Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Small height difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light emitting device

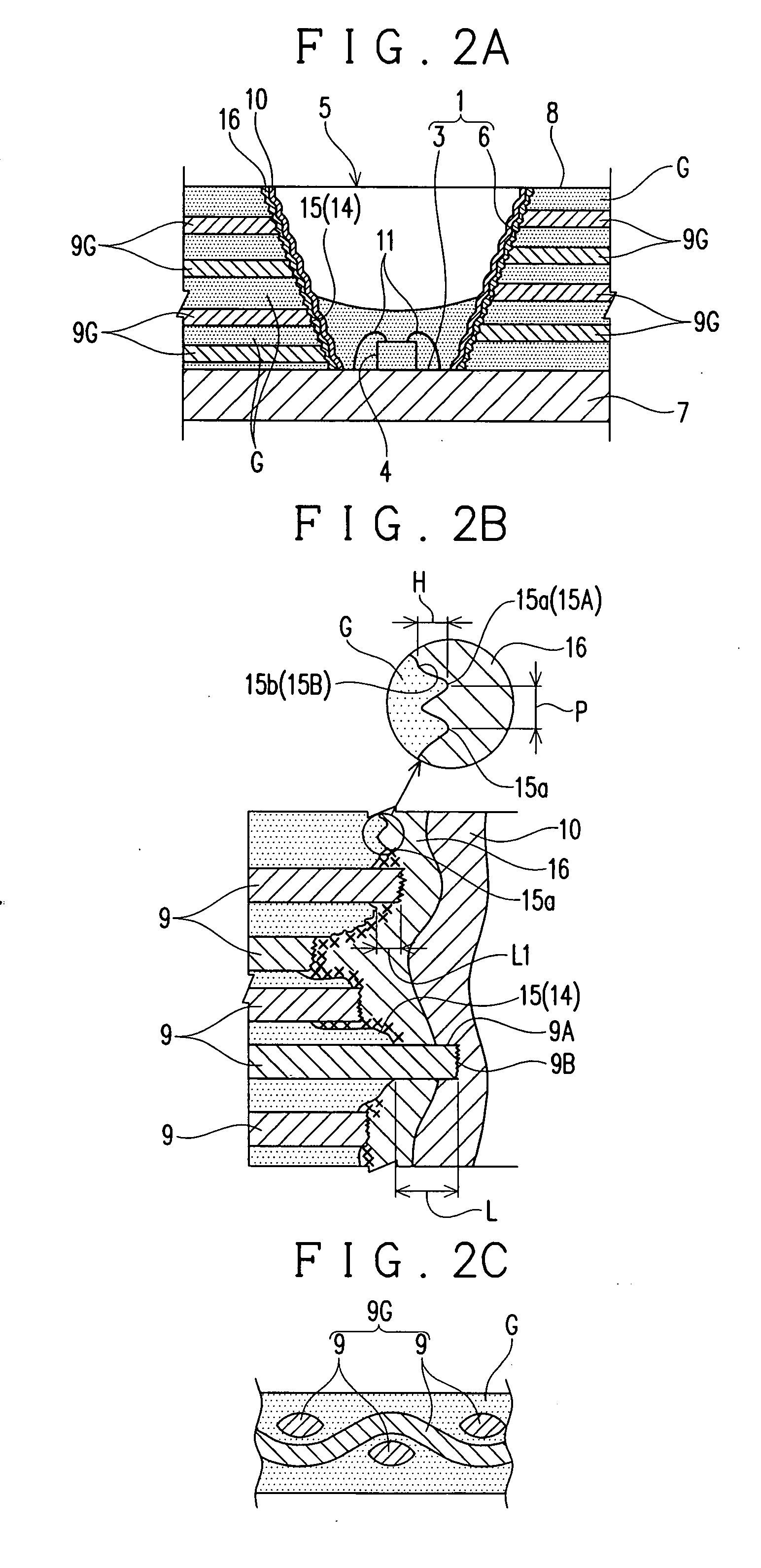

InactiveUS20070262336A1Small height differenceImprove adhesionDischarge tube luminescnet screensLamp detailsFiberLight emitting device

A light emitting device includes a package having a recessed portion defined by a bottom surface and a side surface and a light emitting element mounted on the bottom surface of the recessed portion, in which the package has fibrous fillers, and at least some of the fillers are projected outwards through the side surface and coated with a reflection film made of metal.

