Thin foamed polyethylene sheets and manufacture method thereof

A thin sheet, sheet technology, applied in the field of manufacturing these foam sheets, to achieve the effect of increasing the cushioning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

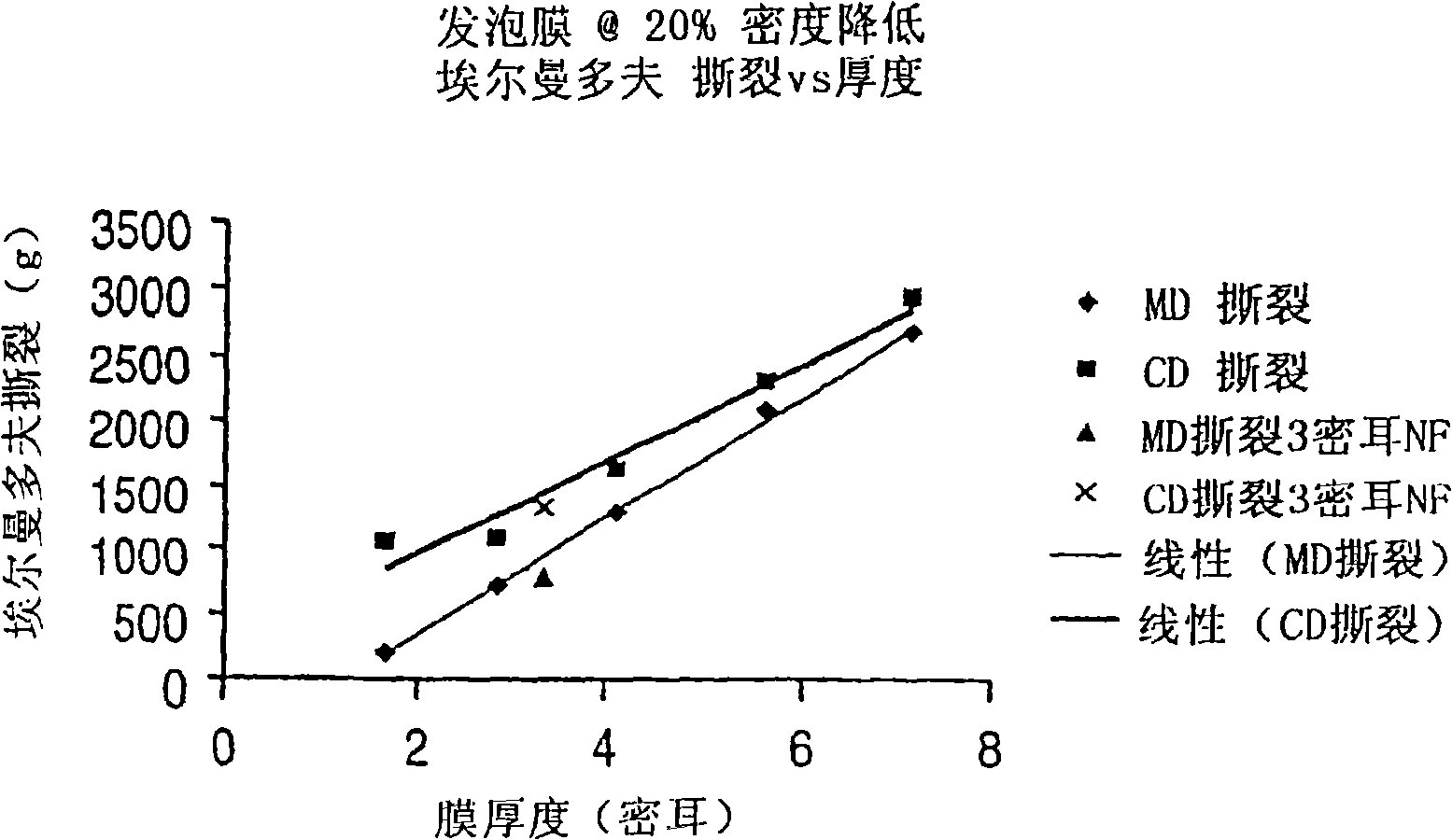

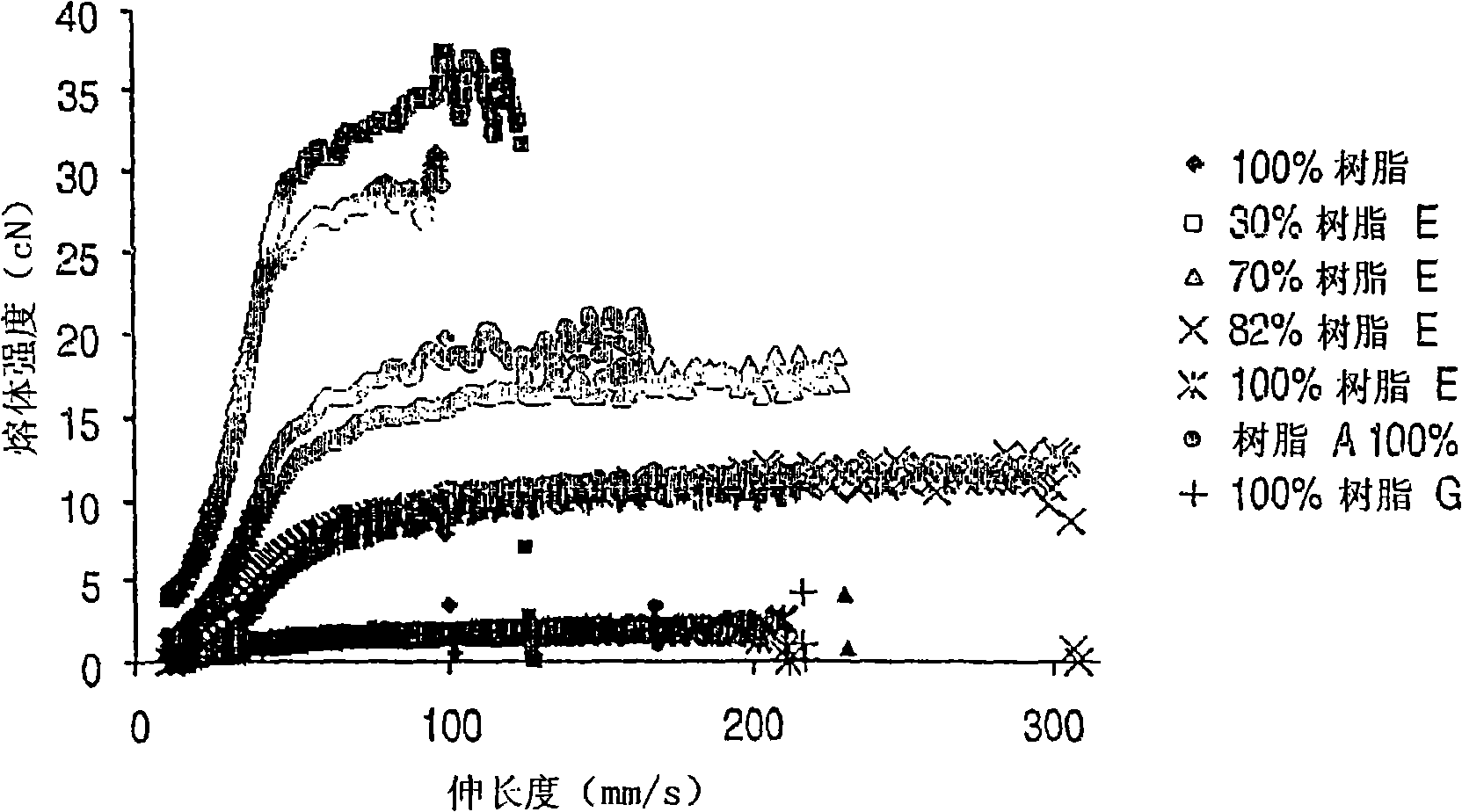

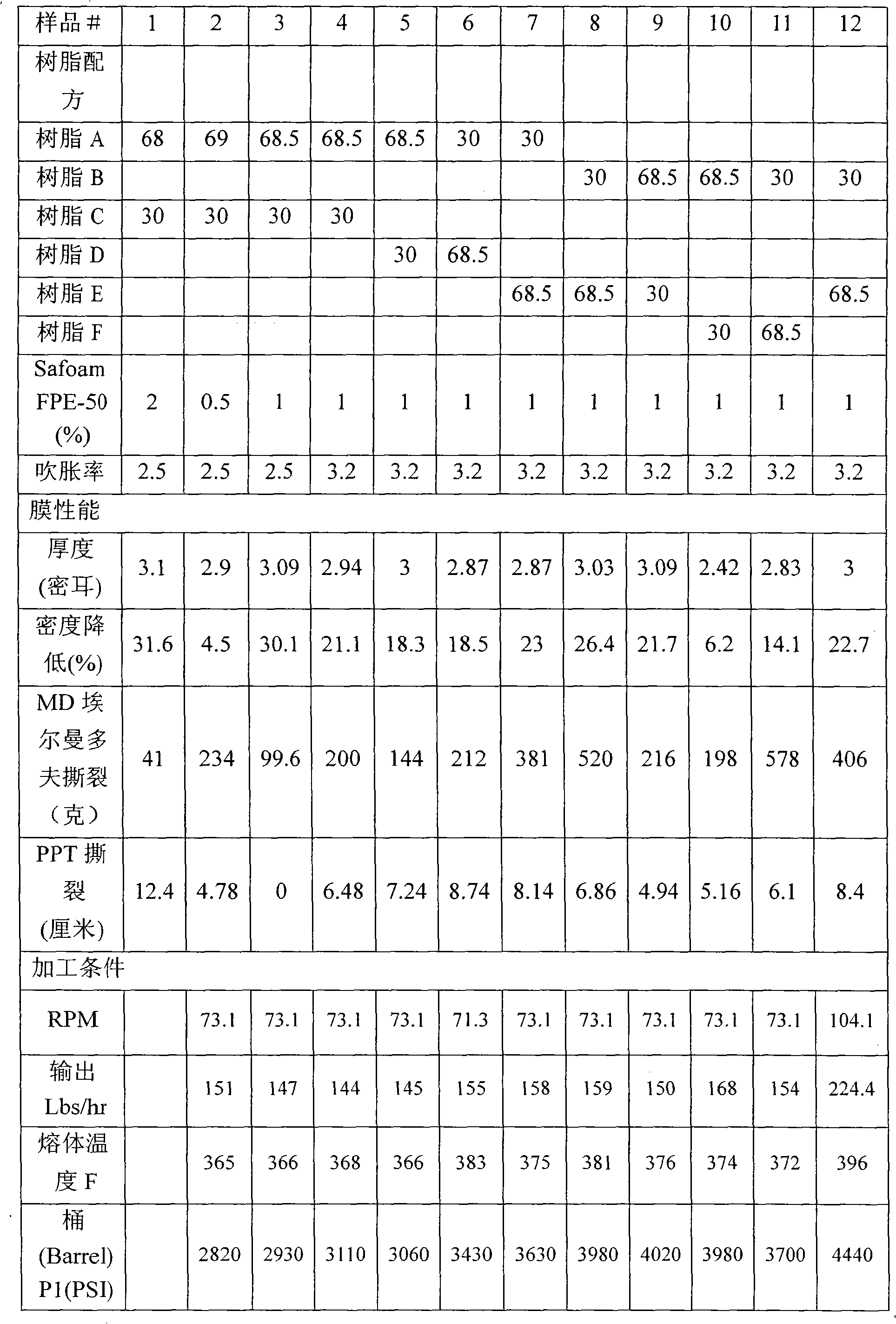

[0039] Sheets were formed from the LDPE and LLDPE resins shown in Table I. Resin A is an LDPE with a melt index (MI) (at 190°C / 2.16 kg) of 2.3 and a density of 0.920. Resin B is an LDPE with a MI of 0.47 g / 10 min and a density of 0.920. Resin C is LLDPE with a MI of 0.5 and a density of 0.920. Resin D is LLDPE with a MI of 1.0 and a density of 0.920. Resin E is LLDPE with a MI of 2.3 and a density of 0.917. Resin F is a ULDPE with a MI of 4 and a density of 0.904 g / cc. The chemical blowing agent or CBA used was SAFOAM FPE-50 containing 50% encapsulated sodium salt active ingredients of carbonic and polycarboxylic acids in a polyethylene carrier. A 3 mil thick film was made using a 2.5 inch extruder equipped with an 8 inch low pressure die and a medium shear barrier screw. A 40 mil lip with a 1 / 2 inch land length was used. The route runs at 220lbs.hr. MD tear strength was then measured according to ASTM D 1922 Elmendorf type B method. Puncture Propogation Tear (PPT) was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com