Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Bulky assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

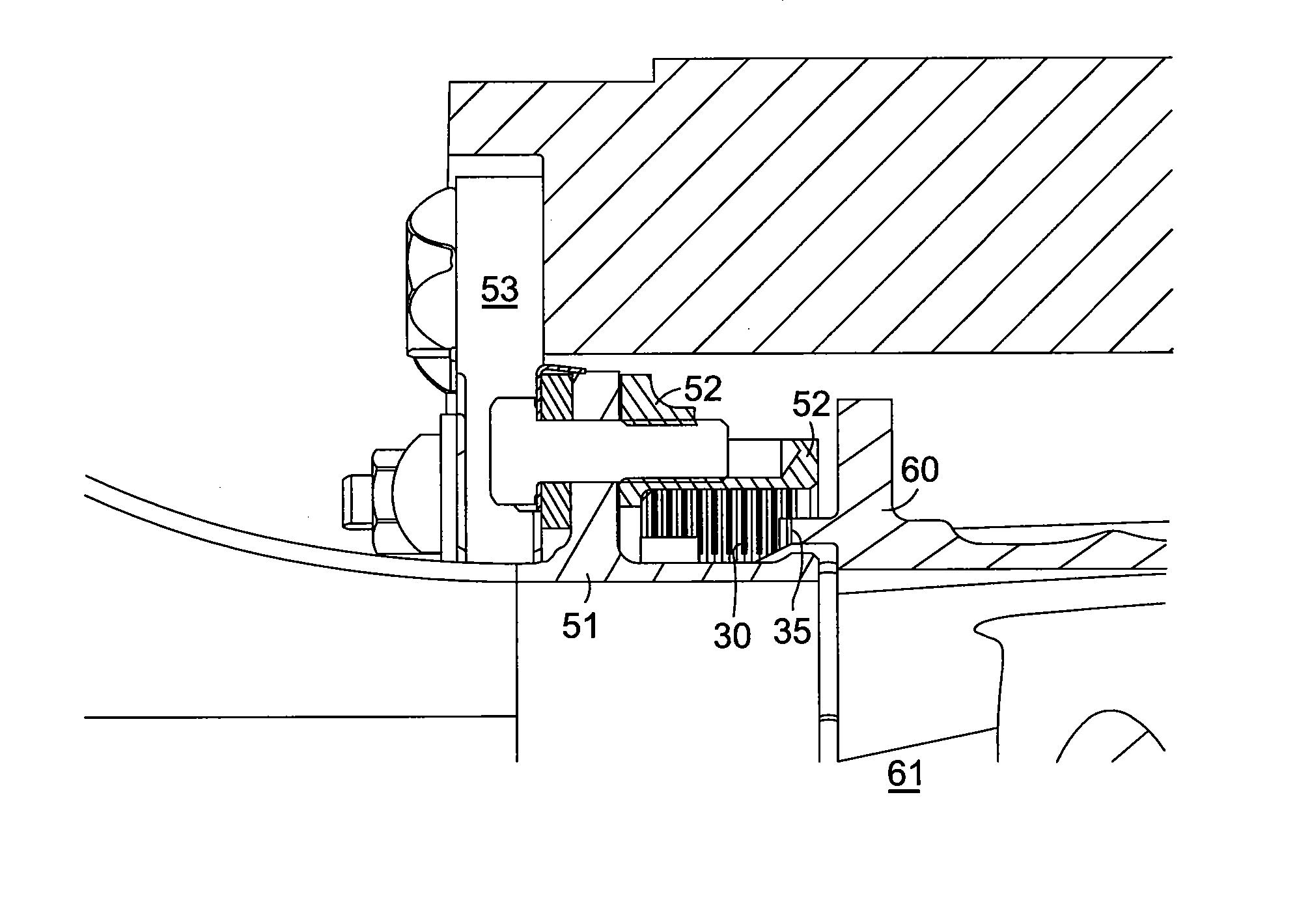

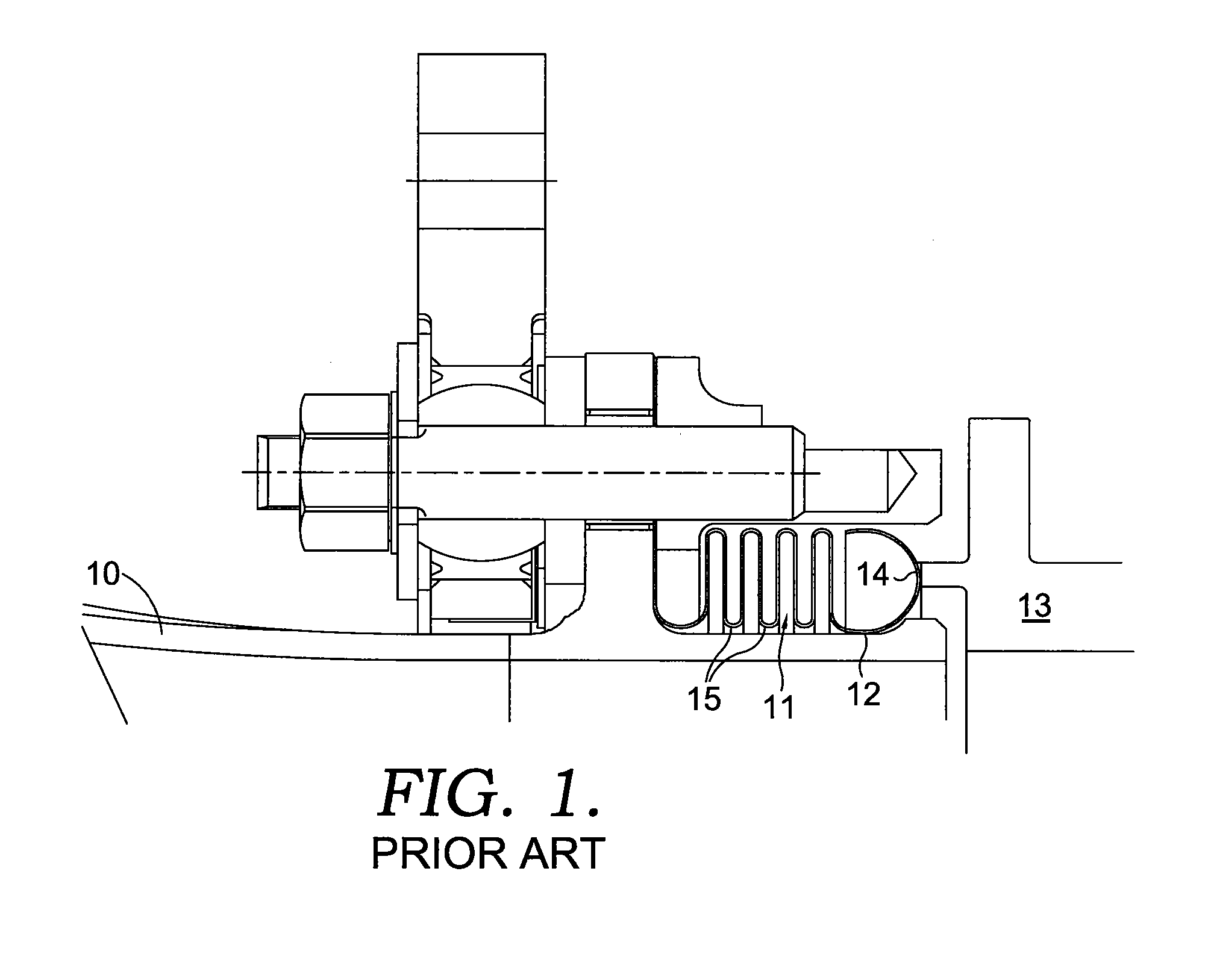

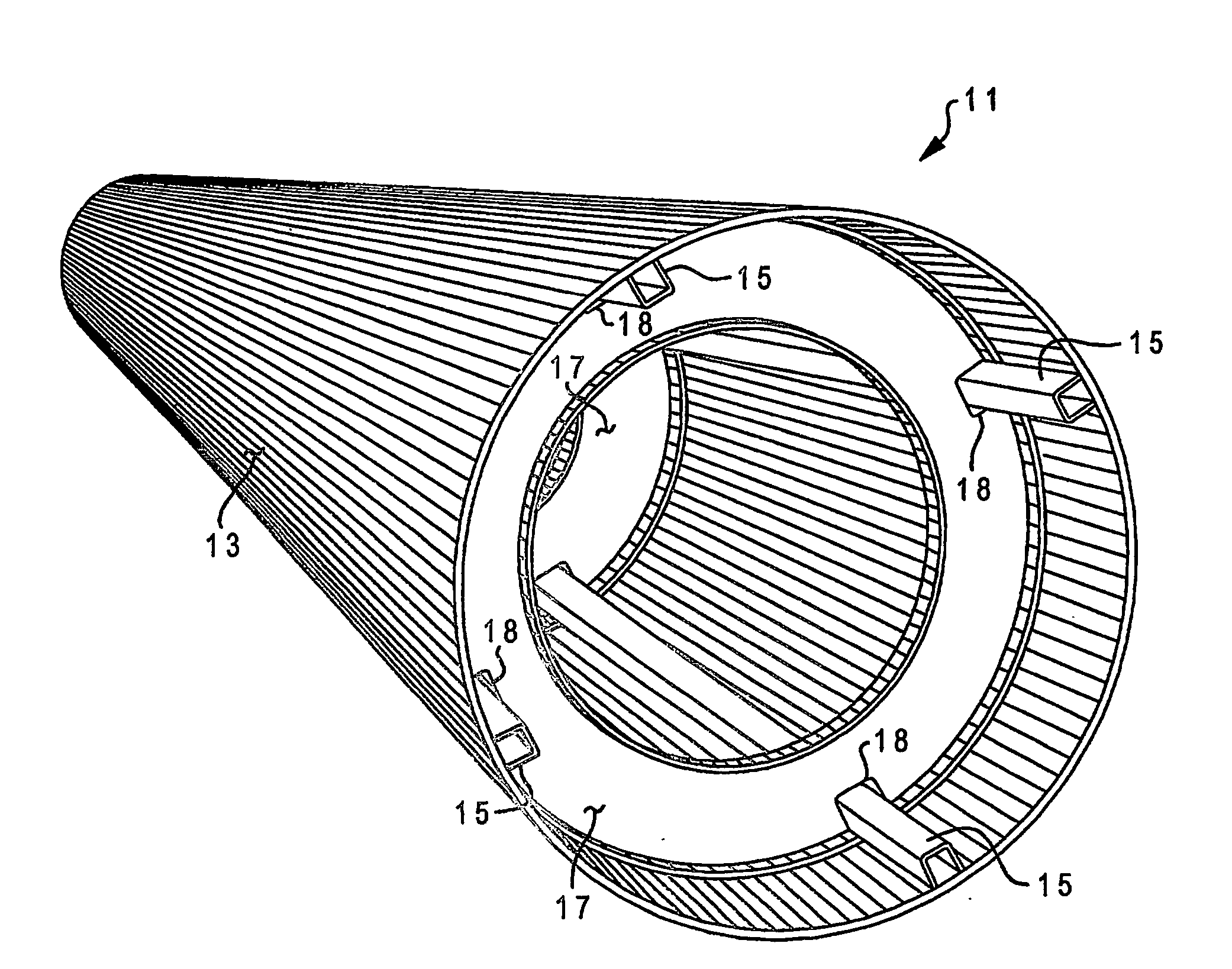

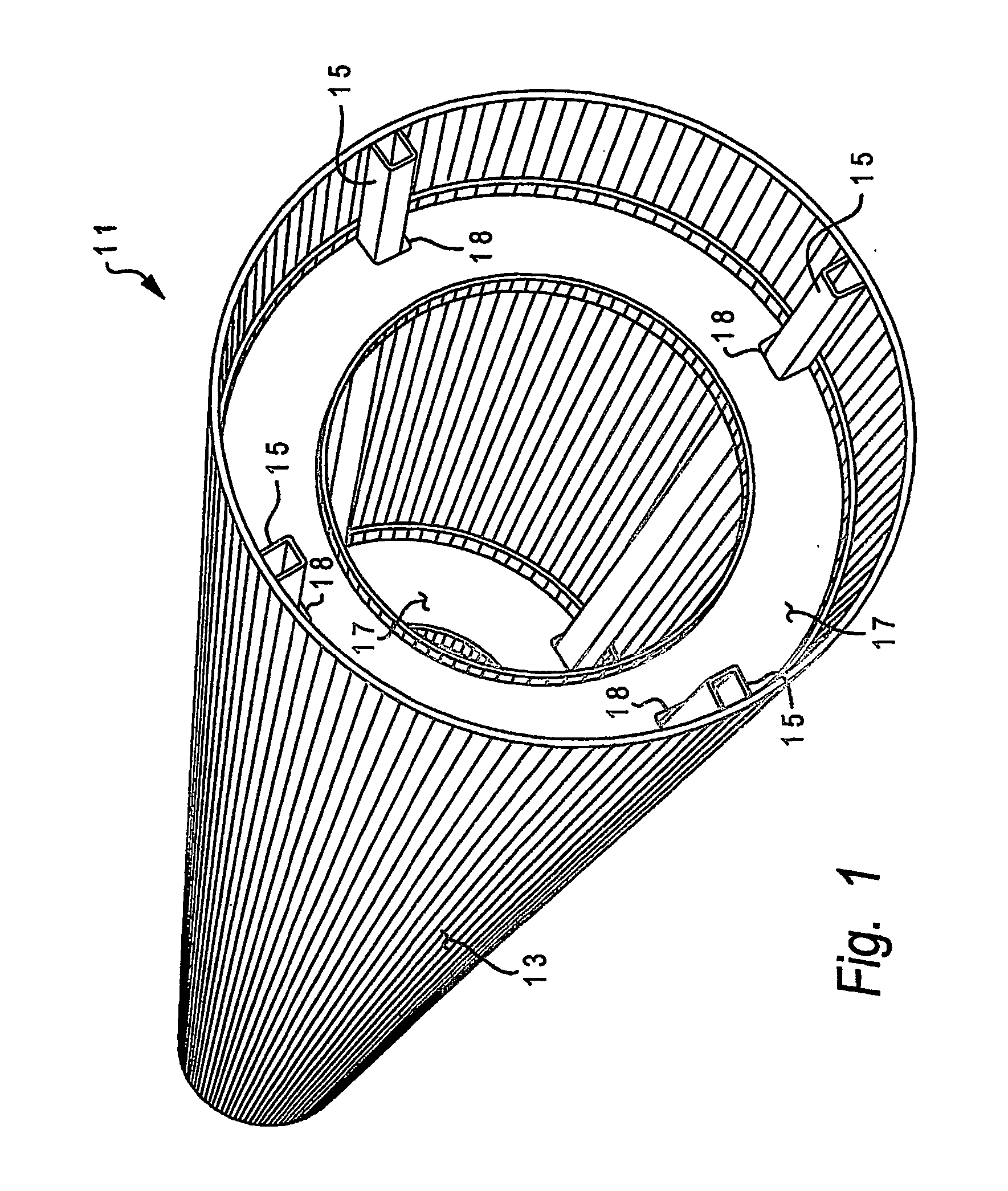

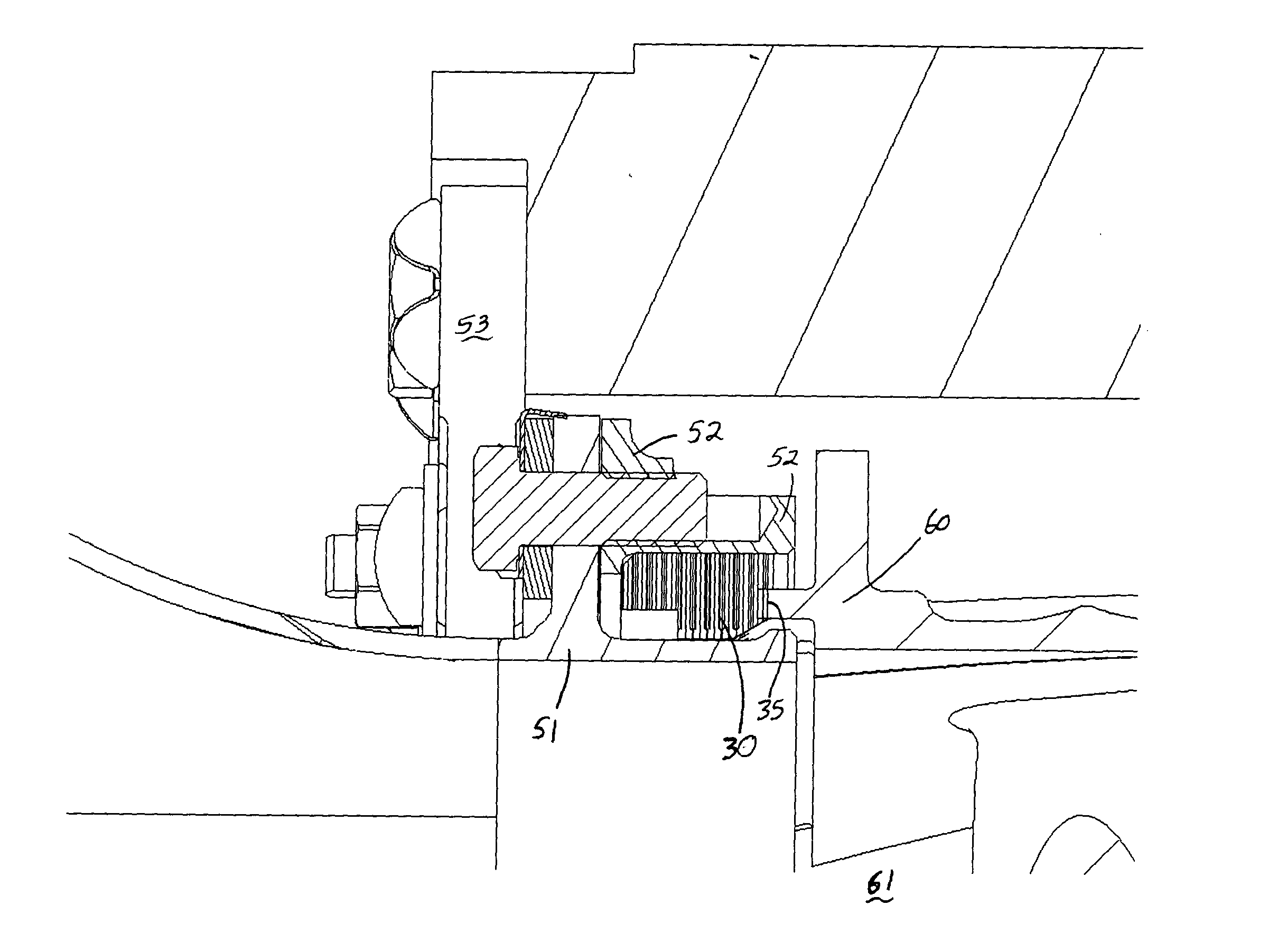

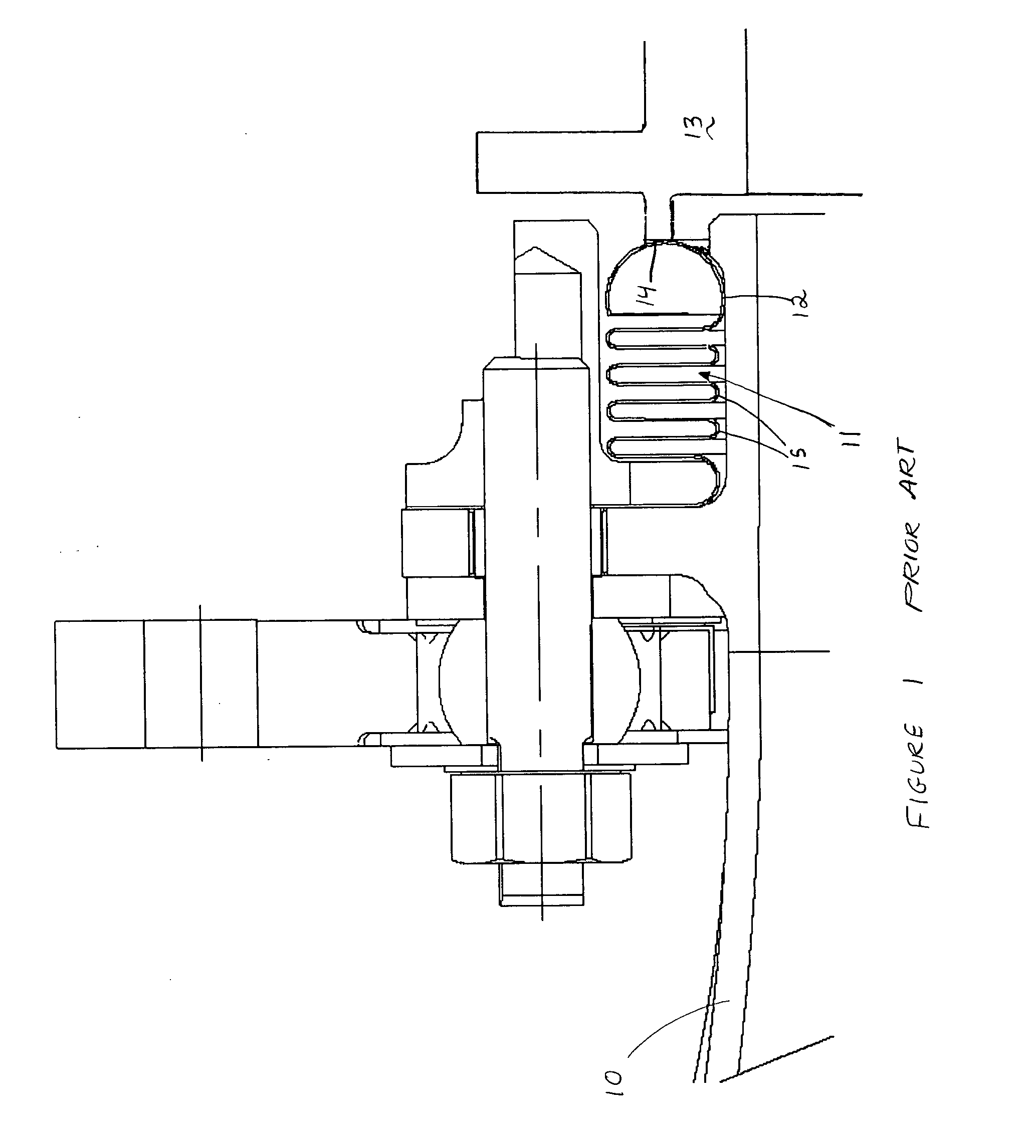

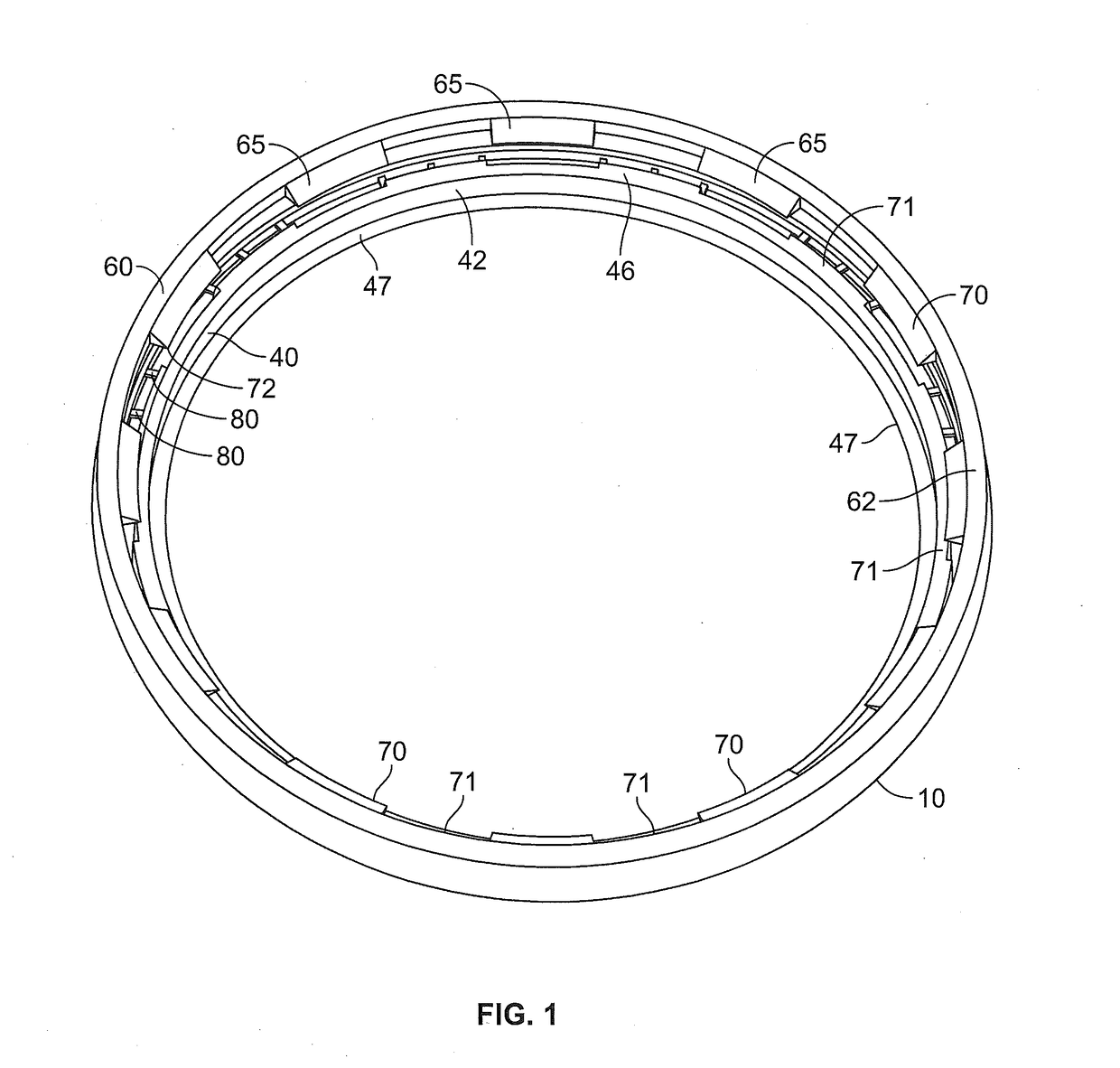

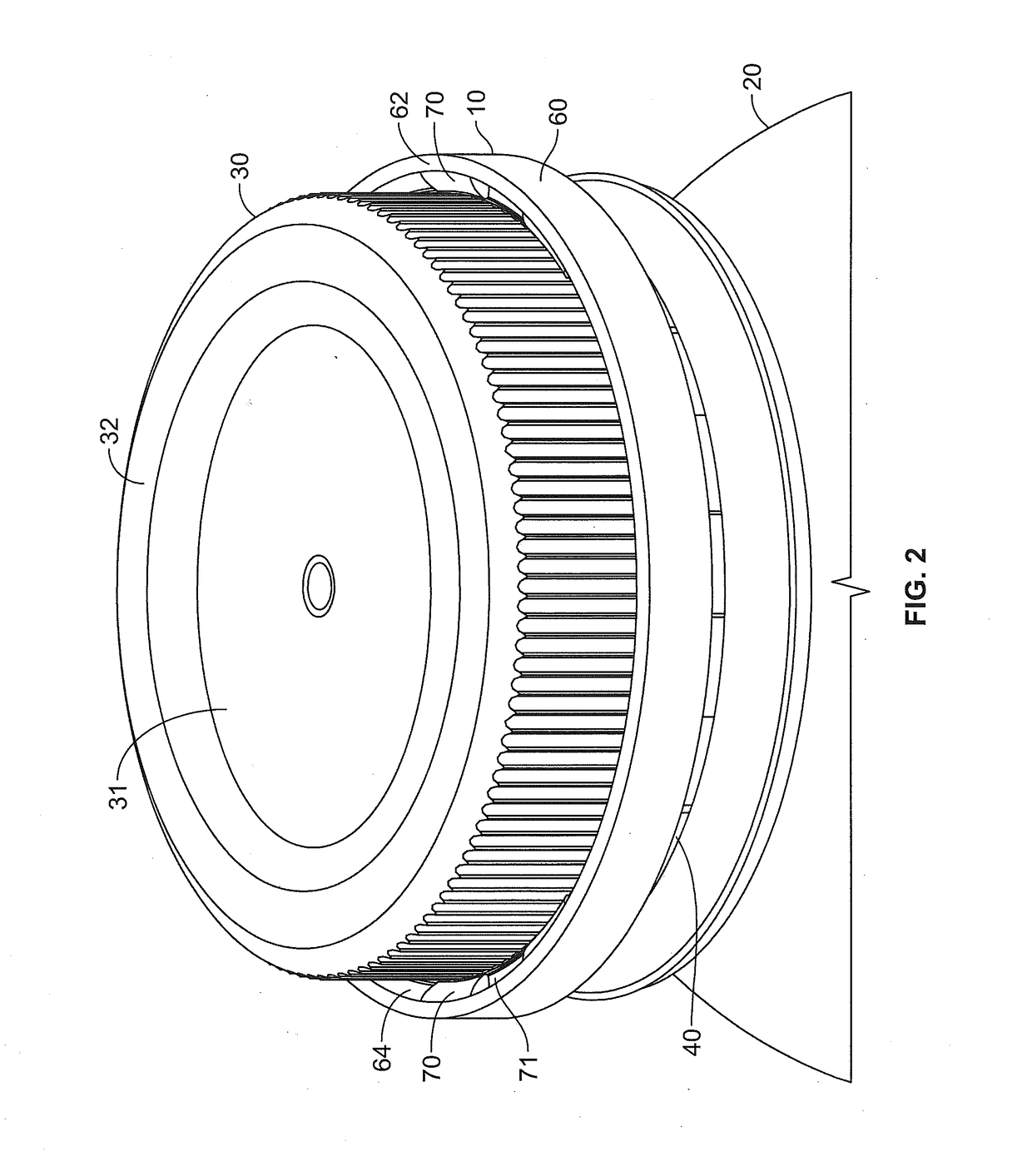

Transition duct honeycomb seal

A sealing device for use between a gas turbine combustor transition duct aft frame and a turbine inlet having improved durability, reduced wear on the mating turbine vane, and reduced manufacturing costs, is disclosed. The sealing device has a circumferential length, an axial width, and a radial height and contains a plurality of channels extending axially along the seal inner surface for passing a controlled amount of cooling air to a turbine inlet. The sealing device is formed of abradable honeycomb having a plurality of honeycomb cells with the honeycomb cells oriented to ensure maximum control against cooling air leakage while also providing maximum flexibility during assembly. The sealing device is captured between the transition duct aft frame, bulkhead, and turbine vane platform, thereby allowing easy replacement of the seal without requiring major disassembly of the transition duct aft frame section.

Owner:H2 IP UK LTD

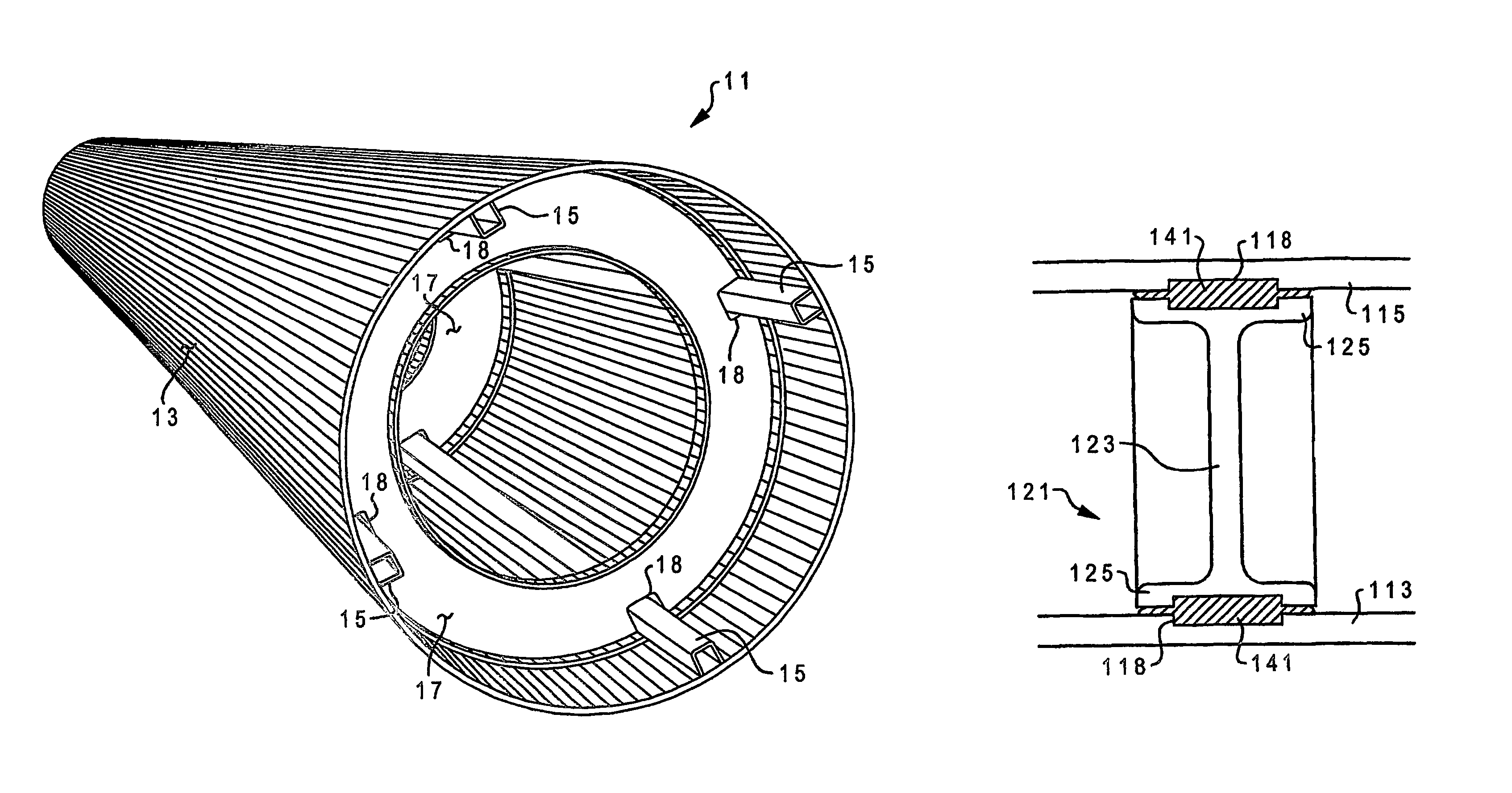

Structural element with rib-receiving member

InactiveUS7205066B1Elimination of extensive assembly toolingReduce the number of partsFuselage framesLayered productsBiomedical engineeringAirplane

A structural element for use in aerospace applications such as a structural element suitable as an aircraft component is described. In one embodiment of the invention, the composite structure comprises: (a) at least one member having an inner surface and an outer surface; (b) a rib having a first end and a second end; (c) a rib-receiving member integral to the inner surface of the at least one member, wherein the rib-receiving member comprises a plurality of rib-receiving elements and openings therein for receiving the first end of the rib and at least one cover sheet having an opening therein for receiving the first end of the rib; and (d) at least one anchoring element interconnecting the rib-receiving elements. In another embodiment of the invention, the composite structure comprises: (a) at least one member having an inner surface and an outer surface; (b) a rib having a first end and a second end; and (c) a rib-receiving member integral to the inner surface of the at least one member, wherein the rib-receiving member comprises a rib-receiving sleeve having an open end for receiving the rib and a closed end, and two sleeve support members, wherein the sleeve support members are disposed on opposite sides of the sleeve and interconnect the sleeve to the inner face of the at least one member.