Owner:NICHIA CORP

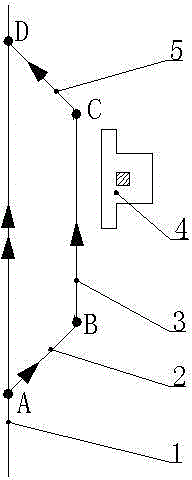

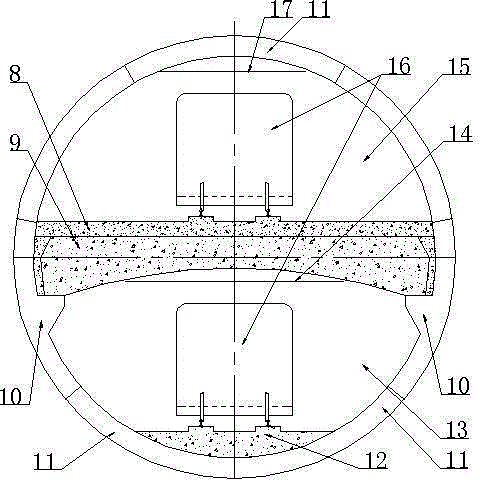

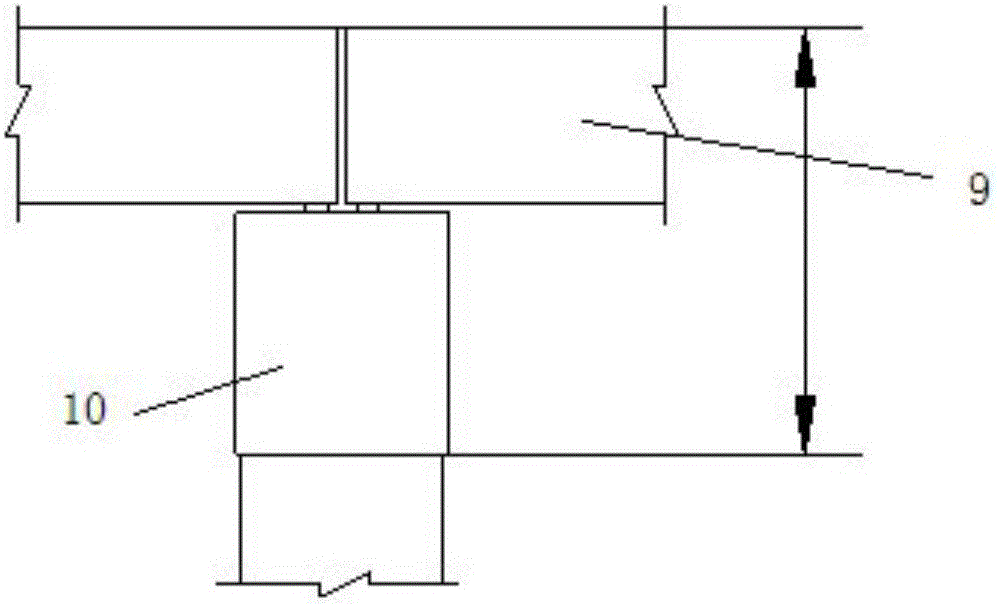

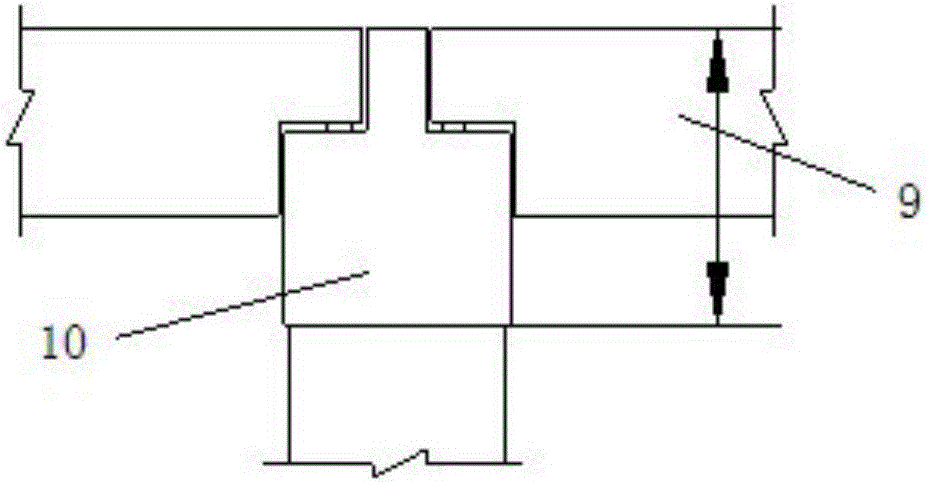

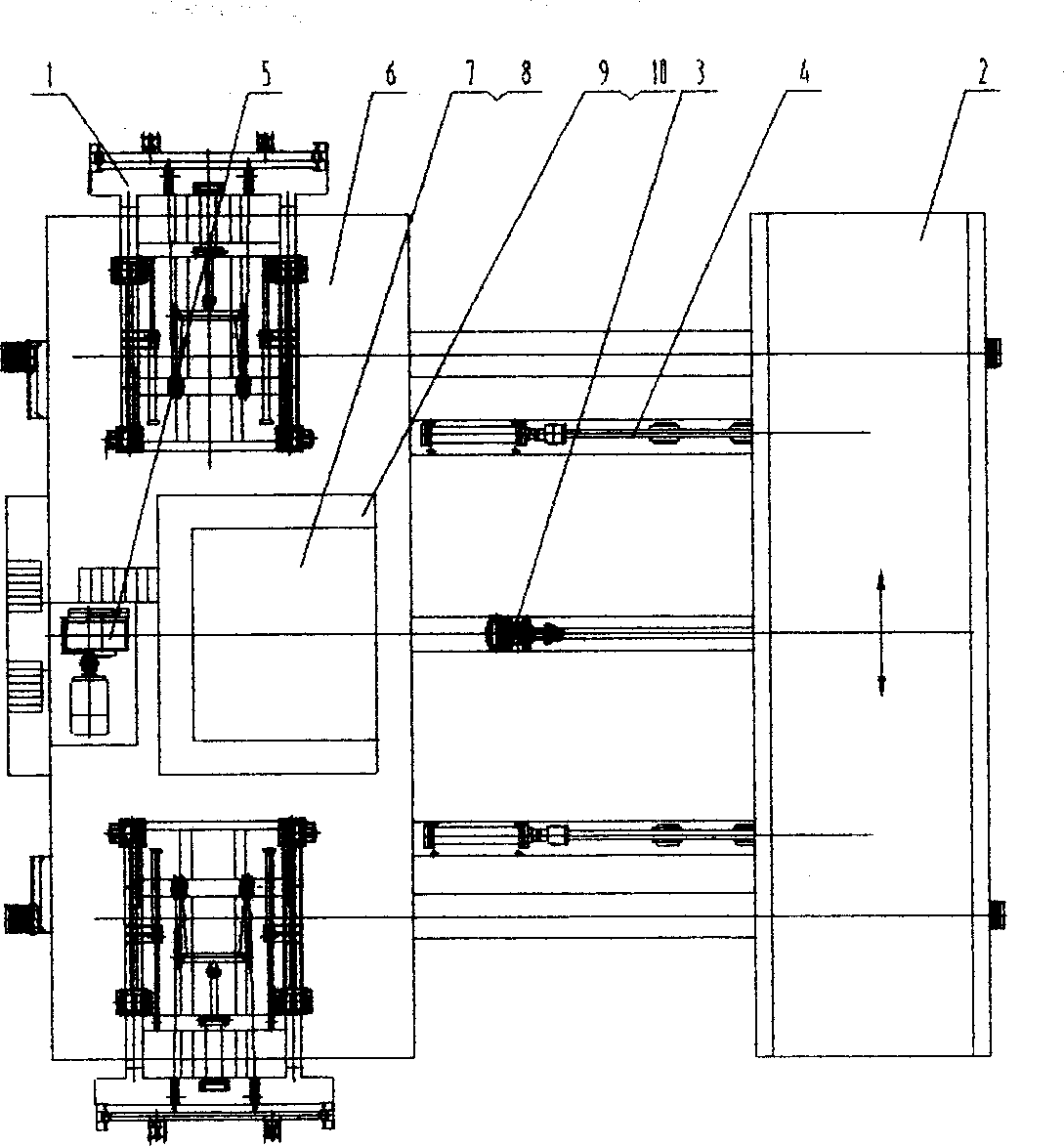

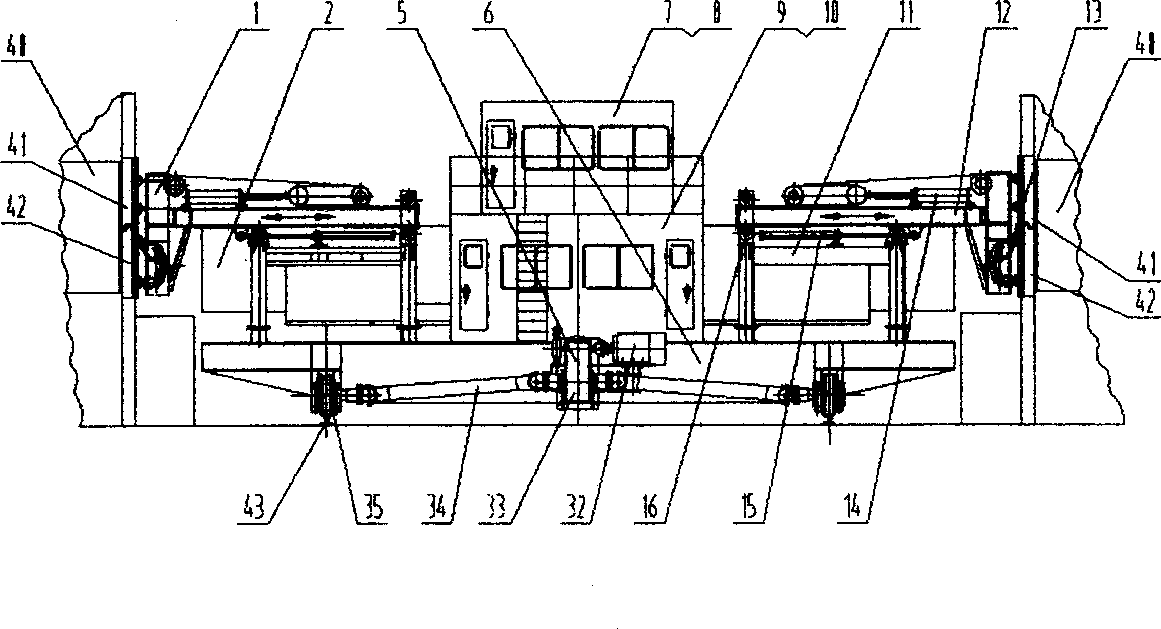

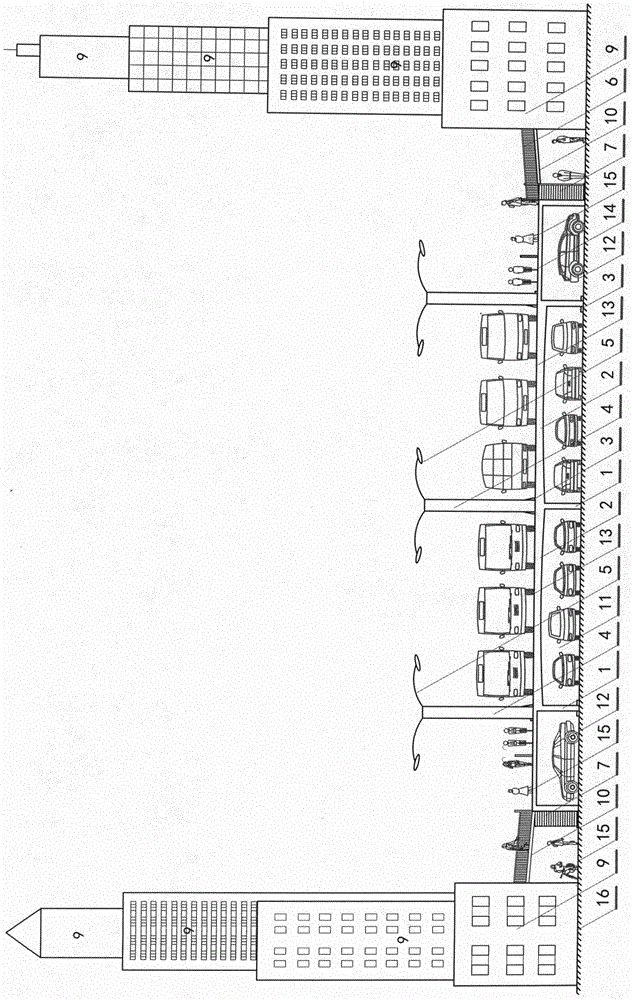

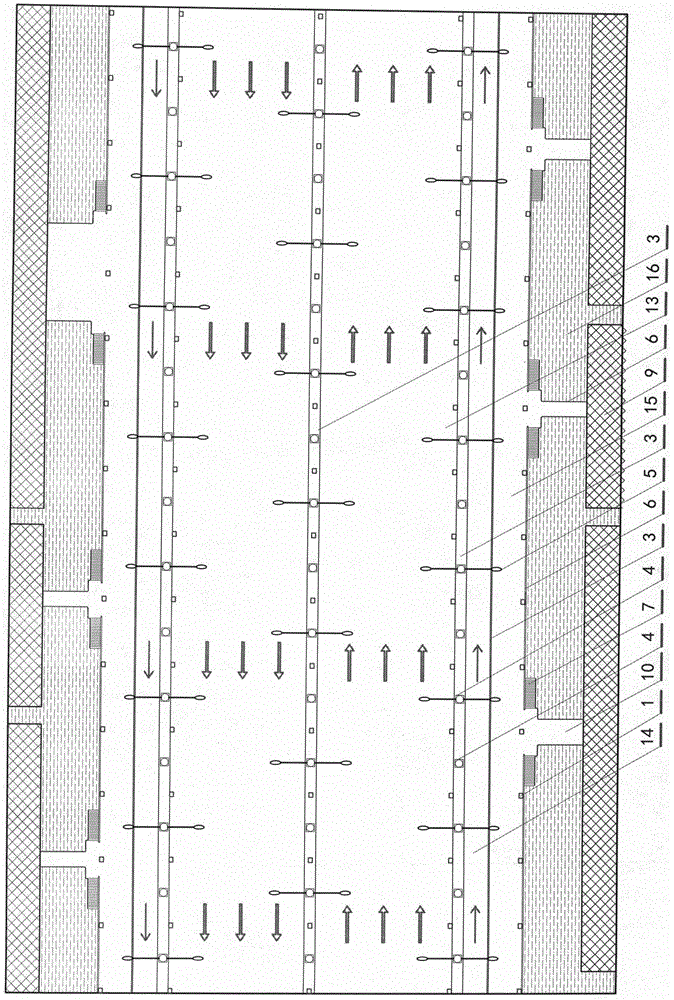

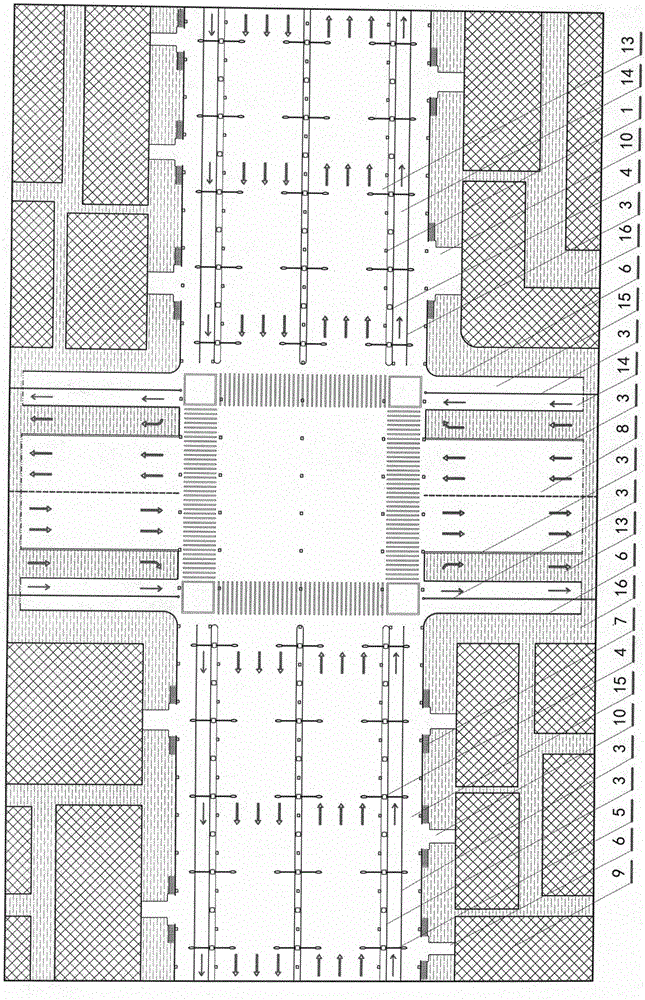

Rapid shuttle single-tunnel double-decker track subway

ActiveCN104816732AImprove effective time utilizationAvoid the restriction of short station distanceRailway tunnelsDouble deckerVehicle frame

The invention discloses a rapid shuttle single-tunnel double-decker subway, a train running space configured by shuttle tunnels with a upper and a lower track and double stereo train stations, the subway herein requiring less land occupation and digging work load. According to the subway herein, lines are composed of express lines, train stations, and launching lines, allowing separation of trains which are running from trains which stop for allowing passengers to get on and get off. The subway herein allows changes to train tracking operation, launches of express shuttles as needed, reduction of stops, and increasing of train operating density and running velocity. The subway herein also allows using train hooks to conduct rapid train re-arrangements, increasing train re-arrangements in peak time, operating non-stop trains or limited-stops trains so as to increase passenger capacity. The subway herein further allows decreasing of train re-arrangements in normal time or low peak time in a manner whereby trains stop at each and every train station so as to reduce operation cost. According to the subway herein, a recessed bottom train frame structure is adopted in the train for reducing train height and center of gravity, and tunnel diameter is decreased. By planning of different passenger capacities, selecting different train re-arrangements, and adopting various running patterns based on passenger flow time frames, the subway herein obtains an improved cascade-type passenger capacity ranging from 10,000 to more than 90,000 per hour for a single direction. The rapid shuttle single-tunnel double-decker subway of the invention adjusts to capacity demands in megacities, and can reduce starting-point requirements for building subways, like size of city passenger flow and population.

Owner:谭培炎

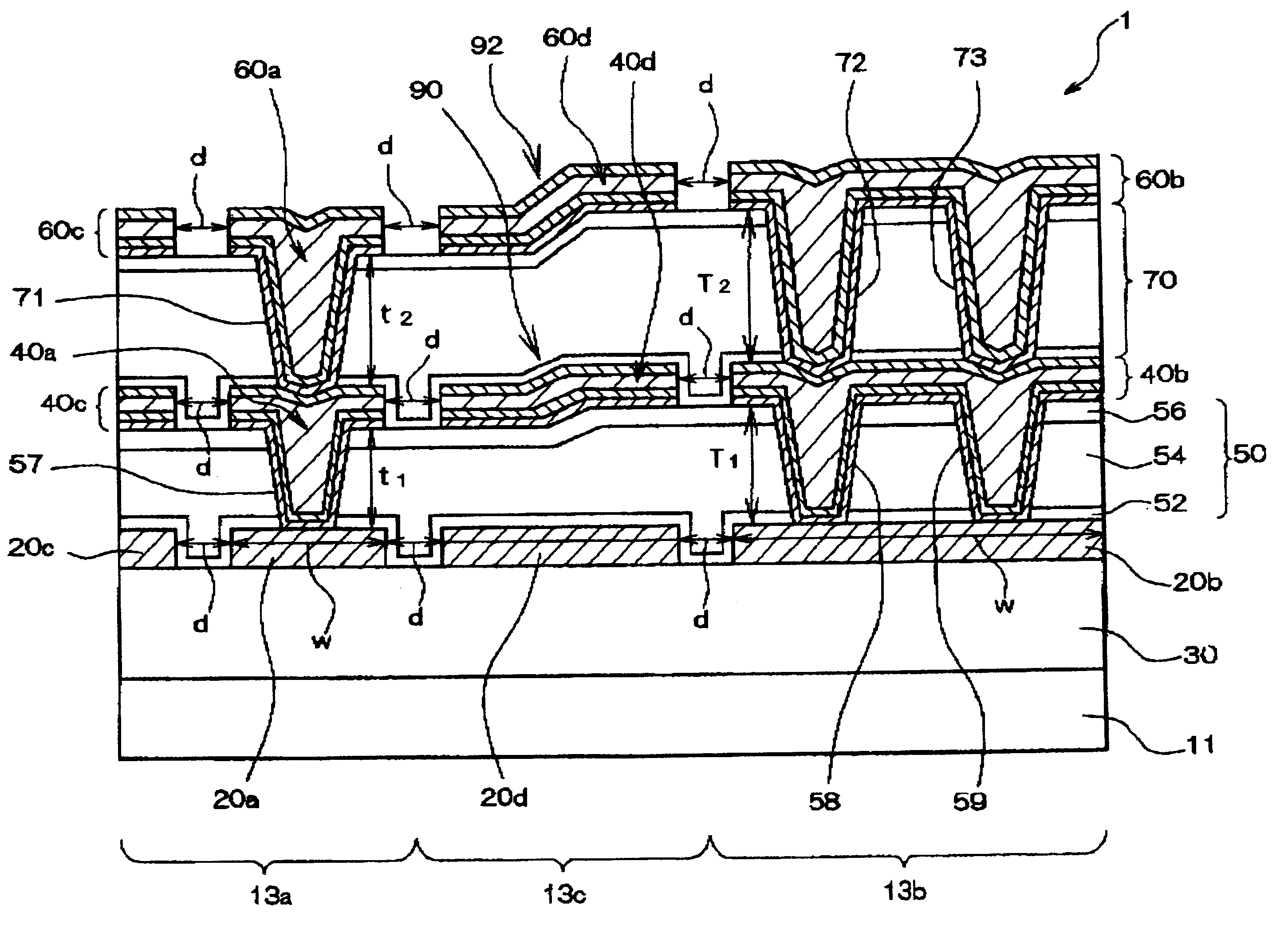

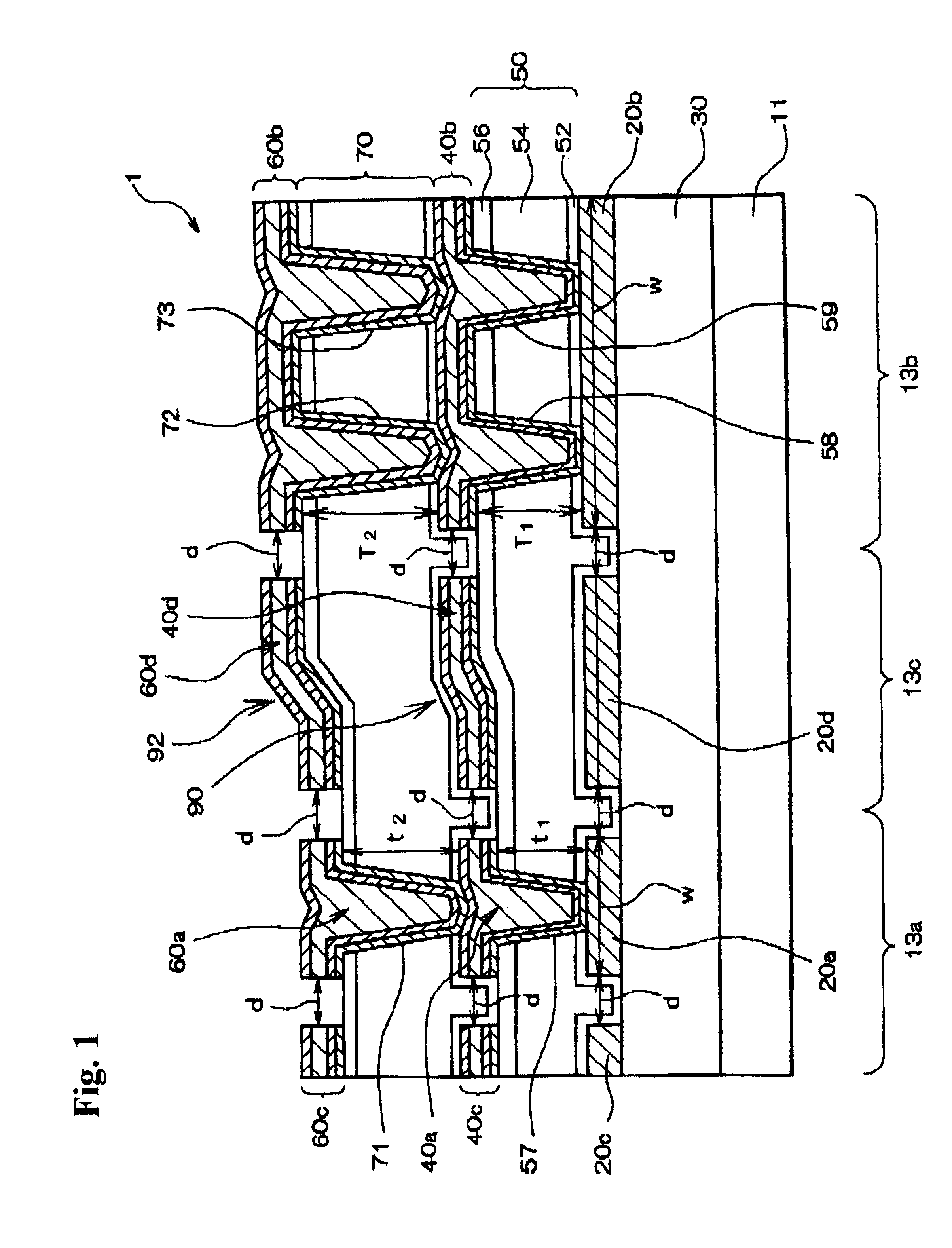

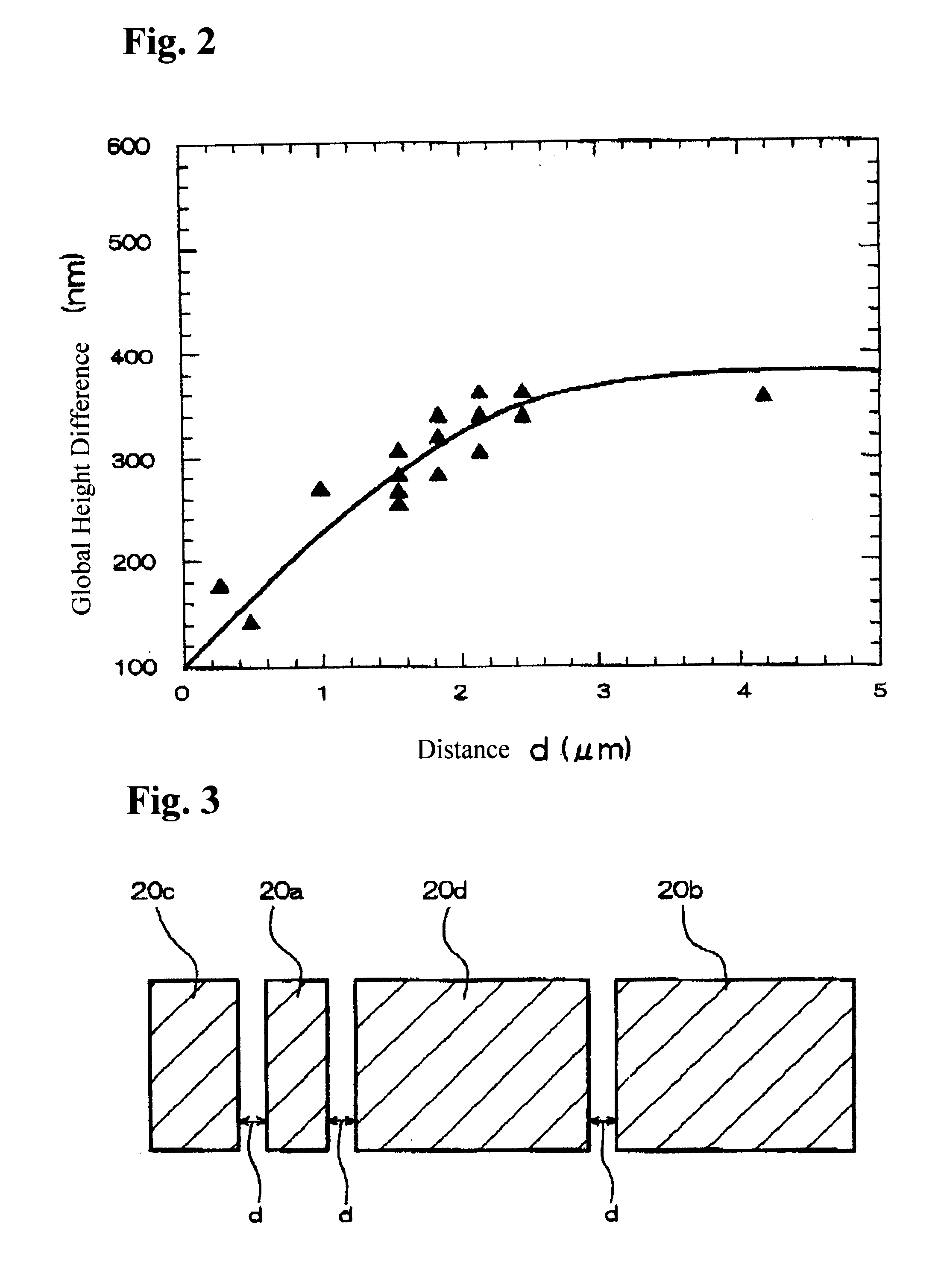

Semiconductor device and method for making pattern data

InactiveUS6287948B1Small height differenceOvercome lack of focusTransistorSemiconductor/solid-state device detailsSilanesEngineering

