Integral multifunctional positioning transmission mechanism

A transmission mechanism and multi-functional technology, which is applied in the direction of transmission box, transmission device, gear transmission device, etc., can solve the problems of high processing cost of ball screw, increase of friction force of worm gear and worm gear, difficult processing, etc., and achieve the adjustment of transmission gap Convenience, strong anti-overturning moment and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

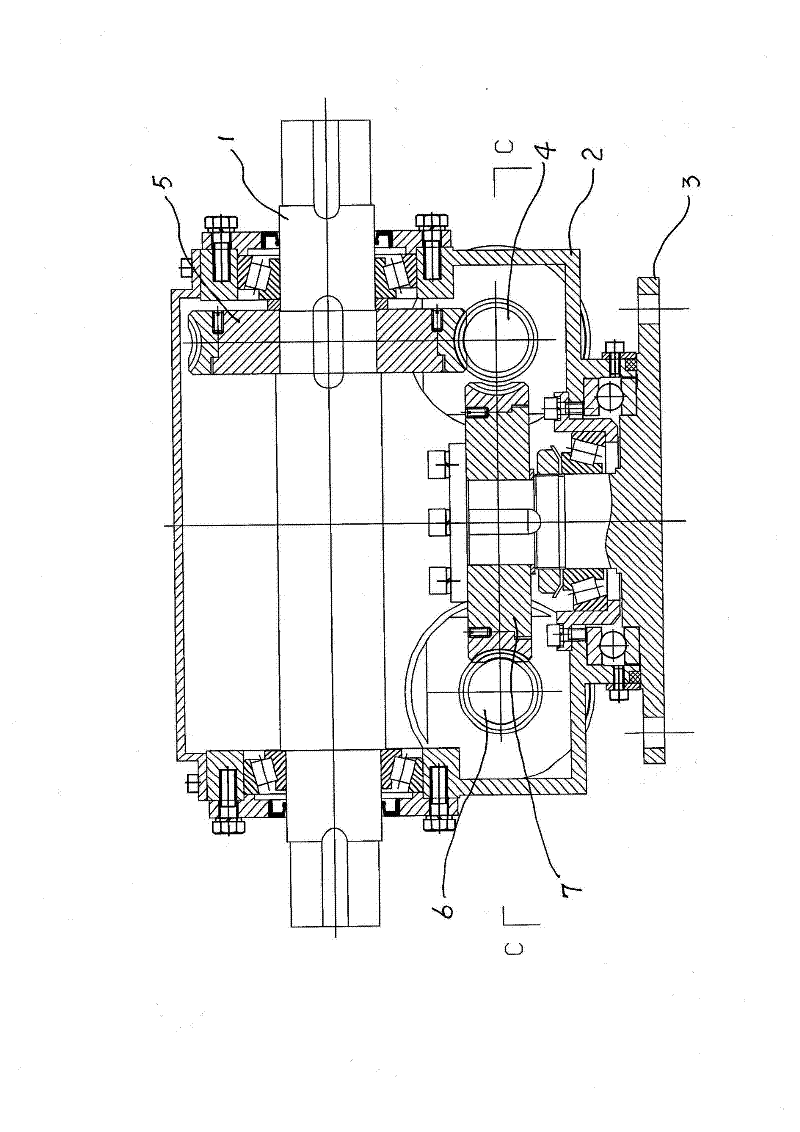

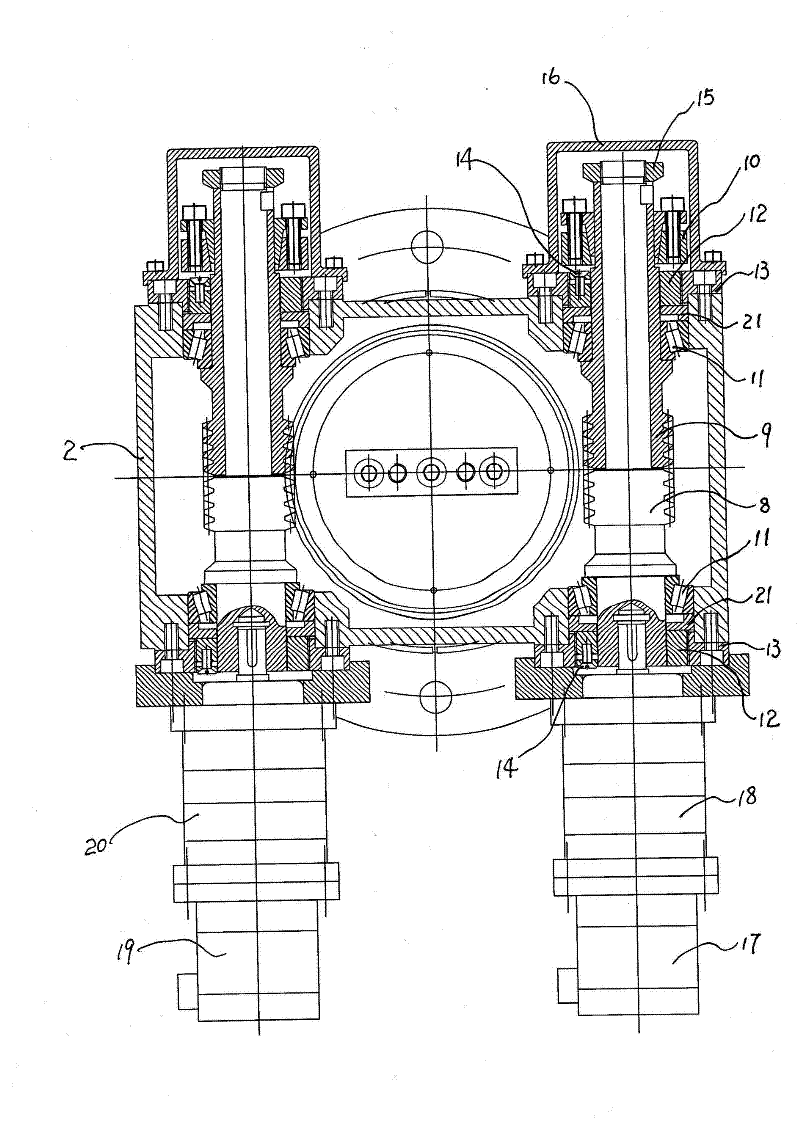

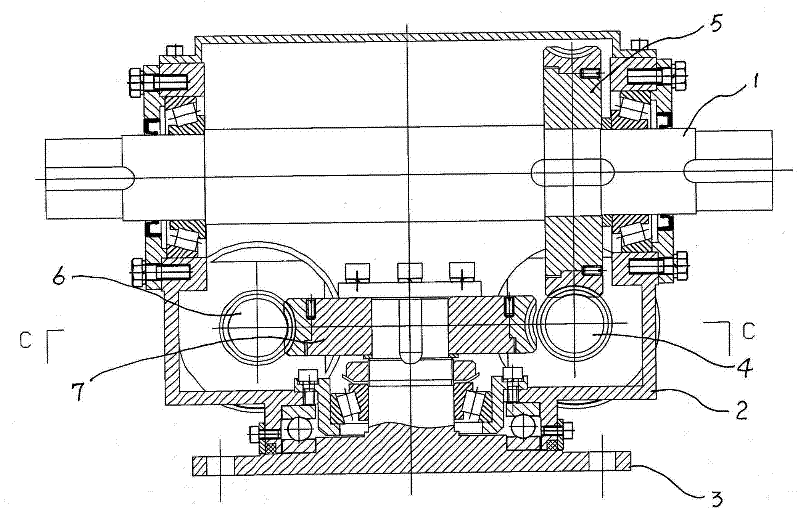

[0013] As shown in the figure, the present invention includes a bracket housing 2 with an output shaft 1, a horizontal transmission mechanism for controlling the horizontal rotation of the bracket housing 2 supported on the fixed seat 3, and a control output shaft 1 relative to the horizontal rotation direction of the bracket housing 2 The vertical transmission mechanism of vertical rotation, the horizontal transmission mechanism and the vertical transmission mechanism adopt the worm gear transmission mechanism, the horizontal transmission mechanism and the vertical transmission mechanism are both arranged in the bracket shell 2, the vertical transmission worm 4 is arranged on the side of the horizontal transmission worm wheel 7, and the horizontal transmission mechanism The transmission worm wheel 7 meshes with the horizontal transmission worm 6, the vertical transmission worm wheel 5 and the horizontal transmission worm wheel 7 are distributed at ninety degrees, and the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com