Owner:ROHR INC

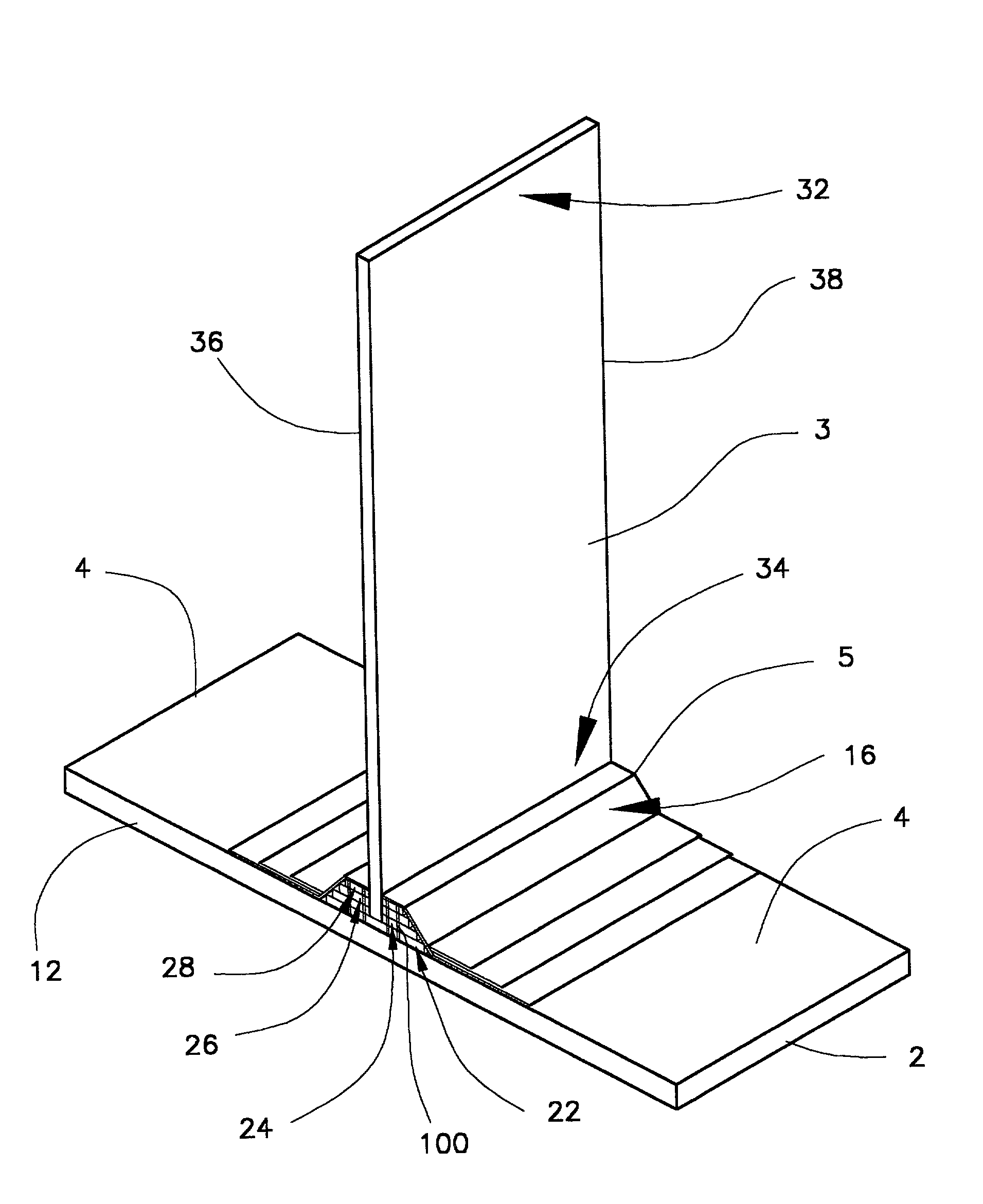

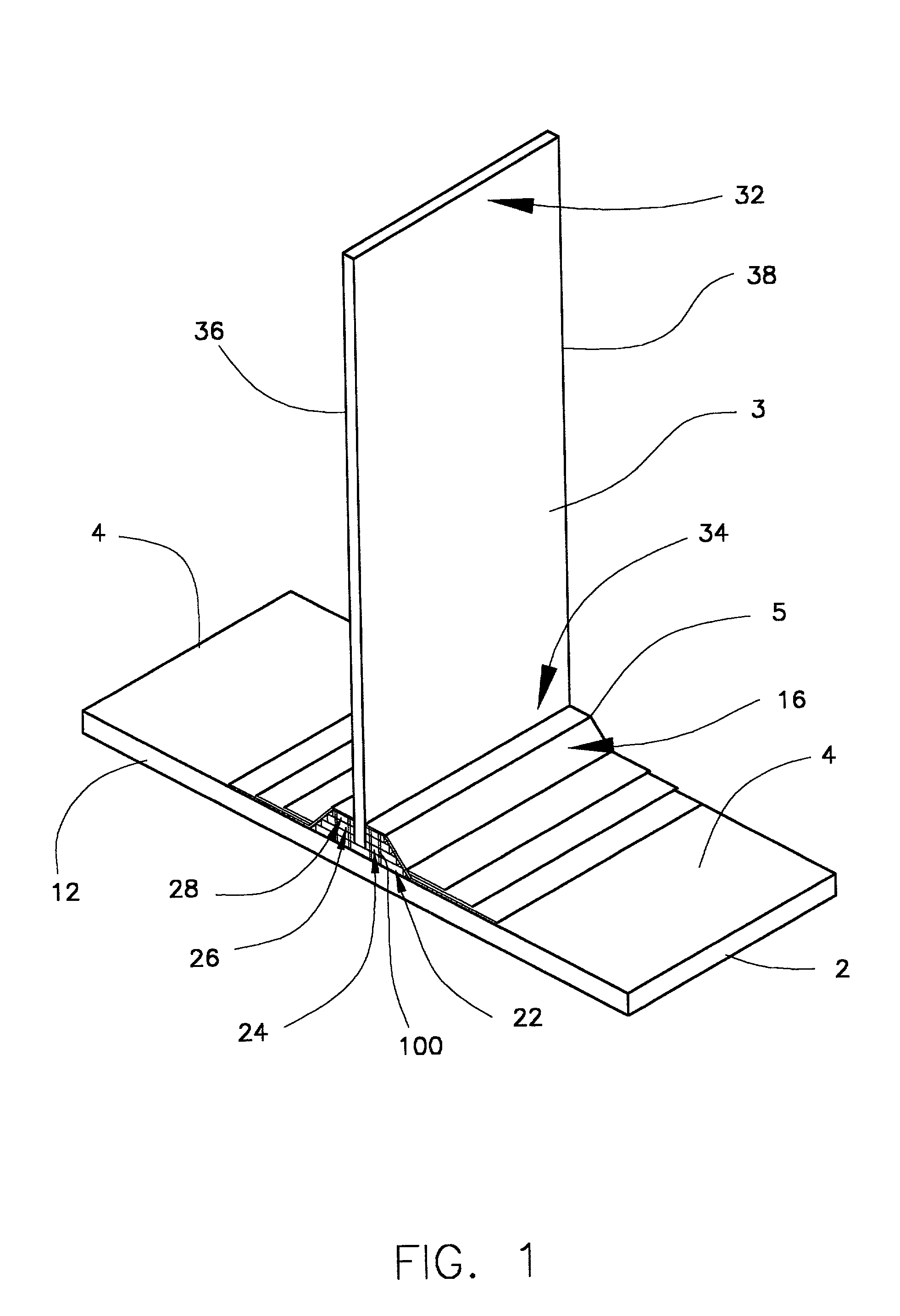

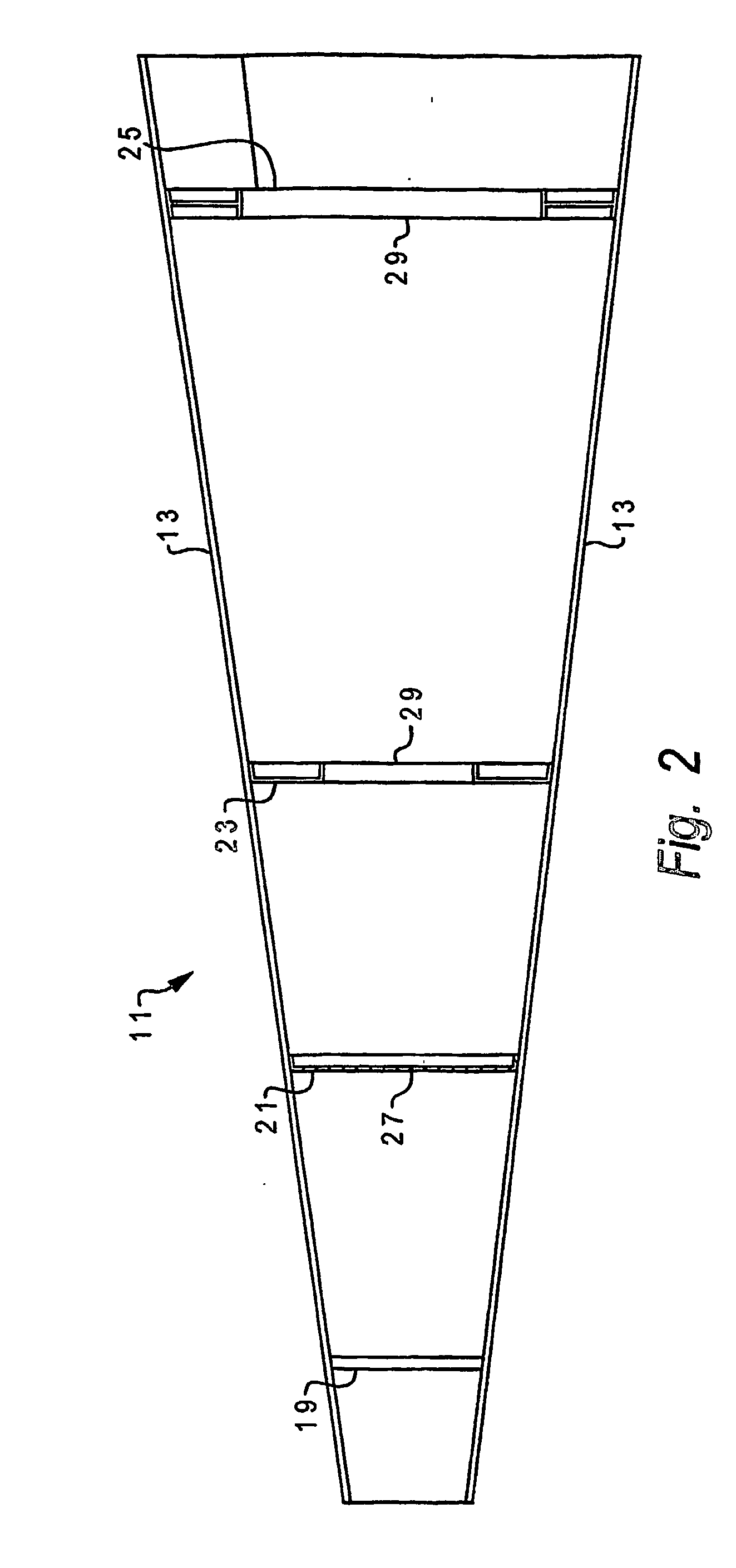

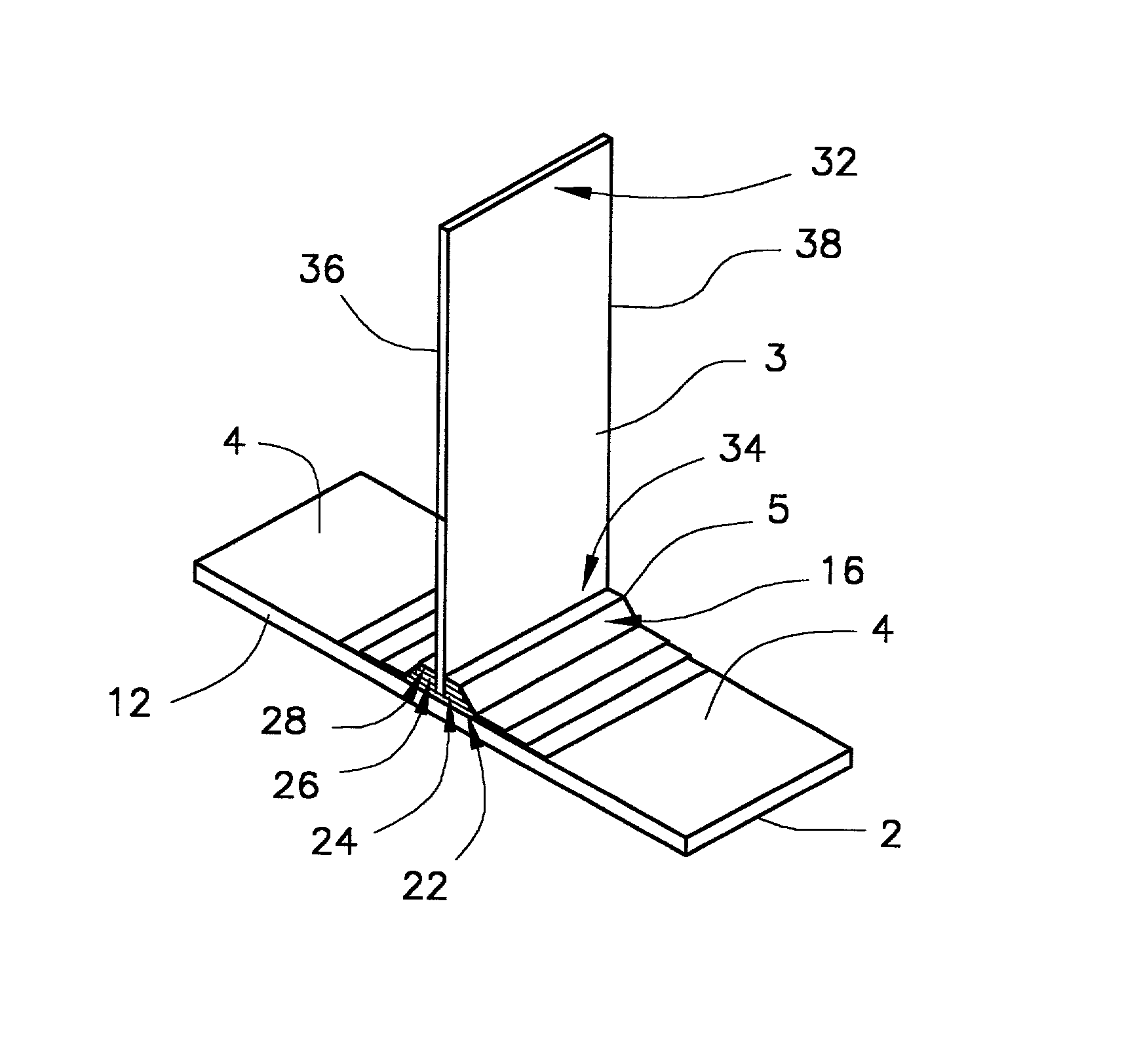

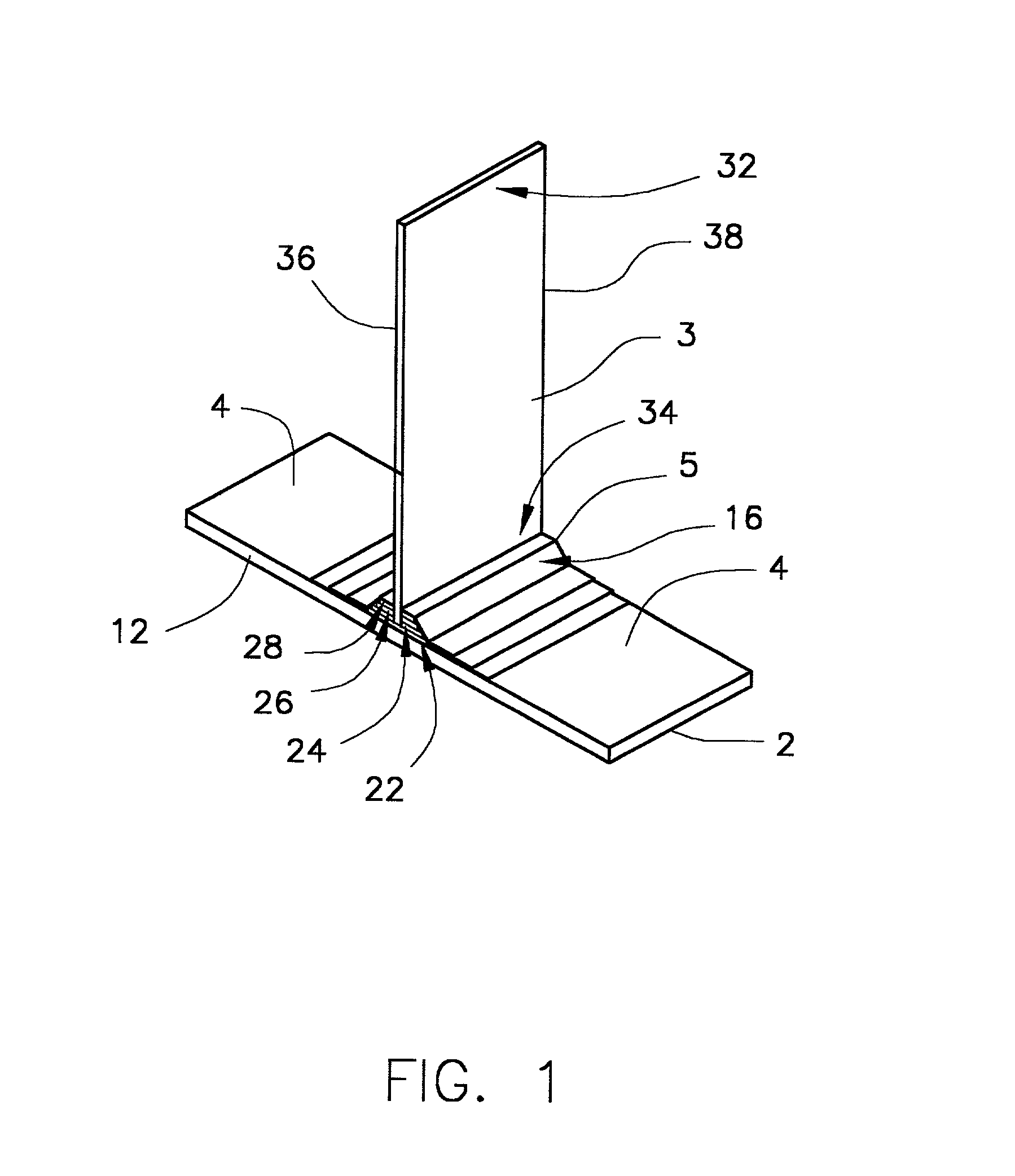

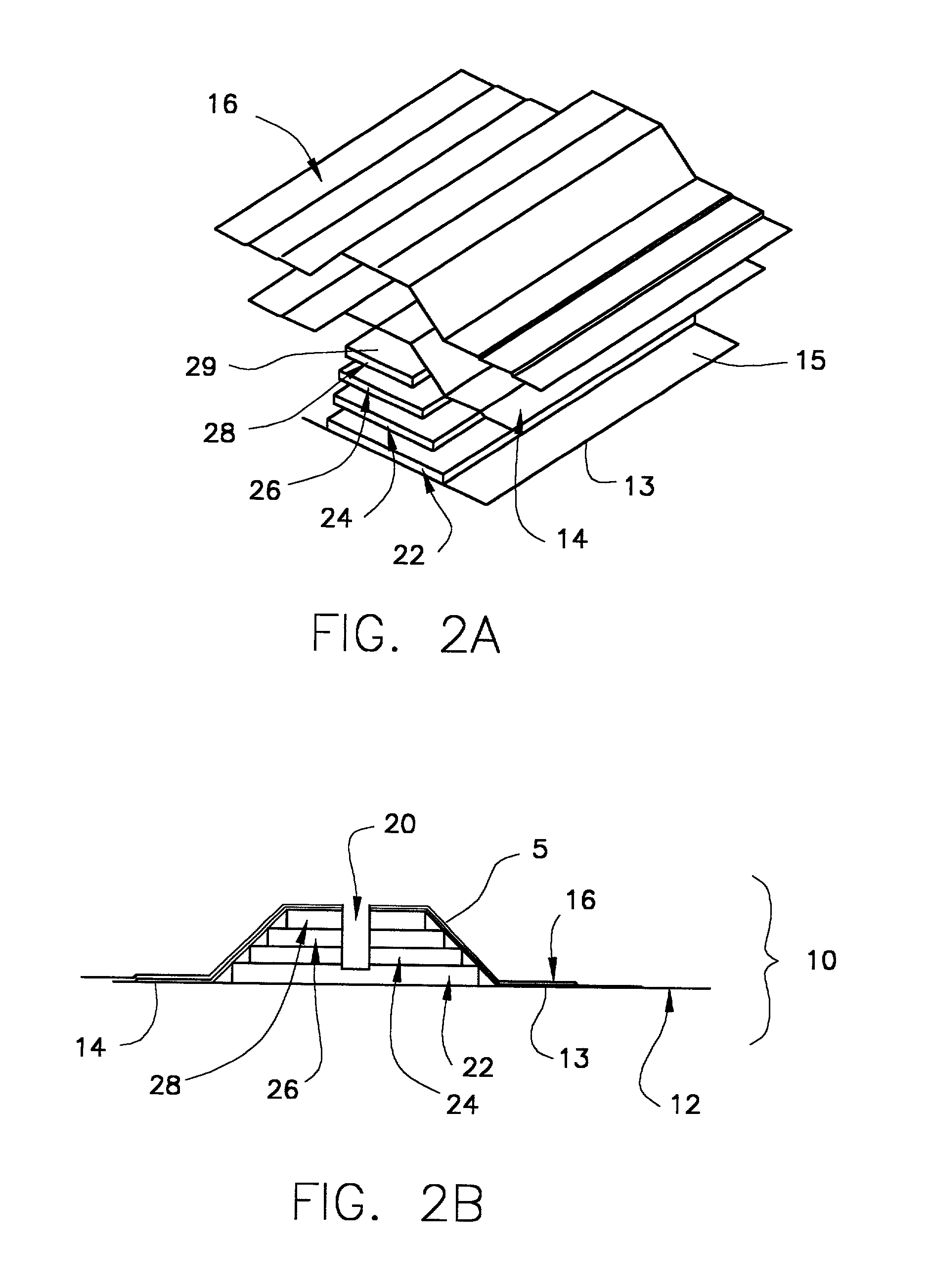

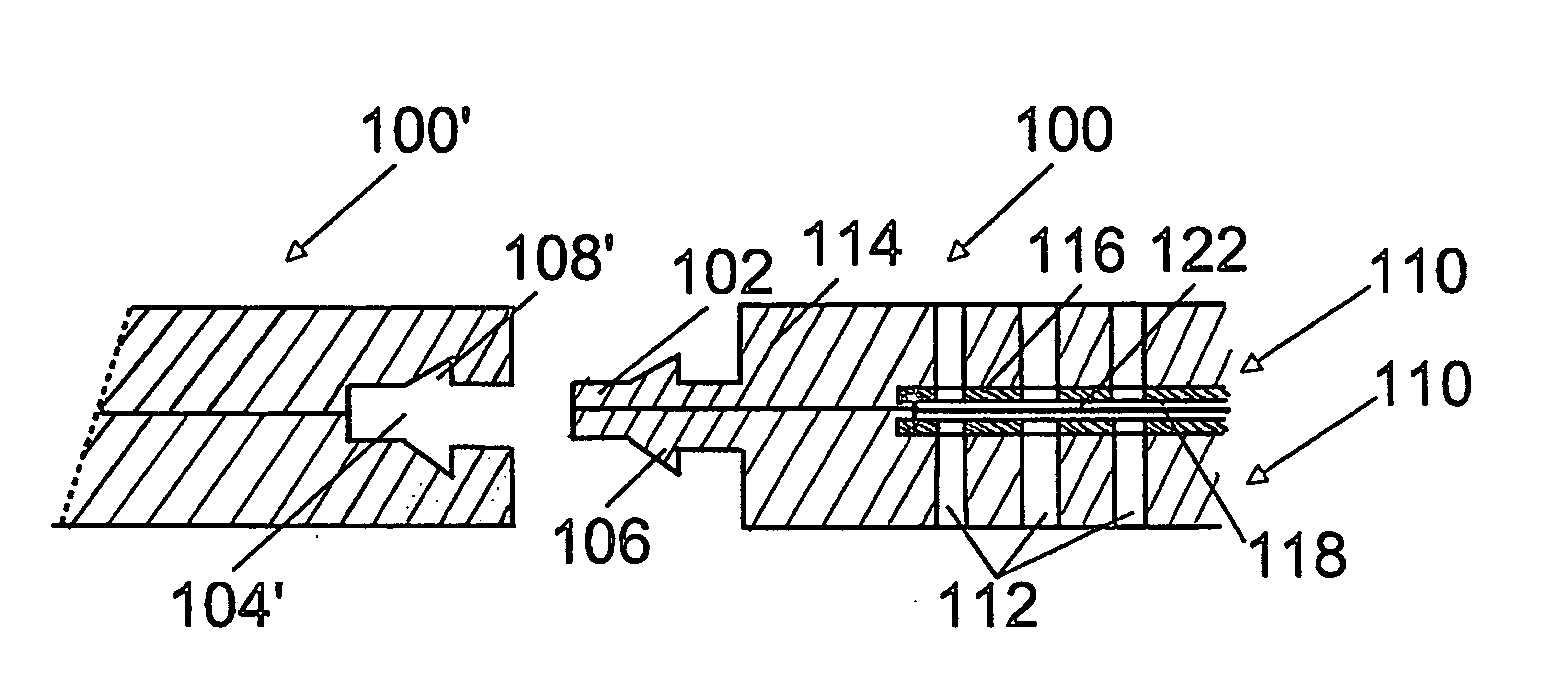

Contact stiffeners for structural skins

ActiveUS20070011970A1Reduce manufacturing costBulky assemblyAircraft stabilisationSpars/stringersAdhesiveFilling materials

An internal stiffening member of varying configurations in which the stiffening elements support the skin using a compression-only load path is dislcosed. In the preferred embodiment, the stiffening element has a peripheral edge that is adapted to be press fit into contact with the skin. The stiffening member may be held in place by various retention devices. Another configuration is a slip-in rib having a flange with a peripheral channel in which a filler material is disposed. The rib is inserted into an assembled structural box beam, and the filler material is used to fill any gaps between the slip-in rib and the interior surface of the structural box beam. The filler material is preferably an expandable material, such as an expandable foam-type material. However, in situations where a slip-in rib forms a primary structural rib, the filler material is preferably a structural adhesive or liquid shim material. A solid adhesive or filler would not crush under the clamping forces from fasteners or bolts at localized fitting attachments.

Owner:BELL HELICOPTER TEXTRON INC

Contact stiffeners for structural skins

ActiveUS8156711B2Reduce manufacturing costBulky assemblyAircraft stabilisationSpars/stringersAdhesiveFilling materials

An internal stiffening member of varying configurations in which the stiffening elements support the skin using a compression-only load path is disclosed. In the preferred embodiment, the stiffening element has a peripheral edge that is adapted to be press fit into contact with the skin. The stiffening member may be held in place by various retention devices. Another configuration is a slip-in rib having a flange with a peripheral channel in which a filler material is disposed. The rib is inserted into an assembled structural box beam, and the filler material is used to fill any gaps between the slip-in rib and the interior surface of the structural box beam. The filler material is preferably an expandable material, such as an expandable foam-type material. However, in situations where a slip-in rib forms a primary structural rib, the filler material is preferably a structural adhesive or liquid shim material. A solid adhesive or filler would not crush under the clamping forces from fasteners or bolts at localized fitting attachments.

Owner:BELL HELICOPTER TEXTRON INC

Structural element with rib-receiving member

InactiveUS7238409B1Bulky assemblyShorten the counting processLayered productsThin material handlingEngineeringFace sheet

A structural element for use in aerospace applications such as a structural element suitable as an aircraft component is described. The composite structure comprises: (a) a rib having a first end and a second end; (b) at least one member such as a face sheet having an inner surface and an outer surface; and (c) a rib-receiving member integral to the inner surface of the at least one member, wherein the rib-receiving member comprises at least one rib-receiving element having an opening therein for receiving the first end of the rib and at least one cover sheet having an opening therein for receiving the first end of the rib.

Owner:ROHR INC

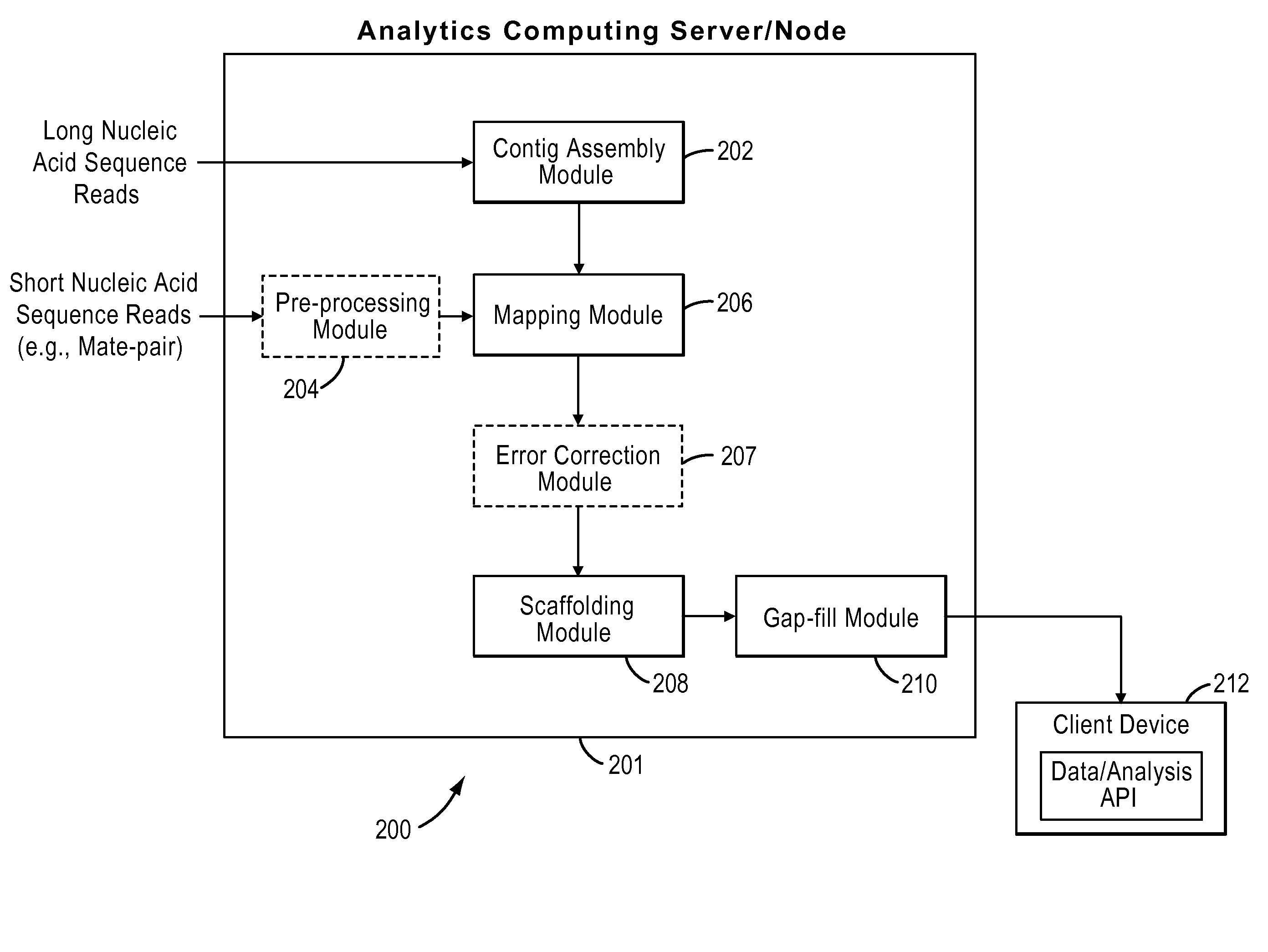

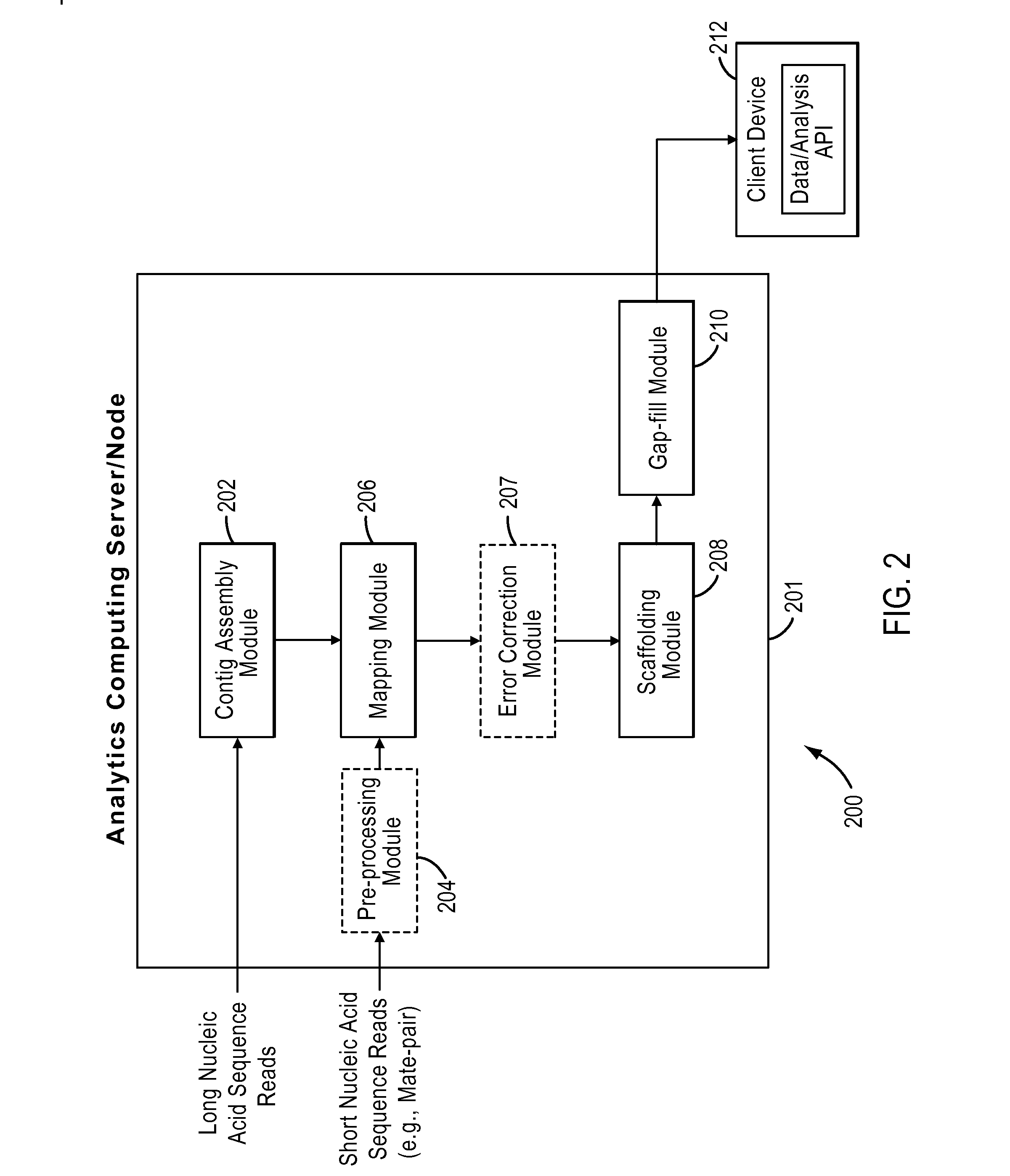

Systems and methods for hybrid assembly of nucleic acid sequences

InactiveUS20120330559A1Bulky assemblyBiological testingSequence analysisContigNucleic acid sequencing

Systems and methods for assembling a nucleic acid sequence are disclosed. A plurality of single fragment sequence reads and a plurality of paired fragment sequence reads are received. Each paired fragment sequence read comprises at least two sequence reads separated by an insert. Single fragment sequence reads are assembled into a plurality of contigs, and the paired fragment sequence reads are mapped to the contigs. Further, gap regions comprising a portion of the partially assembled nucleic acid sequence for which the single fragment sequence reads do not map are identified, and hanging pairwise sequence reads of the mapped paired fragment sequence reads are used to fill in the gap region.

