Preparation method for bionic super-hydrophobic film taking copper foam as substrate and application thereof

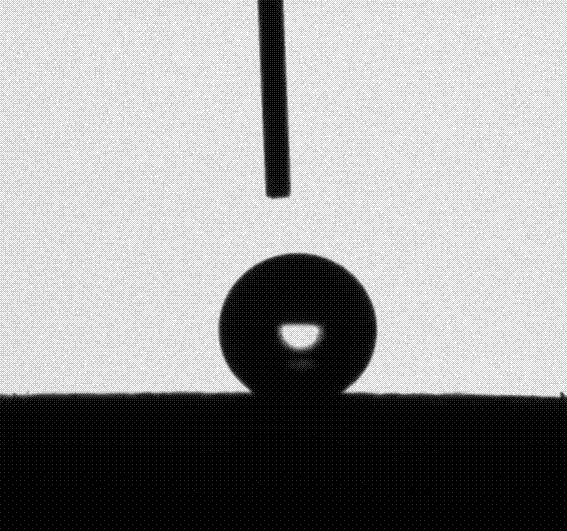

A copper foam, super-hydrophobic technology, applied in the field of composite materials, can solve the problems of difficulty in obtaining super-hydrophobicity and super-lipophilicity, secondary pollution of fluorine-containing materials, poor mechanical properties of polymers, etc., and achieve oil-water separation efficiency and oil-water separation efficiency. Improve and improve the effect of surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of a biomimetic superhydrophobic membrane based on copper foam, comprising the steps of:

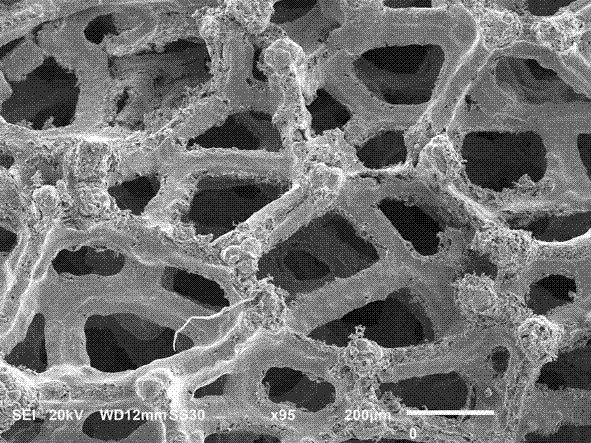

[0031] a) Pretreatment of copper foam: Cut the copper foam with a thickness of 1.6 mm into blocks with a length and width of 40 mm and 20 mm respectively, ultrasonically clean it with 1 mol / L HCl solution for 10 min, and then wash it with deionized water and ethanol Wash for 3 minutes each to remove oxides and impurities on the copper foam surface.

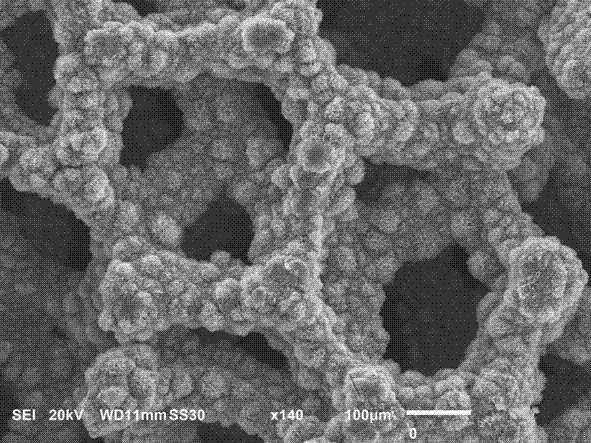

[0032] b) Surface structure design: At room temperature, the copper foam obtained in a) was soaked in 2.5 ml of (NH 4 ) 2 S 2 o 8 (0.1 mol / L) and 2.5 ml of NaH 2 PO 4 (0.5 mol / L) aqueous solution for 6 h, removed, rinsed with deionized water three times, and vacuum dried at 40 °C for 3 h to obtain copper foams with hierarchical structure on the surface.

[0033]c) Surface chemical modification: Add 1 mL of γ-glycidyloxypropyltrimethoxysilane solution (KH-560) and 0.25 mL of deionized water to the bottom of ...

Embodiment 2

[0036] A preparation method of a biomimetic superhydrophobic membrane based on copper foam, comprising the steps of:

[0037] a) Pretreatment of copper foam: Cut the copper foam with a thickness of 1.6 mm into blocks with a length and width of 40 mm and 20 mm respectively, ultrasonically clean it with 2 mol / L HCl solution for 10 min, and then wash it with deionized water and ethanol Wash for 3 minutes each to remove oxides and impurities on the copper foam surface.

[0038] b) Surface structure design: At room temperature, the copper foam obtained in a) was soaked in 3 ml of (NH 4 ) 2 S 2 o 8 (0.2 mol / L) and 3 ml of K 2 HPO 4 (0.6 mol / L) aqueous solution for 10 h, taken out, rinsed with deionized water three times, and dried in vacuum at 40 °C for 3 h to obtain copper foams with hierarchical structure on the surface.

[0039] c) Surface chemical modification: Add 3 mL of γ-aminopropyltriethoxysilane solution (KH-550) and 0.75 mL of deionized water to the bottom of the r...

Embodiment 3

[0042] A preparation method of a biomimetic superhydrophobic membrane based on copper foam, comprising the steps of:

[0043] a) Pretreatment of copper foam: cut the copper foam with a thickness of 1.6 mm into blocks with a length and width of 40 mm and 20 mm respectively, ultrasonically clean it with 3 mol / L HCl solution for 10 min, and then wash it with deionized water and ethanol Wash for 3 minutes each to remove oxides and impurities on the copper foam surface.

[0044] b) Surface structure design: at room temperature, soak the copper foam obtained in a) in 5 ml of (NH 4 ) 2 S 2 o 8 (0.3 mol / L) and 5 ml of Na 2 HPO 4 (0.8 mol / L) aqueous solution for 12 h, taken out, rinsed with deionized water three times, and dried in vacuum at 40 °C for 3 h to obtain copper foams with hierarchical structure on the surface.

[0045] c) Surface chemical modification: 2 mL of γ-propyltrimethoxysilane solution (KH-570) and 0.5 mL of deionized water were added to the bottom of the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com