Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

150 results about "Foam film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

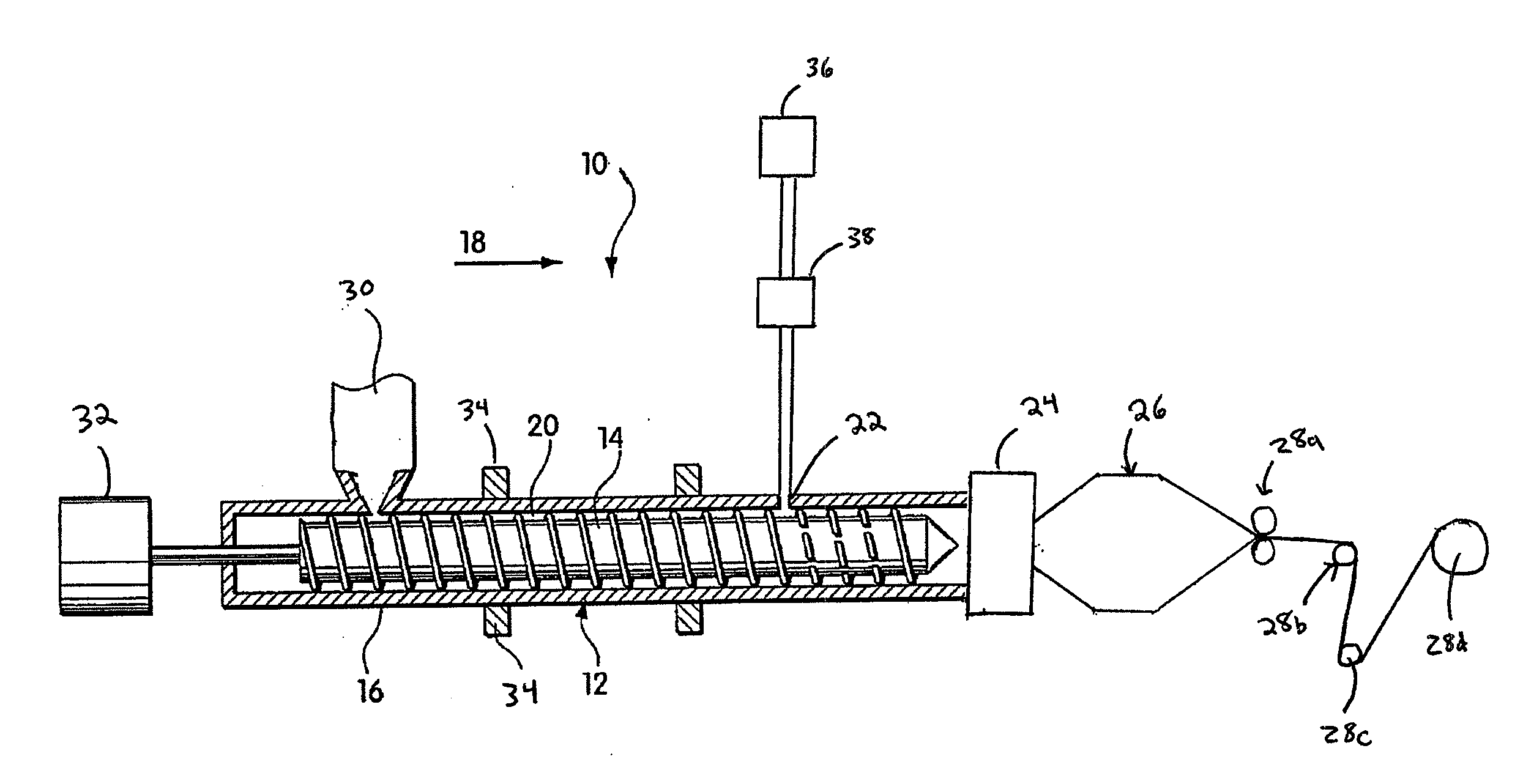

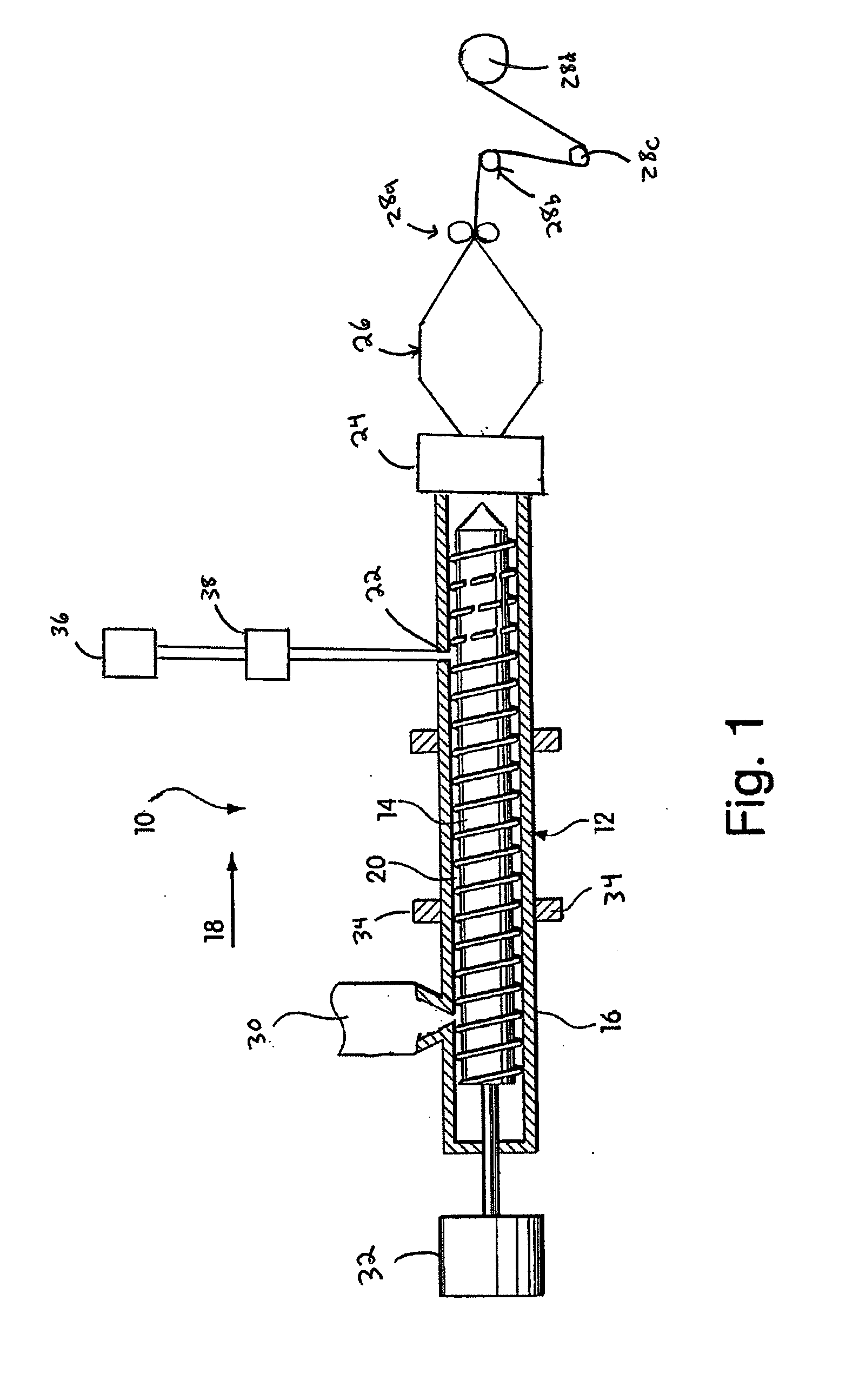

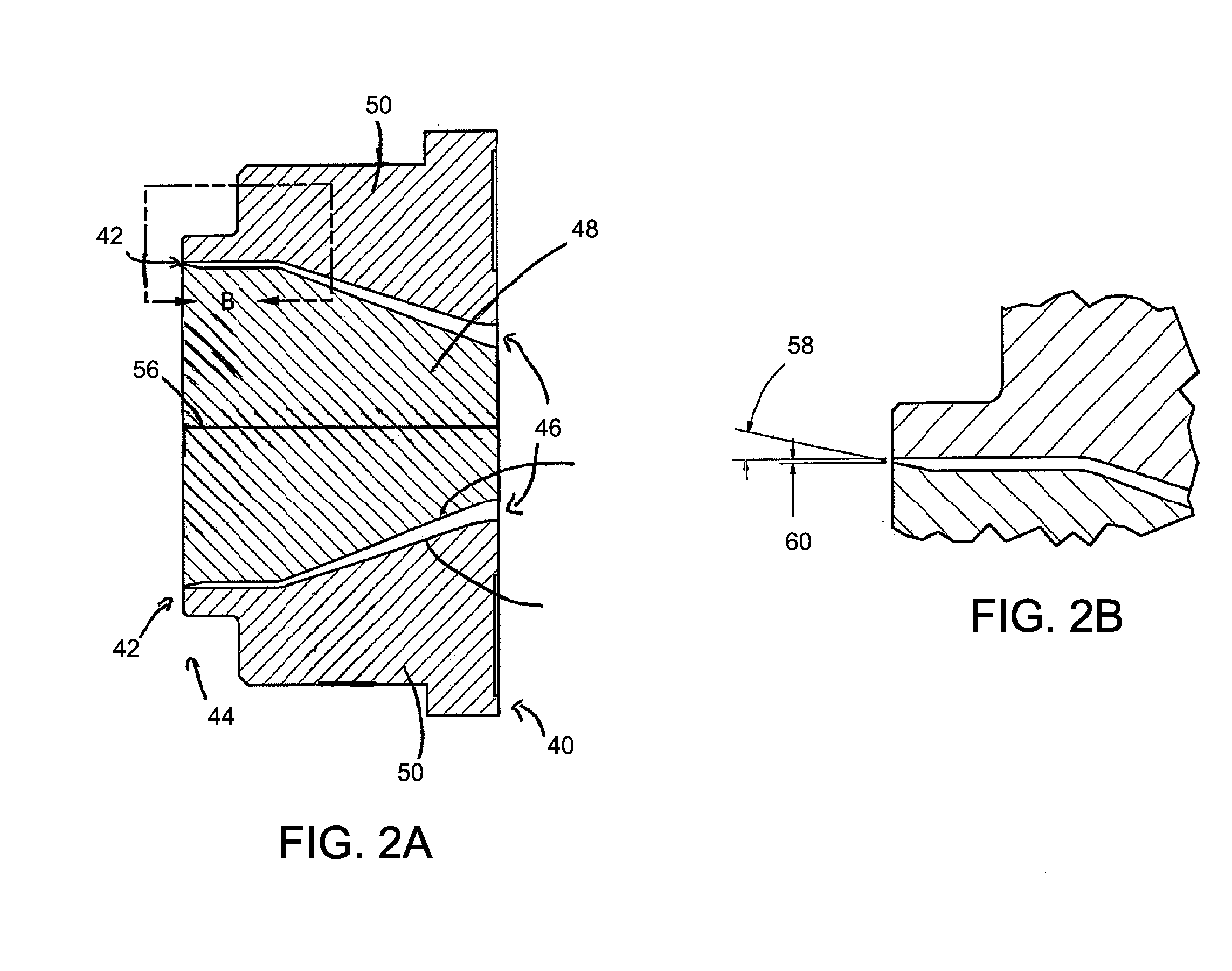

Method of forming blown polymeric foam film

A method of forming a blown polymeric foam film is described herein. As described further below, equipment design (e.g., die design) and processing conditions may be controlled to form blown films having desired characteristics.

Owner:TREXEL

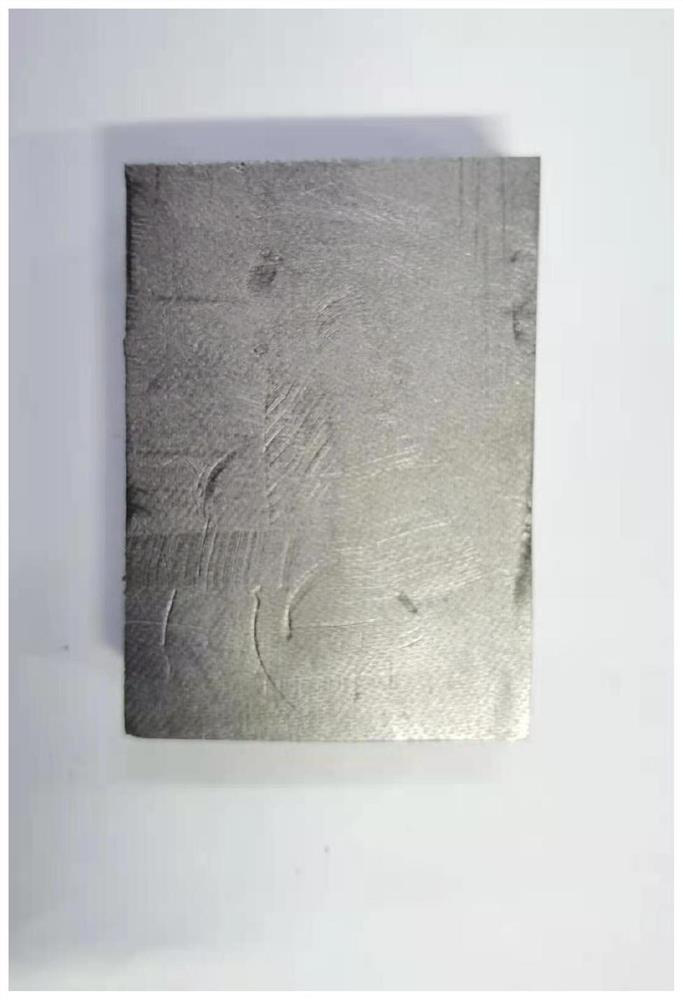

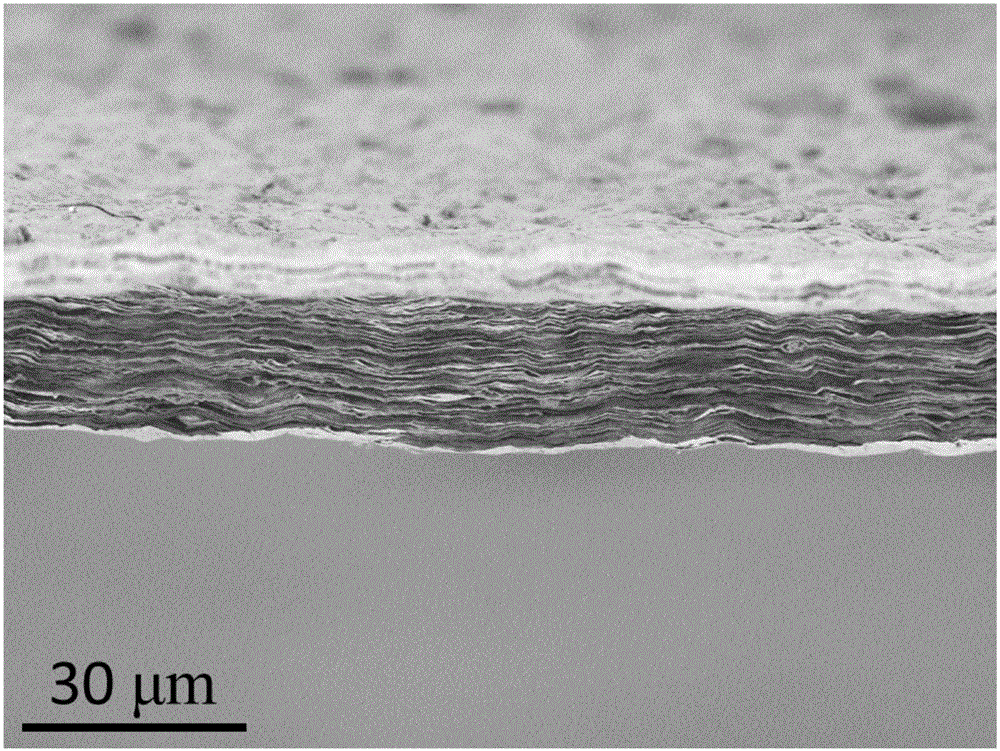

Graphene foam film enhanced heat-conducting gasket and preparation method thereof

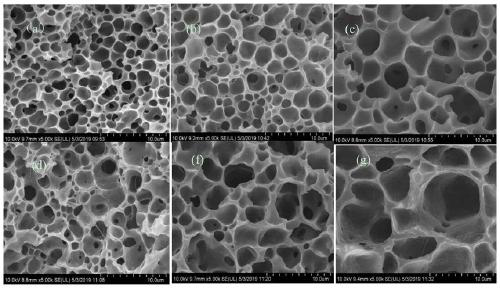

PendingCN113290958ALarge poresHigh porosityLamination ancillary operationsLaminationAdhesive cementPolymer science

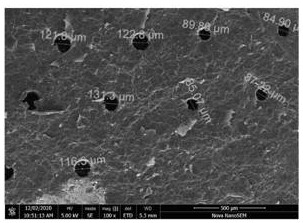

The invention discloses a graphene foam film enhanced heat-conducting gasket and a preparation method thereof. The graphene foam film enhanced heat-conducting gasket comprises a plurality of layers of graphene foam films and adhesives filled in the graphene foam films and among the layers, and the graphene foam films account for 60-95 wt% of the total weight of the heat-conducting gasket. The graphene is arranged in the heat-conducting gasket in the thickness direction, and the gasket has good heat-conducting performance in the thickness direction; besides, the combination of the graphene foam film and the adhesive has good compressibility and compression resilience, and the application thermal resistance is small.