A semiconductor device has a first region, a second region and a border region between the first region and the second region. The semiconductor device has an interlayer dielectric layer, covering at least the first region and the second region. A first wiring layer is located in the first region and defines a relatively small pattern. A second wiring layer is located in the second region and defines a relatively large pattern that is wider than the small pattern. A first dummy pattern is formed in the first region and a second dummy pattern is formed in the border region. The interlayer dielectric layer includes a planarization silicon oxide film. The planarization silicon oxide film is one of a silicon oxide film formed by a polycondensation reaction between a silicon compound and hydrogen peroxide, an organic SOG (Spin On Glass) film an inorganic SOG film and a silicon oxide film formed by reacting an organic silane with ozone or water. The interlayer dielectric layer located over the first wiring layer is thinner than the interlayer dielectric layer located over the second wiring layer such that a global height difference occurs in the border region between the first region and the second region.

Owner:ADVANCED INTERCONNECT SYST LTD

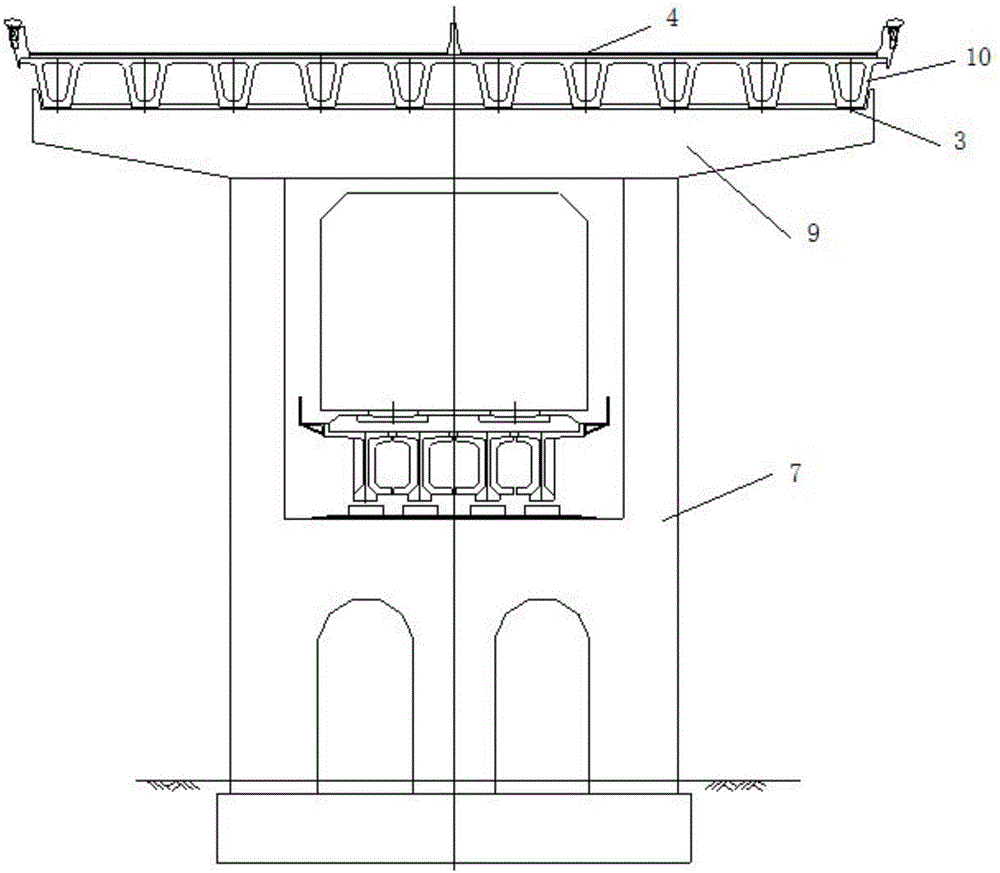

Double-layer bridge capable of reducing interlayer height difference

ActiveCN105019347ASmall height differenceLow costBridge structural detailsRoad surfaceHeight difference

The invention discloses a double-layer bridge capable of reducing interlayer height difference. The double-layer bridge capable of reducing the interlayer height difference comprises a road surface paving protective layer, gate-type pier studs and an under layer bridge floor, the double-layer bridge capable of reducing the interlayer height difference further comprises a road beam and longitudinal beams, the road beam is laid on the longitudinal beams, the road surface paving protective layer is laid on the upper surface of the road beam, one end of each longitudinal beam is connected with the lower surface of the road beam, the other end of each longitudinal beam is connected with the corresponding gate-type pier stud, and the under layer bridge floor is arranged between the road beam and the gate-type pier studs. According to the double-layer bridge capable of reducing the interlayer height difference, the idle space without occupying a building line is skillfully utilized, therefore, the interlayer height difference of the double-layer bridge is reduced by a large margin, the double-layer bridge capable of reducing the interlayer height difference can be used for road-railway co-built double-layer bridges, similar double-layer structures can all adopt the structure style, and the actual efficacy of the double-layer bridge capable of reducing the interlayer height difference is reflected in the aspects of reducing the scale of construction and reducing the construction cost.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

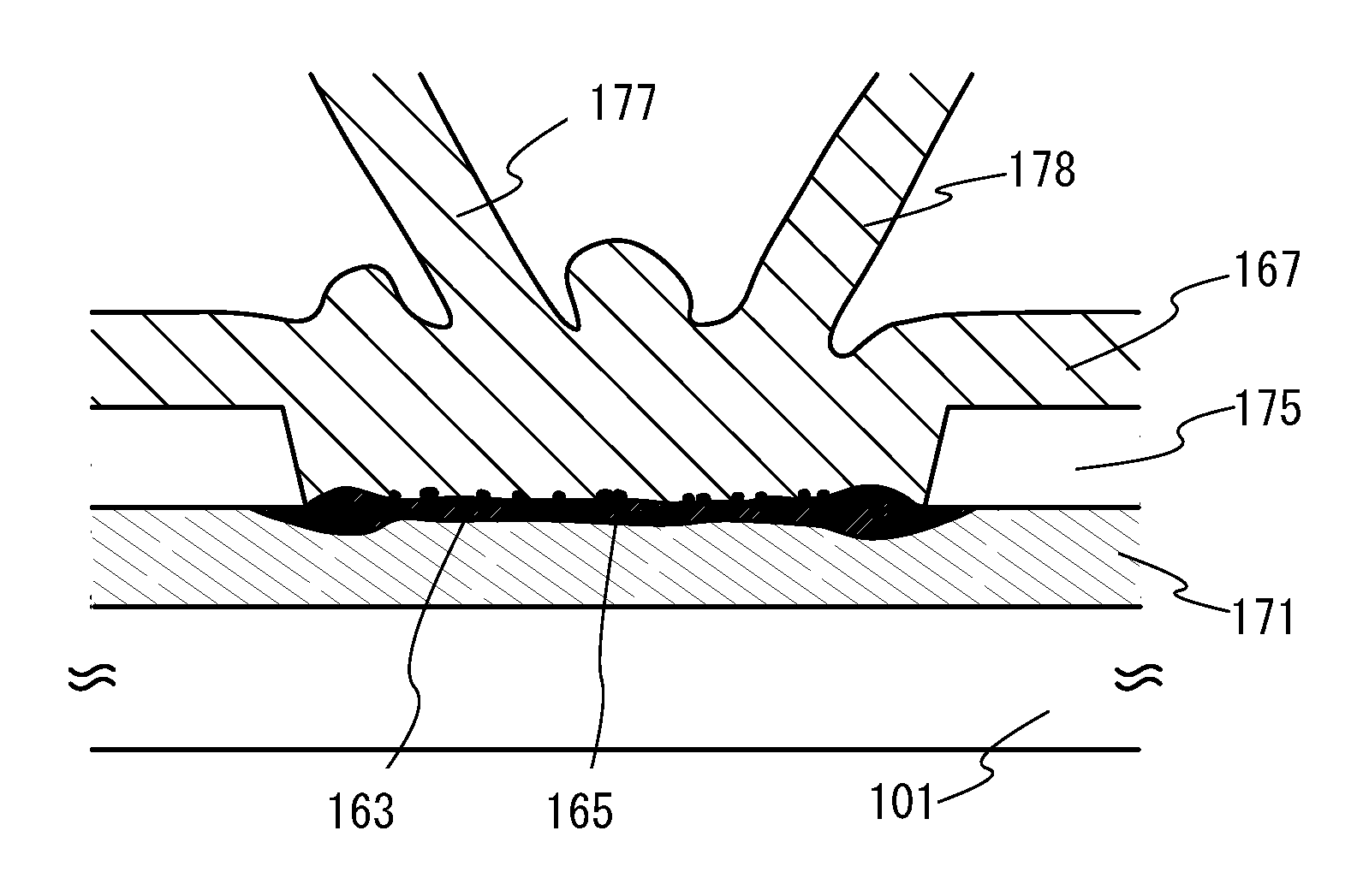

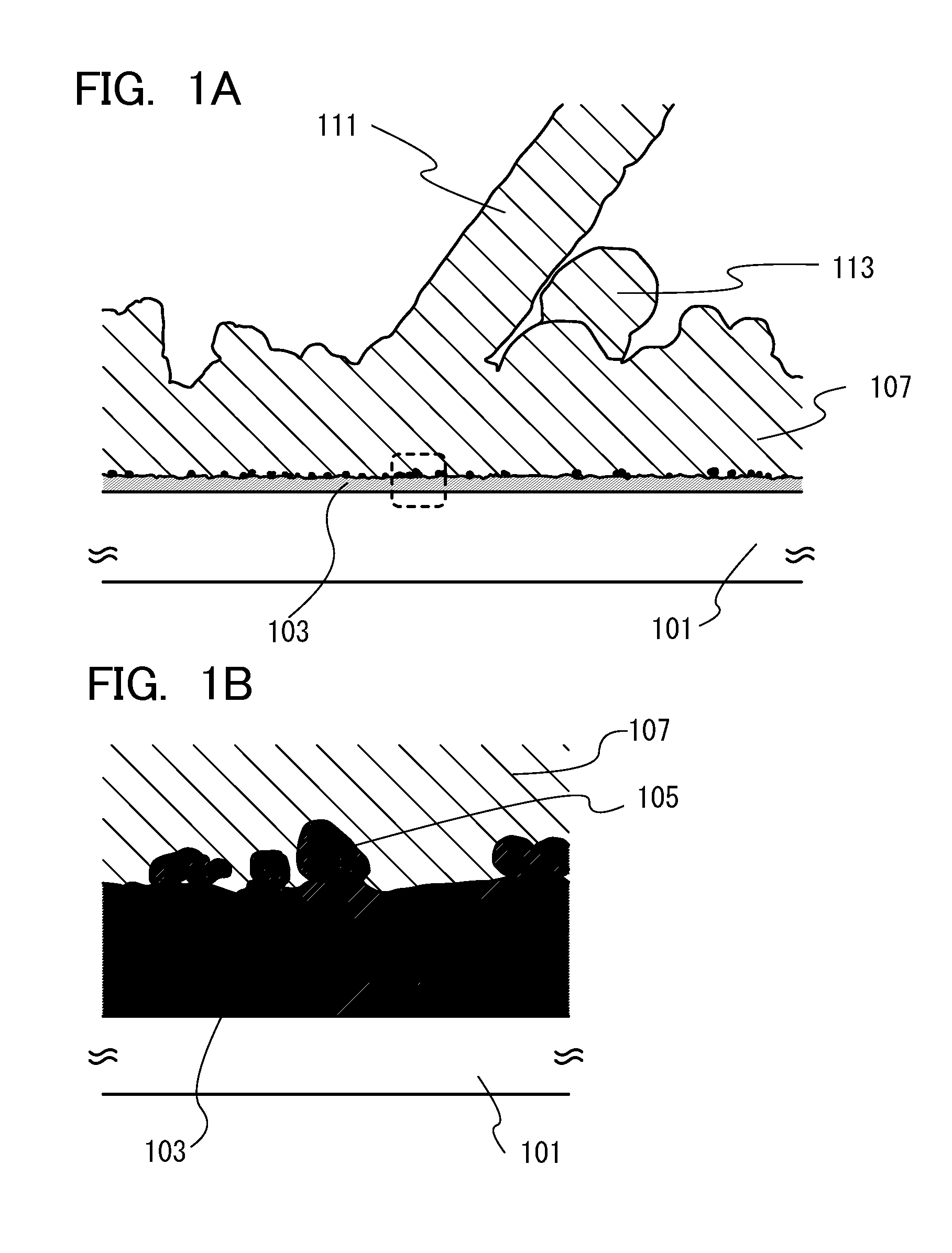

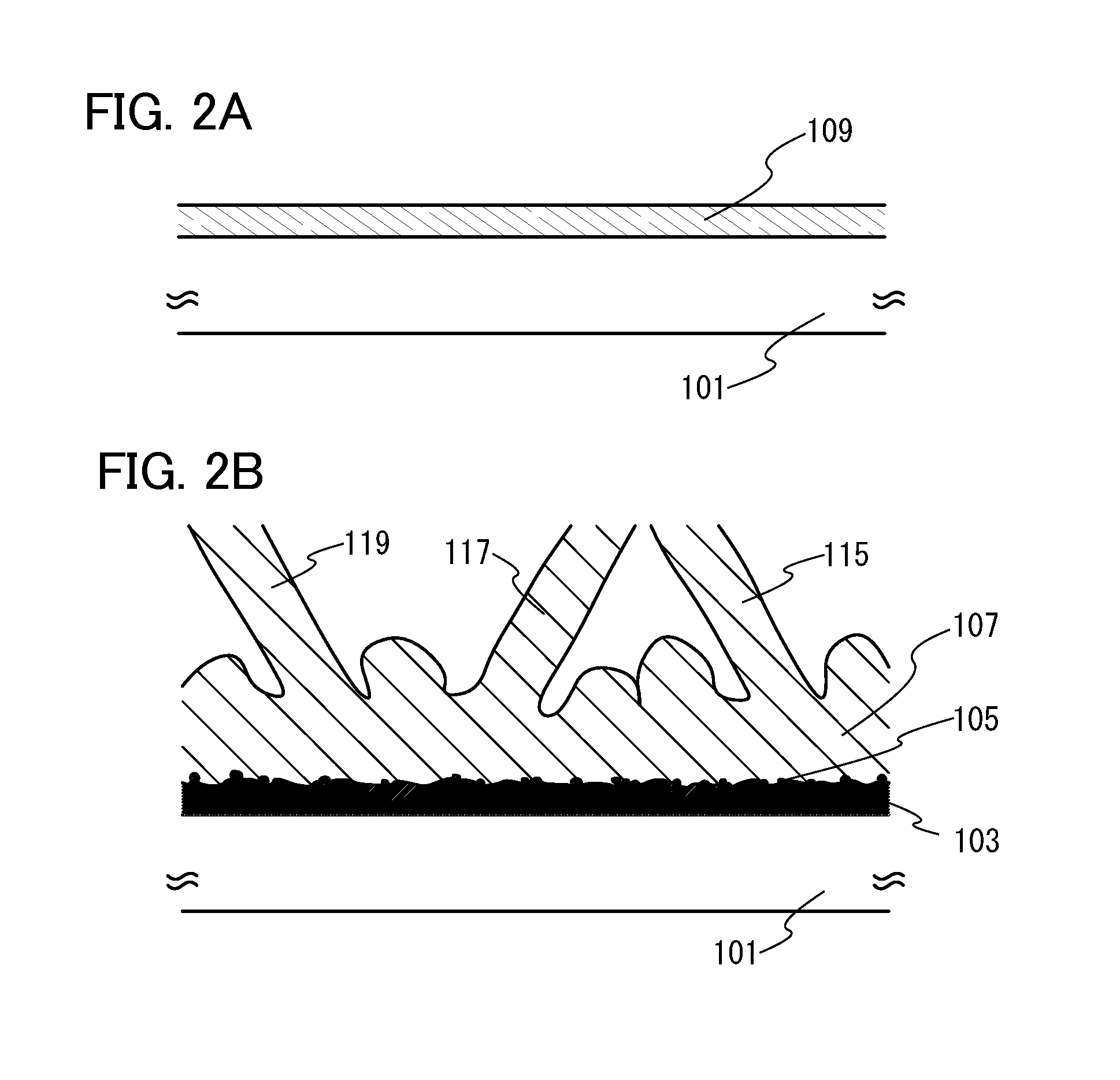

Semiconductor film, method for manufacturing the same, and power storage device

ActiveUS20120135302A1High charge and discharge capacityEnhanced vapor depositionHybrid capacitor electrodesSemiconductor/solid-state device detailsHigh densityCharge discharge

