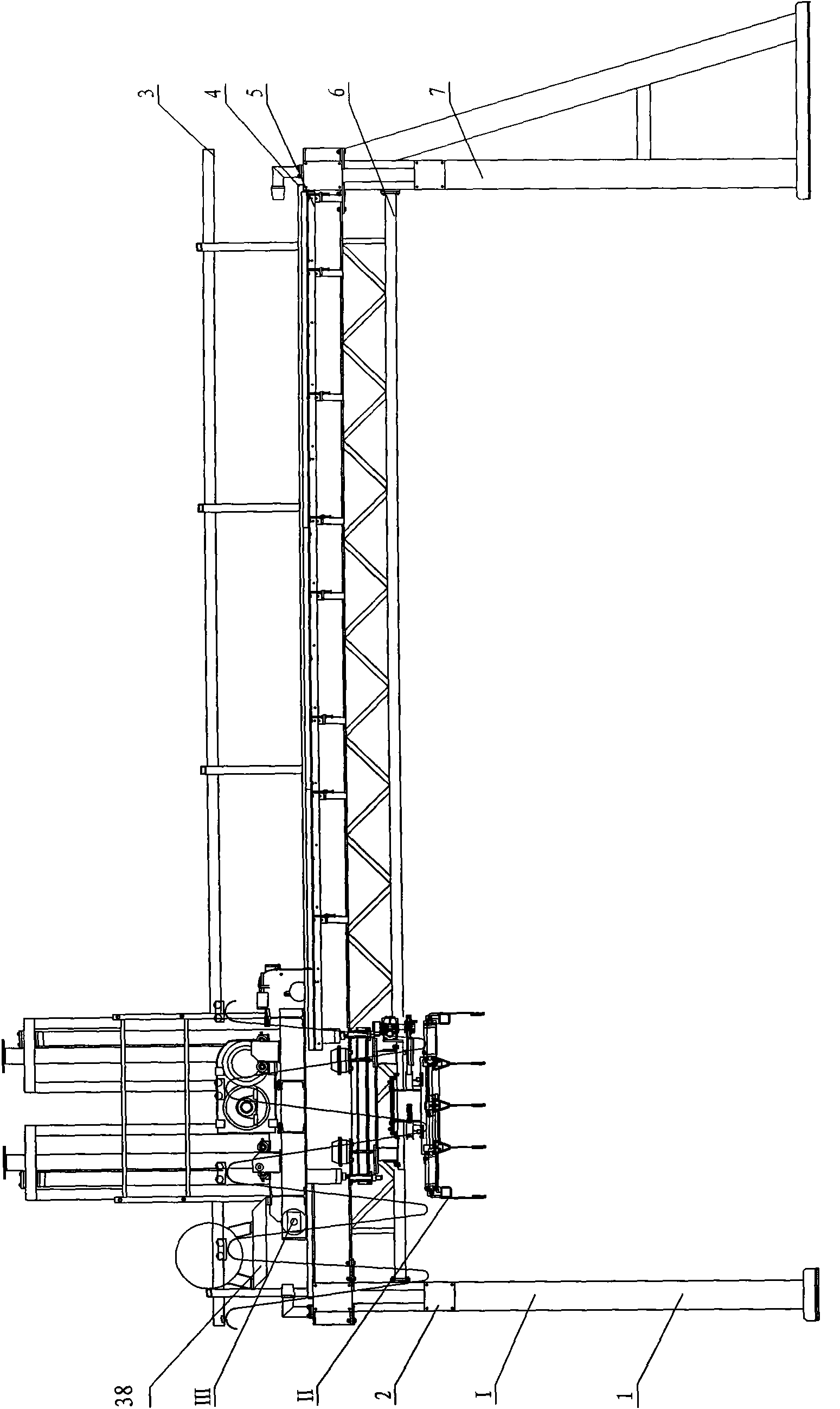

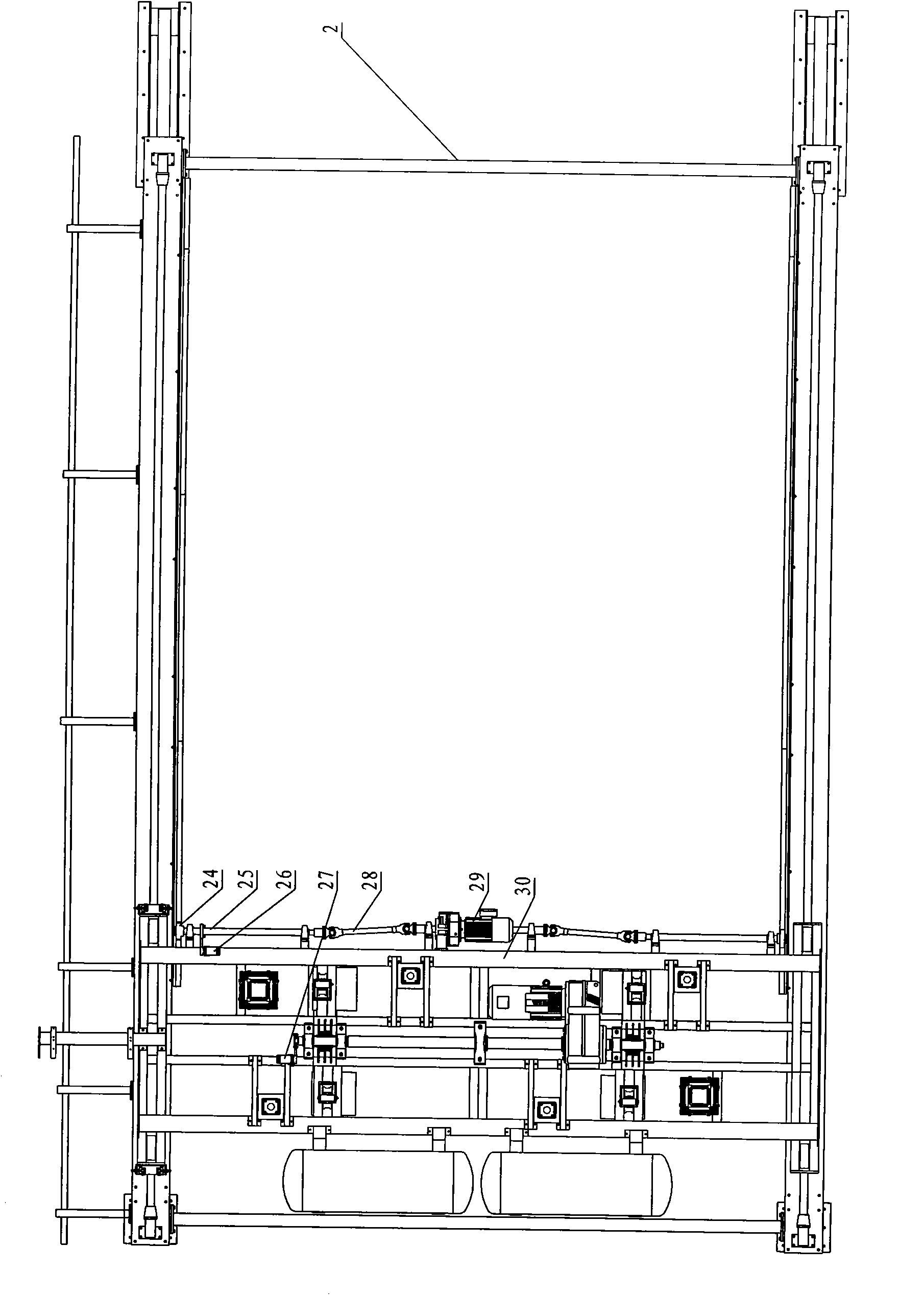

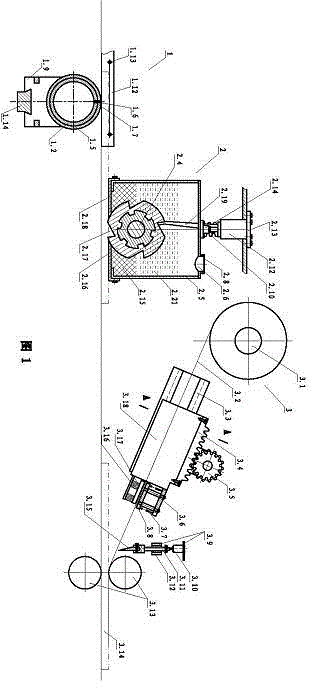

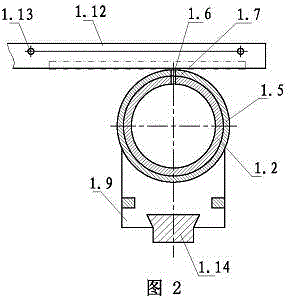

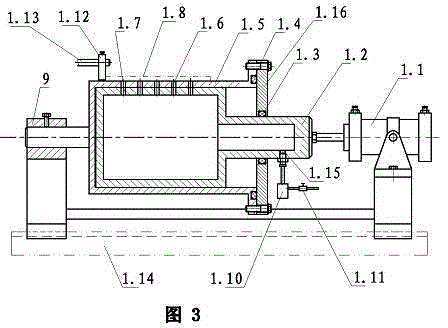

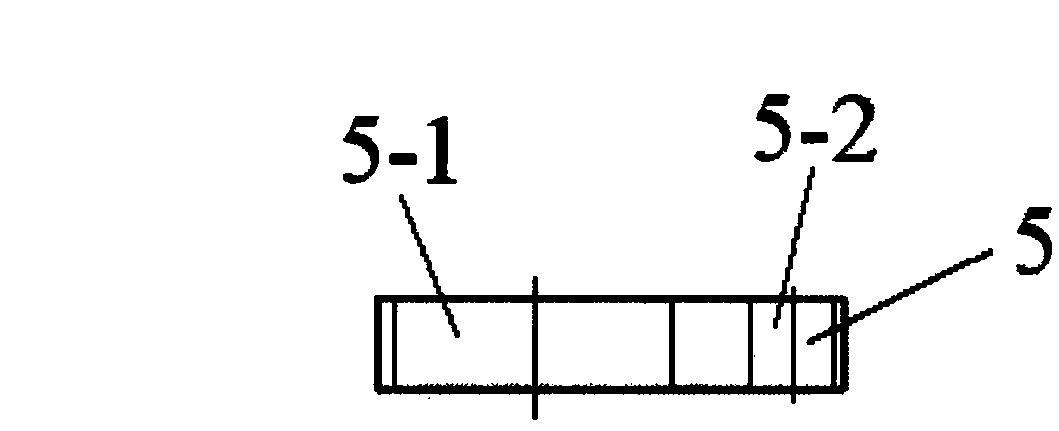

Glue coating automatic turnover machine

InactiveCN101745491AFast rotation positioningAccurate rotation positioningLiquid surface applicatorsCoatingsEngineeringAutomation

The invention discloses a glue coating automatic turnover machine, which comprises a turnover mechanism, a mechanical hand mechanism, a lifting mechanism, a distance measuring mechanism and a controller, wherein the turnover mechanism is arranged on a glue coating frame, the mechanical hand mechanism is connected with a rotating shaft and a bearing seat in the turnover mechanism through the glue coating frame, the lifting mechanism is arranged on the glue coating frame and is positioned in front of the mechanical hand mechanism, the distance measuring mechanism is arranged on the glue coating frame and is positioned under the mechanical hand mechanism, and the controller is connected with each mechanism. The invention adopts a mechanical hand for tightly clamping work pieces, the mechanical hand is provided with a clamp which consists of a clamp press plate and a clamp base, then, a servo driver is used for driving a servo motor to drive the rotating shaft for turning small combining surfaces of the work pieces to a position where the glue coating surface faces up, the distance measuring mechanism provided with a displacement sensor is used for detecting the positions of the work pieces, and the lifting mechanism provided with a tray positioning pin is used for lifting the work pieces to the glue coating positions. The invention has the characteristics of accurate turnover positioning and high automation degree.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Catheters and Related Devices for Forming Passageways Between Blood Vessels or Other Anatomical Structures

InactiveUS20100094259A1Precise rotation controlPrecise positioningUltrasonic/sonic/infrasonic diagnosticsCannulasAnatomical structuresDistal portion

The inventions described in this patent application include i) a torqueable introducer sheath which is useable in conjunction with a transvascular passageway forming catheter to effect precise rotational control of the catheter; ii) an anchorable guide catheter which is useable in conjunction with an intravascular imaging catheter and a transvascular passageway-forming catheter to effect precise positioning and aiming of the passageway-forming catheter; iii) a passageway forming catheter having a torqueable proximal portion to facilitate precise rotational positioning of the distal portion of the catheter; iv) a deflectable-tipped passageway forming catheter, v) various markers and other apparatus useable in conjunction with any of the passageway-forming catheters to facilitate precise positioning and aiming of the catheter, and vi) an apparatus which may be formed within a catheter to prevent a member, apparatus of flow of material from being inadvertently advanced through a lumen of the catheter.

Owner:MEDTRONIC VASCULAR INC

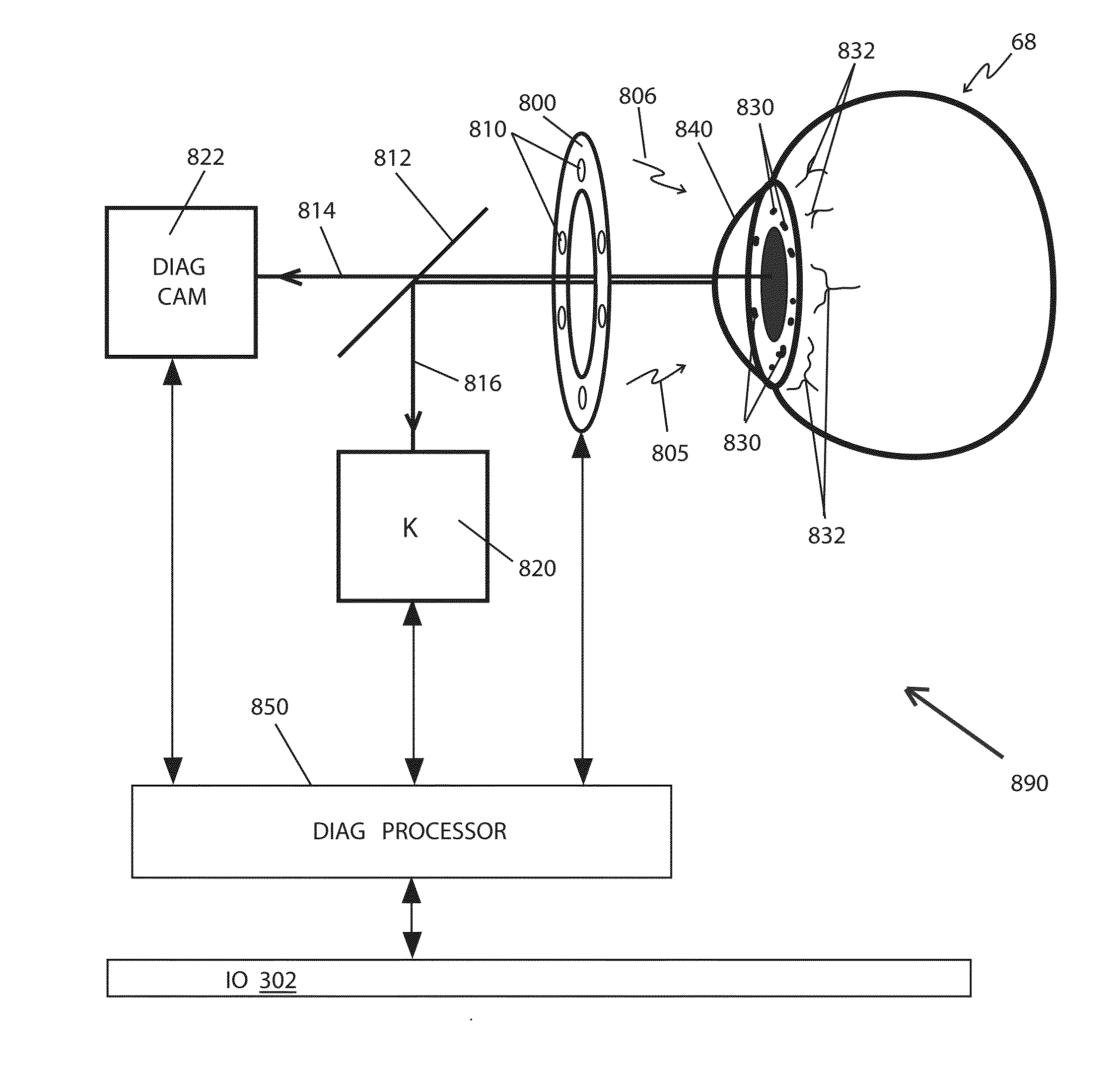

Method for Alignment of Intraocular Lens

InactiveUS20160089271A1Accurate rotation positioningInherent optical rotational asymmetriesLaser surgerySurgical instrument detailsOptical axisLight beam

A method for precise intraocular delivery of an astigmatic intraocular lens in a patient's eye includes recording traceable eye landmarks, recording the corneal astigmatism, registering the recorded astigmatism axis to the recorded traceable eye landmarks, providing a light source for generating a light beam, providing a scanner for deflecting the light beam to form an enclosed treatment pattern that includes a visible registration feature, providing a delivery system that delivers the enclosed treatment pattern to target tissue in the patient's eye to form an enclosed incision therein including the visible registration feature linkable to the recorded traceable eye landmarks registered to the corneal astigmatism axis. Inserting an intraocular lens within the enclosed incision, wherein the intraocular lens has an astigmatism axis registration feature visible to the surgeon to align with the patient's eye visible astigmatism axis registration feature of the enclosed incision.

