Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

258results about How to "Refining issue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

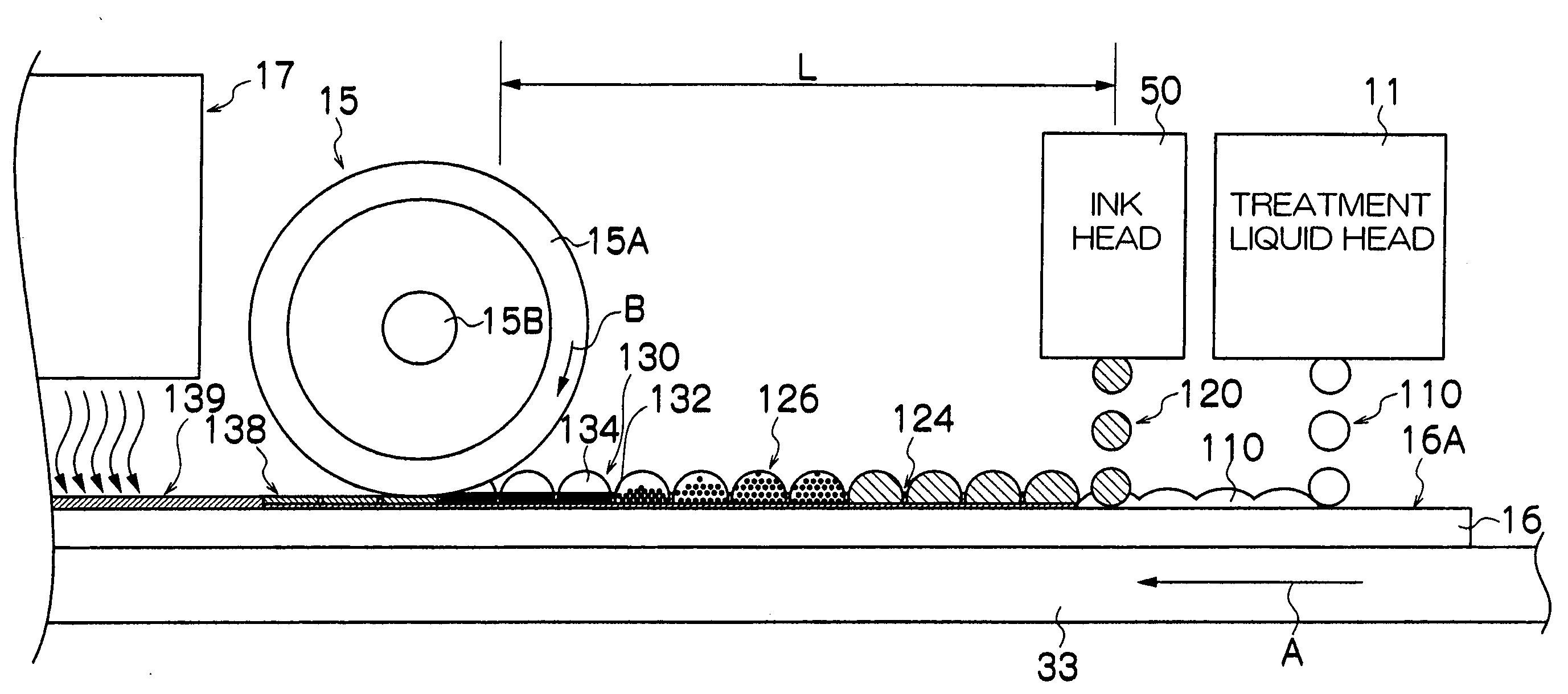

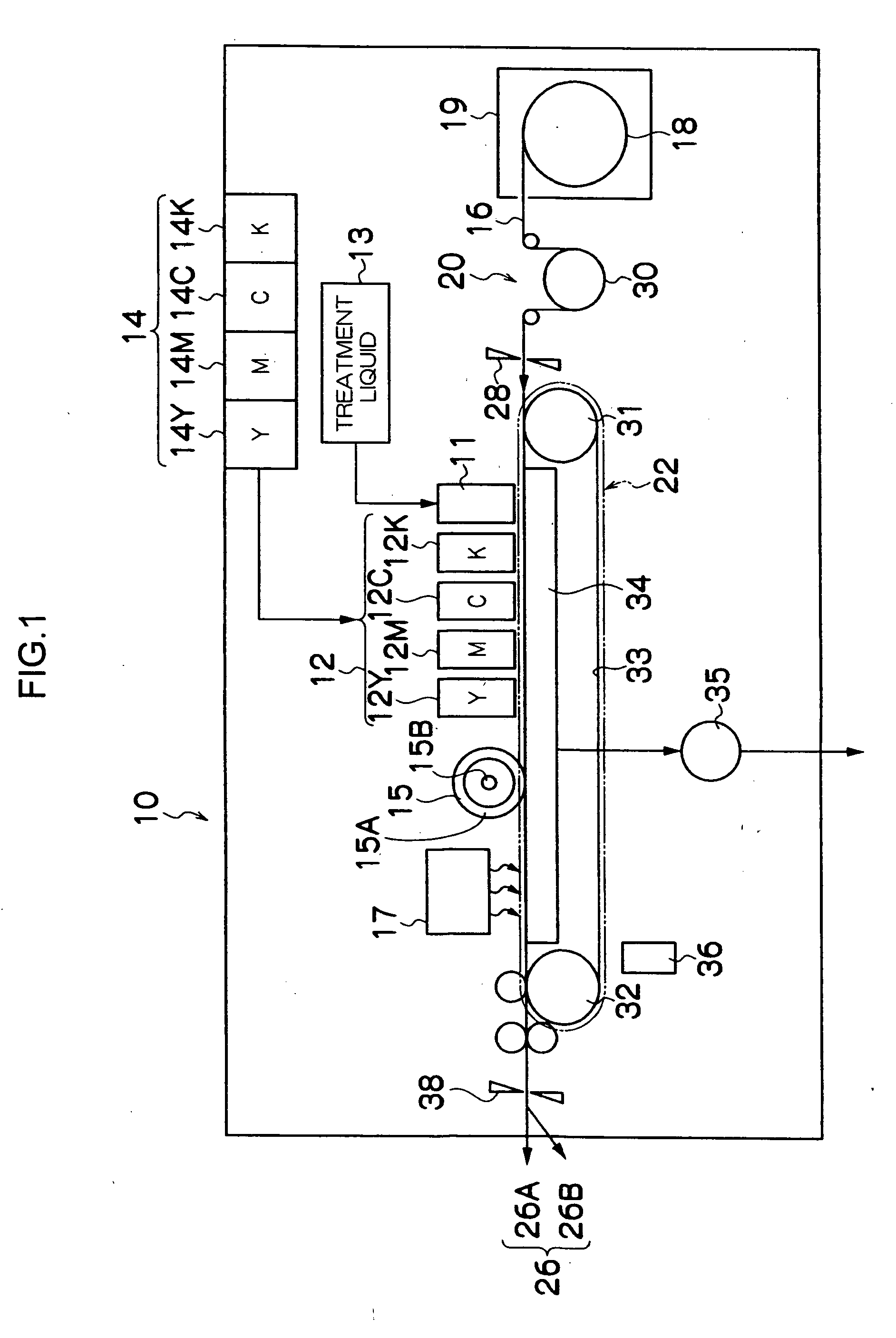

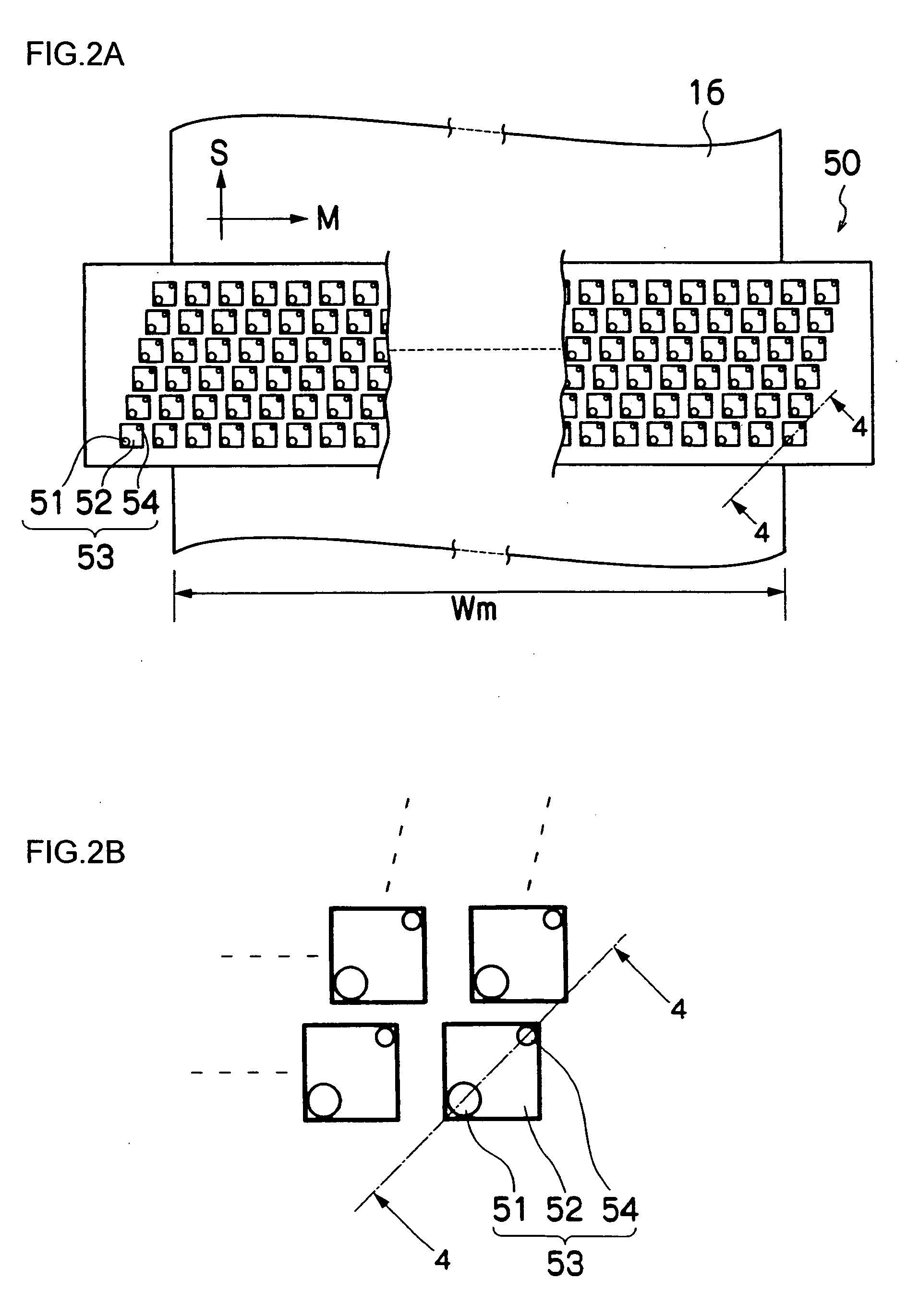

Ink set for inkjet recording, and image recording method and image recording apparatus

ActiveUS20070229577A1Improve featuresEnsuring optical densityMeasurement apparatus componentsDuplicating/marking methodsImage recordingWater soluble

The ink set for inkjet recording includes: a first liquid which contains at least a water-soluble solvent, water, and pigment particles dispersed and retained in a medium including the water-soluble solvent and the water; and a second liquid which does not contain coloring material but contains at least a water-soluble solvent, water, and a liquid composition which enhances printing characteristics, wherein: an image is formed by making the first liquid and the second liquid come into contact with each other on a recording medium; and a ratio of pigment particles having a particle diameter of not less than 150 nm is not greater than 2 volume percent with respect to a whole of the pigment particles contained in the first liquid.