Owner:CHANGZHOU FUXI TECH CO LTD

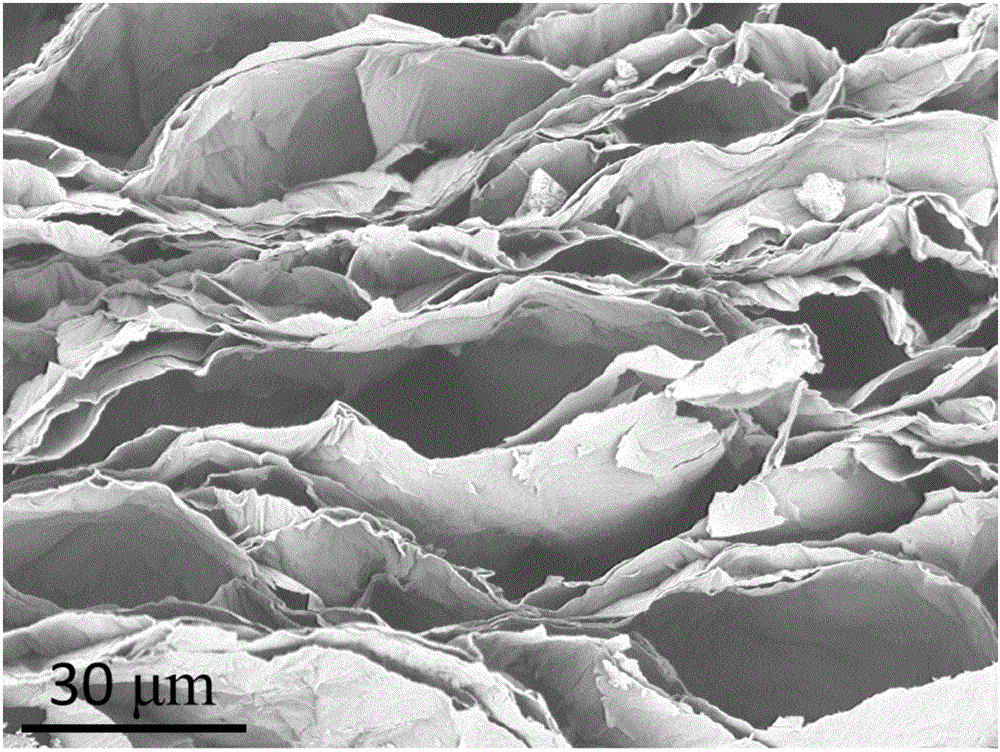

Method for quickly preparing large-area graphene foam/polymer fiber three-dimensional network composite foam film

InactiveCN103625085AHigh mechanical strengthImprove conductivitySynthetic resin layered productsGrapheneFiberPorosity

The invention relates to a method for quickly preparing a large-area graphene foam / polymer fiber three-dimensional network composite foam film. The method mainly comprises the processes of preparation of high-viscosity graphene oxide hydrosol, film formation by rolling, drying and reduction to finally obtain the large-area graphene foam / polymer fiber three-dimensional network composite foam film. The method has the technical effects that the graphene foam / polymer fiber three-dimensional network composite foam film which is controllable in thickness, large-area, high in mechanical strength, high in conductivity, light in weight and high in porosity and has certain elasticity is prepared. The composite film is similar to foam, is a self-supported flexible film, and can be bent and folded; the thickness of the composite film is 5 to 10 times that of a graphene oxide composite film prior to reduction; in the preparation process, expensive equipment and severe conditions are not needed; the composite film is easy to operate, low in cost, short in preparation period and simple in experiment condition, and industrial production can be realized.

