Device for determining dilational viscoelasticity of liquid film

A measuring device and viscoelasticity technology, which is applied in the field of foam film physical and chemical property measuring devices, can solve problems such as difficulty in level adjustment, and achieve the effect of convenient and fast adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

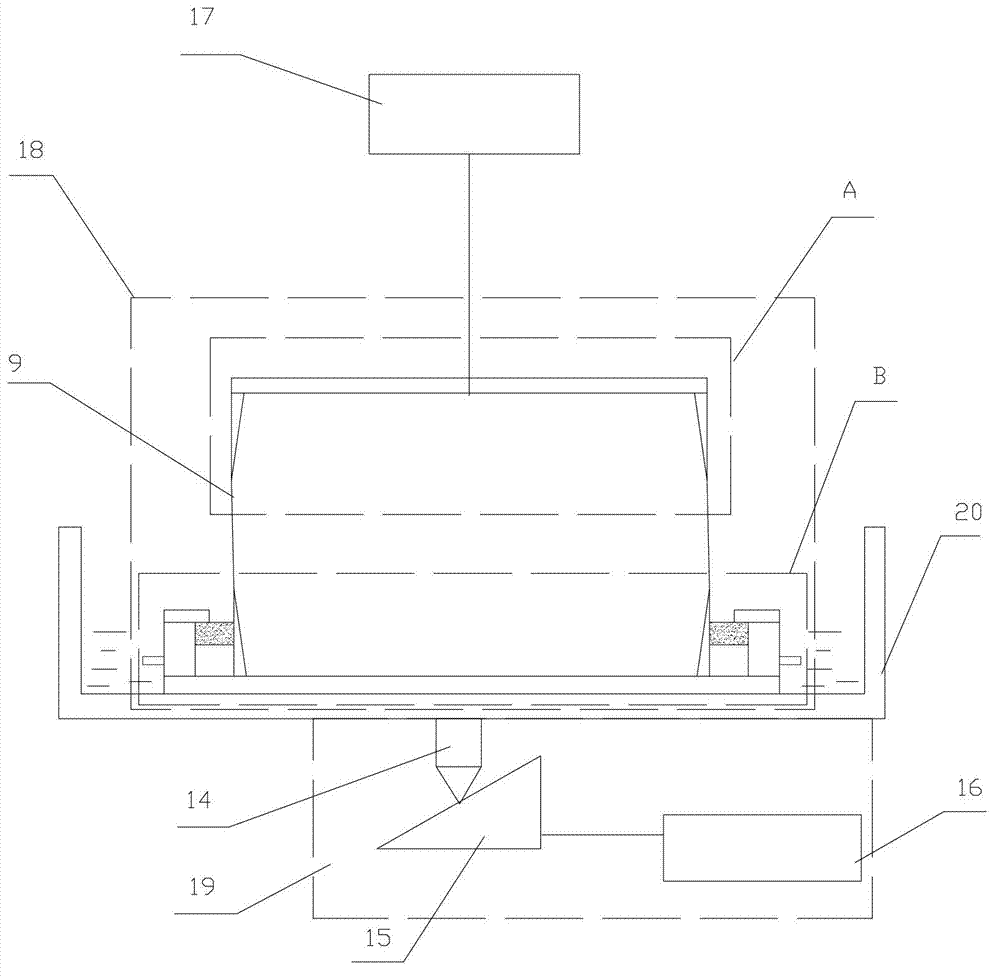

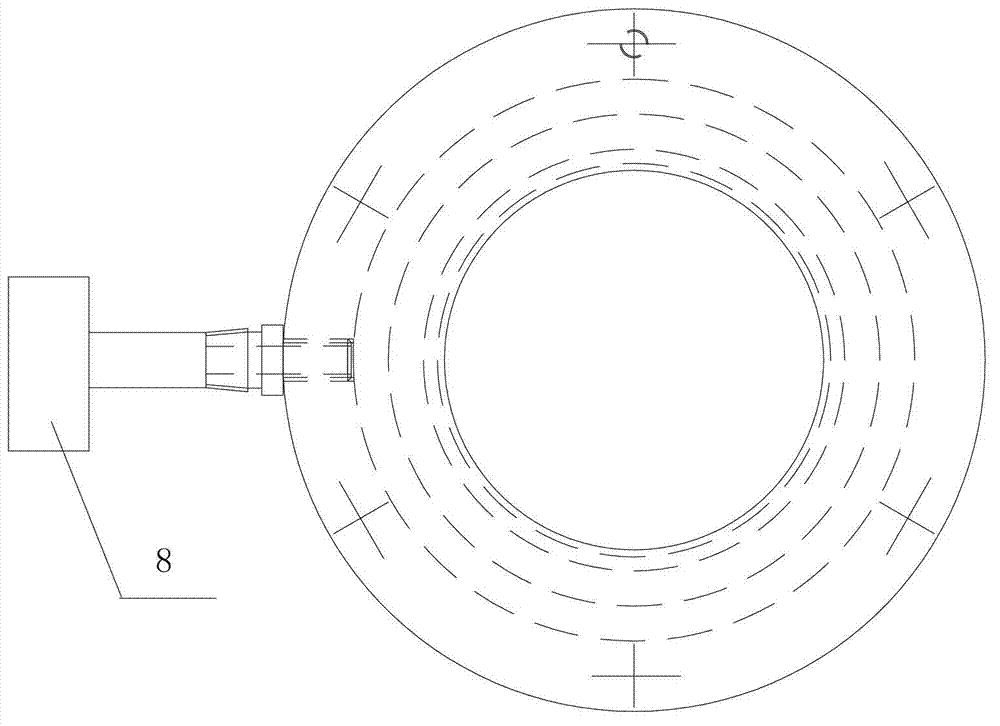

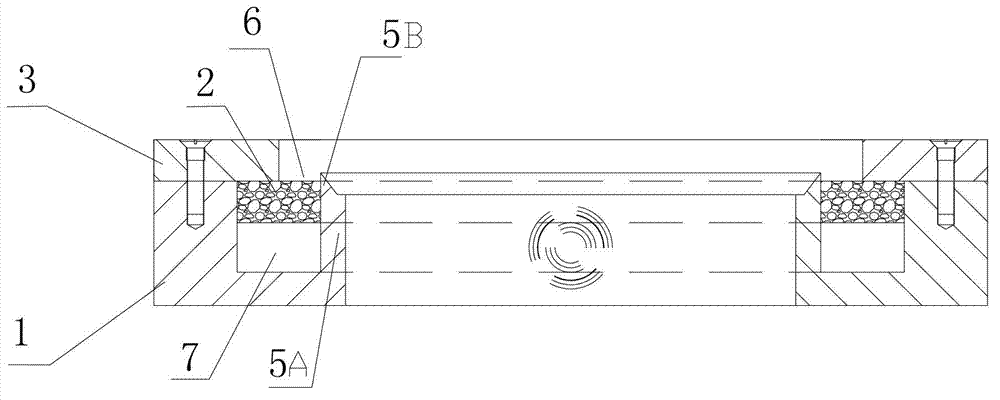

[0041]The liquid film expansion viscoelasticity measurement device includes a liquid film generating device and an upper and lower displacement and sinusoidal vibration generating device. The liquid film generating device is composed of an upper ring assembly, a lower ring assembly and a liquid holding plate. The film pulling ring is suspended by an electronic analytical balance. The lower ring assembly is located in the liquid holding pan and can be integrated with the liquid holding pan to move under the drive of the upper and lower displacement and sinusoidal vibration generating devices. The lower ring assembly is The ring assembly is composed of a metal ring sleeve with a ring groove, a pull-down membrane ring, a liquid-conducting layer of a porous medium material, and a hydrophobic ring-shaped cover plate. The pull-down membrane ring is located in the middle of the metal ring sleeve, and is connected The size is the same and they are coaxial and horizontal; the porous med...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com