Kraft compounded double-layer air bubble film

A technology of air cushion film and composite film, which is applied in the field of packaging materials for postal parcels. It can solve the problems of loss of efficacy, bubble chambers are easy to be squeezed, easy to be damaged, etc., and achieve the effect of increasing the force-bearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

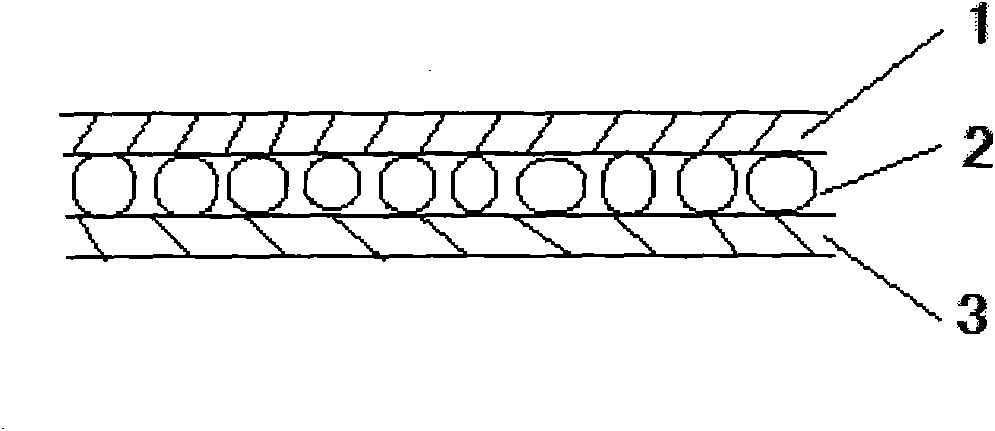

[0011] refer to figure 1 As shown, a kraft paper composite double-layer air cushion film includes a kraft paper layer 1, a foam film layer 2 on the surface of the kraft paper layer, and a composite plastic film 3 on the surface of the foam film layer to seal the airbag.

[0012] The production process is: firstly coat the rough surface of the paper with a film, then perform corona treatment, and use electric shock treatment to make the surface of the paper have higher adhesion, then compound the paper and foam film through a dry lamination process, cool and wind. , you can.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com