Owner:XIANGTAN UNIV

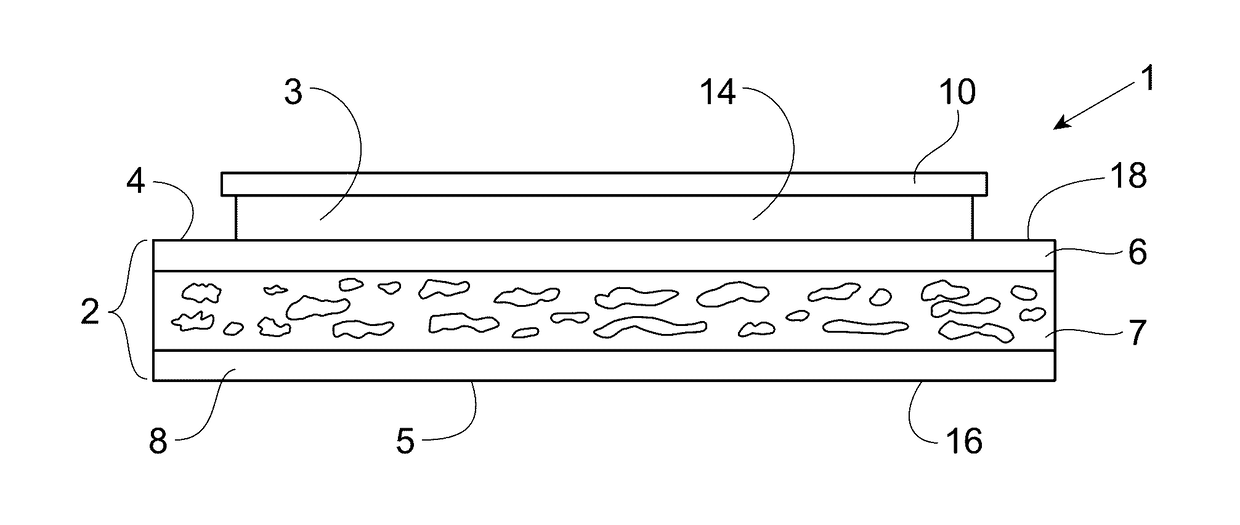

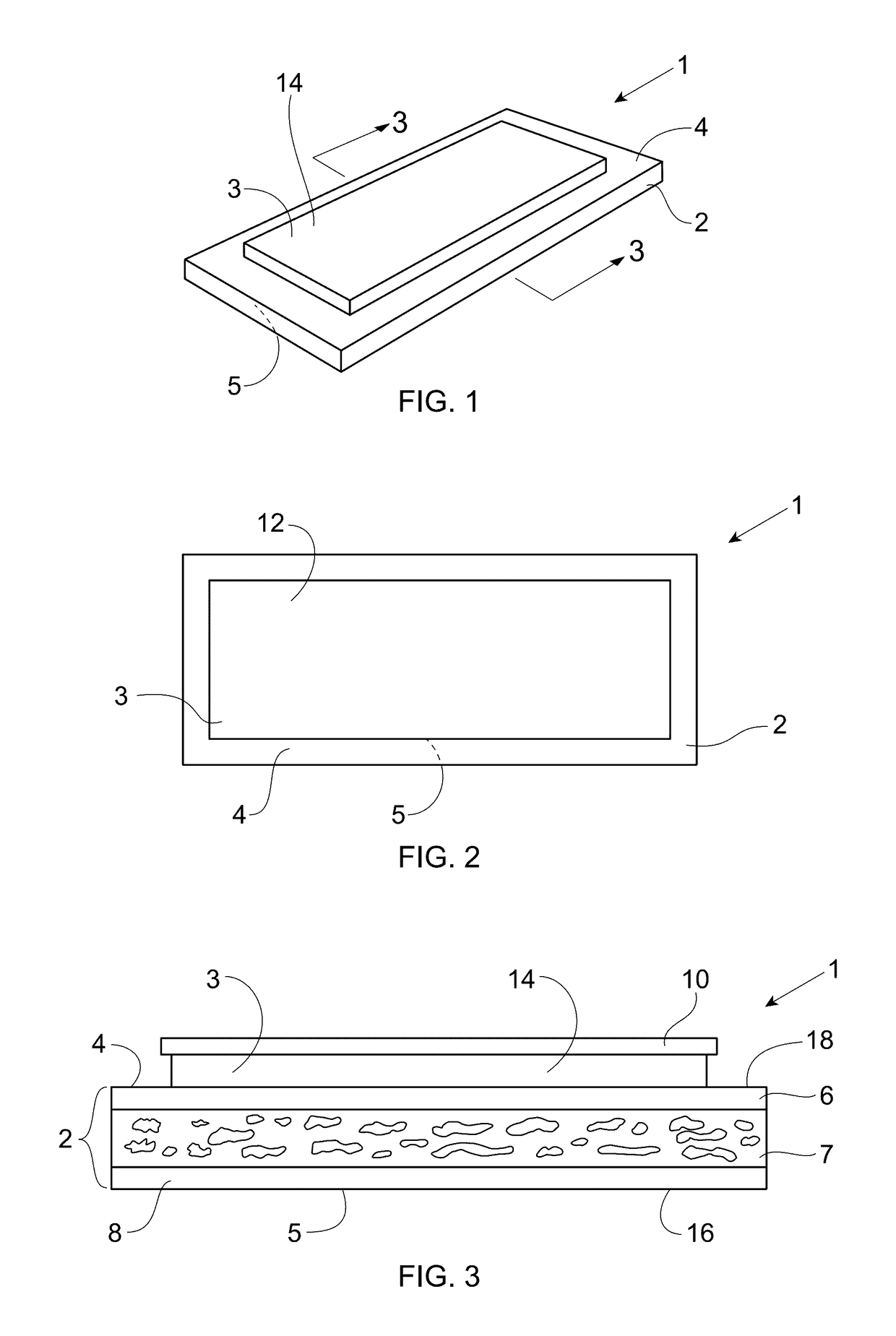

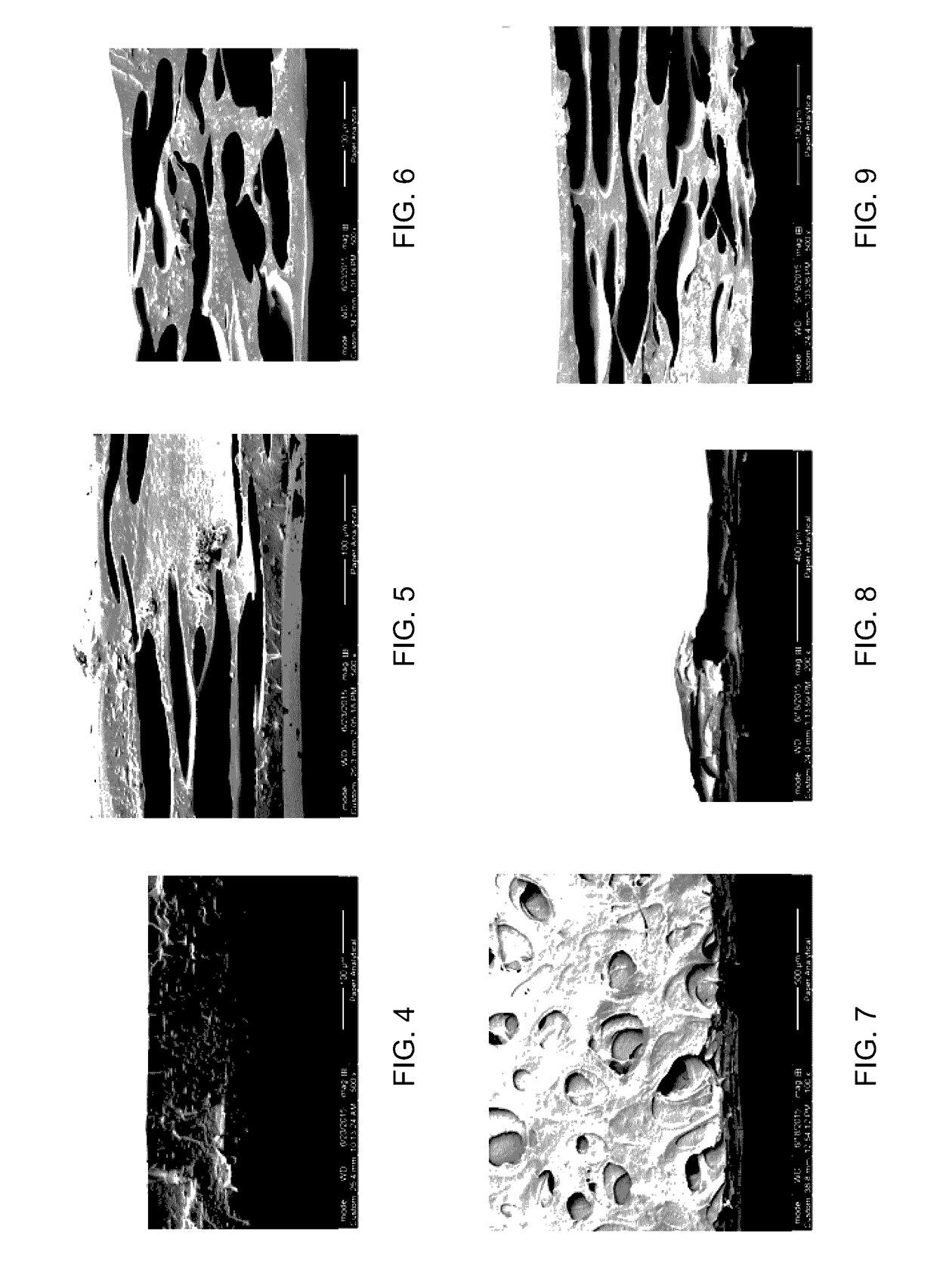

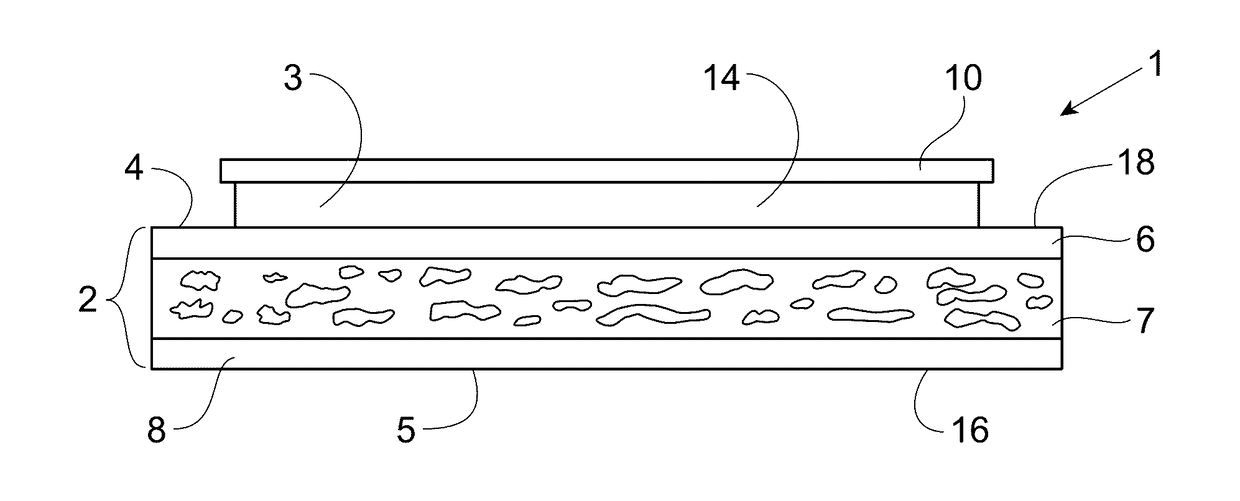

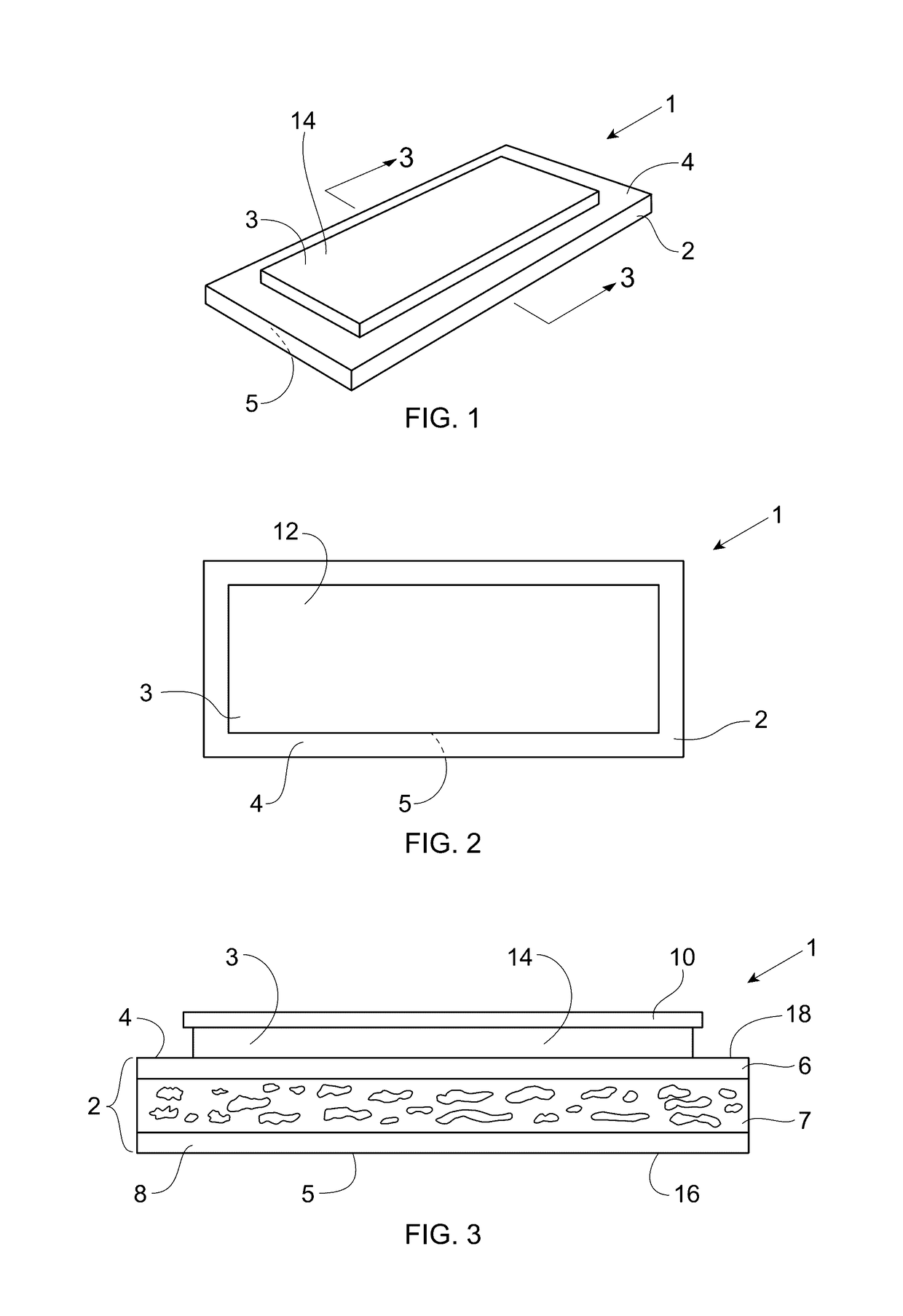

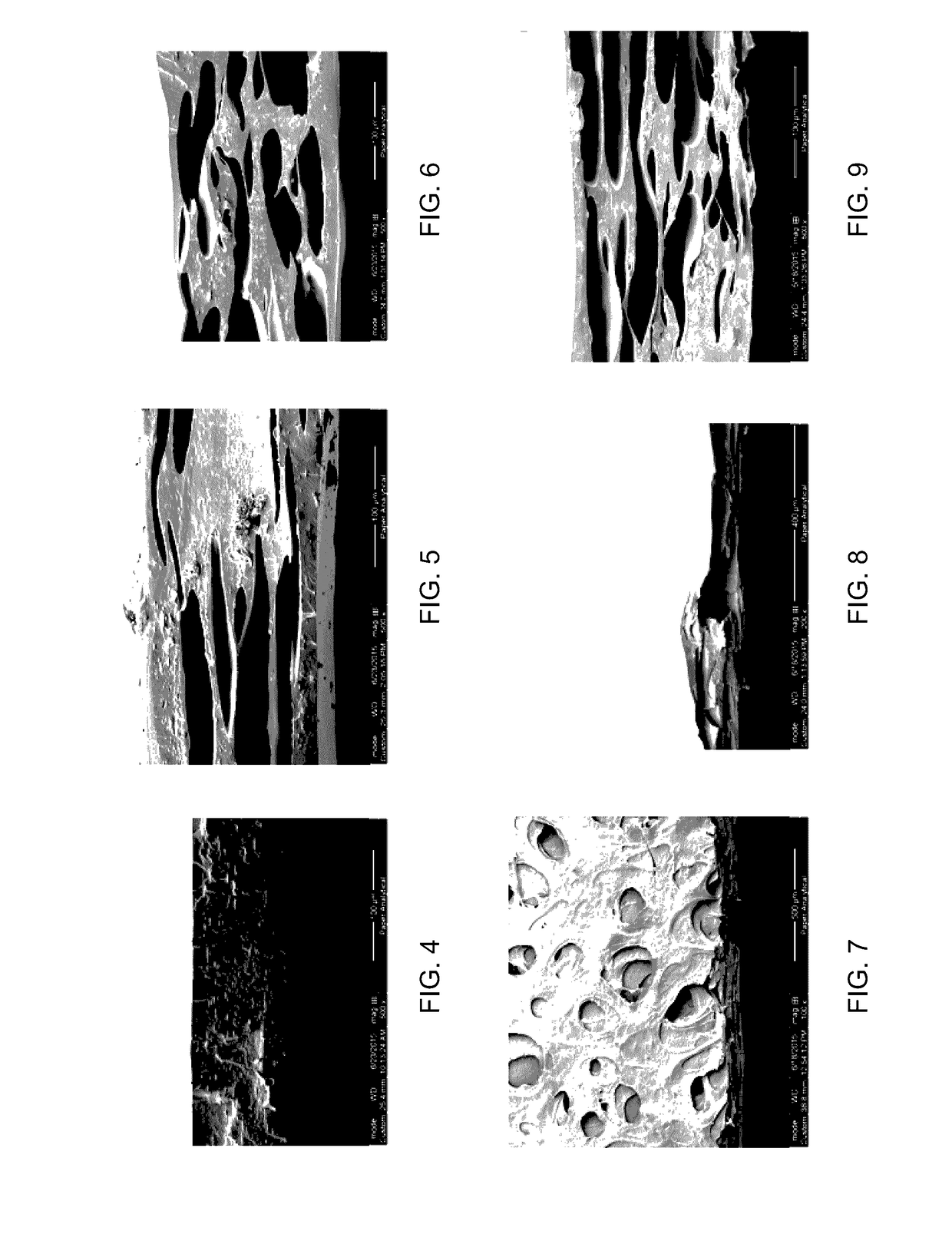

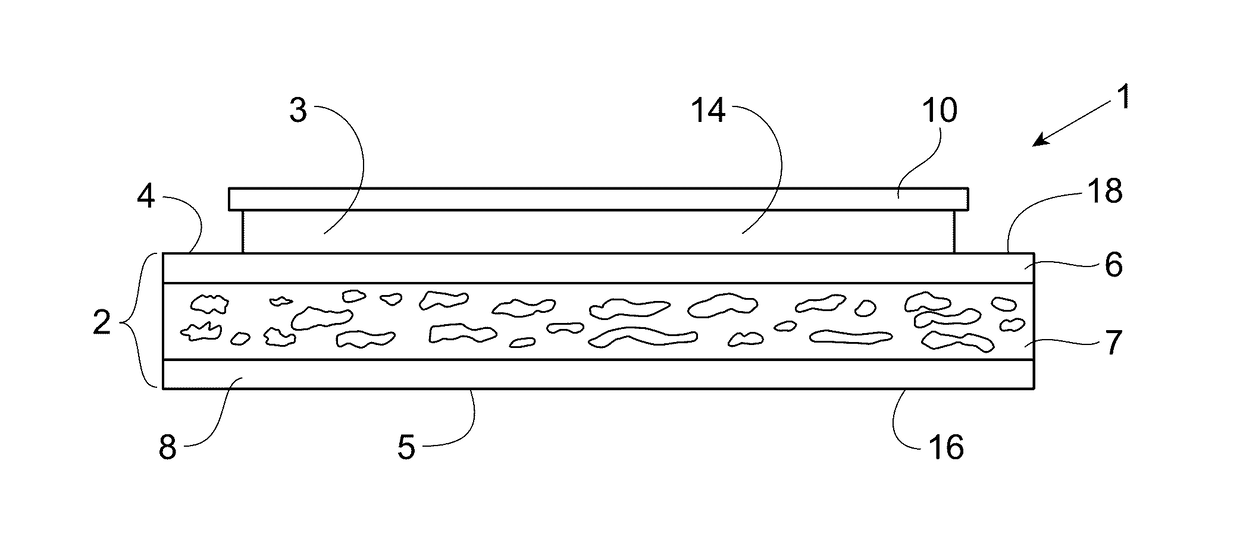

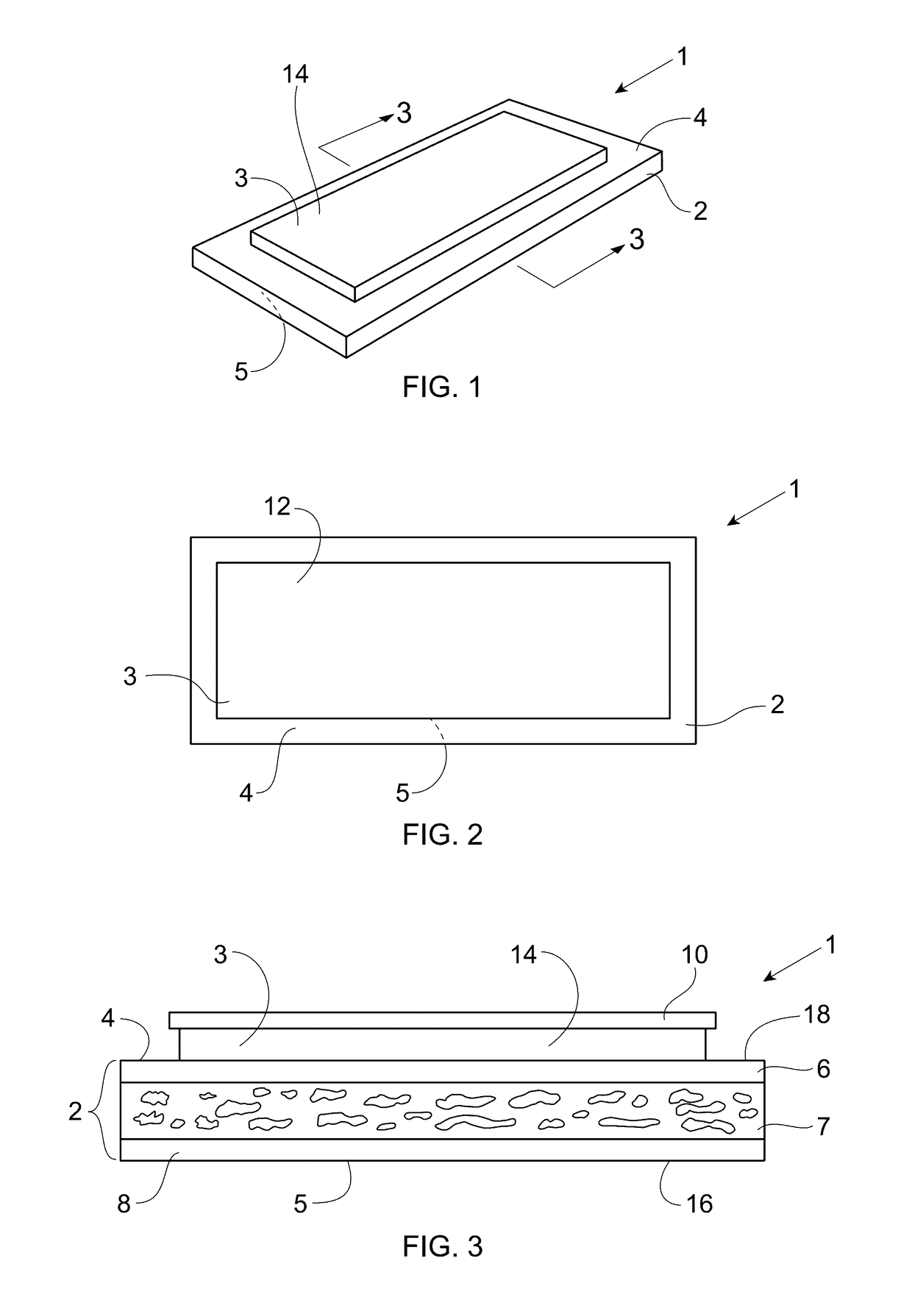

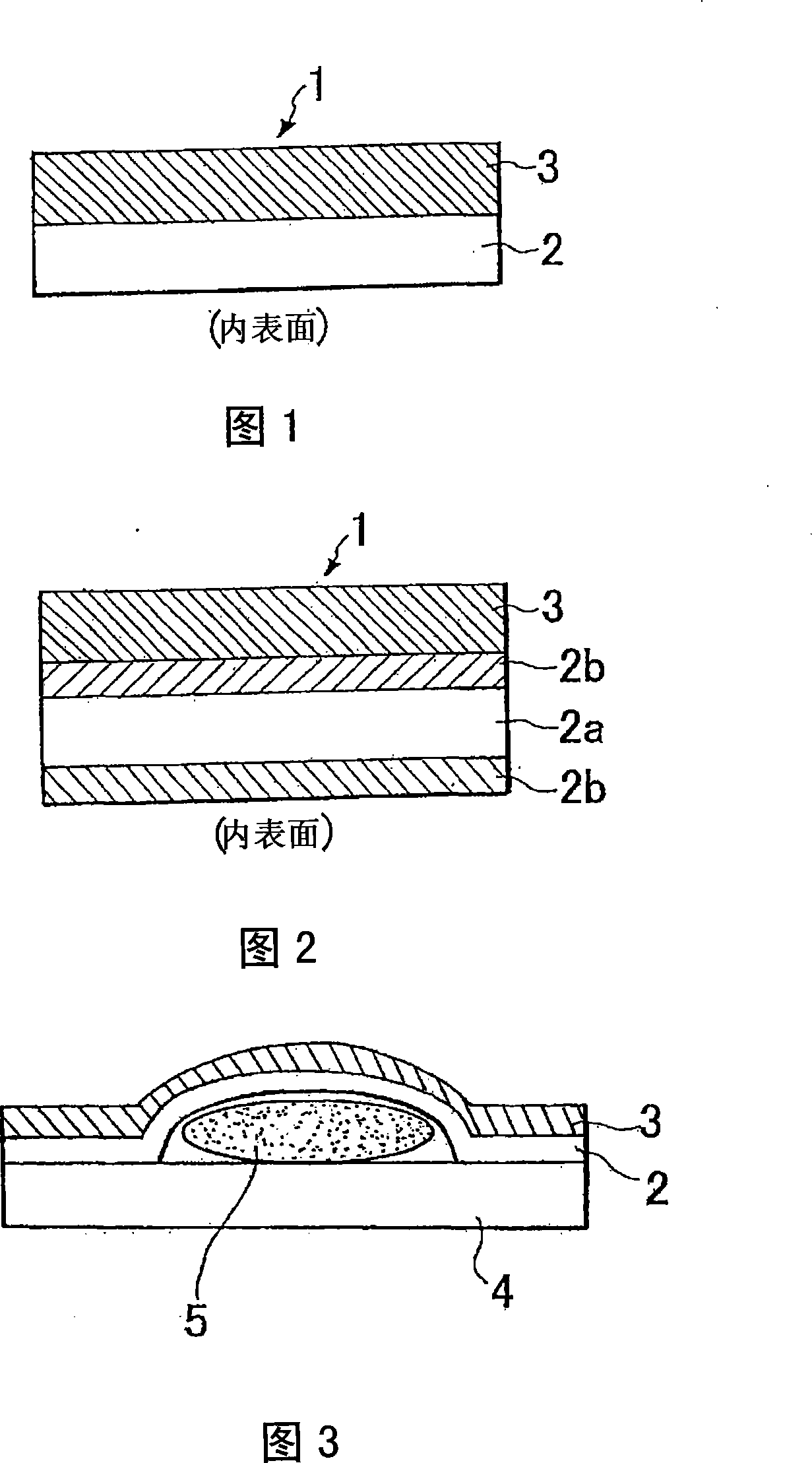

Barrier Patch of a Foamed Film and Methods of Improving Skin Appearance

A beauty care product is provided. The beauty care product has a multi-layered barrier patch with a non-foamed first layer and a foamed second layer. The non-foamed first layer has a non-foamed polymer film with a first surface and a thickness from 5 microns to 250 microns. The foamed second layer has a foamed polymer film comprising a Mean Void Volume Percentage from 45% to 80% and a thickness of from 10 microns to 250 microns. The beauty care product also has a cosmetic composition with an effective amount of a skin active agent and a pressure sensitive adhesive.

Owner:THE PROCTER & GAMBLE COMPANY

Barrier Patch of a Foamed Film and Methods of Improving Skin Appearance

A beauty care product is provided. The beauty care product has a multi-layered barrier patch with a non-foamed first layer and a foamed second layer. The non-foamed first layer has a non-foamed polymer film with a first surface and a thickness from 5 microns to 250 microns. The foamed second layer has a foamed polymer film comprising a Mean Void Volume Percentage from 45% to 80% and a thickness of from 10 microns to 250 microns. The beauty care product also has a cosmetic composition with an effective amount of a skin active agent and a pressure sensitive adhesive.

Owner:THE PROCTER & GAMBLE COMPANY

Heat-shrinkable foam films

InactiveUS20070026175A1Maintain good propertiesImprove rigidityClosuresClosure using stoppersMethacrylateMultilayer membrane

To provide a foamed film or multilayer foamed film excellent in heat insulating properties, a heat shrinkable foamed film or heat shrinkable multilayer foamed film made thereof, a heat shrinkable label, and a container covered therewith. A styrene foamed film characterized by having at least one foamed layer which contains a resin composition comprising from 20 to 100 parts by mass of the following (a) and from 0 to 80 parts by mass of the following (b) and which has a thickness of from 30 to 200 μm and a specific gravity of from 0.3 to 0.9: (a) a block copolymer wherein the ratio of a vinyl aromatic hydrocarbon to a conjugated diene is from 50 / 50 to 90 / 10, (b) at least one vinyl aromatic hydrocarbon polymer selected from the following (i) to (v): (i) a block copolymer of a vinyl aromatic hydrocarbon with a conjugated diene, (ii) a vinyl aromatic hydrocarbon polymer, (iii) a copolymer of a vinyl aromatic hydrocarbon with (meth)acrylic acid, (iv) a copolymer of a vinyl aromatic hydrocarbon with a (meth)acrylate, and (v) a rubber-modified styrene polymer.

Owner:DENKA CO LTD

Manufacturing method of graphite heat-conduction membrane

ActiveCN104495798AImprove yieldSmooth and soft surfaceCarbon compoundsHeat-exchange elementsPhysical chemistryThin membrane

The invention relates to a manufacturing method of a graphite heat-conduction membrane. The manufacturing method comprises the following steps of 1, carrying out plasma treatment on a polyimide film, 2, arranging the 3-50 polyimide films treated by the step 1 between two graphite papers, and carrying out heating treatment to obtain a crystalline carbon foam film and 3, carrying out rolling or lamination so that the crystalline carbon foam film is processed to form the graphite heat-conduction membrane with the smooth surface. Compared with the existing manufacturing method, the manufacturing method improves production power by 1-5 times and has a stable yield rate. The graphite heat-conduction membrane has the soft and smooth surface and has no adverse surface and a heat conduction coefficient more than 1800w / (m.k). The heat conduction coefficient of the graphite heat-conduction membrane is higher than the highest value of 1000w / (m.k) of the product shown in the Panasonic patent with an application number of CN1816504A.