Owner:FUJIFILM CORP

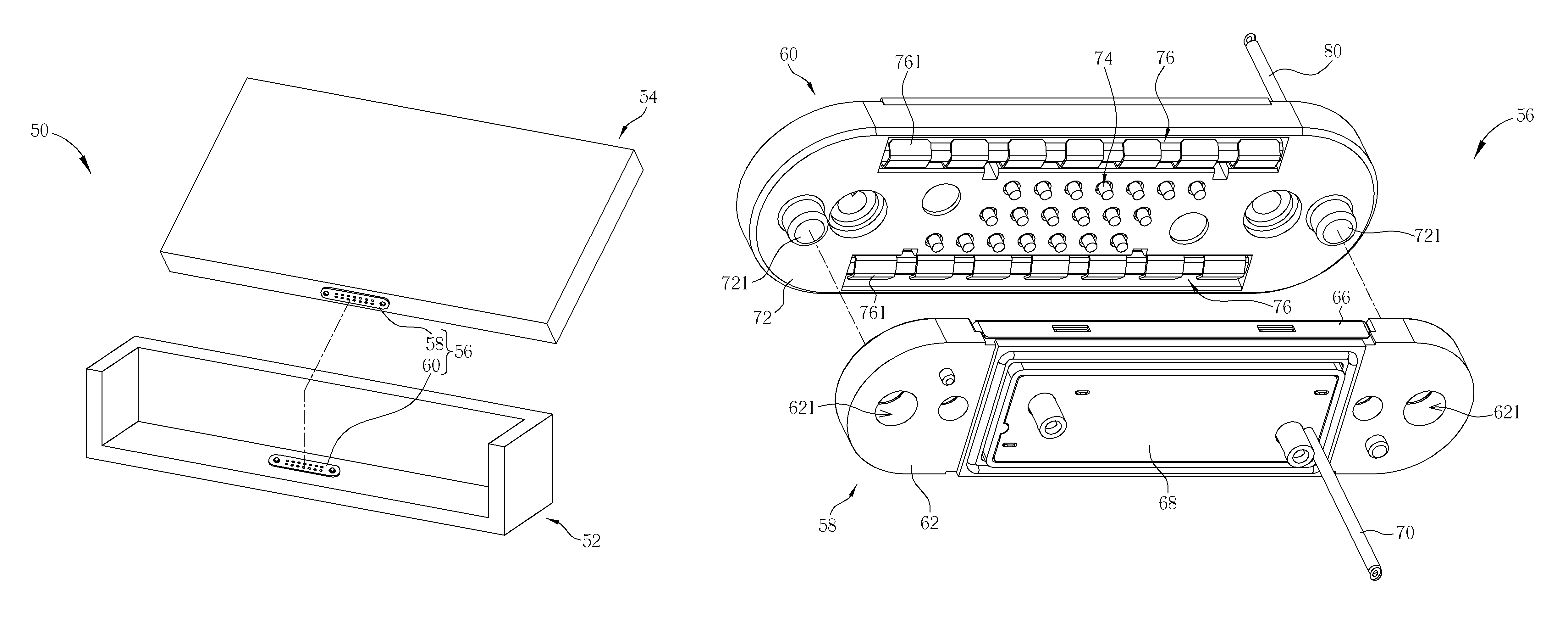

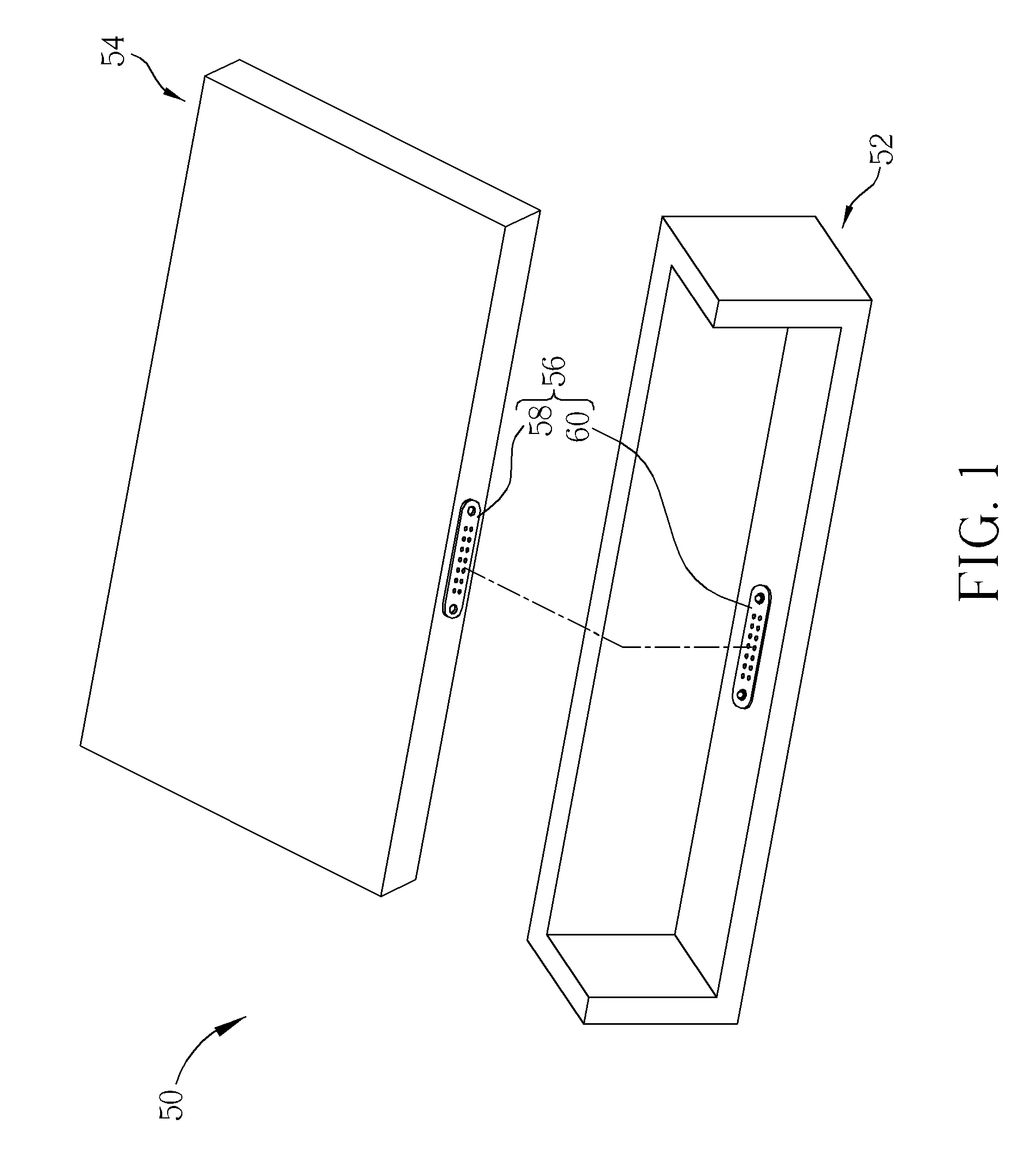

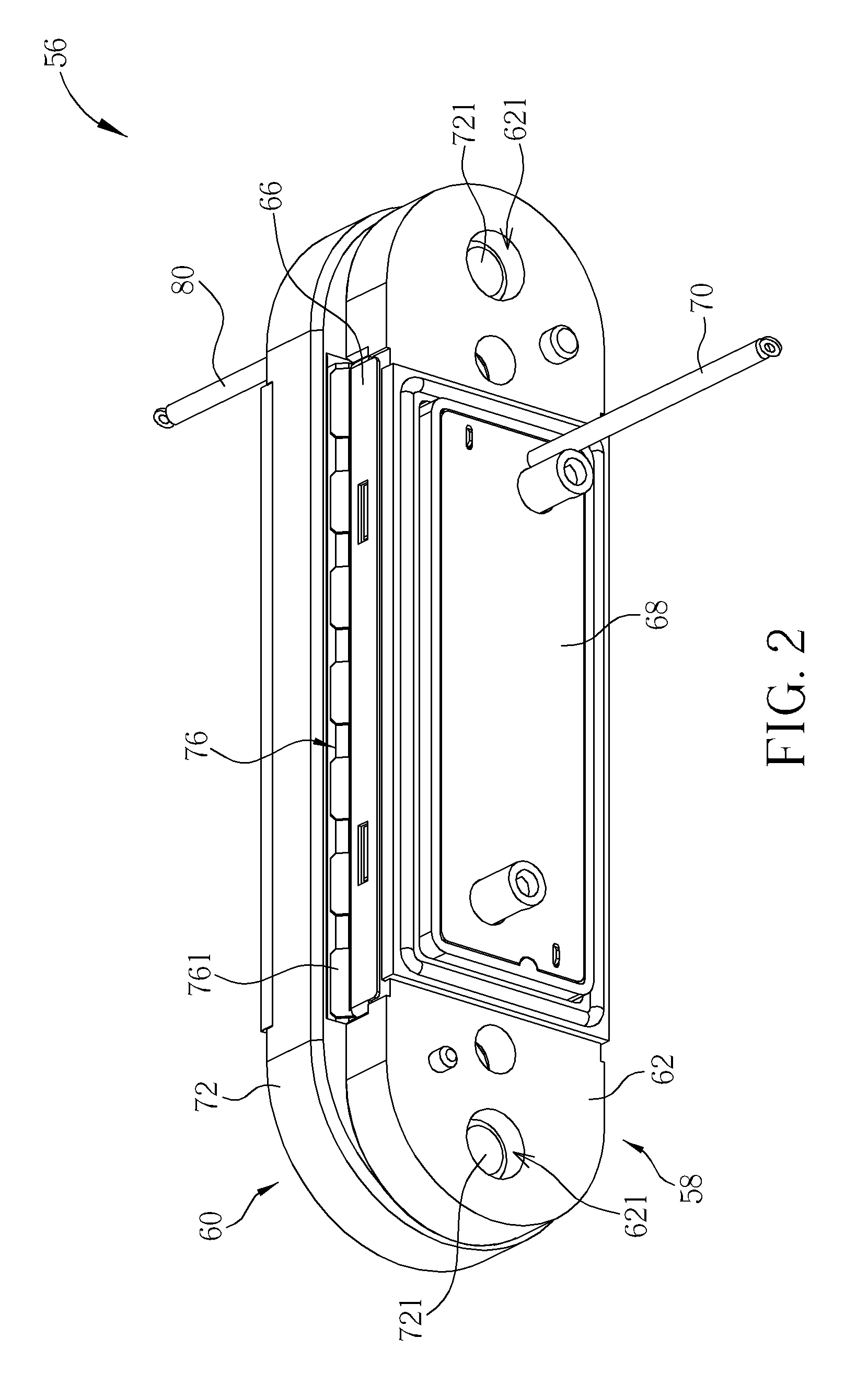

Grounding a docking station with a host device using grounding layers of multilayer printed circuit boards

ActiveUS8414312B2Refining issueLong labor hourComputer periphery connectorsCoupling protective earth/shielding arrangementsDocking stationEngineering

A connector structure includes a first connector installed on a host device. The first connector includes a first base, a first terminal set installed on the first base, and a first grounding component installed on the first base. The connector structure further includes a second connector installed on a docking station for connecting with the first connector. The second connector includes a second base, a second terminal set installed on the second base for contacting with the first terminal set so as to transmit signals between the host device and the docking station with the first terminal set when the host device is docked in the docking station, and a second grounding component installed on the second base for contacting with the first grounding component so as to ground with the first grounding component when the host device is docked in the docking station.

Owner:WISTRON CORP

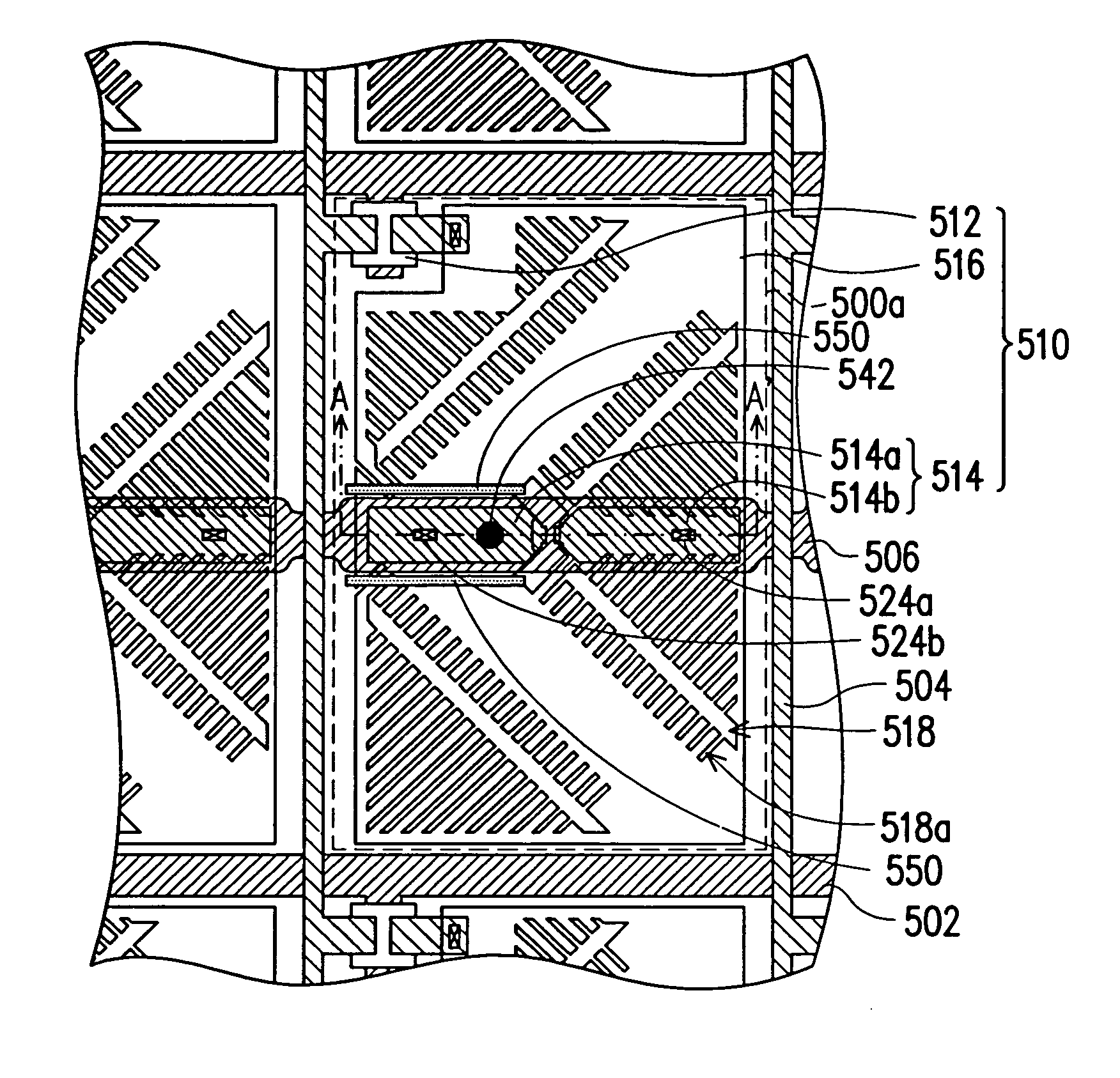

Thin film transistor array substrate and method for repairing the same

ActiveUS20060092341A1Improve manufacturing yieldReduce decreaseNon-linear opticsCapacitanceTransistor array