Provided are a semiconductor film including silicon microstructures formed at high density, and a manufacturing method thereof. Further, provided are a semiconductor film including silicon microstructures whose density is controlled, and a manufacturing method thereof Furthermore, a power storage device with improved charge-discharge capacity is provided. A manufacturing method in which a semiconductor film with a silicon layer including silicon structures is formed over a substrate with a metal surface is used. The thickness of a silicide layer formed by reaction between the metal and the silicon is controlled, so that the grain sizes of silicide grains formed at an interface between the silicide layer and the silicon layer are controlled and the shapes of the silicon structures are controlled. Such a semiconductor film can be applied to an electrode of a power storage device.

Owner:SEMICON ENERGY LAB CO LTD

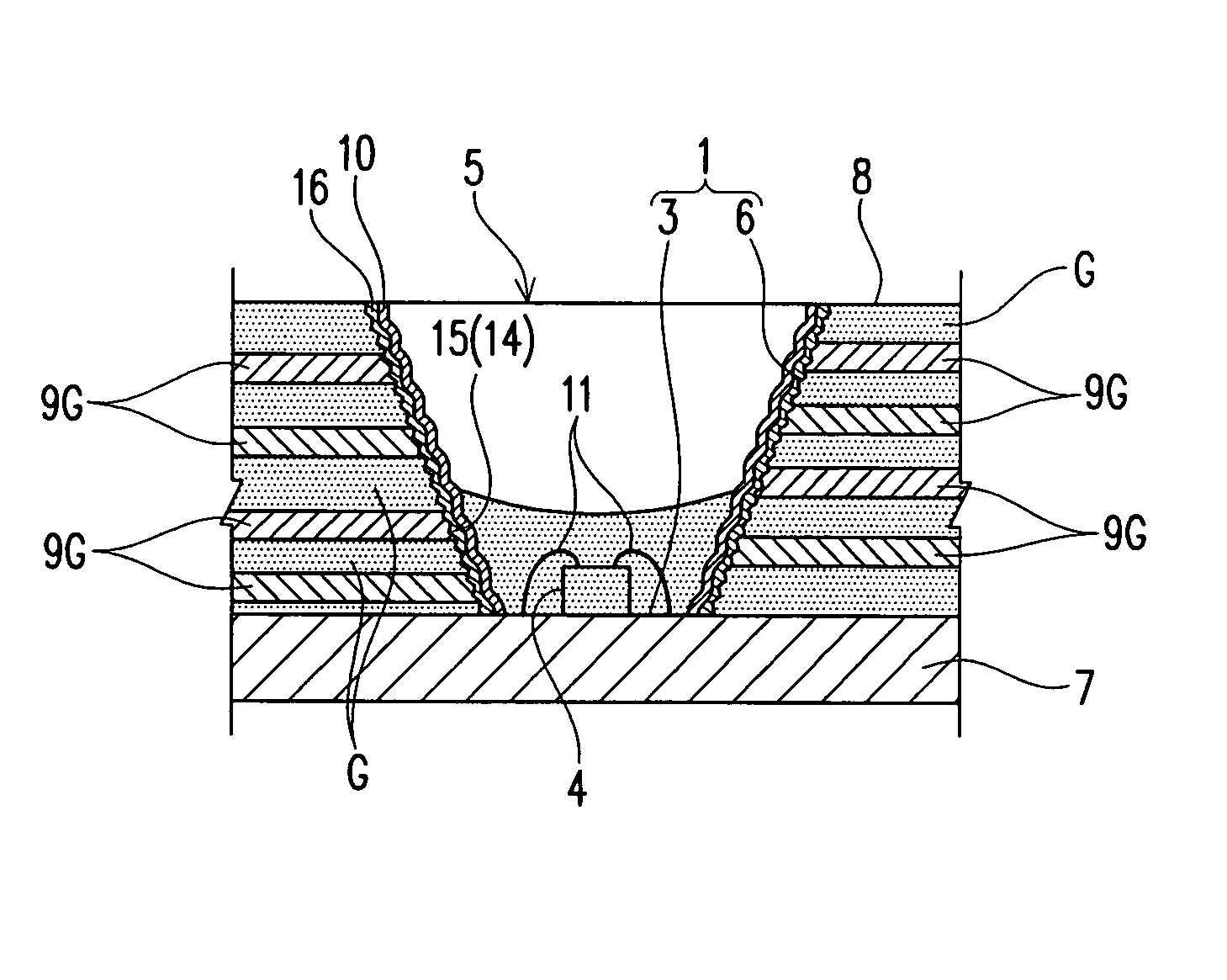

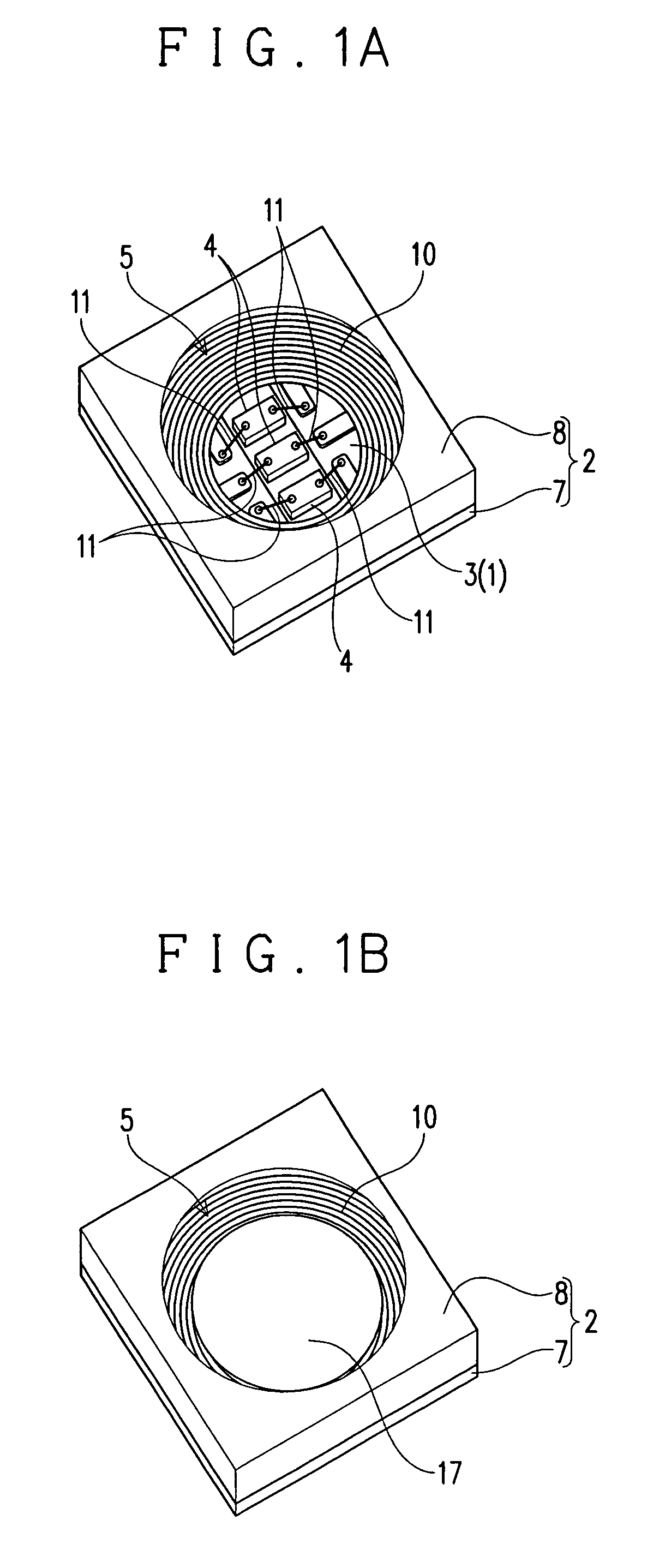

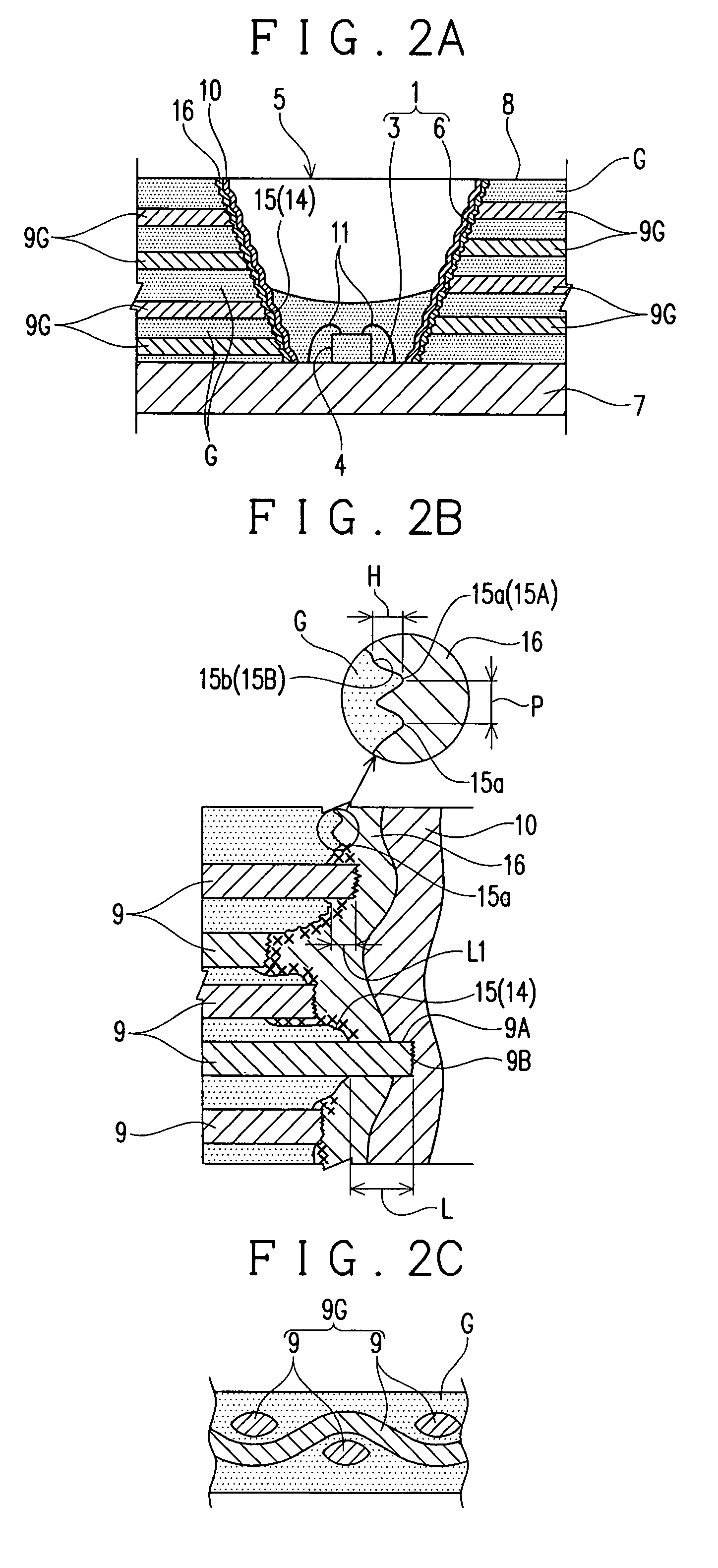

Light emitting device having a package formed with fibrous fillers

InactiveUS7830079B2Small height differenceImprove adhesionDischarge tube luminescnet screensLamp detailsFiberLight emitting device

A light emitting device includes a package having a recessed portion defined by a bottom surface and a side surface and a light emitting element mounted on the bottom surface of the recessed portion, in which the package has fibrous fillers, and at least some of the fillers are projected outwards through the side surface and coated with a reflection film made of metal.