Owner:SHUZHOU GU CARBON NEW MATERIAL

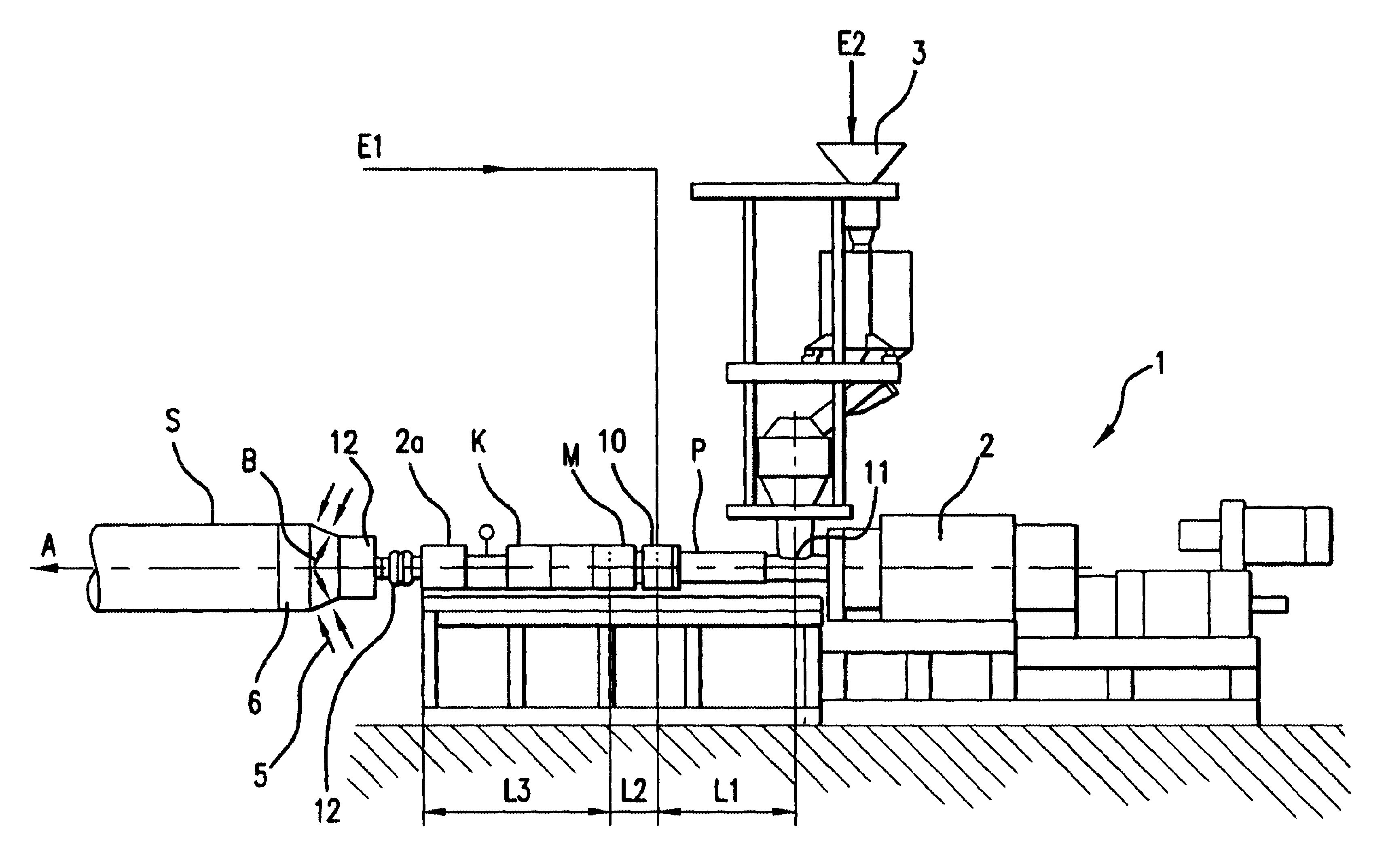

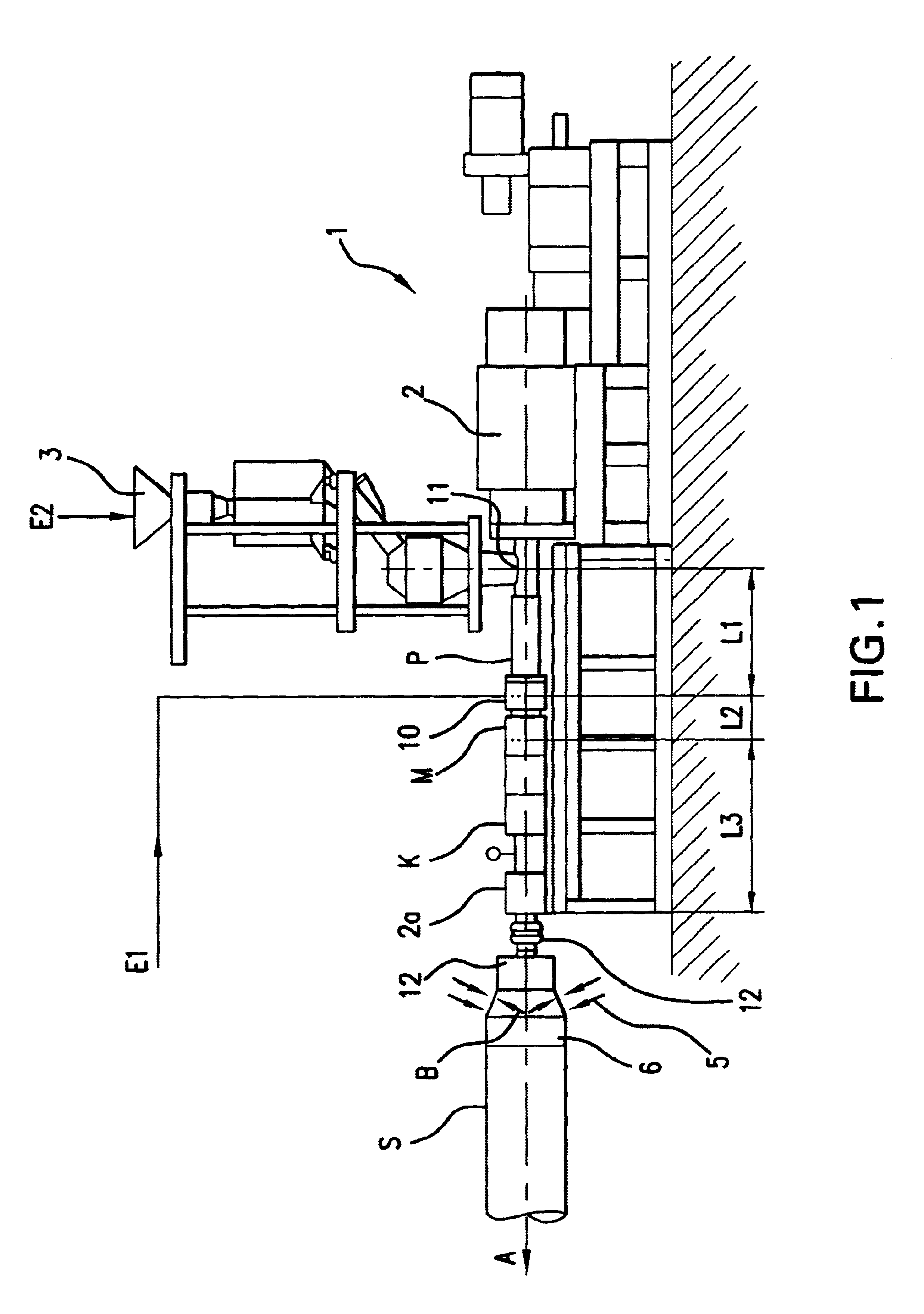

Method and device for producing at least partially open-celled foam films from styrene polymers

InactiveUS6666998B2Reduced strengthOpenness of the cellsSynthetic resin layered productsAbsorbent padsFoaming agentInvestment material

A method for producing an at least partially open-celled foam foil on a basis of styrene polymers, nucleating agents, surfactants, physical foaming agents and, if required, further additives, such as foreign polymers and auxiliary materials, comprising a twin-screw extruder with identical parallel screws rotating in the same direction, wherein the twin-screw extruder has a length of at least 25 D (D=screw diameter), in particular 30 to 42 D, with a draw-in and plastification zone of a length of 10 to 15 D, and a mixing zone of a length of 3 to 6 D, and a following cooling zone.

Owner:REIFENHAUSER GMBH & CO

Antistatic EPE foaming film

The invention relates to an antistatic EPE foaming film. The antistatic EPE foaming film comprises the following components: 90 to 95 portions of carriers, 0.5 to 2.0 portions of antistatic master batches, 1 to 3 portions of lubricant, 1 to 2 portions of auxiliary agent and colored master batches; the preparation process comprises the steps of mixing resin carriers, an antistatic agent, a colored pigment master batches, french chalk and distilled glycerin monostearate according to the formula dosage; extruding and plasticizing according to the conventional method; then conducting cooling and shaping on the film; conducting corona treatment and dry lamination after dissection; and compounding other base materials or films together after conducting rubber roll pressurization on the composite surface of the manufactured antistatic film, thereby preparing double-layered antistatic air cushion film with different functions. The antistatic EPE foaming film has low content of antistatic agent, no toxic material exists, and the manufactured product can be applied to the packages of products such as electronic elements.

Owner:昆山市金鑫塑料制品有限公司

Barrier Patch of a Foamed Film and Methods of Improving Skin Appearance

A beauty care product is provided. The beauty care product has a multi-layered barrier patch with a non-foamed first layer and a foamed second layer. The non-foamed first layer has a non-foamed polymer film with a first surface and a thickness from 5 microns to 250 microns. The foamed second layer has a foamed polymer film comprising a Mean Void Volume Percentage from 45% to 80% and a thickness of from 10 microns to 250 microns. The beauty care product also has a cosmetic composition with an effective amount of a skin active agent and a pressure sensitive adhesive.

Owner:THE PROCTER & GAMBLE COMPANY

Method for preparing graphite film with high heat conductivity

The invention relates to a method for preparing a graphite film with high heat conductivity. According to the method, a macromolecular film serves as a main raw material, surface groups of the film are activated through plasma treatment, then, a crystalline carbon foam film, of which the main component is carbon, is prepared through stepwise heating while factors, such as atmosphere and pressure, are controlled, and then the graphite film with high heat conductivity, which has soft and smooth surfaces and uniform thickness, is obtained through a rolling or laminating process. The graphite film prepared by using the method disclosed by the invention is uniform in thickness and high in heat conductivity.

Owner:SHUZHOU GU CARBON NEW MATERIAL

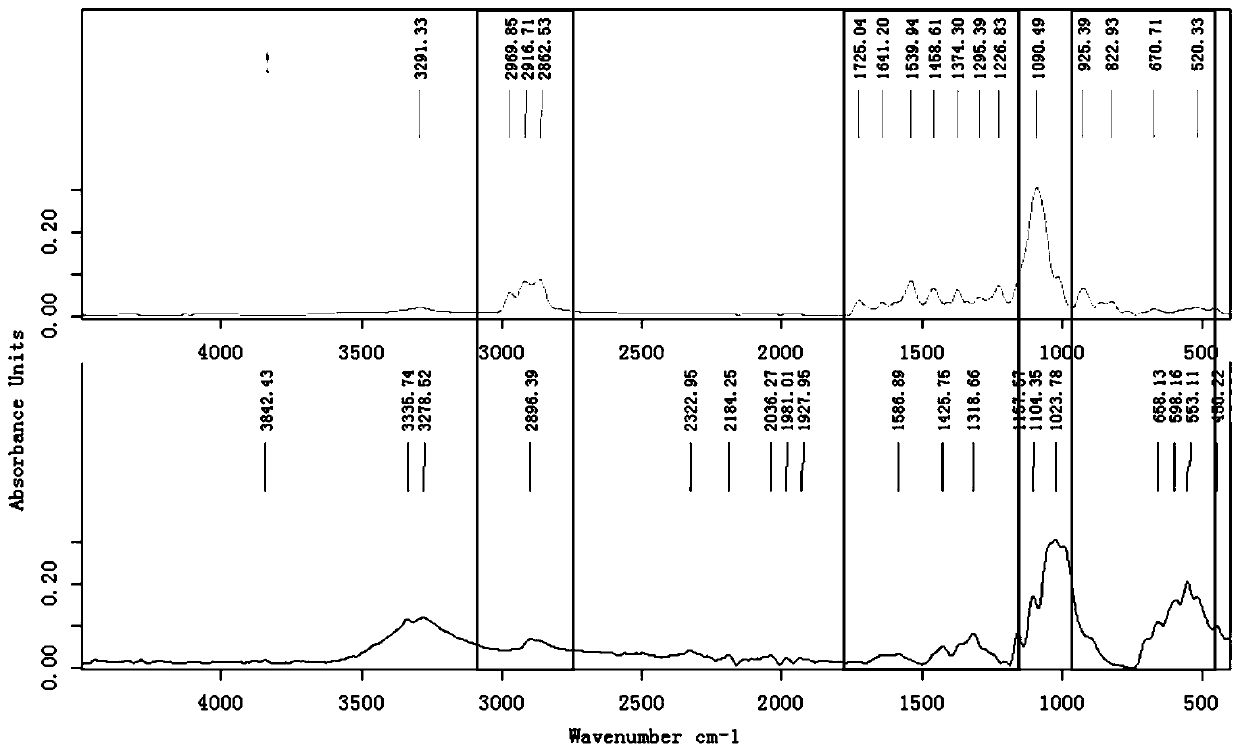

Composite high molecular surfactant, preparation method thereof and application of composite high molecular surfactant in foam coating process

ActiveCN104844729ABiocompatibleHas antibacterial propertiesVegetal fibresPolymer sciencePtru catalyst

The invention relates to a composite high molecular surfactant, a preparation method thereof and application of the composite high molecular surfactant in a foam coating process. Enabling chitosan, maleic acid and dimethyl 2, 3-trifluoropropenyl ammonium chloride to react at 90 DEG C to 110 DEG C under the action of a catalyst, the composite high molecular surfactant is formed. By compounding the composite high molecular surfactant and a micromolecule surfactant, and then adding a thickener and a three-proofing agent, a foam coating agent with good foaming performance, high solution viscosity, high foam film strength and good compactness is formed, and is applied to the foam coating process in the textile dyeing and finishing industry, the control on foam film thickness can be realized, and the liquid carrying quantity of foam is increased in a certain range, so that the thickness of a single-face coating is increased, the firmness of the coating is strengthened, and the problem that the single-face coating is not washable is solved.

Owner:SUZHOU TANGHUA NANO TECH

Graphene composite foam film and preparation method thereof

The invention discloses a graphene composite foam film. The graphene composite foamfilm comprises a graphene foam film and a high-molecular polymer, the graphene foam film is provided with pores, the high-molecular polymer is distributed in the pores and on the surface of the graphene foam film, and the graphene foam film accounts for 40-95 wt% of the total weight of the graphene composite foam film.

Owner:CHANGZHOU FUXI TECH CO LTD

Composite foam film and preparation method thereof

PendingCN110358136ALarge apertureGood conductive pathMagnetic/electric field screeningFreeze-dryingNanoparticles dispersion

The invention discloses a composite foam film and a preparation method thereof. Nano-particles are used as a filler, a polymer is used as a base material, the nano-particles are dispersed in a solution of the polymer, and then curing film formation and freeze-drying treatments are carried out to prepare the nano-particle / polymer composite foam film with a light, soft and porous structure and an electromagnetic shielding property. The addition of the nanoparticles increases the pore size of the composite foam film, improves the conductive pathway of the composite foam film and significantly improve the electrical conductivity and the electromagnetic shielding property of the composite foam. The composite foam film prepared in the invention has a great application scenario in the field of electromagnetic shielding.