Owner:LIFE TECH CORP

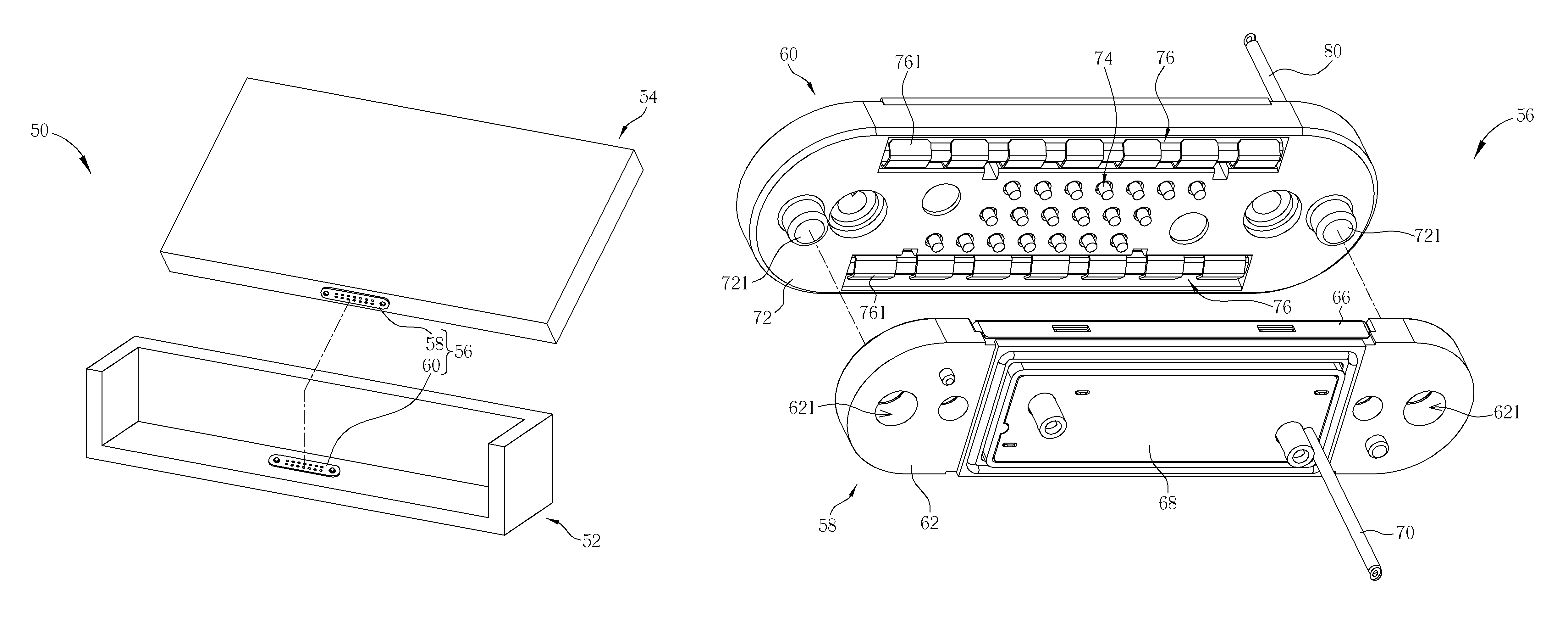

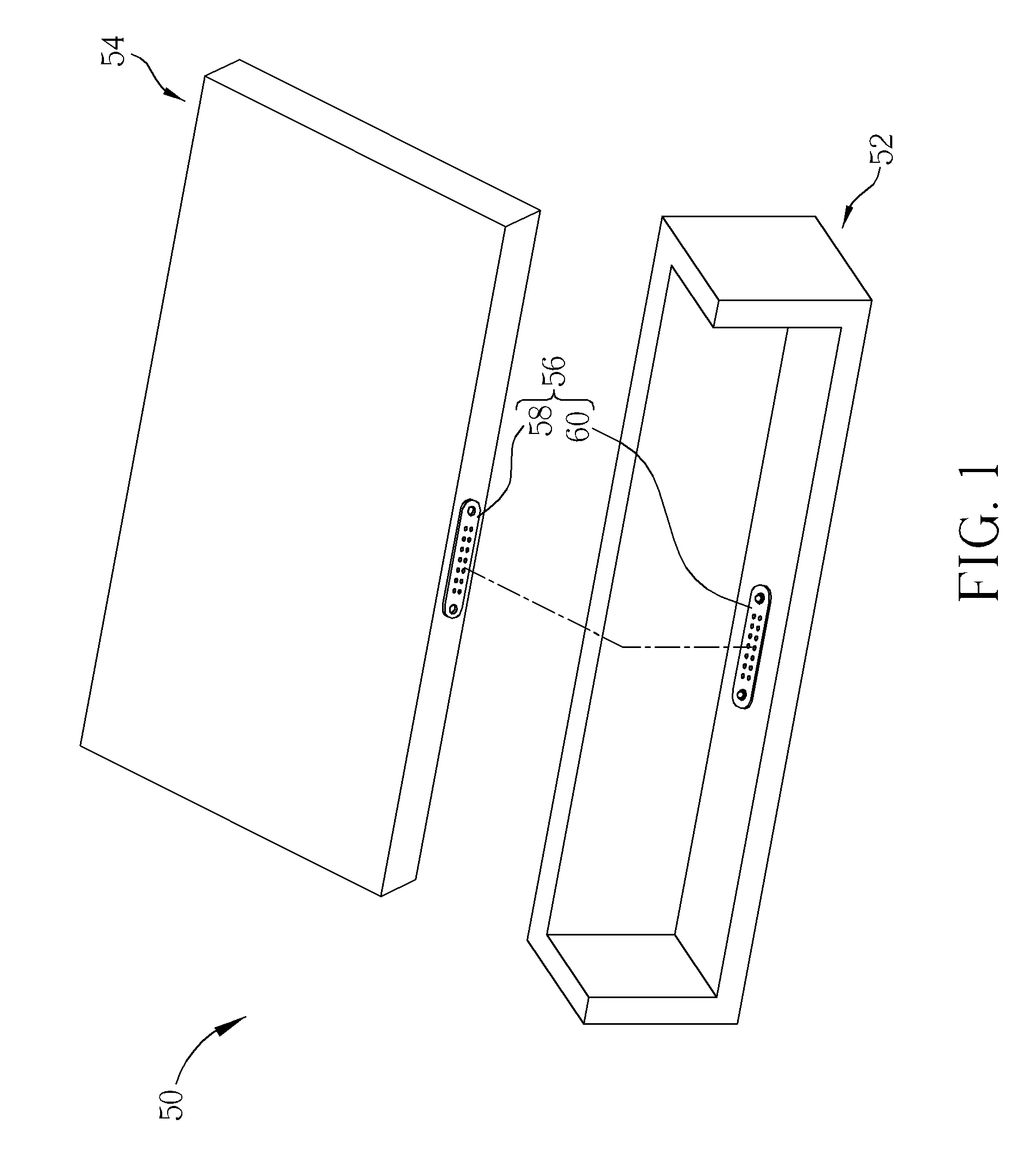

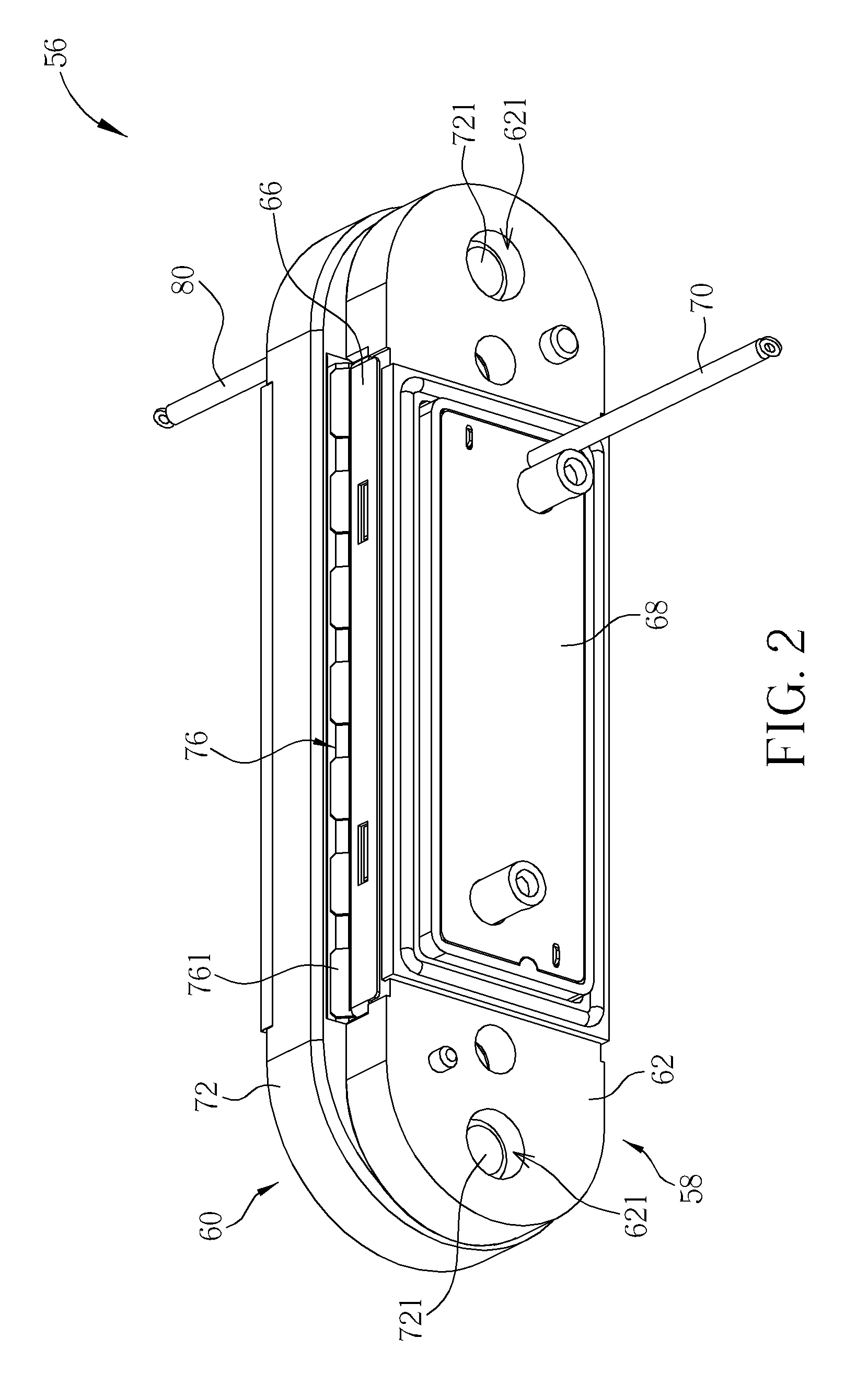

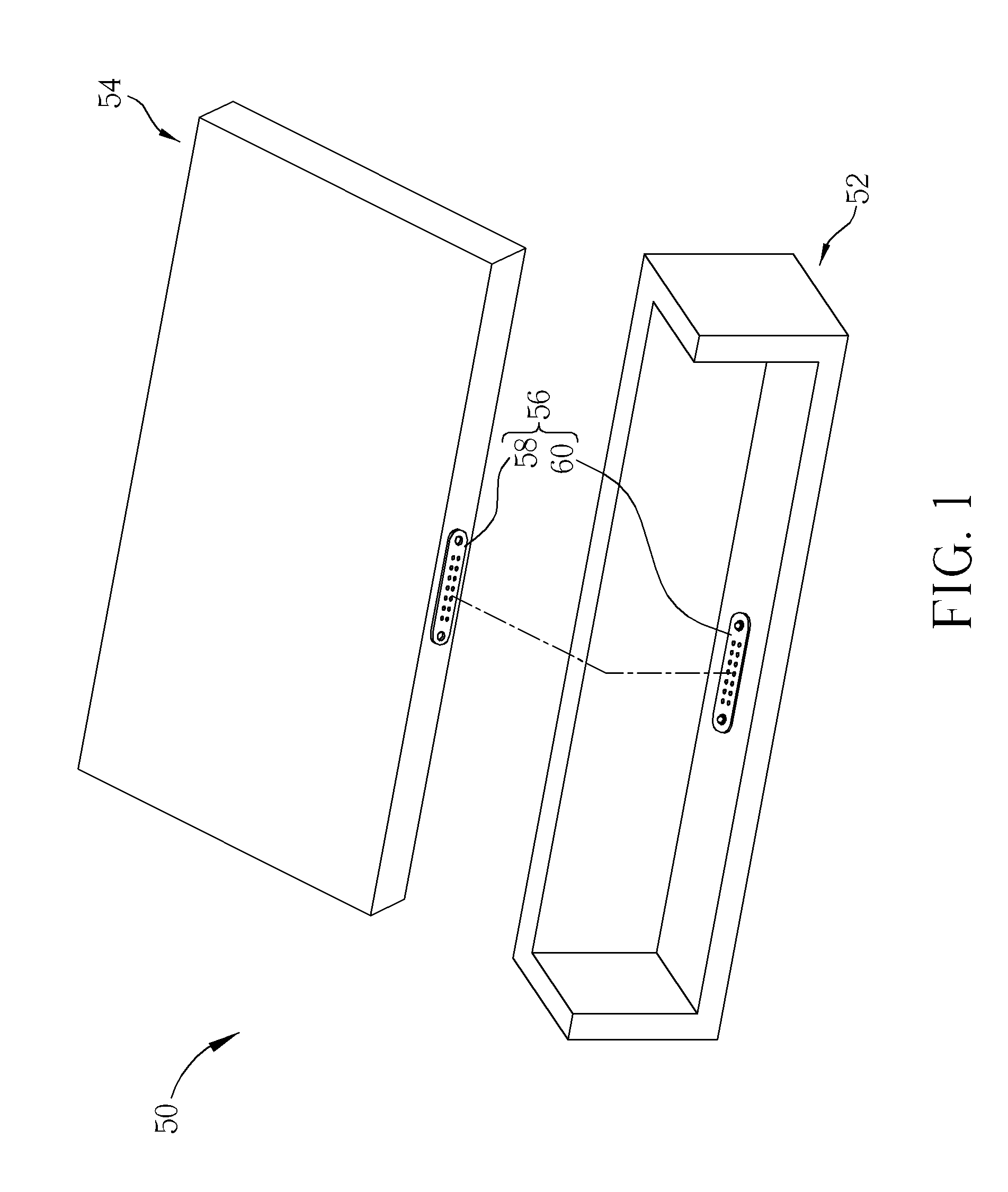

Grounding a docking station with a host device using grounding layers of multilayer printed circuit boards

ActiveUS8414312B2Refining issueLong labor hourComputer periphery connectorsCoupling protective earth/shielding arrangementsDocking stationEngineering

A connector structure includes a first connector installed on a host device. The first connector includes a first base, a first terminal set installed on the first base, and a first grounding component installed on the first base. The connector structure further includes a second connector installed on a docking station for connecting with the first connector. The second connector includes a second base, a second terminal set installed on the second base for contacting with the first terminal set so as to transmit signals between the host device and the docking station with the first terminal set when the host device is docked in the docking station, and a second grounding component installed on the second base for contacting with the first grounding component so as to ground with the first grounding component when the host device is docked in the docking station.

Owner:WISTRON CORP

Transition duct honeycomb seal

ActiveUS20050063816A1Increased durabilityReduce wearEngine sealsPump componentsHoneycombGas turbines

A sealing device for use between a gas turbine combustor transition duct aft frame and a turbine inlet having improved durability, reduced wear on the mating turbine vane, and reduced manufacturing costs, is disclosed. The sealing device has a circumferential length, an axial width, and a radial height and contains a plurality of channels extending axially along the seal inner surface for passing a controlled amount of cooling air to a turbine inlet. The sealing device is formed of abradable honeycomb having a plurality of honeycomb cells with the honeycomb cells oriented to ensure maximum control against cooling air leakage while also providing maximum flexibility during assembly. The sealing device is captured between the transition duct aft frame, bulkhead, and turbine vane platform, thereby allowing easy replacement of the seal without requiring major disassembly of the transition duct aft frame section.