Owner:NICHIA CORP

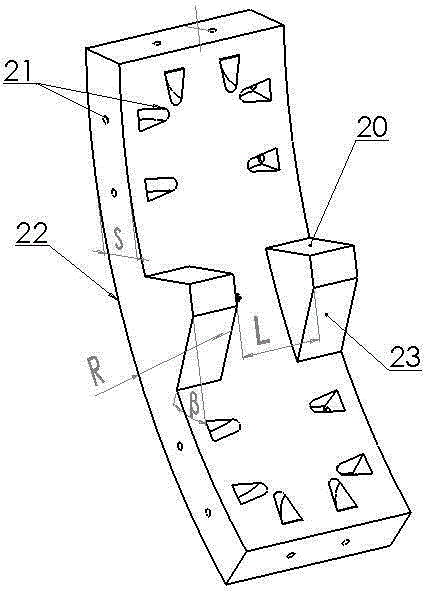

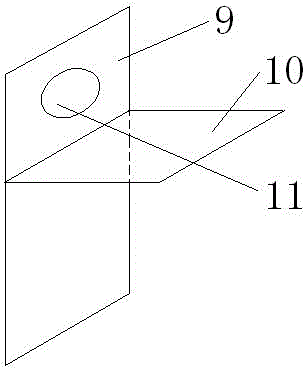

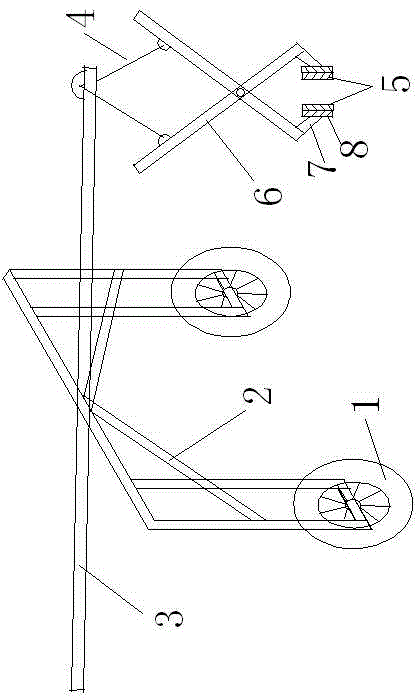

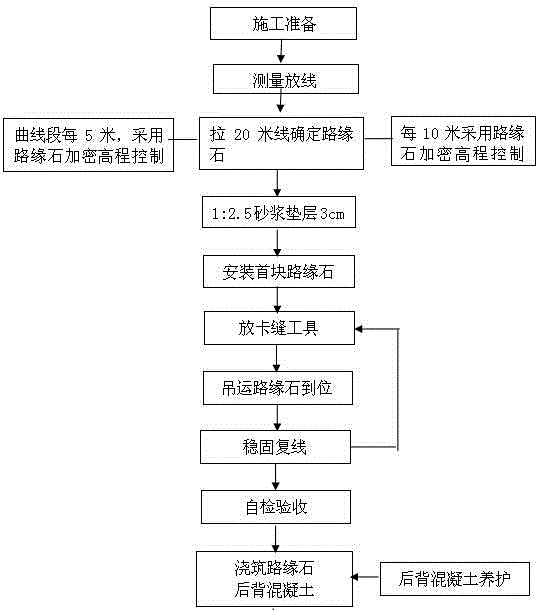

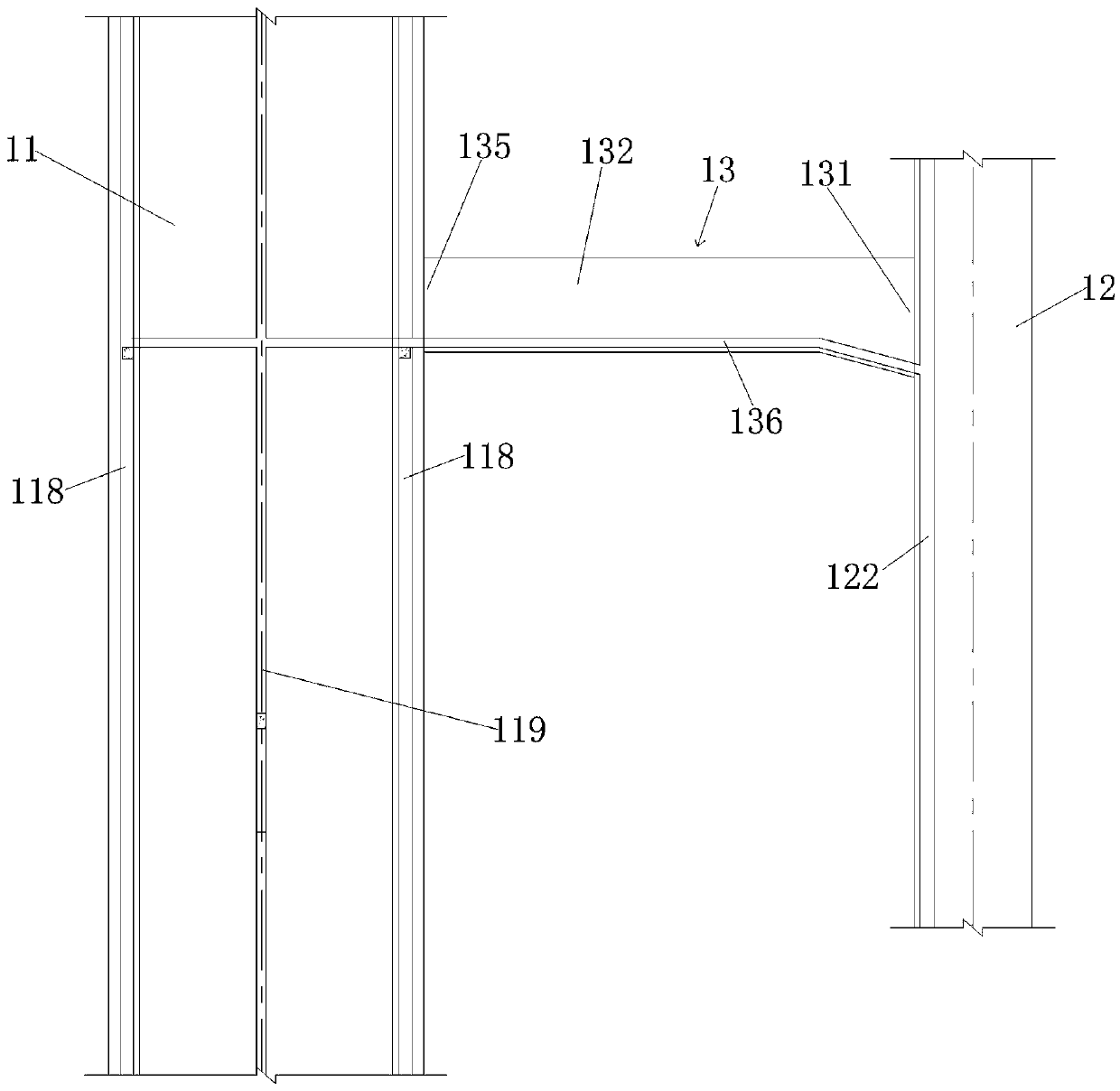

Kerbstone mechanical-hoisting and seam-spacing method-based construction method, hoisting tool and seam-spacing tool

InactiveCN104313984ASimple structureEasy to usePortable liftingRoads maintainenceEconomic benefitsCement mortar

The invention discloses a kerbstone mechanical-hoisting and seam-spacing method-based construction method, a hoisting tool and a seam-spacing tool. The kerbstone mechanical-hoisting and seam-spacing method-based construction method comprises the following steps of 1, preparing construction, 2, carrying out measurement and line laying, 3, bracing 10-20m of a line and determining a kerbstone directional line and elevation line, 4, arranging a 1: 2.5-3 cement mortar cushion layer having thickness of 3cm, 5, installing first kerbstone, 6, arranging the seam-spacing tool, 7, hoisting kerbstone to a designated position by the hoisting tool, 8, carrying out complex line stabilizing, 9, carrying out self-inspection checking, 10, pouring back concrete of the kerbstone, 11,maintening the back concrete and 12, carrying out inspection and acceptance by a supervisor. The method provided by the invention has strong operationality and simple installation method with low technical difficulty, reduces kerbstone manual-carrying labor intensity, improves efficiency, saves a labor cost and has economic benefits better than those of the traditional construction method.

Owner:JINAN URBAN CONSTR GRP

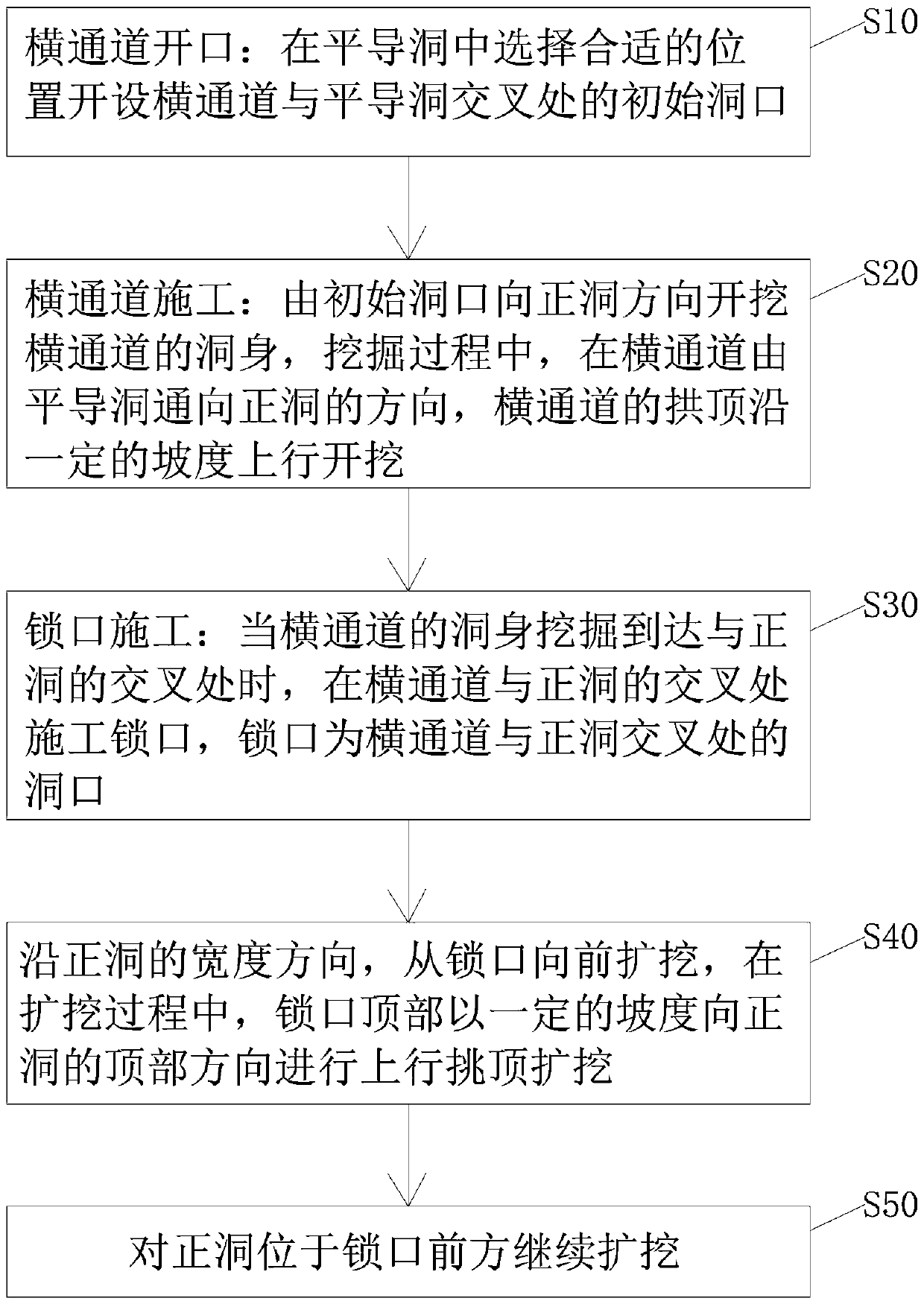

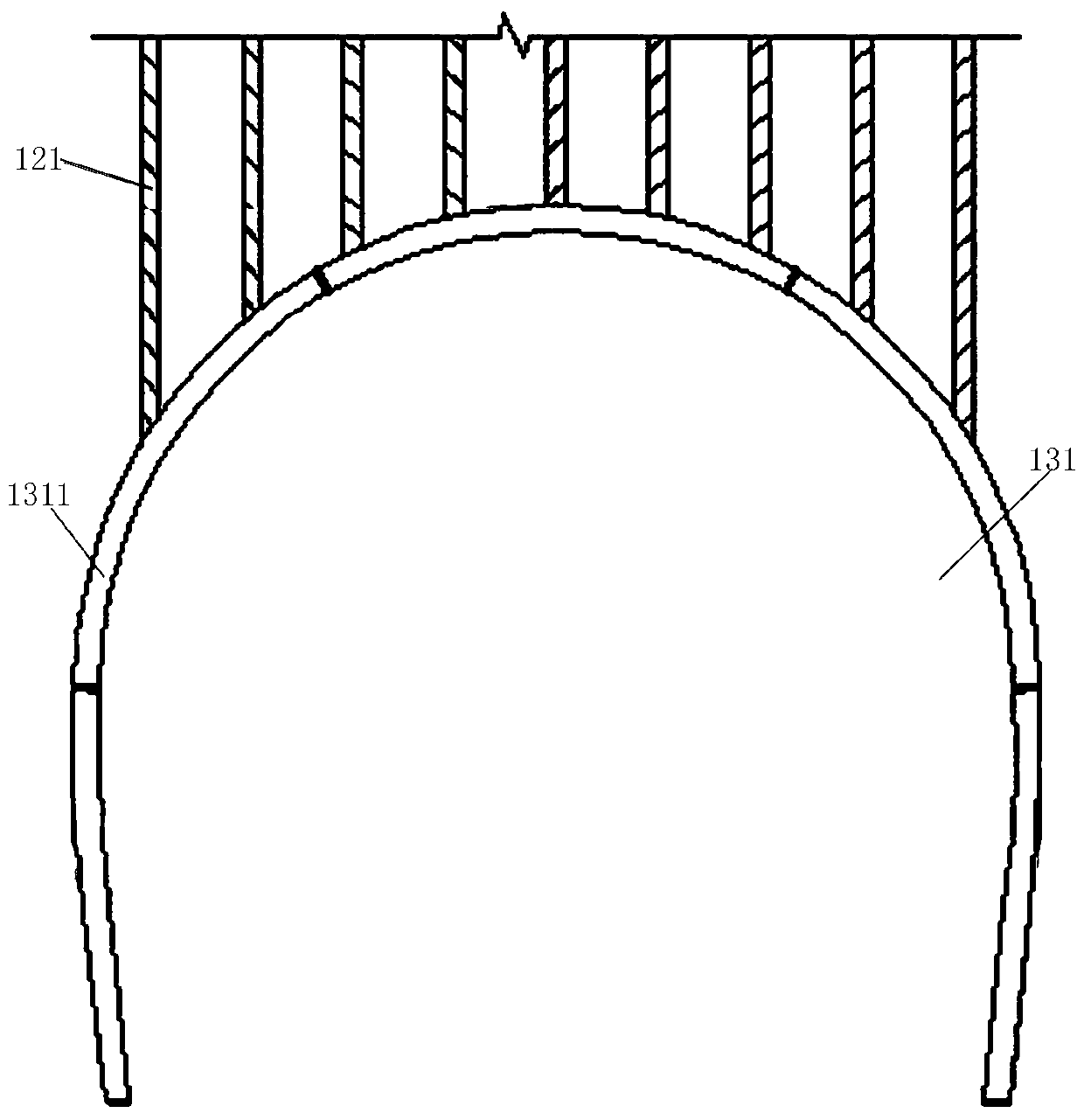

Construction method of cross passage from horizontal pilot tunnel to main tunnel and cross passage

ActiveCN110439571AReduce difficultyPrevent collapseUnderground chambersDrainageHeight differenceBuilding construction

The invention discloses a construction method of a cross passage from a horizontal pilot tunnel to a main tunnel and the cross passage. The construction method of the cross passage from the horizontalpilot tunnel to the main tunnel includes the following steps that firstly, a suitable position is selected in the horizontal pilot tunnel for forming an initial tunnel opening at the intersection ofthe cross passage and the horizontal pilot tunnel; secondly, a passage body of the cross passage is excavated from the initial tunnel opening to the direction of the main tunnel, the tunnel top of thecross passage is excavated upward along a certain slope in the direction from the horizontal pilot tunnel to the main tunnel during excavation, and then opening locking construction is conducted. According to the construction method of the cross passage from the horizontal pilot tunnel to the main tunnel, the height difference between the roof brushing of the cross passage and the roof brushing of the main tunnel is reduced by raising the tunnel top of the cross passage, the difficulty of the roof brushing construction is reduced, and collapse of roof brushings is prevented; in the roof brushing construction process, excavation and supporting can be performed at any time through temporary gantries to prevent the unstable collapse caused by long exposure time of surrounding rock. In addition, the construction progress of the main tunnel can be accelerated by excavating the cross passage from an excavated section of the horizontal pilot tunnel to a non-excavation section of the main tunnel.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

