Graphene composite foam film and preparation method thereof

A technology of graphene foam and graphene composite, which is applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems that affect graphene composite and no longer communicate with each other, so as to achieve rich pores, uniform mutual integration, and guarantee The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066]In this embodiment, the graphene foam film accounted for 40 wt.%, And the polymer polymer accounted for 60 wt.%;

[0067]The thermal conductivity of the graphene foam film 50W / (m k);

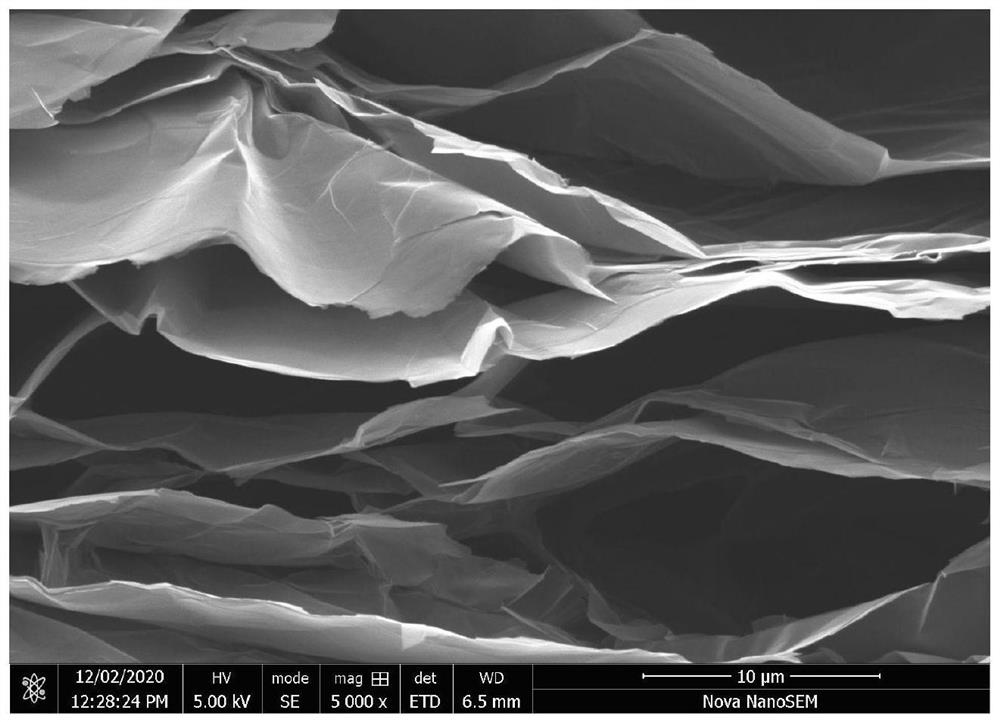

[0068]Gallene foam film thickness 50 μm, density 0.1 g / cm3;