Owner:ZACHARIAS JAIME

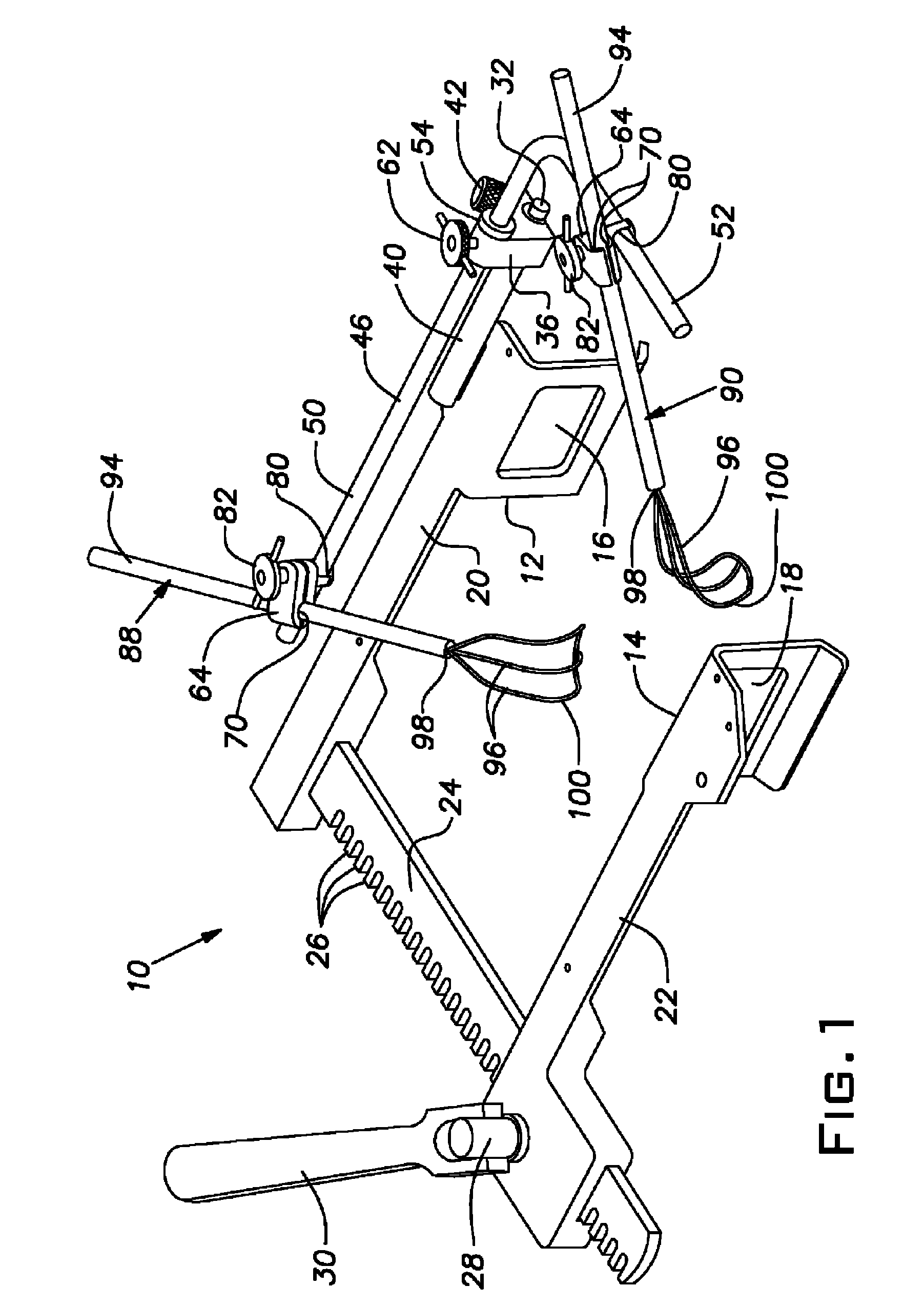

Surgical retractor

A surgical retractor includes a pair of parallel arms that are mounted to a toothed crossbar. One of the arms is fixed to one end of the crossbar, while the other arm is movable along the crossbar by means of a pinion. One or both of the arms includes on its upper surface a bar having a longitudinally extending flat surface. A rod is connected to the bar by means of a bracket. The bracket can be locked in position relative to the bar by a first set screw that engages the flat surface. A rod extends through an opening in the bracket and is retained in place there by a second set screw. The rod includes a circumferentially extending shoulder that engages the bracket so as to locate the rod in a desired position. One or more flat surfaces are formed on the rod adjacent the shoulder for engagement by the second set screw. One of the flat surfaces causes the rod to be positioned precisely as necessary to perform a surgical procedure, while the other of the flat surfaces enables the rod to be moved to an out-of-the way position and locked in place there. One or more retractor blades of the wire basket type are connected to the rod by means of universal clamps. The basket portions of the retractor blades are made of a malleable wire that enables the configuration of the blades to be changed by the surgeon as desired.

Owner:MCCARTHY PATRICK M +1

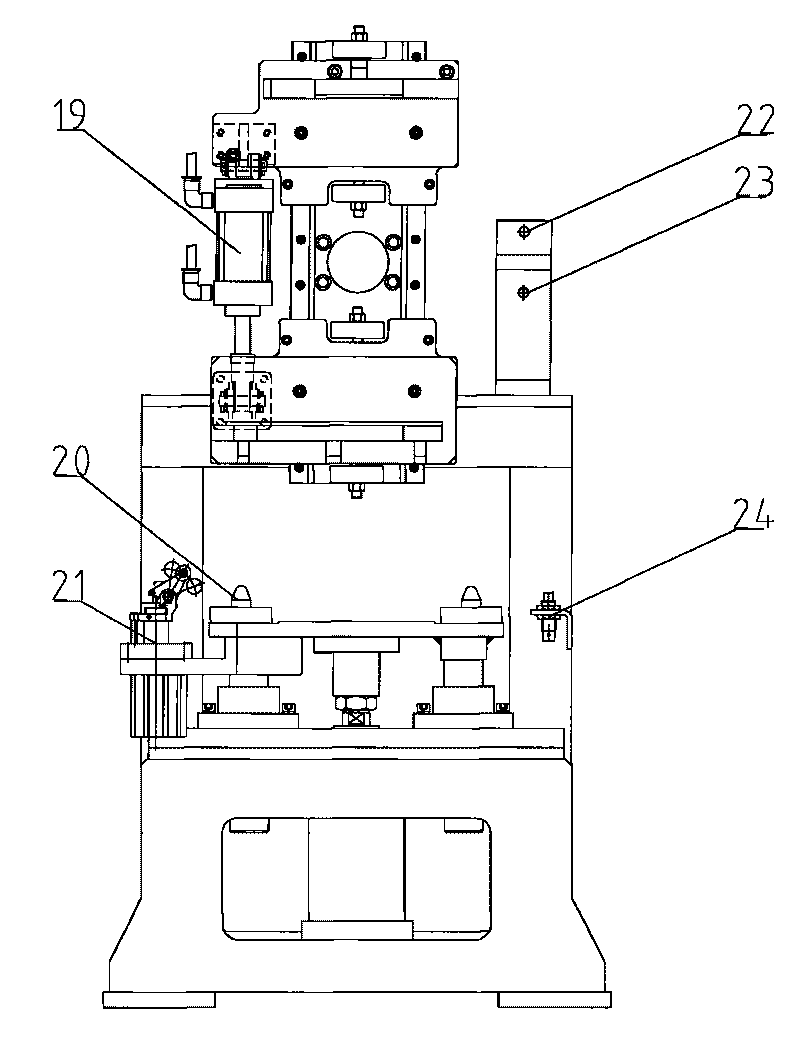

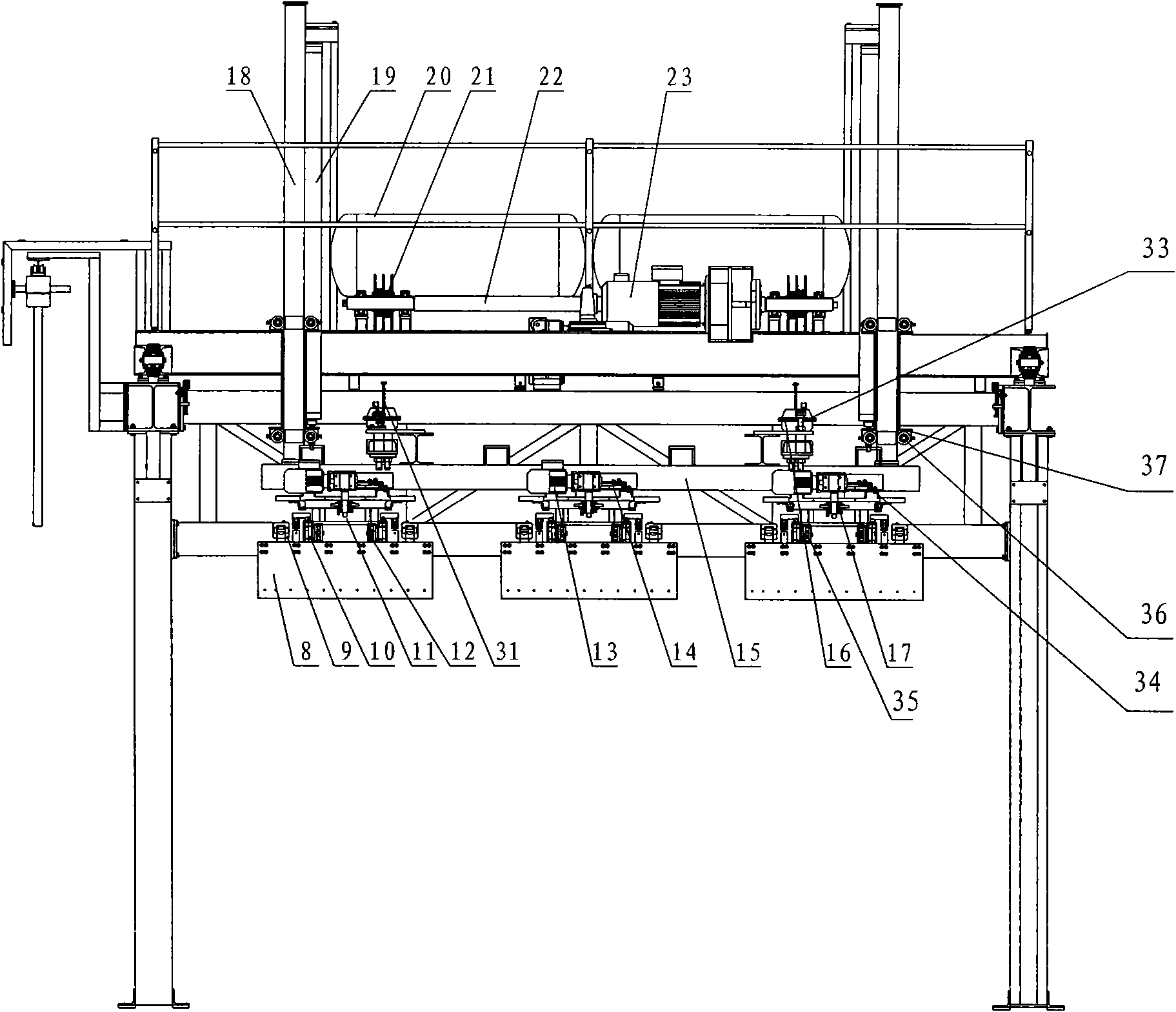

Automatic setting machine

ActiveCN101575054APrecise liftingAccurate rotation positioningGripping headsStacking articlesReducerControl theory

The invention discloses an automatic setting machine, which comprises parallel cross beams arranged on a stander. Guide rails are arranged above the two parallel cross beams; travel trolleys capable of moving along the transverse direction of the guide rails transversely span the guide rails; the travel trolleys are provided with a travel motor reducer and a coil motor reducer; output shafts of the travel motor reducer are provided with travel coders; output shafts of the coil motor reducer are provided with lifting coders; the travel trolleys are provided with coil wheels driven by the coil motor reducer; the coil wheels are hung with chunk brackets through coil chains; rotatable chunks are arranged below the chunk brackets through rotator devices which are driven by a rotating motor reducer; an output shaft of the rotating motor reducer is provided with a torque limiter; and the travel coder, the lifting coder and the torque limiter are in signal connection with a control center through signal wires. The automatic setting machine has smooth running, accurate positioning and high production efficiency.

Owner:山东矿机迈科建材机械有限公司

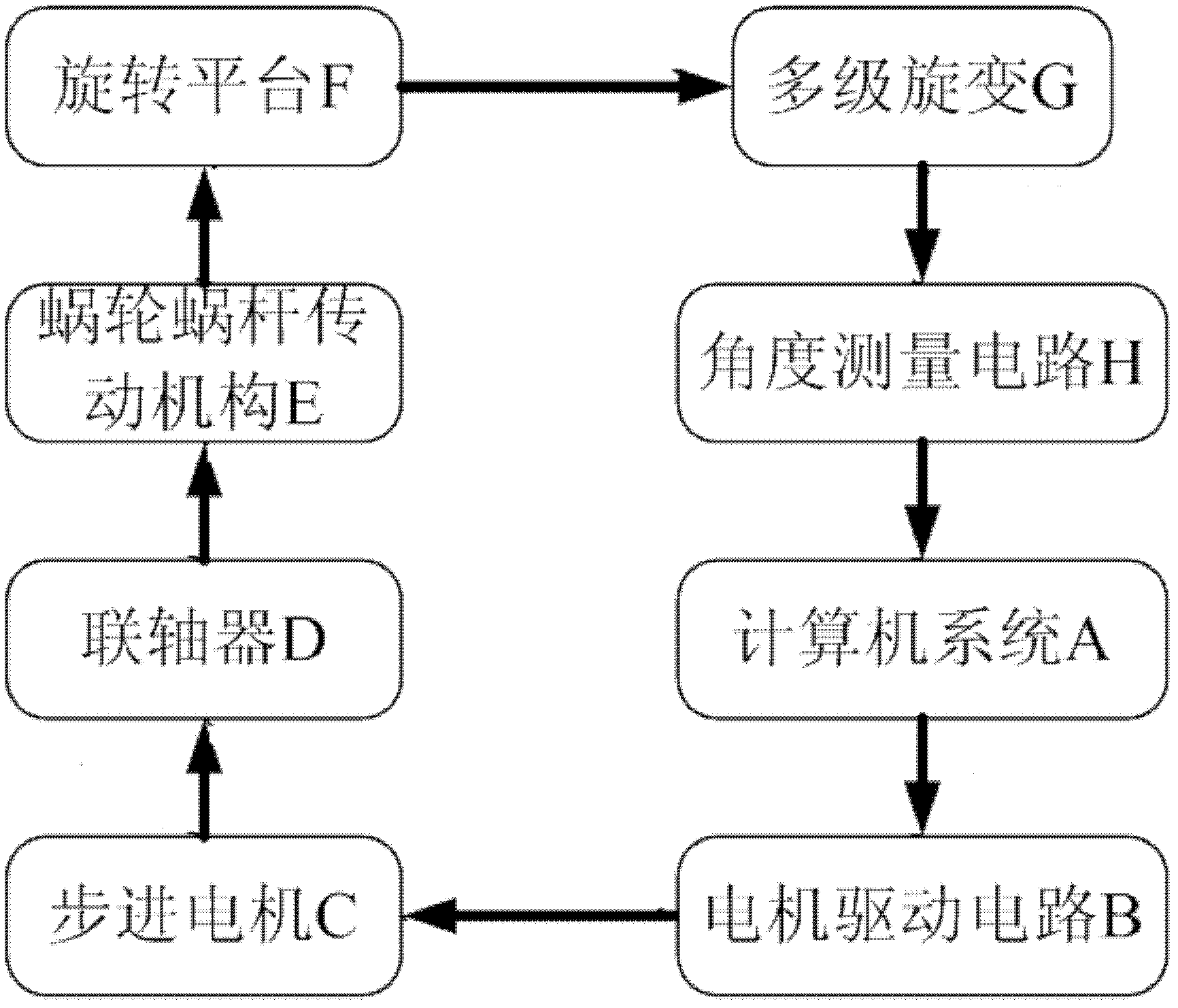

Electric control rotating platform and position measuring method for inertial navigation instrument

InactiveCN102589547AWith transmission self-locking functionRealize precise rotation angle positioningNavigation by speed/acceleration measurementsCouplingEngineering

The invention provides an electric control rotating platform and a position measuring method for an inertial navigation instrument. The lower platform body of the rotating platform is directly connected with a measurement carrier; a support bracket, the outer platform body of the rotating platform and an outer adjusting bracket are fixedly connected to the lower platform body of the rotating platform; the support bracket is contacted with the outer ring of an angular contact bearing for positioning; a hollow shaft is connected with the inner ring of the angular contact bearing; the inner rings of two pairs of angular contact bearings are positioned by two tightening nuts; a positioning bracket is fixedly connected with the hollow shaft and a plurality of stages of spirally variable rotors are positioned at the same time; a plurality of stages of spirally variable stators are fixedly connected with the outer platform body of the rotating platform; a worm wheel is fixedly connected to the positioning bracket; a worm is connected with the outer adjusting bracket through double-end bearing support; and the output shaft of a stepping motor is connected with the input shaft of the worm by a coupling. The electric control rotating platform is small in error and high in precision, provides a solution for the precise rotation and the position measurement of the inertial navigation instrument, and simultaneously provides the guarantee for the accurate and reliable measurement of the inertial navigation instrument.

