Turbocharger with variable turbine cross section and variable flow control function

A turbocharger and variable flow technology, which is applied to gas turbine devices, machines/engines, internal combustion piston engines, etc., and can solve problems such as single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

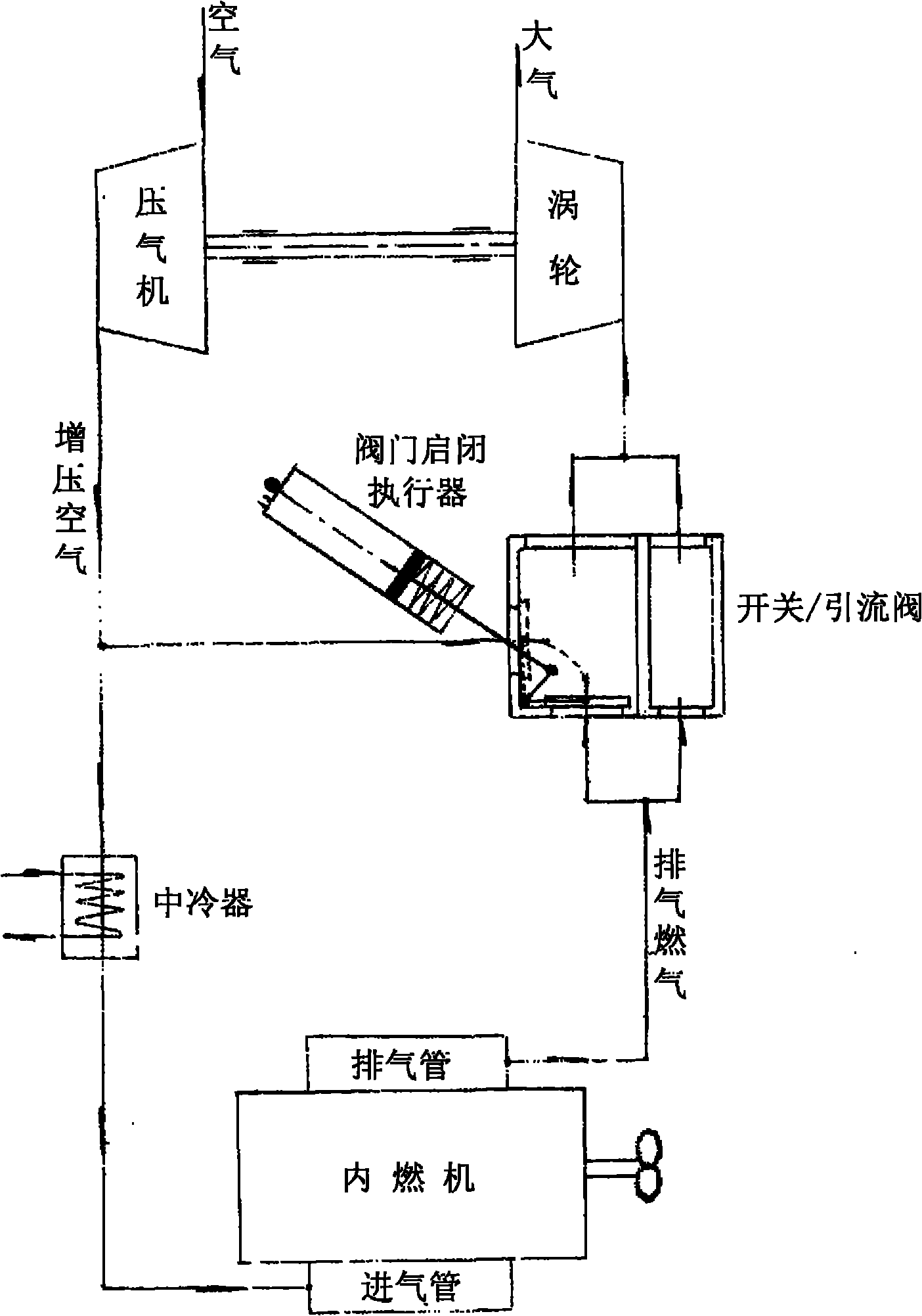

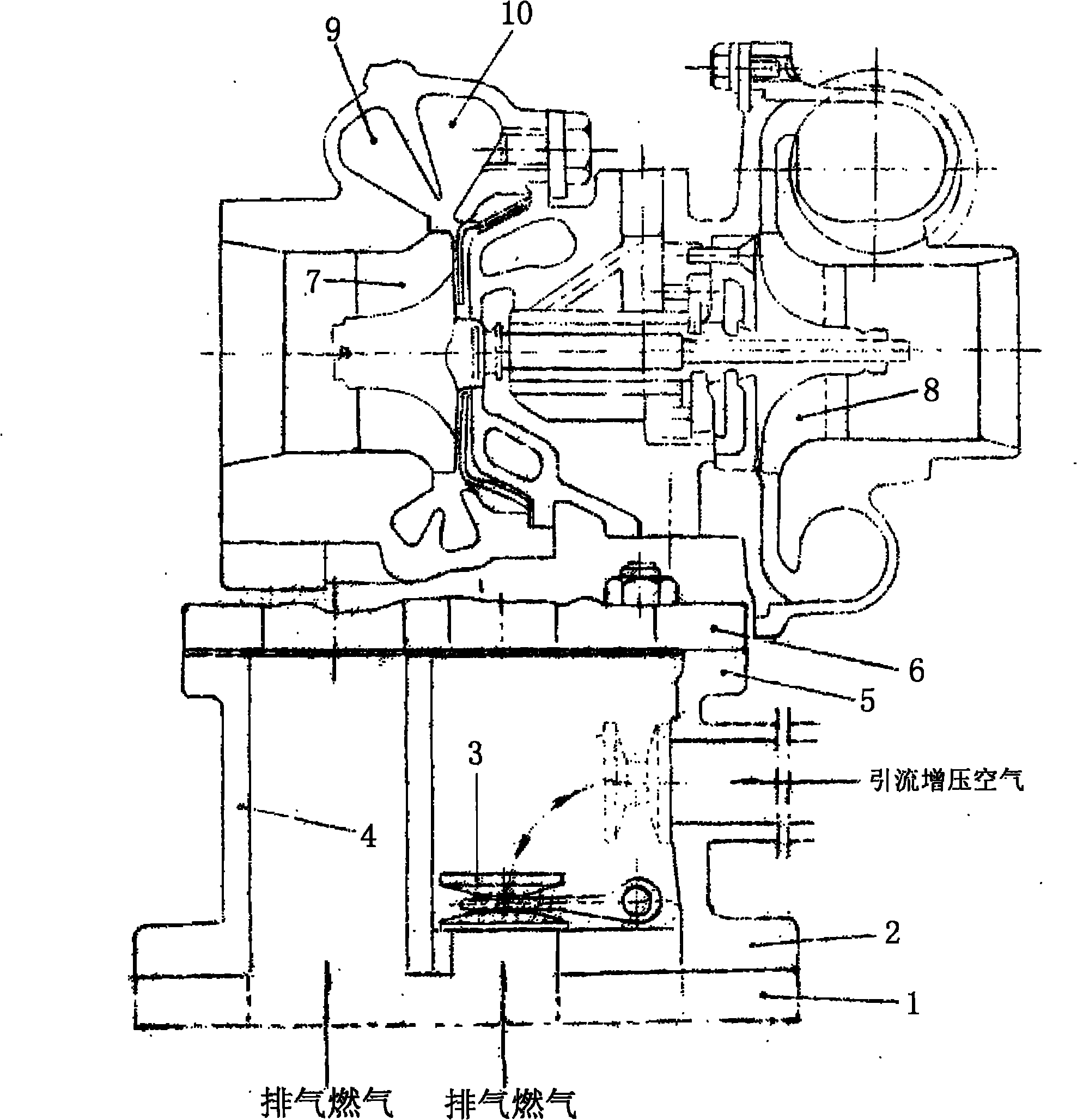

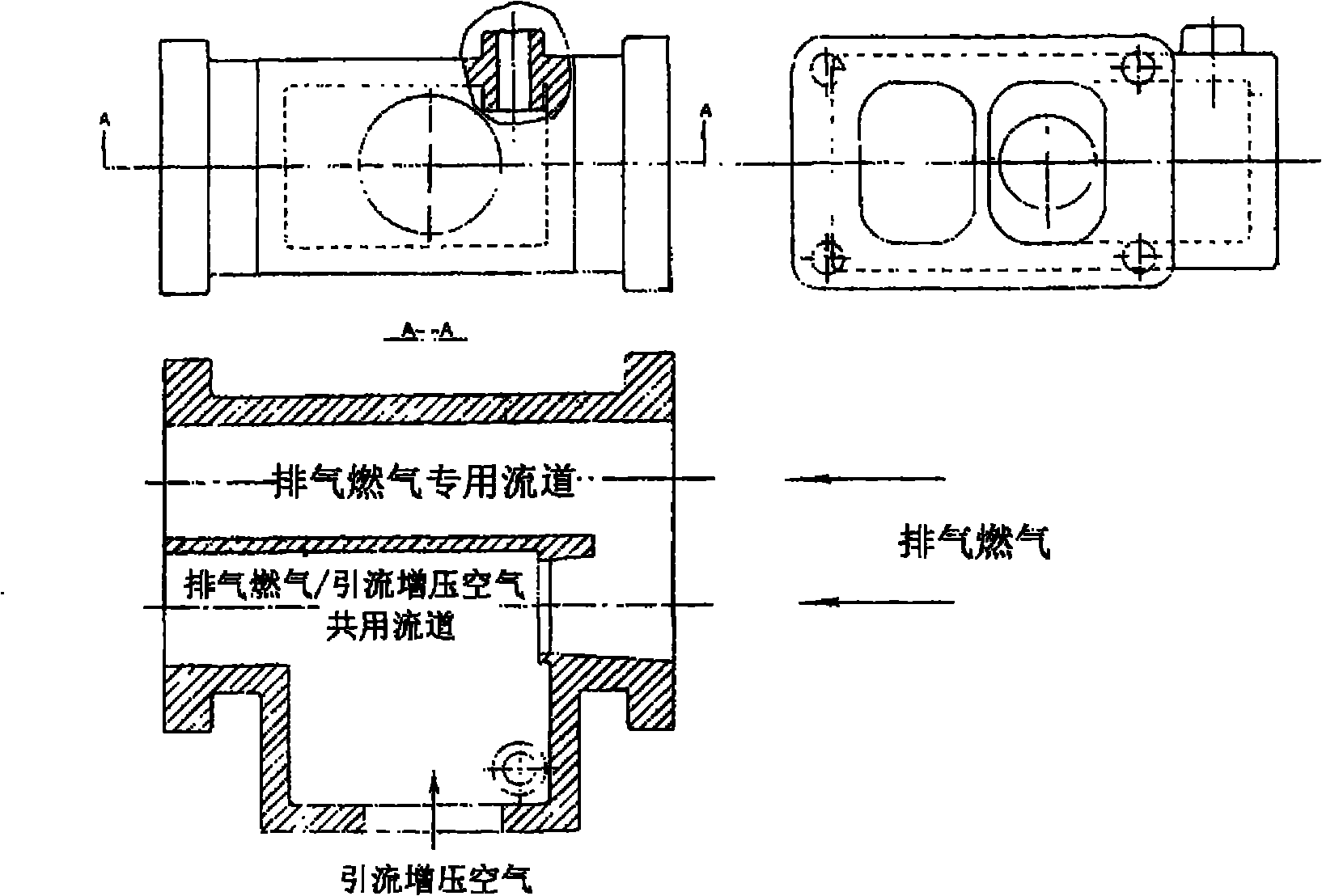

[0029] The typical structure of the turbocharger used by the internal combustion engine of the passenger / truck vehicle in the prior art is a small-diameter (mixer) with a double-channel turbine volute structure and an exhaust gas bypass purge valve structure installed on the outlet pipe of the turbine shell. ) flow turbocharger. In this supercharger, except for the exhaust gas bypass and purge valve, there are no other mechanisms and components that can adjust the relationship between the flow cross-sectional area and the flow configuration to improve the increase in the low (speed, load) working conditions of the internal combustion engine. For press fitting machine performance. In order to greatly increase and improve the performance of the low (rotating speed, load) operating conditions of the external characteristics of the high-supercharged vehicle internal combustion engine, it is necessary to greatly increase its corresponding supercharging pressure value in the low ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com