Owner:WUHAN TEXTILE UNIV

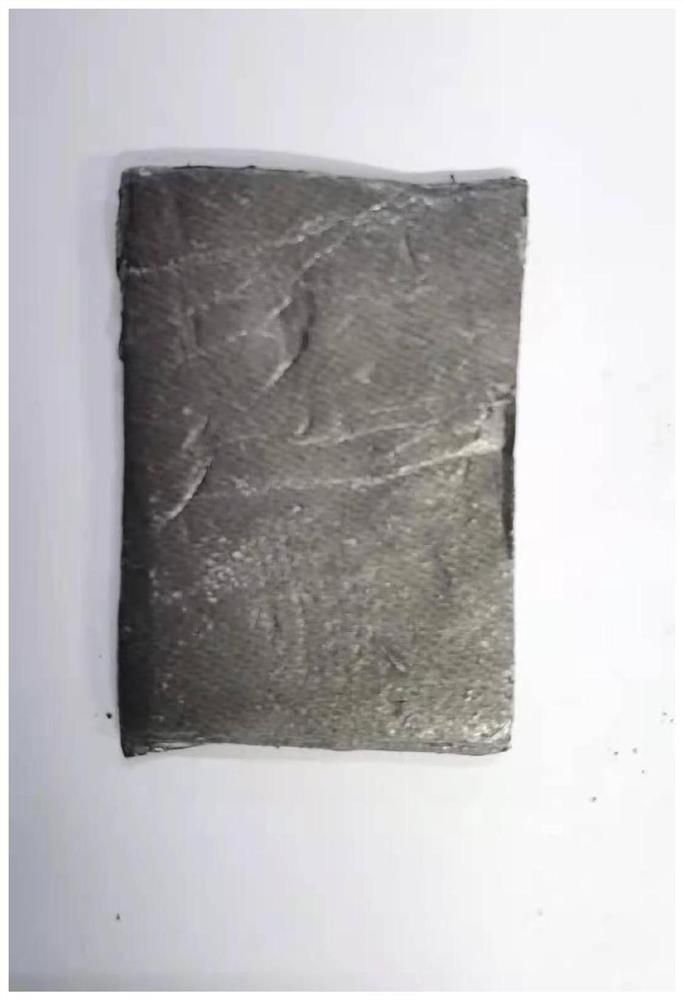

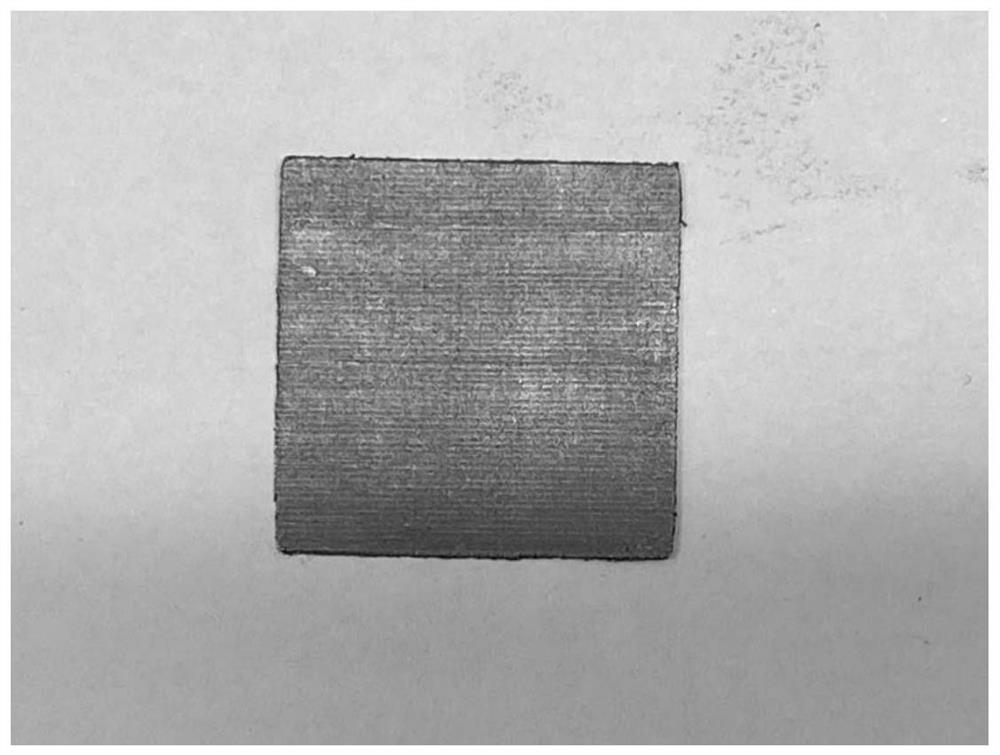

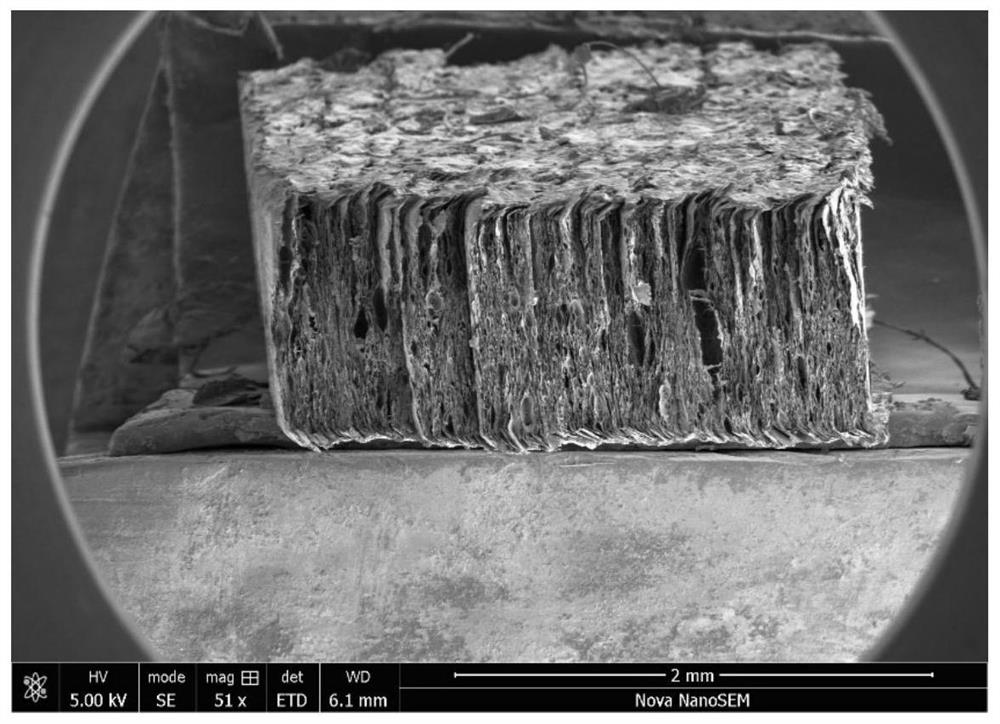

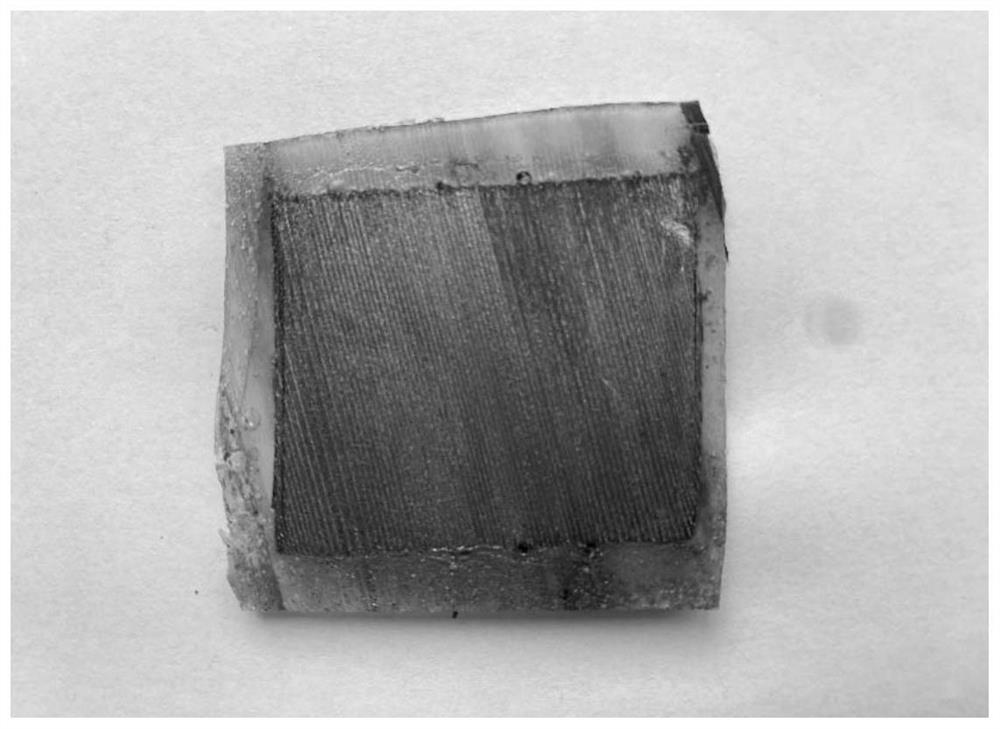

Graphene composite heat-conducting gasket and preparation method thereof

ActiveCN113510979AReduce gum contentImprove reliabilityLamination ancillary operationsLaminationPolymer scienceGraphite

The invention provides a graphene composite heat-conducting gasket which comprises a plurality of layers of graphene foam films arranged in the thickness direction and an adhesive, and the graphene foam films account for 50 wt.%-95 wt.%. The invention also provides a preparation method of the graphene composite heat-conducting gasket, wherein the preparation method comprises the steps: stacking the graphene foam films layer by layer and putting the graphene foam films into a mold, and applying pressure to tightly fit the films; uniformly coating the periphery of the graphene heat-conducting foam films subjected to pressure application with the adhesive, so as to completely coating a plurality of layers of graphene heat-conducting foam films into a block body; after the block body is cured and formed, cutting the block body into sheets along the stacking direction; dipping the cut sheets in dipping glue, taking out the sheets, and carrying out hot press molding on the taken-out sheets; and trimming the edge of the formed sheets, and removing an adhesive bonding area on the edge to obtain the graphene composite heat-conducting gasket. The heat-conducting gasket is low in density, high in heat conductivity in the thickness direction and low in heat resistance.

Owner:CHANGZHOU FUXI TECH CO LTD

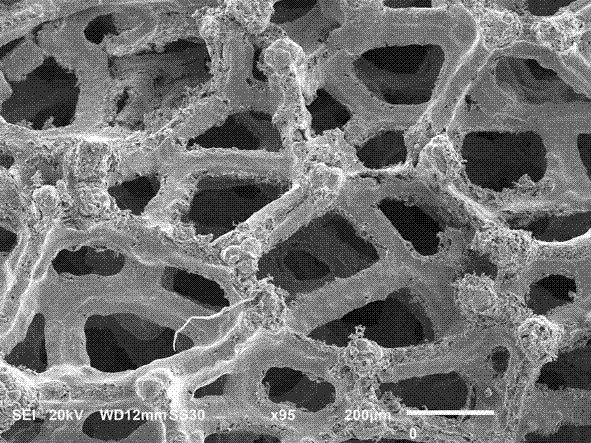

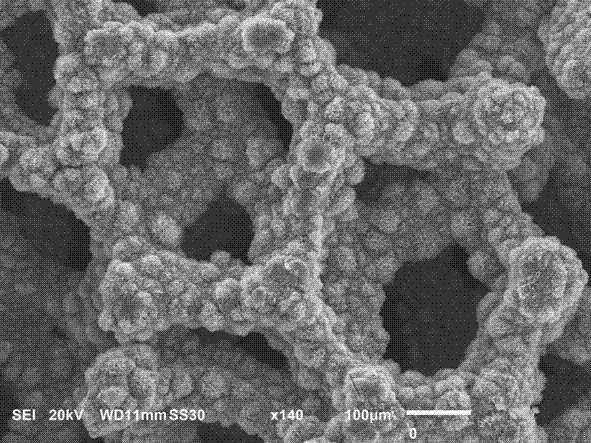

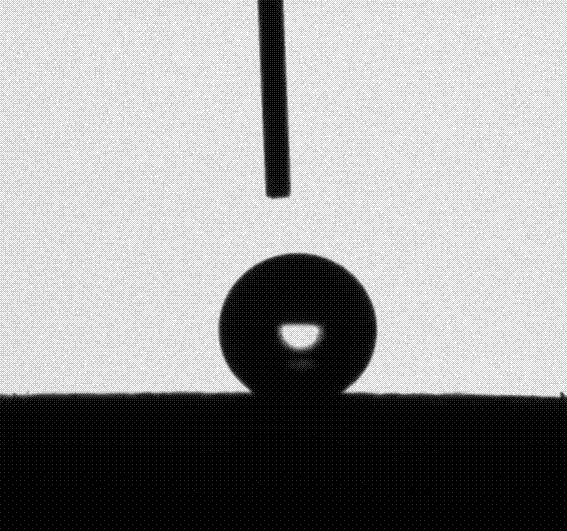

Preparation method for bionic super-hydrophobic film taking copper foam as substrate and application thereof

ActiveCN107497302AStrong intermolecular forcesWon't breakMembranesSemi-permeable membranesMicro nanoPhosphate

The invention belongs to the field of a composite material, relates to a copper foam film material and especially relates to a preparation method for a bionic super-hydrophobic film taking copper foam as a substrate and an application thereof. The method comprises the following steps: firstly, pre-treating the copper foam and removing surface impurities; soaking in an aqueous solution containing ammonium persulfate and phosphate, thereby forming a hierarchy structure on the surface thereof; modifying the surface with the hot steam of silane coupling agent aqueous solution, thereby acquiring the bionic super-hydrophobic film taking the copper foam as the substrate. The prepared hydrophobic film is subjected to bionic in-situ growth and chemical steam modification on the copper foam surface; the papillary micro-nano scale dual roughness is formed by the nanosheet on the surface; the prepared hydrophobic film can be used for separating oil from water; the acquired super-hydrophobic film inherits the advantages of developed pore structure, excellent mechanical properties, stable surface rough structure and hydrophobic property, high reusability and high operability of the copper foam; the soil-water separation efficiency is obviously increased; the continuous efficient soil-water separation is realized; the bionic super-hydrophobic film is an oil-water separating material with prospects.

Owner:JIANGSU SAFELY ENVIRONMENT ENG

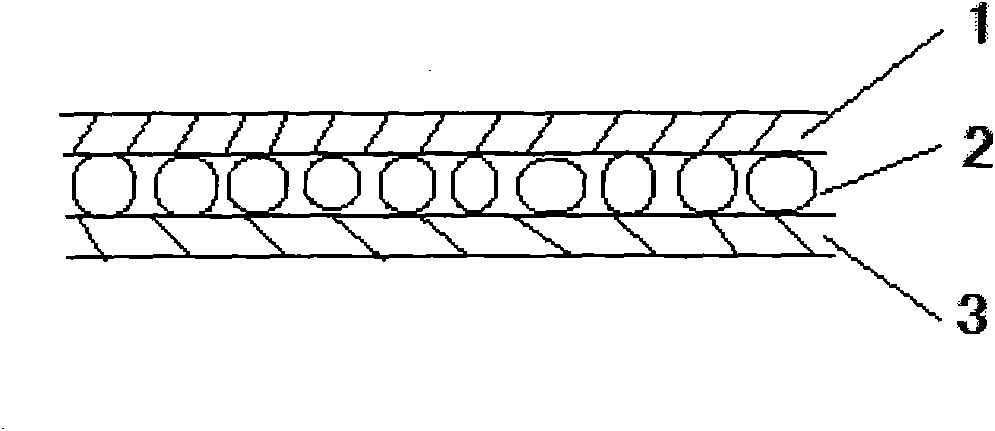

Kraft compounded double-layer air bubble film

The invention relates to a kraft compounded double-layer air bubble film, which comprises a kraft layer, a foaming film layer, and a film layer. The double-layer air bubble film effectively combines the conventional kraft and an air bubble film; the air bubble film provides the cushion function; and the whole packaging material has the effects of facilitating writing on the surface of an outer layer, being printed with various patterns and added with easy open strips on the surface of the outer layer, resisting shock and water, and preventing dampness. The weight of the packaging material is nearly not increased, the surface of the air bubble film with protruding bubbles is provided with a layer of plastic film to increase stressed areas of the bubbles so as to overcome a defect that a single air bag is easy to break after the surface of the prior air bubble film is stressed is over.

Owner:昆山市金鑫塑料制品有限公司

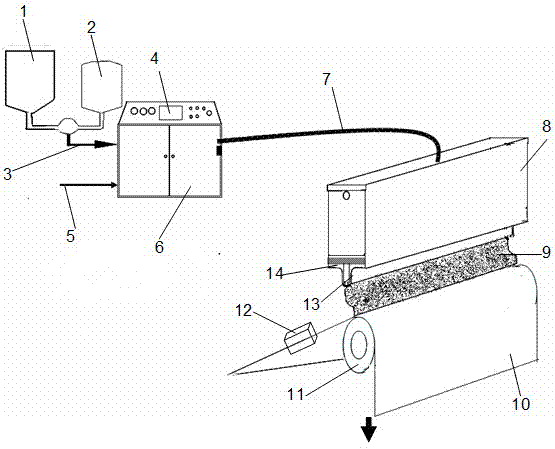

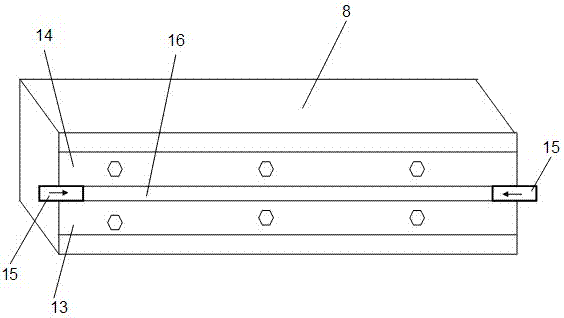

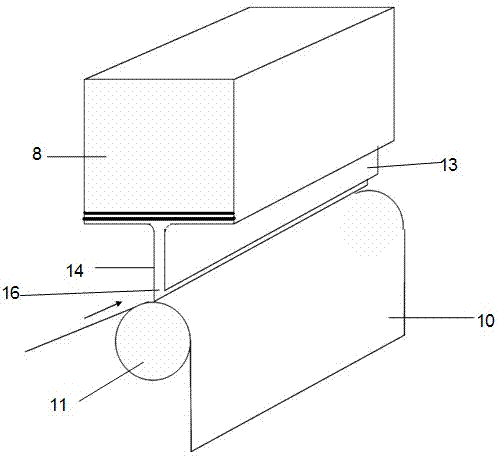

Method for applying foam chemical by extruding foam film through flow paving

ActiveCN102409496AReduce dosageIncrease profitFibre treatmentLiquid/gas/vapor textile treatmentFoam filmMaterials science

The invention provides a method for applying a foam chemical by extruding a foam film through flow paving. The method is characterized by comprising the following steps: forming chemical foams by virtue of a foam generating device, applying the chemical foams on a fabric, and breaking the chemical foams to transfer the chemical onto the fabric. The method for applying the chemical foams on the fabric is as follws: the chemical foams pass through slit type foam extrusion devices which are distributed transversely and evenly to form the foam film and are applied on the fabric through flow paving or on a rotating guide roller to be transferred onto the fabric. Therefore, the water consumption is reduced and the traditional process is optimized.

Owner:上海虹馨管理咨询有限公司

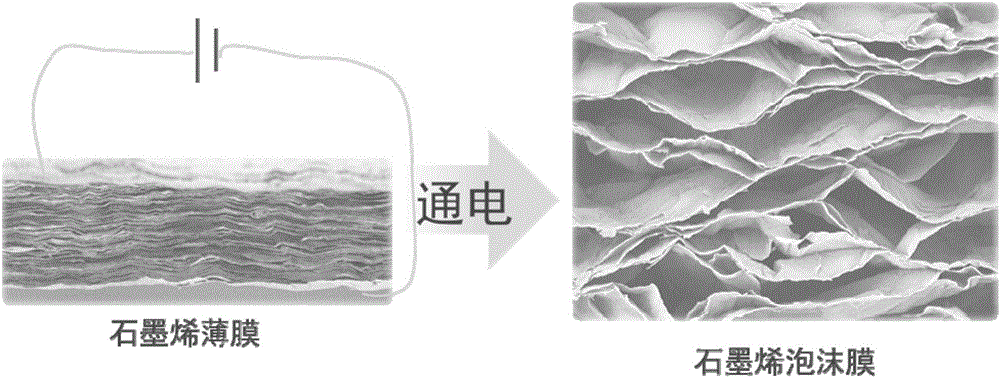

Graphene foam film, and preparation and application thereof

The invention relates to a graphene foam film, and preparation and application thereof. The graphene foam film has a continuous rhombic three-dimensional porous structure. The graphene foam film is prepared by applying direct current to both ends of an obtained graphene film. The application refers to application of the graphene foam film in the aspects of energy storage, flexible electronic sensors, smart clothing, electromagnetic shielding prevention cover layers, heat insulation and noise prevention. According to the invention, the preparation method is simple; the graphene foam film can be quickly prepared at low direct current voltage; large-scale low-cost production can be easily implemented; the cross section of the obtained graphene foam film forms a continuous three-dimensional porous structure; and the graphene foam film has favorable mechanical property, low density, excellent electric conductivity and other properties, and has important practical values in the fields of flexible energy storage, sensing and the like.

Owner:DONGHUA UNIV

Production process of prefabricated concrete wallboard containing rough surface

The invention discloses a production process of a prefabricated concrete wallboard containing a rough surface. The production process of the prefabricated concrete wallboard containing the rough surface comprises the steps of cleaning die table, pasting double-sided glue, cutting foam film, laying and pasting foam film, assembling die, spraying release agent, binding steel bar, fixing pre-embeddedparts, checking and accepting, pouring concrete, maintaining member, removing die, cleaning rough surface and stacking member. When the rough surface of the prefabricated wallboard is manufactured, water washing is not required, the surface of the die is not required to be cleaned, only a foam film is required to be removed, the time is shortened, and the labor is saved.

Owner:龙信集团江苏建筑产业有限公司

Film for PTP or blister pack, and packaging container for PTP or blister pack

The present invention provides a PTP or film for foam packaging in which the heat shrinkage ratios of the outermost barrier layer and the moisture absorption layer containing a desiccant are approximately equal, which is a PTP laminated with an adsorption layer and an outermost barrier layer The film for foaming is characterized in that the adsorption layer has at least one adsorbent selected from the group consisting of physical adsorbents and chemical adsorbents.