Owner:H2 IP UK LTD

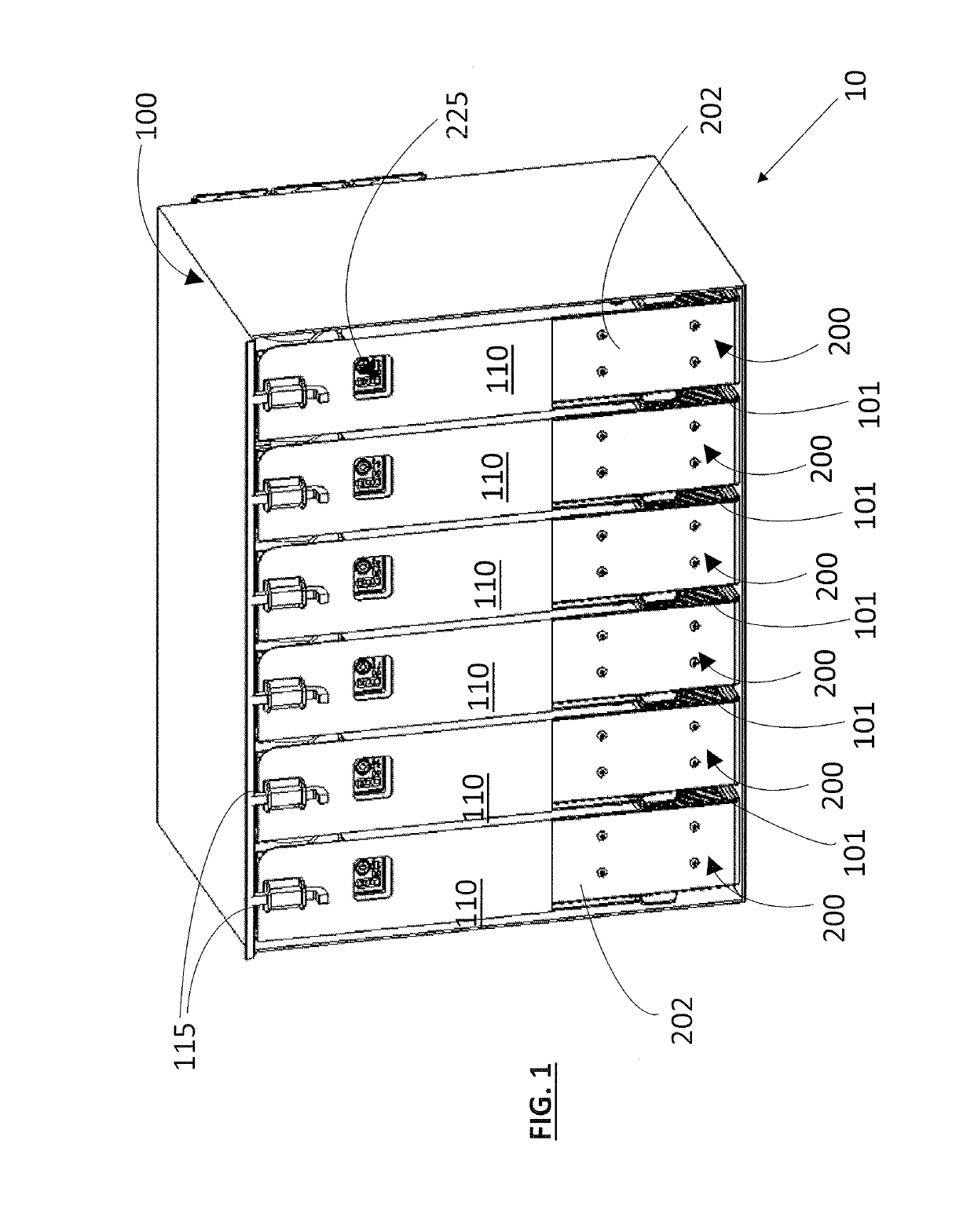

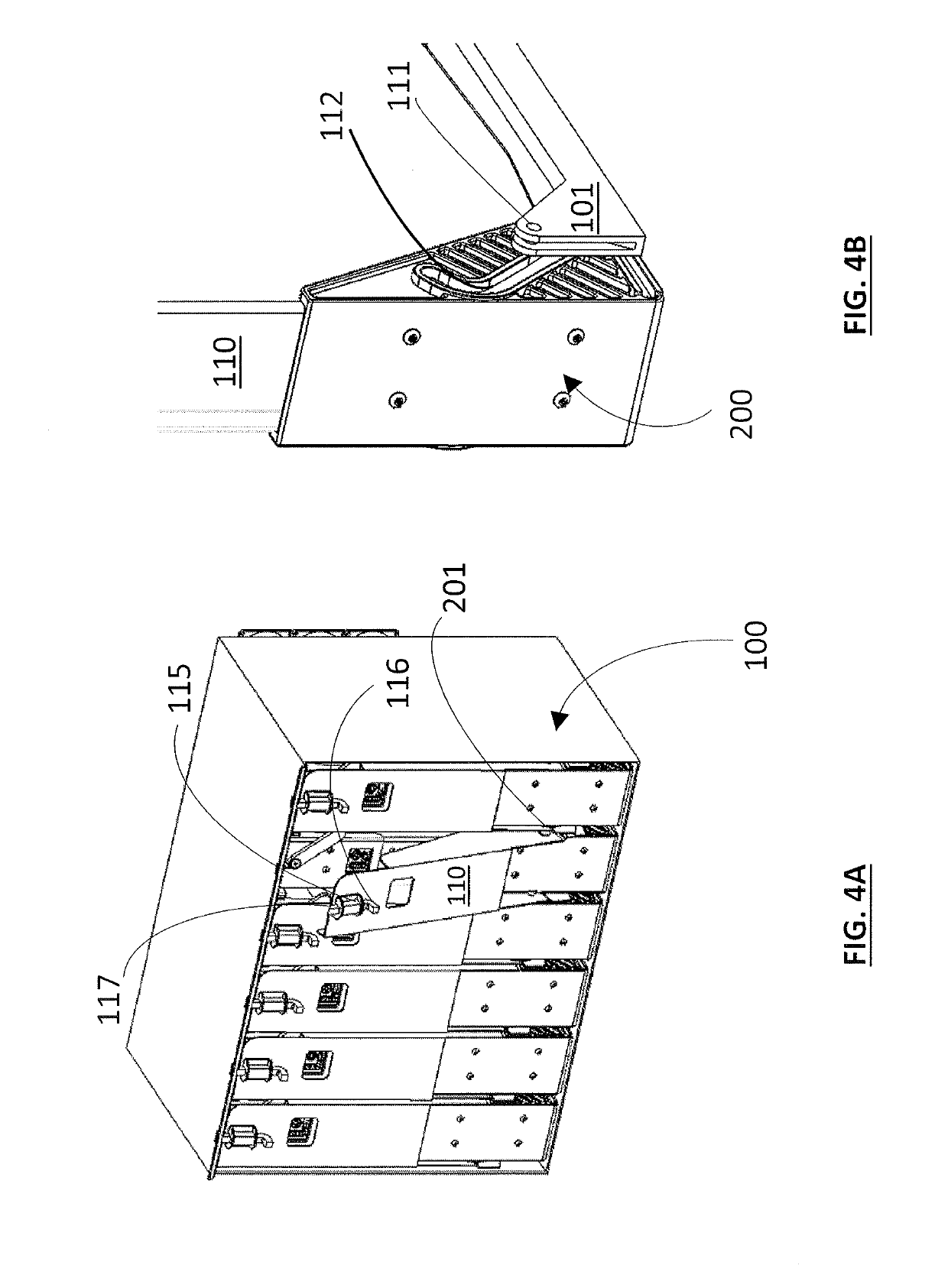

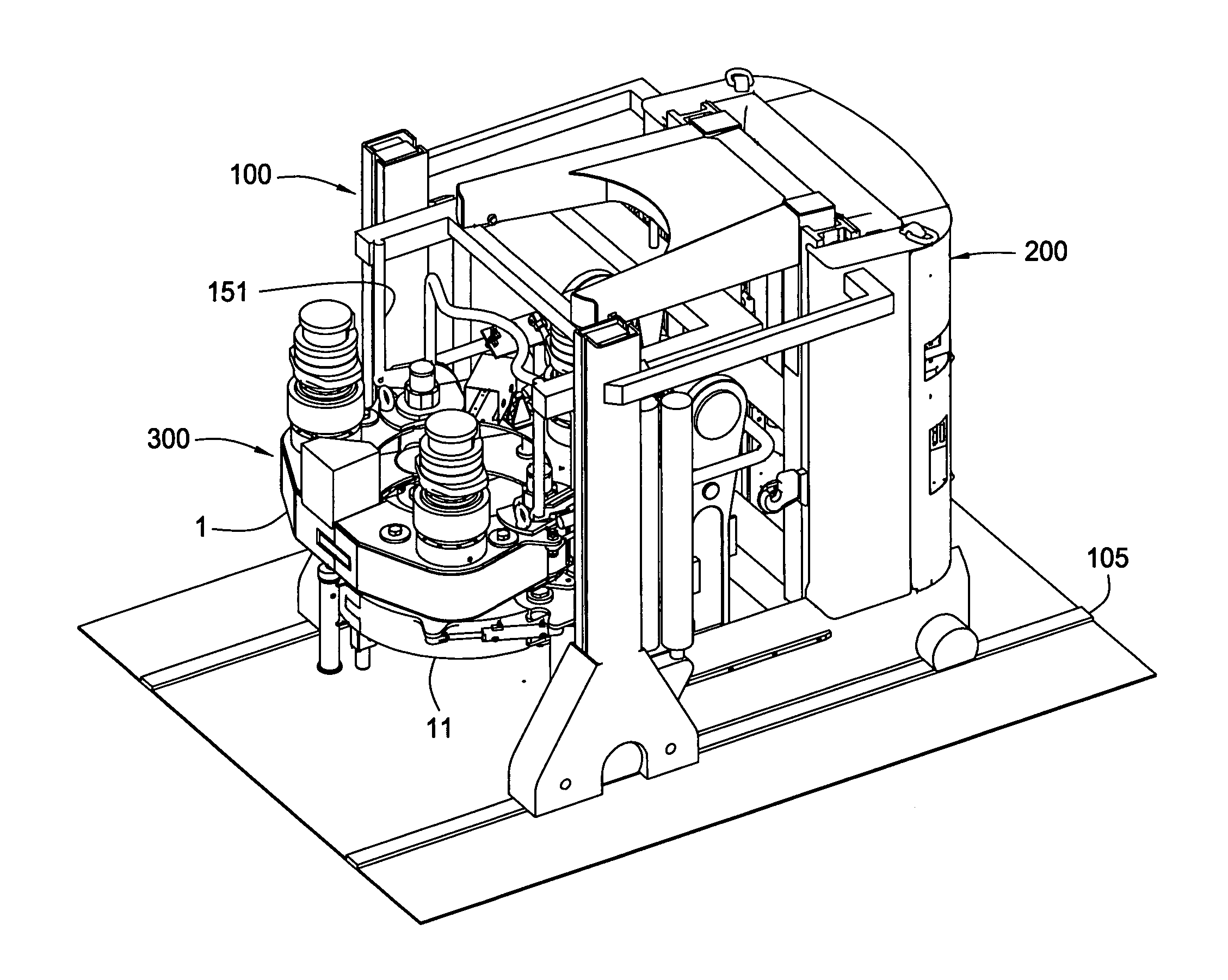

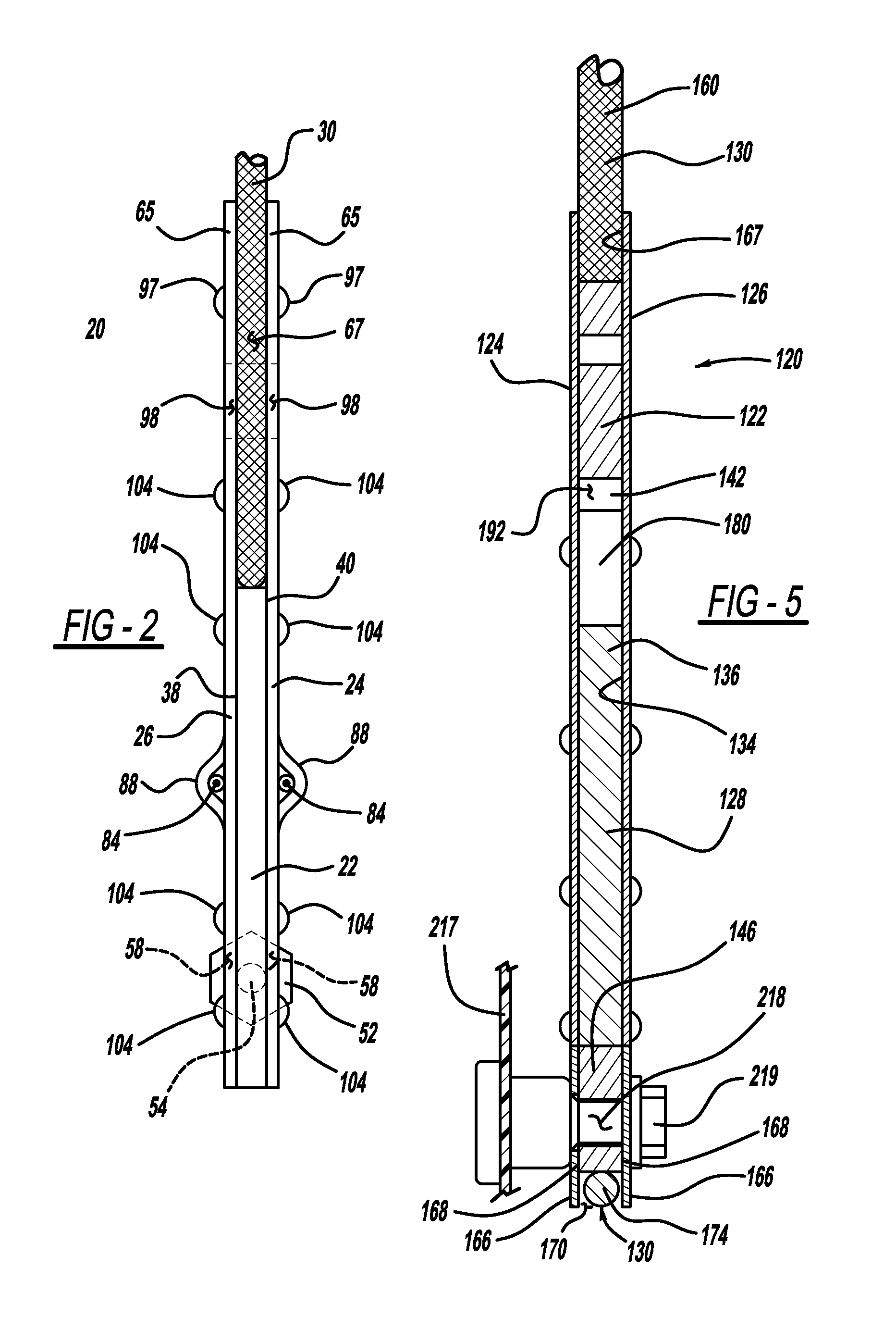

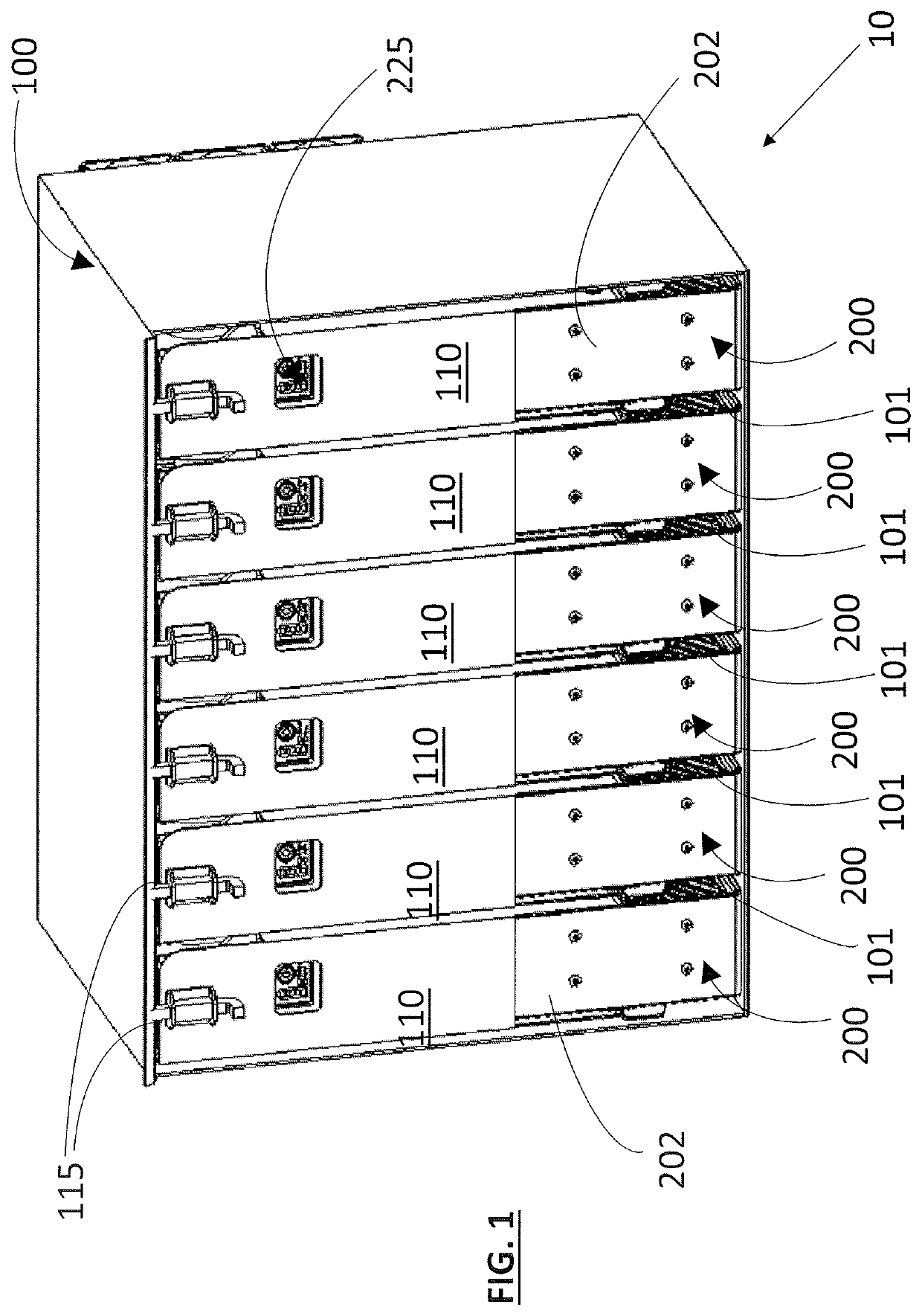

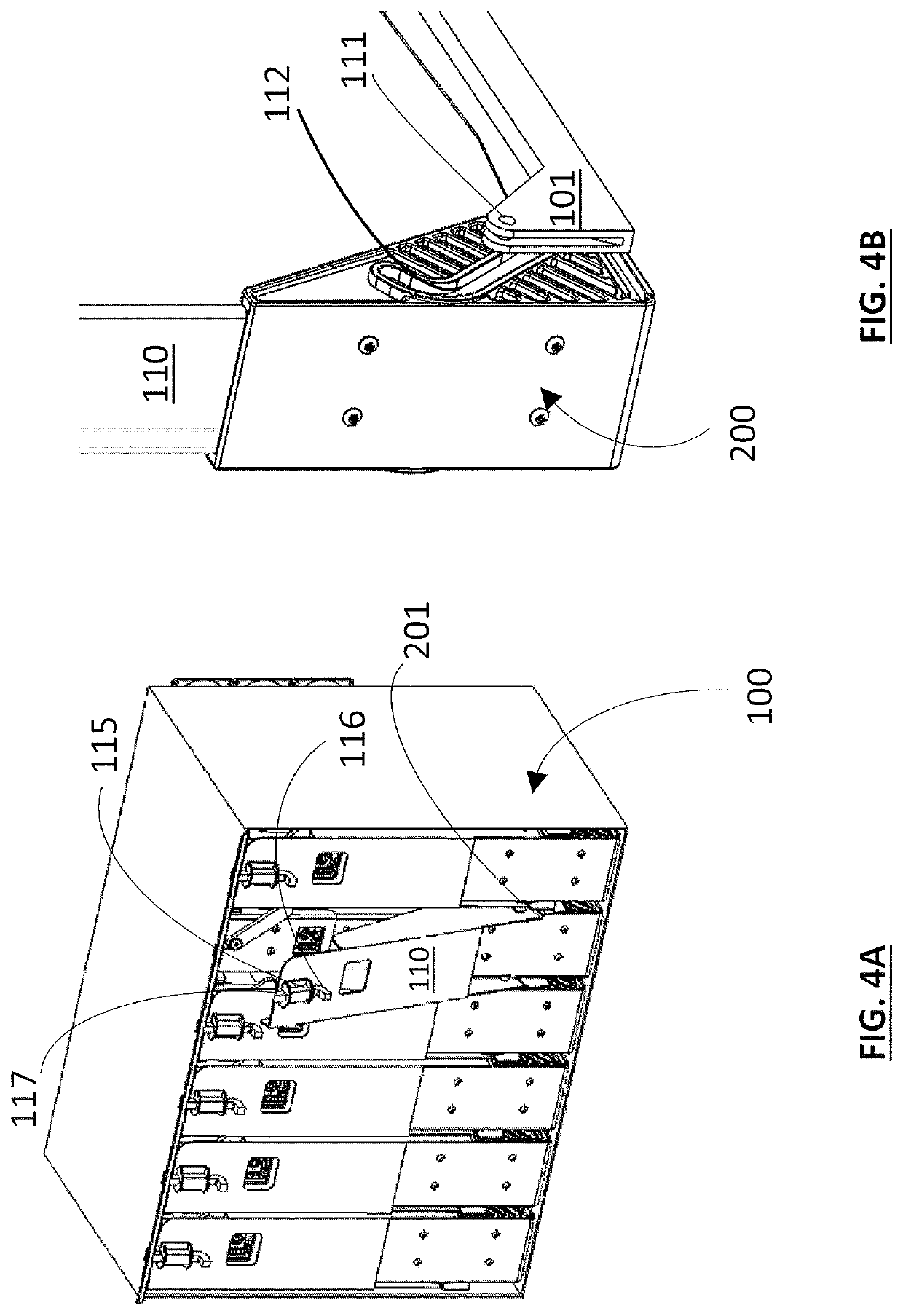

Modular lithium-ion battery system for fork lifts

ActiveUS20190103639A1Improve safe and reliable operationEasy to disassembleIndicating/monitoring circuitsCell electrodesElectrical ProblemData connection

Many embodiments involve rechargeable battery assemblies that are forklift-battery-sized but that comprise multiple removable battery modules. The removable battery modules are individually rechargeable and are interchangeable with each other. A housing contains six battery modules installed vertically on the front side of the assembly, with their electrical and data connections occurring within the housing on the rear side. Assemblies will be two sided so that the system has two racks with six modules per rack. The handles of each module are collapsible and on the top edges of the overall assembly so that they are readily accessible during removal. Each battery module has an integrated battery supervisor system (BSS). A Battery Operating System Supervisor (BOSS) module processor serves as a battery management system for the all the battery modules. The BOSS module grants permissions to battery modules to enable them to connect and disconnect from busbars at the appropriate times to prevent electrical issues.

Owner:ETHIUM LLC

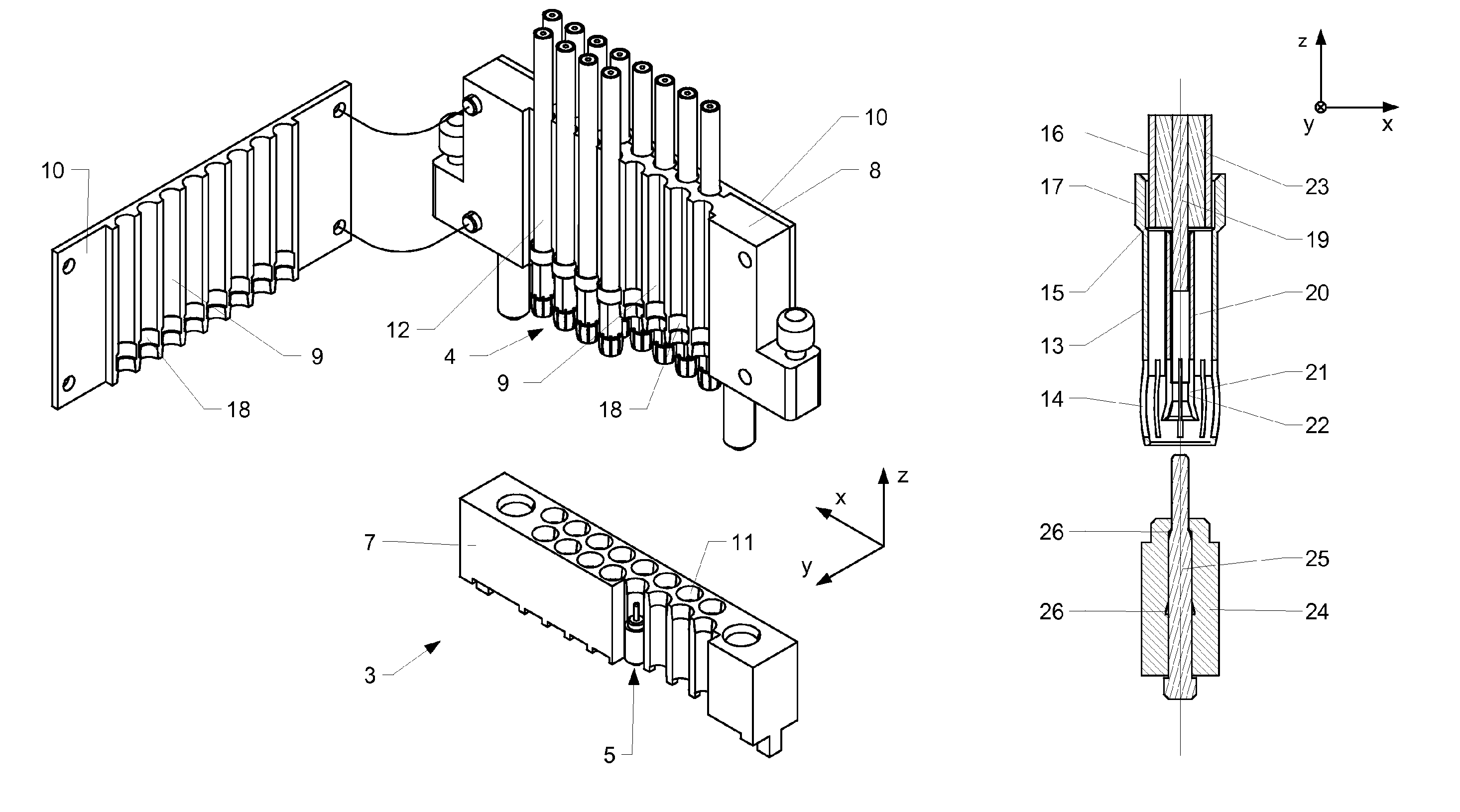

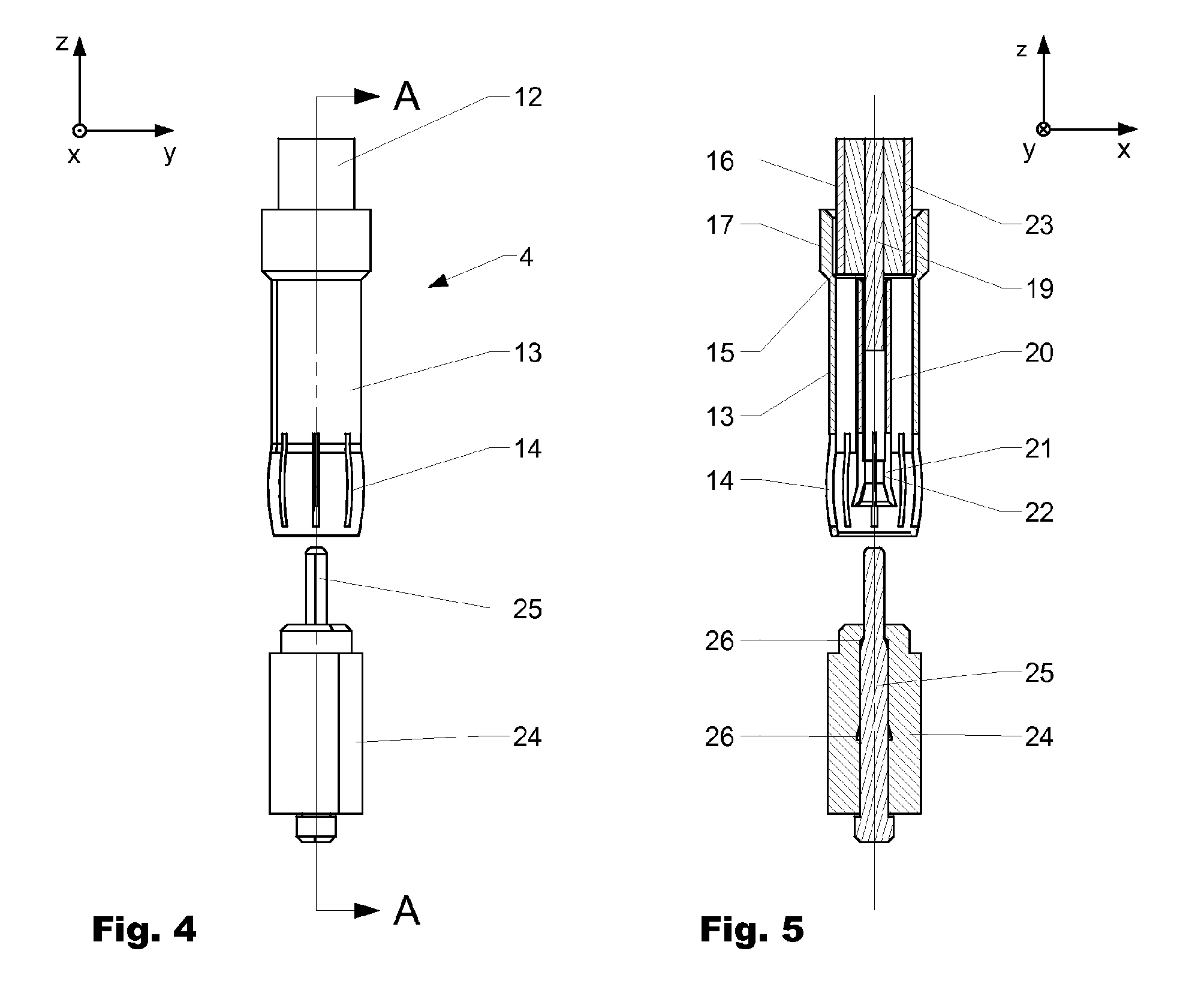

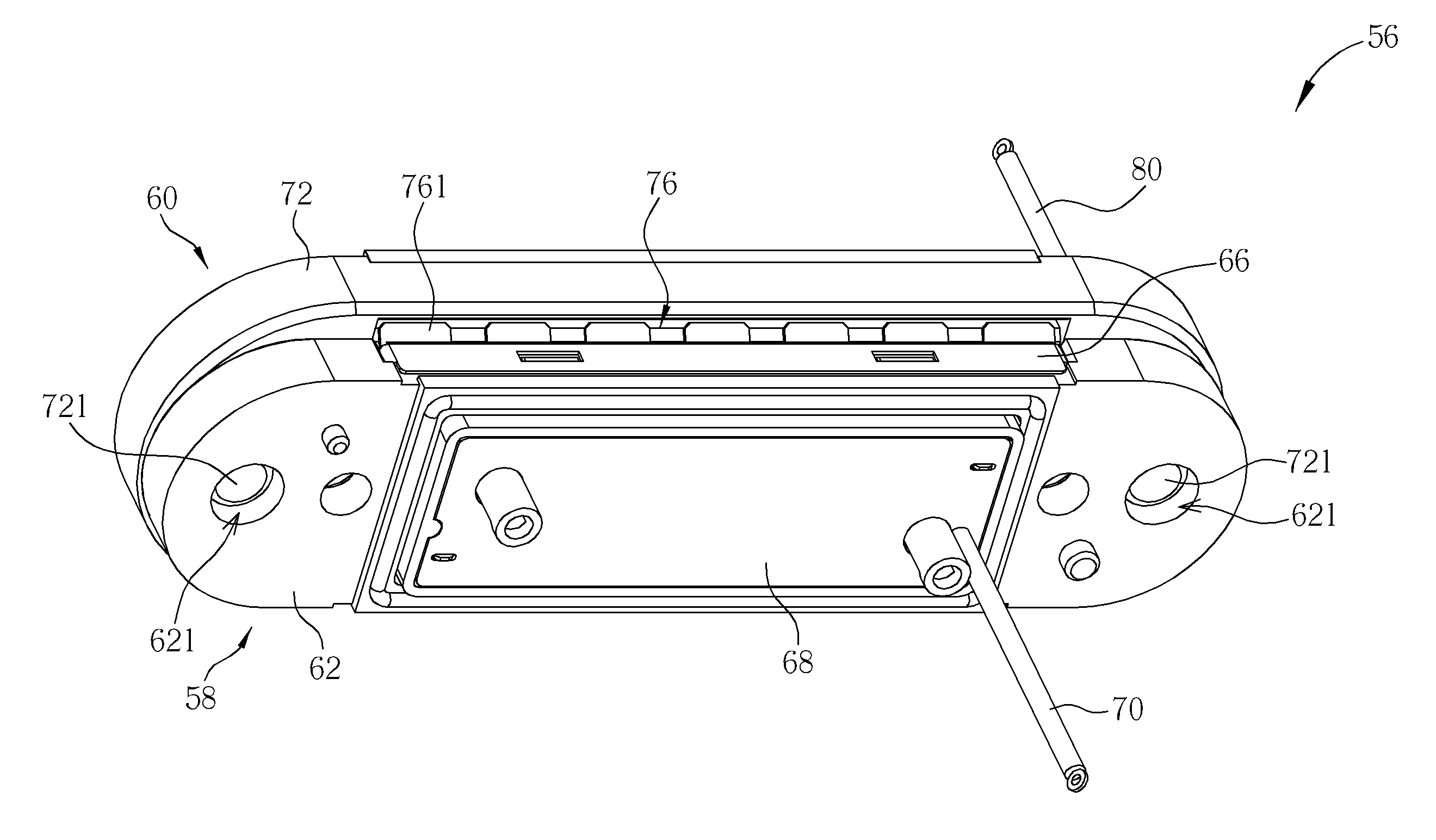

Connector banks arranged in parallel and floating manner

ActiveUS8360805B2Quality improvementThe implementation process is simpleElectrically conductive connectionsTwo pole connectionsEngineeringMechanical engineering

The present disclosure relates to a multiple coaxial connector (30) having a female connector part and a cable-side male connector part (31,33). The male connector part (31) comprises at least one single-row or double-row connector bank (2) having a housing (6), which has a base body (8) having openings (9) accessible from one or two sides, which are used for receiving individual connectors (4,5).

