Automatic adjusting and sealing mechanism for uplift riser tube of antigravity casting machine

An anti-gravity casting and automatic adjustment technology, which is applied in the field of sealing mechanism, can solve the problem of sealing failure of the riser pipe, and achieve the effect of reliable operation, simple mechanism structure and overcoming the problem of sealing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

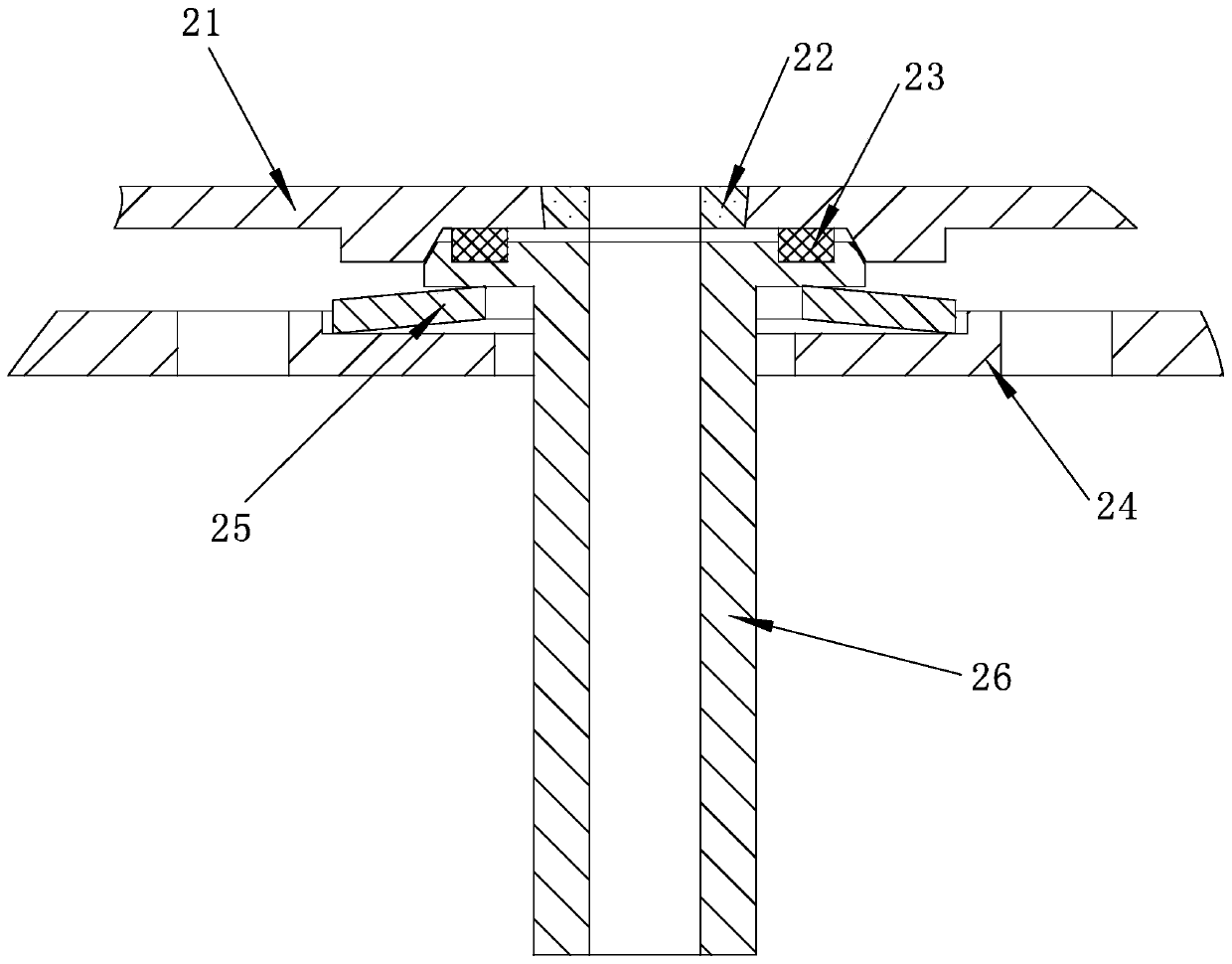

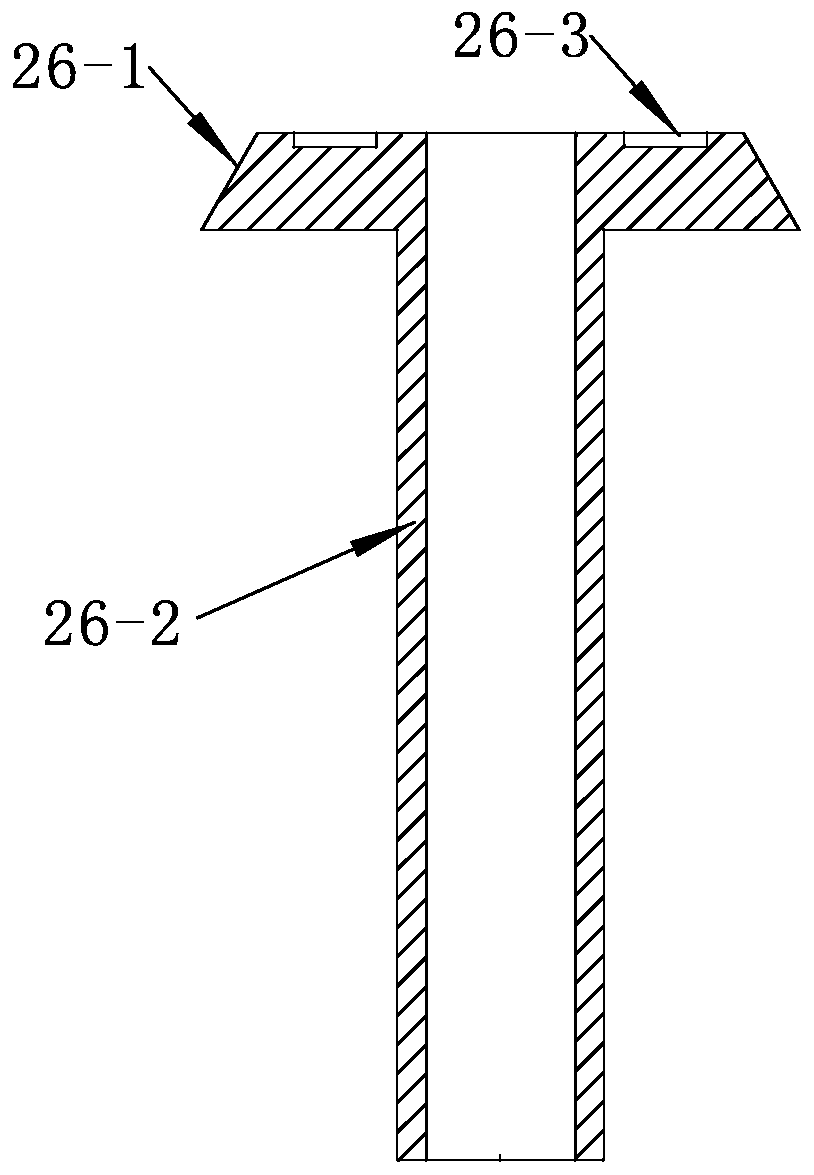

[0020] Such as figure 1 As shown, the upper top type riser pipe of the anti-gravity casting machine automatically adjusts the sealing mechanism, which includes a riser pipe 26 and a middle partition 21, and the riser pipe 26 is mainly composed of a flange 26-1 and a pipe body 26-2 from top to bottom. Made into one; it also includes a gasket 23, a riser support plate 24 and an elastic element 25;

[0021] The middle part of the riser support plate 24 is processed with an insertion hole 24-3, and the upper end surface of the riser support plate 24 is arranged with an elastic element 25 with a through hole, and the pipe body 26-2 is passed through the insertion hole. 24-3 and the through hole of the elastic element 25, and the pipe body 26-2 is fixedly connected to the support plate 24 of the riser pipe, the flange 26-1 is in contact with the elastic element 25, and the middle partition 21 is inserted Installed on the upper end surface of the flange 26-1, the intermediate partit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com