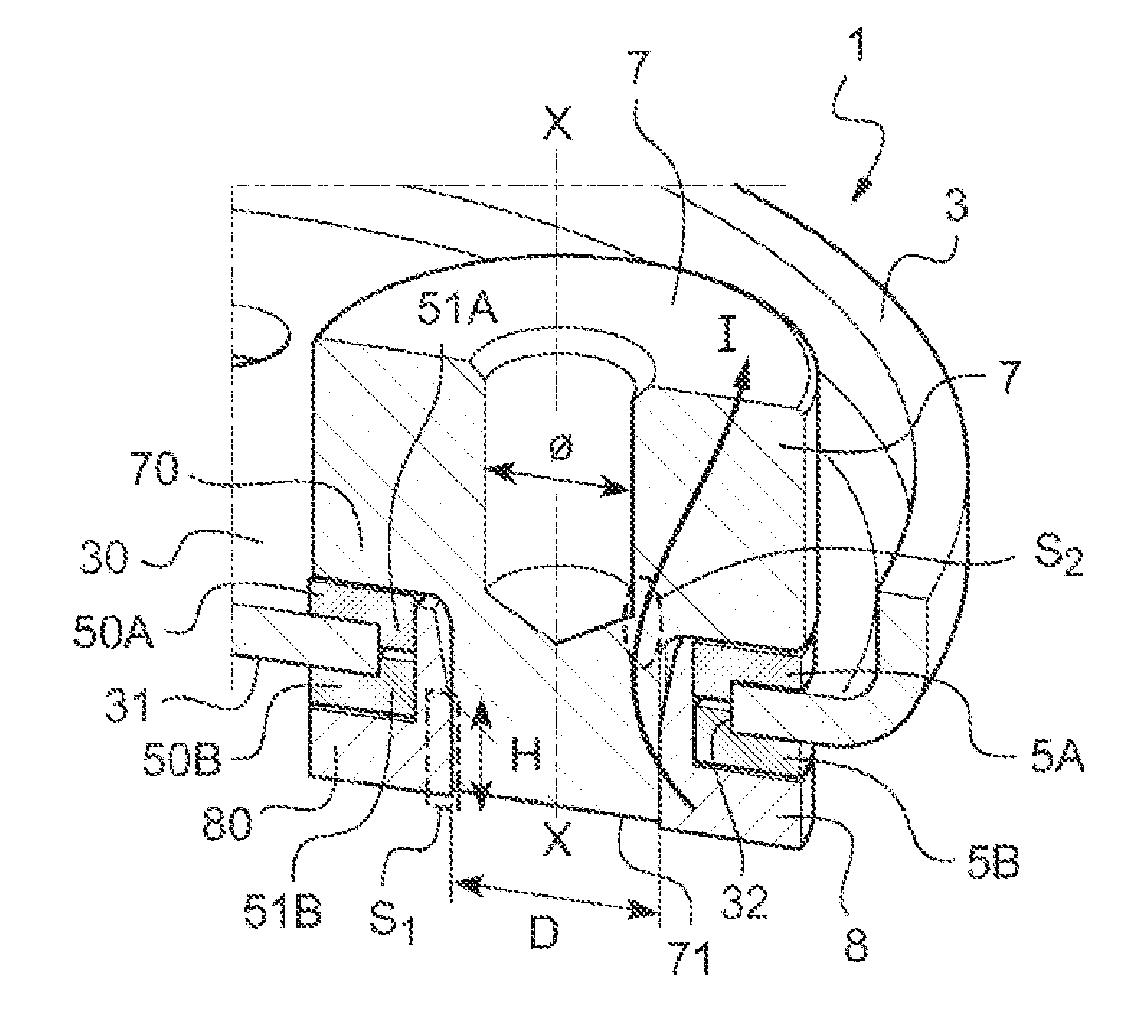

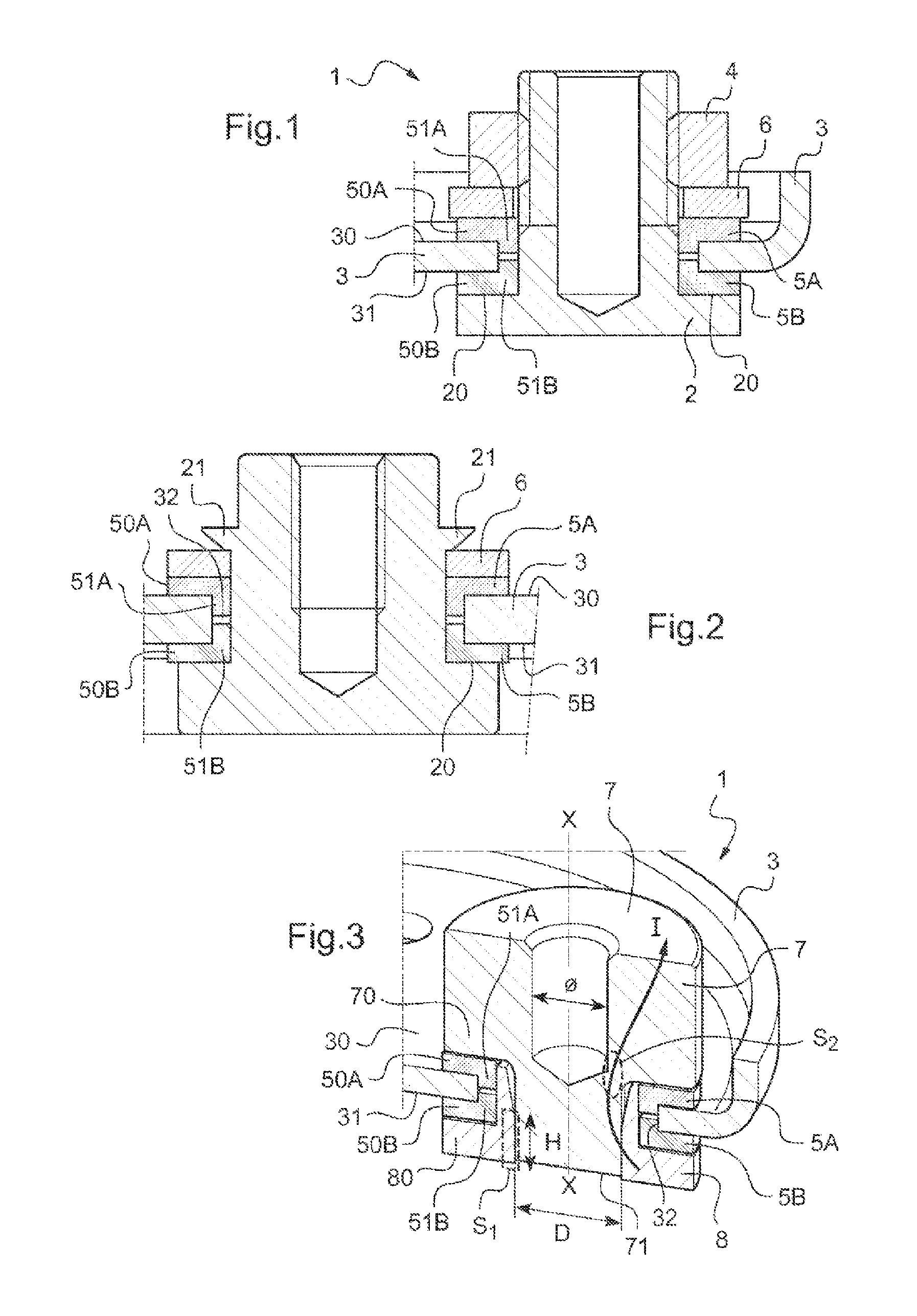

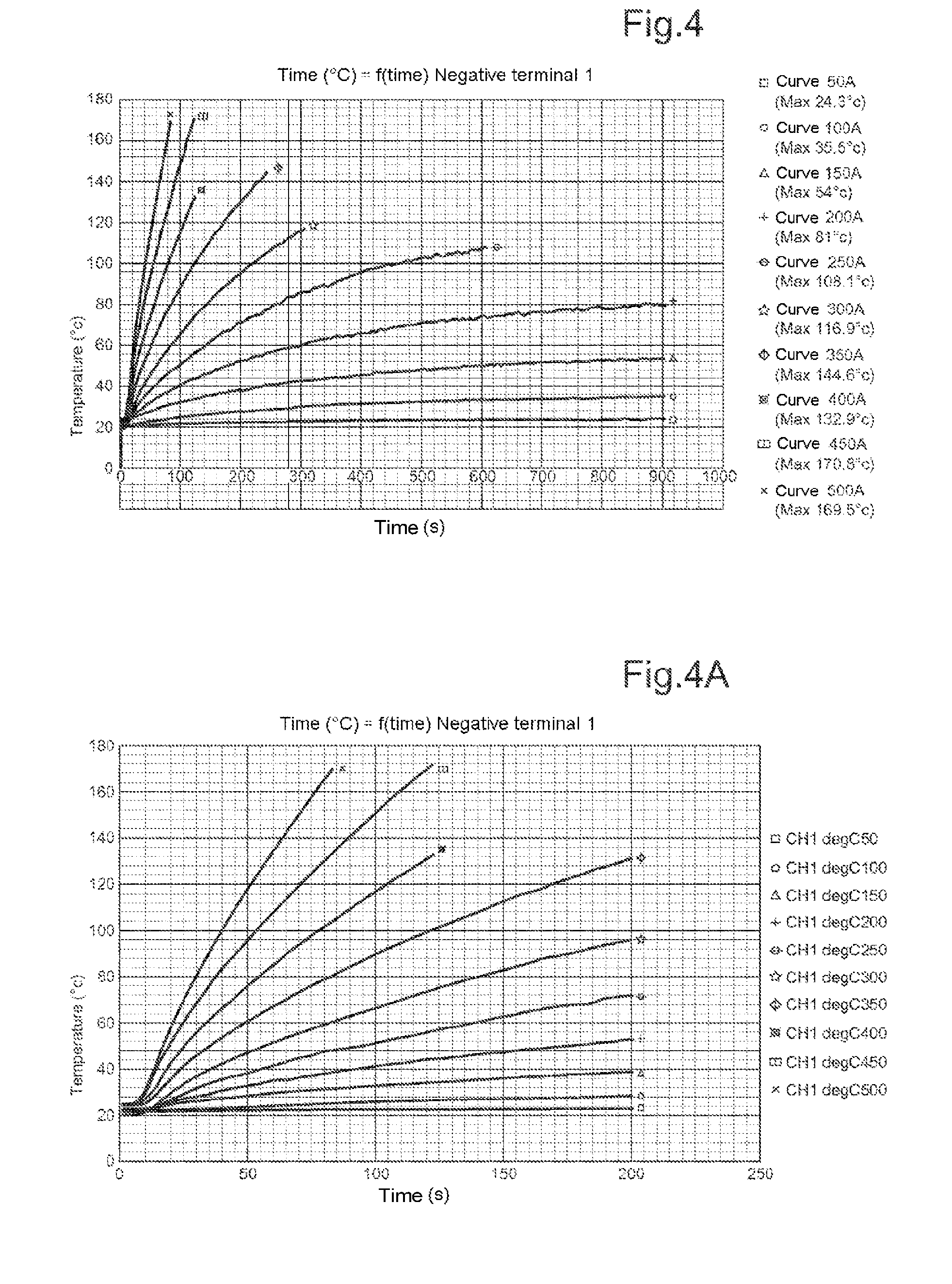

Bushing Forming a Terminal for a Lithium Storage Battery and Related Storage Battery

ActiveUS20150118547A1Small height differenceImprove sealingSmall-sized cells cases/jacketsPrimary cellsElectrically conductiveEngineering

The present invention relates to a bushing forming a terminal for a storage battery, made through an opening connecting to either side of a wall comprising two opposing surfaces, which comprises: two electrically insulating washers, each comprising a bearing portion resting by the surface thereof under pressure against one of the surfaces of the wall and a guiding portion projecting from the bearing portion and resting under pressure against the edge of the opening; two electrically conductive parts, in which a male part is adjusted clamped inside the female part, each one of the parts comprising a bearing portion resting by the surface thereof under pressure against a bearing portion of the washers, the female part resting by the surface thereof under pressure against the guiding portions of the washers. The material(s) of the parts is / are fitted, and the section(s) thereof is / are sized so as to enable the flow of an electric current with a value of no less than 100 A.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