Owner:HUBERSUHNER AG

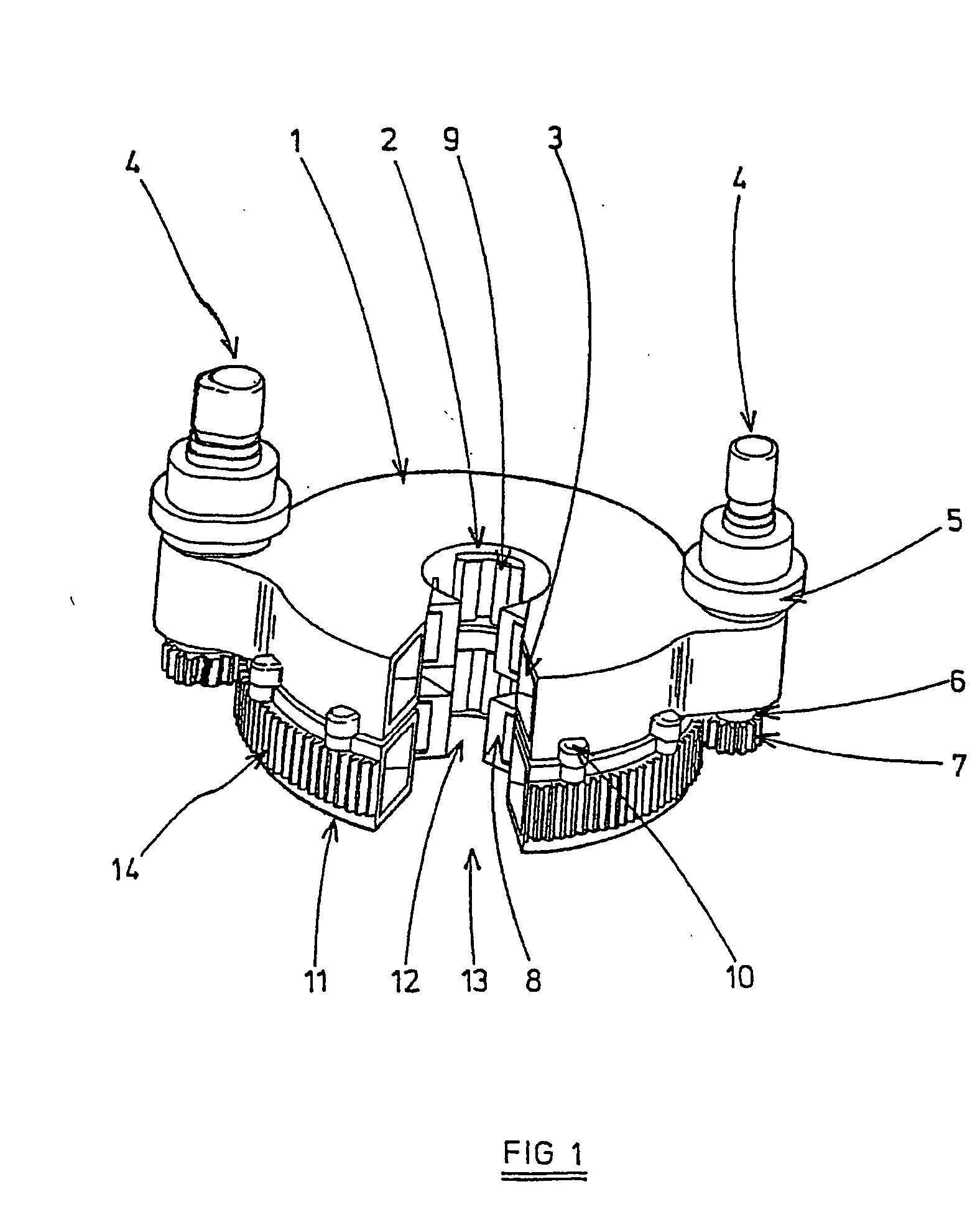

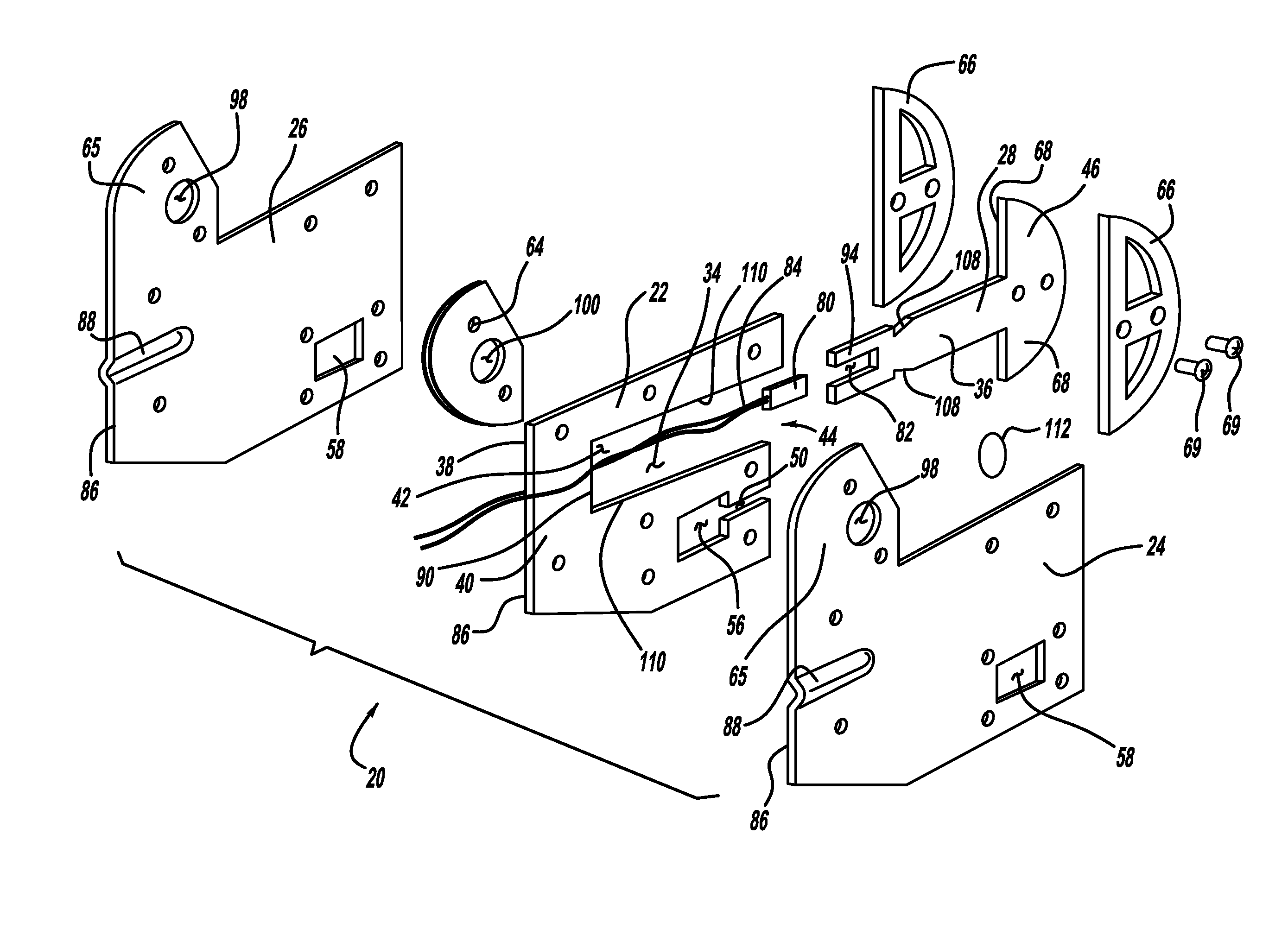

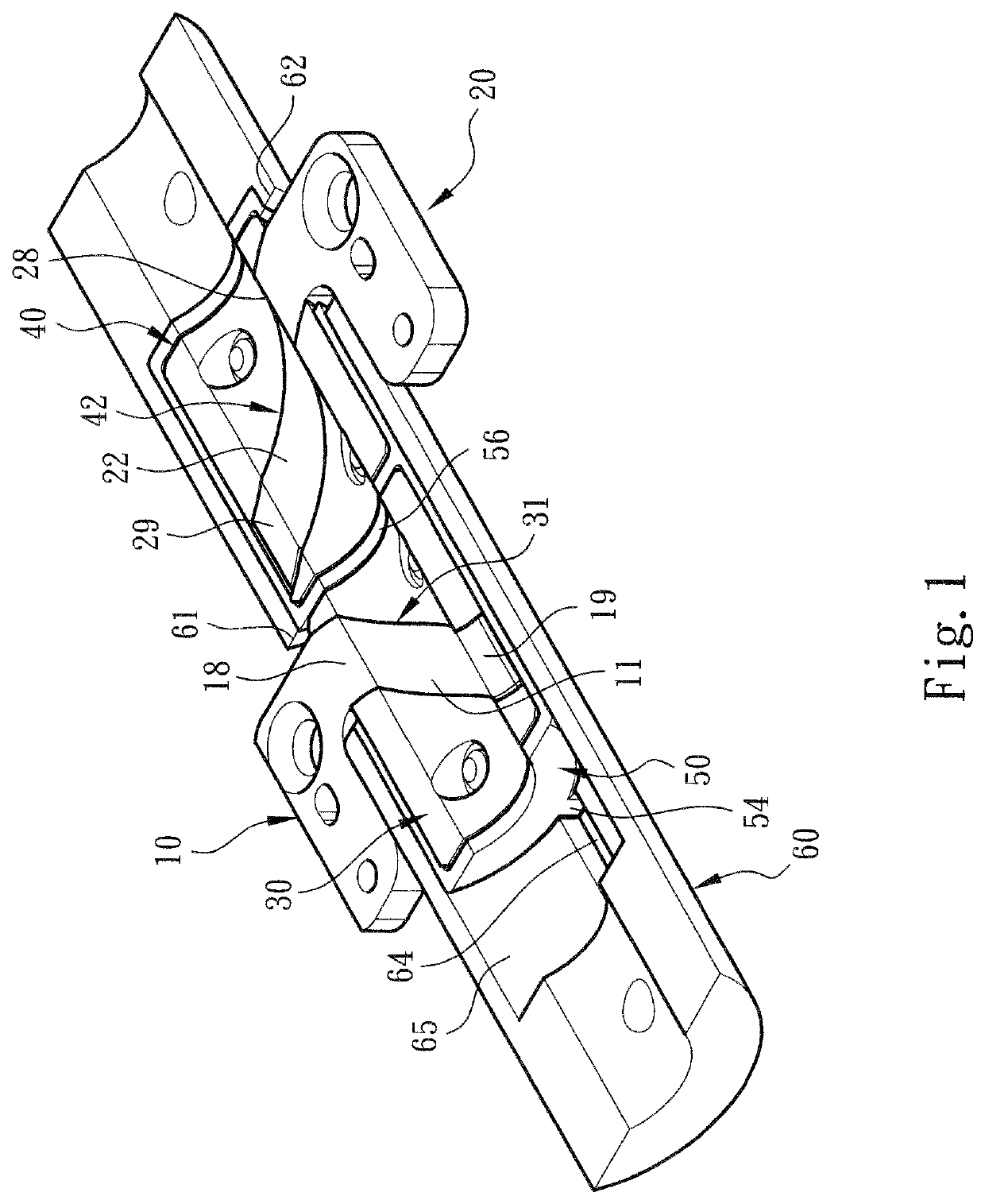

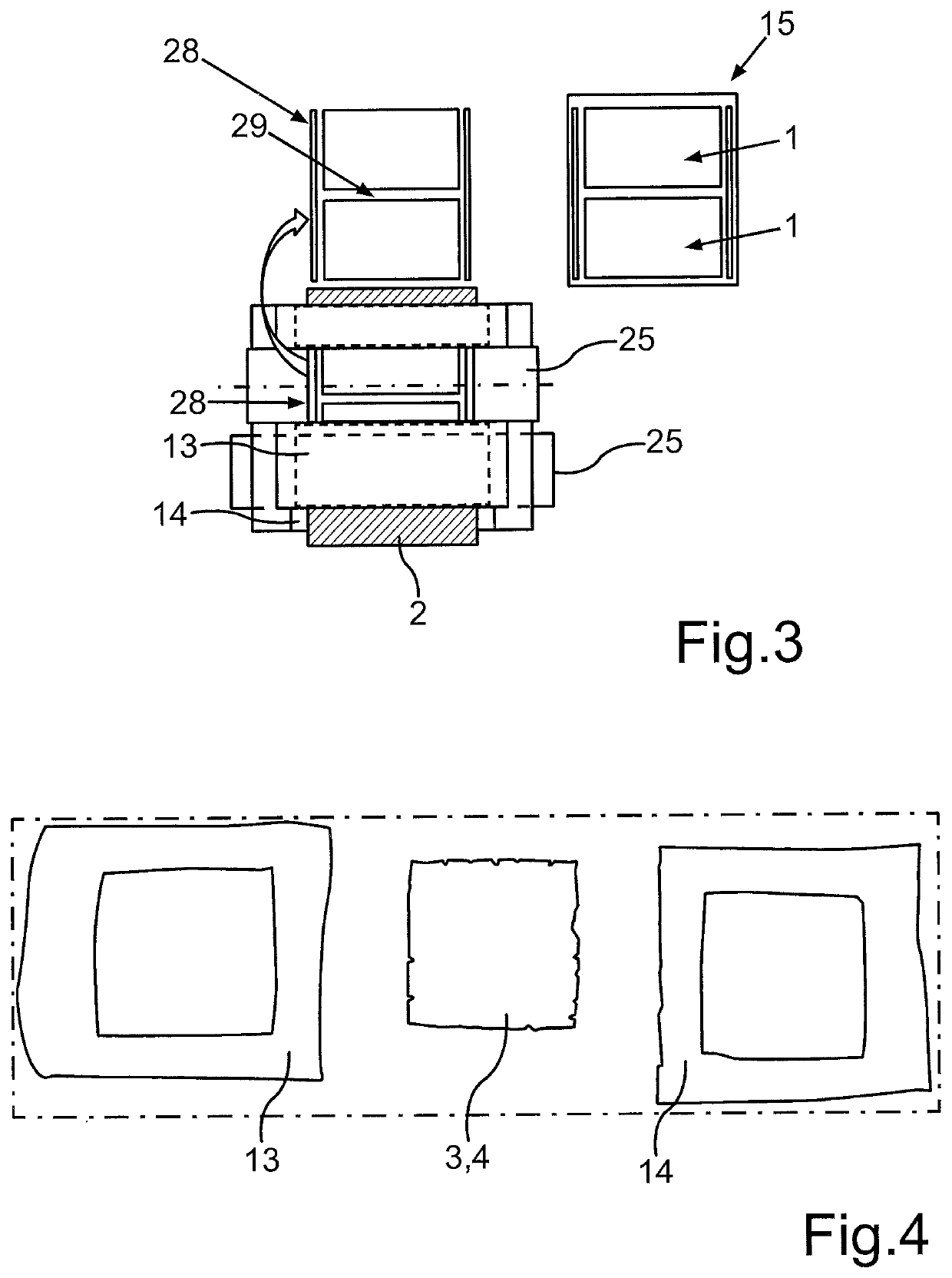

Adapter frame for a power frame

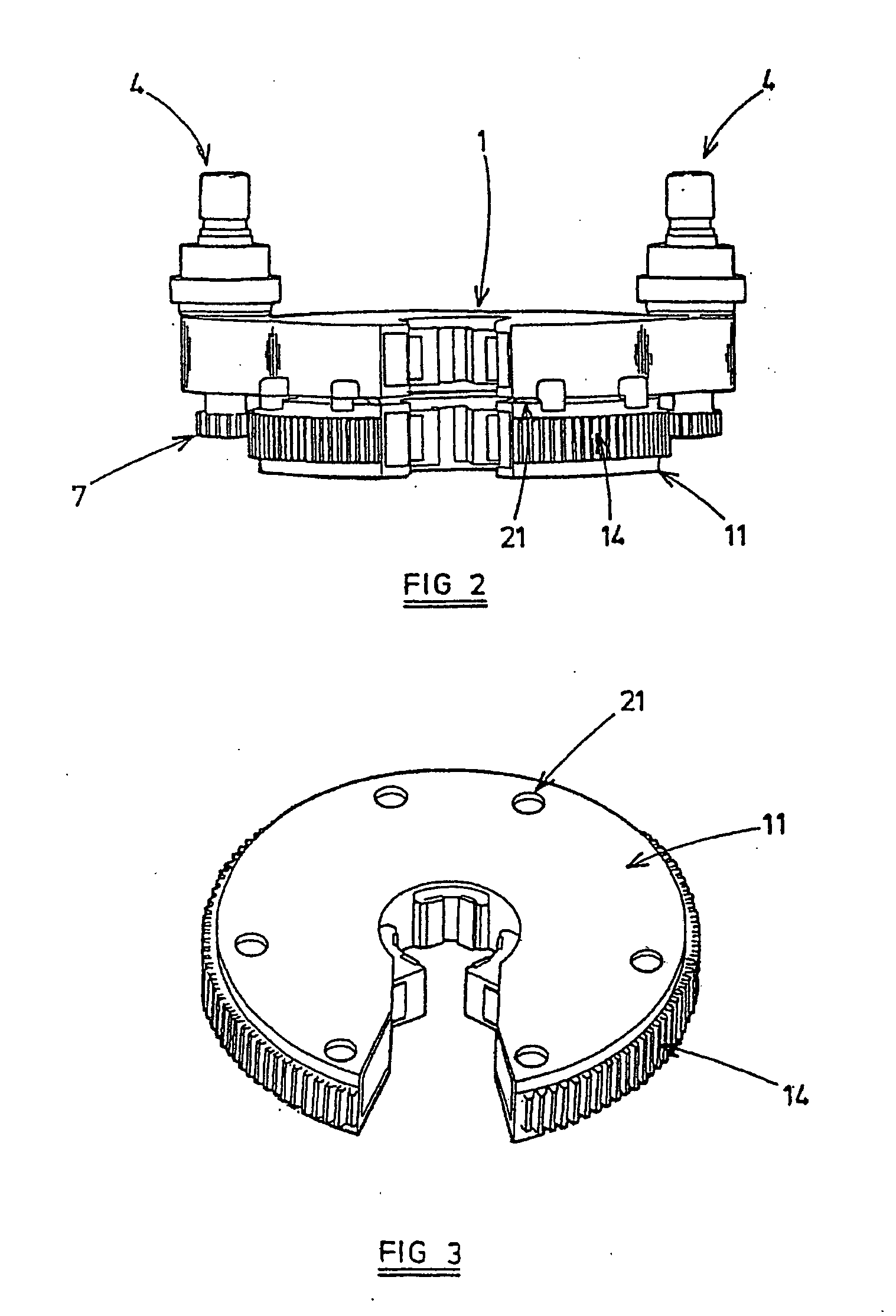

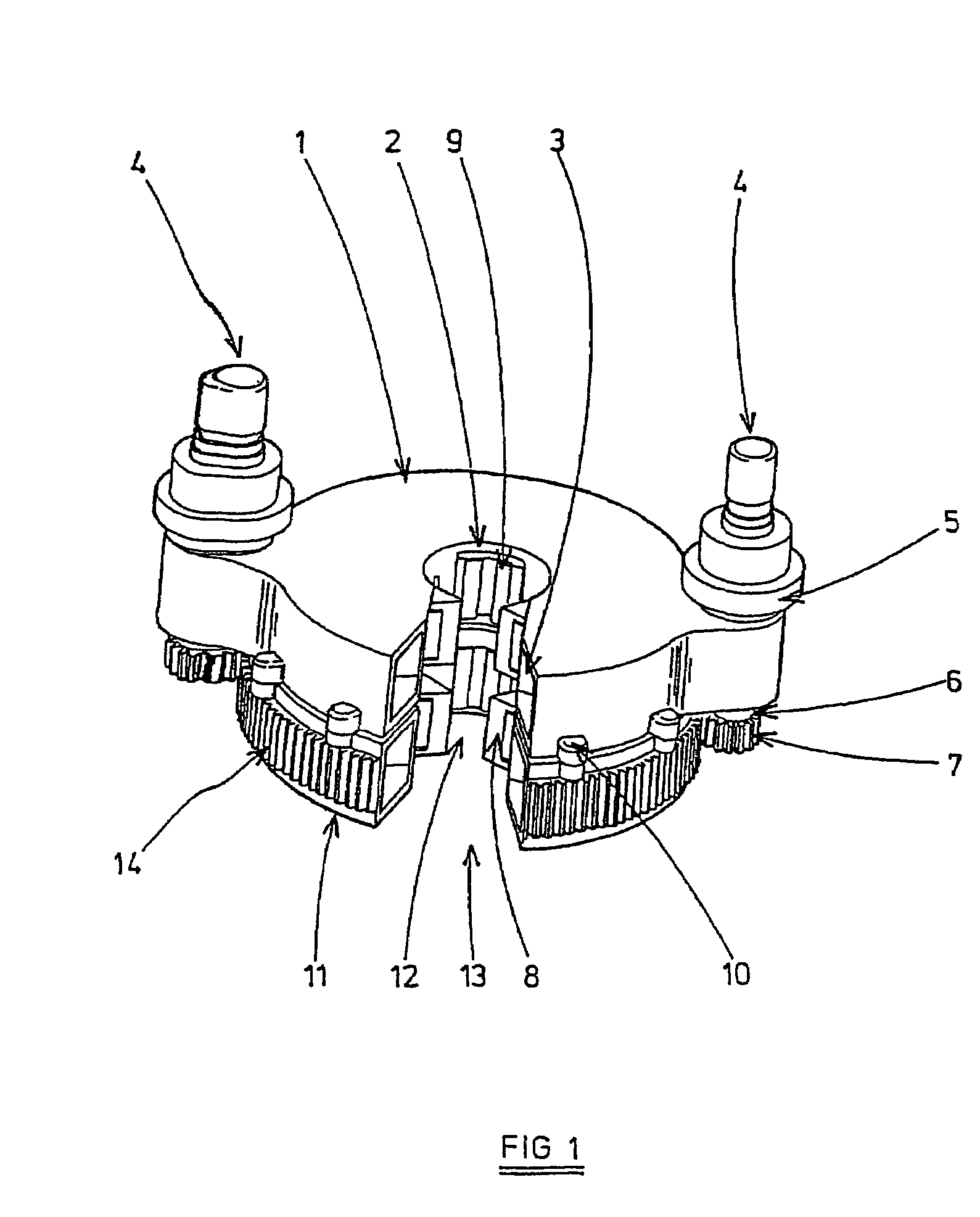

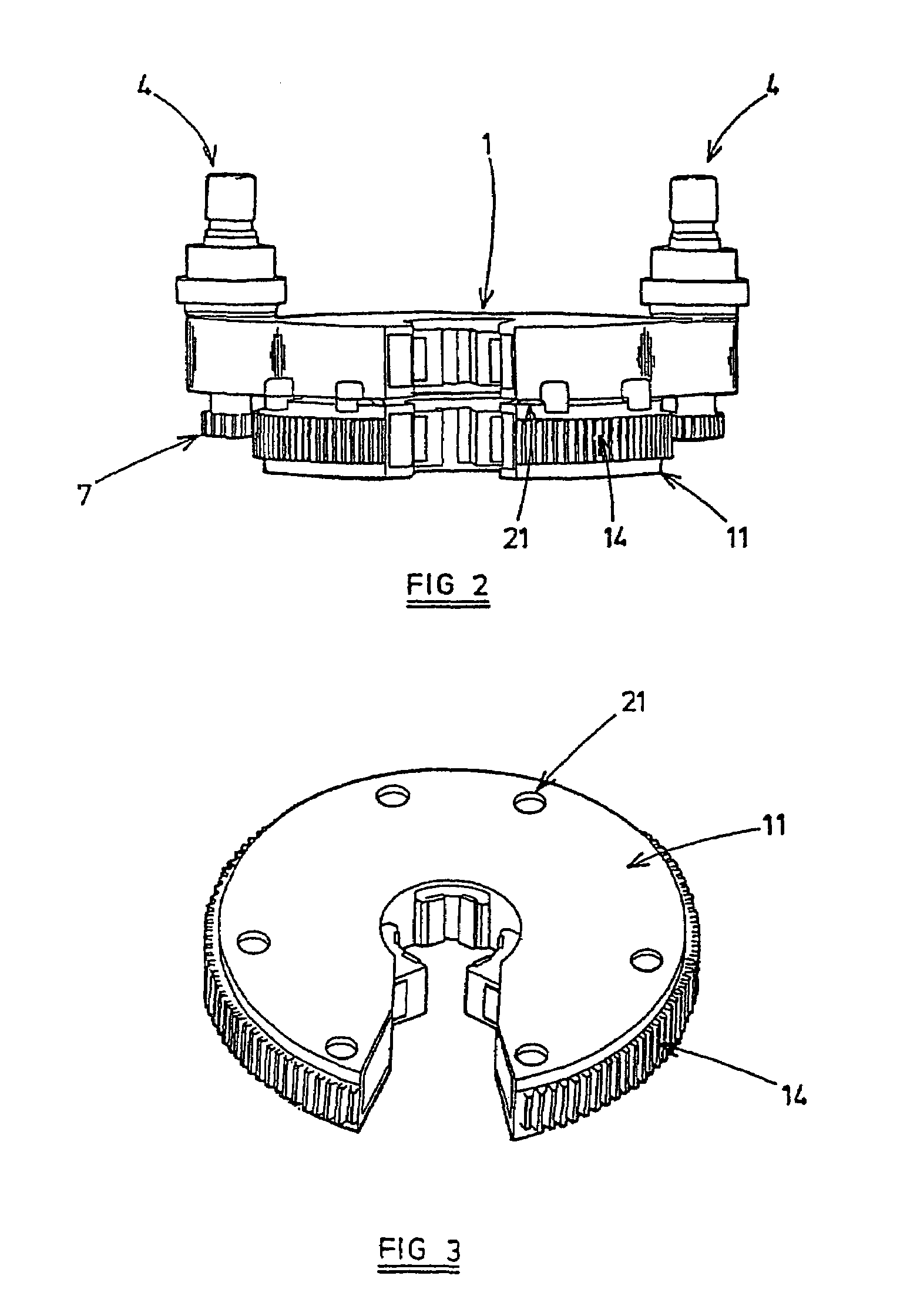

ActiveUS20050061112A1Increase load capacityBulky assemblyDrilling rodsSpannersLoad capacityElectrical and Electronics engineering

In one embodiment, an adapter frame is provided for use with a power frame to support a tong assembly. When the adapter frame is coupled to the power frame, the load capacity of the power frame is increased, thereby allowing the power frame to be used with larger tongs or tong assemblies such as a riser tong.

Owner:WEATHERFORD TECH HLDG LLC

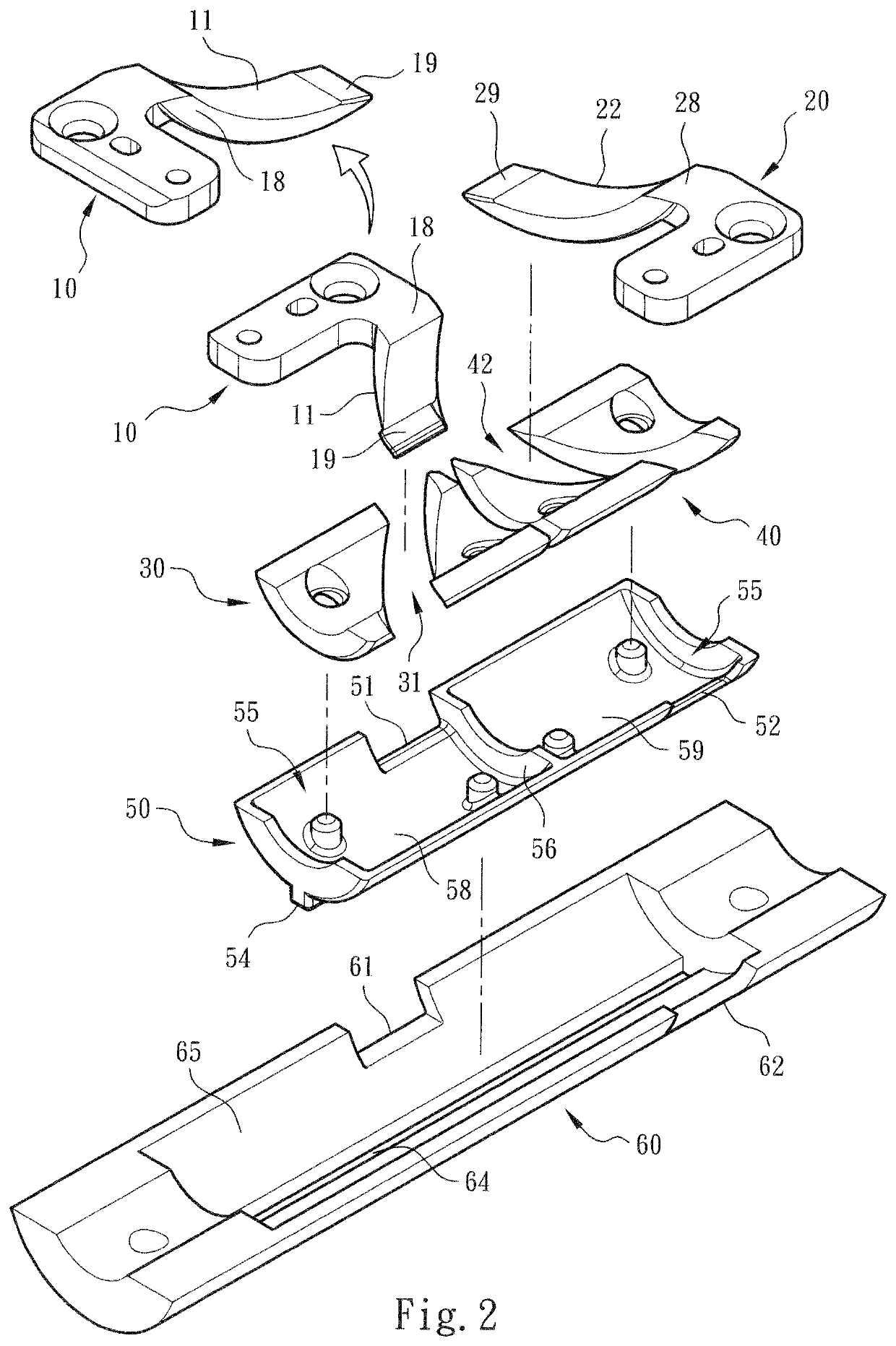

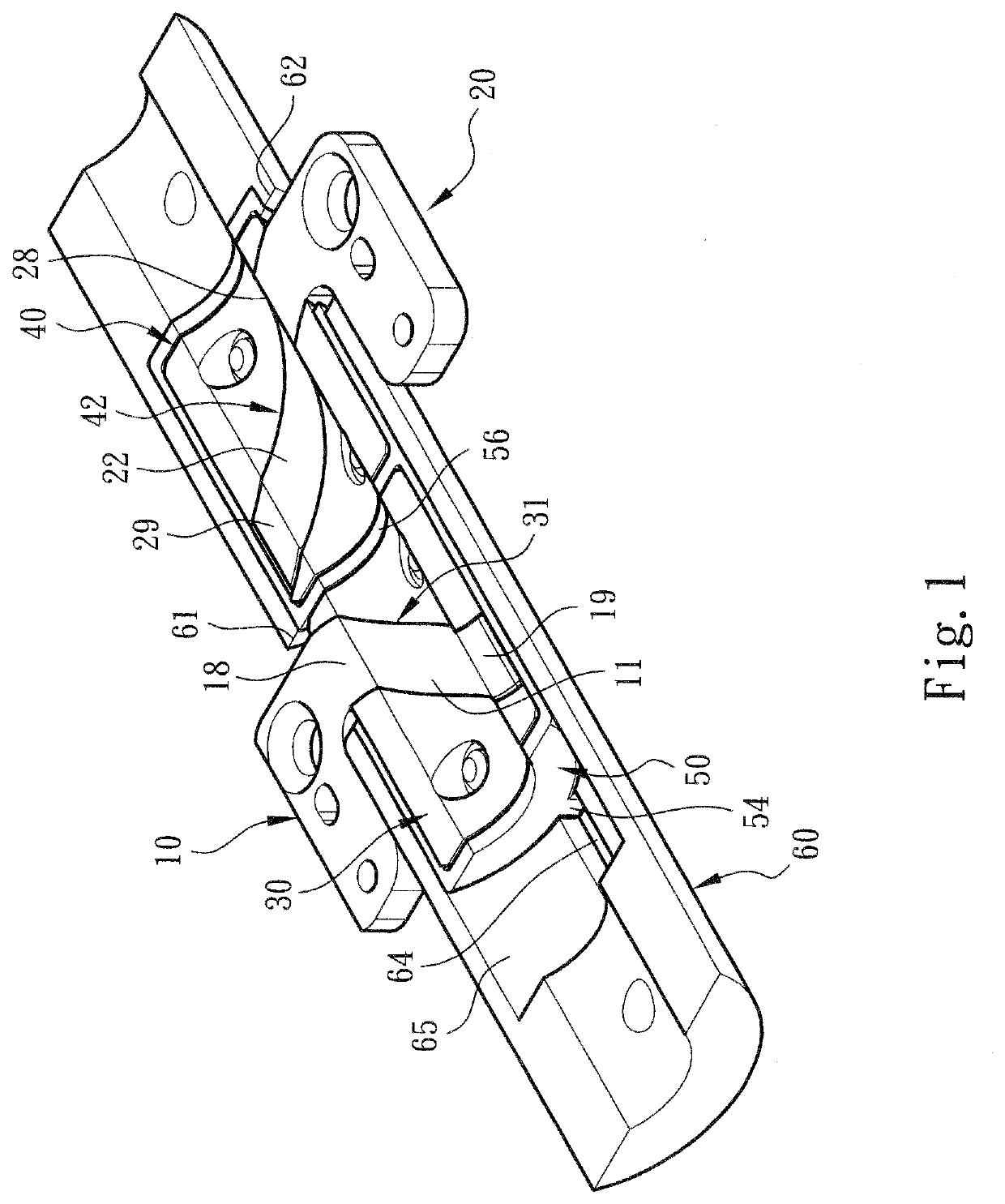

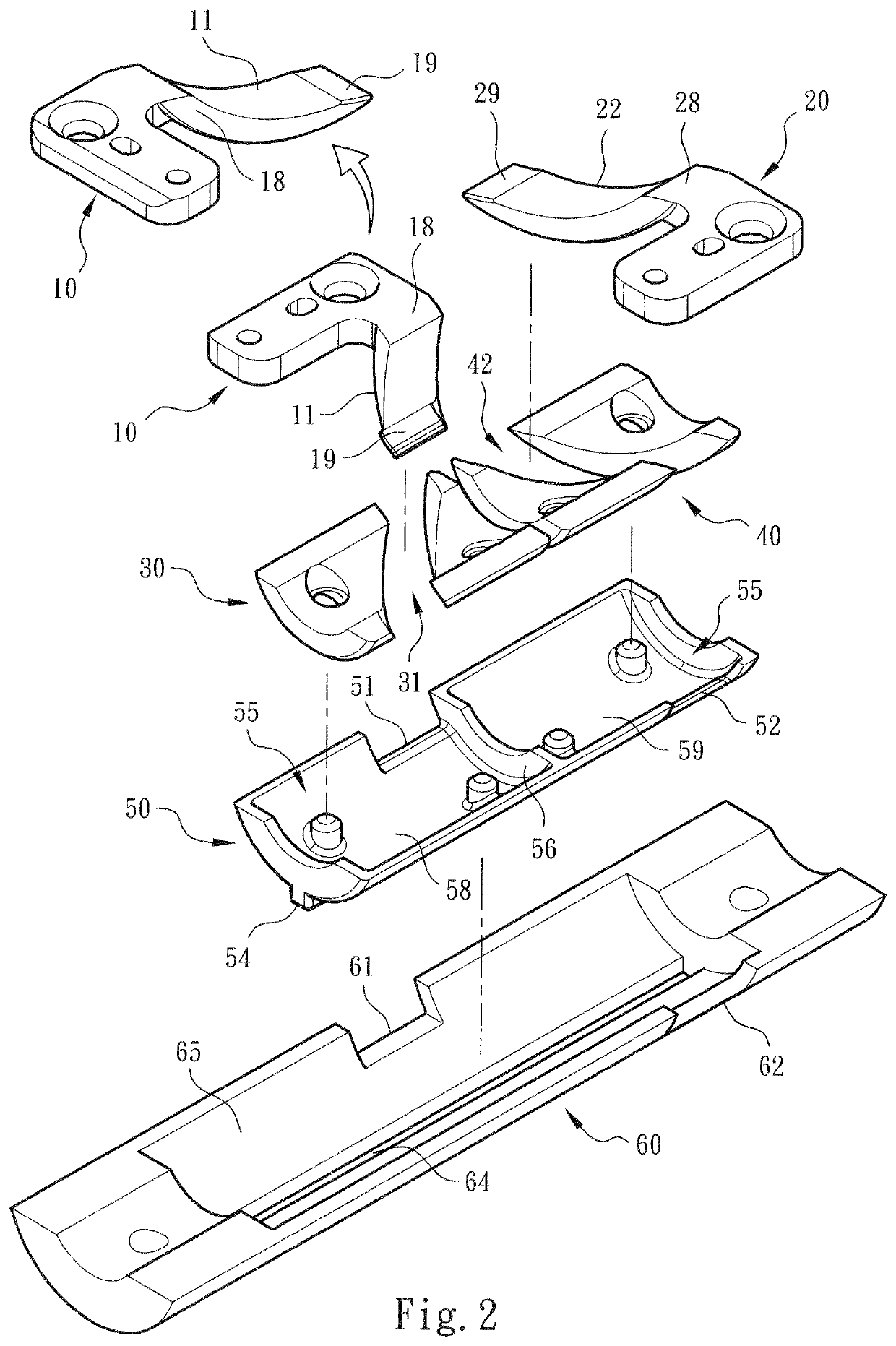

Adapter frame for a power frame

ActiveUS7188548B2Increase load capacityBulky assemblyPolishing machinesDrilling rodsEngineeringLoad capacity

In one embodiment, an adapter frame is provided for use with a power frame to support a tong assembly. When the adapter frame is coupled to the power frame, the load capacity of the power frame is increased, thereby allowing the power frame to be used with larger tongs or tong assemblies such as a riser tong.

