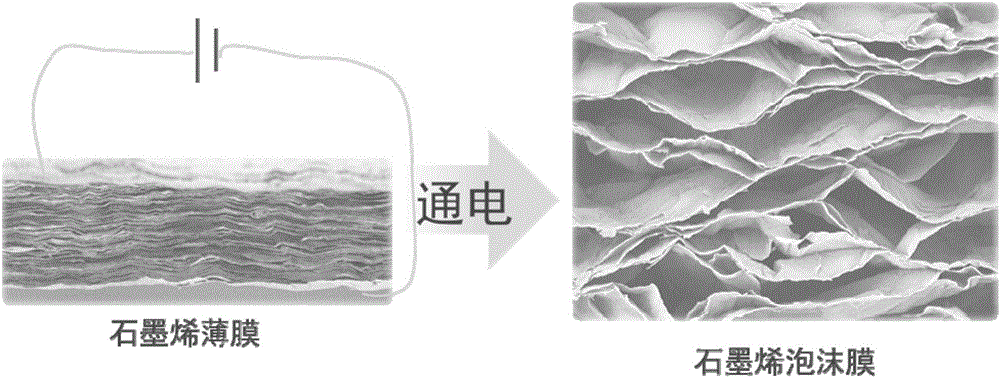

Graphene foam film, and preparation and application thereof

A technology of graphene foam and graphene film, which is applied in the direction of graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of low cost and safe preparation of graphene foam technology, and achieve convenient, fast and good preparation process. The effect of electrical conductivity and maintaining mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) At room temperature, weigh 250 mg of graphite oxide prepared by the improved Hummers method, place it in a 100 mL beaker, then make a dispersion with a concentration of 5 mg / mL with 50 mL of deionized water, and then put the beaker into the ultrasonic pool After 4 hours of medium treatment, the graphite oxide was stripped into graphene oxide to obtain 50 mL of a uniform graphene oxide dispersion; the dispersion was poured into a polytetrafluoroethylene petri dish with a diameter of 10 cm, and the petri dish containing the graphene oxide dispersion was Placed on a hot stage at 60°C, evaporated on the hot stage for 12 hours to obtain a graphene oxide film;

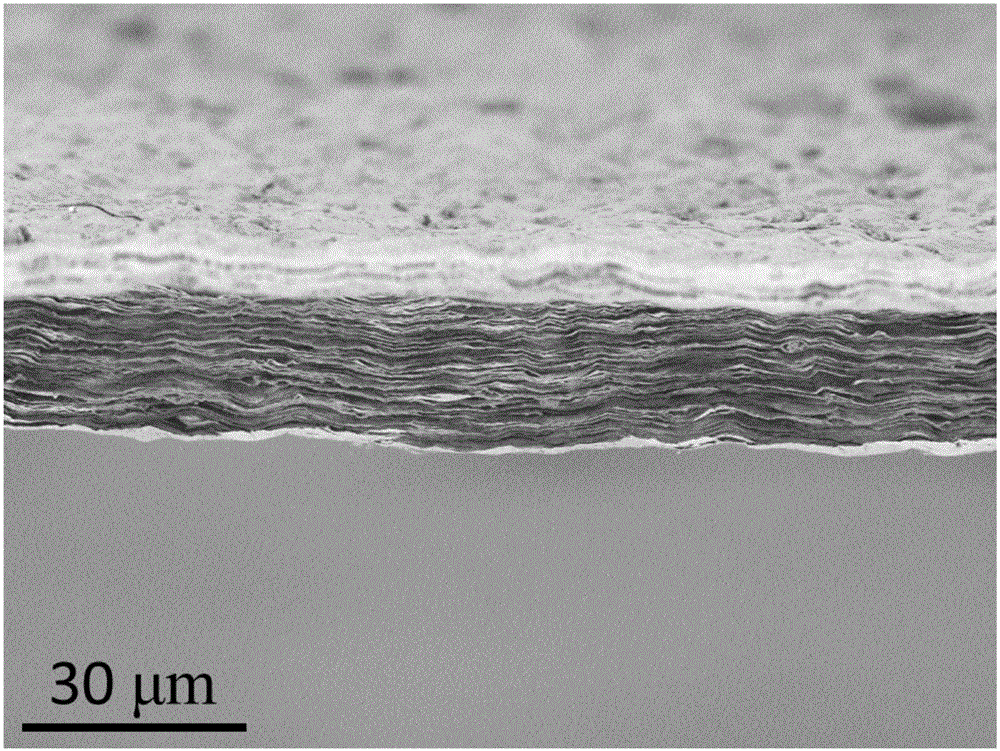

[0034] (2) Place the prepared graphene oxide film in 55wt% hydriodic acid solution for reduction for 1h, then wash with alcohol for 3 times to remove residual hydriodic acid on the surface, obtain graphene film after natural drying, and its cross-section scanning electron microscope photos such as figure 2 As sh...