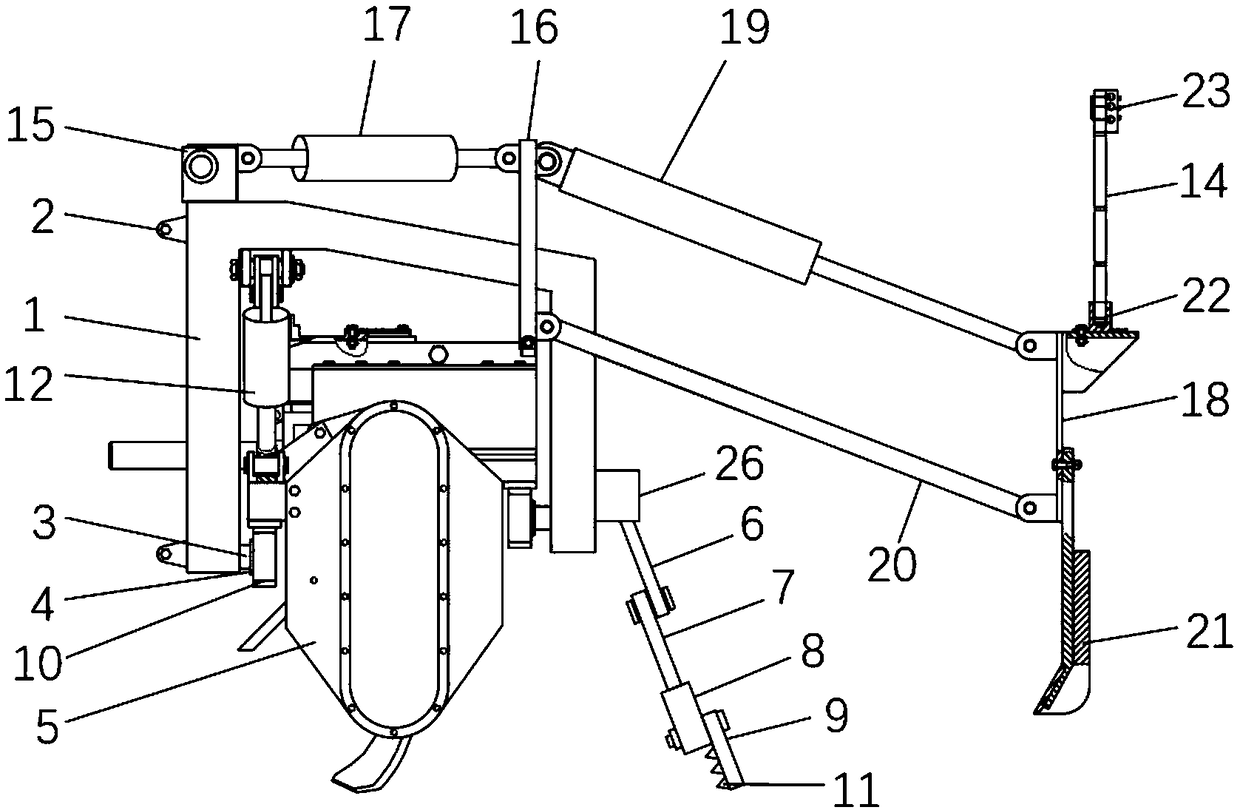

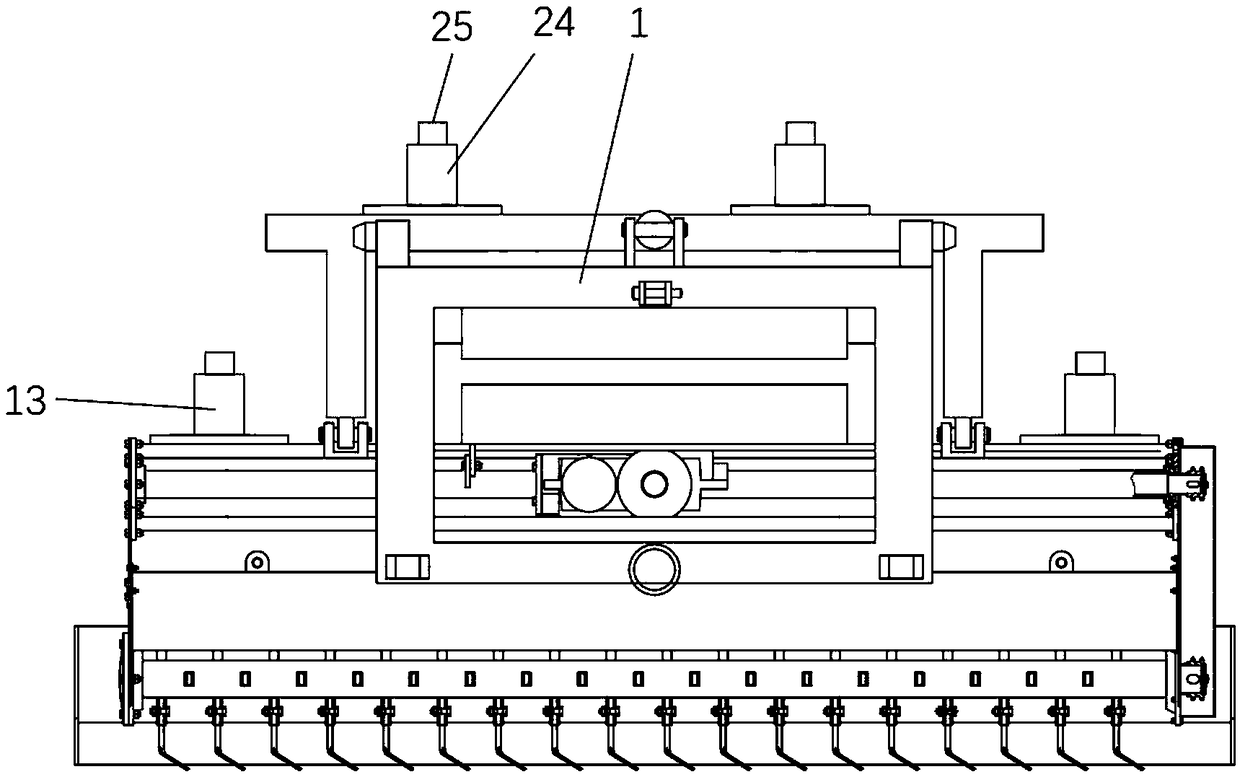

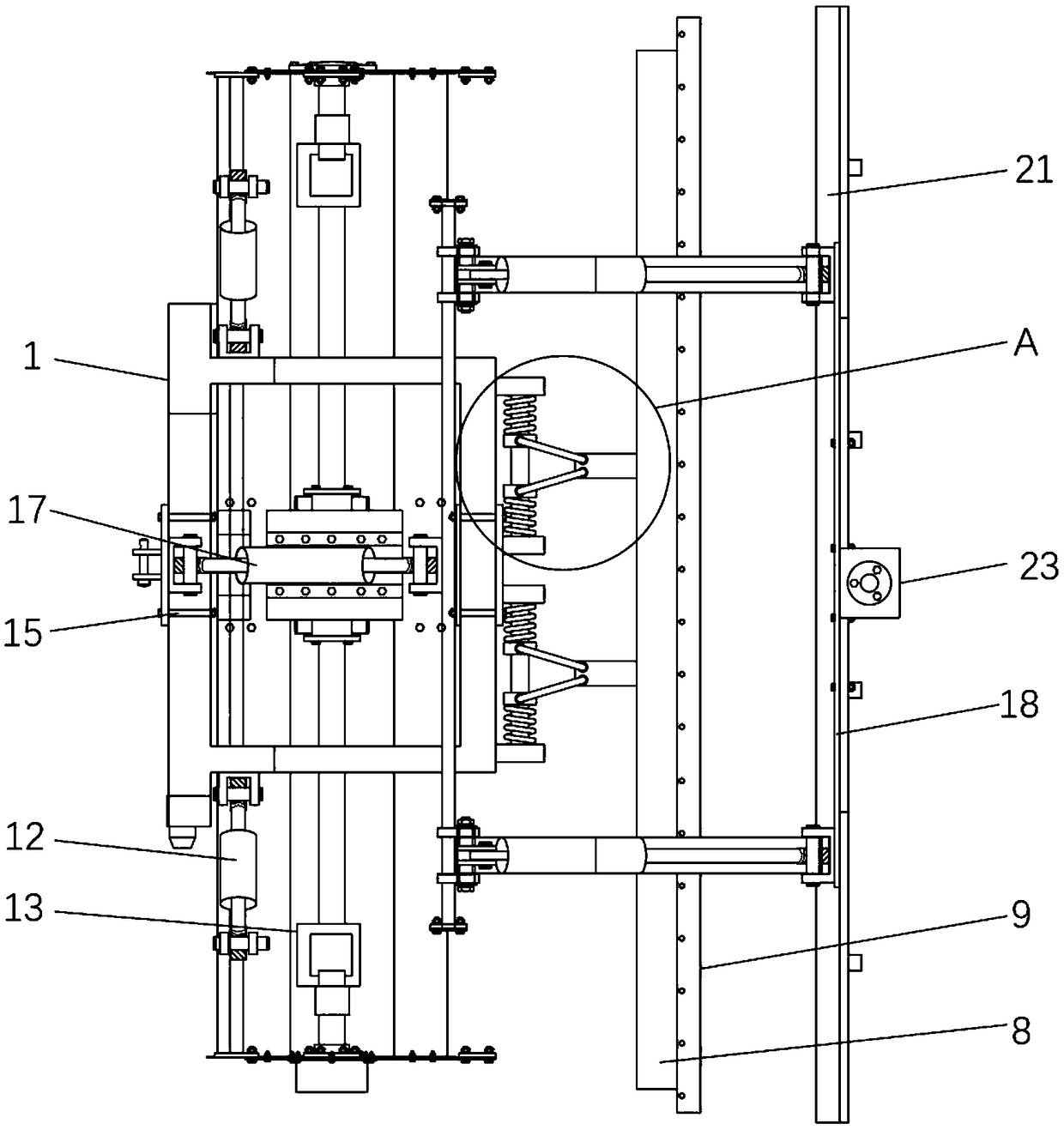

Self-balancing slurry harrowing and soil flatting operation machine for paddy field

ActiveCN109220014AGuaranteed free spinsConsistent rotary tillage depthSpadesAgricultural machinesEcological environmentWater resources

The invention discloses a self-balancing slurry harrowing and soil flatting operation machine for a paddy field. The self-balancing slurry harrowing and soil flatting operation machine comprises a rotary support and a slurry harrowing machine body, and is characterized in that a bearing pedestal is installed below the middle of a front cross beam of the slurry harrowing machine body, a three-pointsuspension is welded to the front end of the rotary support, the front end of the rotary support is connected with a tractor, and rotating shafts are welded to the middles of a front cross beam and arear cross beam below the rotary support. The self-balancing slurry harrowing and soil flatting operation machine has the advantages that during operation, the left-and-right and horizontal inclination angle of the slurry harrowing machine body can be automatically adjusted, rotary tillage depth is free of influences of unevenness of the paddy field surface, slurry harrowing, stub burying and soil flatting operation can be completed at a time, and grinding pressure of the tractor on the paddy field is reduced. After the operation, the height differential value of paddy field blocks is small,the utilization rate of water resources can be increased, water consumed for irrigation can be saved greatly, intermittent irrigation is easy, accurate water consumption is realized, and the efficiency of irrigation reaches 90%. Meanwhile, fertilizer loss and fertilizer shortage are reduced, and the utilization rate of chemical fertilizer is increased by 10% or more. Fundamentally, the ecologicalenvironment of whole countries is protected, and discharging of harmful substances is controlled.

Owner:HUAIHAI INST OF TECH

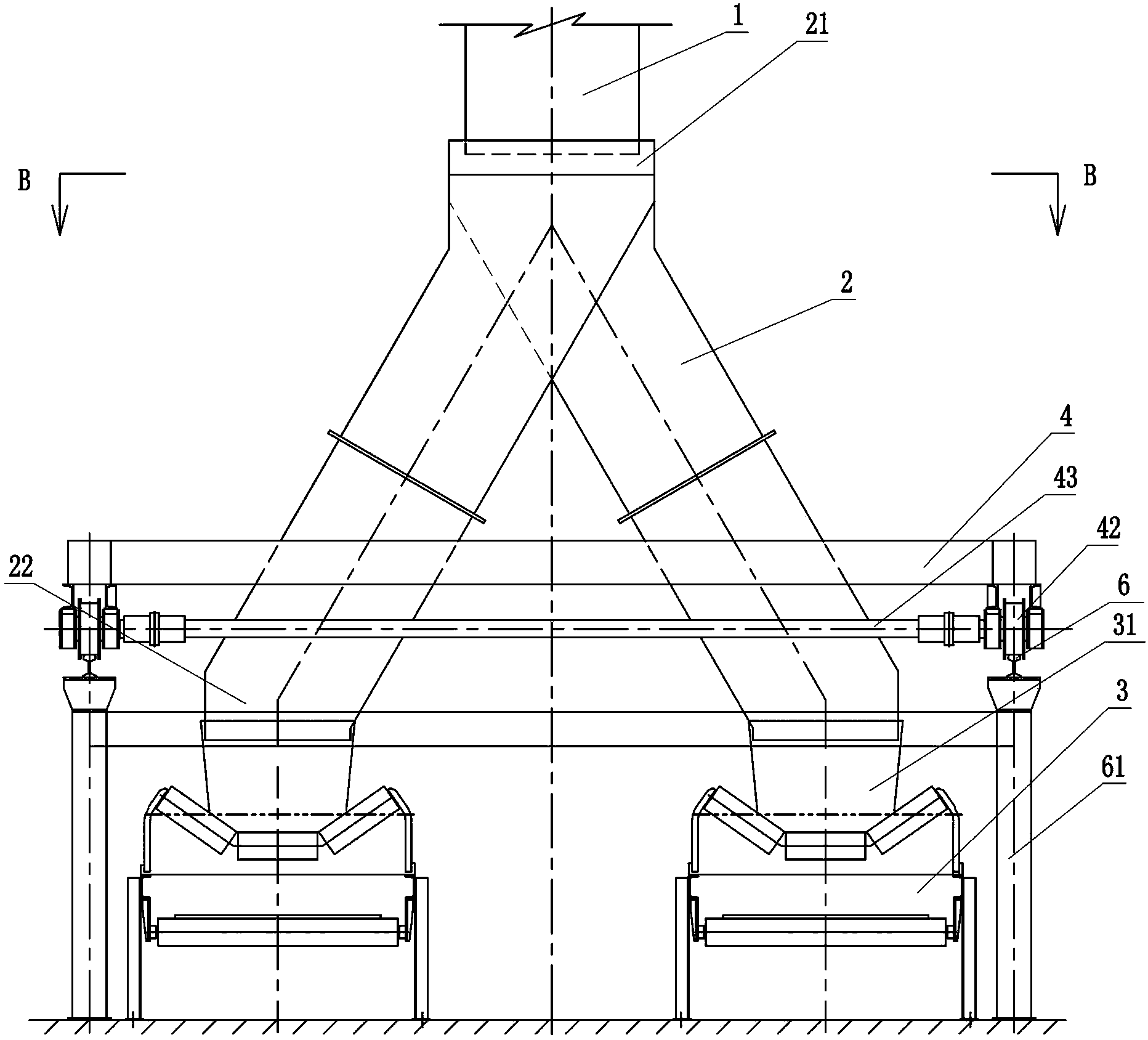

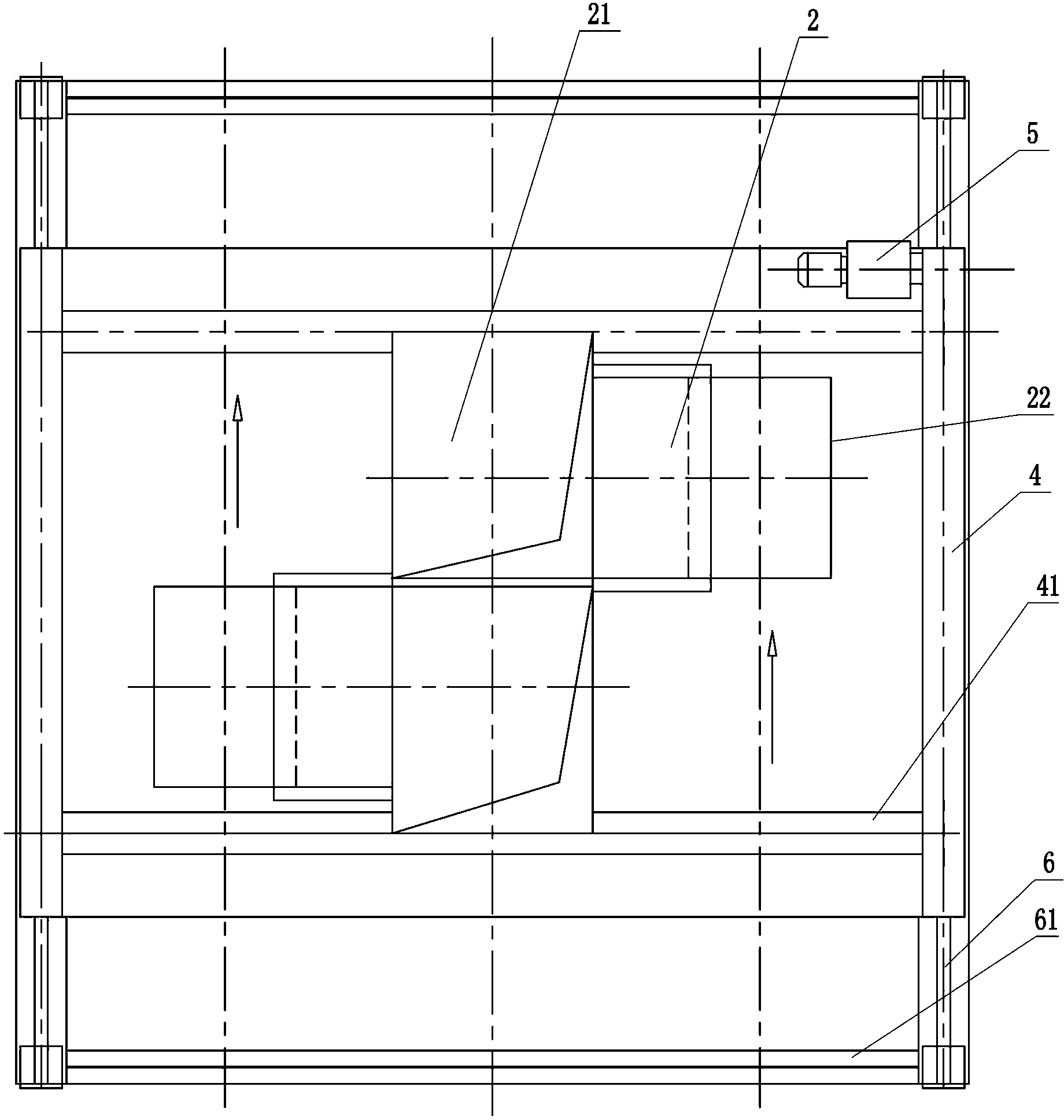

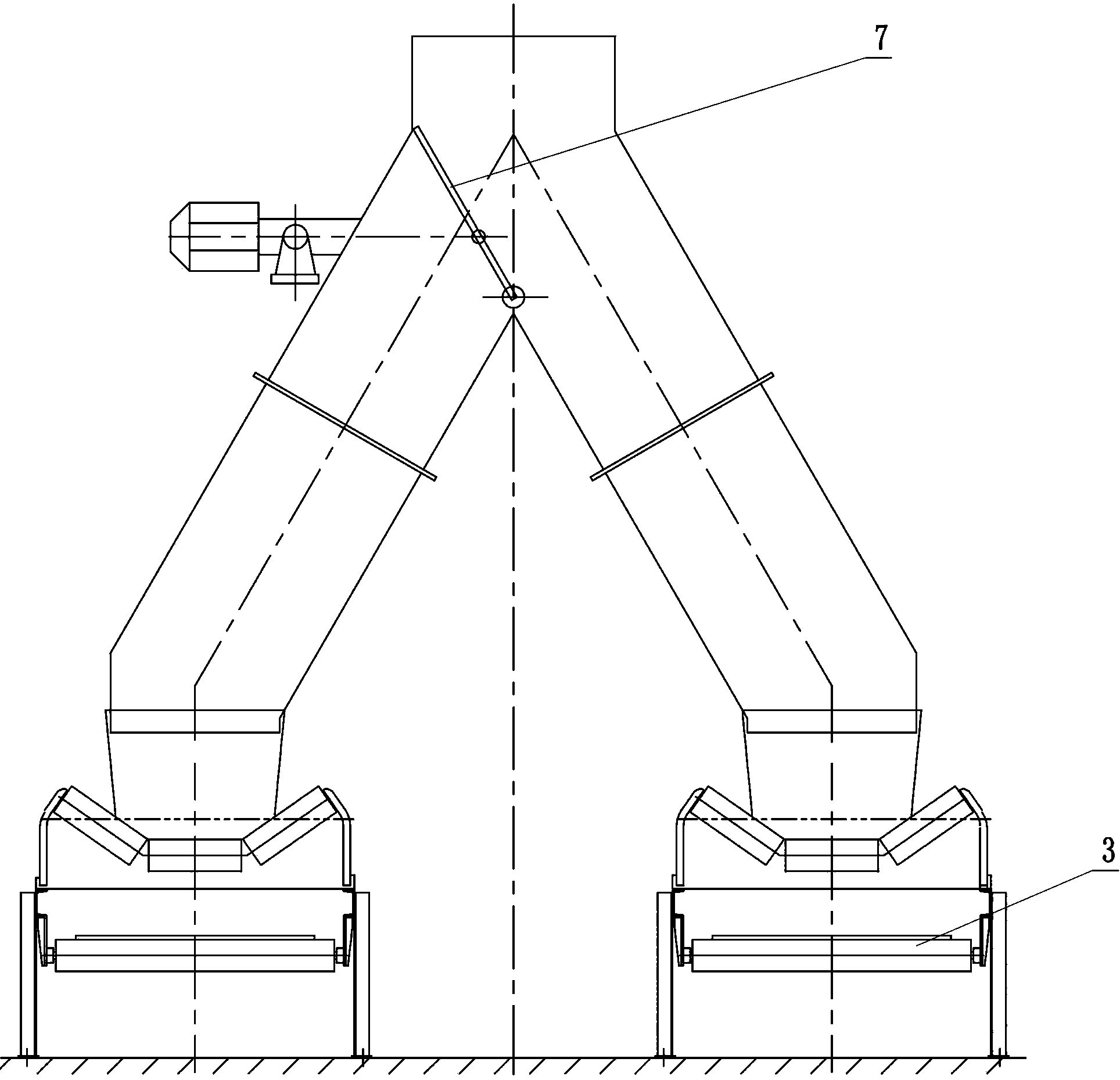

Movable distributing device

ActiveCN103359478ASimple structureEasy to operateConveyor partsUtilization rateElectrical and Electronics engineering

