Flow cell ion exchange membrane assembly, preparing method of flow cell ion exchange membrane assembly and flow cell comprising flow cell ion exchange membrane assembly

A technology of ion exchange membrane and flow battery, which is applied in the field of flow battery, can solve problems such as sealing failure, achieve the effect of avoiding sealing failure, reducing processing cost and assembly difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

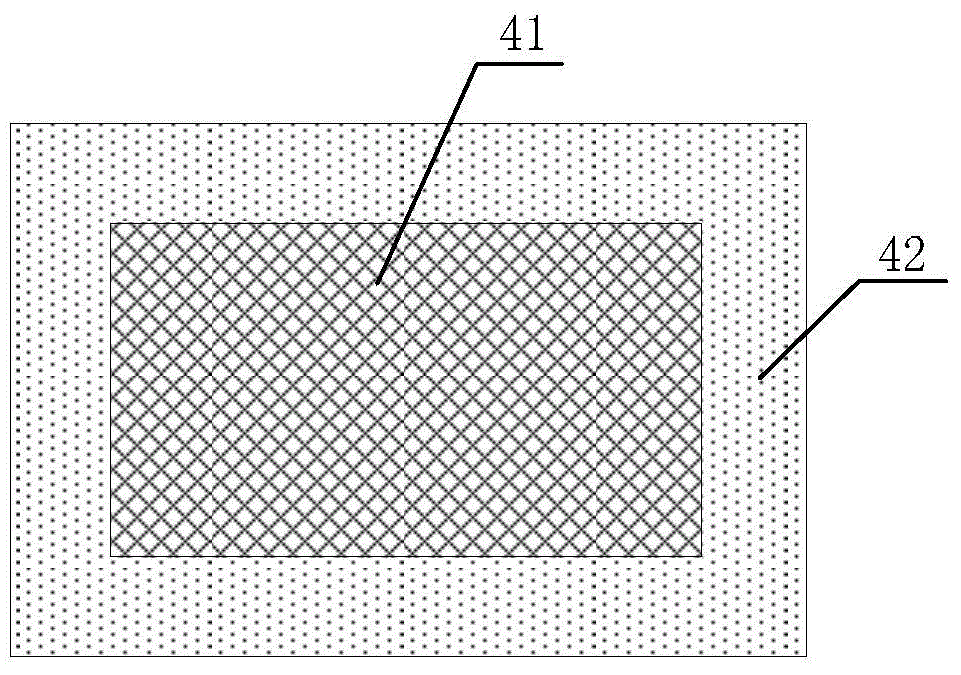

[0034] According to a typical embodiment of the present invention, the porous membrane is an organic porous membrane, such as polytetrafluoroethylene, polyvinylidene fluoride, polysulfone, polyimide, polypropylene, polyethylene, polyaryletherketone, or polyether Porous membranes made of sulfone and other materials. The porous membrane provides a supporting framework for the integrated ion-exchange membrane module, so that the ion-exchange tree area coating and the sealing coating are combined into one. At the same time, the porous membrane framework also plays a role of mechanical reinforcement, which can reduce the amount of coating resin. Thereby reducing production costs. The porous membrane has an upper surface, a lower surface and a plurality of penetrating holes, such as figure 2 As shown, the ion exchange zone coating 41 is formed by coating the ion exchange resin in the hole in the middle region of the porous membrane, the upper surface and / or the lower surface; the ...

Embodiment 1

[0052] Raw materials: PTFE (polytetrafluoroethylene) porous membrane with a thickness of 50mm and a pore diameter of 0.1-0.3mm is used as the organic porous membrane matrix, 10wt% PTFE emulsion is used as the sealing resin solution, and 5wt% Nafion (perfluorosulfonic acid) solution It is an ion exchange resin solution, and 0.5% surfactant TritonX-100 (polyethylene glycol octyl phenyl ether) is added to the Nafion solution.

[0053] Implementation process: first soak the PTFE porous membrane in isopropanol for 30 minutes, then take it out and let it dry naturally. Clamp the pretreated PTFE porous membrane on the jig, evenly brush the PTFE emulsion on the upper and lower sides of the porous membrane in the sealing area, then put it in an oven, heat-treat at 120°C for 30 minutes to remove the solvent, and then heat up to 300°C Heat treatment at ℃ for 20min to make it solidify, take it out after cooling. Clamp the PTFE porous membrane coated with the sealing material to a specifi...

Embodiment 2

[0055] Raw materials: Polyimide porous membrane with a thickness of 30mm and a pore diameter of 0.2-0.5mm is used as the organic porous membrane matrix, fluororubber is used as the sealing material, and sulfonated polyether ether ketone is used as the ion exchange resin.

[0056] Implementation process: First, add 2% crosslinking agent benzoyl peroxide to fluorine rubber raw rubber, use a double-roller mixer for mixing, and then dissolve the mixed rubber in ethyl acetate to obtain 10% fluorine rubber Rubber glue. Clamp the polyimide porous membrane on the fixture, evenly brush the fluororubber glue on the upper and lower sides of the porous membrane in the sealing area, then perform one-stage vulcanization at 160°C, and then heat up to 250°C for two-stage vulcanization. Remove after cooling. Clamp the polyimide porous membrane coated with the fluororubber sealing material in a specific fixture, and evenly coat the Nafion solution on the upper and lower sides of the porous mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com