Owner:DAIICHI SANKYO CO LTD +1

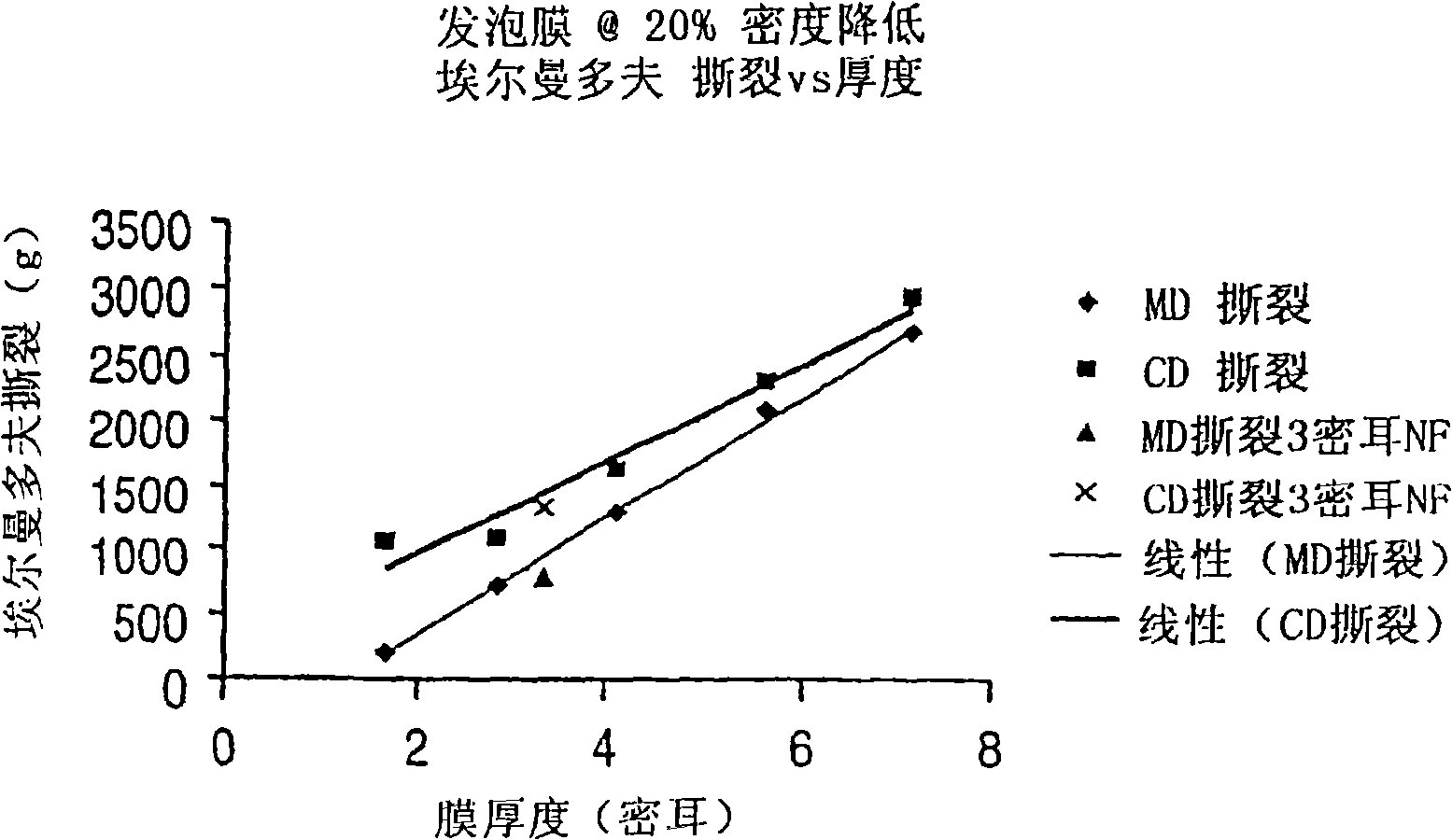

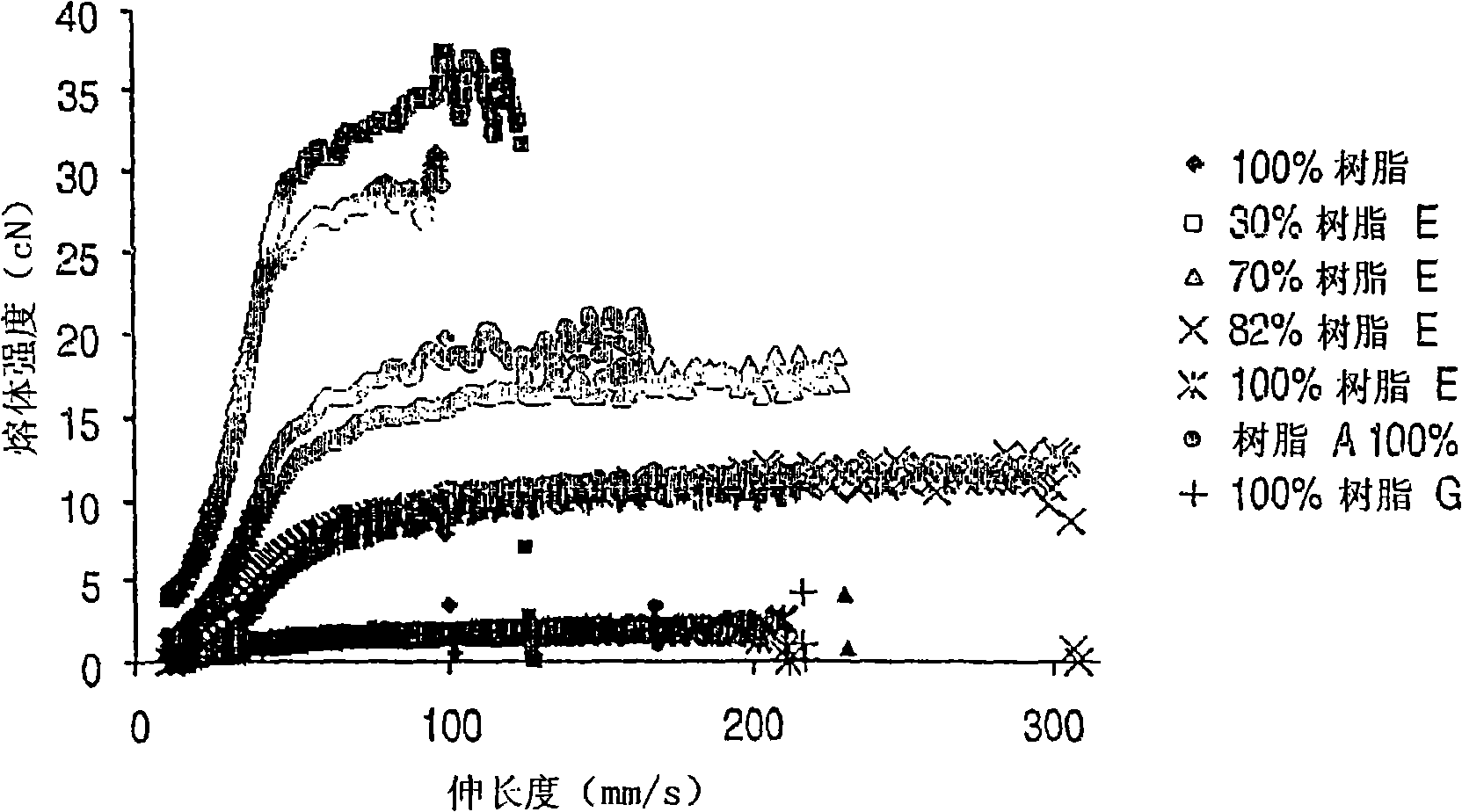

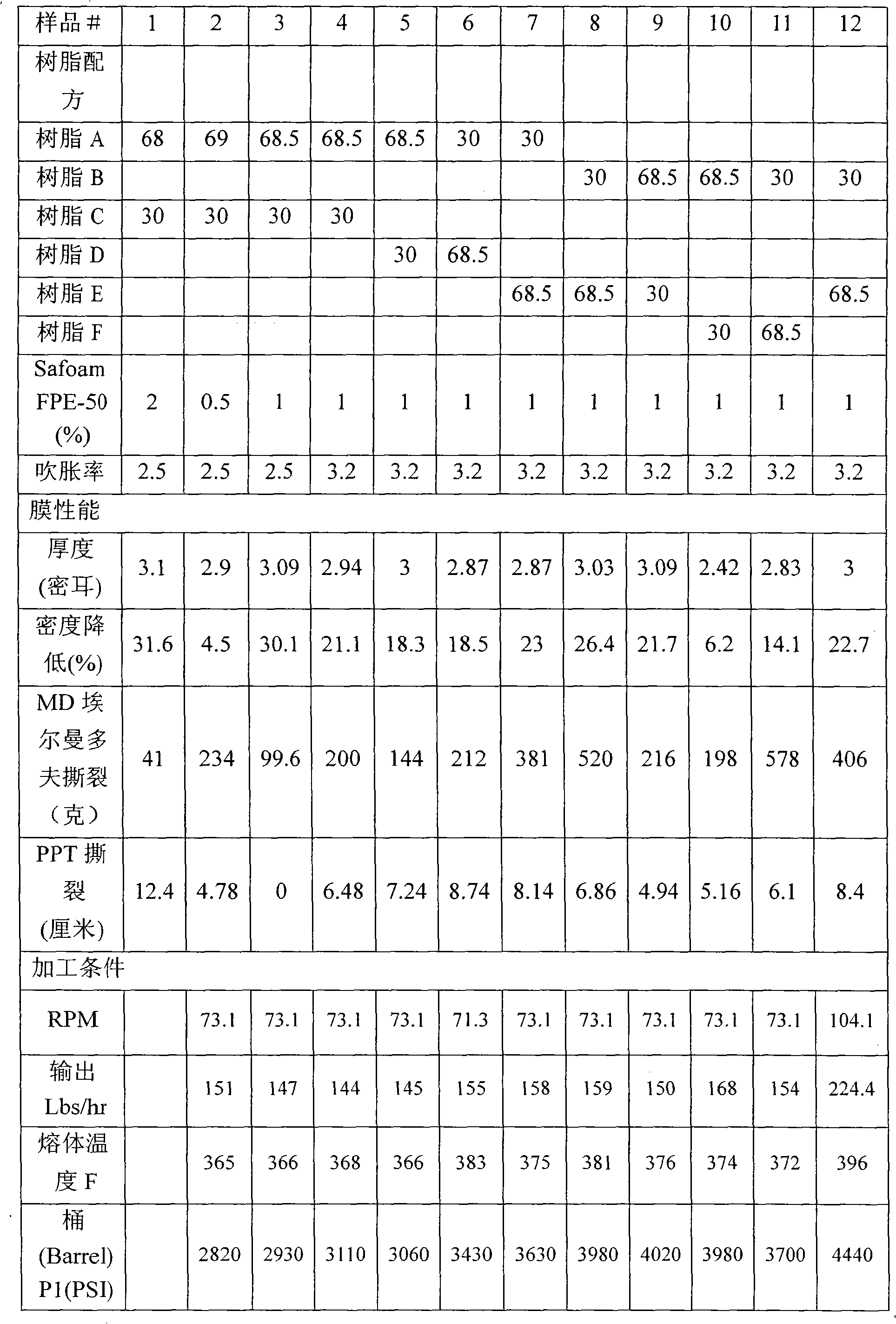

Thin foamed polyethylene sheets and manufacture method thereof

ActiveCN101323676AReduce adhesionImprove buffering effectThin material handlingExtensibilityPolymer science

The present invention relates to the use of particular blends of LLDPE and LDPE together with specific fabrication conditions to make foamed sheets of thin gauge with MD tear properties similar to an equivalent gauge non-foamed sheet of the same composition. In particular, blends which combine a high MI LLDPE rich fraction with a low MI branched LDPE minor fraction provide the adequate balance ofmechanical strength of the polymer base with its melt strength, extensibility and stress relaxation, allowing a thin foam film with MD tear strength which is comparable to non foamed counterparts of similar gauge and composition. The foamed films of the present invention are thin (generally from about I to 10 mils thick), and have an MD tear strength of at least about 160 grams for a 3 mil film as measured by ASTM D 1922. The foamed films of the present invention are preferably made at least in part from blends which comprise from 10 to 95 percent by weight of LLDPE having a relatively high (1.5 to 6) MI and from 5 to 90 percent of an LDPE resin having a relatively low MI (0.5 to 2.0).

Owner:DOW GLOBAL TECH LLC

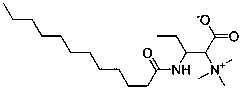

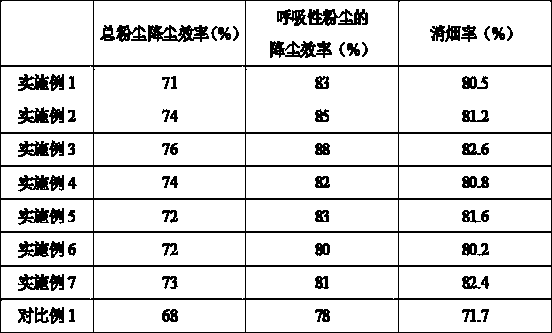

Dust and smoke suppressor for mines

InactiveCN107502294AEasy to getReduce surface tensionOther chemical processesDust removalBetaineAlkylphenol

The invention relates to a dust and smoke suppressor for mines. The dust and smoke suppressor is prepared from the following raw materials in parts by weight: 15-25 parts of alkylphenol ethoxylates, 15-25 parts of alpha-olefin sulfonate, 15-25 parts of alkyl amide propyl betaine, 0.5-1 part of calcium chloride, 0.5-1 part of calcium glycinate, 0.05-0.1 part of 2-methyl sodium isocitrate, 1-5 parts of sodium polyglutamate, 1-5 parts of 1,2-propylene glycol and 100 parts of water. A surface active agent used by the dust and smoke suppressor for the mines and the compound product of the surface active agent are free from toxicity, easily soluble in water and easy to obtain, so that the dust and smoke suppressor is relatively cheap and economical; the dust and smoke suppressor for the mines has lower surface tension, can produce a foam film with certain viscosity and elasticity, and can avoid secondary pollution.

Owner:ANSTEEL GRP MINING CO LTD

Process for producing thermoplastic resin foam film and thermoplastic resin foam film