A thin film transistor array substrate and method for repairing the same are provided. Each pixel unit of the thin film transistor array substrate has a plurality of upper electrodes, which are coupled to a common line to form a plurality of storage capacitors. If a storage capacitor defects, the portion of the pixel electrode corresponding to the defective storage capacitor is electrically isolated from the other portion of the pixel electrode in the pixel unit. Therefore, the other storage capacitors in the pixel unit can normally display. The thin film transistor array substrate and method for repairing the same provided by the present invention repair the defective storage capacitor in the thin film transistor array substrate and improve the manufacturing yield.

Owner:AU OPTRONICS CORP

Pressure-actuated toy rocket system

InactiveUS6957526B1Improve economic efficiencyPleasing to eyeCompressed gas gunsToy aircraftsDetonatorRocket

A pressure-actuated rocket system comprises a bottom base, a detonator and a rocket body. A top base is placed on a top surface of the bottom base. At least one through hole is located on a side of the top base and extended to an opening of the top surface. The hollow detonator has a closed and an opened ends. The rocket body is a bottle with fins. After soda powder is placed inside the detonator and vinegar is filled into the rocket body, the bottom base, the detonator and the rocket body are held inclined. The openings are aimed at the inclined bottom base in turn, the pressure-actuated rocket system is then turned upside down. Soda powder subsequently falls and reacts with vinegar, and gas is generated. A pressure accumulates inside the rocket body until it is high enough to shoot the rocket body up.

Owner:LIN CHITSAN

Light Emitting Device and Fabrication Thereof

InactiveUS20100258813A1Reduced junction temperatureEnhancing emission efficiency and lifetimeSemiconductor/solid-state device manufacturingSemiconductor devicesLaser scribingThermal conductivity

A light emitting diode of the invention via laser scribing method is used to build up the mesh texture on the backside of the sapphire of light emitting diodes. Then high reflectivity and thermal conductivity metals are deposited onto the mesh structure. Since the multiple-reflection from the texture, the light extraction efficiency will be increased. Meanwhile, the high thermal conductivity metal filled into the sapphire also lead to the better heat dissipation within the light emitting diodes, it will decrease the junction temperature and avoid the thermal effect to reduce light efficiency and the lifetime.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

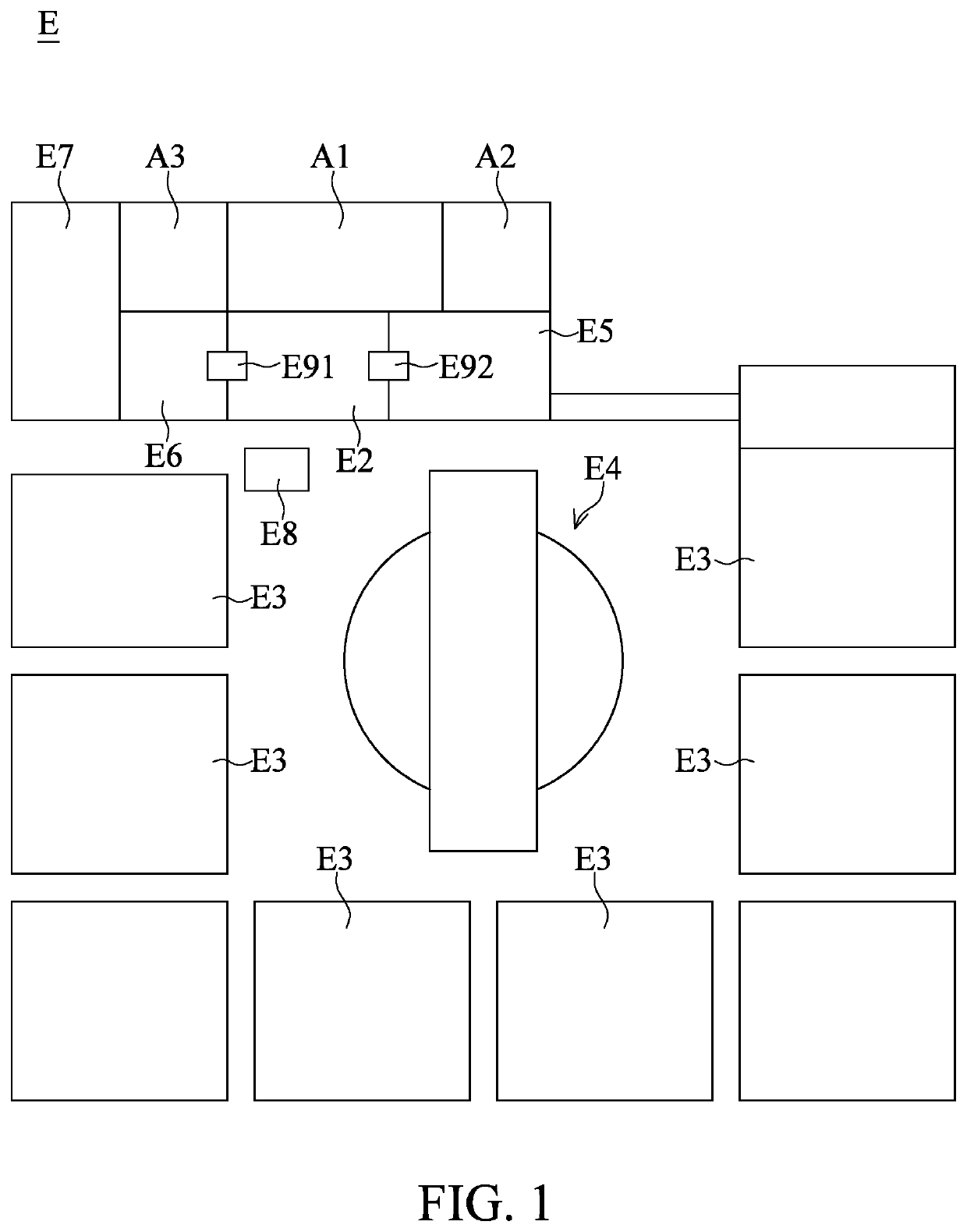

Environment control apparatus

ActiveUS10955466B2Refining issueElectronic circuit testingElectrical measurement instrument detailsProcess engineeringMechanical engineering

An environment control apparatus includes an apparatus body, a processing device, and a plurality of temperature adjusting devices. The apparatus body includes a plurality of accommodating chambers each having one of the temperature adjusting devices. Each of the temperature adjusting devices has a heater and a cooler. When a chip testing device carrying a plurality of chips is arranged in one of the accommodating chambers, the chip testing device is supplied with electricity, and the heater and the cooler of the corresponding temperature adjusting device are controlled to operate, the chip testing device performs a testing process on the chips disposed thereon.

Owner:ONE TEST SYST

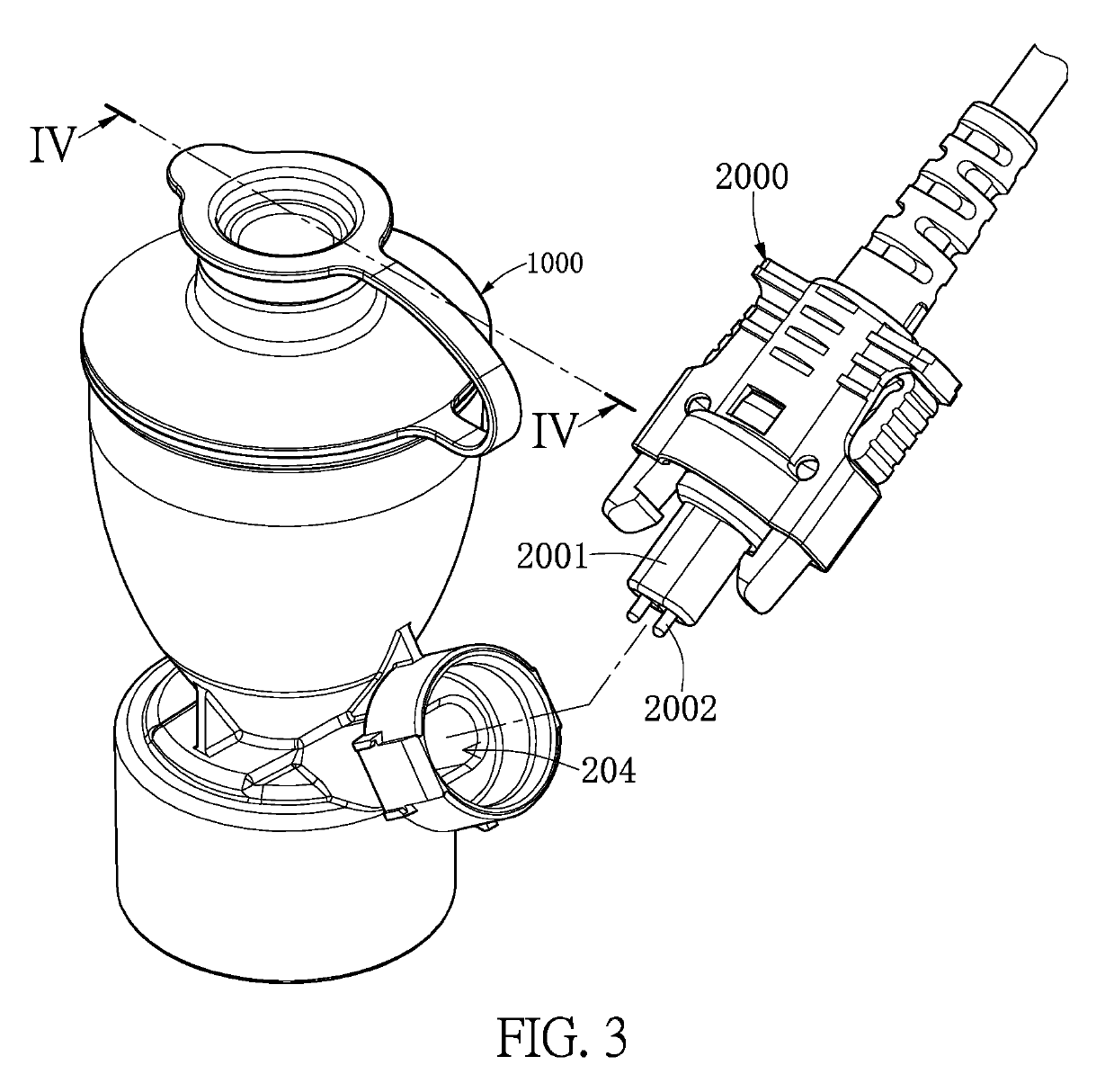

Aerosol generating device and aerosol generator

ActiveUS20190329281A1Refining issueReliable electrical connectionTwo-part coupling devicesMechanical vibrations separationElectricityElectrical polarity

An aerosol generating device includes an aerosol generator and a plug. The aerosol generator includes a container and an atomizing module arranged in the container. The container has a liquid chamber, an aerosol chamber, and an insertion slot defining an insertion direction. The liquid chamber and the aerosol chamber are respectively arranged at two opposite sides of the atomizing module, and are in spatial communication with each other through the atomizing module. The atomizing module includes two electrode regions having the same polarity and being electrically connected to each other. The plug is detachably inserted into the insertion slot of the container along the insertion direction, and a conductive terminal of the plug contacts the two electrode regions.

