Polyethylene foamed packaging film and processing method thereof

A technology of polyethylene foaming and processing methods, applied in chemical instruments and methods, lamination devices, lamination, etc., can solve the problems of stretchability, mechanical strength, surface strength and surface flatness, etc., and achieve enhanced stretchability , Improve the effect of quality performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

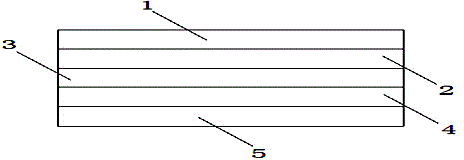

[0017] A polyethylene foam packaging film and its processing method, characterized in that: the polyethylene foam packaging film is sequentially composed of high polymer layer one, foam layer, high polymer layer two, metal composite layer, barrier layer Composition, the high polymer layer one is PET 12 The high polymer layer of the material, its thickness accounts for 5% of the total thickness of the polyethylene foam packaging film, and the foam layer is EPE 147 The foam layer of the material, its thickness accounts for 65% of the total thickness of the polyethylene foam packaging film, and the second high polymer layer is PET 12 The high polymer layer of the material, its thickness accounts for 5% of the total thickness of the polyethylene foam packaging film, and the metal composite layer is AL 12 Aluminum foil layer made of aluminum foil, its thickness accounts for 5% of the total thickness of polyethylene foam packaging film, and the barrier layer is PEY 45 The barrie...

Embodiment 2

[0025] A polyethylene foam packaging film and its processing method, characterized in that: the polyethylene foam packaging film is sequentially composed of high polymer layer one, foam layer, high polymer layer two, metal composite layer, barrier layer Composition, the high polymer layer one is PET 12 The high polymer layer of the material, its thickness accounts for 10% of the total thickness of the polyethylene foam packaging film, and the foam layer is EPE 147 The foaming layer of material, its thickness accounts for 55%% of the total thickness of polyethylene foaming packaging film, and described high polymer layer two is PET 12 The high polymer layer of the material, its thickness accounts for 10% of the total thickness of the polyethylene foam packaging film, and the metal composite layer is AL 12 Aluminum foil layer made of aluminum foil, its thickness accounts for 10% of the total thickness of polyethylene foam packaging film, and the barrier layer is PEY 45 The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com