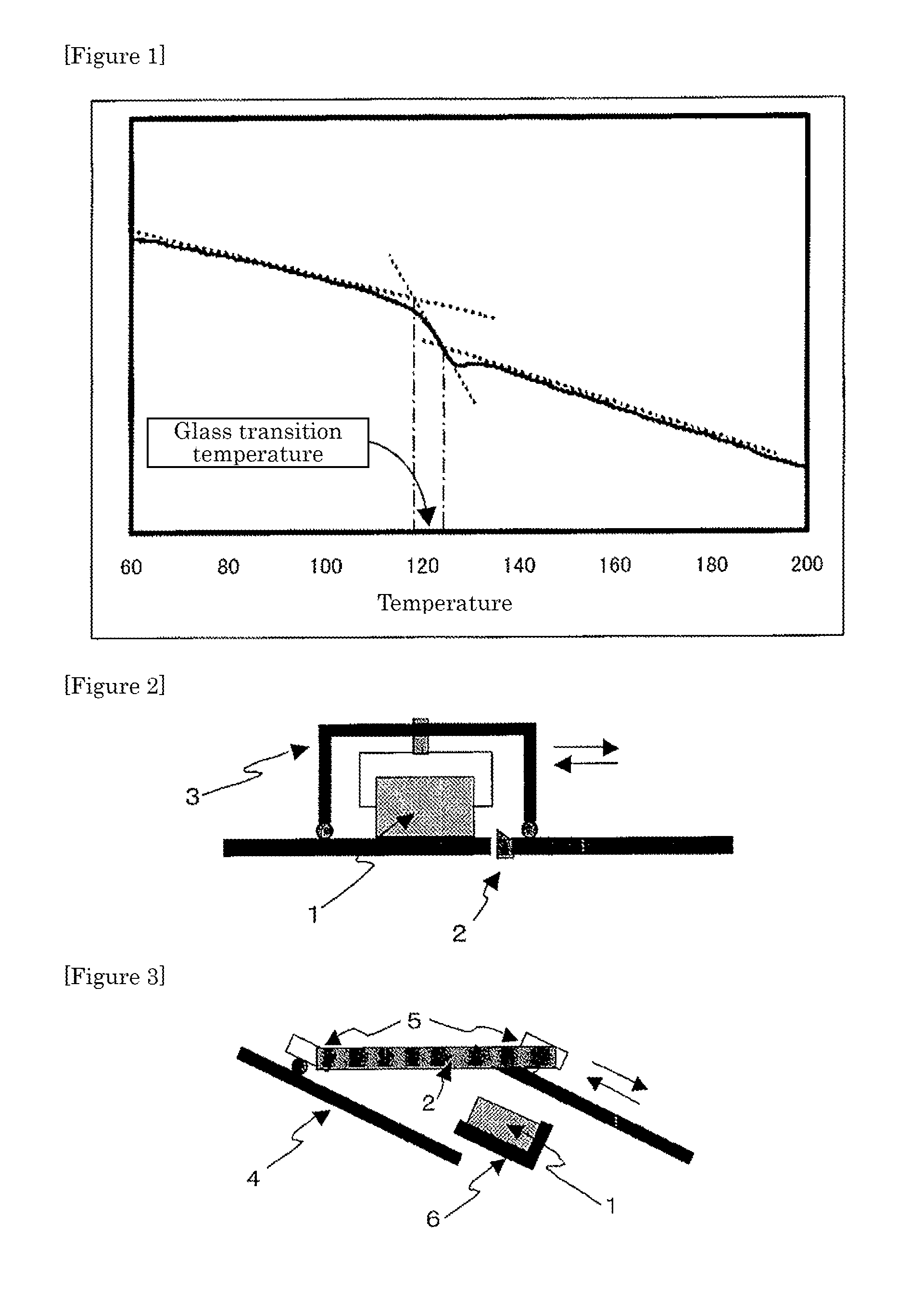

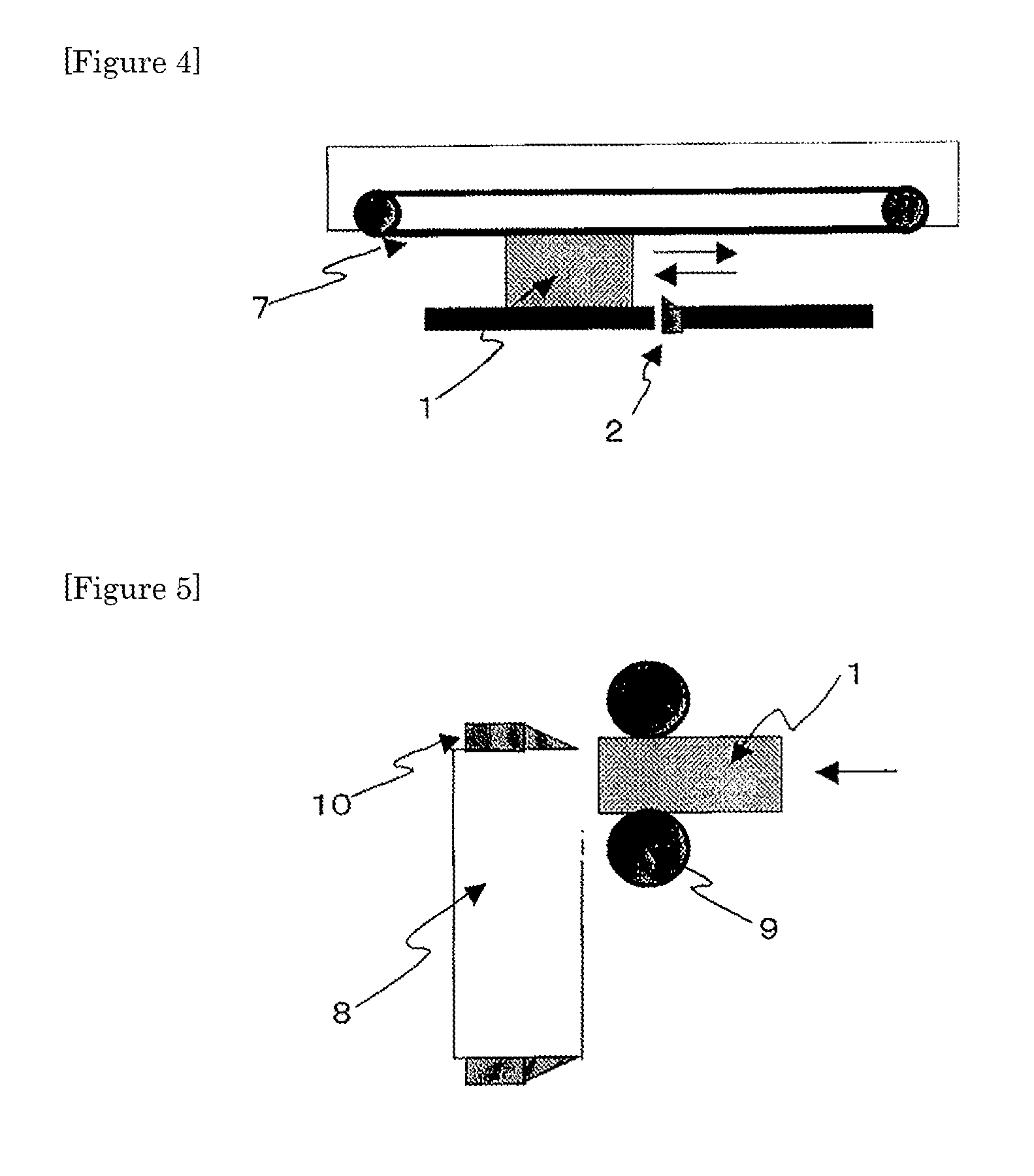

InactiveUS20110200813A1High thickness accuracyLight weightSynthetic resin layered productsMetal working apparatusThermoplasticFoam film

Disclosed is a process for producing a thermoplastic resin foam film that can produce a thin thermoplastic resin foam film. The process comprises the step of cutting a thermoplastic resin foam. The process is characterized in that, in the step of cutting the thermoplastic resin foam, at least one of the thermoplastic resin foam and a blade is reciprocated, and, when at least one of the thermoplastic resin foam and the blade is reciprocated, and the thermoplastic resin foam and the blade are slid in the movement of the foam or the blade on at least one of the advancement path and the return path of the reciprocation movement, whereby the thermoplastic resin foam is intermittently cut.

Owner:KANEKA CORP

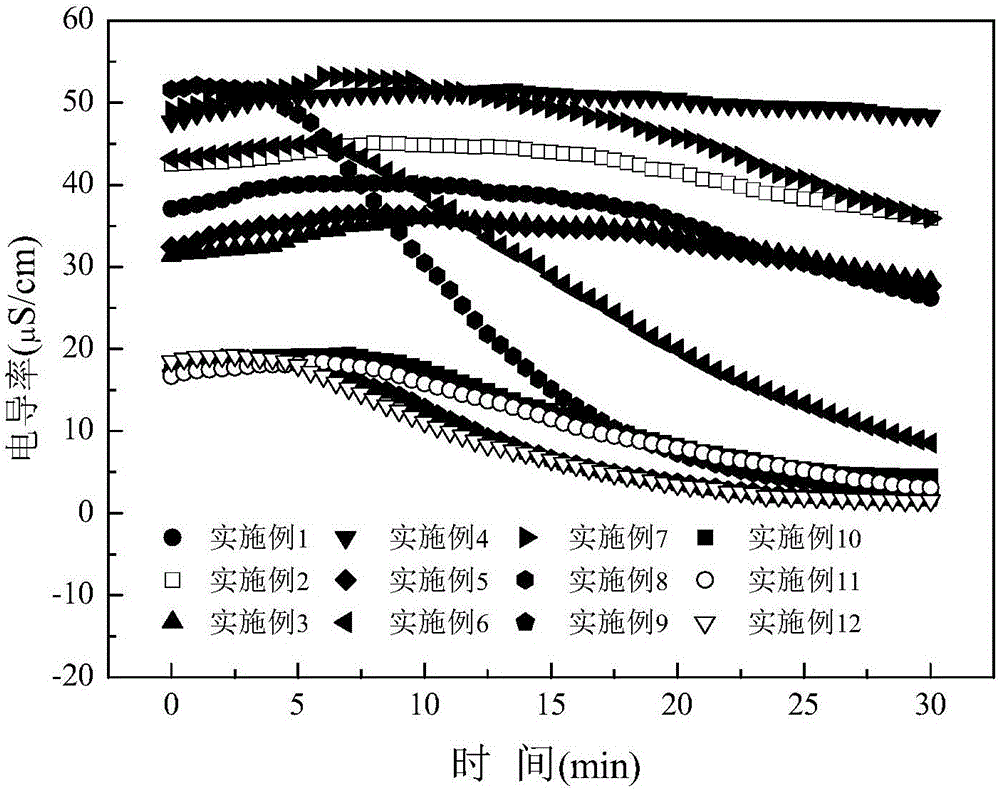

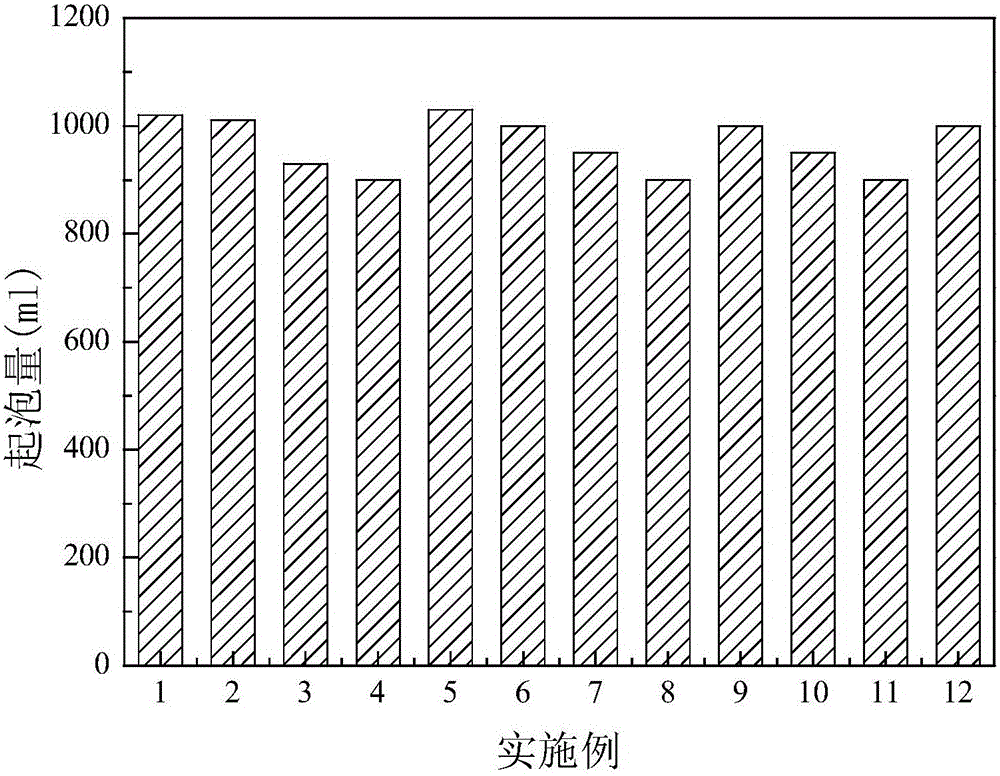

Composite protein surfactant foaming agent

ActiveCN105819726AFoamingWith foam stabilizing propertiesSodium Lauryl SarcosinateCocamidopropyl dimethylamine

The invention discloses a composite protein surfactant foaming agent. The foaming agent is prepared by mixing an anionic surfactant or an ampholytic surfactant with a protein anionic surfactant according to the mass ratio of 1:(0.5-3), wherein sodium caseinate is adopted as the protein anionic surfactant, lauryl sodium sulfate or lauryl sodium glycinate or sodium lauryl sarcosinate is adopted as the anionic surfactant, and lauramidopropylamine oxide or cocamidopropyl dimethylamine oxide is adopted as the ampholytic surfactant. According to the composite protein surfactant foaming agent, through the synergistic effect among the different types of surfactants, the surface tension of the system solution is reduced, the water carrying capacity of a film is improved, the thickness of the foam film is increased, and therefore the foam strength is improved. The foaming agent has the advantages that few components are contained, the using amount is little, no other auxiliary needs to be added, foaming is rapid, the foaming amount is large, the stability is very good, and the compatibility with concrete grout is good.

Owner:SHAANXI NORMAL UNIV

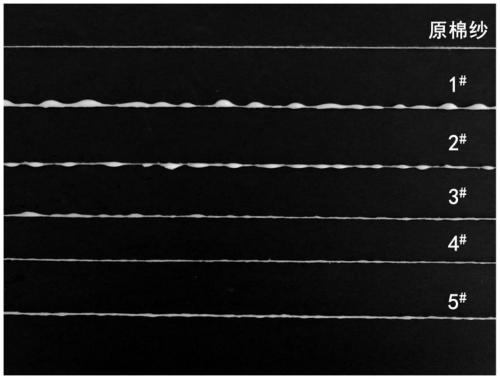

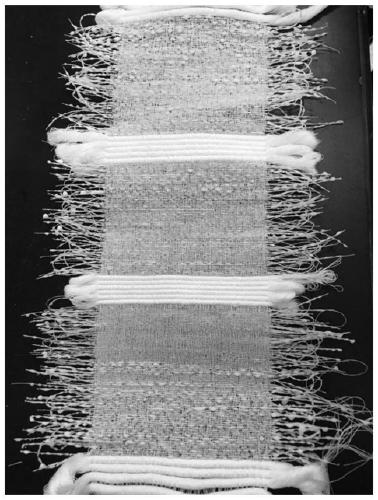

Preparation method for foamed yarns

ActiveCN110219177AUnique appearanceImprove plasticityVegetal fibresLiquid/gas/vapor yarns/filaments treatmentYarnPolymer science

The invention discloses a preparation method for foamed yarns. The preparation method includes preparation of a main material, preparation of an auxiliary agent, padding treatment and preparation of the foamed yarns. The preparation method has the advantages that polyether polyol, isocyanate and a tin catalyst are mixed to obtain the main material, a mixed solution of the polyether polyol, an amine catalyst, a foaming agent and a foam stabilizer is used as the auxiliary agent, an in-situ polymerization method is applied, the raw materials required for reaction are respectively padded on two yarns, solution mixing is simulated through twisting, uniform and compact polyurethane foam is formed by the yarns from inside to outside, the adhesion of a foam film layer is improved, and accordingly,the foamed yarns with unique appearances are obtained; different base materials can be prepared into fabrics with different shapes according to needs, and accordingly, the plasticity is high; the preparation method is simple, the consumed time is short, the equipment requirements are low, and wide application can be realized.

Owner:WUHAN TEXTILE UNIV

Preparation method of thermoplastic polyurethane foam leather

InactiveCN106739319AAvoid densityAvoid the defects of large cellsSynthetic resin layered productsLaminationHigh densityThermoplastic polyurethane

The invention discloses a preparation method of thermoplastic polyurethane foam leather. The method comprises steps as follows: 1) performing dry mixing on TPU resin, a chain extender, a gas barrier, a compatilizer and a nucleating agent; 2) adding a mixture to a barrel of an extruder, heating the mixture by the extruder to obtain TPU melt, injecting supercritical N2 into the TPU melt at the speed of 1-30 ml / min, uniformly mixing the TPU melt and the supercritical N2, gradually decreasing the temperature of the melt to 155 DEG C by a heat exchanger after mixing, and extruding the mixed melt through a slit die to obtain an expanded TPU film, wherein the temperature of the die of the extruder in the extrusion process is 140-160 DEG C and the pressure of the die of the extruder is 5-25 MPa; 3) performing drawing thinning on the TPU film by an uniaxial drawing device at the temperature of 130-160 DEG C for less than 15 s to prepare a TPU foam film, and attaching the TPU foam film to cloth at the high temperature to obtain TPU foam leather. With the adoption of the method, the defects that the TPU foam film in the TPU foam leather has higher density and larger foam are overcome.