Owner:WEATHERFORD TECH HLDG LLC

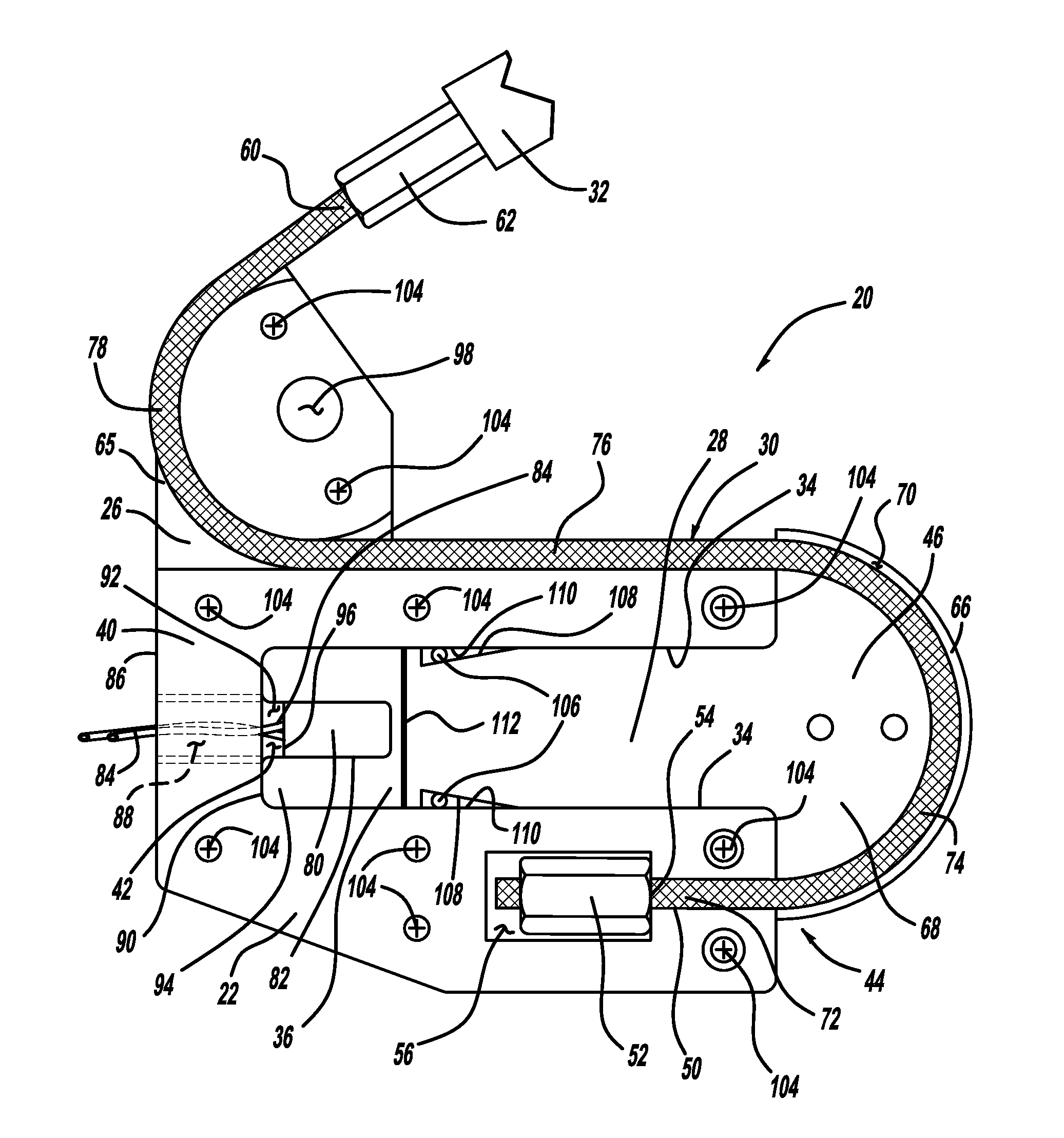

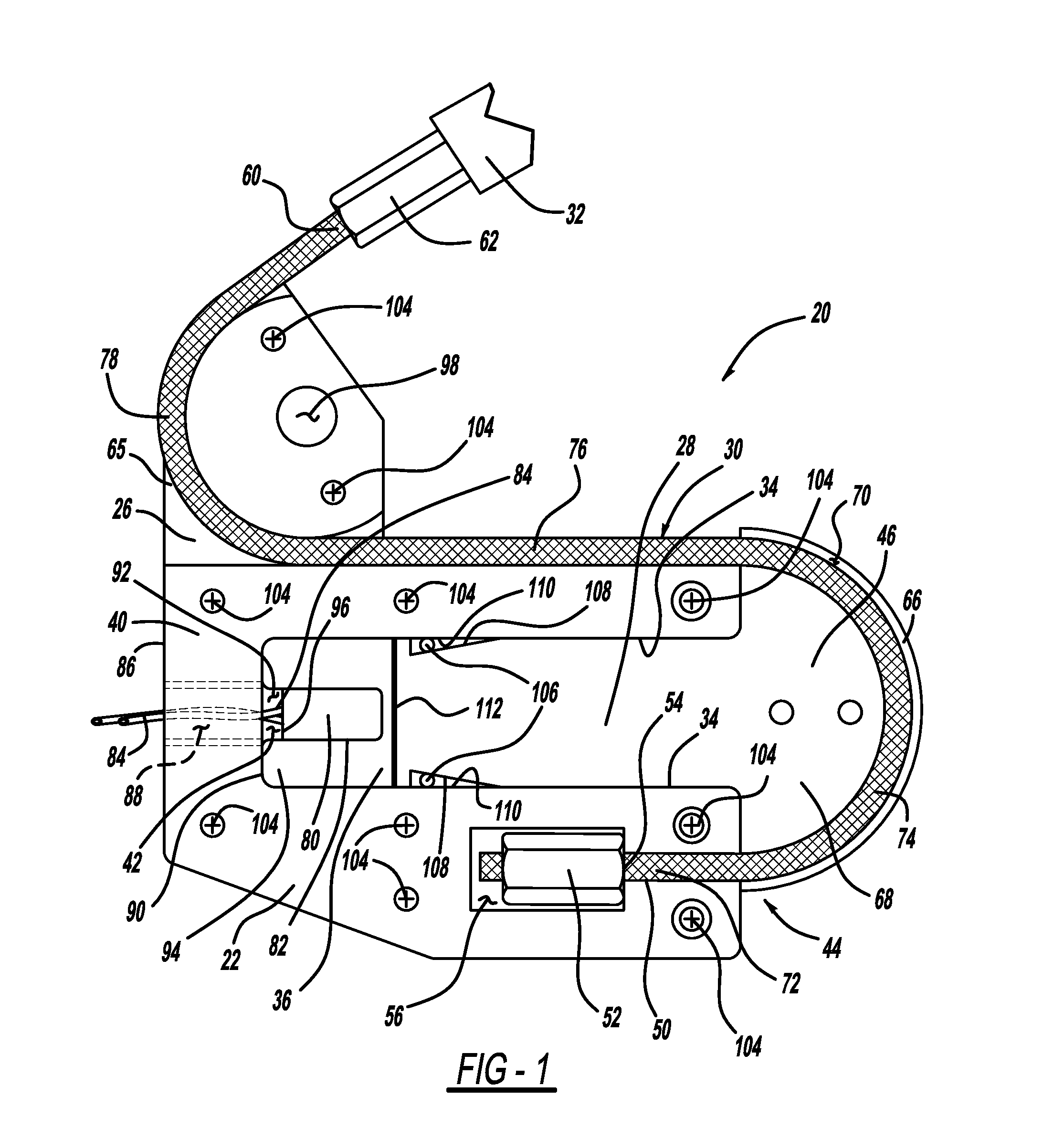

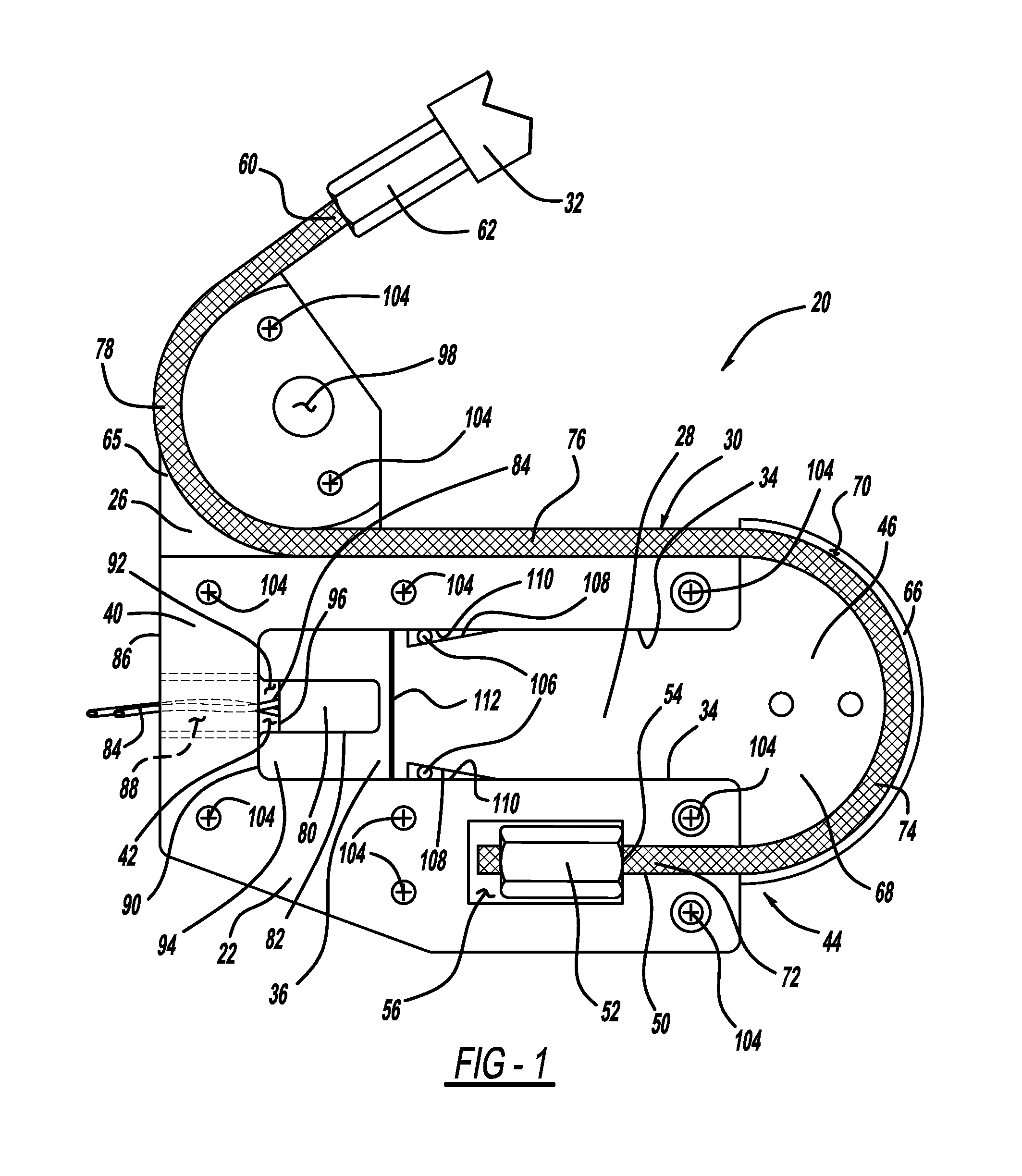

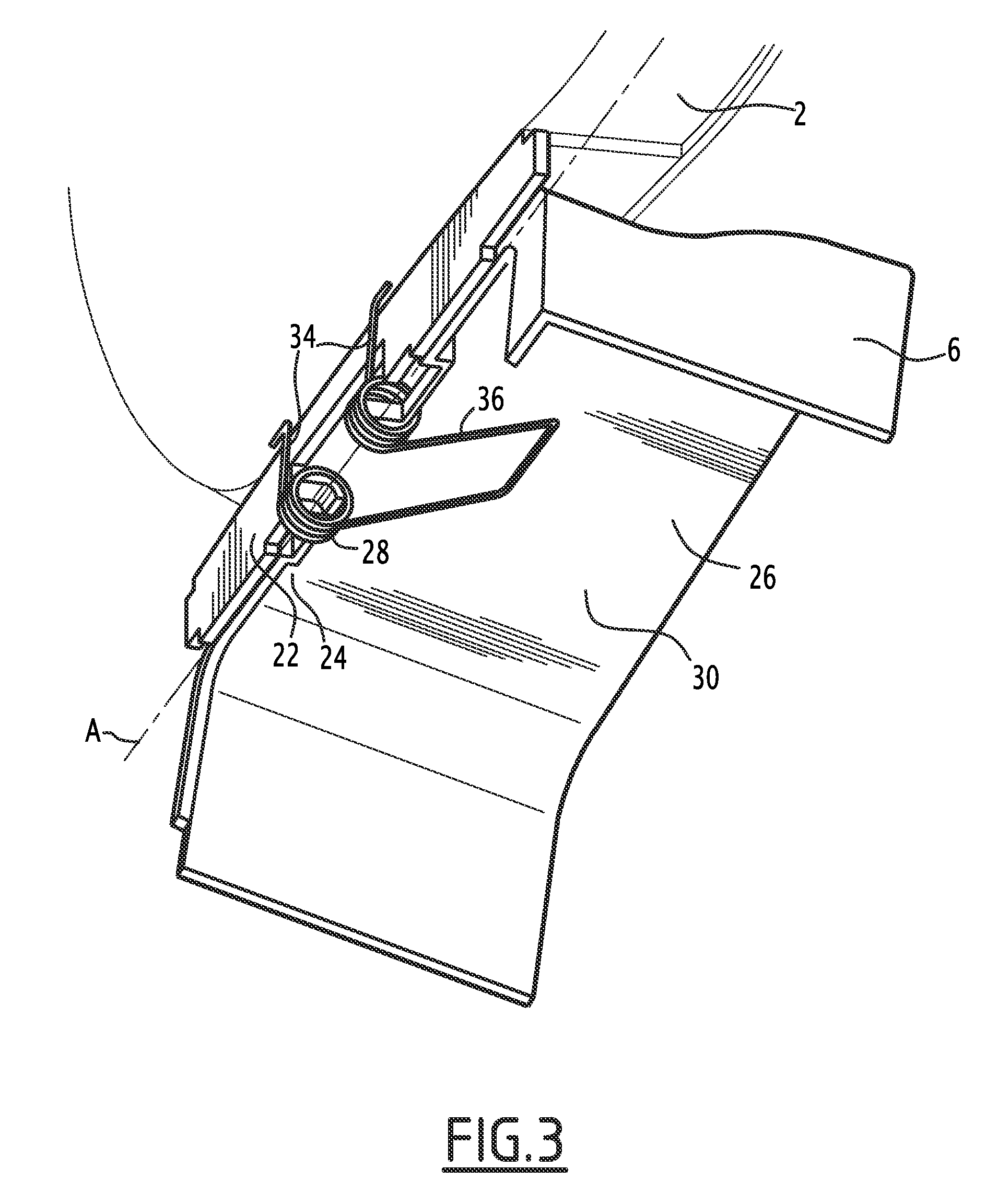

Thin Linear Seatbelt Pretensioner

ActiveUS20120119478A1Reduce leakage pathShorten travel distanceSafety beltsBelt retractorsEngineeringGas generator

A linear pretensioner for use as part of a motor vehicle occupant belt restraint system mountable to vehicle structure and coupled with a belt restraint system component. The pretensioner includes at least one base plate having a slot and at least one closure plate fixedly attached to the base plate. The closure plate(s) and the slot of the base plate(s) form a cavity having an open end. A piston plate has a piston tail slidably disposed within the cavity and a piston head extending from the open end. A cable is coupled with the piston plate, the base plate(s), and / or the closure plate(s). The piston plate, the slot of the base plate(s), and the closure plate(s) cooperate to form an expanding chamber that enlarges when pressurized by a gas generator, which drives the piston plate and the base plate relative to each other to exert tension on the cable.

Owner:AUTOLIV ASP INC

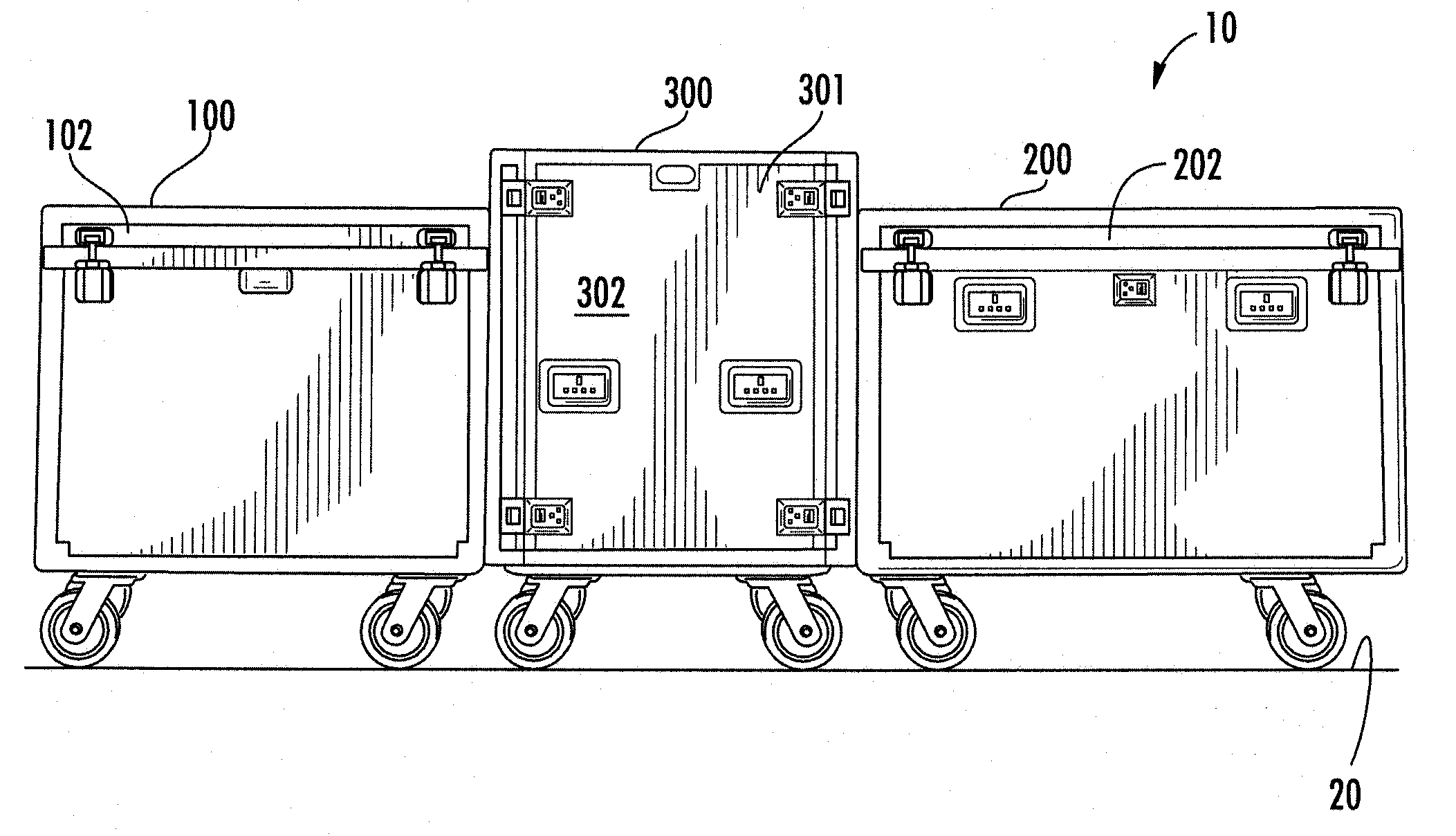

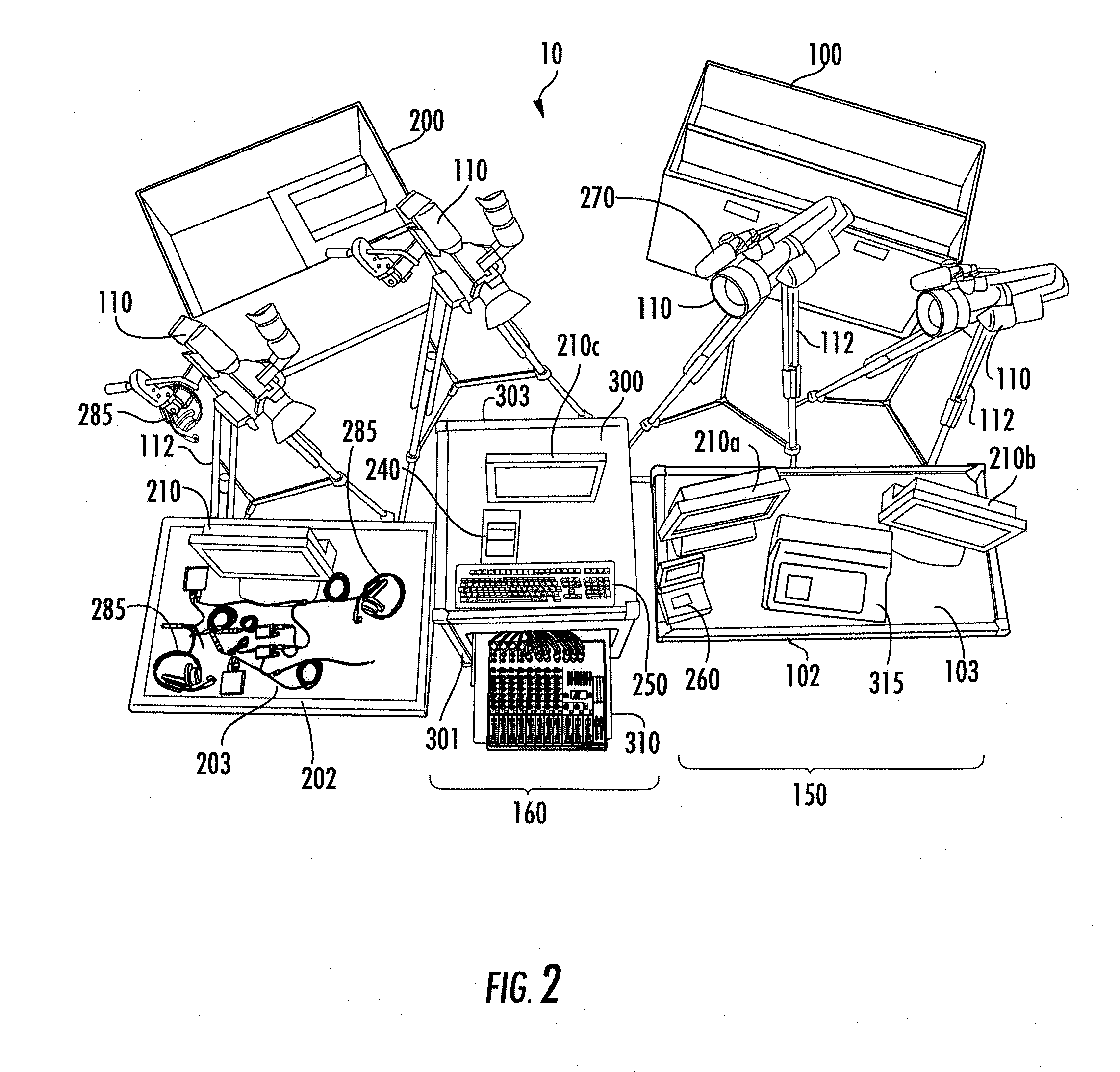

Event production kit

According to various embodiments, an event production kit is provided that includes storage cases for storing production equipment, such as cameras, monitors, and microphones, and an electronic production equipment case for storing an audio mixer, a video switcher, and computers for encoding and distributing the production. In addition, in one embodiment, the electronic production equipment case includes a vertical panel that includes a plurality of ports that are pre-wired to the audio mixer, video switcher, and the computers for coupling the production equipment together. The storage cases and the pre-wired panel facilitate transporting the kit to the event location and reduce the amount of time and resources required for setting up the equipment prior to the event, according to various embodiments. In addition, the selection of the type of equipment included in the kit, according to one embodiment, provides for a high quality, lower cost production than is currently available.

Owner:2080 MEDIA

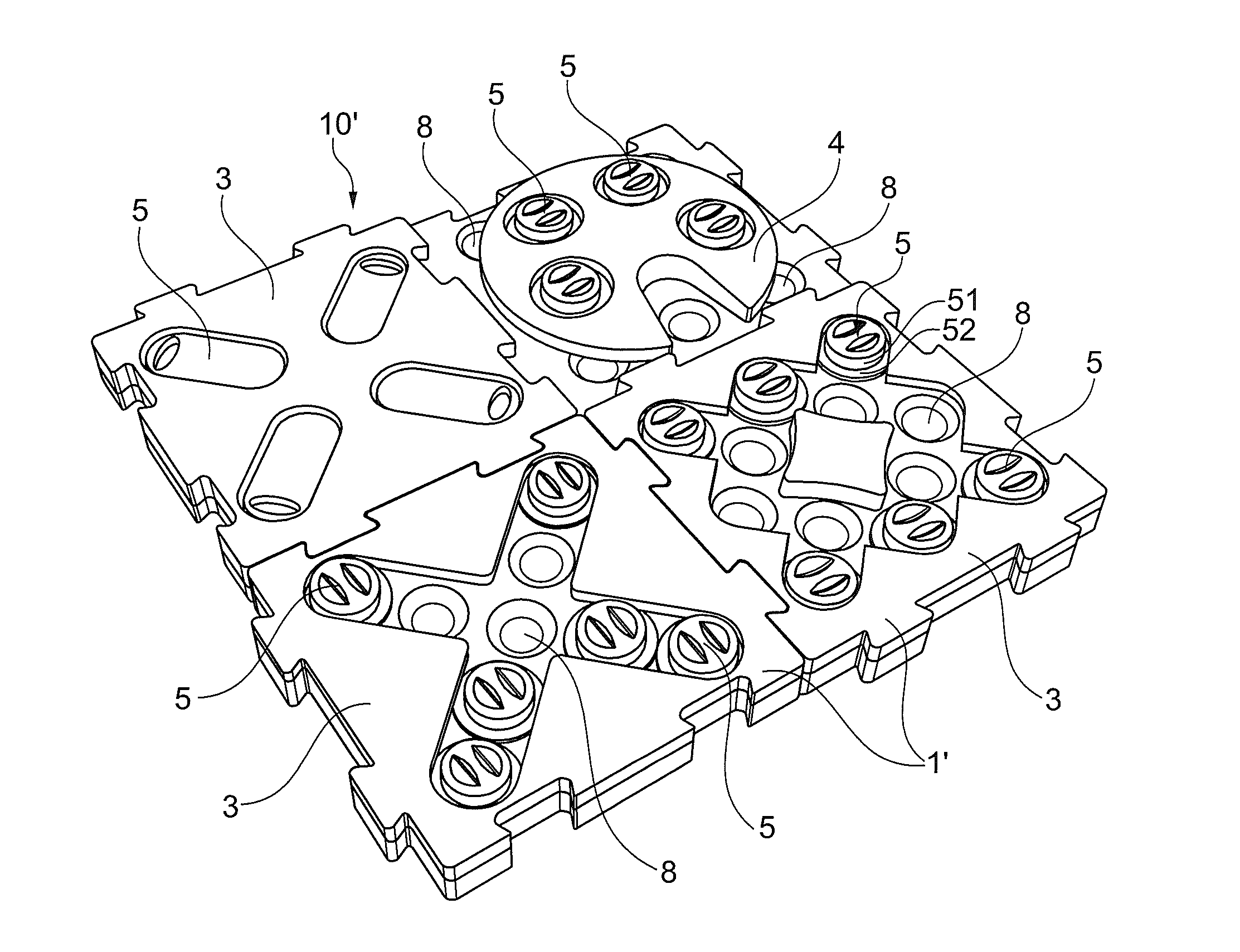

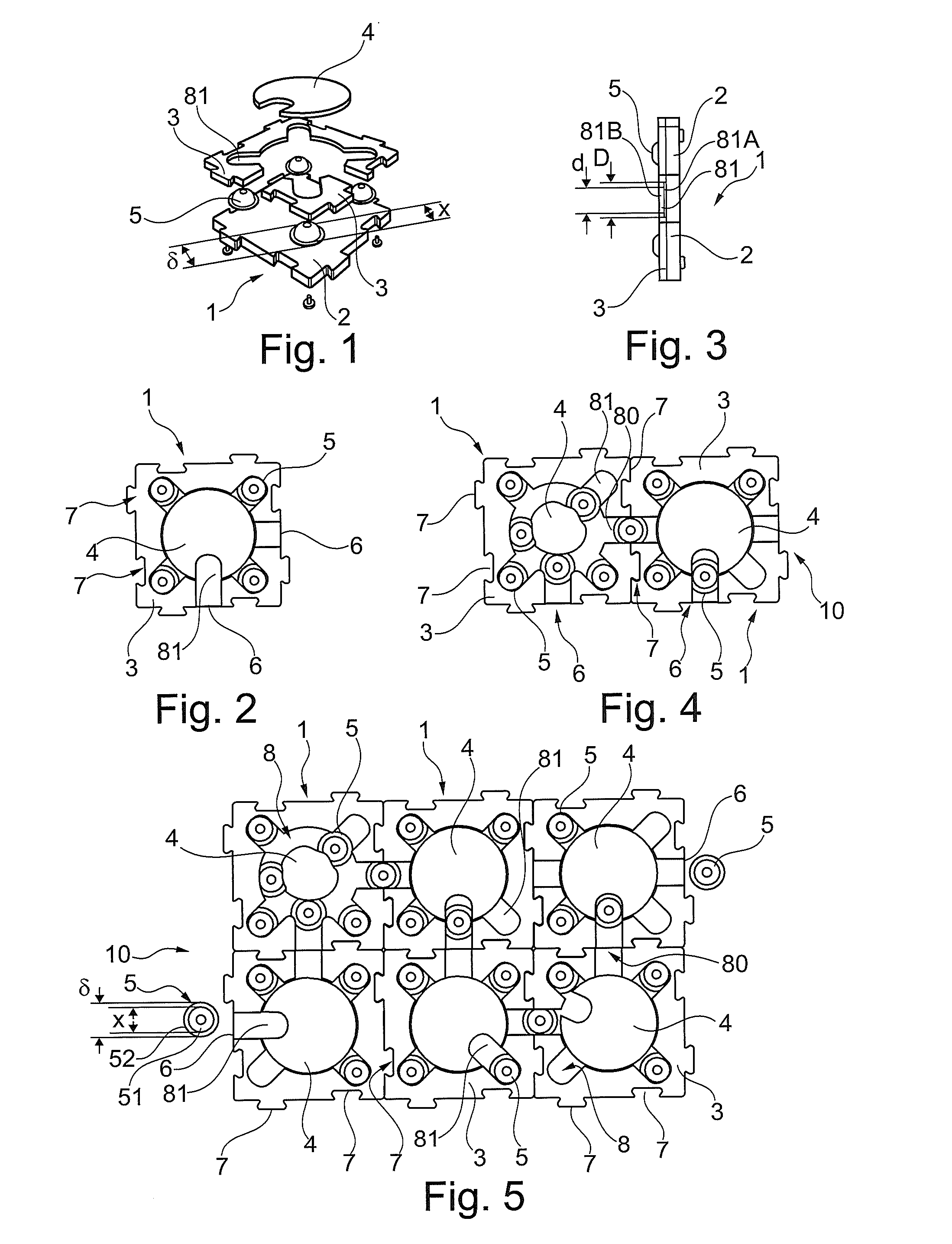

Motivational toy for a pet

InactiveUS20150296746A1Eliminates and at least minimizes disadvantageBulky assemblyOther apparatusTaming and training devicesEngineeringCompanion animal

The present invention relates to a motivational toy assembly for a pet, comprising a toy having a base with at least one treat area, and said toy further comprising at least one treat cover for covering a pet treat placed in said treat area, and wherein said base having at least one interacting portion for connecting said base to another toy.

Owner:THE KYJEN CO LLC

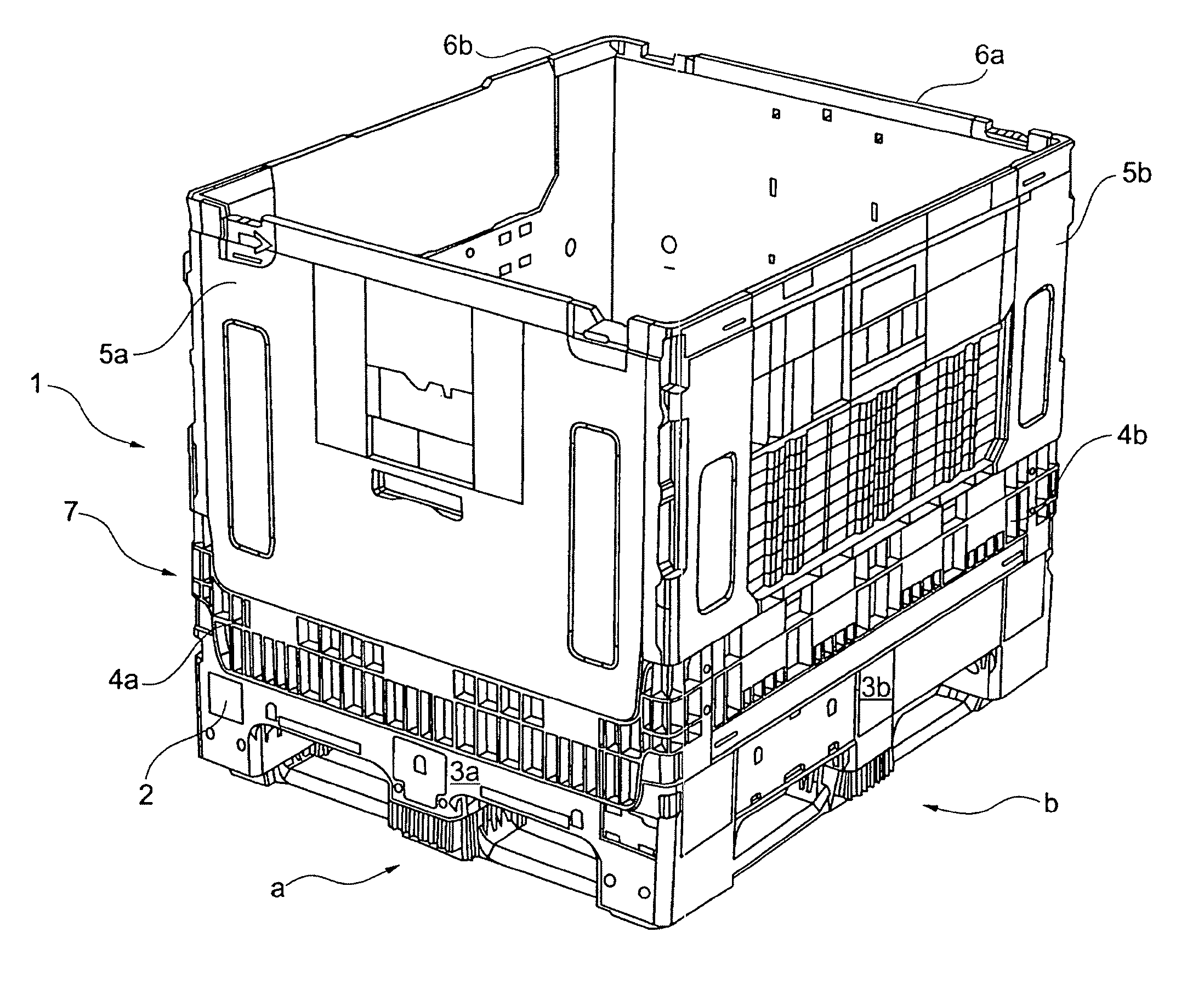

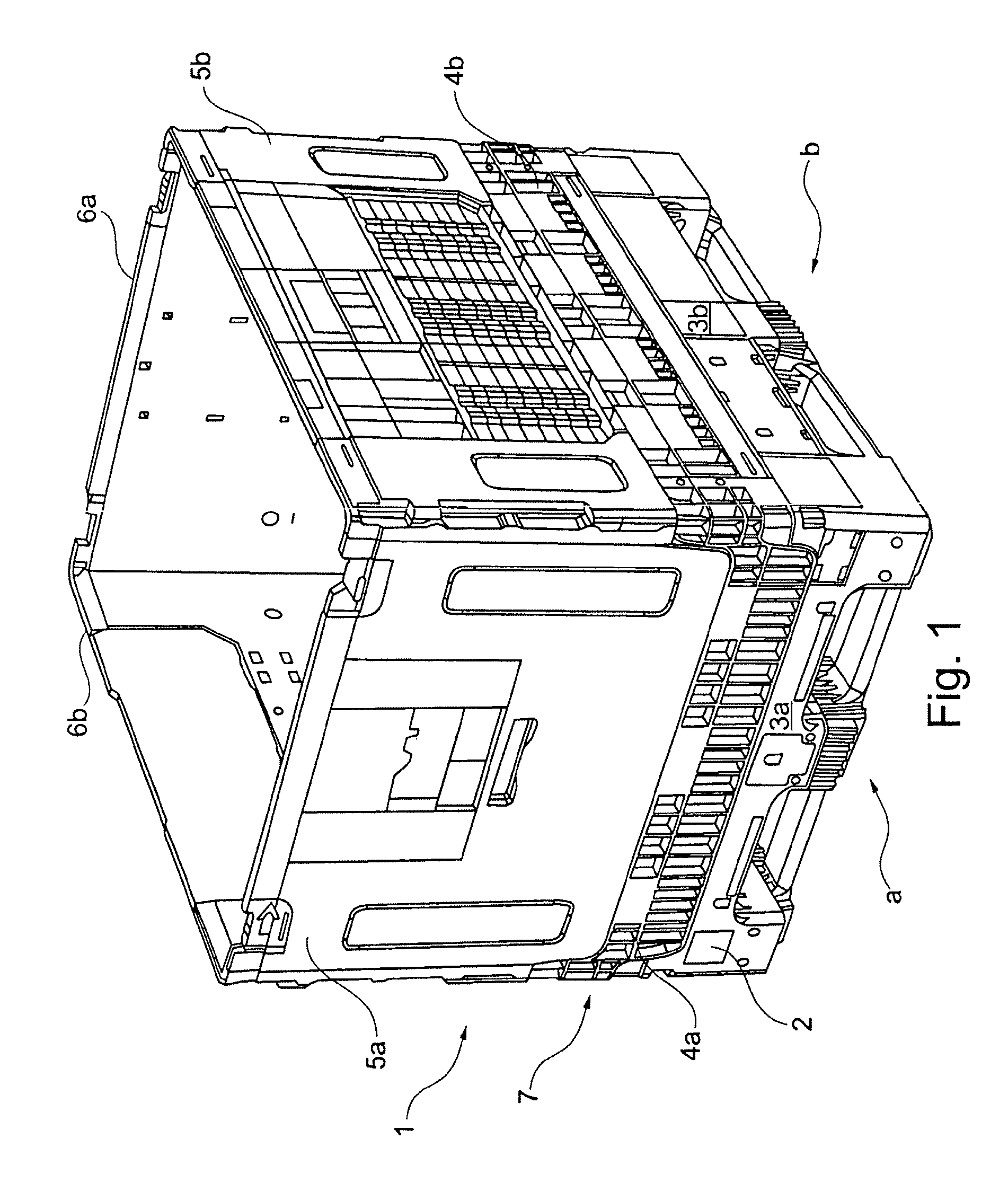

Large cargo carrier

The invention relates to a large load carrier (1) including a pallet-shaped base element (2) and at least one detachably fastened side wall (5a, 5b). According to the invention, the large cargo carrier includes at least one pedestal element (4a, 4b), which is configured so that the pedestal element is detachably fastened at the pallet-shaped base element and is detachably fastened at the at least one side wall. The invention further relates to a kit for constructing such a large cargo carrier.

Owner:SCHOELLER ARCA SYST

Thin linear seatbelt pretensioner

ActiveUS8226122B2Reduce leakage pathShorten travel distanceBelt retractorsSafety beltsMobile vehicleEngineering

A linear pretensioner for use as part of a motor vehicle occupant belt restraint system mountable to vehicle structure and coupled with a belt restraint system component. The pretensioner includes at least one base plate having a slot and at least one closure plate fixedly attached to the base plate. The closure plate(s) and the slot of the base plate(s) form a cavity having an open end. A piston plate has a piston tail slidably disposed within the cavity and a piston head extending from the open end. A cable is coupled with the piston plate, the base plate(s), and / or the closure plate(s). The piston plate, the slot of the base plate(s), and the closure plate(s) cooperate to form an expanding chamber that enlarges when pressurized by a gas generator, which drives the piston plate and the base plate relative to each other to exert tension on the cable.

Owner:AUTOLIV ASP INC

Connector structure and computer system with grounding function

ActiveUS20120071013A1Refining issueLong labor hourComputer periphery connectorsCoupling protective earth/shielding arrangementsDocking stationComputerized system

A connector structure includes a first connector installed on a host device. The first connector includes a first base, a first terminal set installed on the first base, and a first grounding component installed on the first base. The connector structure further includes a second connector installed on a docking station for connecting with the first connector. The second connector includes a second base, a second terminal set installed on the second base for contacting with the first terminal set so as to transmit signals between the host device and the docking station with the first terminal set when the host device is docked in the docking station, and a second grounding component installed on the second base for contacting with the first grounding component so as to ground with the first grounding component when the host device is docked in the docking station.