Owner:MICRO BASE TECH CORP

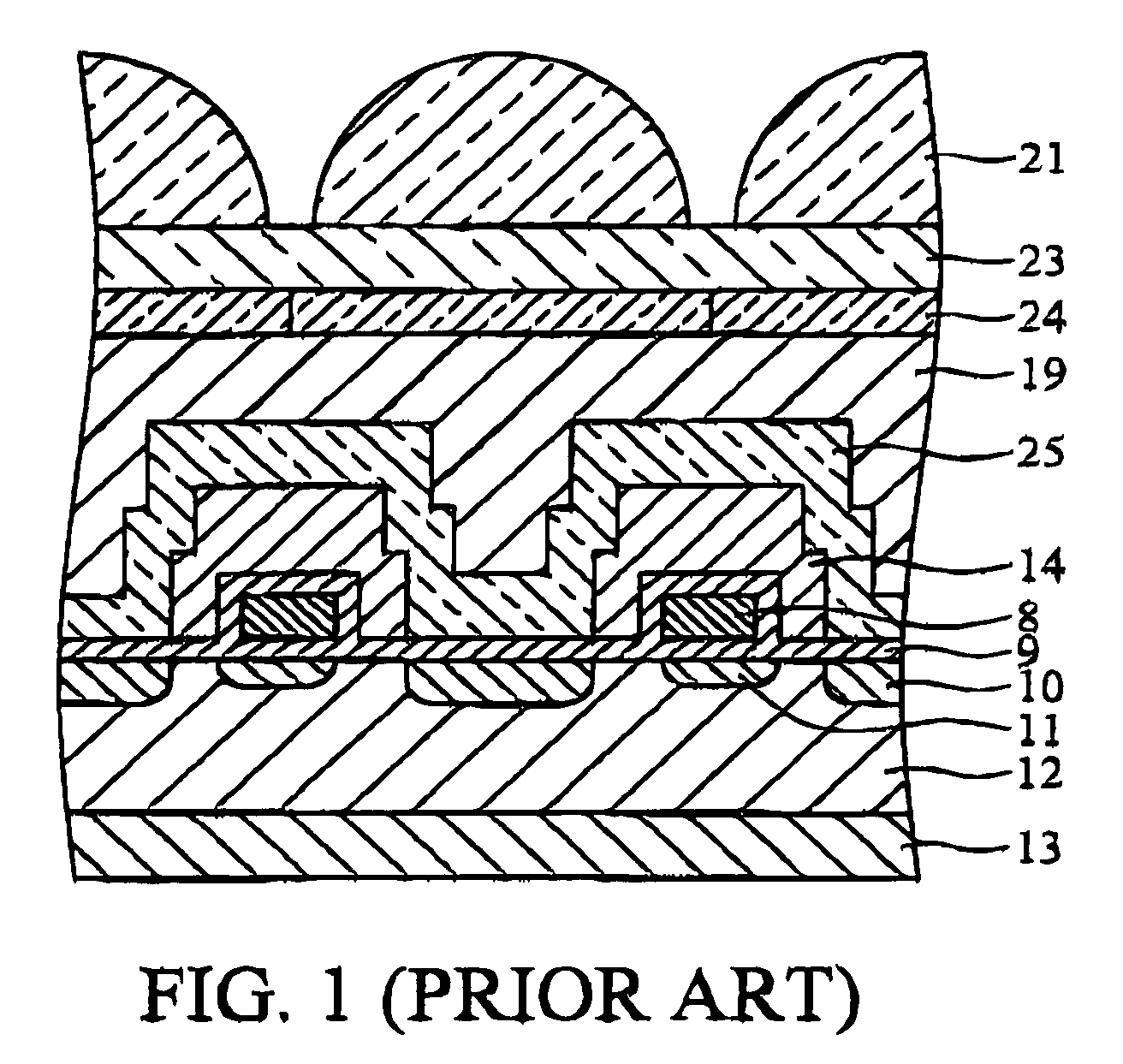

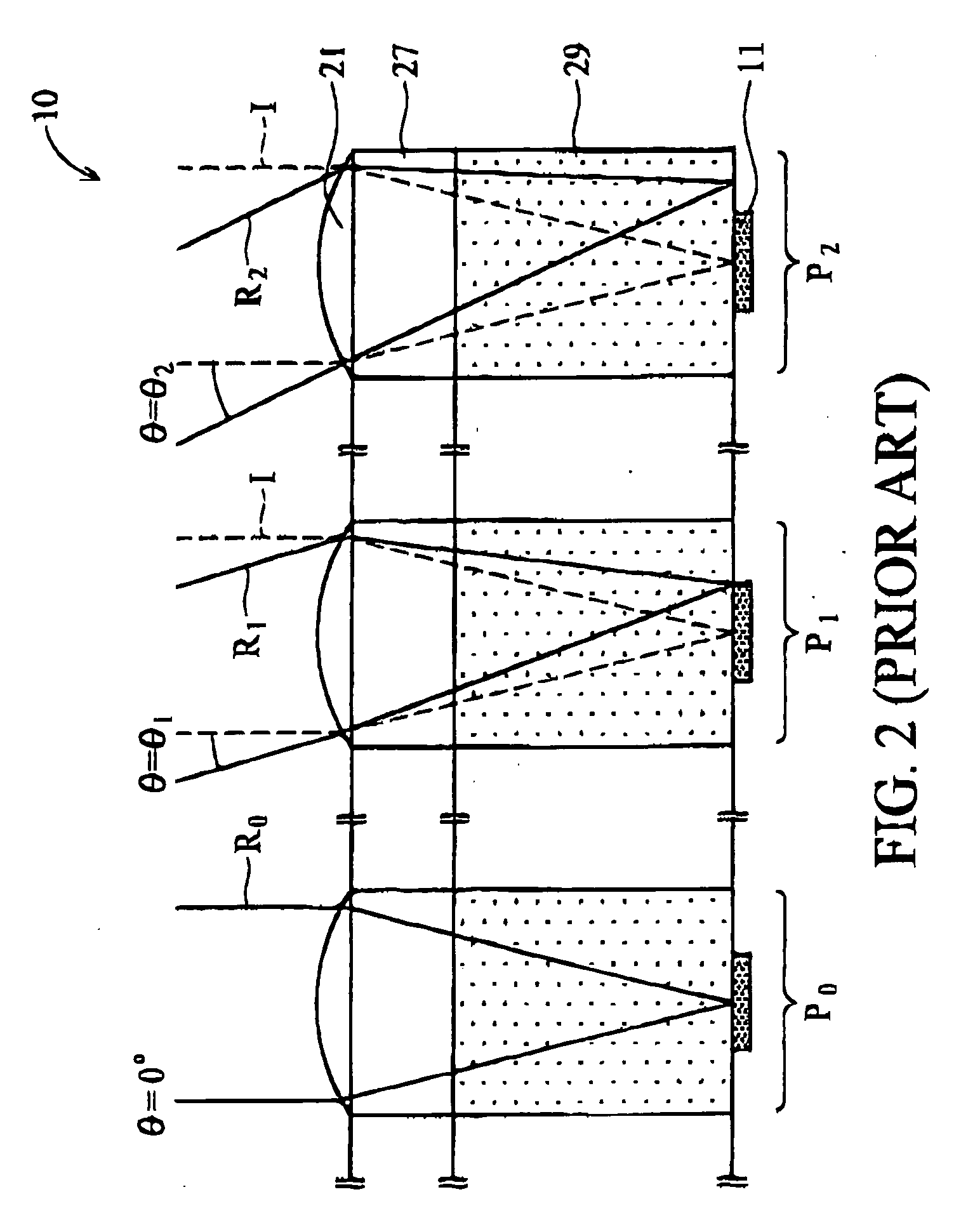

Image sensor with improved uniformity of effective incident light

ActiveUS7126099B2Avoid crosstalkRefining issueTelevision system detailsTelevision system scanning detailsLightnessBrightness perception

Owner:TAIWAN SEMICON MFG CO LTD

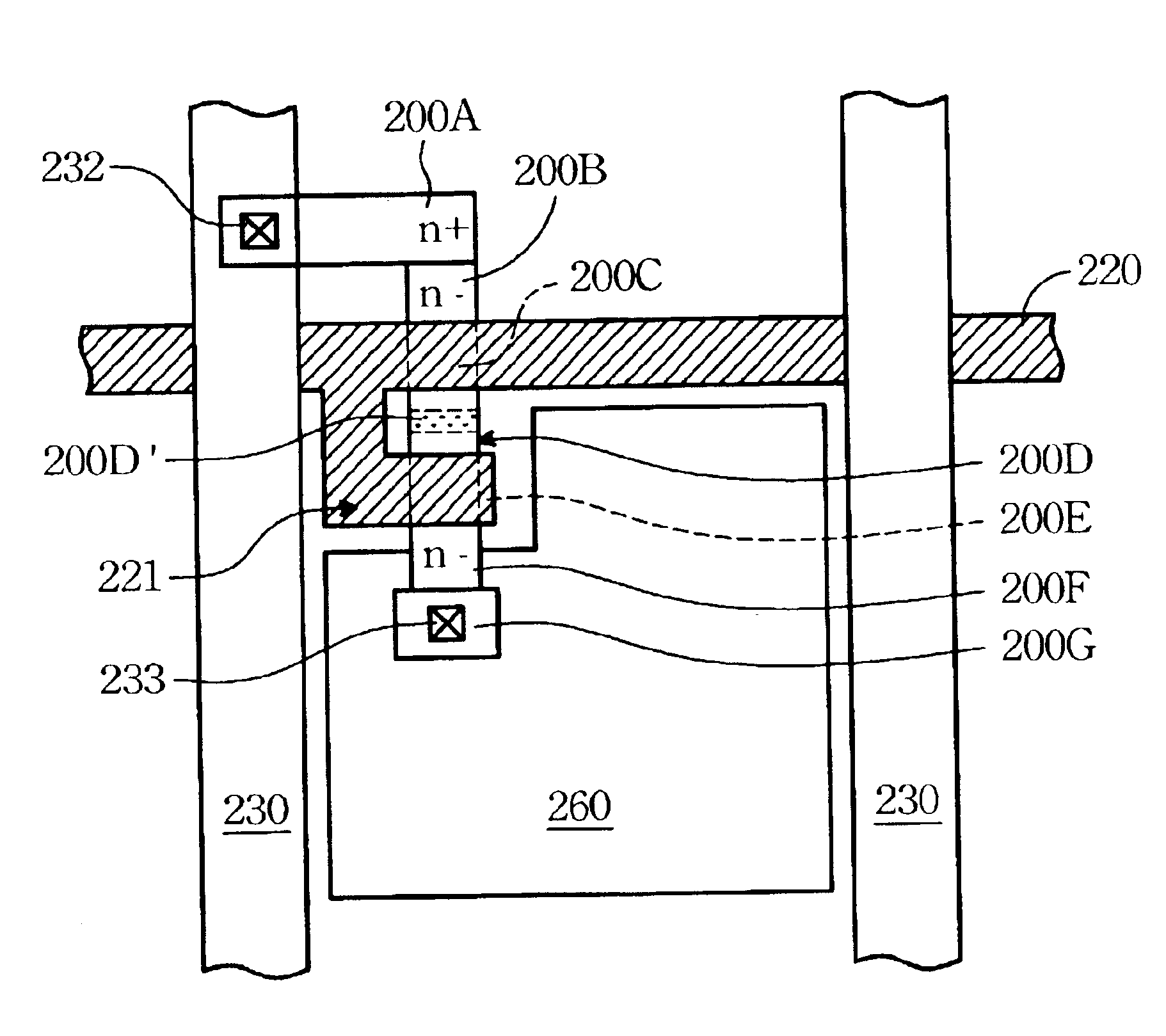

Dual gate layout for thin film transistor

ActiveUS6936848B2Suppress leakage currentInhibit currentTransistorSolid-state devicesLiquid-crystal displayGate oxide

A dual gate layout of a thin film transistor of liquid crystal display to alleviate dark current leakage is disclosed. The layout comprises (1) a polysilicon on a substrate having a L-shaped or a snake shaped from top-view, which has a heavily doped source region, a first lightly doped region, a first gate channel, a second lightly doped region, a second gate channel, a third lightly doped region and a heavily doped drain region formed in order therein; (2) a gate oxide layer formed on the polysilicon layer and the substrate, (3) a gate metal layer then formed on the gate oxide layer having a scanning line and an extension portion with a L-shaped or an I-shaped. The gate metal intersects with the polysilicon layer thereto define the forgoing gate channels. Among of gate channels, at least one is along the signal line, which is connected to the source region through a source contact.