Owner:ZHEJIANG HUANLONG NEW MATERIAL SCI & TECH

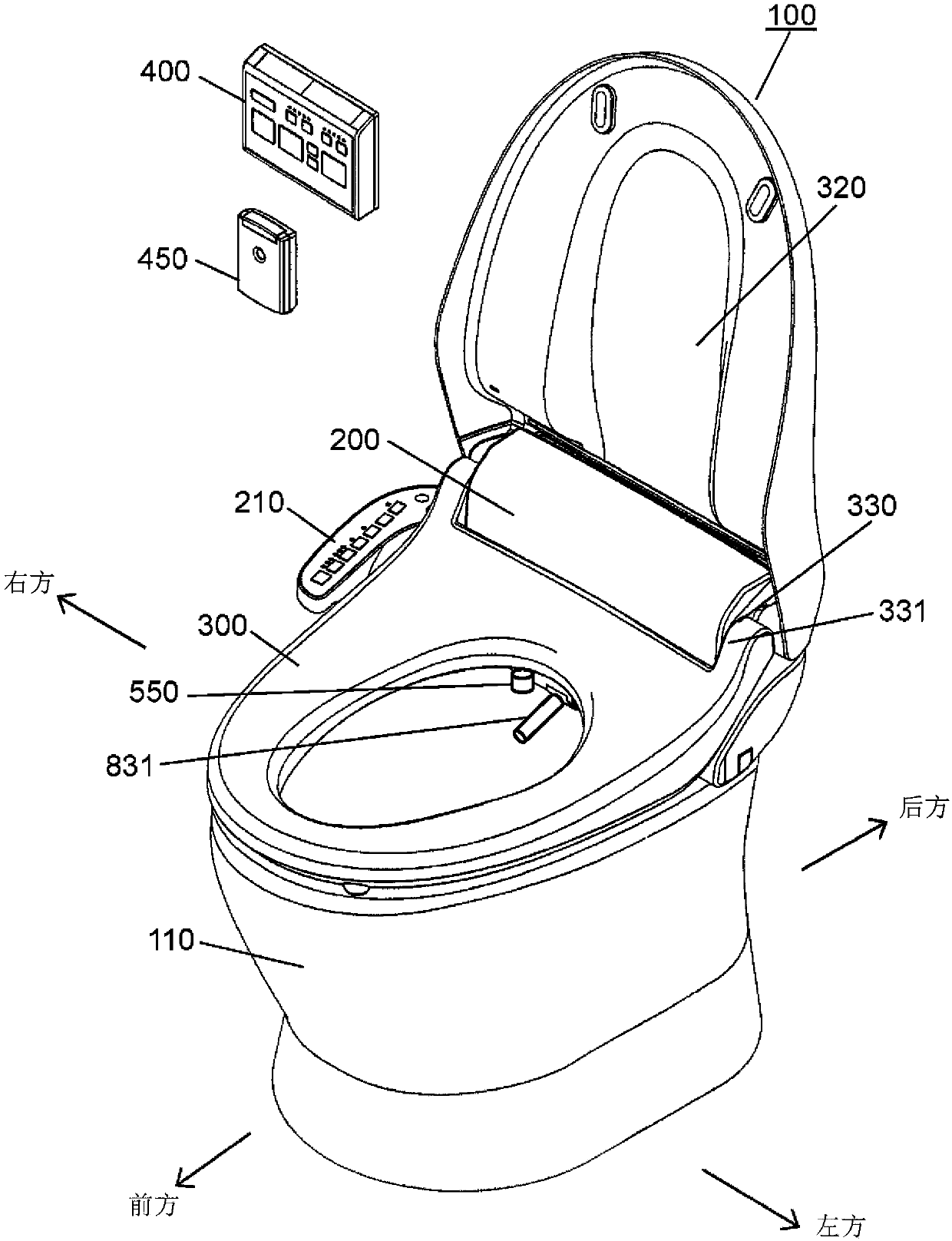

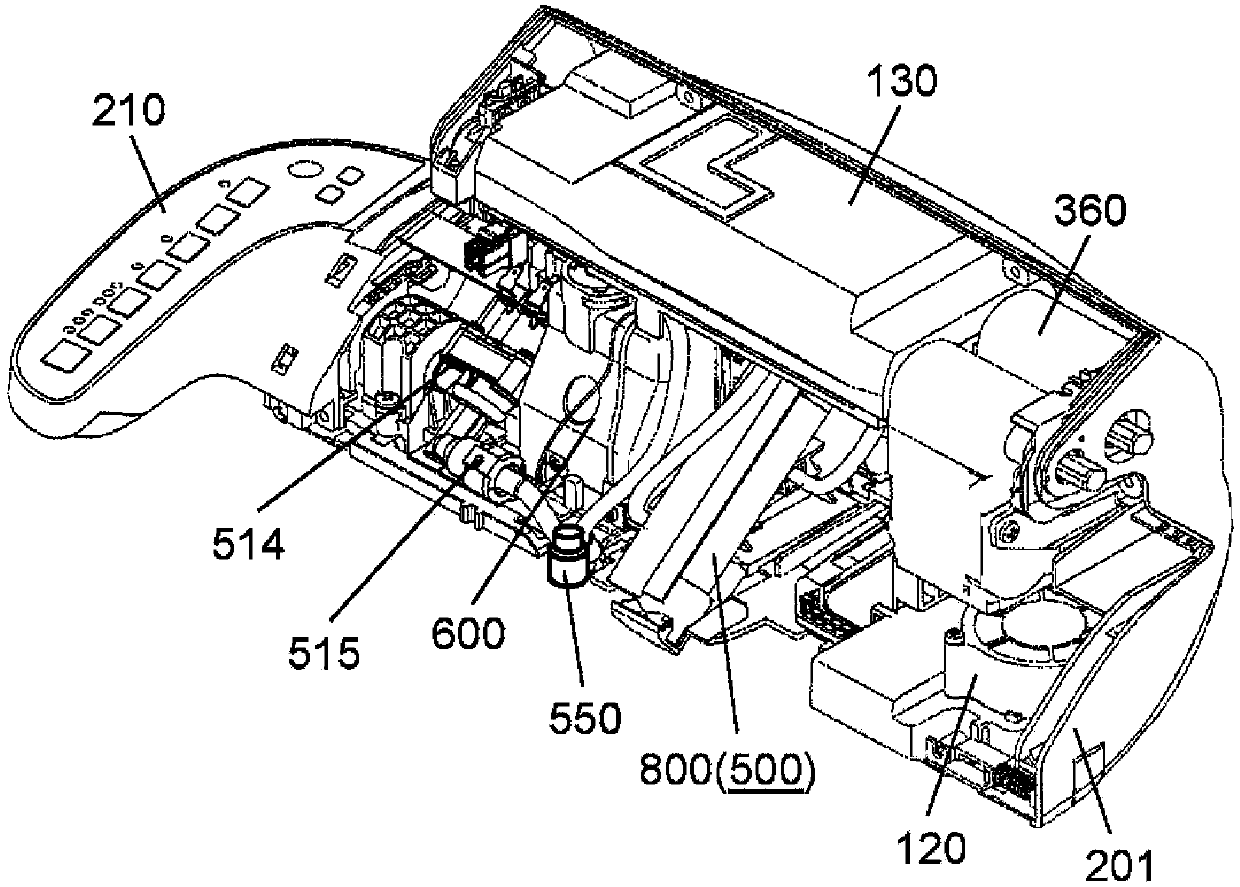

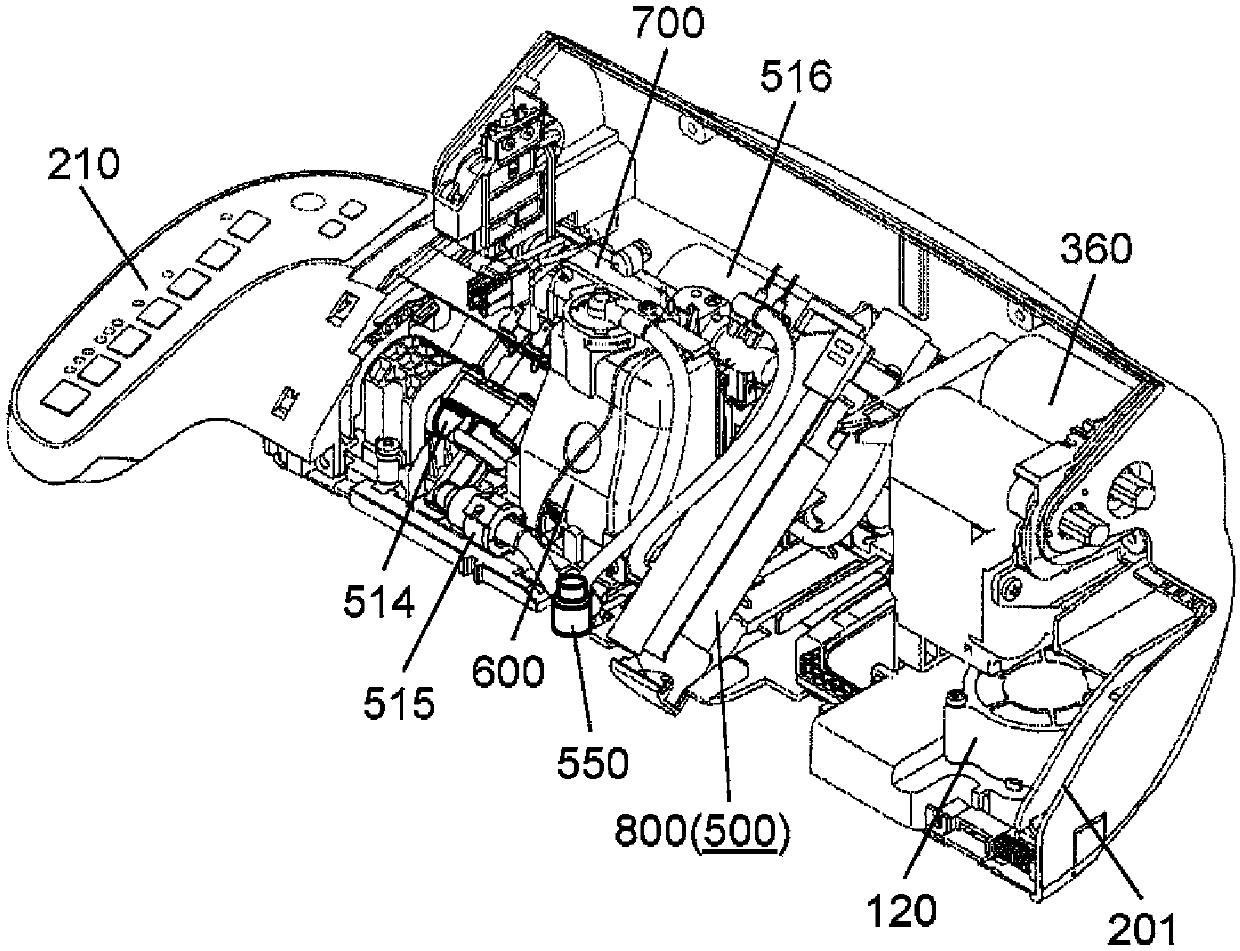

Sanitary Cleaning Device

A sanitary cleaning device comprises a heat exchanger (700), a cleaning nozzle (831), a foam generating unit (560) to generate cleaning foam, a spray nozzle (550) to discharge cleaning water or cleaning foam, a spray nozzle driving unit (550a) to drive and rotate the spray nozzle (550), an on-off valve (530a) to open and close a branching channel to the spray nozzle (550), and a controlling unit (130). The spray nozzle (550) is disposed in a body by the axis of rotation Ax of the spray nozzle (550) being inclined in the front-rear direction and the right-left direction. The inclination in thefront-rear direction is such that the lower part in the direction of the axis of rotation inclines toward the front part of a toilet, and the inclination in the right-left direction is such that the lower part in the direction of the axis of rotation inclines toward the cleaning nozzle (831). Thus, adhesion of contaminants is suppressed by a foam film being formed on the inner face of the toilet from the front to the rear.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

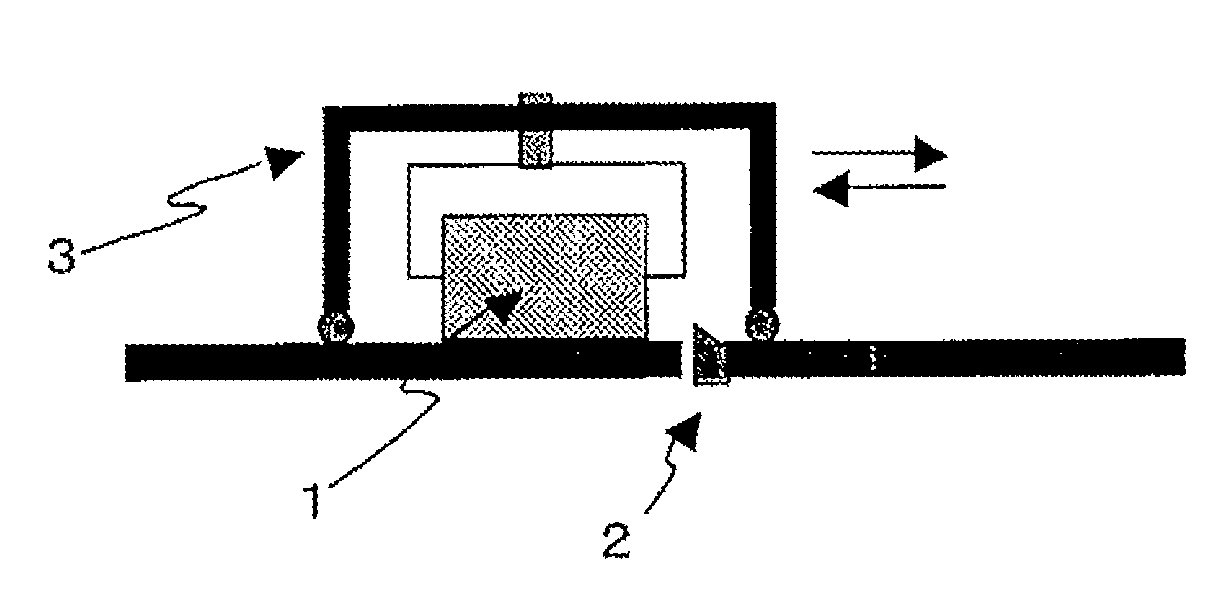

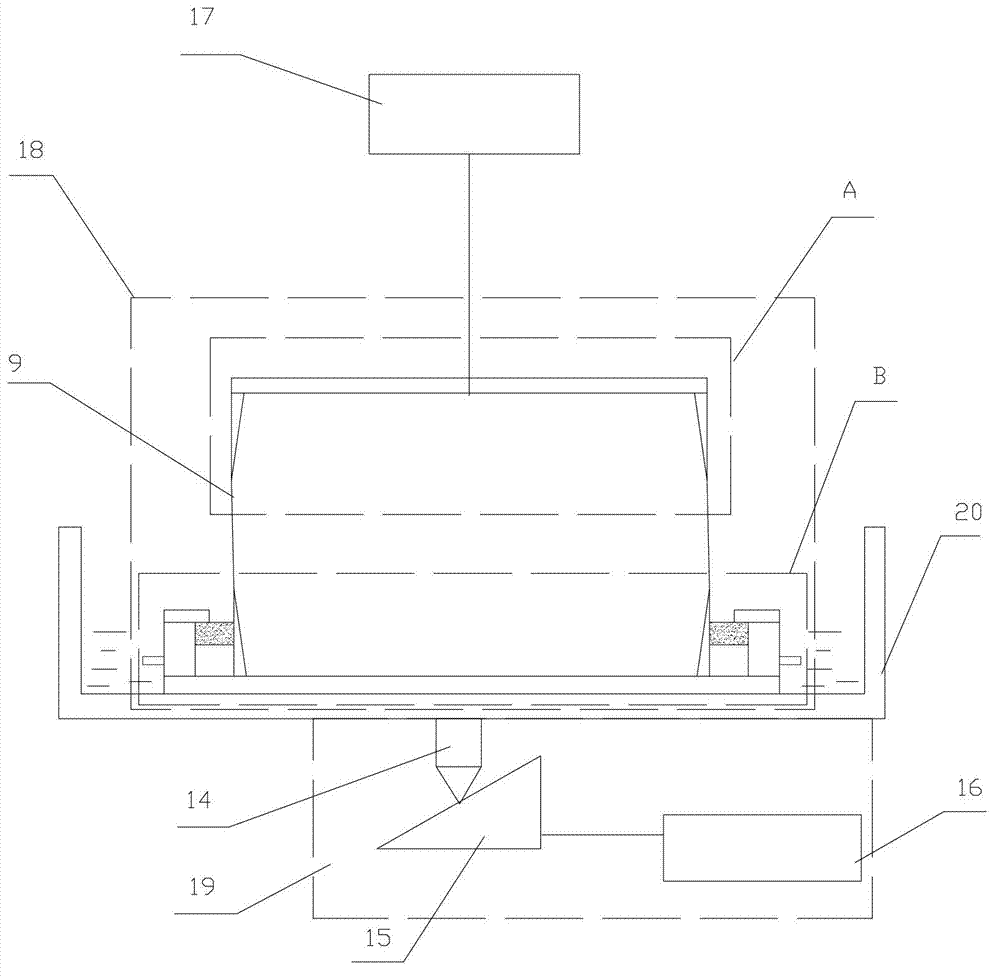

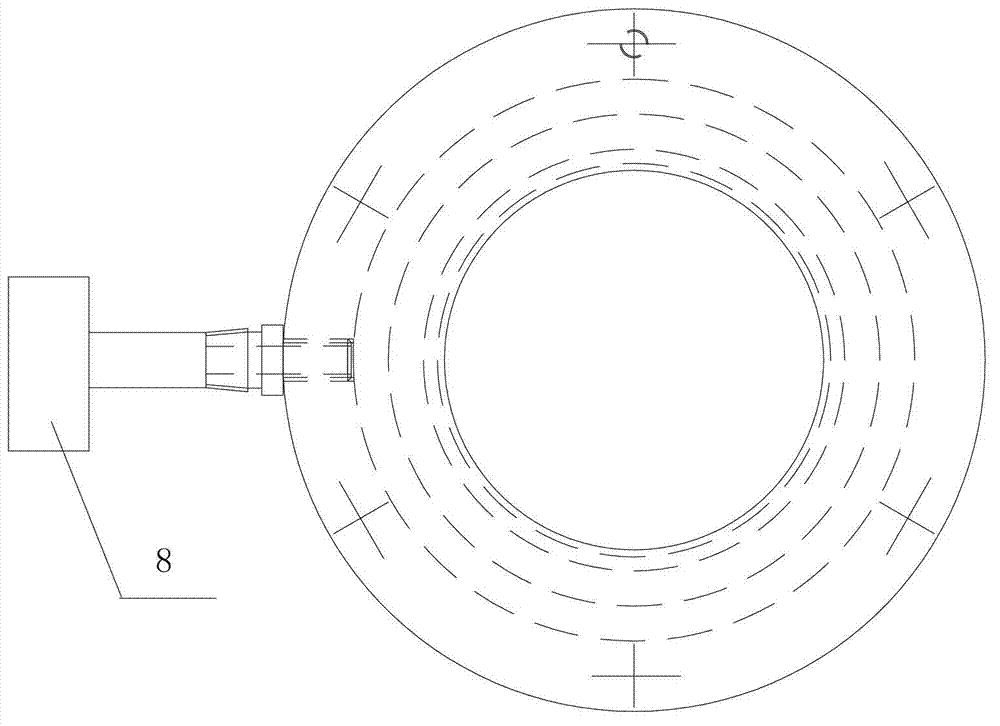

Device for determining dilational viscoelasticity of liquid film

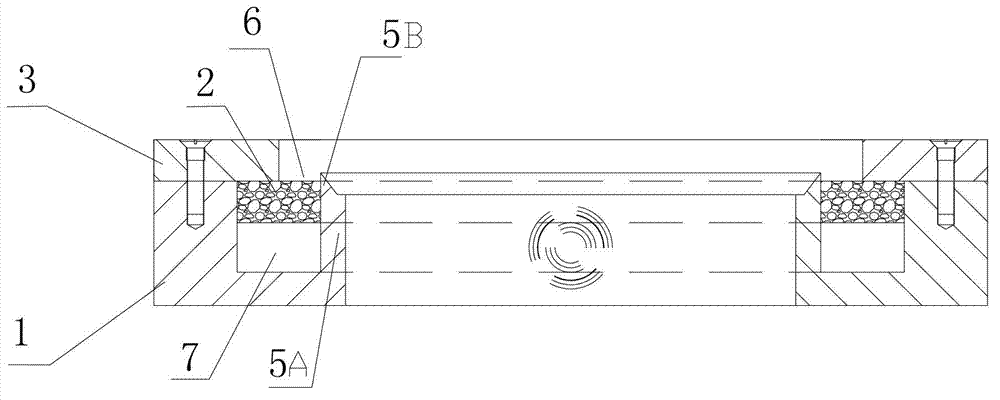

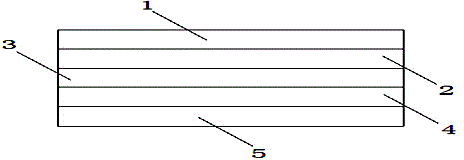

ActiveCN102818750AEasy to adjustDetermination of viscoelasticityFlow propertiesPreparing sample for investigationEngineeringViscoelasticity

The invention relates to a device for determining dilational viscoelasticity of a liquid film, belonging to devices for determining physical and chemical properties of a foam film and comprising a liquid film generating device and an upward-downward displacement and sinusoidal vibration generating device. Due to the design of a liquid feeding pressure adjustment system and an overflow groove of the liquid film generating device, a liquid film thicker or thinner than that generated by natural gravity liquid-discharging can be obtained, furthermore, the liquid-discharging progress is reversible, and the film thickness control is more accurate, a repeat experiment and a comparative experiment are facilitated, and the level of an upper ring of the device is easy to adjust.

Owner:PETROCHINA CO LTD

Polyethylene foamed packaging film and processing method thereof

InactiveCN104802470AImprove quality performanceImprove scalabilityLamination ancillary operationsSynthetic resin layered productsAluminum foilFoam film

The invention discloses a polyethylene foamed packaging film and a processing method thereof. The polyethylene foamed packaging film is characterized by comprising a high polymer layer I, a foaming layer, a high polymer layer II, a metal composite layer and a partition layer in sequence, wherein the high polymer layer is made of a PET12 material; the foamed layer is made of an EPE147 material; the high polymer layer is made of the PET12 material; the metal composite layer is an aluminum foil layer made of an AL12 material; the partition layer is made of a PEY45 material. The polyethylene foamed packaging film is of a five-layer structure, the quality performance of the polyethylene foamed film is greatly improved, the high polymer layer I is combined with the partition layer after being combined with the foamed layer, the high polymer layer II and the metal composite layer in a processing process, and finally total compounding is peformed, so that the quality performance of the polyethylene foamed film is improved, and the flexibility, the mechanical strength, the surface strength and the surface evenness of the polyethylene foamed film are improved.

Owner:ANHUI YUANZHOU PACKAGING MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com