Owner:WISTRON CORP

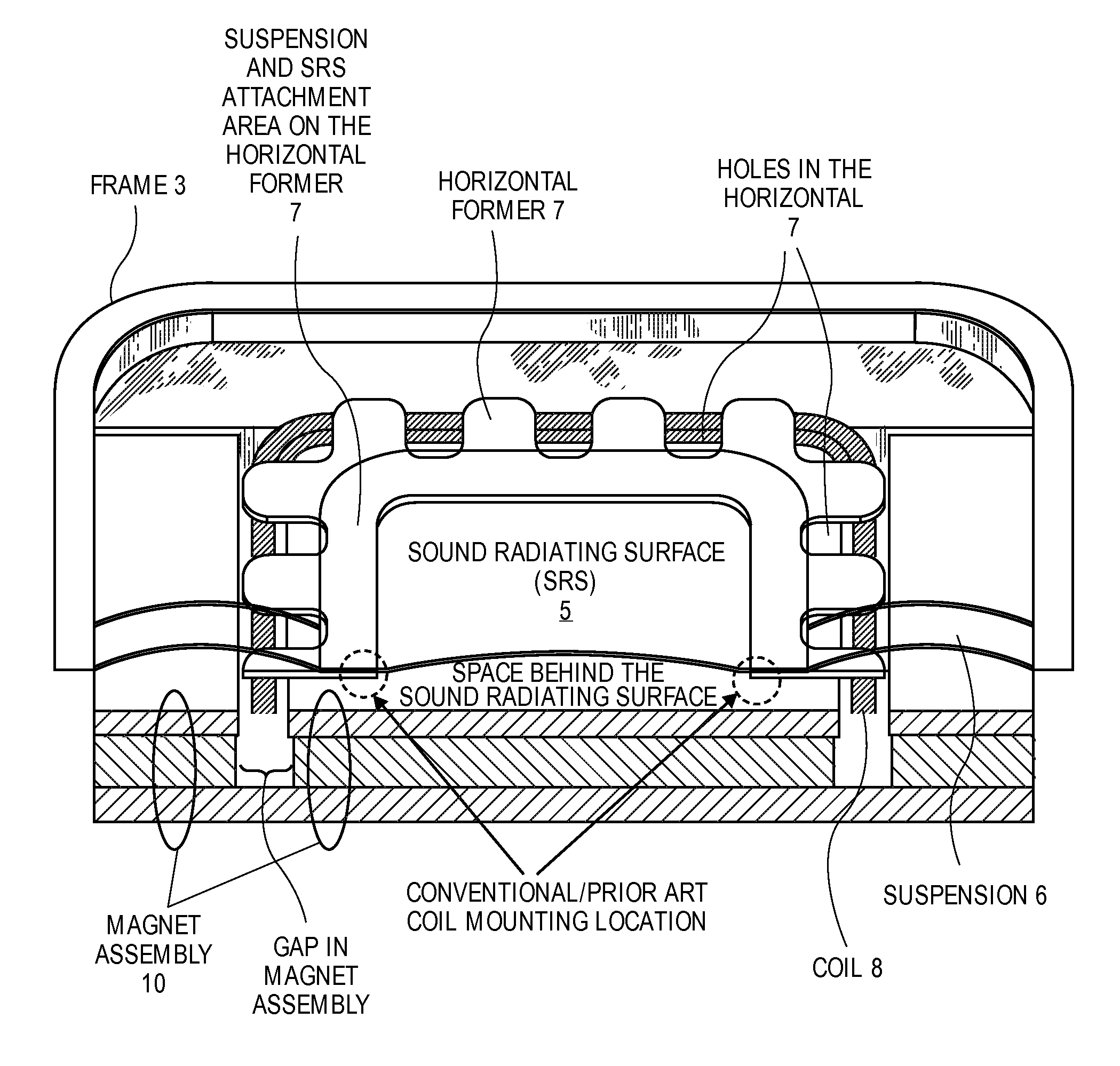

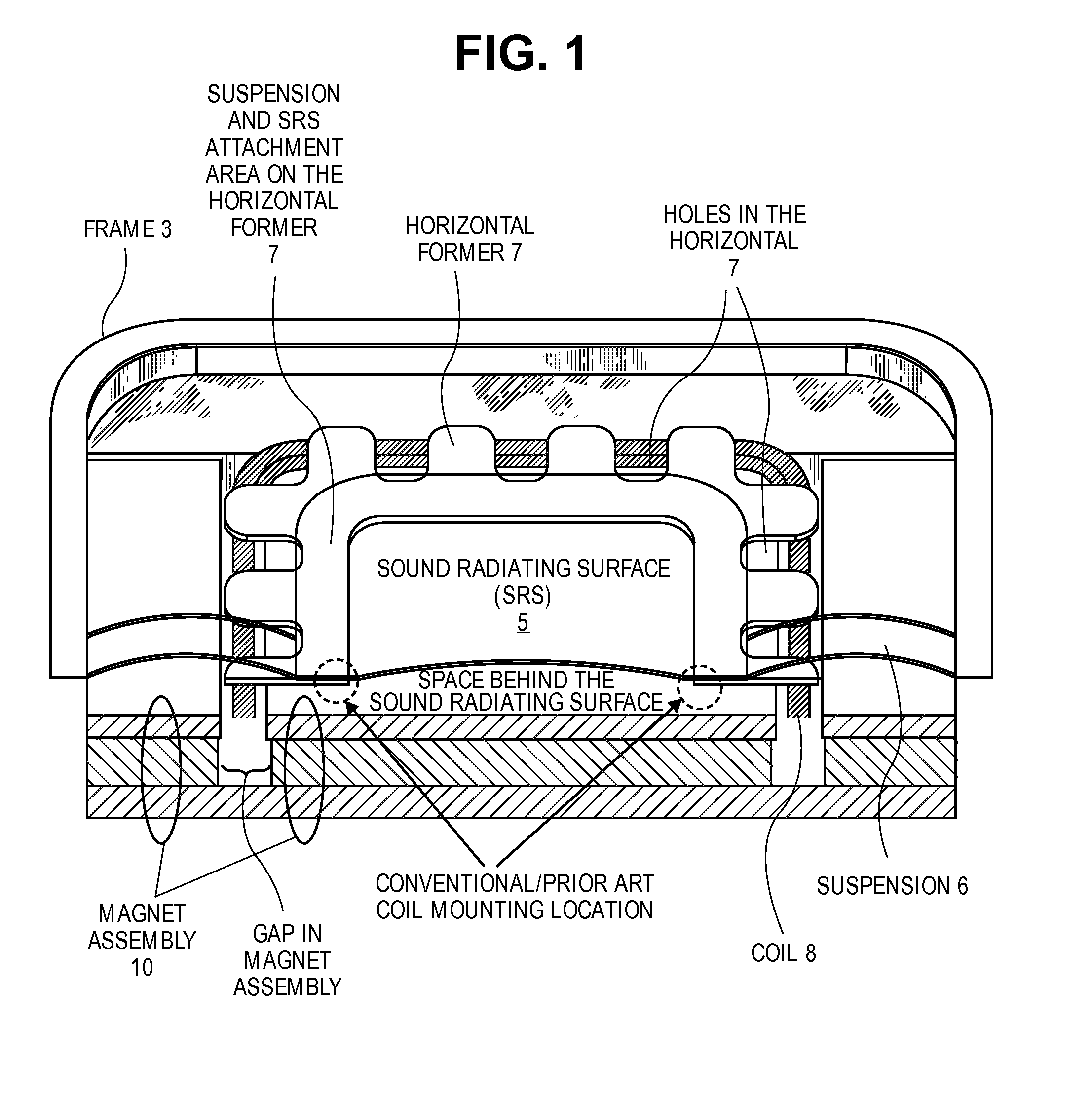

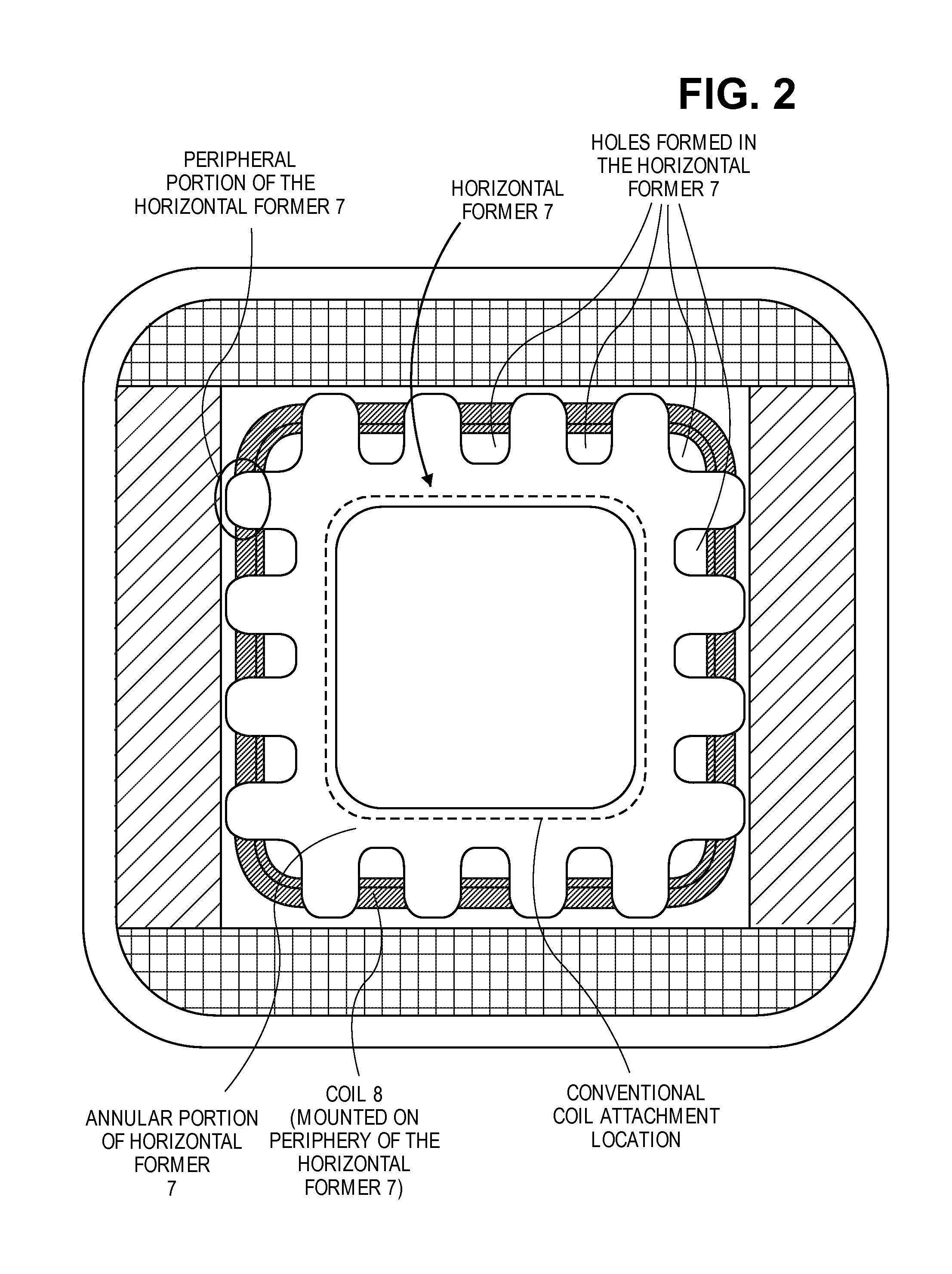

Speaker having a horizontal former

ActiveUS20120121121A1Increase in sizeIncrease the areaFrequency/directions obtaining arrangementsTransducer casings/cabinets/supportsEngineeringLoudspeaker

A speaker includes a frame, a sound radiating surface, and a suspension that couples the sound radiating surface to the frame. A horizontal former is coupled to the radiating surface. The former extends substantially horizontally outward of a peripheral portion of the radiating surface, to a peripheral portion that is separate from the suspension. A coil is coupled to the peripheral portion of the horizontal former. Other embodiments are also described and claimed.

Owner:APPLE INC

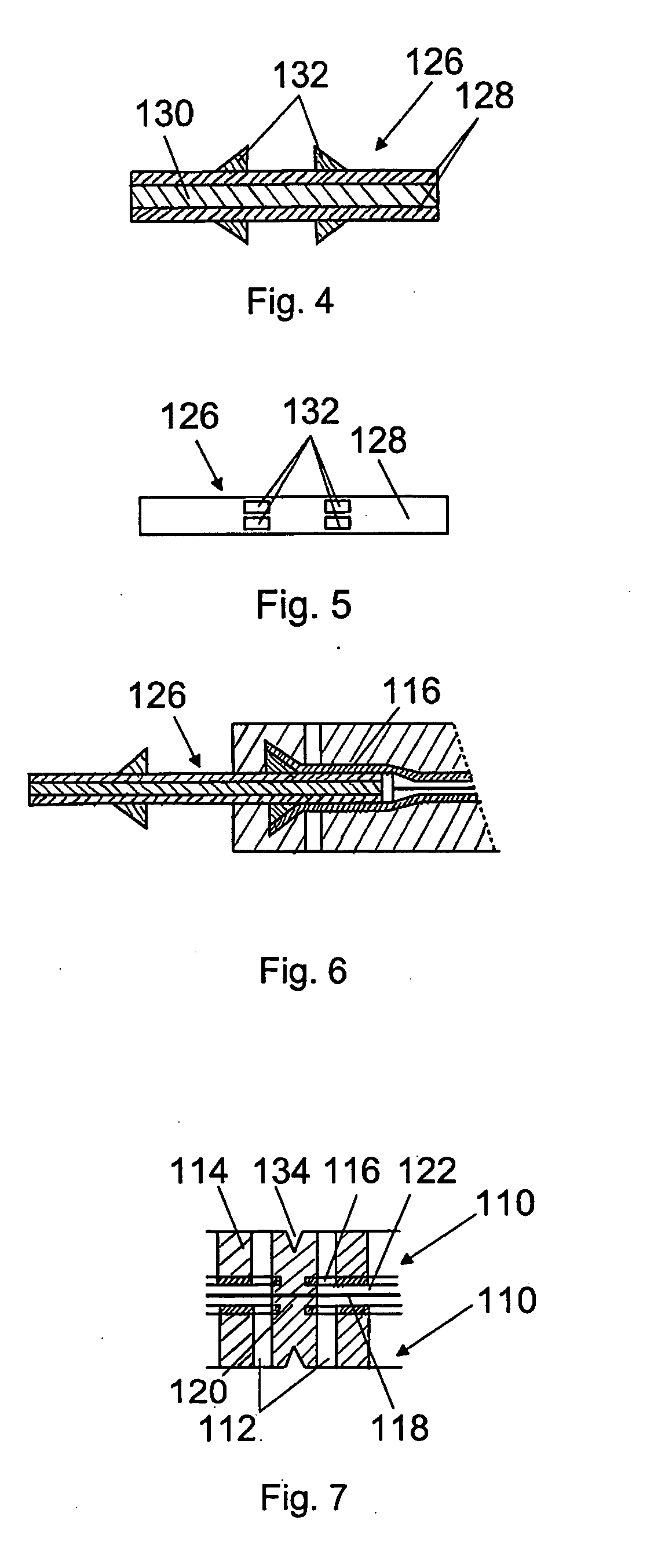

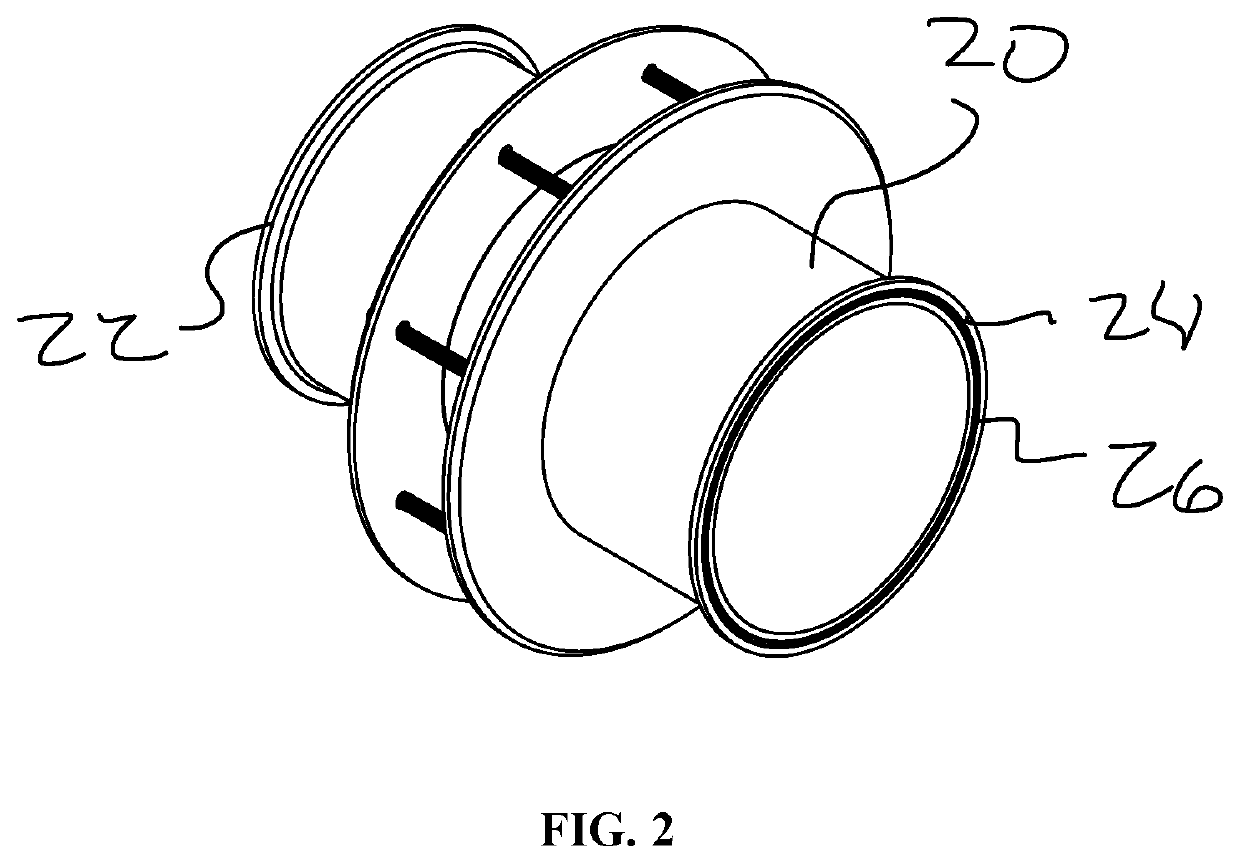

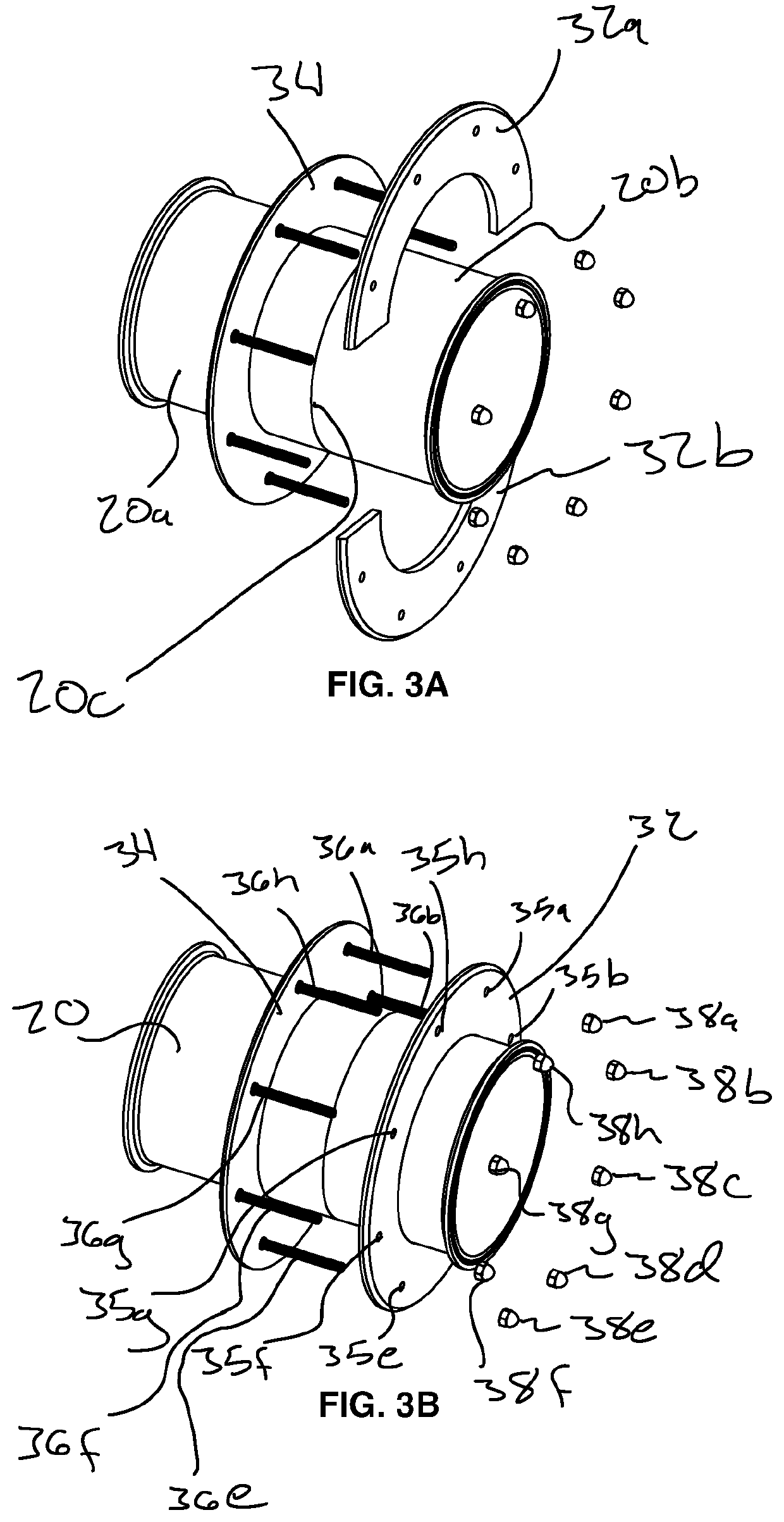

Electrostatic transducer, method for connecting the same and manufacturing method

InactiveUS20060245607A1Fast and simple to manufactureBulky assemblyCircuit lead arrangements/reliefElectrostatic transducersEngineeringElectrostatic transducer

An electrostatic transducer, a method for connecting the same and a manufacturing method. The electrostatic transducer comprises at least one stator, which comprises an insulating layer and a conducting layer, and a film element which is arranged to vibrate in response to voltage supplied to it and which is provided in such a manner that an air gap is formed between the conducting layer and the film element. The electrostatic transducer also comprises at least one fastening edge arranged on the outer edge of the electrostatic transducer, the fastening edge being arranged to be fastened to a fastening element of a second electrostatic transducer.

Owner:PANPHONICS OY

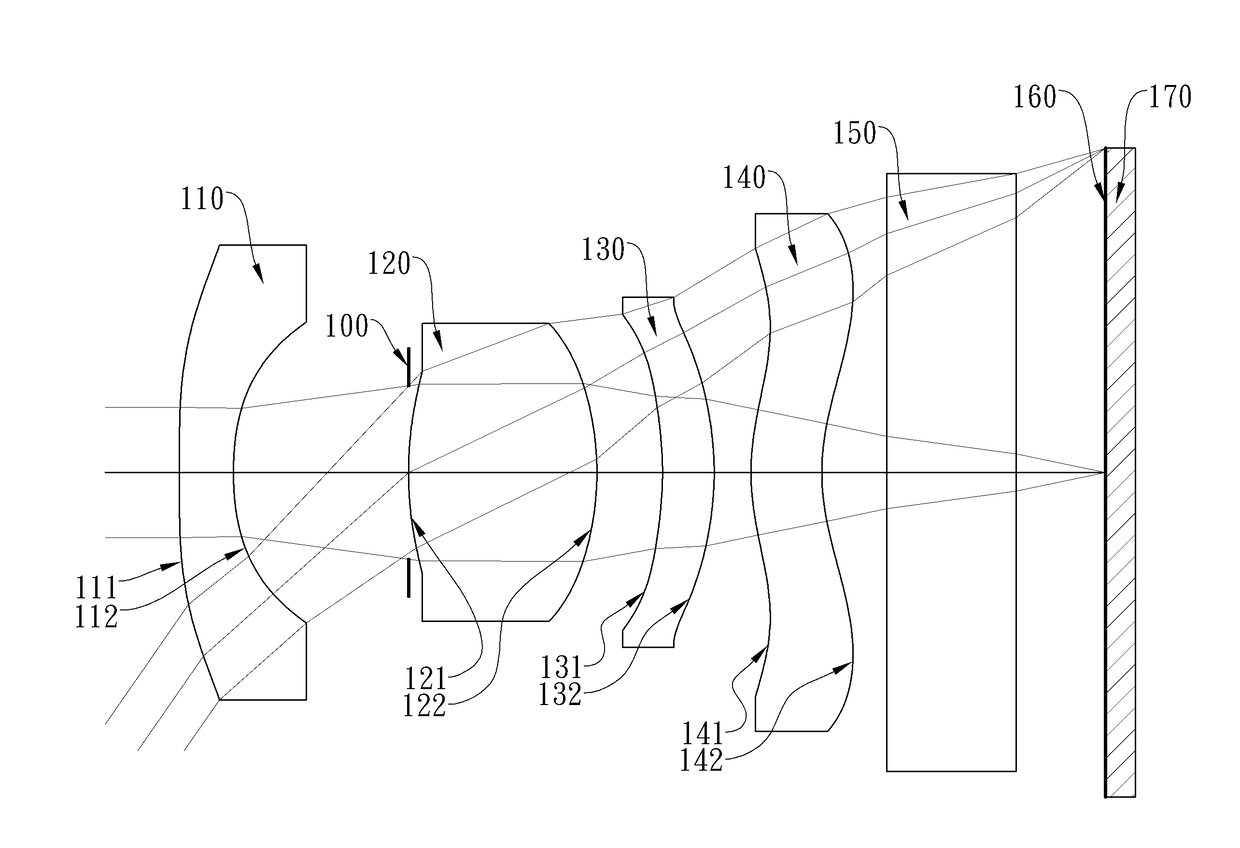

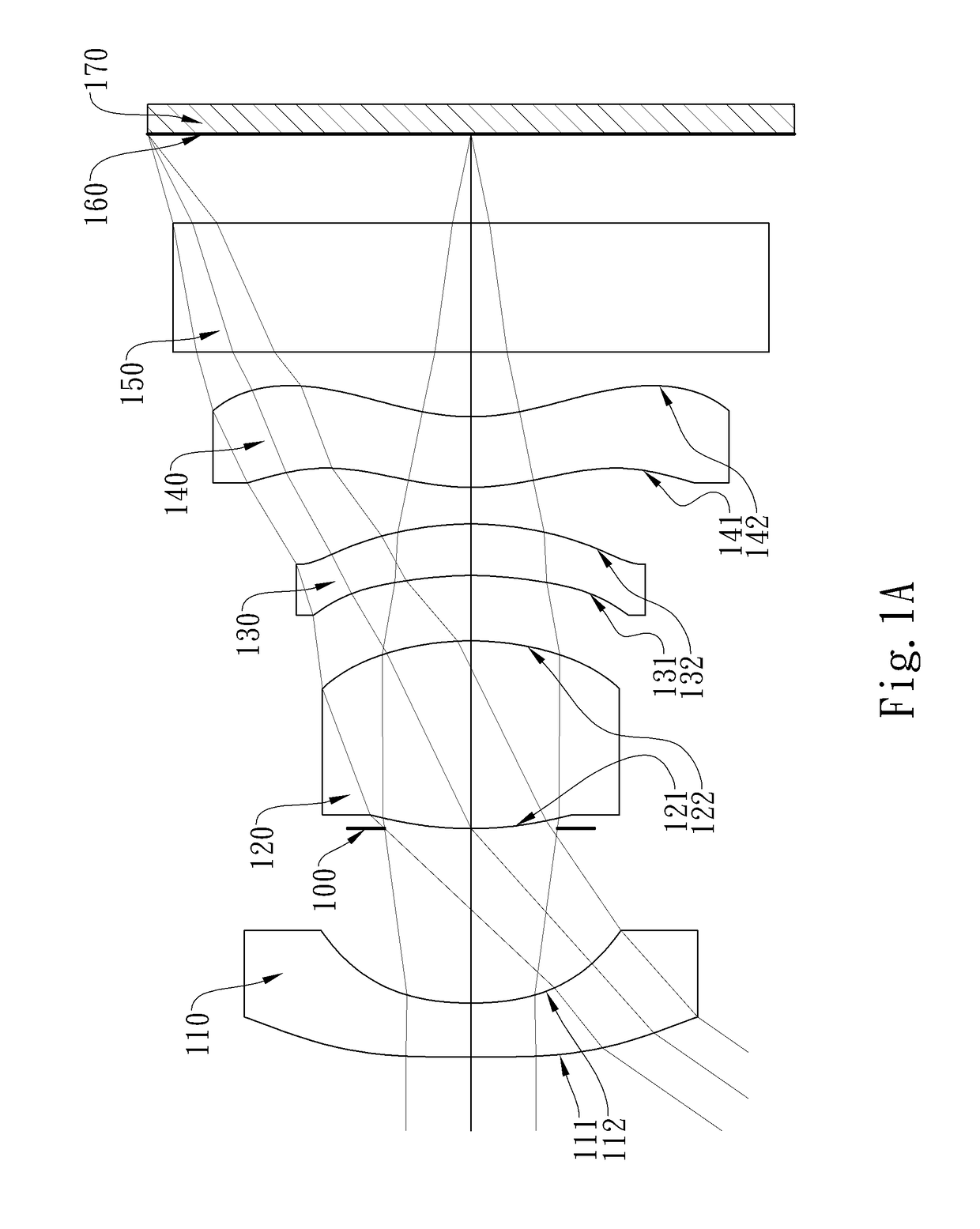

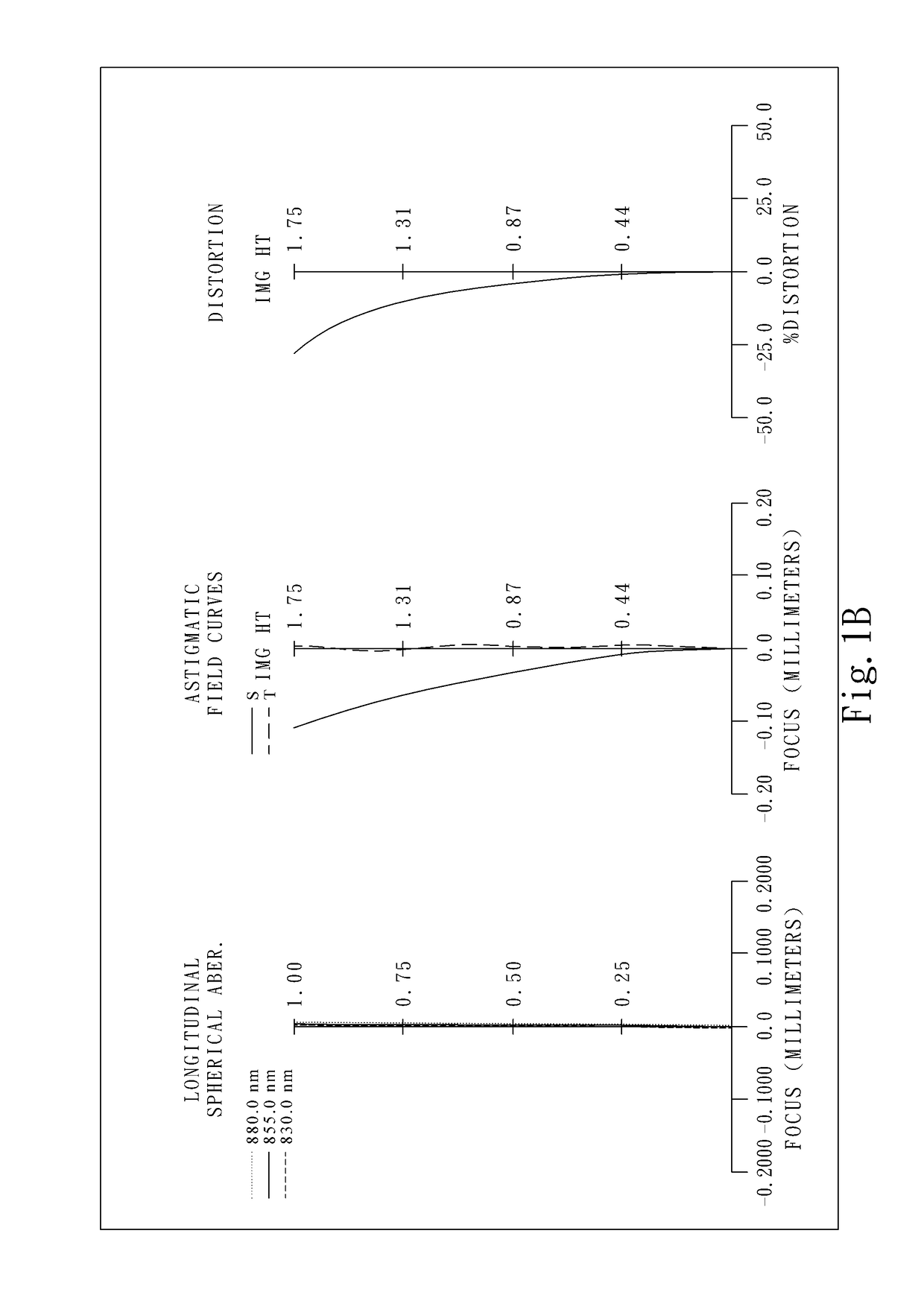

Optical lens assembly, image capturing apparatus and electronic device

ActiveUS20170293108A1Form evenlyEffectively correct the field curvatureOptical elementsWide fieldReduced size

This invention provides an optical lens assembly comprising, in order from an object side to an image side: a first lens element with negative refractive power having an image-side surface being concave in a paraxial region thereof; a second lens element having positive refractive power; a third lens element having an object-side surface being concave in a paraxial region thereof; and a fourth lens element having an object-side surface being convex in a paraxial region thereof and an image-side surface being concave in a paraxial region thereof, the image-side surface thereof having at least one convex shape in an off-axis region thereof; wherein the optical lens assembly has a total of four lens elements. With such configuration, the optical lens assembly of the present disclosure is characterized by a reduced size and a wide field of view.

Owner:LARGAN PRECISION

Pass-thru window and orifice cap

InactiveUS20200240558A1Simple yet versatile designSimplify the assembly processPipe supportsFlanged jointsClassical mechanicsEngineering

A sanitary pass-through window with a sanitary ferrule spool assembly including one or two orifice cap or solid cap assemblies to allow the passage of a tube, hose, or cable from an environmentally controlled room to an environmentally different area. The assembly minimizes the transfer of air and particles from one room into another. The assembly can include a seamed or seamless flange on one side of the wall opening for ease of clean-ability, and a solid or split flange clamp on the opposing side for ease of installation. The orifice cap is a subassembly featuring a cap and gate component, which can mate together by locating external bosses on the gate with internal grooves in the cap, and then secure together with a friction fit, spring pin, or other mechanism.

