Electromagnetic valve with hard sealing structure

A hard seal and solenoid valve technology, applied in the field of solenoid valves, can solve problems such as difficult sealing and easy leakage, and achieve the effects of avoiding seal failure, increasing service life and improving assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

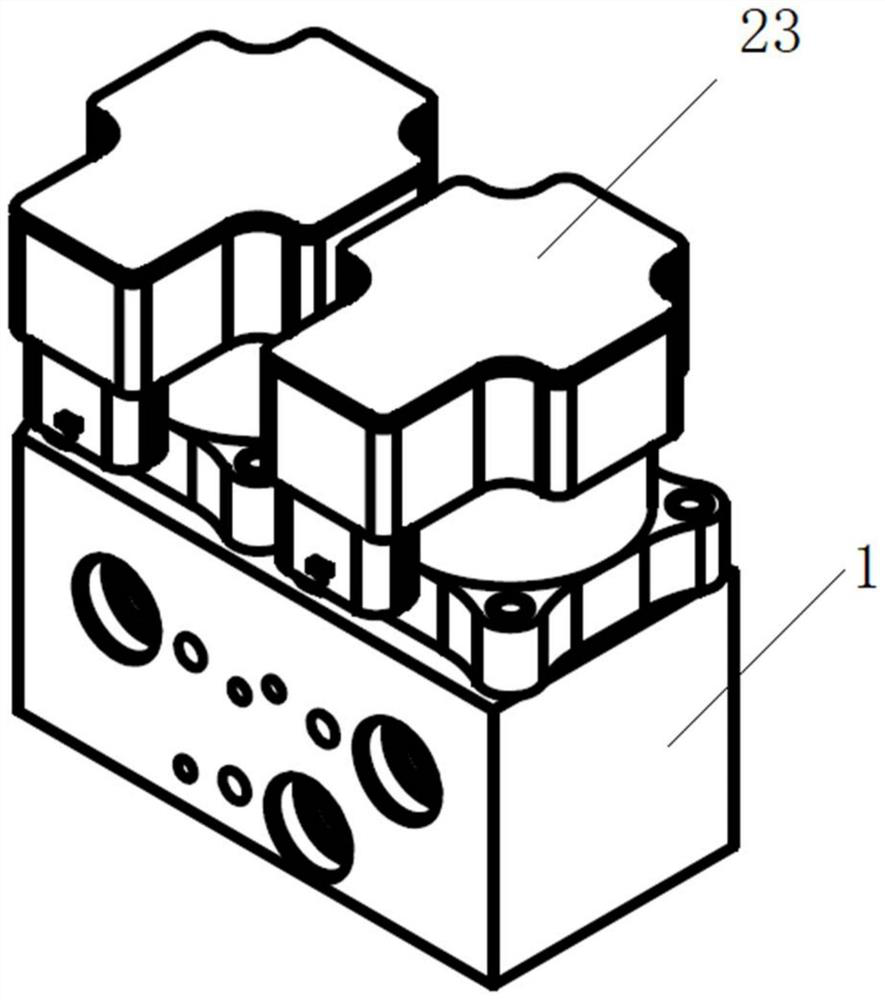

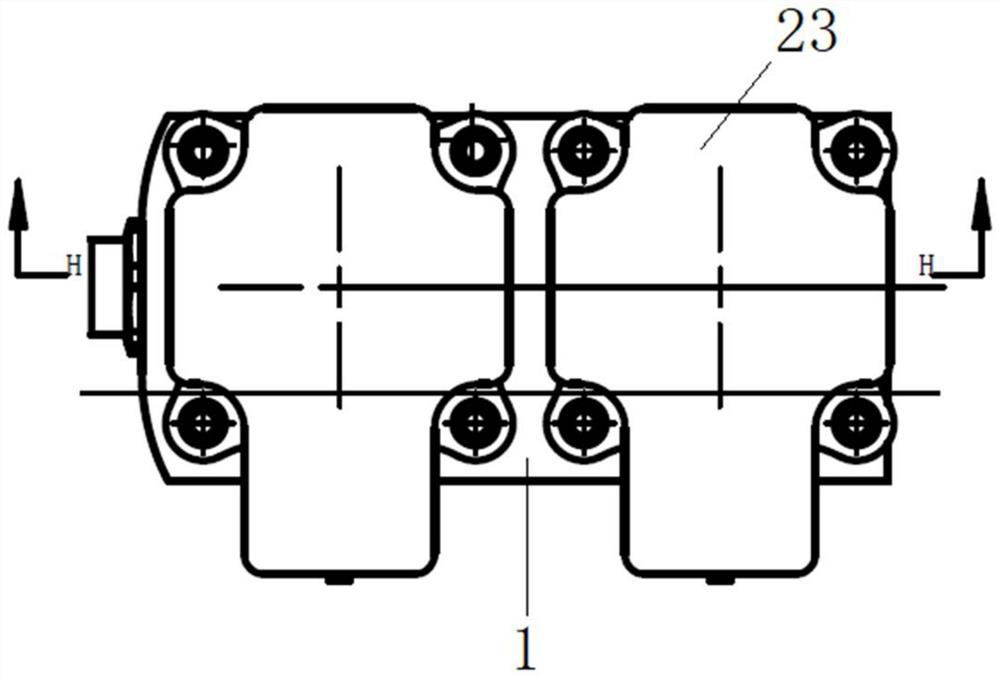

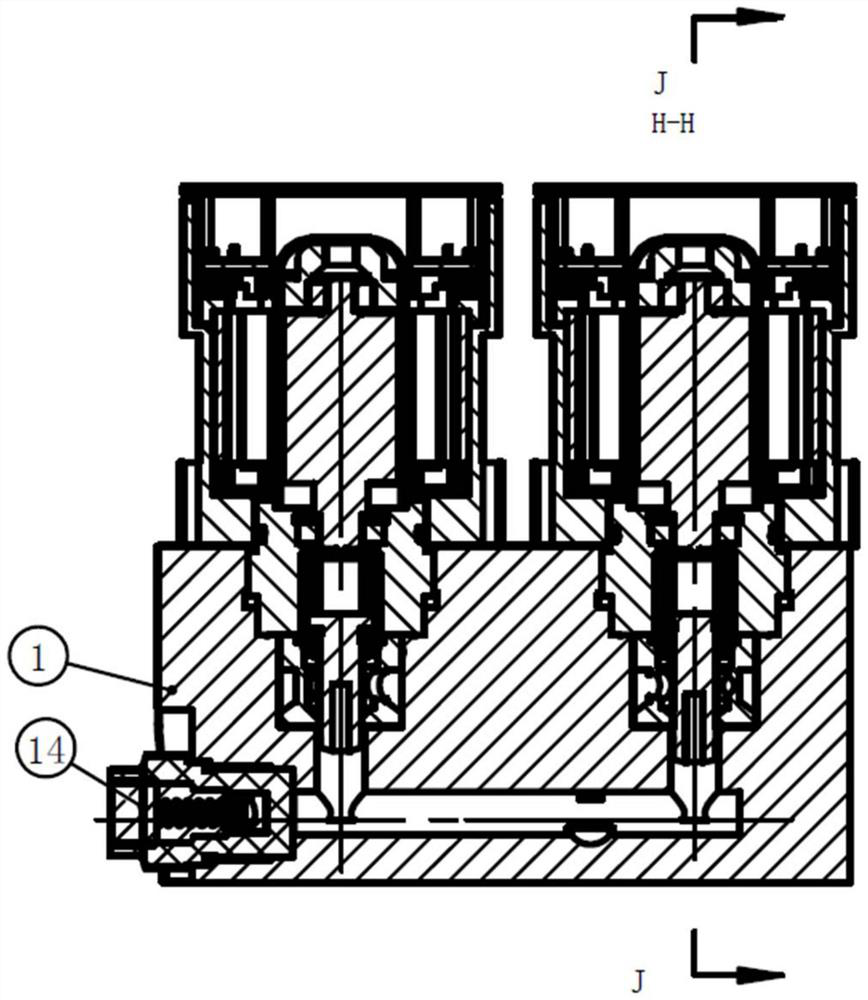

[0047] A solenoid valve with a hard seal structure, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5As shown, it includes valve body 1, liquid inlet seat 3, rotor mounting seat 4, valve core 5, screw rod 6, rotor 7, lower bearing 8, upper bearing 9, bearing housing 10, sealing case 11, stator 12, stator Control board 13, pressure relief valve 14, stator housing 23 and other valve components.

[0048] Such as Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, the valve body 1 is provided with a first accommodation chamber 101, a second accommodation chamber 102, a longitudinal passage 103, a first transverse passage 104, a second transverse passage 105, and a third transverse passage 106; A transverse passage 104 communicates with the longitudinal passage 103, the first accommodation chamber 101 and the second accommodation chamber 102 are communicated with the longitudinal passage 103 through respective vertical passages, the end of the longitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com