Owner:HARBIN ENG UNIV

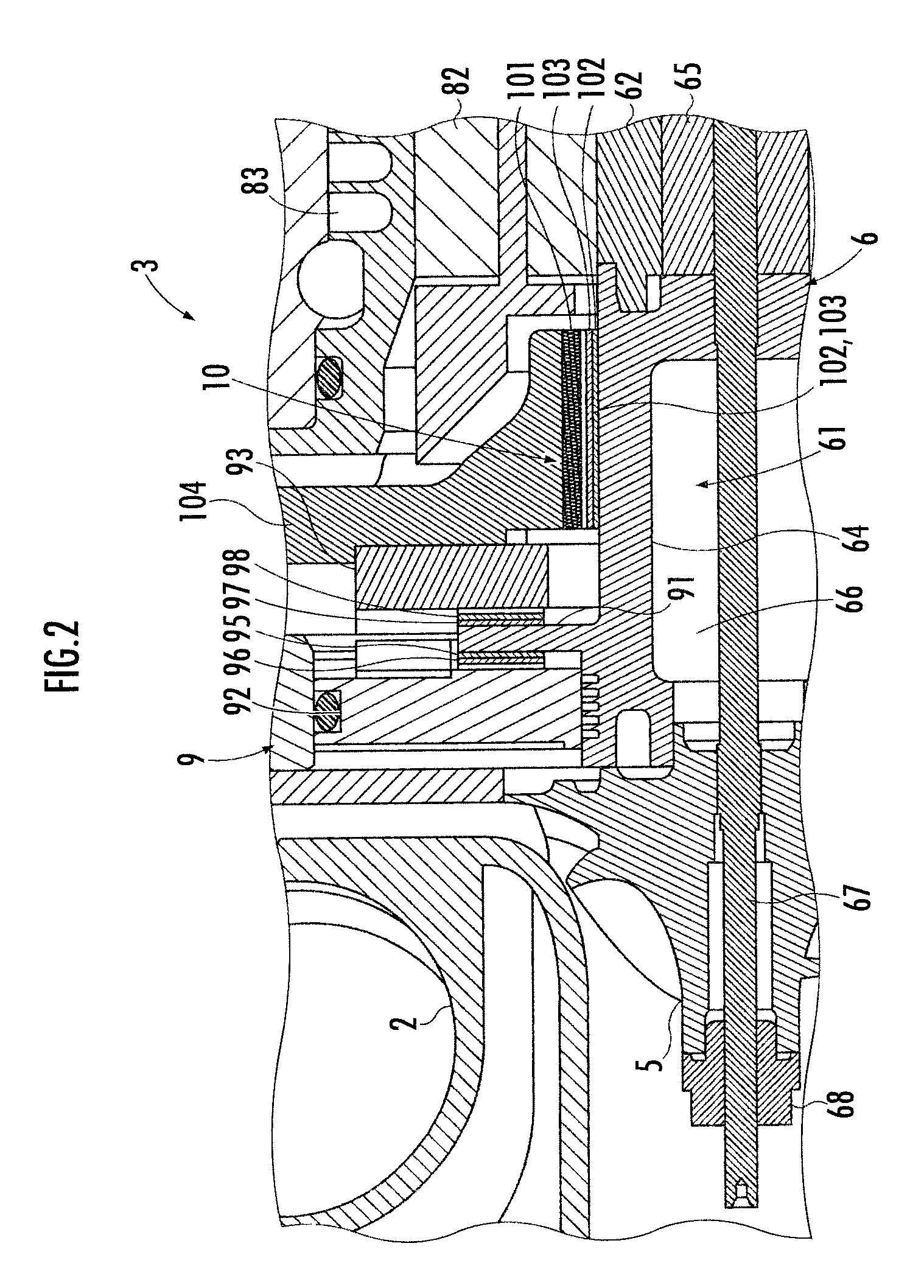

Electric compressor

ActiveUS20090257895A1Reduction in size and costHigh efficiencyPump componentsShaftsImpellerLinear compressor

An electric turbo compressor is an air compressor to be used in a fuel cell system, and includes a housing comprised o a compression casing, a motor casing, and a canceller casing, and the housing houses therein an impeller, a rotary shaft, a thrust canceller (a load cancellation section), and a motor unit. The rotary shaft is supported by a thrust air bearing in its thrust direction, and is axially supported by a radial air bearing in its rotating direction. A thrust load is generated at the rotary shaft when the number of rotations of the impeller increases. The pressure of the compressed air acts to the pressure chamber from the compressed air lead-out section of the compression casing via the compressed air passage, and this pressure acts on the canceller flange of the canceller shaft so as to generate a load towards the rear of the rotary shaft. Therefore, the thrust load is cancelled out.

Owner:HONDA MOTOR CO LTD

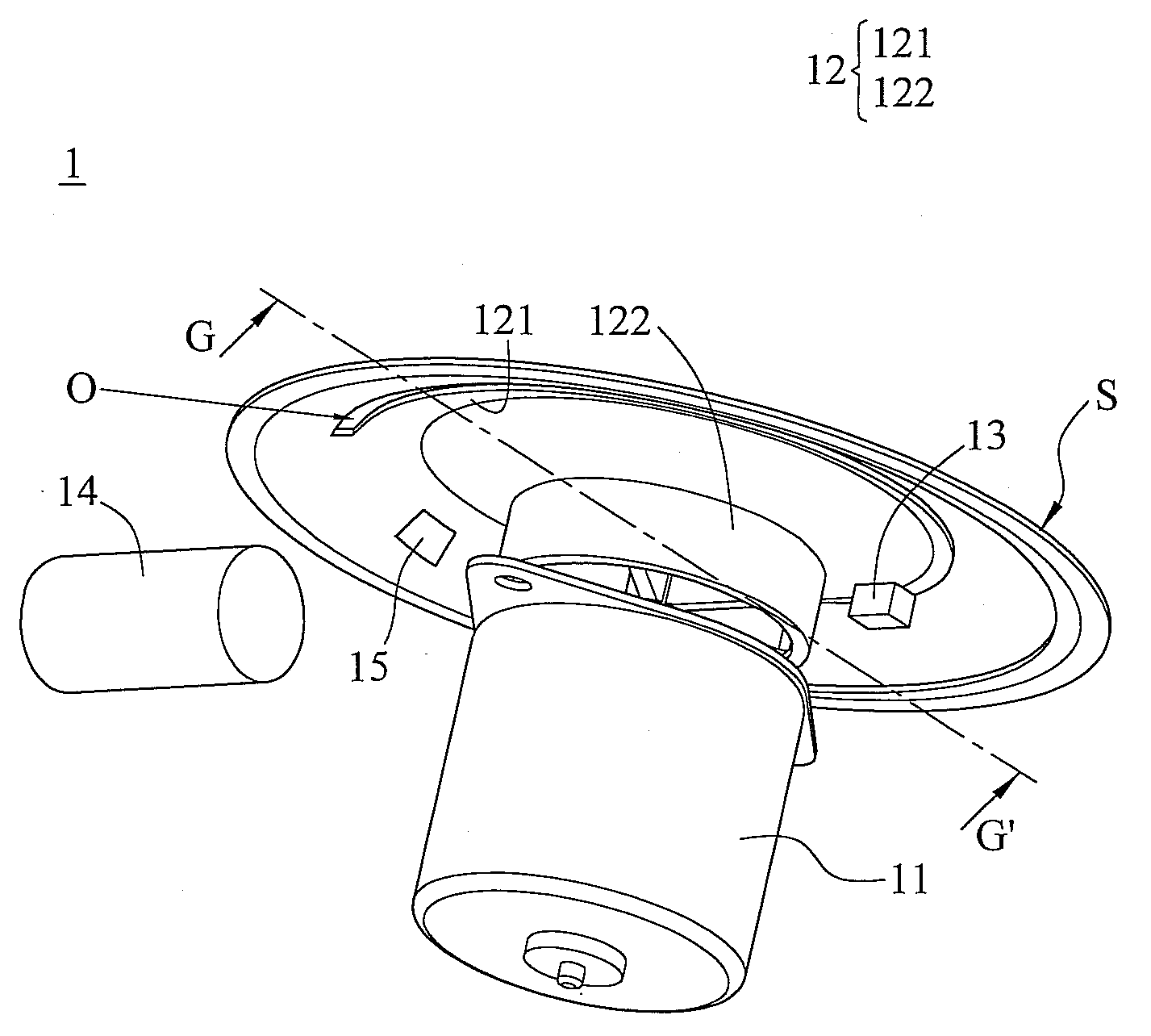

Electric rotating locating device used for camera polarized lens

Owner:广州市信康科技电子有限公司

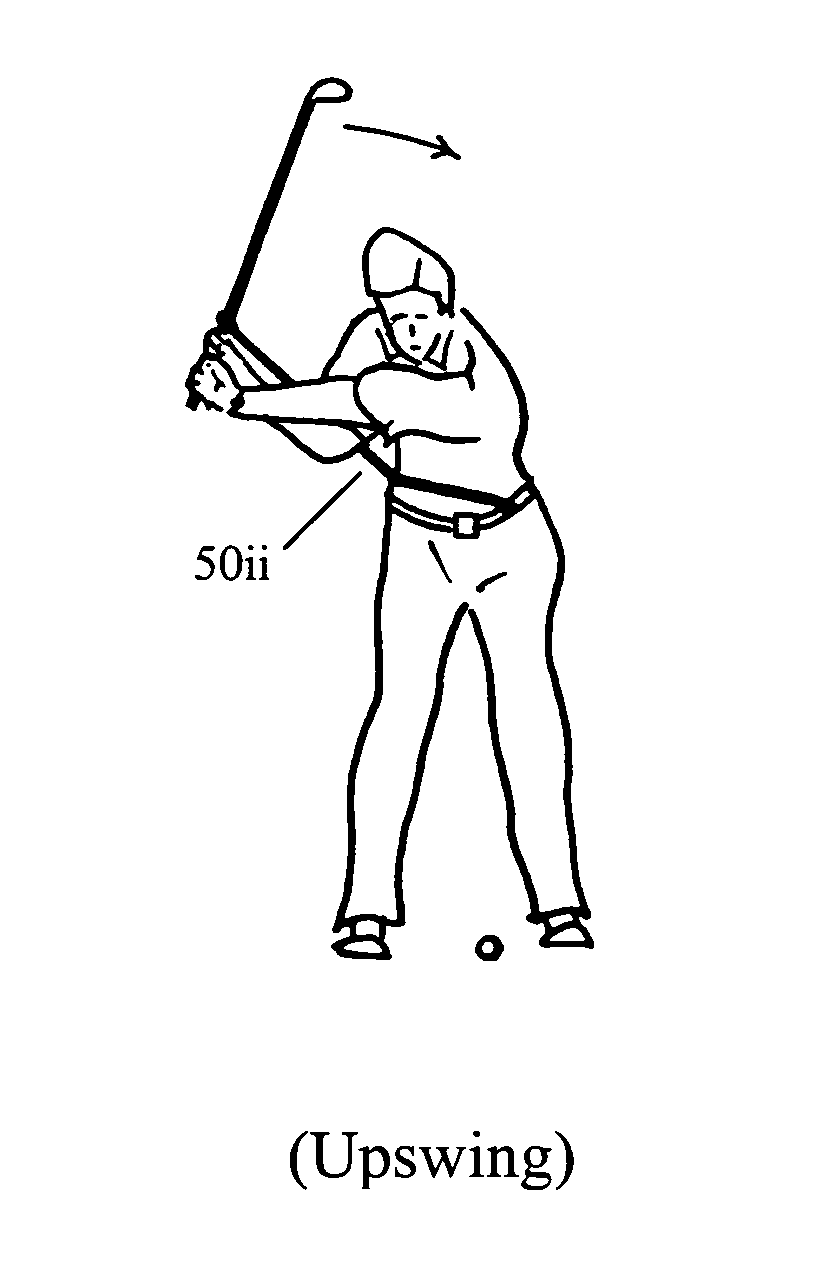

Golf swing training device

InactiveUS8500569B2Good muscle memoryAccurate rotation positioningGolfing accessoriesMuscle exercising devicesSports equipmentEngineering

A training device properly develops a sports equipment swing, particularly for golf equipment, to counter an overpowered back-swing that results in an uncontrolled out-of-plane downswing. The device may comprise a strap having one end secured to a latch plate, and the other end securable to a latch that releasably receives a portion of the latch plate. At least one bungee cord may have one end attached to the strap at a position relative to the latch, being approximately 4-12 inches displaced therefrom. The other bungee cord end may have a cinching device located thereon to adjustably secure the bungee cord therein to engage a golf club shaft or shaft of a sports racquet, bat or stick. The bungee cord may comprise first and second cord portions being joined together, where the first cord portion has a low elastic modulus, and the second cord portion a high elastic modulus.

Owner:MOORE ALEXANDREA

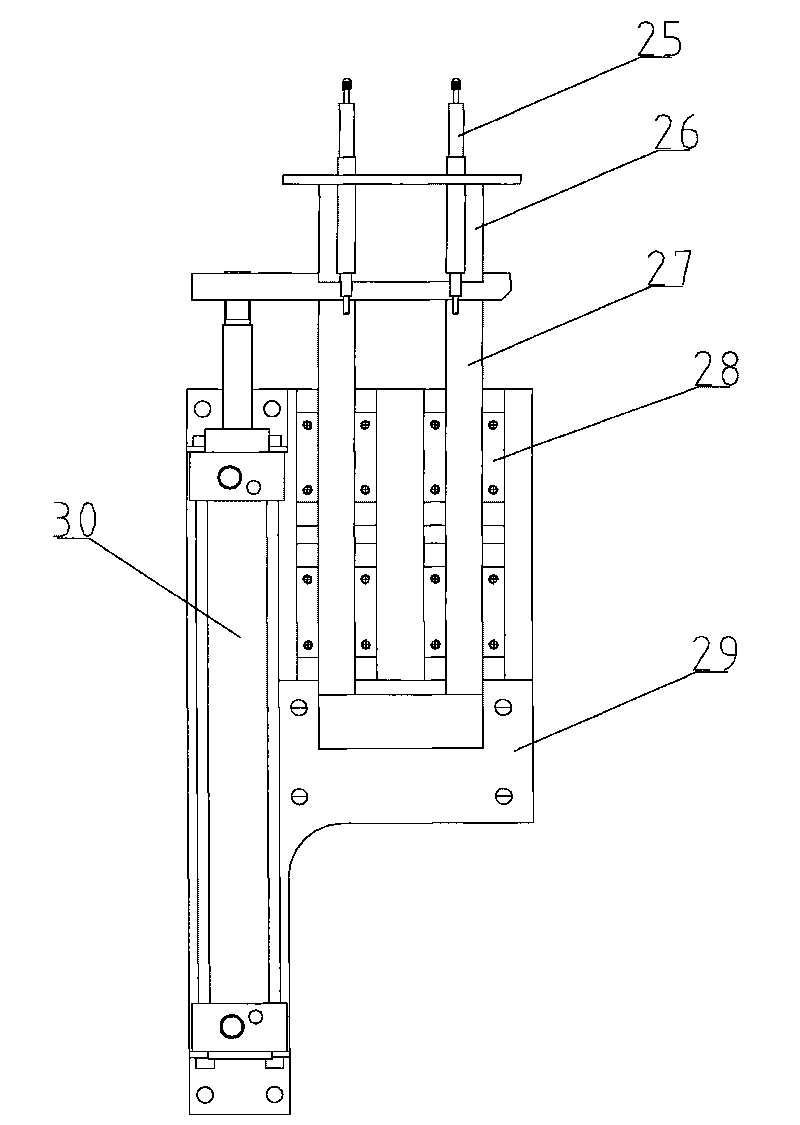

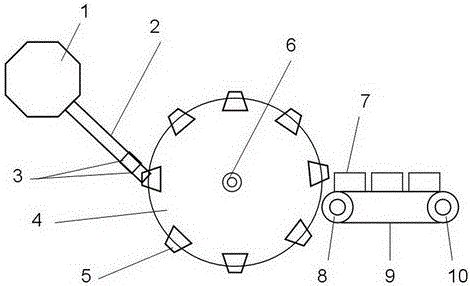

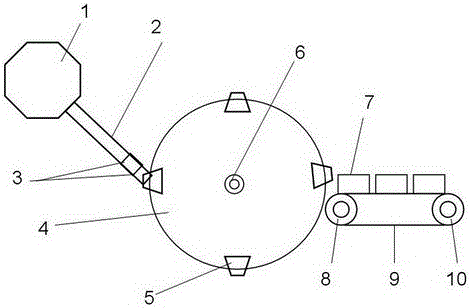

Weighting test instrument device and manufacturing method thereof

InactiveCN106493088AAccurate rotation positioningRealize automatic flipWeighing apparatus for materials with special property/formSortingTester deviceEngineering

The invention provides a weighing test instrument device and a manufacturing method thereof. The weighing test instrument device comprises a feeding unit, a weighing sorting unit, a discharging unit and a control unit. The control unit controls the feeding unit to deliver to-be-weighed materials to overturning balances of the weighing sorting unit separately; the overturning balances weigh the materials separately and feed weighing data back to the control unit; and the control unit controls a rotary table to rotate to the positions above target material receiving cases according to sorting standards, the overturning balances are overturned, and weighed and sorted materials are placed into the target material receiving cases separately. By adoption of the weighing test instrument device and the manufacturing method thereof, the technical problems that when an existing weighing test instrument device is used for weighting, testing and sorting batch materials, time and labor are wasted, and much manpower is needed for sorting out the materials are solved, and accordingly, the technical effects that the batch materials are automatically fed separately, rapidly weighed, precisely sorted and discharged in a batched mode in time through the weighing test instrument device are achieved.