Owner:G & G TECH

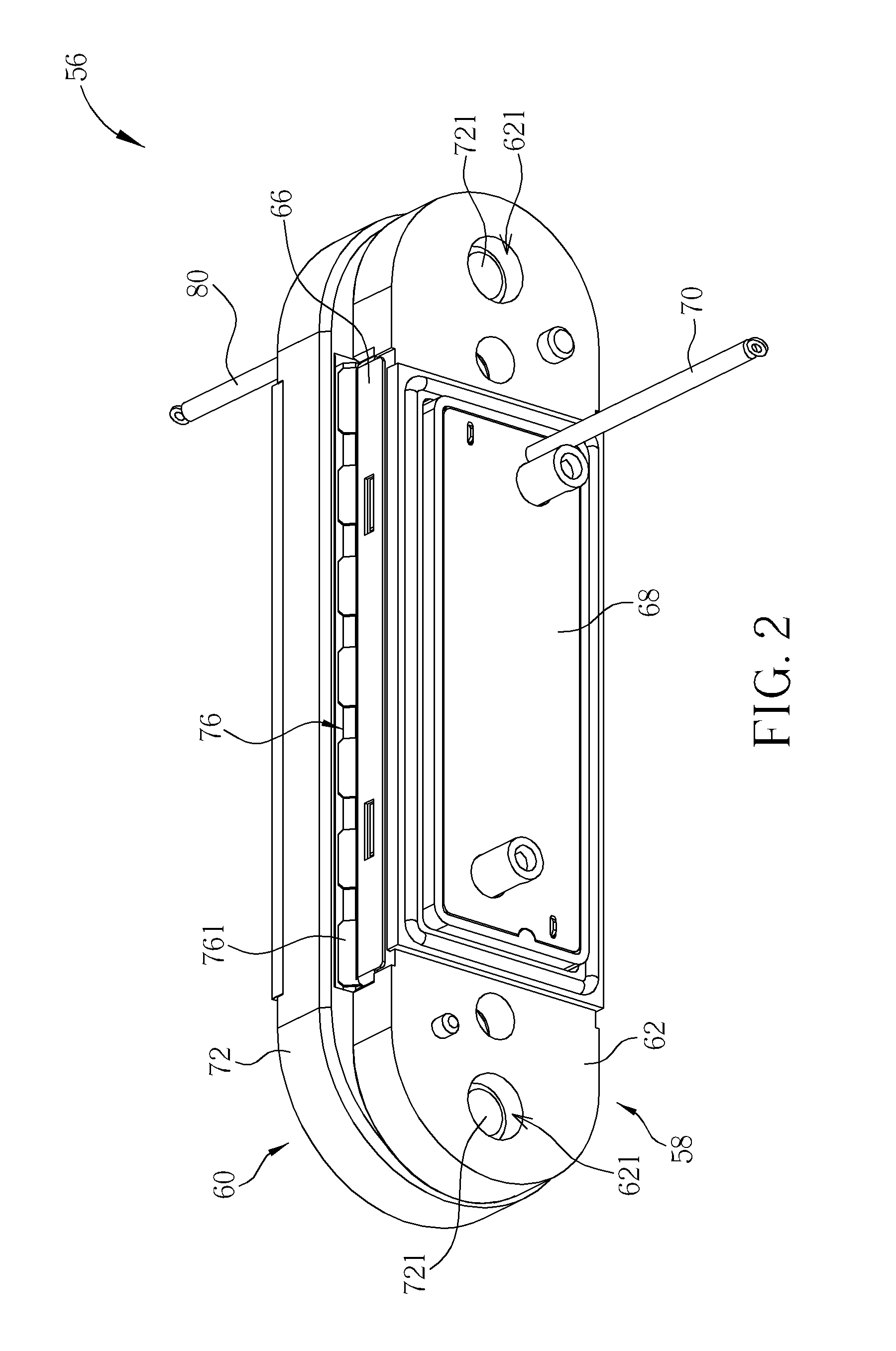

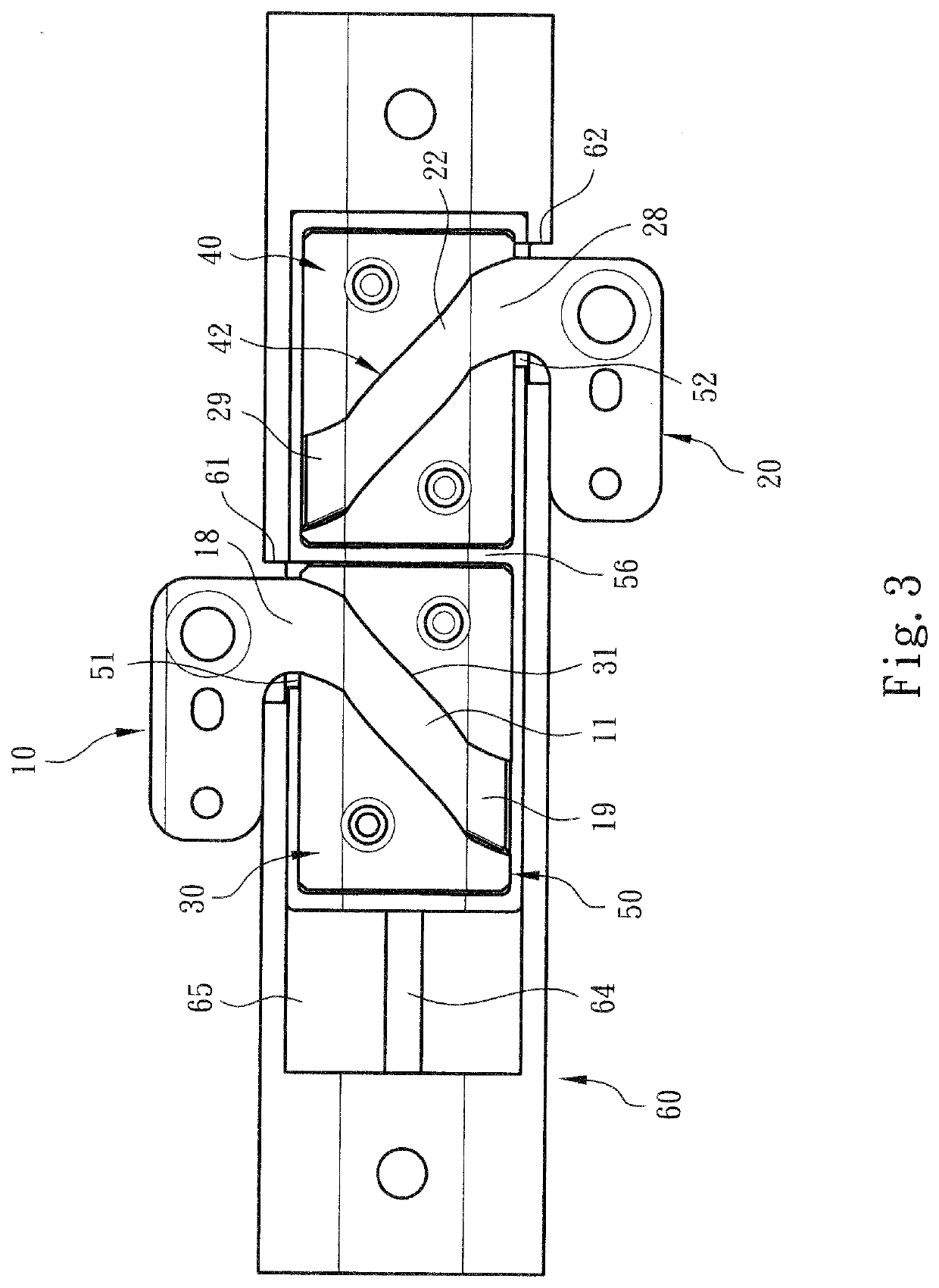

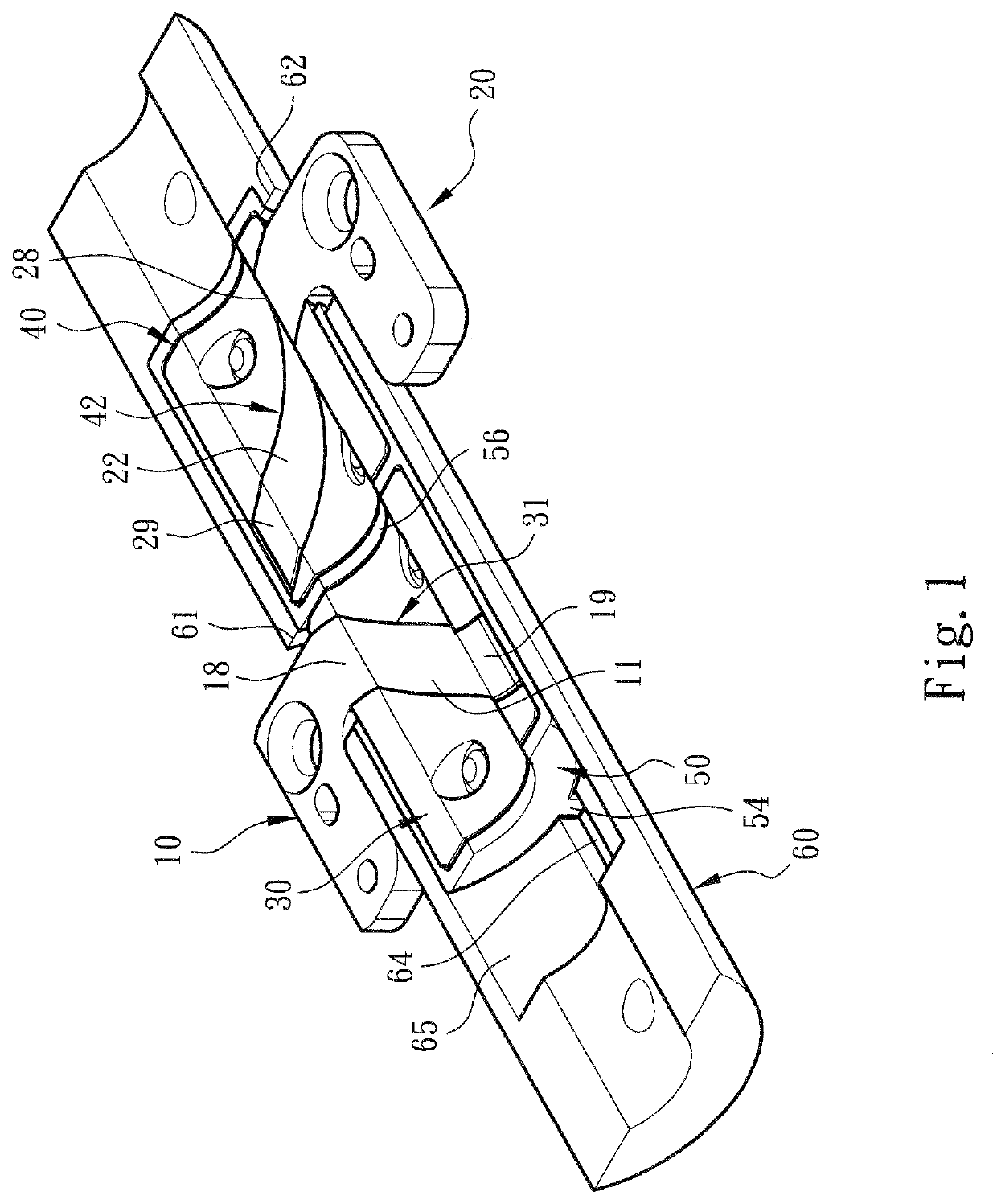

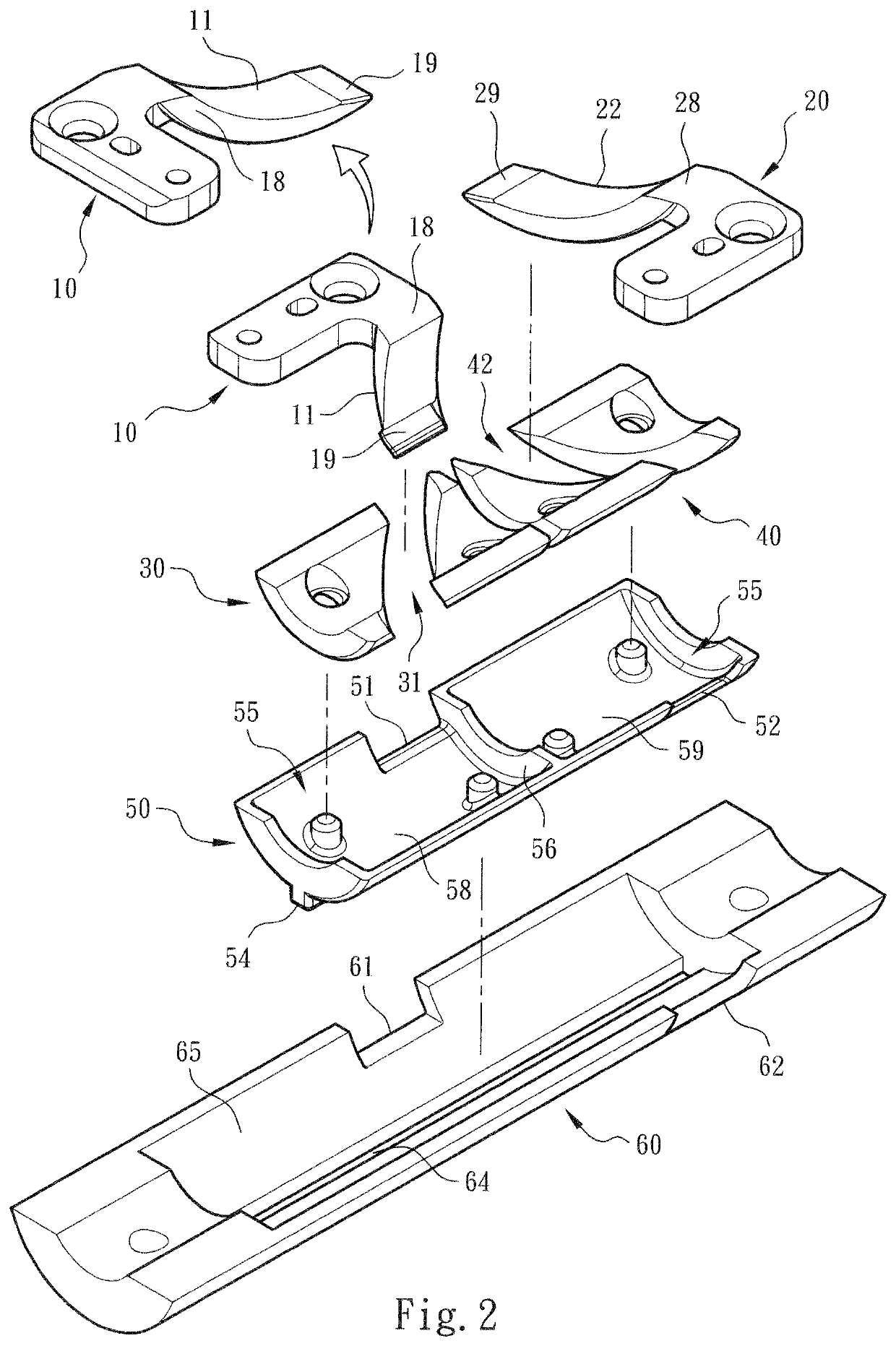

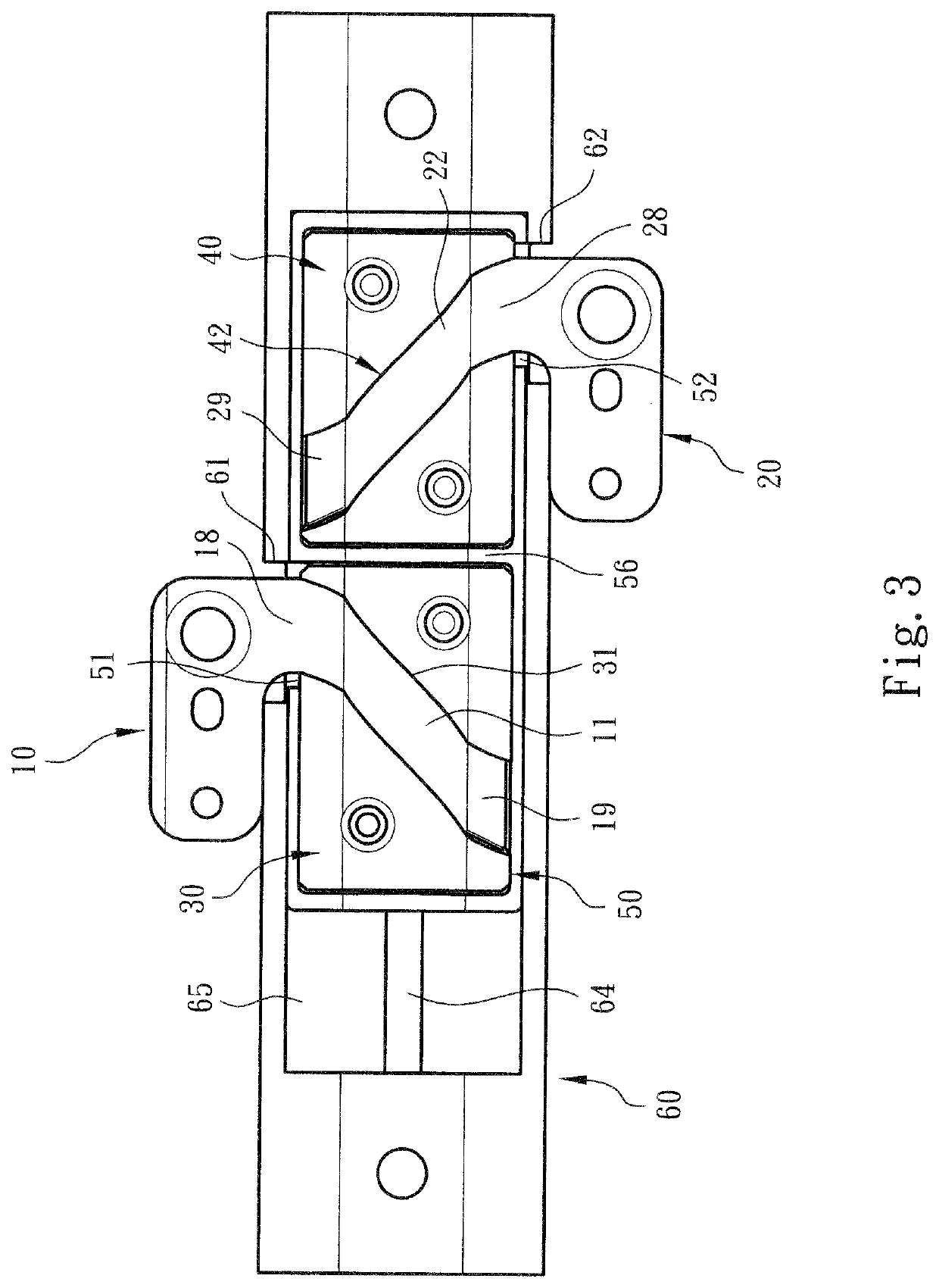

Pivot shaft structure moving around virtual axis

ActiveUS20210048852A1Reduce assembling/motional spaceSimple structureWing accessoriesCasings/cabinets/drawers detailsClassical mechanicsEngineering

The pivot shaft structure moving around virtual axis includes an assembly of a main body, a first operation board and a second operation board disposed on the main body. The first operation board has an arm section. The second operation board has an arm section. The arm sections of the first and second operation boards are respectively received in a first arched rail and a second arched rail of the main body. The first and second arched rails are arched and disposed around a virtual axis. When a user operates the first operation board or the second operation board to move, the first operation board or the arm section thereof and the second operation board or the arm section thereof respectively synchronously move around the virtual axis along the first and second arched rails toward each other to achieve opening / closing effect.

Owner:FIRST DOME

Trim assembly for a vehicle making it possible to conceal a technical space

ActiveUS8997433B2Reduce volumeEfficiently concealedPedestrian/occupant safety arrangementBuilding componentsEngineeringMechanical engineering

A trim assembly having a trim element and a first concealing element extending away from the trim element and being movable relative to the trim element. The trim assembly further includes at least one second rigid concealing element, extending from the trim element to the first concealing element and designed to conceal the space between the trim element and the first concealing element. The second concealing element is secured to the trim element and is biased against part of the first concealing element so as to bear against that part of the first concealing element in all positions of the first concealing element with respect to the trim element.

Owner:FAURECIA INTERIEUR IND

Pivot shaft structure moving around virtual axis

ActiveUS20210048844A1Reduce assembling/motional spaceSimple structureWing accessoriesDetails for portable computersClassical mechanicsControl theory

The pivot shaft structure moving around virtual axis includes an assembly of a main body, a first operation board and a second operation board disposed on the main body. The first operation board has an arm section. The second operation board has an arm section. The arm sections of the first and second operation boards are respectively received in a first arched rail and a second arched rail of the main body. The first and second arched rails are arched and disposed around a virtual axis. When a user operates the first operation board or the second operation board to move, the first operation board or the arm section thereof and the second operation board or the arm section thereof respectively synchronously move around the virtual axis along the first and second arched rails toward each other to achieve opening / closing effect.

Owner:FIRST DOME

Pivot shaft structure moving around virtual axis

ActiveUS11169578B2Reduce assembling/motional spaceSimple structureWing accessoriesCasings/cabinets/drawers detailsClassical mechanicsControl theory

The pivot shaft structure moving around virtual axis includes an assembly of a main body, a first operation board and a second operation board disposed on the main body. The first operation board has an arm section. The second operation board has an arm section. The arm sections of the first and second operation boards are respectively received in a first arched rail and a second arched rail of the main body. The first and second arched rails are arched and disposed around a virtual axis. When a user operates the first operation board or the second operation board to move, the first operation board or the arm section thereof and the second operation board or the arm section thereof respectively synchronously move around the virtual axis along the first and second arched rails toward each other to achieve opening / closing effect.

Owner:FIRST DOME

Modular lithium-ion battery system for fork lifts

ActiveUS11056727B2Improve safe and reliable operationEasy to disassembleIndicating/monitoring circuitsCell electrodesData connectionElectrical battery

Owner:ETHIUM LLC

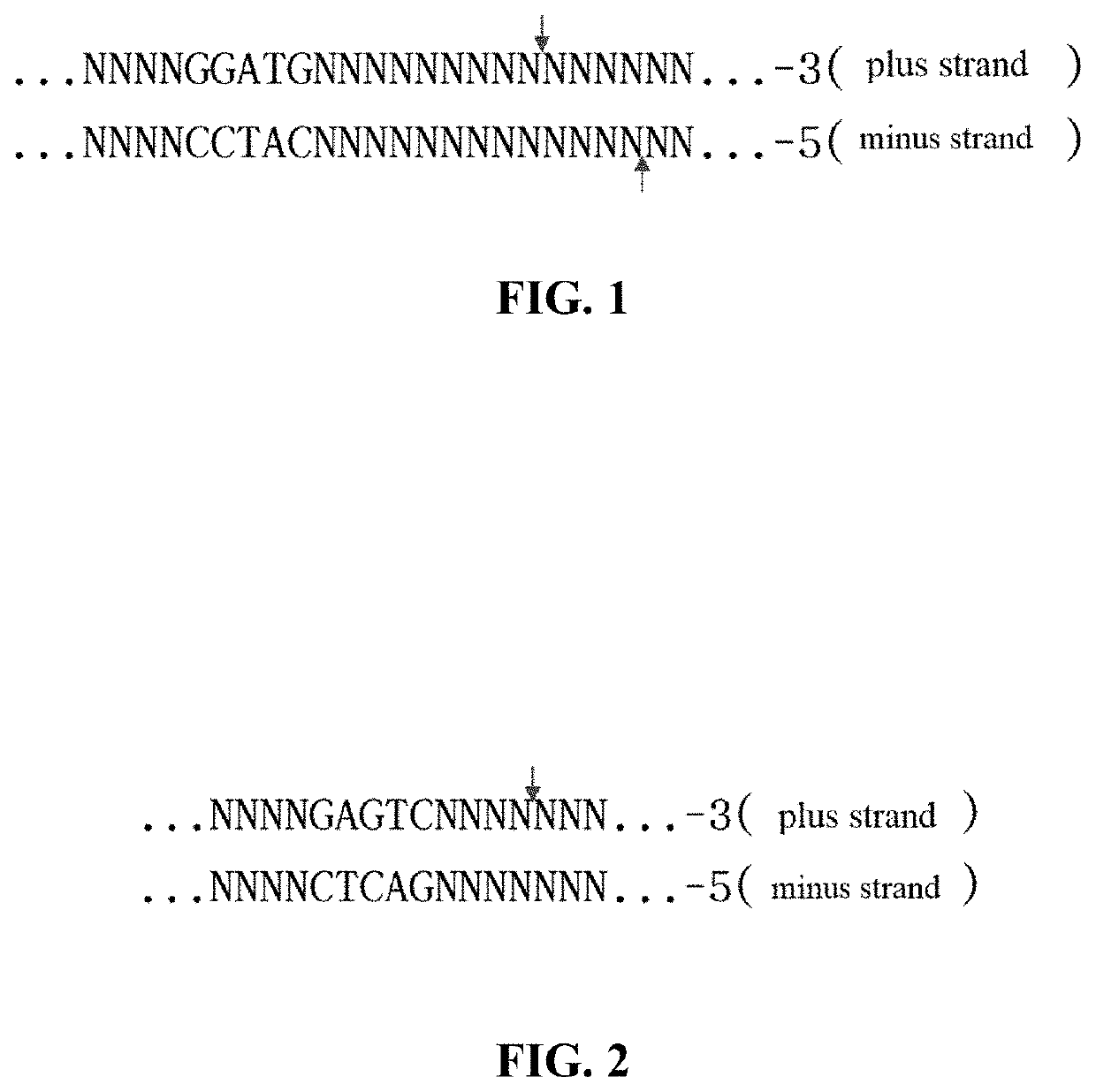

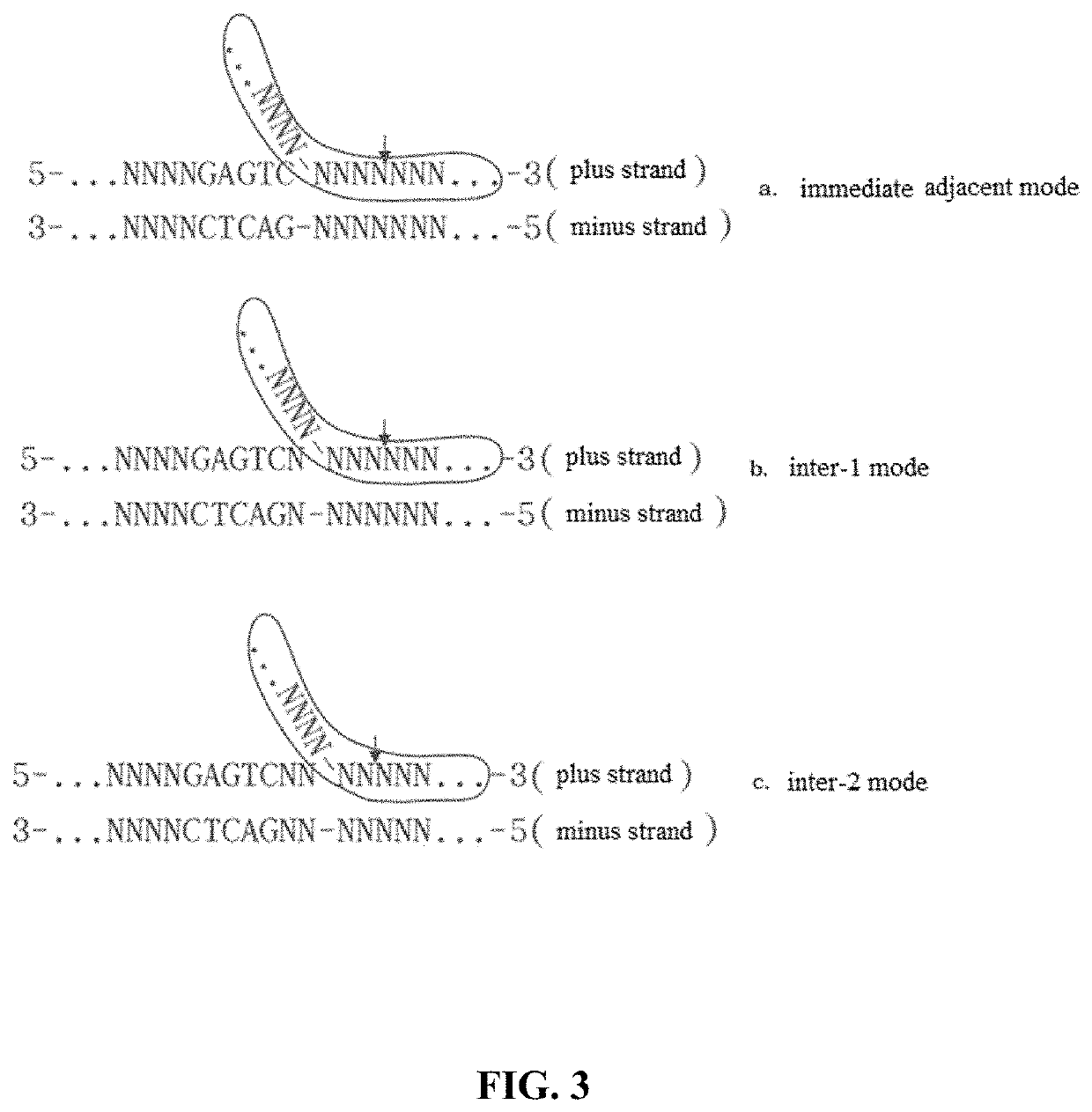

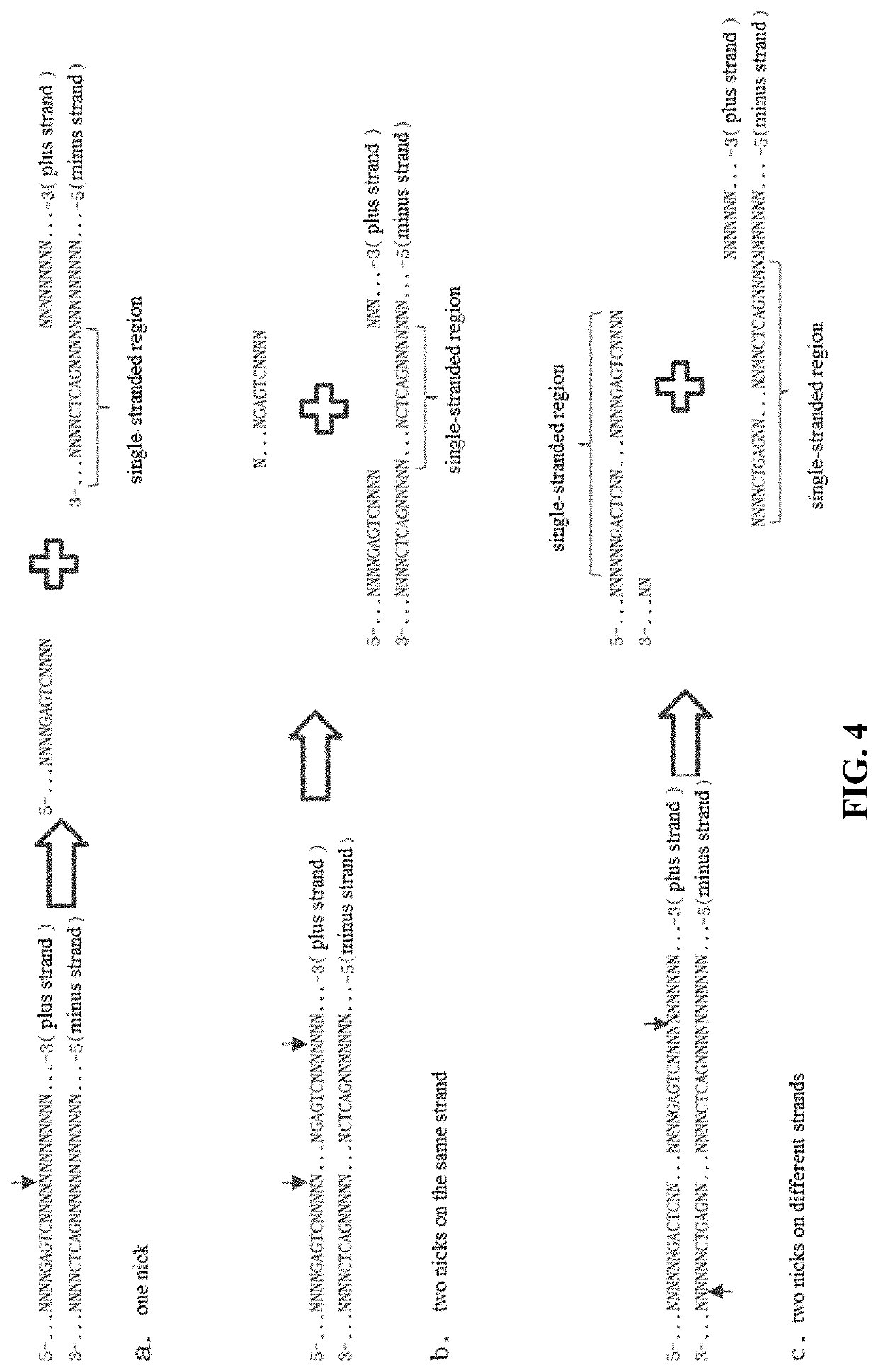

Method for manipulating terminals of double stranded DNA

PendingUS20220290163A1Eliminate needBulky assemblyVector-based foreign material introductionDNA preparationOligonucleotide LinkerDouble strand

A method for manipulating the terminals of a double-stranded DNA. The principle thereof is using a restriction nicking enzyme to first generate one or more nicks on one strand of a double-stranded DNA, then using an oligonucleotide adaptor to bind the same or a different restriction nicking enzyme to generate cleavage on the other strand of the double-stranded DNA, the position of cleavage being determined by the design of the oligonucleotide adapter, and eventually cleaving the double-stranded DNA of interest and generating various lengths of 5′ io protruding terminals and various lengths of 3′ protruding terminals or blunt terminals at the nicks. The bases at the terminals of a double-stranded DNA generated by means of this method can be designed at will, and such terminals can be used for double-stranded DNA splicing, particularly seamless splicing of double-stranded DNA.

Owner:WUXI QINGLAN BIOLOGICAL SCI & TECH

Tamper-evident band assembly

ActiveUS20170217653A1Improve efficiencyLow costClosure capsRemovable lids/coversMechanical engineeringEngineering

A two-piece tamper-evident band assembly for use with a container and closure combination, where the container has a peripheral collar and the closure has a skirt, is shown. The tamper-evident band assembly includes a breakaway band frangibly connected to a staying ring. The staying ring has decreased flexibility where it connects to the container and closure combination, which prevents the assembly from deforming in a manner that will cause the assembly to fail to indicate that the container has been opened. The tamper-evident band assembly also indicates whether the container has been compromised without requiring modification of the container or the closure and can be applied to existing container and closure combinations that lack a tamper-evident system, allowing the assembly to be used with a variety of container and closure combinations.

Owner:PHOENIX CLOSURES

Method for manufacturing a membrane assembly for a fuel cell with catalyst free edge areas; membrane assembly and fuel cell with membrane assembly

ActiveUS11201344B2Bulky assemblyEasy to separateCell electrodesFinal product manufactureFuel cellsPtru catalyst

A method for manufacturing a membrane assembly for a fuel cell. To overcome a problem of chemical degradation at an edge of the membrane, the method comprises the following steps:positioning a first decal layer, which is made of the same material as a first catalyst layer, on a first side of the membrane,positioning a second decal layer, which is made of the same material as a second catalyst layer, on a second side of the membrane,pressing a compression pad, which is positioned on the first decal layer with the first decal layer and the second decal layer fully overlapping the compression pad, and the second decal layer against each other with the first decal layer and the membrane positioned in-between, whereby pressure on the first and the second decal layer is applied only in an area covered by the compression pad.

Owner:FORD MOTOR CO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com