Embodiment 2

[0037] (1) At room temperature, weigh 250 mg of graphite oxide prepared by the improved Hummers method, place it in a 100 mL beaker, then make a dispersion with a concentration of 5 mg / mL with 50 mL of deionized water, and then put the beaker into the ultrasonic pool After 4 hours of medium treatment, the graphite oxide was stripped into graphene oxide to obtain 50 mL of a uniform graphene oxide dispersion; the dispersion was poured into a polytetrafluoroethylene petri dish with a diameter of 10 cm, and the petri dish containing the graphene oxide dispersion was Place it on a hot stage at 60°C, and obtain a graphene oxide film by evaporating on the hot stage for 12 hours;

[0038] (2) Place the prepared graphene oxide film in 55wt% hydroiodic acid solution for reduction for 1h, then wash with alcohol for 3 times to remove residual hydroiodic acid on the surface, and obtain the graphene film after natural drying;

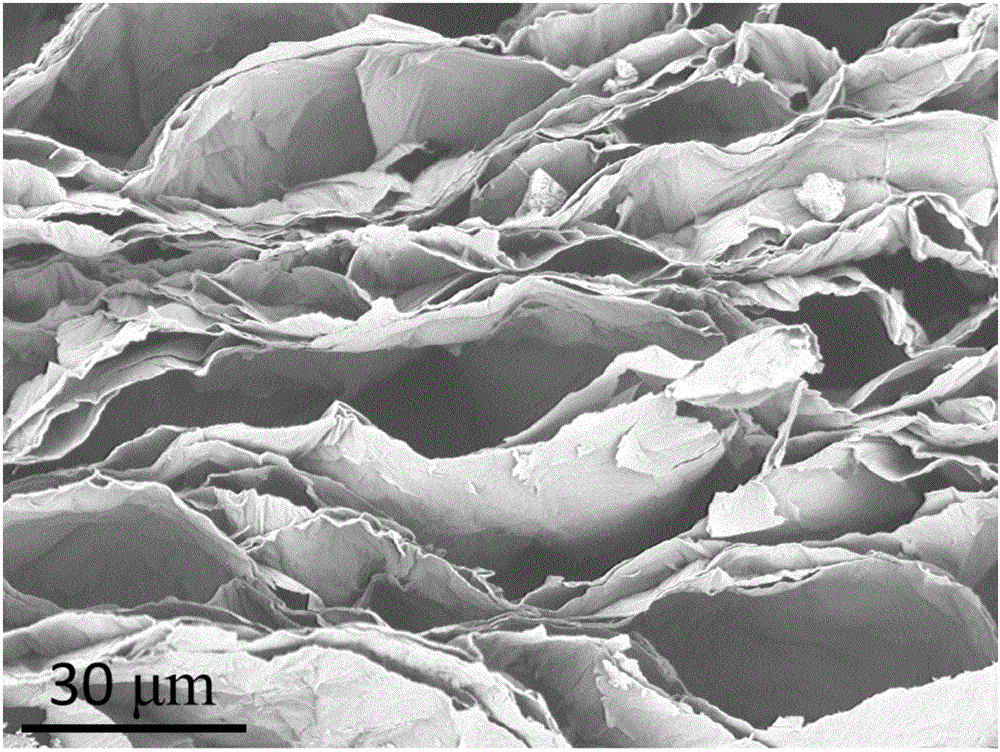

[0039] (3) Connect the closed circuit with wires at both ends o...

Embodiment 3

[0041](1) At room temperature, weigh 250 mg of graphite oxide prepared by the improved Hummers method, place it in a 100 mL beaker, then make a dispersion with a concentration of 5 mg / mL with 50 mL of deionized water, and then put the beaker into the ultrasonic pool After 4 hours of medium treatment, the graphite oxide was stripped into graphene oxide to obtain 50 mL of a uniform graphene oxide dispersion; the dispersion was poured into a polytetrafluoroethylene petri dish with a diameter of 10 cm, and the petri dish containing the graphene oxide dispersion was Place it on a hot stage at 60°C, and obtain a graphene oxide film by evaporating on the hot stage for 12 hours;

[0042] (2) Place the prepared graphene oxide film in 55wt% hydroiodic acid solution for reduction for 1h, then wash with alcohol for 3 times to remove residual hydroiodic acid on the surface, and obtain the graphene film after natural drying;

[0043] (3) Connect the closed circuit with wires at both ends of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com