Owner:SUZHOU SICHUANGYUANBO ELECTRONICS TECH CO LTD

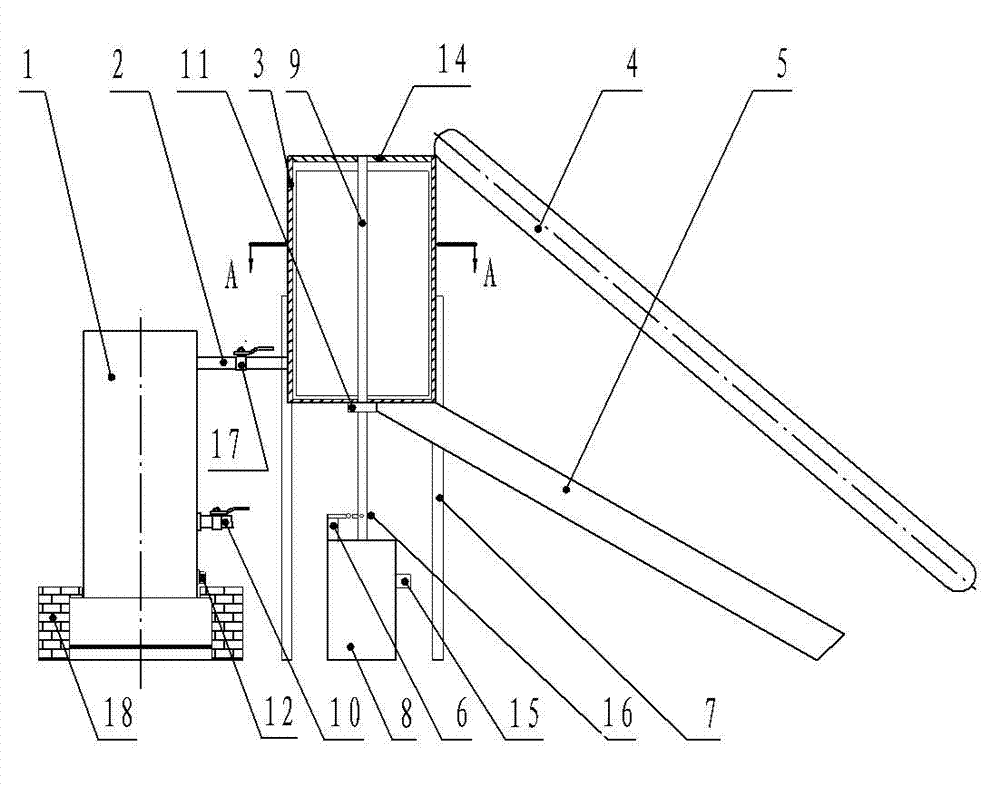

Tea steaming device

ActiveCN102960477AIncrease productivityAccurate rotation positioningPre-extraction tea treatmentAgricultural engineering

The invention discloses a tea steaming device which relates to the technical field of tea manufacturing. A tea steaming barrel which is a cylinder with an open upper end is installed on a bracket. A plurality of blocks are arranged on a bottom plate of the tea steaming barrel, wherein one of the blocks is a gap connected with the outside at the bottom of the tea steaming barrel. Pores are densely distributed on the rest of blocks. The tea steaming barrel is internally provided with a rotary shaft which is longitudinally provided with a plurality of separators. The separators are equal to the blocks in number. The separators divide the tea steaming barrel into a plurality of cavities. The bottom of the rotary shaft extending out of the tea steaming barrel is connected with a driving device. A travel switch connected with a relay is connected to the top of the driving device. Collision blocks corresponding to the separators in position are arranged on the rotary shaft section extending out of the bottom of the tea steaming barrel. A steam generator is arranged on one side of the tea steaming barrel. The steam generator is communicated with the tea steaming barrel through at least two pipelines, and a stove is arranged below the steam generator. The tea steaming device provided by the invention can solve the problem that the labor intensity of tea steaming workers is large and the efficiency is low, and meanwhile, the tea steaming quality can be guaranteed.

Owner:广西梧州茶厂有限公司

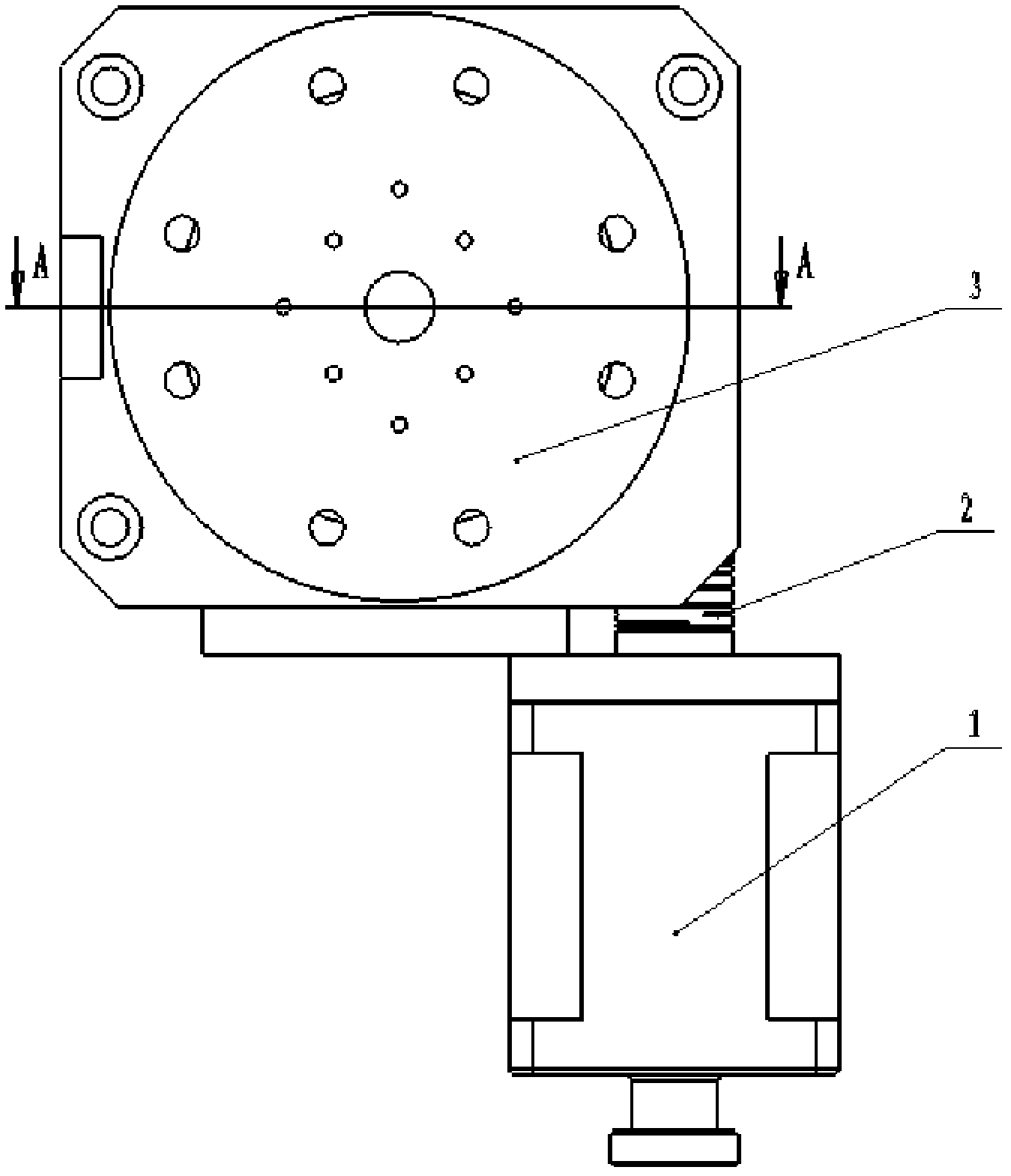

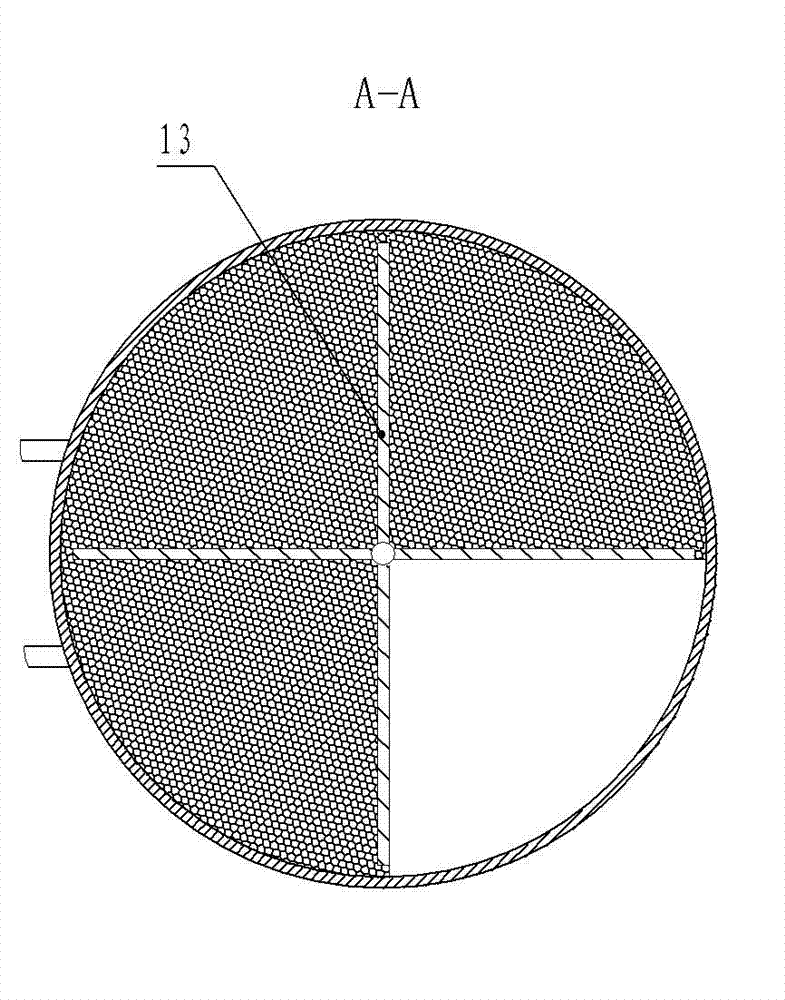

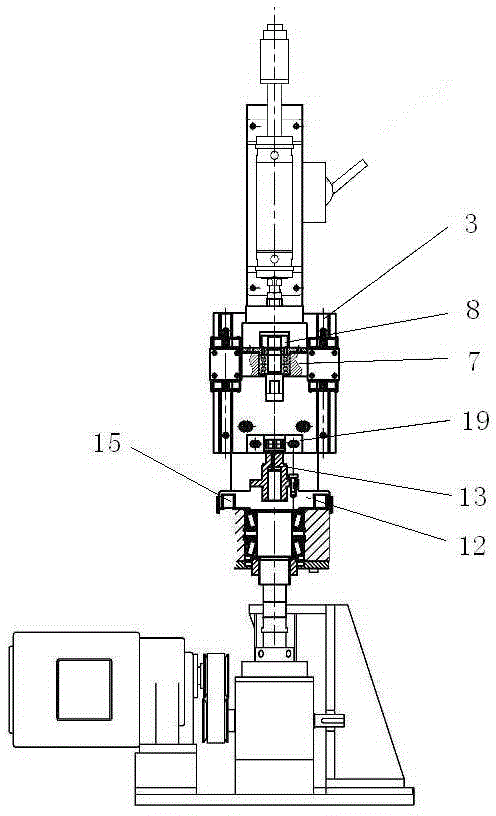

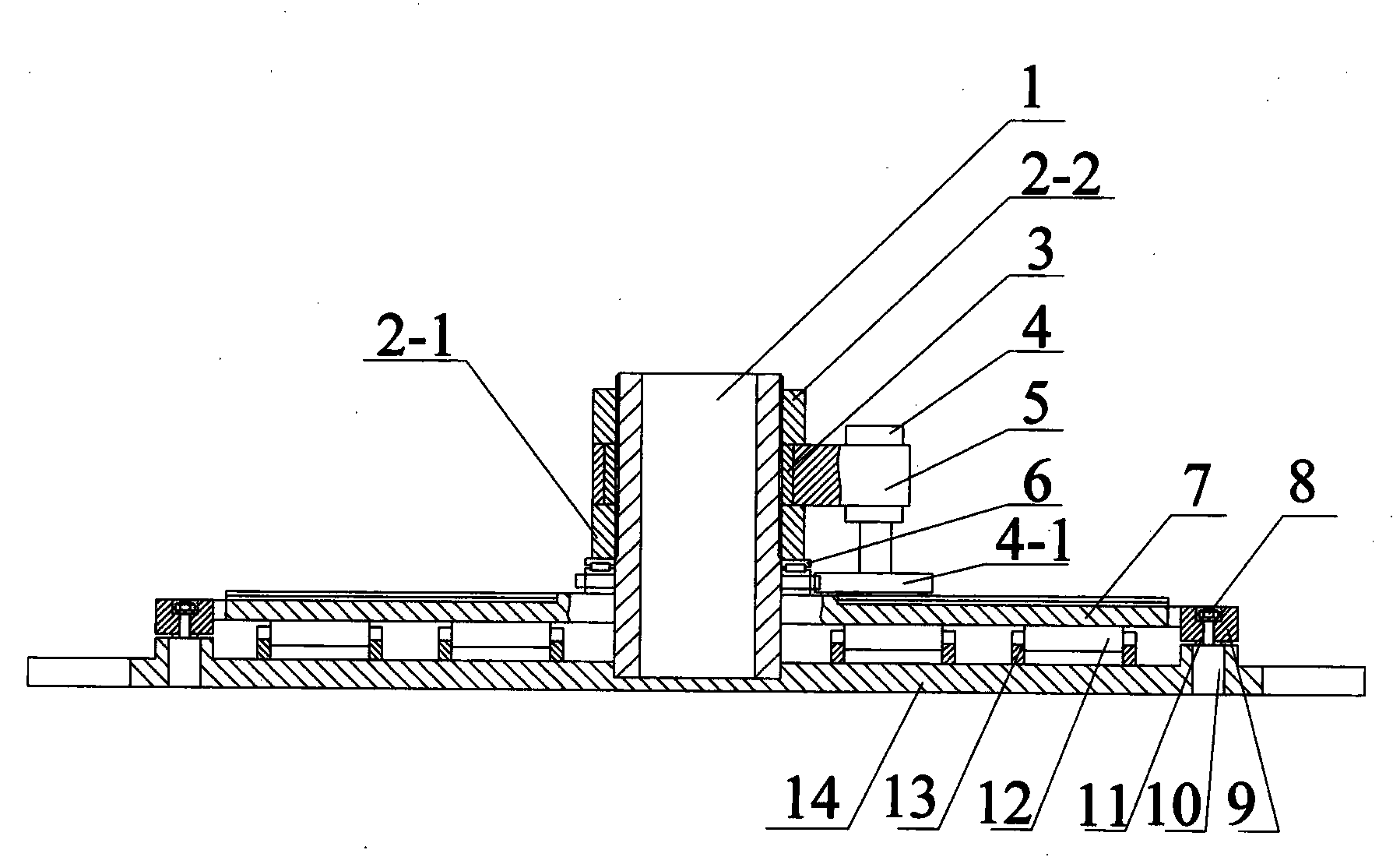

Disc type multi-station compressing rotating clamp

ActiveCN104526372AAccurate rotation positioningMeet the clamping processing requirementsPositioning apparatusMetal working apparatusEngineeringSlide plate

The invention discloses a disc type multi-station compressing rotating clamp. The disc type multi-station compressing rotating clamp comprises a support; a compressing mechanism is arranged above the support, and a rotating mechanism is arranged below the support; the compressing mechanism comprises a guide rail sliding plate, and linear guide rails are arranged on the guide rail sliding plate; a pressing head mounting base is arranged on the linear guide rails, and a rotating pressing head is arranged on the bottom face of the pressing head mounting base; and an adjustable stroke air cylinder for driving the pressing head mounting base to slide along the linear guide rails is fixedly arranged on the support. The rotating mechanism comprises a clamping base, and a rotating connecting shaft is arranged in the clamping base; and a rotating positioning disc is arranged at the upper end, stretching out of the clamping base, of the rotating connecting shaft, and a workpiece clamp corresponding to the rotating pressing head is arranged on the rotating positioning disc. Pin holes are formed in the clamping base, and positioning pins are arranged in the pin holes; a plurality of positioning pin holes matched with the positioning pins are formed in the bottom face of the rotating positioning disc at intervals; and a driving mechanism for driving the rotating connecting shaft to rotate and a pin inserting and pulling mechanism for driving the positioning pins to be inserted into the positioning pin holes or pulled out of the positioning pin holes are arranged below the clamping base.

Owner:CHONGQING WNC INTELLIGENT EQUIP

Box pasting and folding machine with automatic paper correcting and window pasting functions

ActiveCN105172209AAvoid normal shipping impactWill not be affected by normal deliveryContainer making machineryRolling paperGlue line

The invention discloses a box pasting and folding machine with automatic paper correcting and window pasting functions. The box pasting and folding machine comprises a machine frame, a paper rolling shaft, a glue barrel and a paper cutter. The glue barrel can slide up and down in the vertical direction of the machine frame, detachable glue distributing wheels are arranged in the glue barrel, and pawls abut against the outer contour faces of the glue distributing wheels. A shell type moving bar is arranged on the part, located in front of the glue barrel, of the machine frame, and at least a row of outer air suction holes communicated with a shell cavity is formed in the outer wall of the moving bar in the axial direction. An air suction barrel is arranged in the moving bar shell cavity in sealed and sliding modes, and an extraction hole communicated with an inner cavity of the air suction barrel is formed in the shaft body of an extending section and communicated with an air extractor. A row of inner air suction holes is formed in the wall of the air suction barrel. A sliding frame is arranged on a sliding rail in a sliding mode. A sliding table is connected to a fixed guide rail in a sliding mode, a movable holding plate and a fixed holding plate are arranged on the sliding table in parallel, and a pair of paper conveying press rollers is correspondingly arranged behind the paper cutter. According to the box pasting and folding machine, ground paper can be quickly corrected, the glue distributing amount is sufficient, glue lines are uniform, and the box pasting quality is good.

Owner:YANCHENG HONGJING MACHINERY SCI & TECH CO LTD +1

Dynamic aperture device and projector with the same

InactiveUS20090109514A1Reduce vibrationAccurate rotation positioningMountingsDynamic apertureEngineering

A dynamic aperture device includes a motor, a light shielding element and a balancer. The motor has a shaft. The light shielding element has a light shielding portion and a hub connected to the light shielding portion. The hub is coupled to the shaft. The balancer is disposed on the light shielding element, the hub or the shaft.