Owner:AU OPTRONICS CORP

Touch device

ActiveUS20170115775A1Effectively improving the gate driving circuitRefining issueSolid-state devicesNon-linear opticsDriving circuitElectrical and Electronics engineering

A touch device including an array substrate, at least one gate driving circuit, an opposite substrate and a shielding pattern is provided. The array substrate has a display region and a peripheral region connecting to the display region. The gate driving circuit is disposed on the array substrate and located in the peripheral region. The opposite substrate is disposed opposite to the array substrate. The shielding pattern is disposed between the array substrate and the opposite substrate. The shielding pattern projected on the array substrate is formed a first projection, the gate driving circuit projected on the array substrate is formed a second projection, the first projection at least partially overlaps with the second projection.

Owner:INNOLUX CORP

Ink set for inkjet recording, and image recording method and image recording apparatus

ActiveUS7726802B2Improve featuresEnsuring optical densityMeasurement apparatus componentsDuplicating/marking methodsImage recordingWater soluble

The ink set for inkjet recording includes: a first liquid which contains at least a water-soluble solvent, water, and pigment particles dispersed and retained in a medium including the water-soluble solvent and the water; and a second liquid which does not contain coloring material but contains at least a water-soluble solvent, water, and a liquid composition which enhances printing characteristics, wherein: an image is formed by making the first liquid and the second liquid come into contact with each other on a recording medium; and a ratio of pigment particles having a particle diameter of not less than 150 nm is not greater than 2 volume percent with respect to a whole of the pigment particles contained in the first liquid.

Owner:FUJIFILM CORP

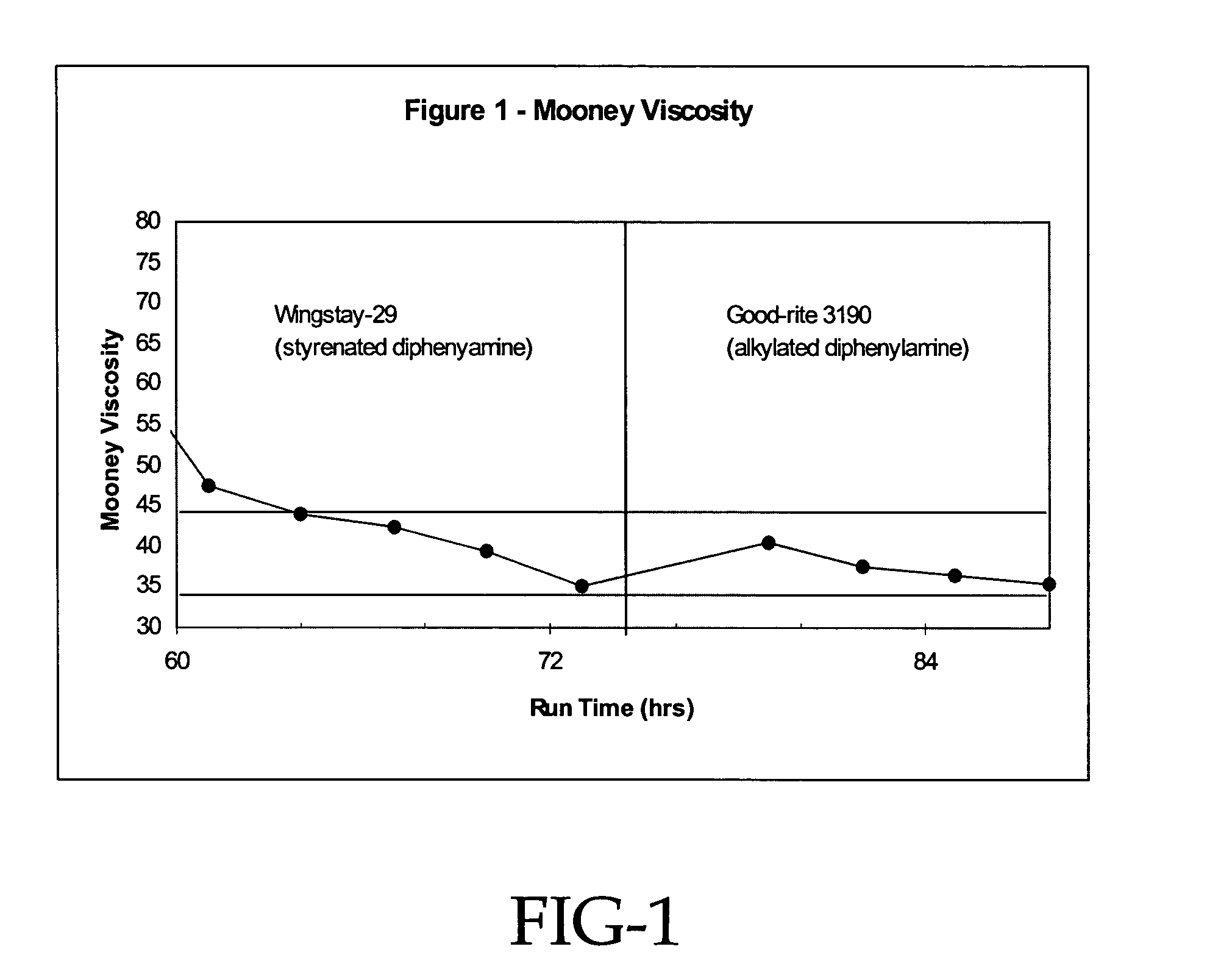

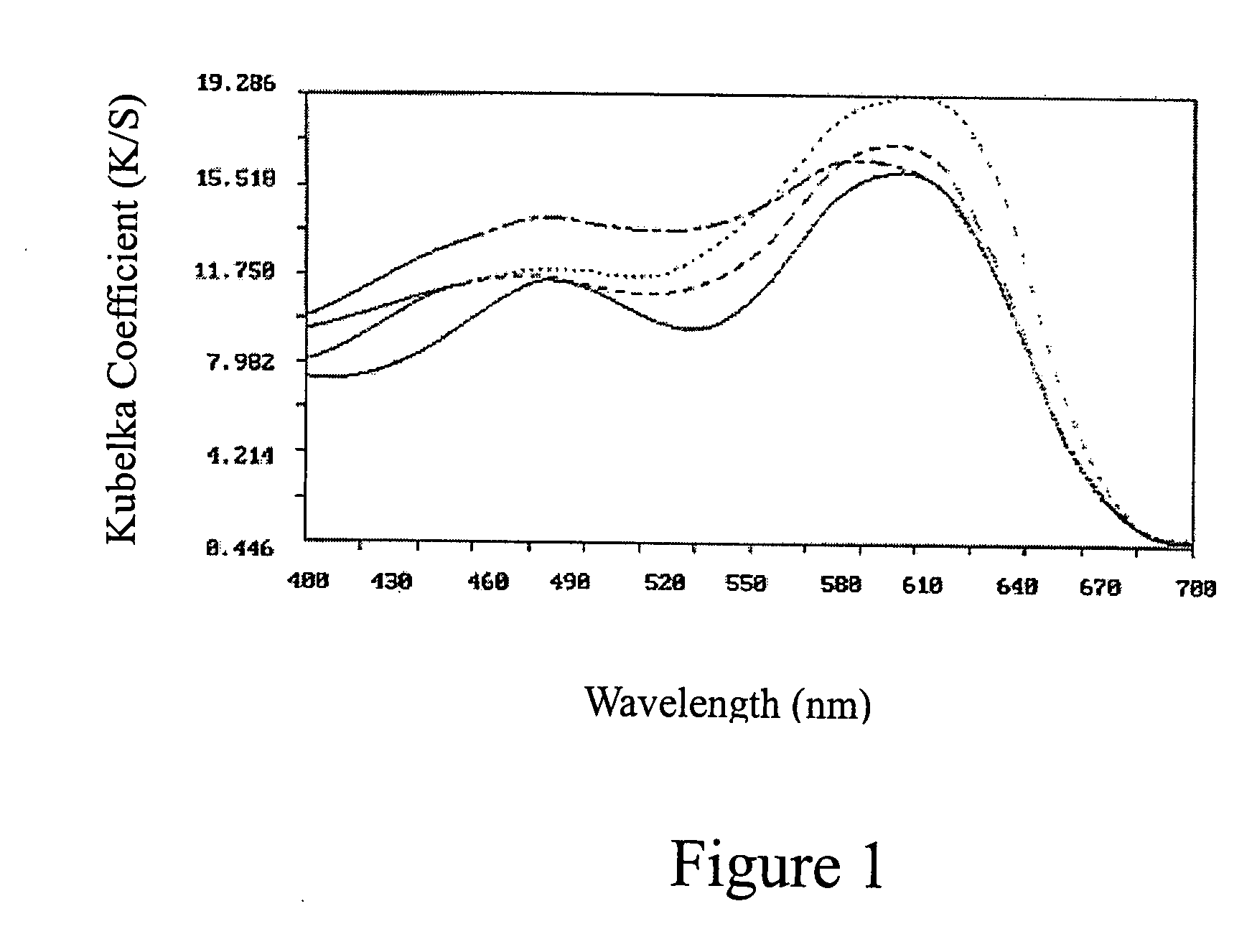

Synthesis of 1,4-polybutadiene

This invention is based upon the unexpected discovery that alkylated diphenylamines can be used in conjunction with nickel based catalyst systems which contain (a) an organonickel compound, (b) an organoaluminum compound, and (c) a fluorine containing compound to produce cis-1,4-polybutadiene having reduced molecular weight and an increased level of branching. This results in the cis-1,4-polybutadiene exhibiting good processability without sacrificing cold flow characteristics. Additionally, the alkylated diphenylamine which remains in the rubber acts in a manner which provides it with antioxidant protection. In other words, the use of alkylated diphenylamines accomplishes the three major objectives that are realized by employing para-styrenated diphenylamines (reduced molecular weight, regulated polymer macrostructure through branching and antidegradant protection). However, the utilization of alkylated diphenylamines, unlike para-styrenated diphenylamines, offers the additional advantage of being soluble in aliphatic solvents. By virtue of this increased level of solubility in aliphatic solvents, such as hexane, alkylated diphenylamines can be employed at greatly reduced levels of aromatic solvents. Likewise, when mixed catalyst streams containing alkylated diphenyl amines are combined precipitation is minimized compared to para-styrenated diphenylamine significantly improving issues related to fouling. The subject invention more specifically discloses a process for producing cis-1,4-polybutadiene having a reduced molecular weight and improved processability which comprises polymerizing 1,3-butadiene in the presence of (a) an organonickel compound, (b) an organoaluminum compound, (c) a fluorine containing compound, and (d) an alkylated diphenylamine; wherein the alkylated diphenylamine has alkyl groups that contain from 2 to 18 carbon atoms, and wherein the organoaluminum compound and the fluorine containing compound are brought together in the presence of the alkylated diphenylamine.

Owner:THE GOODYEAR TIRE & RUBBER CO

Display apparatus with multi screens and display signal control method thereof

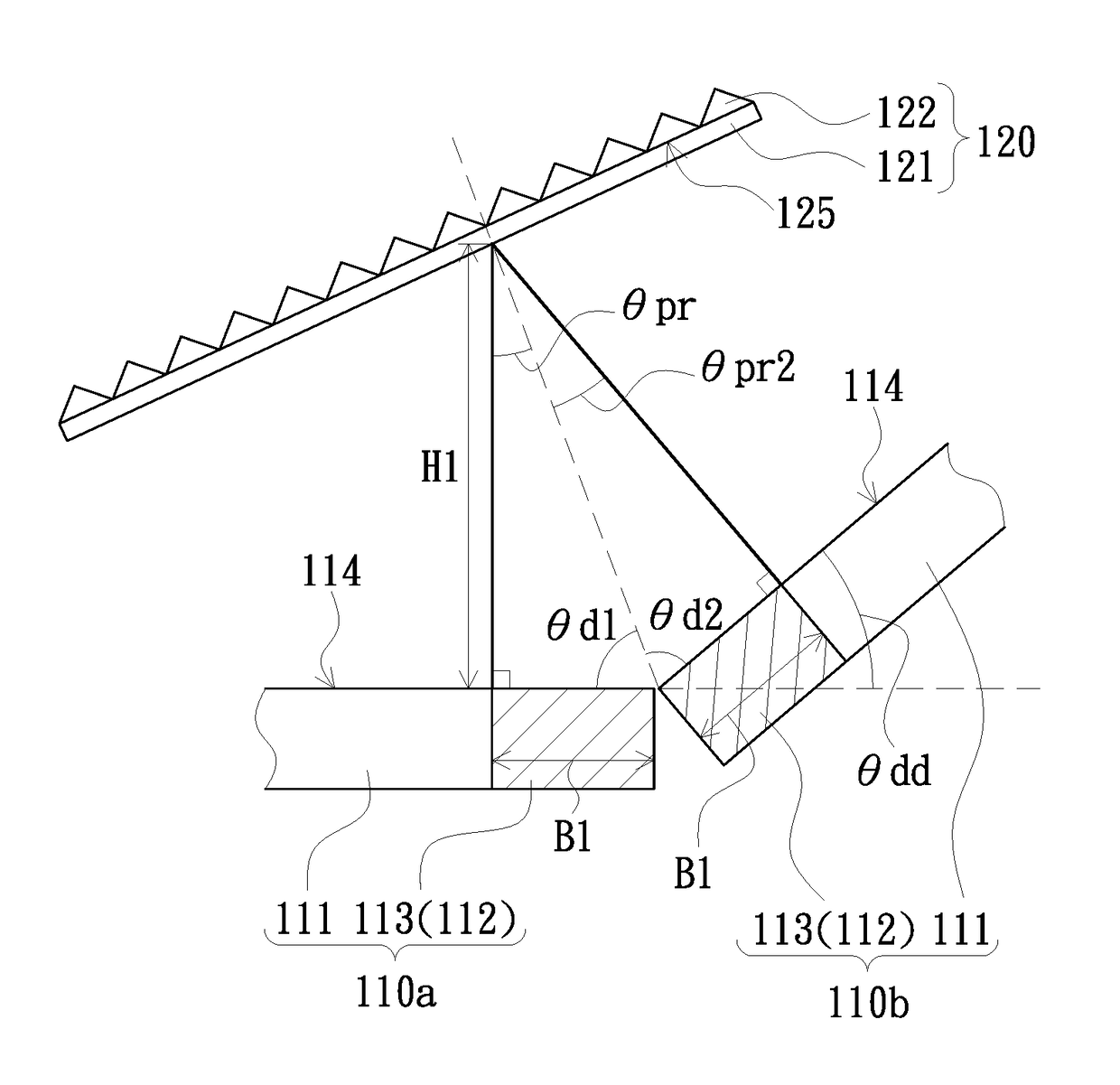

ActiveUS20180040281A1Improve display qualityRefining issuePrismsStatic indicating devicesPrismComputer science

