Sealing structure for extension end of motor shaft

A technology of sealing structure and motor shaft, which is applied in the direction of engine sealing, electromechanical devices, electrical components, etc., can solve the problems of easy to wear motor shaft, shorten the life of seals, and seals are easily affected by the environment, so as to extend the reliability of sealing , prevent air pressure changes, reduce the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The seal of the existing motor sealing structure is easily affected by the environment, the life of the seal is shortened, and the motor shaft is easy to wear, so the motor needs frequent maintenance, which cannot meet the use requirements.

[0024] In order to solve the problem of short service life of the seals and easy wear of the motor shaft in the existing motor sealing structure, the present invention adopts a double oil seal structure, forming an oil storage space between the two oil seals, and injecting lubricating oil, which can provide oil seals necessary for normal operation. lubricated environment, thereby extending oil seal life and seal reliability.

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

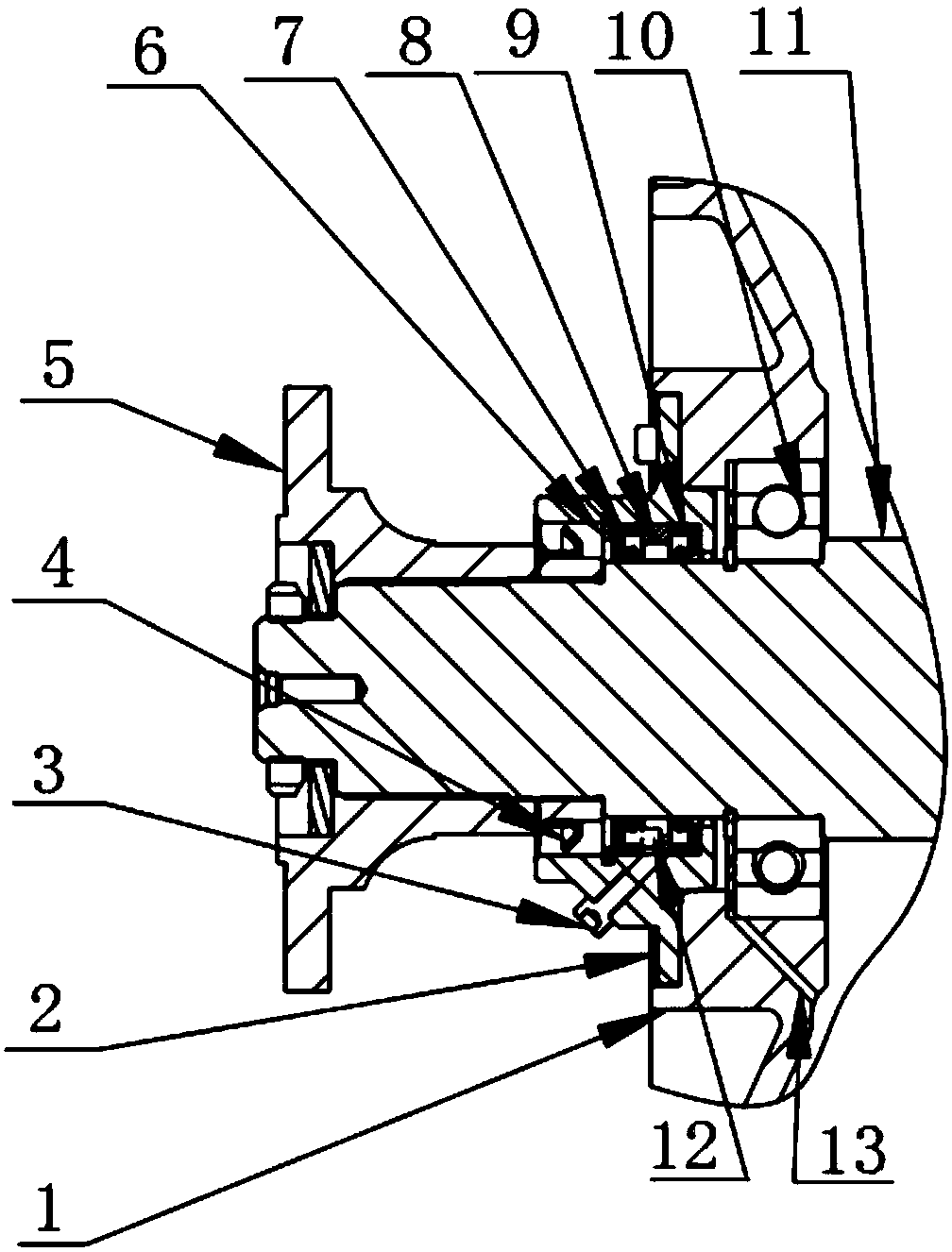

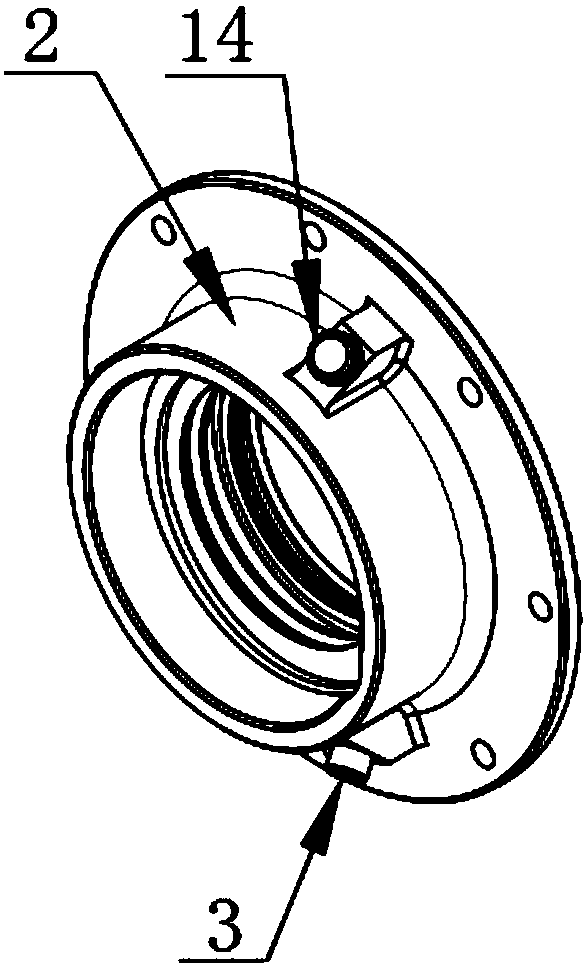

[0026] Such as figure 1 As shown, the sealing structure of a motor shaft en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com