Owner:DELTA ELECTRONICS INC

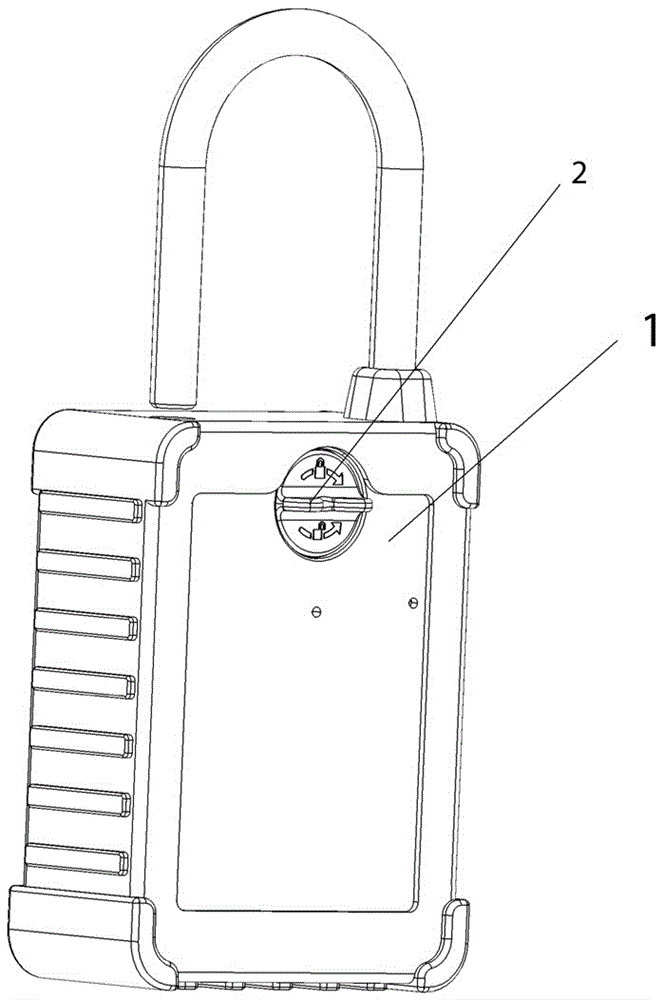

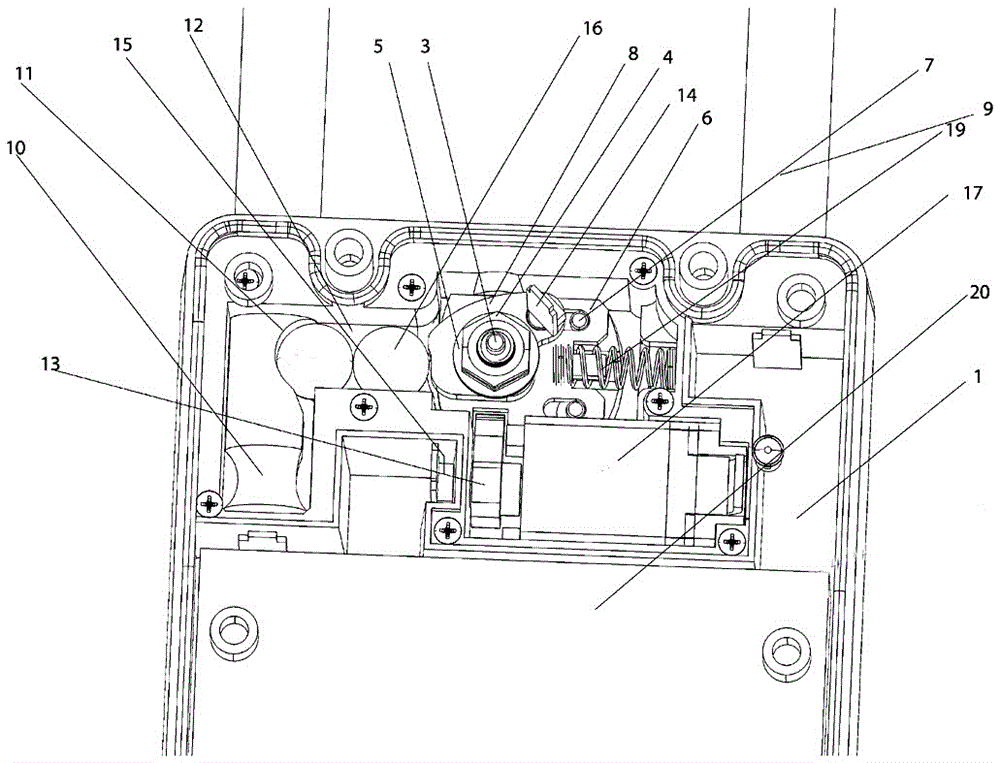

Wireless communication control logistics electronic lock

ActiveCN105909075AImprove reliabilityImprove securityNon-mechanical controlsPadlocksControl engineeringElectric machinery

A wireless communication control logistics electronic lock comprises a lock rod, a lock body and a lock cylinder assembly installed inside the lock body, wherein the lock cylinder assembly comprises a reset spring, a ball, a sliding board, a swinging board, a corrugated washer and a swinging magnetic sensor; the sliding board, a switching knob and the swinging board are coaxially and sequentially connected in series through a screw shaft; the corrugated washer at the tail end of the screw shaft and the swinging board are compressed through a nut, so that the screw shaft drives the swinging board to rotate; the sliding board comprises a locking bayonet arranged correspondingly to a locking convex block on a motor wheel, first sliding grooves buckled with two lock body shaft protrusions arranged on the lock body, a second sliding groove buckled with the screw shaft, a third sliding groove buckled with a swinging shaft protrusion of the swinging board, and a reset spring shaft protrusion; and the swinging board is further provided with a swinging induction magnetic block matched with the swinging magnetic sensor on the lock body. The wireless communication control logistics electronic lock is simple in structure, can protect an internal structure and a motor, prevents malicious damage from external force, and is firmer and more durable.

Owner:深圳途泰科技有限公司

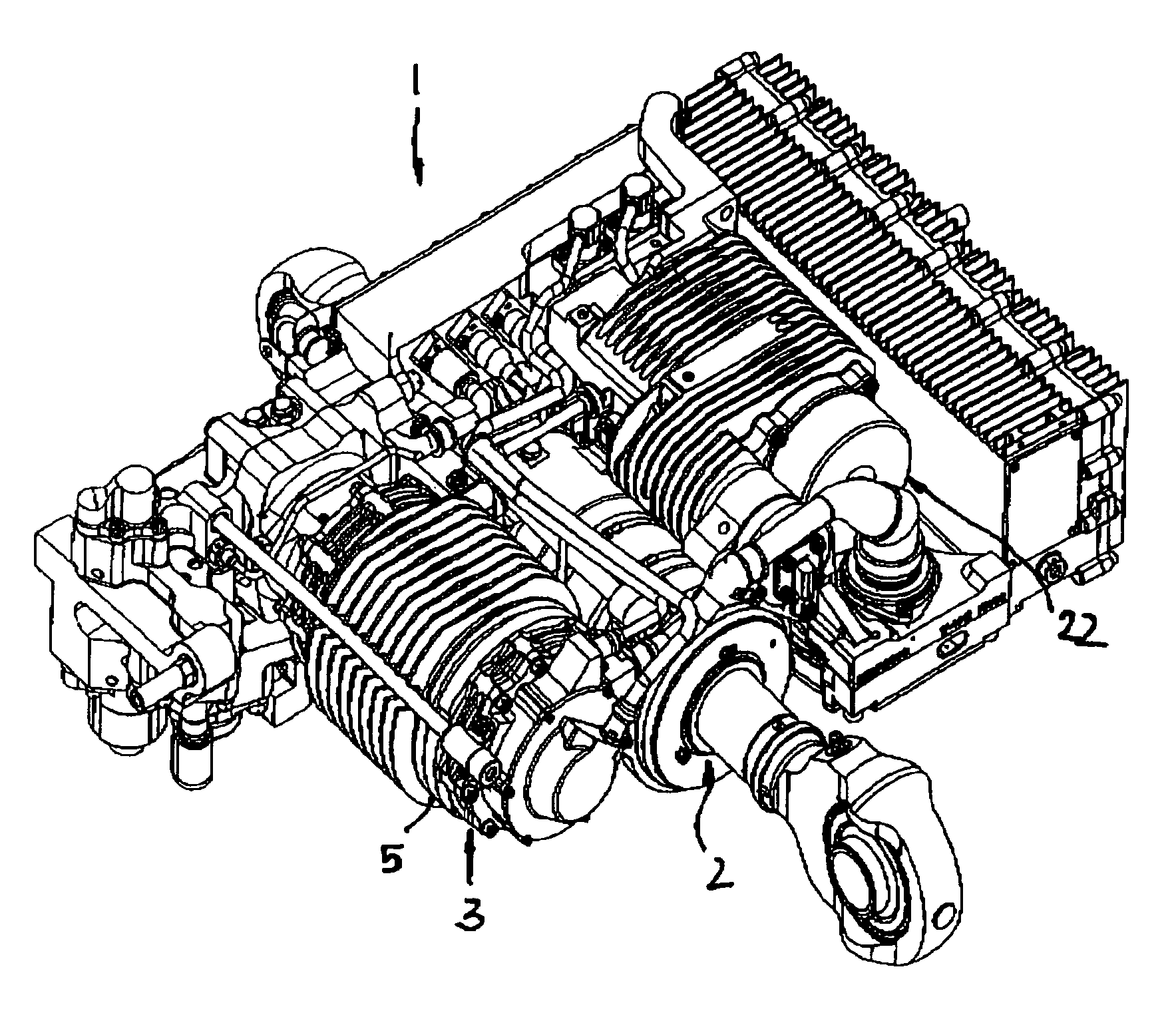

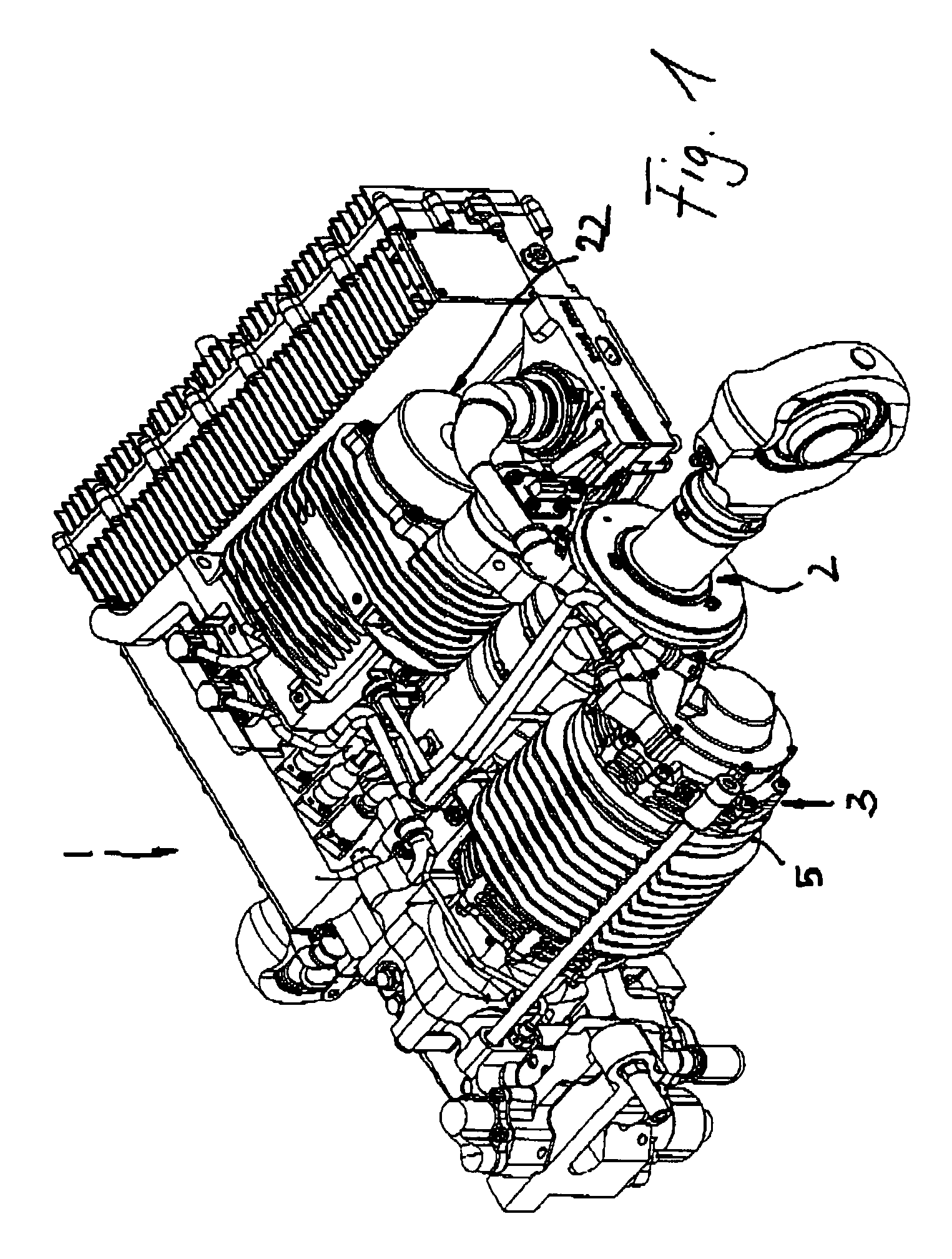

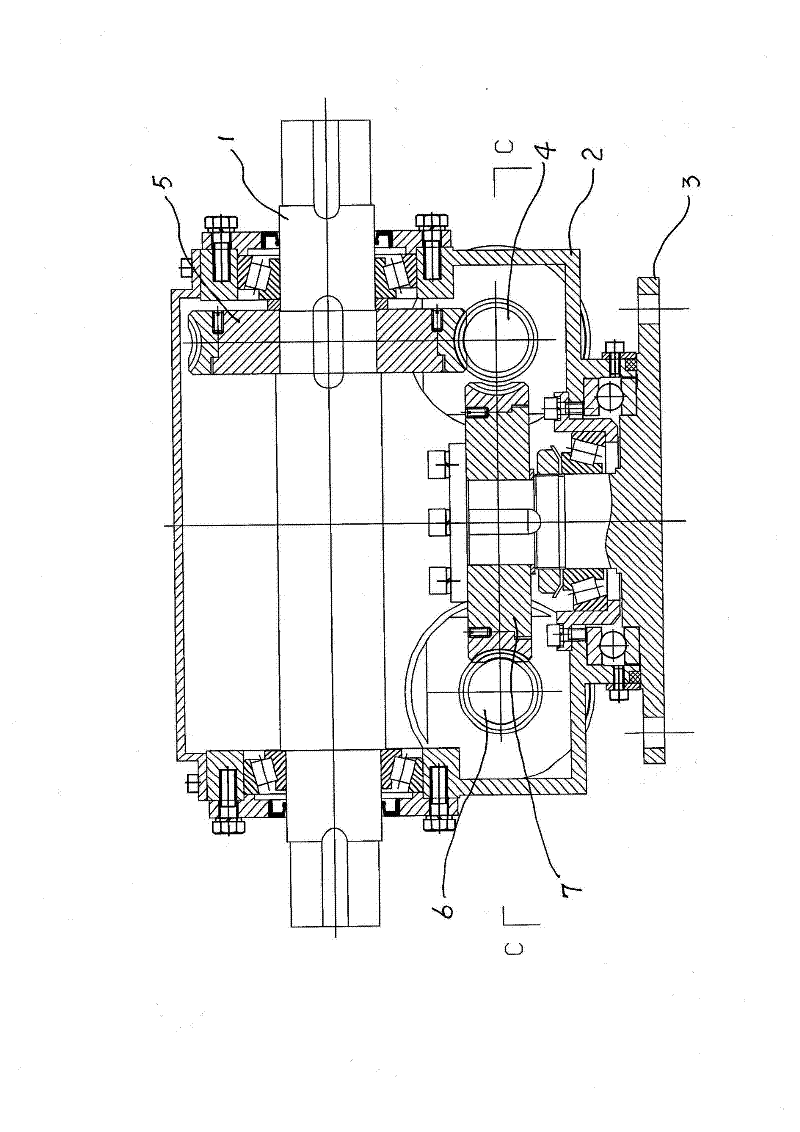

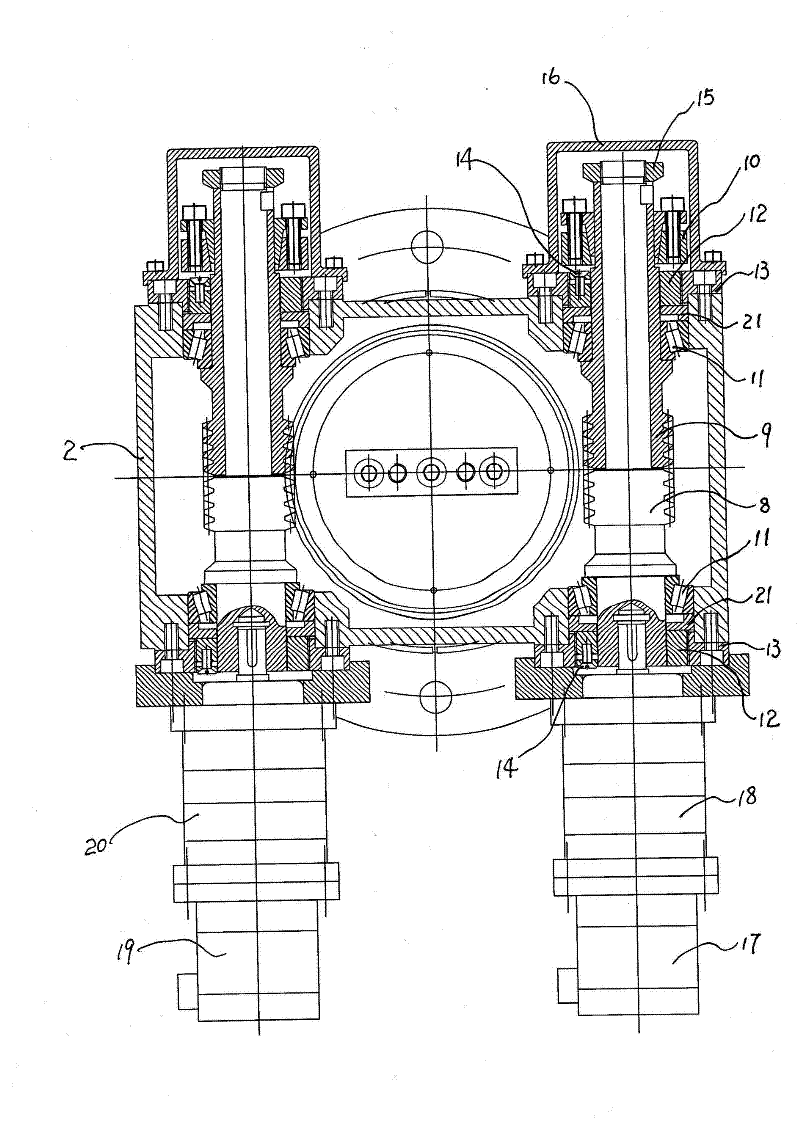

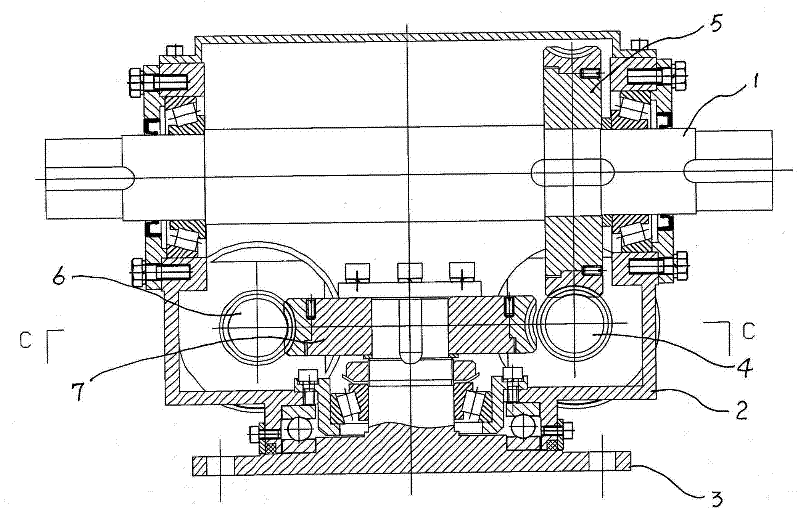

Actuation device

ActiveUS7658066B2Avoid disadvantagesAccurate rotation positioningAircraft controlRotary clutchesEngineeringActuator