Display apparatus with multi screens and corresponding display signal control method are provided. The display apparatus with multi screens includes a plurality of display screens arranged adjacent one by one and a prismatic structure optical element. At least two adjacent display screens of the plurality of display screens have an included angle between 90-180 degrees. Each display screen includes a display area and a frame surrounding the display area. The prismatic structure optical element is arranged between the two adjacent display screens with the included angle and to cover two adjacent side edges of the frames of the two adjacent display screens and a portion of the two display areas. The prismatic structure optical element includes a base and a plurality of prisms disposed on the base and arranged adjacent one by one. An extension direction of the prism is substantially parallel to the two adjacent side edges.

Owner:CHAMP VISION DISPLAY INC

Microwave heating system

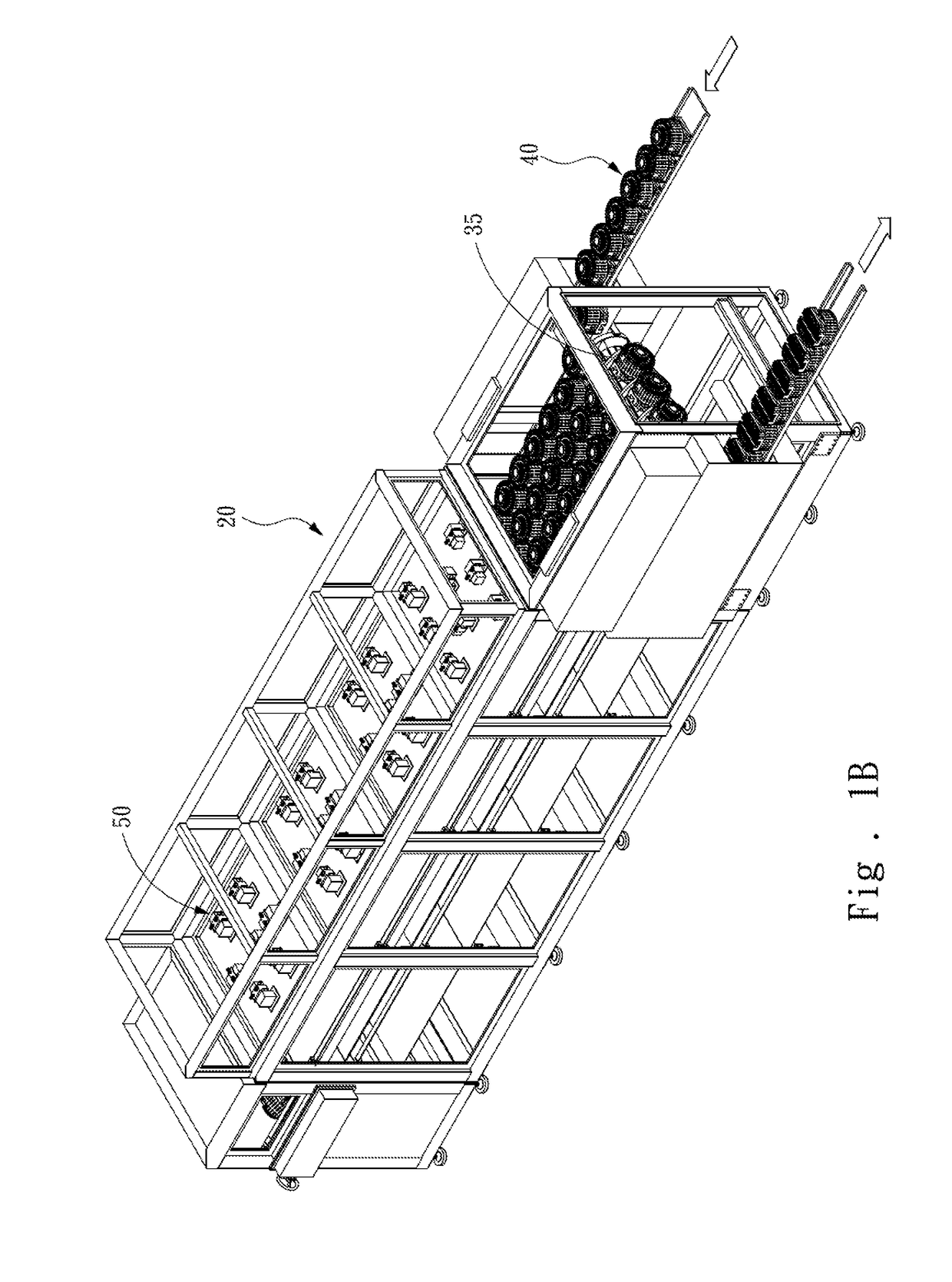

InactiveUS20170142785A1Refining issueReliability of mechanismCharge supportsCharge manipulationTemperature controlHeating time

A microwave heating system heats a hermetic container loaded with a heated object. The hermetic container is accommodated and given pressure by a microwave transparent and pressure resistant module, and is fixed onto a transporting device in a cyclic course. Microwave is generated by a microwave heating device to perform heating. The hermetic container is stirred while the transport device carries and moves the hermetic container. The temperature of the hermetic container or the heated object is measured by a temperature measuring module. The number of times to stir and repeatedly heat the heated object are appropriately determined in the design of the system. The output power and heating time of the microwave heating device and the transmission speed of the transporting device are adjustable during operations of the system, hence forming a closed-loop temperature control system.

Owner:BOTTLE TOP DEV

Chip testing device and chip testing system

ActiveUS20210132140A1Refining issueEasily damagedElectronic circuit testingElectrical measurement instrument detailsElectrical connectionSystem on a chip

A chip testing device and a chip testing system are provided. The chip testing system includes a chip testing device and a plurality of environment control apparatuses. A plurality of electrical connection sockets are disposed on one side of a circuit board, and a plurality of testing modules are disposed on another side of the circuit board. A first fixing member and a second fixing member fix the electrical connection sockets on one side of the circuit board, and no screwing members are required to be screwed between the electrical connection sockets and the circuit board. Each of the electrical connection sockets with a chip disposed thereon can be disposed in a high temperature environment or a low temperature environment for testing along with the chip testing device, so that each of the chips does not need to be detached repeatedly.

Owner:ONE TEST SYST

Photosensitive resin composition, color filter and method for manufacturing the same, and liquid crystal display apparatus

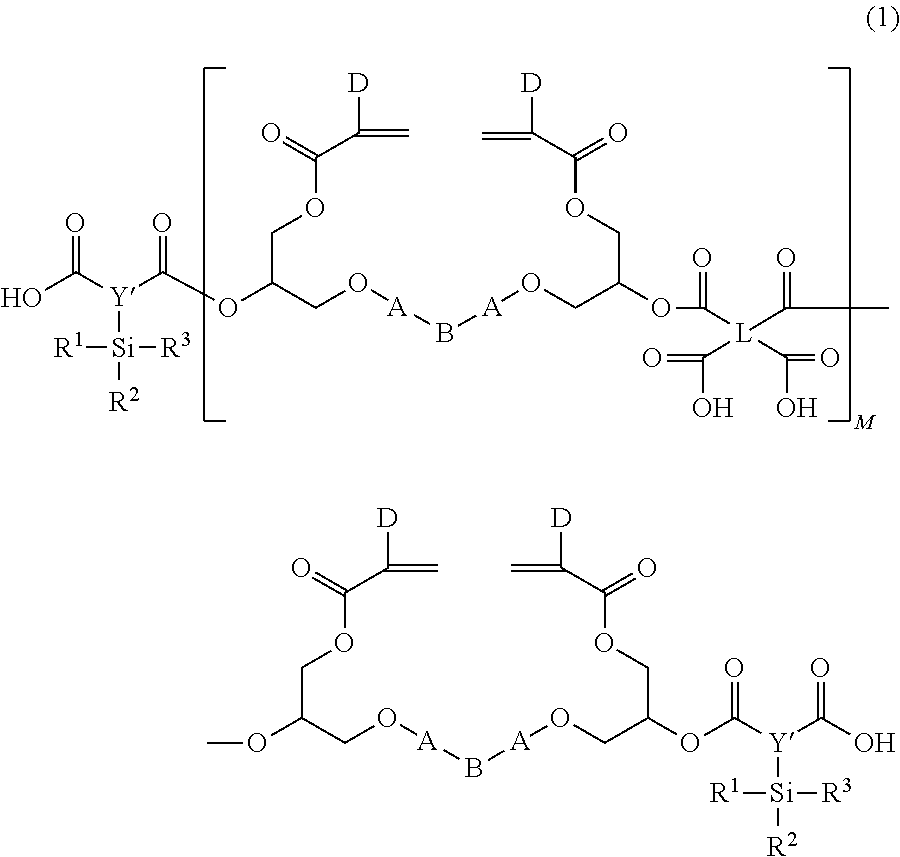

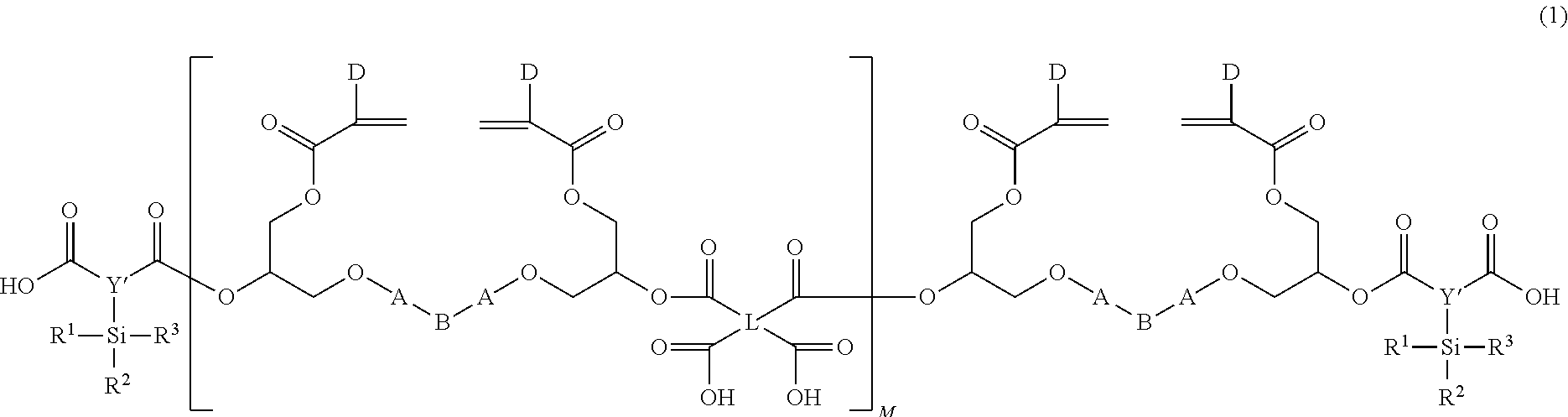

InactiveUS20150153646A1Poor linearityImprovement have become issuePhotosensitive materialsPhotomechanical apparatusPhotoinitiatorLiquid-crystal display

A photosensitive resin composition is provided. The photosensitive resin composition includes an alkali-soluble resin (A), a polysiloxane polymer (B), a compound (C) containing an ethylenically unsaturated group, a photoinitiator (D), and an organic solvent (E), wherein the alkali-soluble resin (A) includes an alkali-soluble resin (A-1) represented by formula 1.

