Film for PTP or blister pack, and packaging container for PTP or blister pack

A packaging container and packaging technology, applied in household packaging, household containers, packaging, etc., can solve problems such as inability to absorb odors, and achieve the effect of reducing costs

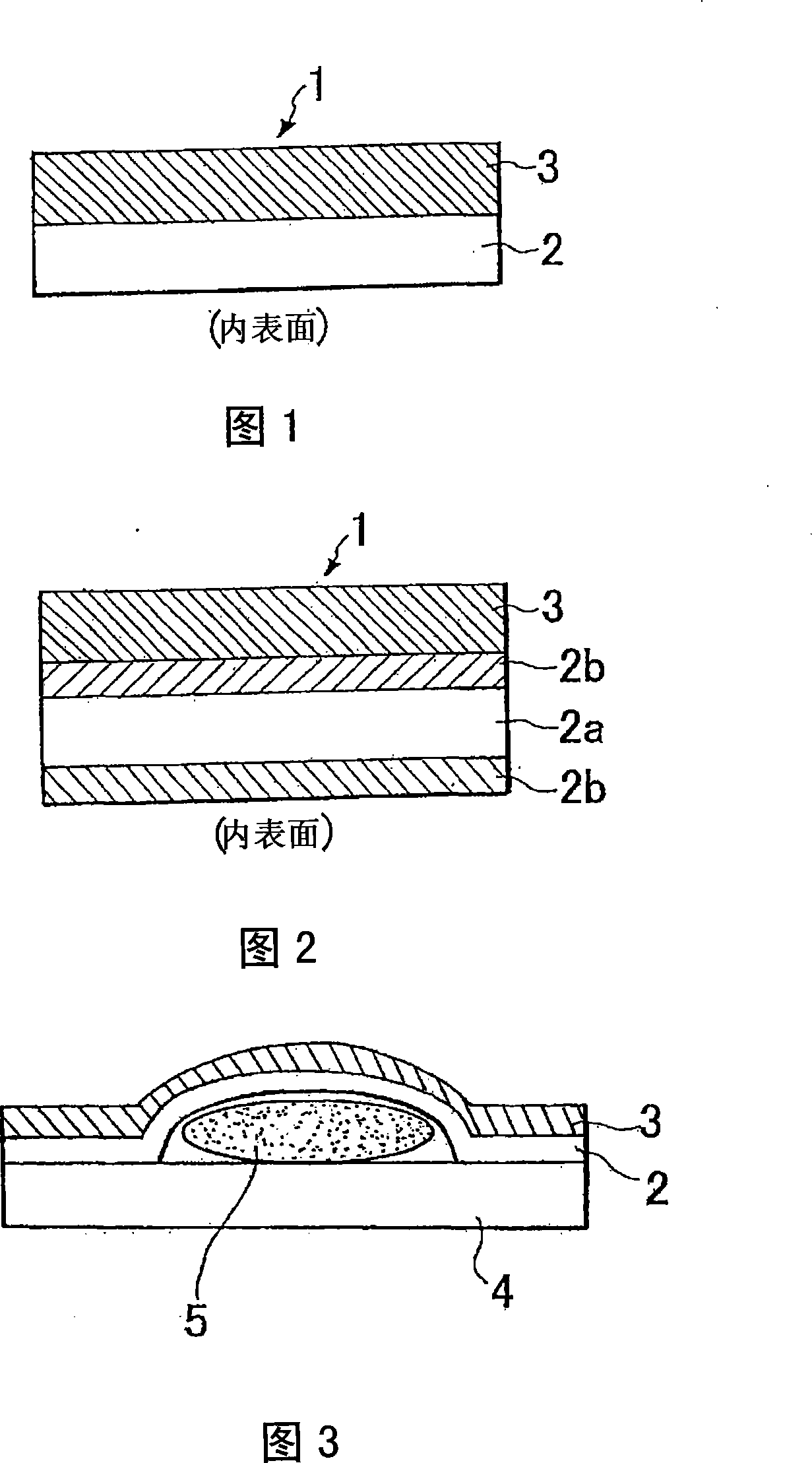

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1-1

[0069] As the resin for the adsorption layer, only MB1-1 was used in the main adsorption layer, and only MB 1-4 was used in the sub-adsorption layer, and two types of three-layer films were produced by the multilayer blown film method. The film thicknesses of the two kinds of three-layer films were sub-absorbent layer / main moisture-absorbing layer / sub-hygroscopic layer=5 μm / 50 μm / 10 μm. Here, the contents of the desiccant in the entire moisture-absorbing layer and the pigment excluding the desiccant were 41% by weight and 0% by weight, respectively, so the total pigments including the desiccant was 41% by weight.

[0070] In order to improve the adhesiveness of the 5 μm sub-adsorption layer side of the obtained two types of three-layer films, the surface was subjected to rough corona treatment. A polypropylene film for PTP with a film thickness of 250 μm (trade name: CPPE0025NA, manufactured by Mitsubishi Plastics Co., Ltd.) that undergoes heat shrinkage by post-calcination is...

Embodiment 1-1-2

[0073] In Example 1-1-1, except having changed MB1-1 of the main moisture absorption layer into MB1-2, it carried out similarly to Example 1-1-1, and manufactured the packaging container for PTP or foam packaging. In this PTP or packaging container for foam packaging, the contents of the desiccant in the entire moisture-absorbing layer and the pigment excluding the desiccant are 65% by weight and 0% by weight, respectively. Therefore, the total pigment containing the desiccant is 65% by weight. .

Embodiment 1-1-3

[0075] In Example 1-1-1, instead of MB 1-1 of the main moisture-absorbing layer, MB1-1 and MB 1-3 were mixed at a mixing ratio of 50:50, except that it was carried out in the same manner, Manufacture of packaging containers for PTP or foam packaging. Here, the contents of the desiccant in the entire moisture-absorbing layer and the pigment excluding the desiccant were 41% by weight and 0% by weight, respectively, so the total pigments including the desiccant was 41% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com