The present invention relates to an actuation device for the actuating of an adjustment surface of an aircraft such as an elevator, a rudder or the like, of landing gear or another aircraft or surface vehicle actuator, comprising an electrohydraulic actuator having a servo control cylinder, a pump for pressure fluid action on the servo control cylinder as well as an electric motor for the actuation of the pump, with the electric motor having a liquid cooling. In accordance with the invention, the actuation device is characterized in that a leak flow of the pump is guided over a leak passage through the electric motor to cool the electric motor.

Owner:LIEBHERR AEROSPACE LINDENBERG

Electric compressor

An electric turbo compressor is an air compressor to be used in a fuel cell system, and includes a housing comprised of a compression casing, a motor casing, and a canceller casing, and the housing houses therein an impeller, a rotary shaft, a thrust canceller (a load cancellation section), and a motor unit. The rotary shaft is supported by a thrust air bearing in its thrust direction, and is axially supported by a radial air bearing in its rotating direction. A thrust load is generated at the rotary shaft when the number of rotations of the impeller increases. The pressure of the compressed air acts to the pressure chamber from the compressed air lead-out section of the compression casing via the compressed air passage, and this pressure acts on the canceller flange of the canceller shaft so as to generate a load towards the rear of the rotary shaft. Therefore, the thrust load is cancelled out.

Owner:HONDA MOTOR CO LTD

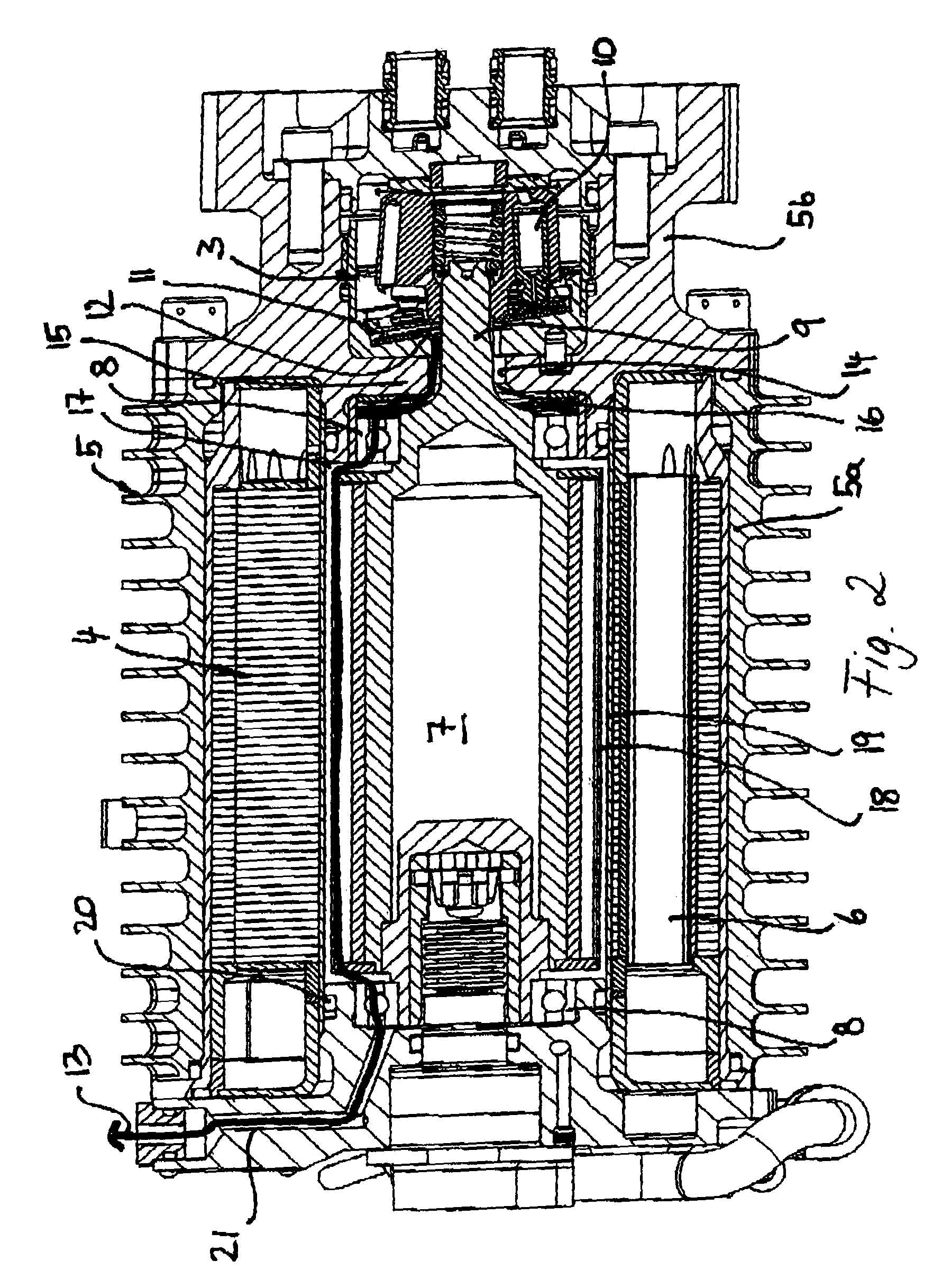

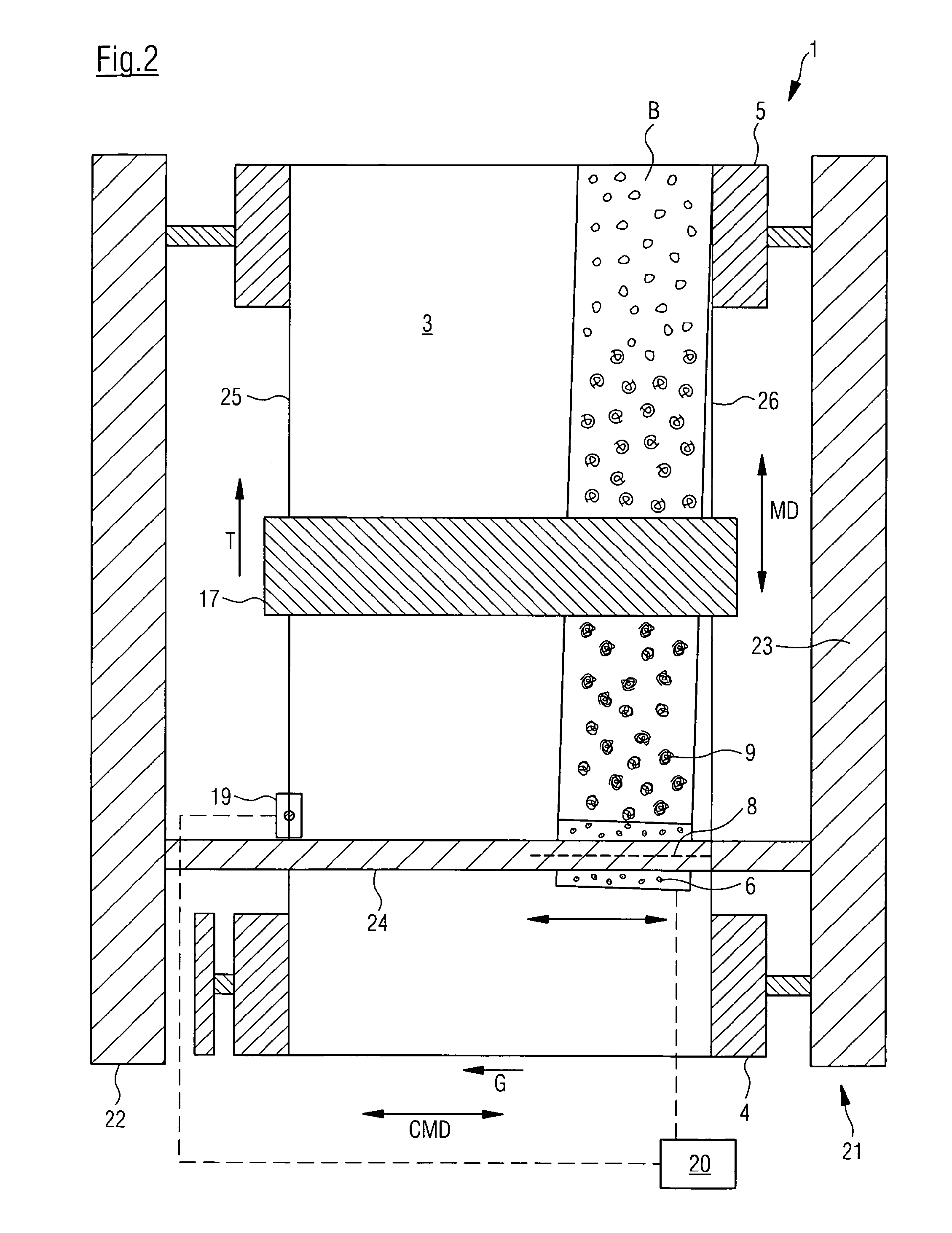

Method for producing a pattern on a continuous strip

InactiveUS20110250355A1Reduced form requirementsAccurate rotation positioningMachine wet endCoatingsTransverse orientationEngineering

A method for producing a polymer topographic pattern on a continuous strip which has a longitudinal orientation and transverse orientation perpendicular thereto. The pattern is applied to an area of the continuous strip to be imprinted by means of an application device moving in relation to the strip in a basic movement which is parallel to the transverse orientation of the strip to produce the pattern. During production of the pattern, the position of the continuous strip parallel to its transverse orientation, relative to a stationary reference position, is measured and the position of the application device is changed by a correction movement parallel to the transverse orientation of the continuous strip when the position of the continuous strip parallel to its transverse orientation is changed, the correction movement being superimposed to the basic movement.

Owner:VOITH PATENT GMBH

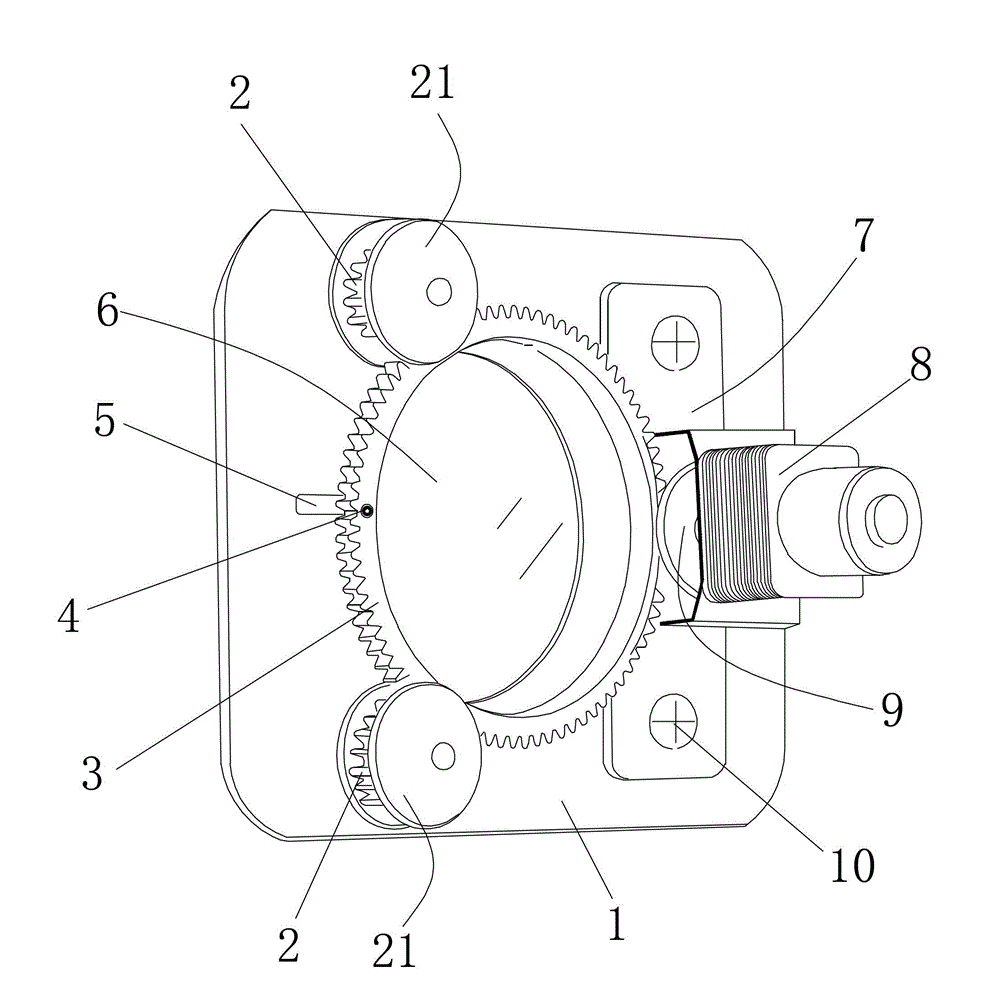

Integral multifunctional positioning transmission mechanism

ActiveCN102269238AEasy to adjustAccurate rotation positioningGearboxesToothed gearingsControl theoryScrew thread

The invention relates to an integral type multifunctional locating transmission mechanism which comprises a support shell with an output shaft, a shaft worm and a hollow worm, wherein a level transmission mechanism and a vertical transmission mechanism are both arranged in the support shell, and a vertical transmission worm connected with the output shaft penetrates out of the outer support shell; and the shaft worm and the hollow worm are mutually plugged, the shaft worm is connected with the hollow worm through a power locking outside the hollow worm, the two ends of the vertical transmission worm and the support shell are respectively provided with a bearing, one side of each bearing is provide with an interval adjusting nut, and the interval adjusting nut is in thread connection with the support shell. The transmission mechanism provided by the invention has the advantages that the defect of the complex axial interval adjustment in the prior art is overcome, the level transmission part and the vertical transmission part are arranged in the support shell, thereby realizing the omnibearing 360 degrees accurate rotate locating; the structure is compact, the anti-upsetting moment is strong, the transmission ratio is large, the return difference is low, the transmission interval adjustment is convenient, and the service life is long.

Owner:ZHEJIANG HENGFENGTAI REDUCER MFG

Automatic feeding, positioning and punching device

ActiveCN105363885AAccurate rotation positioningReduce positioning errorsMetal-working feeding devicesPositioning devicesNumerical control systemEngineering

The invention provides an automatic feeding, positioning and punching device which comprises a body base, a transmission shaft, a rack, an upper die plate, a male die, a female die, a positioning block, a ratchet and a ratchet shaft, wherein the body base is an L-shaped rack; the upper die plate capable of moving up and down is mounted at the top of the body base; and the rotatable transmission shaft is mounted in the middle of the body base in the same direction as the upper die plate. Through the ratchet and an index plate structure, a part can move equidistantly in the circumferential direction by virtue of back and forth movement of a punch and mechanical transmission switching, machining the part at a required position is ensured, the part is rotated and positioned accurately, the positioning error is small, the degree of overall automation is high, the machining process doesn't need to be controlled manually, the part can be machined continuously until all holes are finished in sequence, and the problems of high worker learning cost and high maintenance cost caused by the reason that rotation is controlled by a numerical control system are solved.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Rotary welding workbench

InactiveCN104128719AAccurate rotation positioningGuaranteed welding consistencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a rotary welding workbench and relates to the technical field of welding devices. The rotary welding workbench comprises a support and a rotation driving device controlled by a controller. The support comprises two oppositely arranged uprights which are hinged with rotary arms, the rotation driving device is mounted on one of the uprights, an output shaft of the rotary driving device is connected with the rotary arms, and two welding workbenches are mounted at two ends of the rotary arms and between the rotary arms. Compared with the prior art, the rotary welding workbench adopting a double-station rotary workbench mechanism is capable of welding and dismounting parts and is high in welding efficiency and equipment utilization rate.