Owner:CHI MEI CORP

Black dye composition and black ink composition for textile digital printing

ActiveUS20080184912A1Improve accuracyIncrease color depthReactive dyesInksDigital printingColor depth

The present invention relates to a black dye composition, comprising: (a) at least one azo dye of the following formula (I),(b) at least one azo dye of the following formula (II) or (III),wherein R1, R2, and R3 are defined the same as the specification. The present invention also relates to a black ink composition afforded from the aforementioned black dye composition. The black ink composition of the present invention for textile digital printing exhibits the properties of excellent color depth, fixation, stability of storage, stability and accuracy of printing for long time, and improves the issue of nozzle cloggage.

Owner:EVERLIGHT USA INC

Method and apparatus for message transmission

ActiveUS20150358272A1High loss rateRefining issueData switching networksReal-time computingActivity Status

A method for message transmission is provided. The method includes receiving a message to be transmitted to an application on a terminal, determining whether the application is in an inactive state, and determining whether a push notification switch of the application is turned on when it is determined that the application is in the inactive state. The method also includes, when it is determined that the push notification switch of the application is not turned on, storing temporally the message and detecting whether the application is activated and, after detecting that the application is activated, transmitting the temporally stored message to the application on the terminal. Further, the method includes transmitting the message to a push notification server to cause the push notification server to push the message to the application on the terminal when it is determined that the push notification switch of the application is turned on.

Owner:TENCENT TECH (SHENZHEN) CO LTD

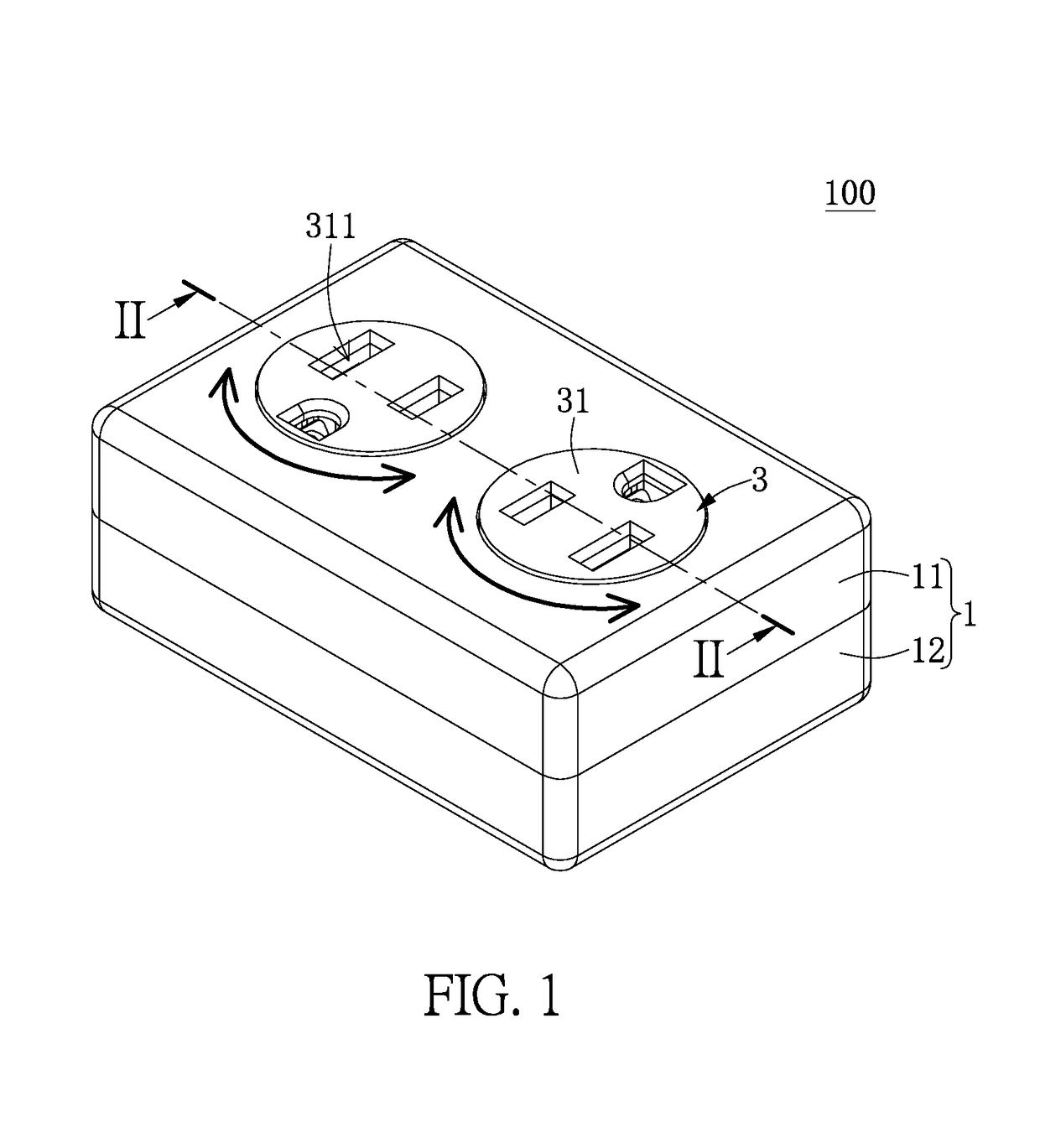

Rotatable socket device and socket module thereof

ActiveUS20190044295A1Refining issueGuaranteed uptimeRotary current collectorTwo pole connectionsElectrical conductorComputer module

Owner:POWERTECH INDAL

Image sensor with improved uniformity of effective incident light

ActiveUS20050045803A1Avoid crosstalkRefining issueTelevision system detailsTelevision system scanning detailsBrightness perceptionLightness

An image sensor improving the uniformity of effective incident light. In one example, the size of microlenses disposed in different regions of the image sensor is changed to balance the brightness in different regions, in which the size of each microlens is a function of the distance between the microlens to the chip center In another example, the distance between the center of the microlens and the center of the corresponding sensing area is changed to balance the brightness in different regions and the corresponding color filters are shifted such that the microlens is overlying a corresponding color filter unit without overlying adjacent regions thereof, in which the distance between the center of the microlens and the center of the corresponding sensing area is a function of the distance between the corresponding sensing area to the chip center.

Owner:TAIWAN SEMICON MFG CO LTD

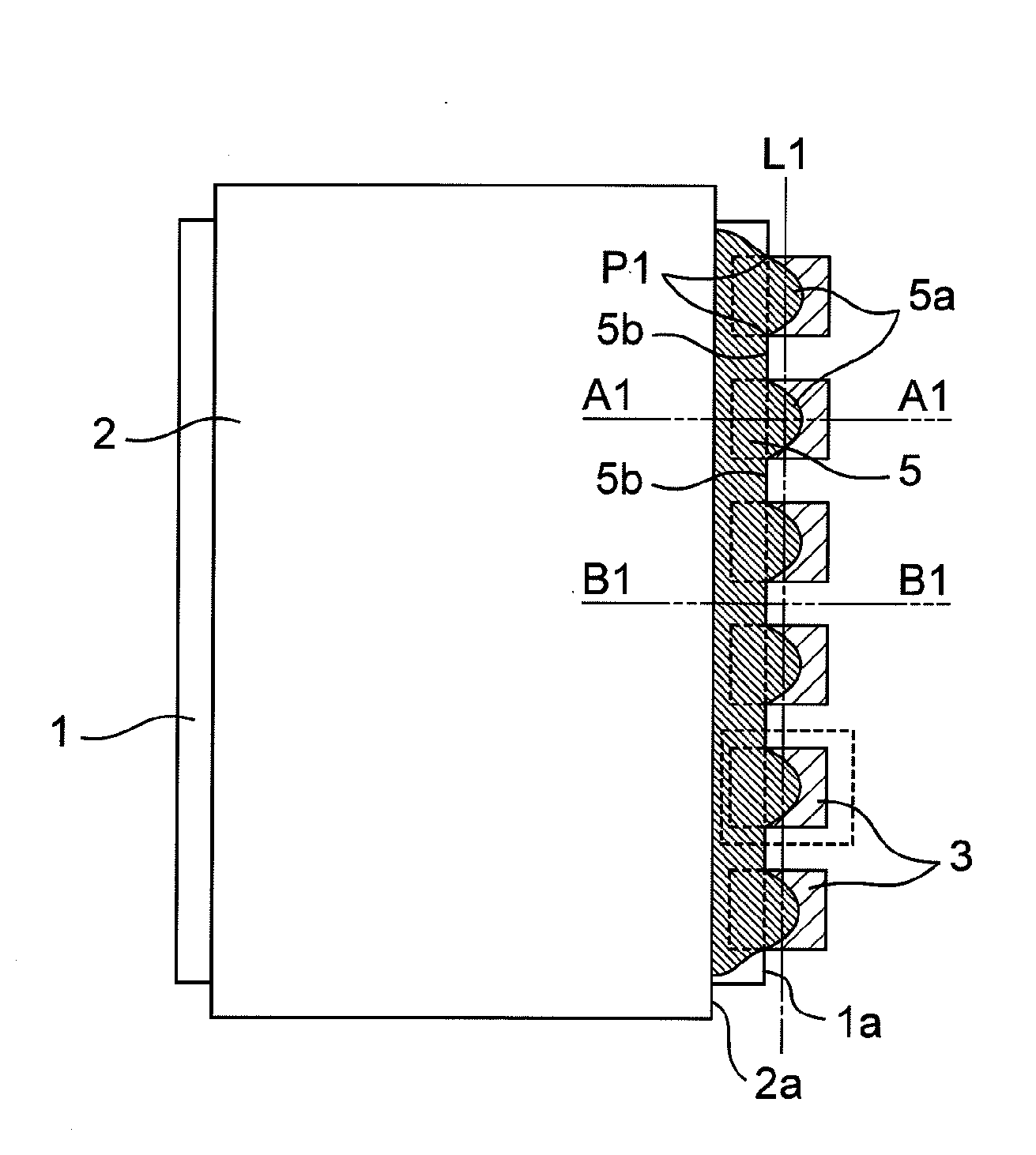

Electrode junction structure and manufacturing method thereof

InactiveUS20100167597A1Avoid stress concentrationEasy to bendPrinted circuit assemblingElectrically conductive connectionsAdhesiveEngineering

The electrode junction structure includes: a glass substrate; a plurality of flexible substrates, in a planar view, arranged to cross over an edge of the glass substrate and arranged to have a space from each other along the edge; an adhesive for joining the glass substrate and each flexible substrate; and a sealing resin for covering junction portions between the glass substrate and each flexible substrate, wherein an edge of the sealing resin is formed so that the edge of the sealing resin has, in the planar view, a consecutive waveform portion in which a convex portion and a concave portion alternate with an imaginary line as a center axis, the imaginary line being parallel to the edge of the glass substrate and locating outer than the edge of the glass substrate, and wherein the convex portions are formed to be located on the flexible substrates.

Owner:PANASONIC CORP

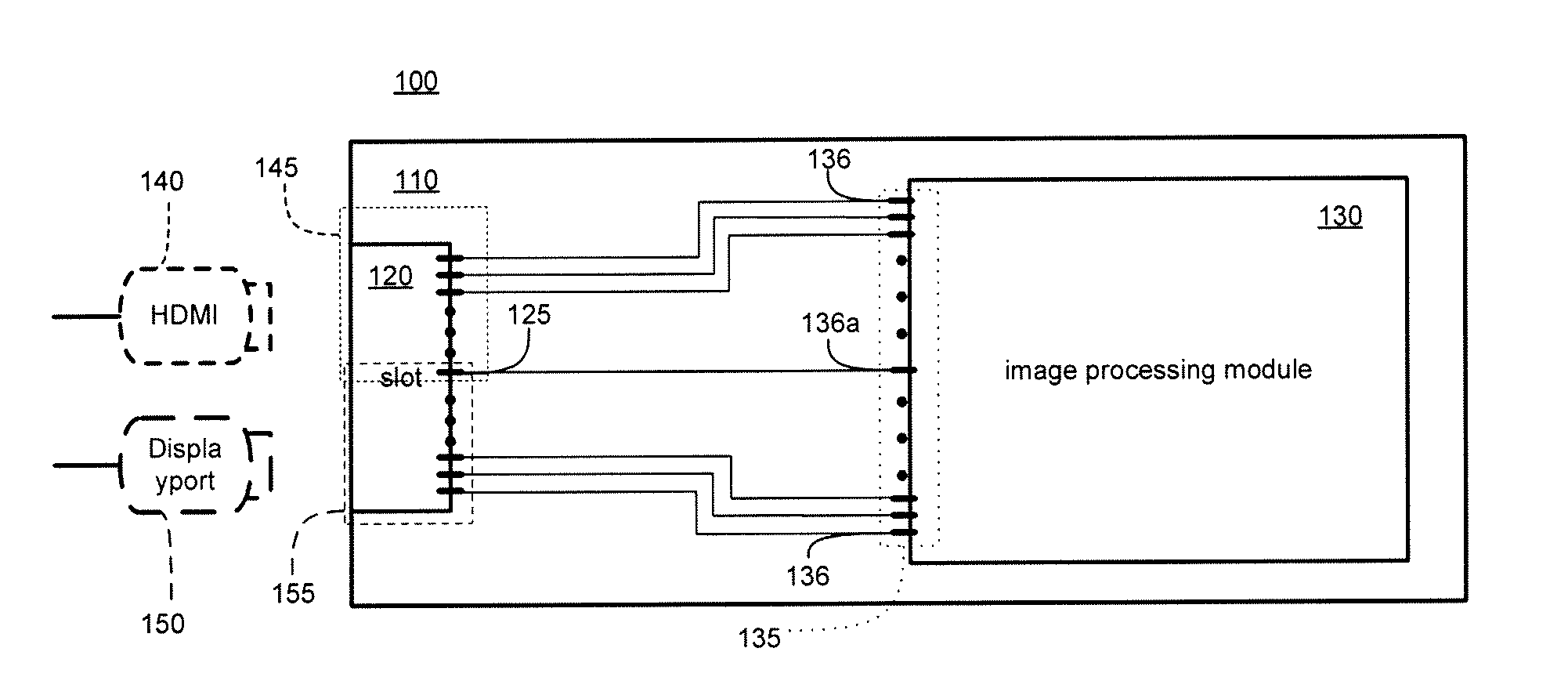

Image processing device, image processing chip and image processing method

ActiveUS20150042879A1Refining issueEasy to optimizeTelevision system detailsColor television detailsImaging processingComputer graphics (images)

