Method for applying foam chemical by extruding foam film through flow paving

A chemical and foam technology, which is applied in the field of uniform application of chemicals, can solve problems such as difficult control of process conditions, difficult control, uneven foam, etc., to improve energy utilization and chemical utilization, reduce water consumption, The effect of reducing pollution emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

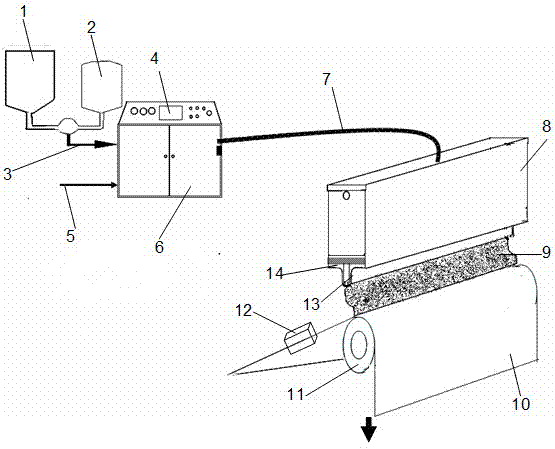

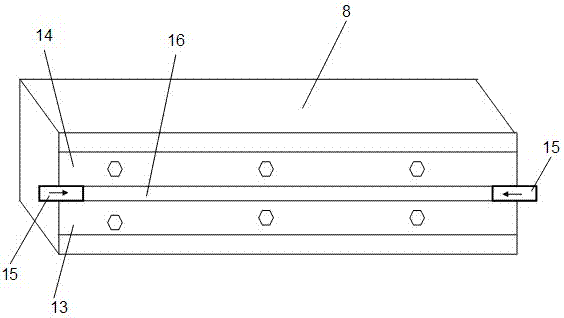

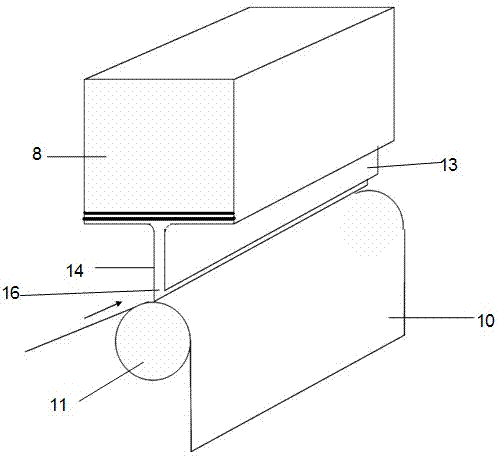

[0039] Embodiment 1: adopt the method for applying foam form softening agent in the mode of extruding foam film by flow laying:

[0040] The foam applicator disclosed in the Chinese patent with application number 200710047713.3 is used as a foam generating device, such as Figure 5d As shown, the double-sided single-application foam film process is carried out on the fabric, and the fabric 10 is a pure cotton knitted fabric with a width of 1.6 meters;

[0041] (1) Put the softener into a foamable solution according to the following formula and place it in the first chemical tank 1,

[0042] Magnasoft 68 50g / L,

[0043] Foaming agent TSZ (produced by Shanghai Yuhui Chemical Industry) 5g / L,

[0044] (2) Set fabric parameters and foam film parameters in the foam generating equipment:

[0045] Fabric width: 1.6m,

[0046] Carrying rate 30%(o.w.f.),

[0047] Bubble ratio 1:35,

[0048] Fabric weight 240g / m 2 ,

[0049] Fabric running speed 50m / min;

[0050] Th...

Embodiment 2

[0056] Embodiment 2: adopt the method for applying foam form dyeing liquor in the mode of extruding foam film by flow laying

[0057] The foam applicator disclosed in the Chinese patent with application number 200710047713.3 is used as a foam generating device, such as Figure 5d As shown, the double-sided single-application foam film process is carried out on the fabric, and the fabric 10 is a pure cotton knitted fabric with a width of 1.8 meters;

[0058] (1) Put the dye into a foamable solution according to the following formula and place it in the first chemical tank 1 and the second chemical tank 2,

[0059] Recipe in first chemical tank 1:

[0060] Reactive dye red M-8B 100g / L,

[0061] Recipe in Second Chemical Tank 2:

[0062] Caustic soda (solid caustic soda) 10 g / L

[0063] Foaming agent TSZ (produced by Shanghai Yuhui Chemical Industry) 5 g / L

[0064] Mix evenly by proportional pump, set fabric parameters and foam film parameters in foam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com