Owner:柳州万众汽车部件有限公司

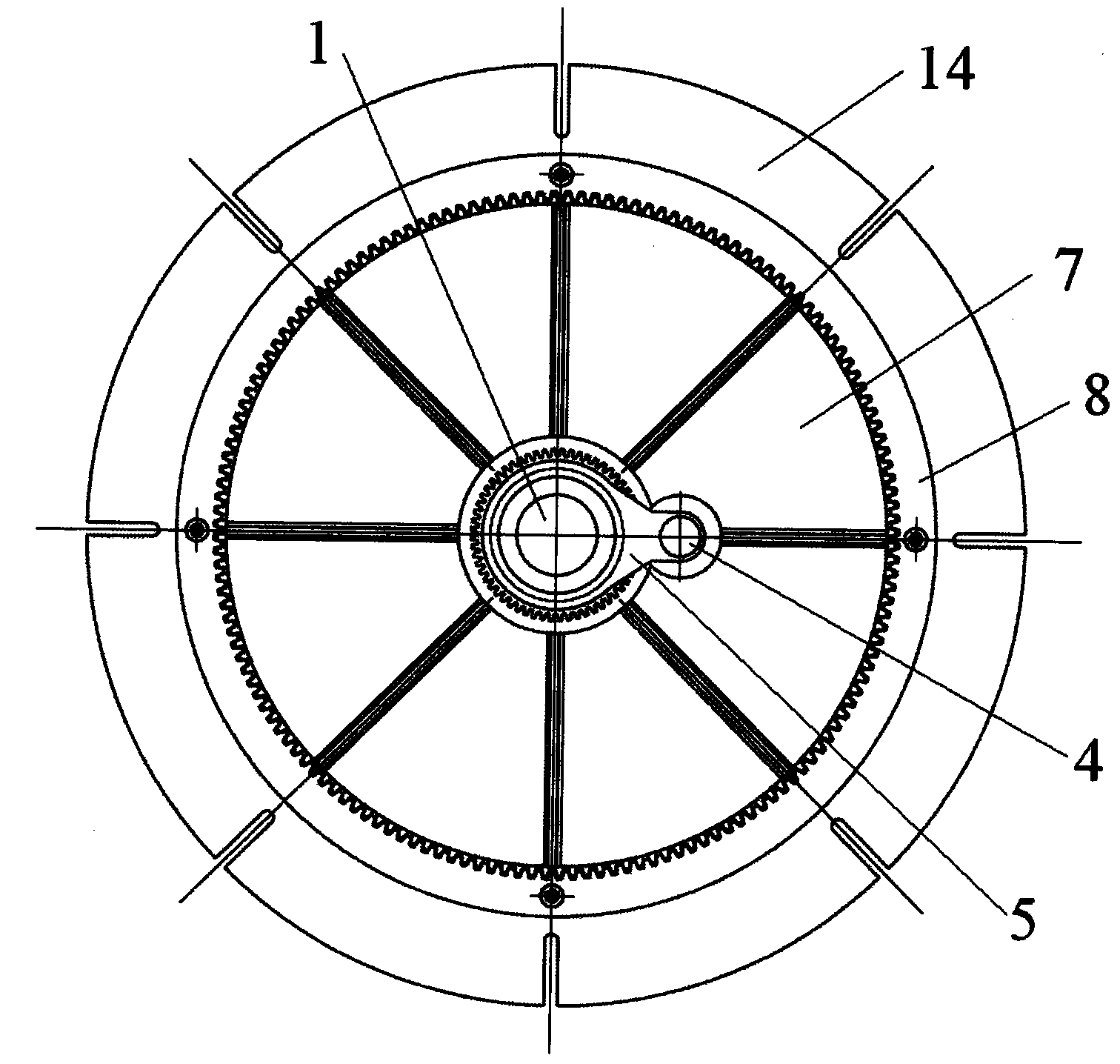

Rotary and rapid positioning device

ActiveCN103894855AQuick rotation positioningAccurate rotation positioningPrecision positioning equipmentMetal working apparatusNeedle roller bearingMachine parts

The invention discloses a rotary and rapid positioning device. The rotary and rapid positioning device is characterized by comprising a positioning central spindle, wherein the positioning central spindle is arranged in the center of a base and sleeved with a rotary ring, a small ring gear of the rotary ring is in contact connection with a lower pressing circle through a roller needle bearing, a large ring gear of the rotary ring is in contact connection with a roller needle, the roller needle is connected with a supporting block on the base, a positioning ring gear is arranged on the outer side of the large ring gear of the rotary ring, the positioning ring gear is connected with the base through a hydraulic jack, and the large ring gear is matched with the positioning ring gear. The rotary and rapid positioning device has the advantages of being simple in structure, low in manufacturing cost, convenient to operate, high in production and machining efficiency and the like, and can clamp and position large-scale boring mill and drilling machine parts and rapidly and accurately position workpieces in a rotating mode. The product machining precision is determined by the number of teeth of the rotary ring. Whether an electric transmission mechanism needs to be added or not is judged according to actual use demands. The rotary and rapid positioning device has high practicability and can be brought into use in manufacturing shops on a large scale.

Owner:SHANGHAI BOILER WORKS

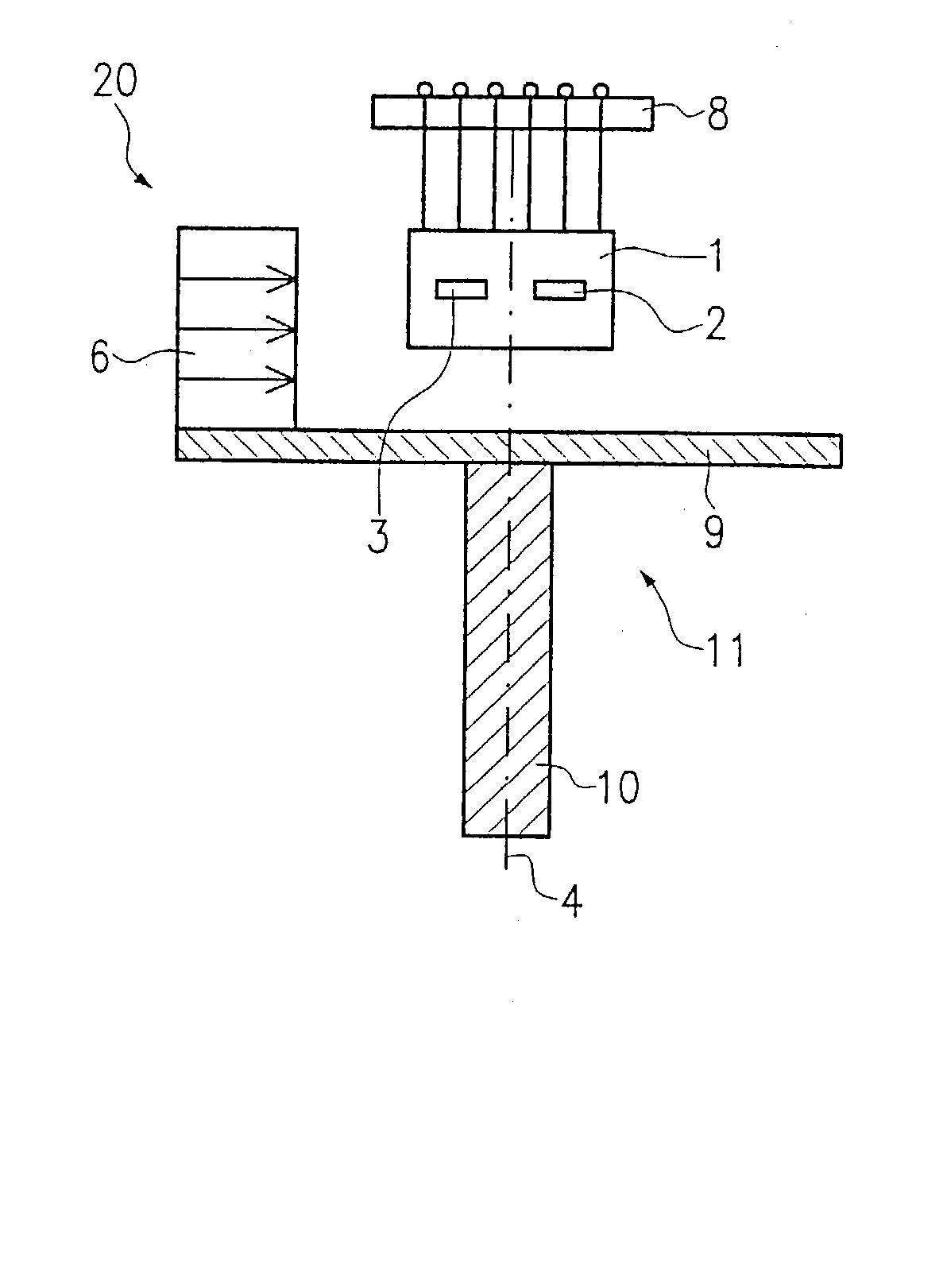

Measuring device for detecting a rotation angle in a contactless manner

InactiveUS20030141863A1Simple designAccurate rotation positioningSolid-state devicesMagnetic field measurement using galvano-magnetic devicesMeasurement deviceMeasuring instrument

A measuring instrument (10) for contactless detection of an angle of rotation comprises a magnetically nonconductive rotor (11), on which a magnet (6) is disposed, and a stationary magnetically sensitive element (1) for generating a measurement signal. The magnetically sensitive element (1) has two sensitive faces (2, 3) spaced apart by a distance (x).