An image processing device for processing an image signal is provided. The image processing device includes a circuit board, a slot and an image processing module. The slot, disposed on the circuit board, is to be plugged in by either a first connector corresponding to a first image interface format or a second connector corresponding to a second image interface format. The image processing module, disposed on the circuit board and coupled to the slot, detects the image signal inputted from either the first connector or the second connector to determine a target image interface format, and processes the image signal by an image processing method corresponding to the target image interface format.

Owner:MEDIATEK INC

Liquid crystal display and driving method thereof

ActiveUS20080266218A1Improve display qualityDesired display performanceCathode-ray tube indicatorsNon-linear opticsLiquid-crystal displayScan line

An LCD panel including scan lines, data lines, first common lines, second common lines and pixels electrically connected to the scan lines and the data lines is provided. Each pixel has a first display region and a pair of second display regions when the pixels are driven. The first display region and the pair of the second display regions of each pixel are coupled by the first common lines and the second common lines, respectively so as to display different levels of brightness. Besides, the first display region and the second display regions of each pixel are aligned in a column direction, and the first display region of each pixel is disposed between the pair of the second display regions.

Owner:AU OPTRONICS CORP

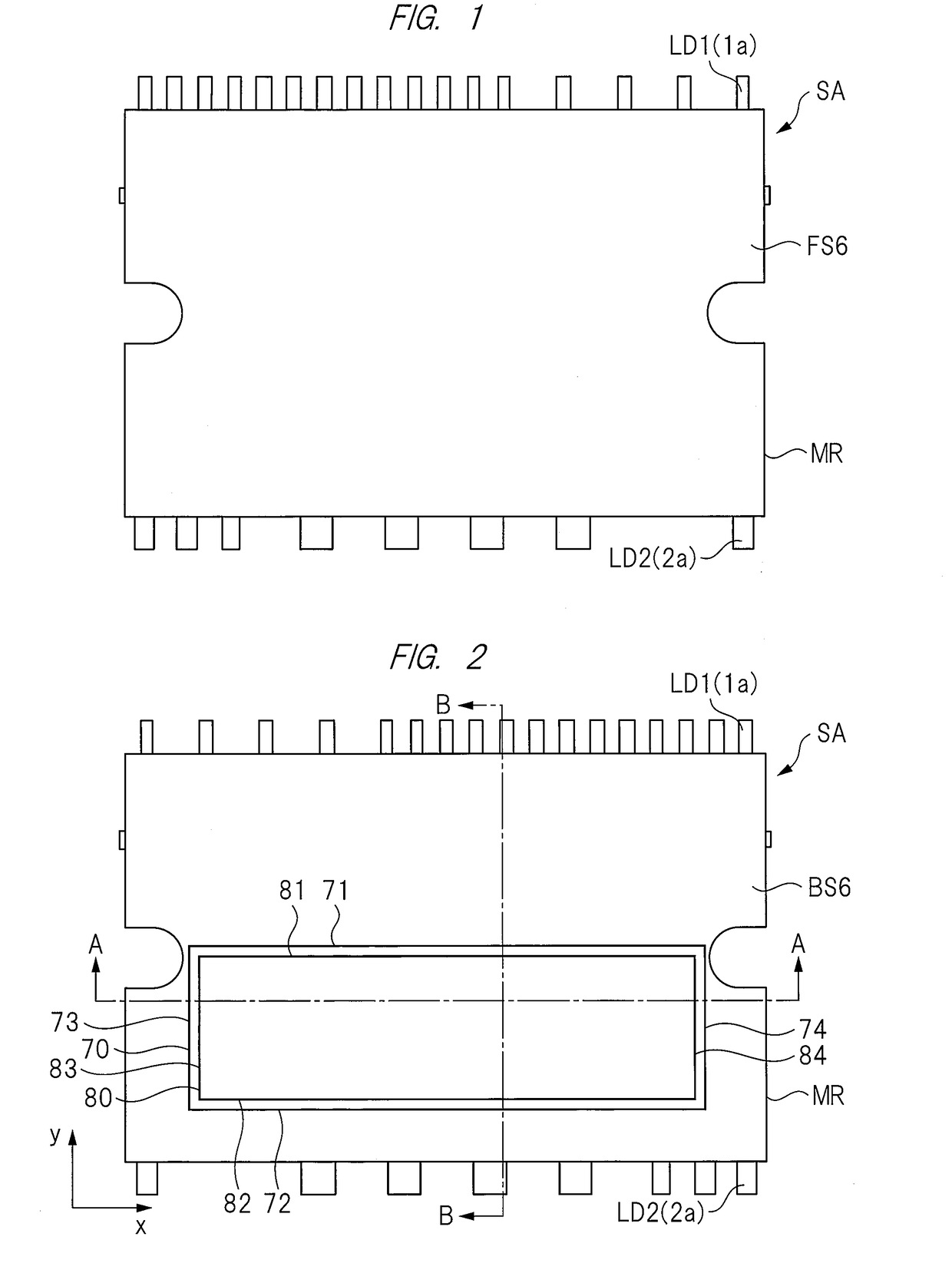

Method of manufacturing semiconductor module and semiconductor module

ActiveUS20190006258A1Refining issueImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

Reliability of a semiconductor module is improved. In a resin mold step of assembly of a semiconductor module, an IGBT chip, a diode chip, a control chip, a part of each of chip mounting portions are resin molded so that a back surface of each of the chip mounting portions is exposed from a back surface of a sealing body. After the resin molding, an insulating layer is bonded to the back surface of the sealing body so as to cover each back surface (exposed portion) of the chip mounting portions, and then, a TIM layer is bonded to an insulating layer. Here, a region of the TIM layer in a plan view is included in a region of the insulating layer.

Owner:RENESAS ELECTRONICS CORP

Electrical connector assembly and male connector

ActiveUS10826245B2Refining issueImproving common ground performance and crosstalkSecuring/insulating coupling contact membersTwo-part coupling devicesElectrical connectionStructural engineering

An electrical connector assembly, a female connector, and a male connector are provided. The electrical connector assembly includes a female connector and a male connector detachably inserted into the female connector. The female connector includes a housing and a plurality of transmission wafers inserted into the housing. Each of the transmission wafers includes an insulating frame and a plurality of grounding terminals fixed to the insulating frame. The male connector includes a carrier and a plurality of shielding terminals fixed to the carrier. Two side walls of each of the shielding terminals are respectively abutted against and electrically connected to two of the grounding terminals each having at least one first contacting portion.

Owner:STARCONN ELECTRONICS SU ZHOU CO LTD

Waterproof indicator light

InactiveUS7192156B1Reduce in quantityIncrease the lengthLighting applicationsPoint-like light sourceLow voltageEngineering

The present invention is a waterproof indicator light, which solves the problem that the length of the space needed for the battery is too long, caused by the battery needing to be in serial connection for the conventional waterproof indicator light. The invention includes a step-up apparatus in the illuminating module to reduce the number of batteries needed, or to change to a button mercury battery that has a lower voltage and is smaller. Then, the step-up apparatus is used to increase the voltage. By so doing, it largely reduces the space needed for the battery set, increases the length of the refracting surface for the illuminating module, and increases the illuminating effect as well.

Owner:HUNG CHIH WEN

Indoor illumination system

InactiveUS20120182764A1Refining issueReduce shadowsPoint-like light sourceLighting support devicesDirect illuminationEffect light

A lighting system for an indoor room or space is designed to provide a diffuse, glare free source that illuminates the room from the cornice, or a similar location around the join between the walls and ceiling. This may be achieved via a direct source of illumination at the cornice location, or by projecting illumination from a remote source. The lighting system is further designed to allow for illumination of certain areas of the cornice, and hence the room, whilst leaving other parts dark. There are multiple advantages of an adaptable system such as this, but in particular the lighting conditions can be adjusted for optimum lighting levels, for example dimming selected areas when viewing a television.

Owner:SHARP KK

Swimming pool safety surveillance system

ActiveUS10163323B1Improve the inconvenienceImprove rescue efficiencyCharacter and pattern recognitionAlarmsSafety surveillanceComputer terminal

A swimming pool safety surveillance system includes a camera identifying module, a terminal controller, and a camera identification monitoring module. The camera identifying module identifies the face of swimmers to generate a face information. The camera identification monitoring module tracks the face information around the facility environment of the swimming pool area, so as to produce a warning signal when the swimmer with corresponding face information is in an accident event, such that the emergency signal is sent to the terminal controller for sending a rescue warning. By intelligently tracking the face of swimmers, the swimming pool environment is under safety surveillance, whereby the rescue operation is immediately carried out for accident occurrence, and the swimming pool safety and the rescue efficiency are improved.

Owner:NAT CHIN YI UNIV TECH

Synthesis of 1,4-polybutadiene

This invention is based upon the unexpected discovery that alkylated diphenylamines can be used in conjunction with nickel based catalyst systems which contain (a) an organonickel compound, (b) an organoaluminum compound, and (c) a fluorine containing compound to produce cis-1,4-polybutadiene having reduced molecular weight and an increased level of branching. This results in the cis-1,4-polybutadiene exhibiting good processability without sacrificing cold flow characteristics. Additionally, the alkylated diphenylamine which remains in the rubber acts in a manner which provides it with antioxidant protection. In other words, the use of alkylated diphenylamines accomplishes the three major objectives that are realized by employing para-styrenated diphenylamines (reduced molecular weight, regulated polymer macrostructure through branching and antidegradant protection). However, the utilization of alkylated diphenylamines, unlike para-styrenated diphenylamines, offers the additional advantage of being soluble in aliphatic solvents. By virtue of this increased level of solubility in aliphatic solvents, such as hexane, alkylated diphenylamines can be employed at greatly reduced levels of aromatic solvents. Likewise, when mixed catalyst streams containing alkylated diphenyl amines are combined precipitation is minimized compared to para-styrenated diphenylamine significantly improving issues related to fouling. The subject invention more specifically discloses a process for producing cis-1,4-polybutadiene having a reduced molecular weight and improved processability which comprises polymerizing 1,3-butadiene in the presence of (a) an organonickel compound, (b) an organoaluminum compound, (c) a fluorine containing compound, and (d) an alkylated diphenylamine; wherein the alkylated diphenylamine has alkyl groups that contain from 2 to 18 carbon atoms, and wherein the organoaluminum compound and the fluorine containing compound are brought together in the presence of the alkylated diphenylamine.

Owner:THE GOODYEAR TIRE & RUBBER CO

Synchronous backlight device and operation method thereof

ActiveUS20190164506A1Improving the issue backlight flickerRefining issueStatic indicating devicesPulse duration/width modulationControl signalVideo processing

A synchronous backlight device and an operation method thereof are provided. The synchronous backlight device includes a pulse width modulation (PWM) control circuit and a backlight driving circuit. The PWM control circuit receives the video sync information from a video processing circuit and generates a PWM control signal. Wherein, the video sync information defines a plurality of video frame periods, the PWM control circuit at least divides each of the video frame periods into a first period and a second period, the lengths of the first periods of the video frame periods are equal to one another. The frequency of the PWM control signal in the first periods is different from the frequency of the PWM control signal in the second periods. The backlight driving circuit drives the backlight source of a display panel in accordance with the PWM control signal.

Owner:NOVATEK MICROELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com