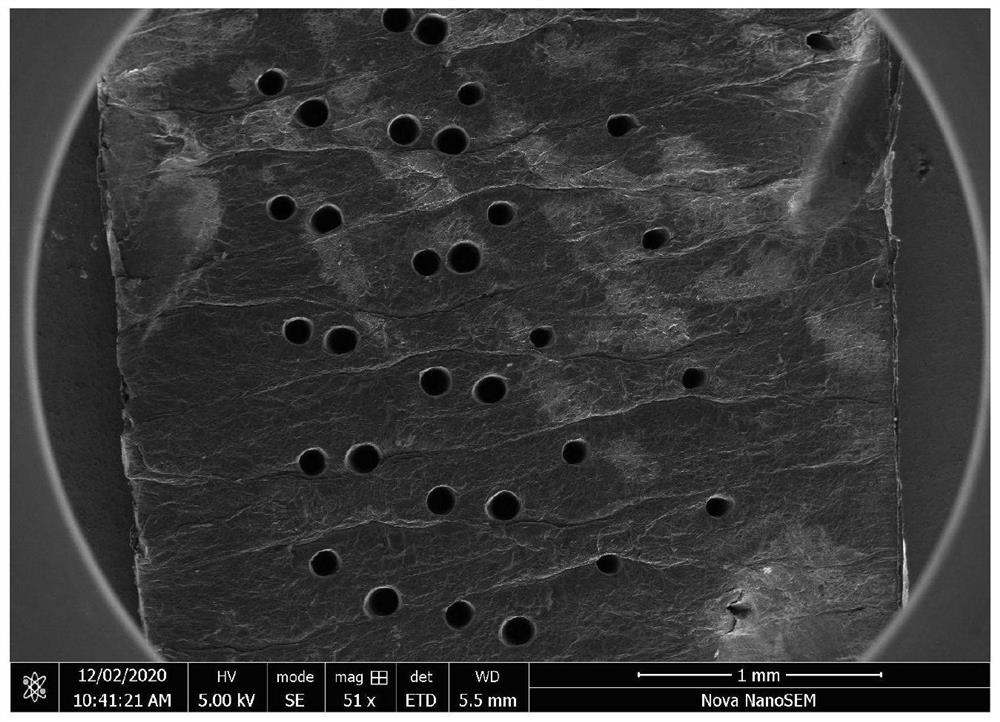

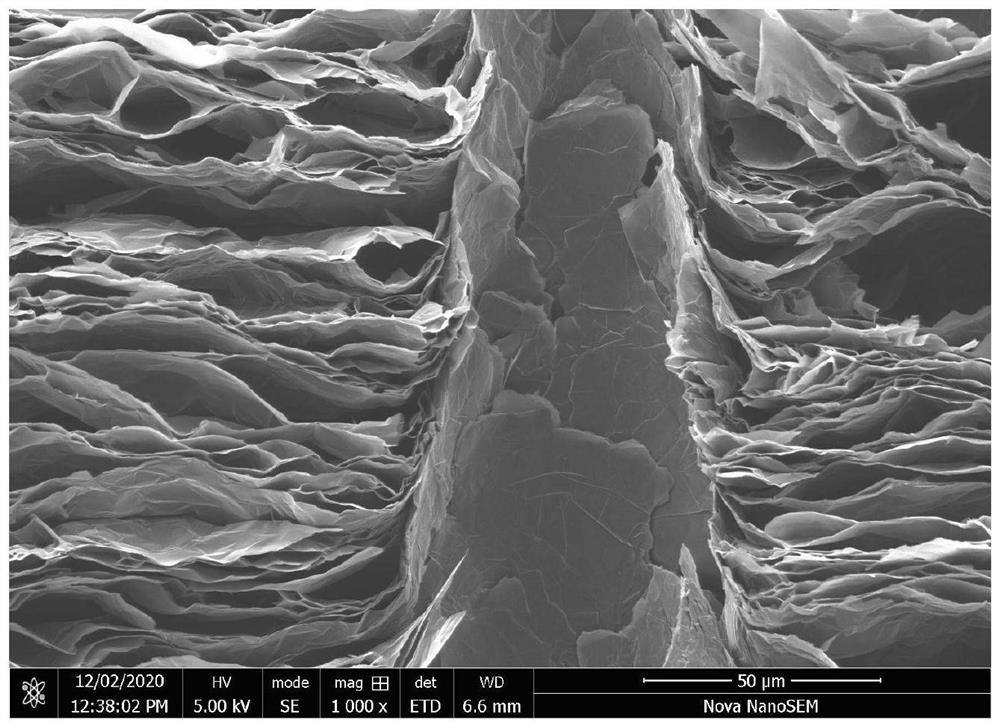

[0069]The inner pore pore diameter of the graphene foam membrane is 10 μm, and a laser punch is used to penetrate 50 μm, and the center spacing of 300 μm through the hole is 300 μm;

[0070]Liquid silica gel is a polymethylcycloysiloxane, which is diluted to a viscosity of 1000 MPa · s using heptane.

[0071]Curing by normal temperature constant pressure conditions;

[0072]After testing, get the following test results:

[0073]

Embodiment 2

[0075]In this embodiment, the graphene foam film accounted for 95 wt.%, The organic polymer polymer accounted for 5 wt.%;

[0076]The thermal conductivity of the graphene foam film is 530w / (m k);

[0077]Graphitene foam film thickness 1000 μm, density 0.9 g / cm3;

[0078]The inner pore pore diameter of the graphene foam membrane is 100 μm, and the hole is 500 μm, and the center spacing of 1000 μm in the center of the hole is performed.

[0079]Liquid silica gel is polydimethylsiloxane, which is diluted with hexane to viscosity 30 MPa · S;

[0080]Curing by 150 ° C is carried out;

[0081]After testing, get the following test results:

[0082]

Embodiment 3

[0084]In this embodiment, the graphene foam film accounted for 75 wt.%, And the polymer polymer accounted for 25 wt.%;

[0085]The thermal conductivity of the graphene foam film is 120 W / (m k);

[0086]Graphite foam film thickness 300 μm, density 0.2g / cm3;

[0087]The inner pore pore diameter of the graphene foam membrane is 15 μm, and the acupuncture method is connected to 100 μm, and the center spacing of 400 μm is formed through the center of the hole;

[0088]Liquid silica gel is α, ω-dihydroxy polyimethylsiloxane, diluted with tetrahydrofuran to a viscosity of 100 MPa · S;

[0089]Curing by 120 ° C is carried out;

[0090]After testing, get the following test results:

[0091]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com