Owner:ROBERT BOSCH GMBH

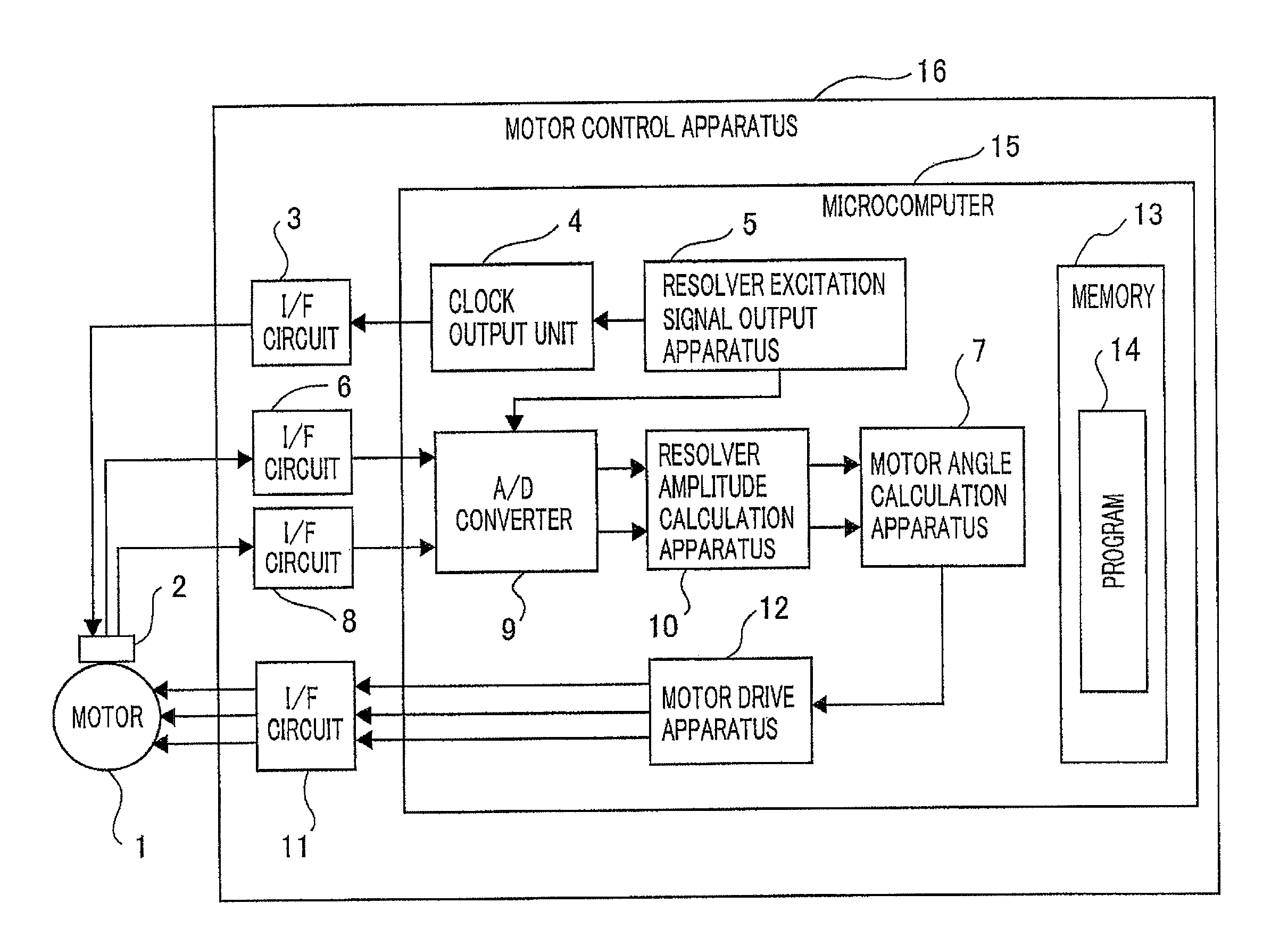

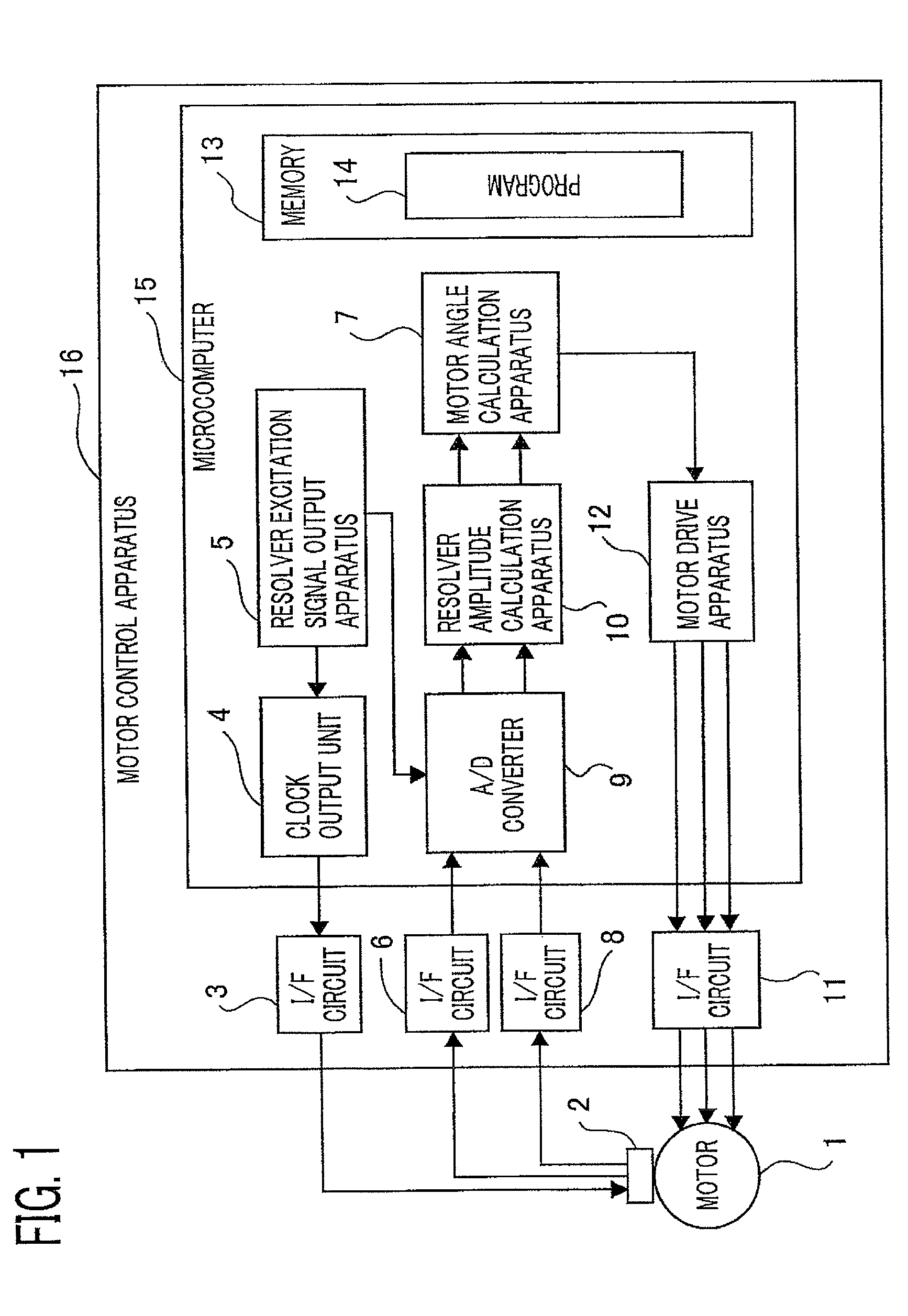

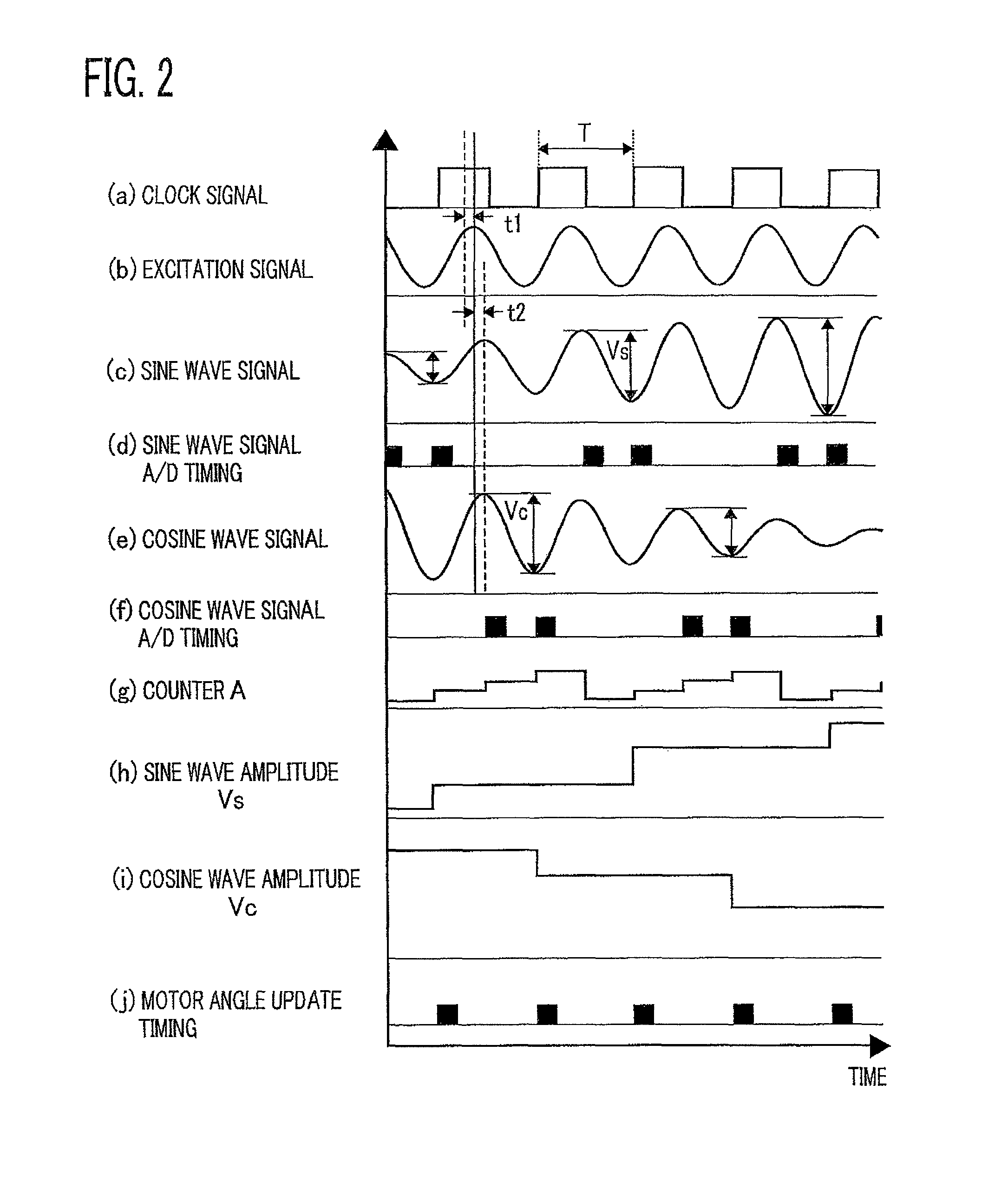

Brushless motor rotation-position detection system

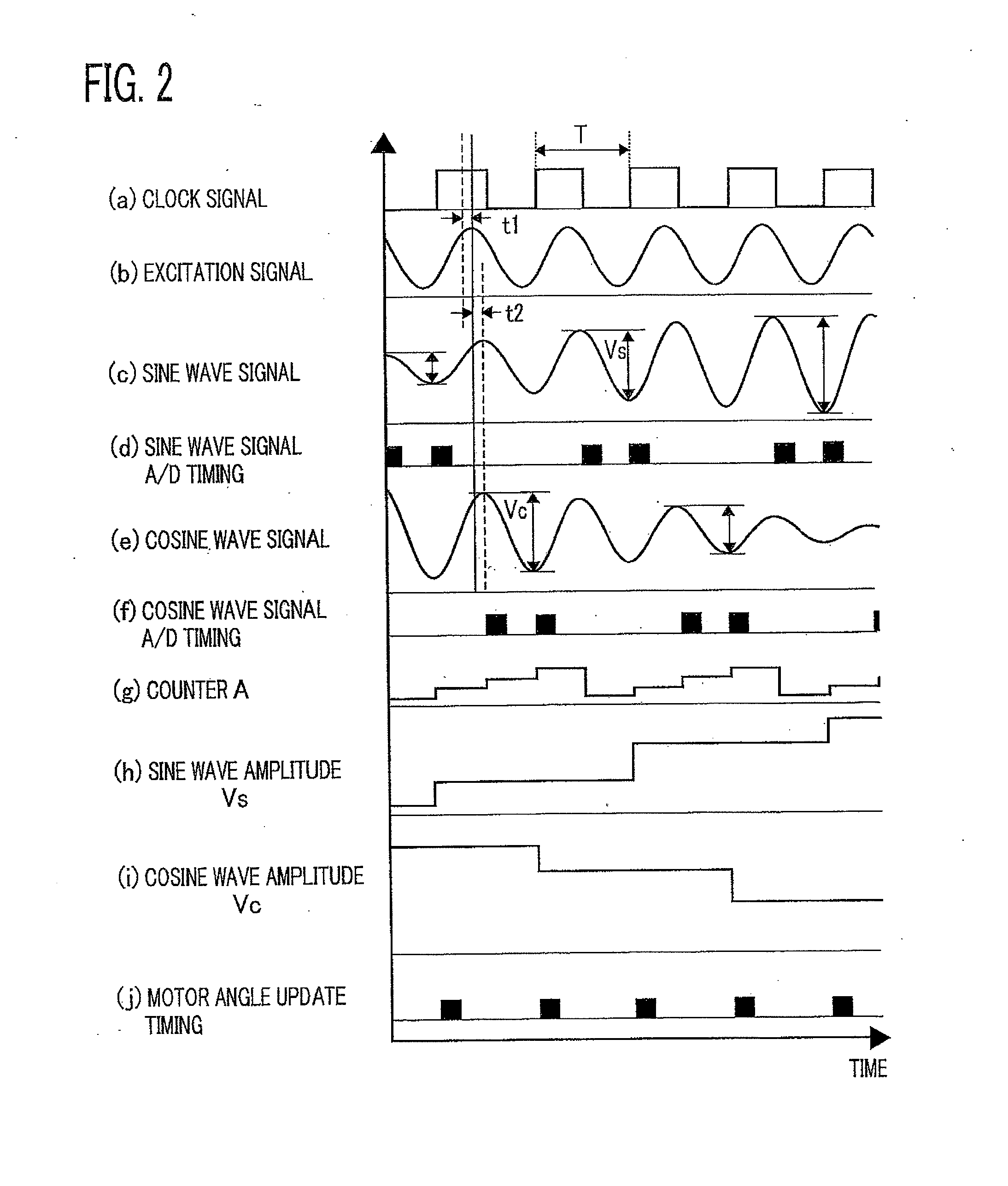

ActiveUS20110254479A1Accurate rotation positioningSimply and inexpensively configuredAnalogue/digital conversionElectric signal transmission systemsLocation detectionBrushless motors

A rotation-position detection system according to the present invention is configured with a resolver mounted in a brushless motor and a motor controller. The motor controller outputs an excitation signal to the resolver and an A / D converter thereof alternately applies analogue / digital conversion to a sine wave signal and a cosine wave signal outputted from the resolver so that a rotation position of the motor is calculated.

Owner:MITSUBISHI ELECTRIC CORP

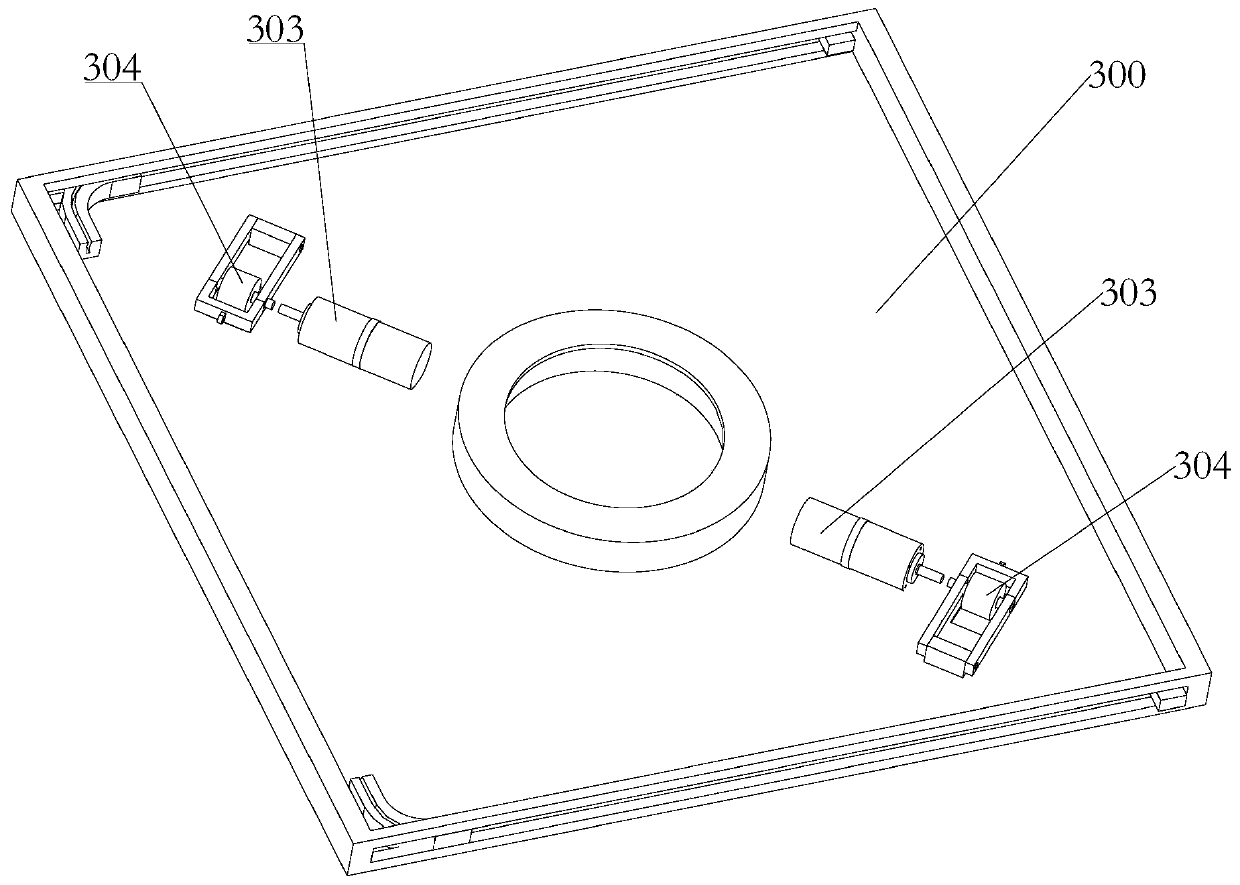

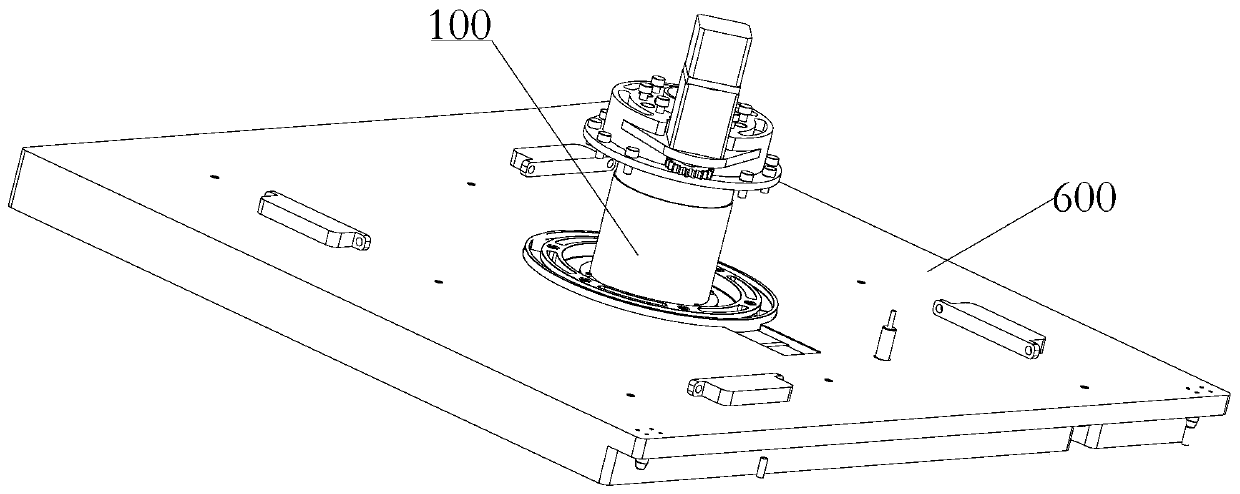

Mutual-inspection-type exposure device outside material cabin

ActiveCN111089863ARealize data collectionAccurate rotation positioningWeather/light/corrosion resistanceMaterial analysis by optical meansExposureTest chamber

The invention relates to a mutual-inspection-type exposure device outside a material cabin. The mutual-inspection-type exposure device includes an exposure device body I and an exposure device body IIwhich are arranged at intervals, both of the exposure device body I and the exposure device body II include force bearing mechanisms, bases and rotating mechanisms; a plurality of test boxes and optical inspection devices are installed on the force bearing mechanisms, the test boxes are arranged around the force bearing mechanisms correspondingly, the test boxes are correspondingly enclosed to form optical inspection channels communicating with the outsides of the force bearing mechanisms, and the optical inspection devices are installed in the optical inspection channels; the force bearing mechanisms are installed in the middles of the upper parts of the bases and can rotate relative to the bases; the rotating mechanisms are installed between the bases and the force bearing mechanisms for driving the force bearing mechanisms and the test boxes thereon as well as the optical inspection devices to rotate relative to the bases; and when the exposure device body I rotates, the optical inspection device on the exposure device body II performs optical inspection on the exposed surface of the test box on the exposure device body I. According to the mutual-inspection-type exposure device, the two exposure device bodies can be used to inspect each other.

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

Brushless motor rotation-position detection system

ActiveUS8541964B2Accurate rotation positioningSimply and inexpensively configuredAnalogue/digital conversionElectric signal transmission systemsBrushless motorsBuck converter

A rotation-position detection system according to the present invention is configured with a resolver mounted in a brushless motor and a motor controller. The motor controller outputs an excitation signal to the resolver and an A / D converter thereof alternately applies analogue / digital conversion to a sine wave signal and a cosine wave signal outputted from the resolver so that a rotation position of the motor is calculated.

Owner:MITSUBISHI ELECTRIC CORP

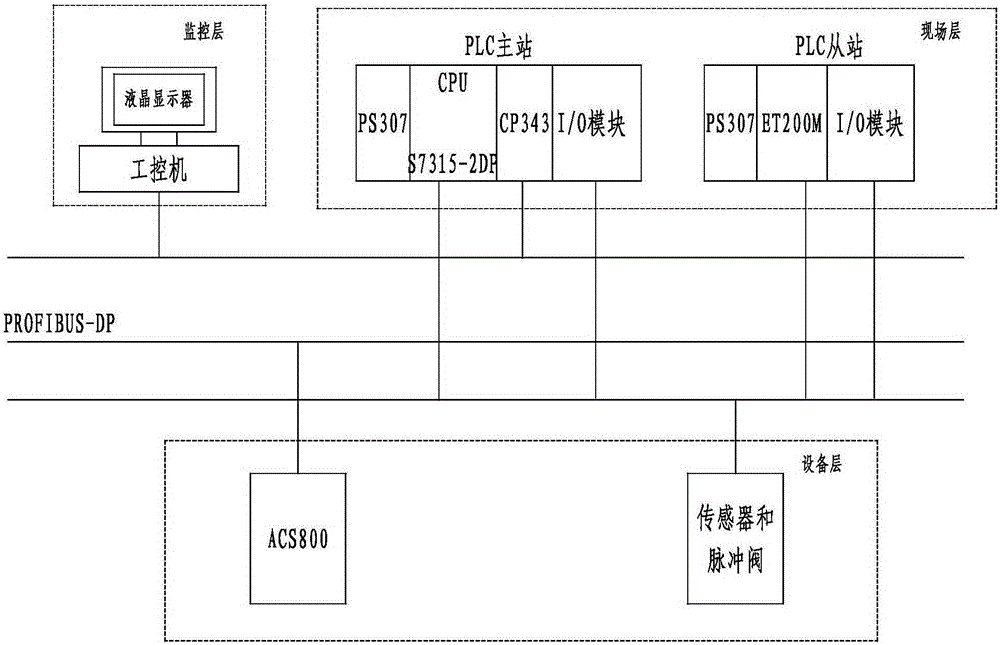

Electronic control system for dust blowing and sucking equipment rotary frame

InactiveCN105334835AAvoid bruisesAccurate rotation positioningPreparing sample for investigationTotal factory controlIndustrial EthernetElectronic control system

The invention discloses an electronic control system for a dust blowing and sucking equipment rotary frame. The electronic control system comprises an equipment layer, a field layer and a monitoring layer. The equipment layer comprises a speed sensor and a frequency converter, and the frequency converter is provided with an absolute value encoder. The field layer comprises a PLC. The PLC comprises a PLC master station and a PLC slave station. The PLC master station comprises an S7 315-2DP controller, a CP343-1 Ethernet communication module and a master station I / O module. The PLC slave station comprises a siemens ET200M and a slave station I / O module. The monitoring layer comprises an industrial personal computer and a touch screen. The industrial personal computer is connected with the touch screen through a data line and carries out data exchange with the CP343-1 Ethernet communication module through an industrial Ethernet. The frequency converter is connected with the S7 315-2DP controller and the siemens ET200M through a profibus. The speed sensor is connected with the master station I / O module and the slave station I / O module through shielding cables.

Owner:TIANJIN SERI MACHINERY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com