The invention discloses a movable distributing device which comprises a fixed hopper jointed with feeding equipment, a movable hopper group formed by connecting more than two movable hoppers, and discharging mechanisms whose number corresponds to that of the movable hoppers, wherein feeding ports of the movable hoppers in the movable hopper group are arranged in the discharging direction of the discharging mechanisms, a discharging port of each movable hopper in the movable hopper group is correspondingly jointed with each discharging mechanism, and the movable hopper group is provided with a drive mechanism. The movable distributing device provided by the invention gets rid of a distributing turning plate and has the advantages of simple structure, convenience for operation, small equipment vibration, high operability, high space utilization rate and low energy consumption, and different materials are not mixed when conveyed.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

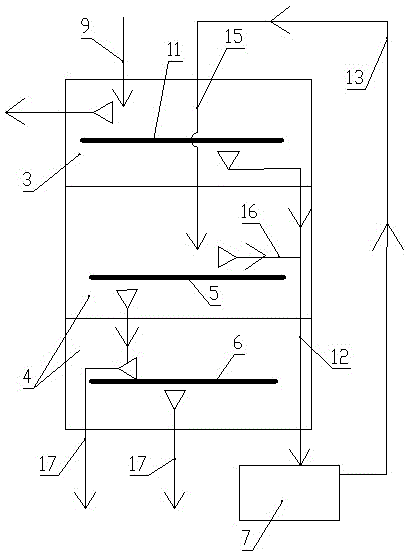

Circulating impact flour milling machine unit and circulating impact flour milling method by using circulating impact flour milling machine

InactiveCN105149045AAvoid damageEliminate the phenomenon of mixing in finished productsGrain treatmentsForeign matterEngineering

The invention discloses a circulating impact flour milling machine unit and a circulating impact flour milling method by using a circulating impact flour milling machine. The unit comprises a machine housing; a screen is mounted in the machine housing; a cleaning bin and a screening bin are arranged in the screen; a circulating screen mesh and a grading screen mesh mechanism are arranged in the screening bin; the impact flour milling machine is arranged in the machine housing; a screen body feed opening and a circulating feed opening are formed in the top of the screen; the cleaning screen mesh used for separating impurities is arranged in the cleaning bin; the discharge opening of the impact flour milling machine is connected with a flour milling machine discharging pipe; after being bent, the upward extending flour milling machine discharging pipe is connected with a discharger; the circulating feed opening is connected with a sieving feed passage; a circulating discharging passage is arranged above the circulating screen mesh, and is communicated with a flour milling machine feed passage; a plurality of screen discharging pipes are connected to each grading screen mesh in the grading screen mesh mechanism. The circulating impact flour milling unit is small in occupied space, low in cost, small in energy consumption, and capable of avoiding damage from large foreign impurities, realizing circulating processing and continuous discharging, avoiding the generation of pulverized materials which cannot reach size requirements, and classifying the processed materials to finished products with different grain sizes to be conveyed out.

Owner:王毅

Main power house allocation structure of high-capacity thermal power station

ActiveCN107060395AReduce production and operation costsImprove production and operation efficiencyIndustrial buildingsPower stationProcess equipment

The invention relates to a main power house allocation structure of a high-capacity thermal power station. The main power house allocation structure of the high-capacity thermal power station comprises a steam engine room, a deaerator room, a bunker room and a boiler room. The ground level of the boiler room is higher than that of the bunker room, the ground level of the bunker room is higher than that of the steam engine room and the deaerator room, and the ground level of the steam engine room is the same as that of the deaerator room. The main power house allocation structure has the beneficial effects that 1, under the premise of remaining the schemes of the whole station ground level layout and relative technology systems unchanged, the main power house structure adopts negative excavation layout to decrease the layout ground level of a condenser so as to decrease the height difference between the condenser and a water taking port, so that the limited technical standard requirements for lifting of relative technology equipment are met; 2, by adopting the stepped negative excavation layout on the main power house structure, under the premise of combining the technology layout, the height difference between the condenser and the water taking port can be decreased maximally; and 3, the main power house allocation structure has high adaptability and practicability.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

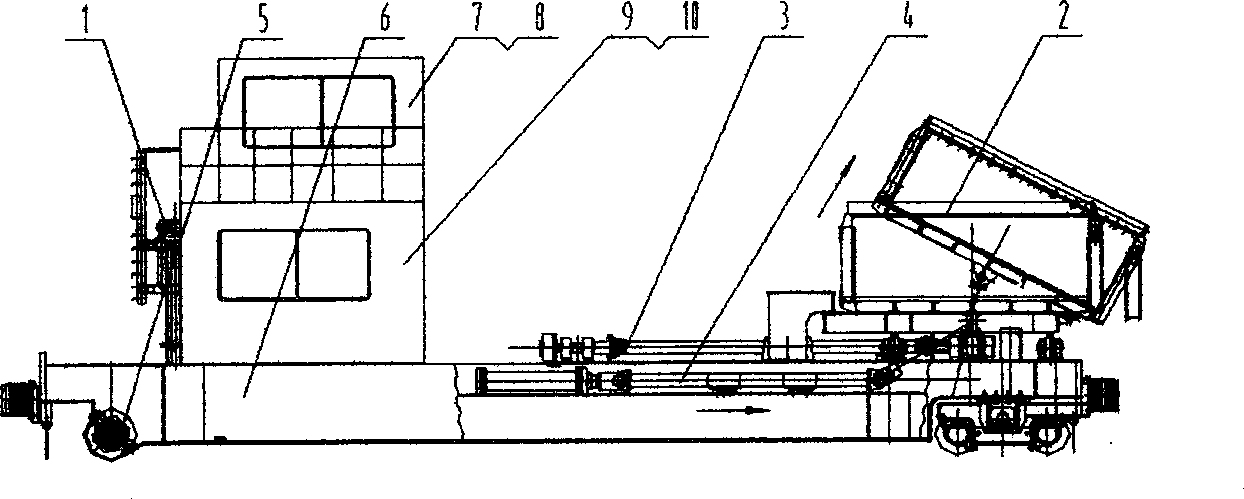

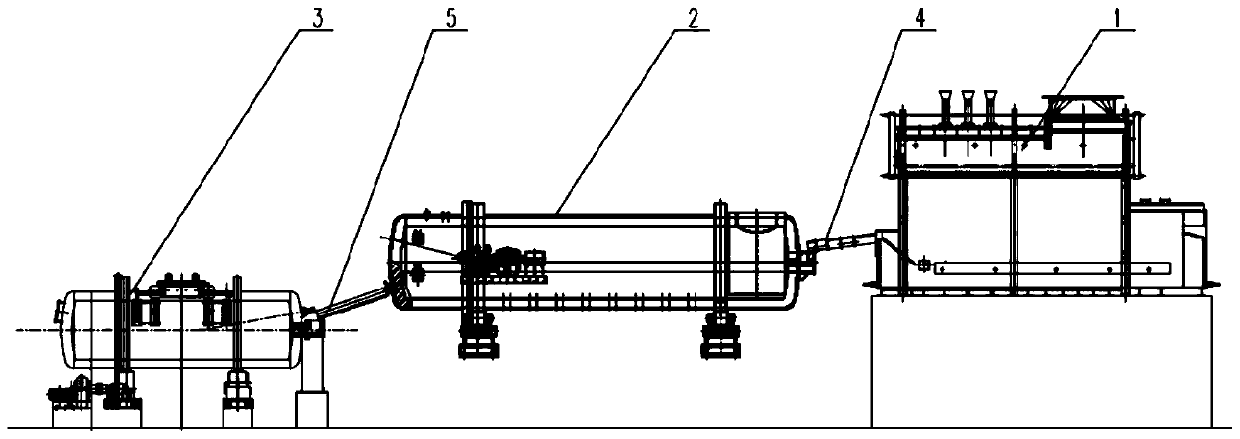

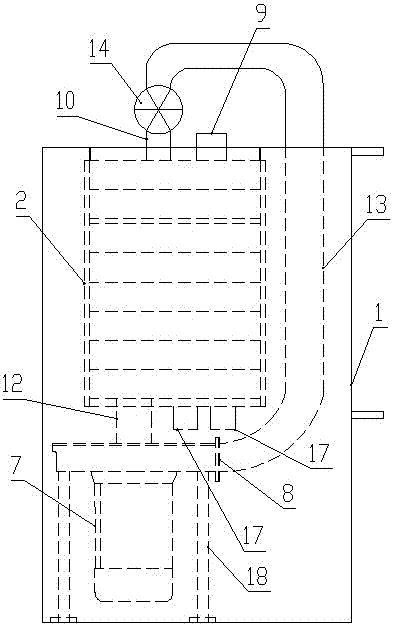

Coke-receiving, core-quenching and coke-discharging equipment for horizontal coke-oven

InactiveCN1354219ASmall height differenceSave engineering investmentCoke quenchingDischarging devicesQuenchingCoke oven

The present invention relates to an aquipment for receiving coke, quenching coke and discharging coke for horizontal coke-oven, and is characterized by that said equipment not only can be forwards and afterwards moved to close up to the over door, but also can be transversely moved to coke-discharging position to turn over and discharging material. When it is used for receiving coke, the bottom surface of coke-oven and coke-receiving tank are smoothly engaged without leakage. When it is used for discharging coke its automatic turnover operation is reliable. As compared with existent techniques, it overcomes their defects and possesses the advantages of reasonable structure, small cost and less floor area.

Owner:TAIYUAN HEAVY IND

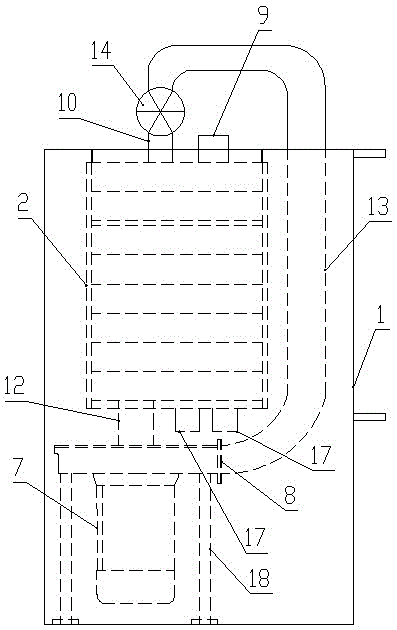

Concentrated sulfuric acid negative pressure discharging system

ActiveCN103723668ASimple unloading processAcid unloading slowed downLiquid transferring devicesAutomationChemistry

The invention belongs to the technical field of concentrated sulfuric acid discharging, and particularly relates to a concentrated sulfuric acid negative pressure discharging system. The concentrated sulfuric acid negative pressure discharging system is characterized in that the concentrated sulfuric acid negative pressure discharging system is mainly composed of an acid discharging device, an acid storage device, two eccentric screw pumps and a control box, wherein the acid storage device is connected with the acid discharging device through an acid discharging pipeline, and the two eccentric screw pumps are connected with the acid storage device. According to the concentrated sulfuric acid negative pressure discharging system, an artesian negative pressure acid discharging mode is adopted, the acid discharging process is simple, acid discharging speed is moderate, and the system is high in automation degree, safe and reliable. The eccentric screw pumps are further adopted to convey and add concentrated sulfuric acid, the conveying and the accurate addition of the concentrated sulfuric acid are blended into a whole, the whole facility is distributed on the ground, height difference is saved, the operation is simple, and investment is small.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

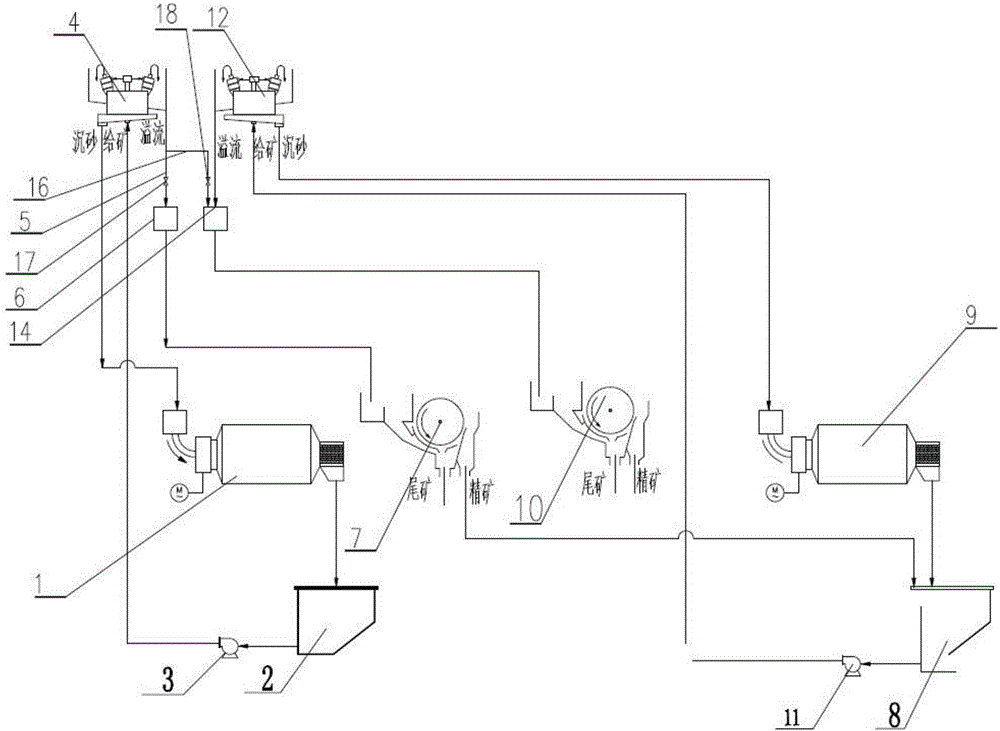

Iron ore beneficiation system and process for two pelletized and sintered products

InactiveCN106179788AWide adaptabilitySwitching is simple and convenientVortex flow apparatusIron powderControl system

The invention belongs to the technical field of iron ore beneficiation and particularly relates to an iron ore beneficiation system and process for two pelletized and sintered products. The iron ore beneficiation system for two pelletized and sintered products comprises a first-stage ball mill-hydrocyclone group, a second-stage ball mill-hydrocyclone group, a first-stage magnetic separator, a second-stage magnetic separator and a conversion device; the conversion device is characterized in that a branch overflow pipe is mounted on a first overflow pipe located between a first-stage hydrocyclone group and a first overflow ore pulp distributer; the tail end of the branch overflow pipe is connected with a second overflow ore pulp distributer; a first switching stop valve is mounted on the first overflow pipe; and a second switching stop valve is mounted on the branch overflow pipe. The system is controlled by the conversion device when fine iron powder for pelletizing and fine iron powder for sintering are produced. The process disclosed by the invention is switched on the basis of an energy-saving stage grinding and stage separation process which is most frequently used for producing the fine iron powder for pelletizing so as to become a production process for a sintered ore, the adaptability of the switched process is wide, and the investment is reduced.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

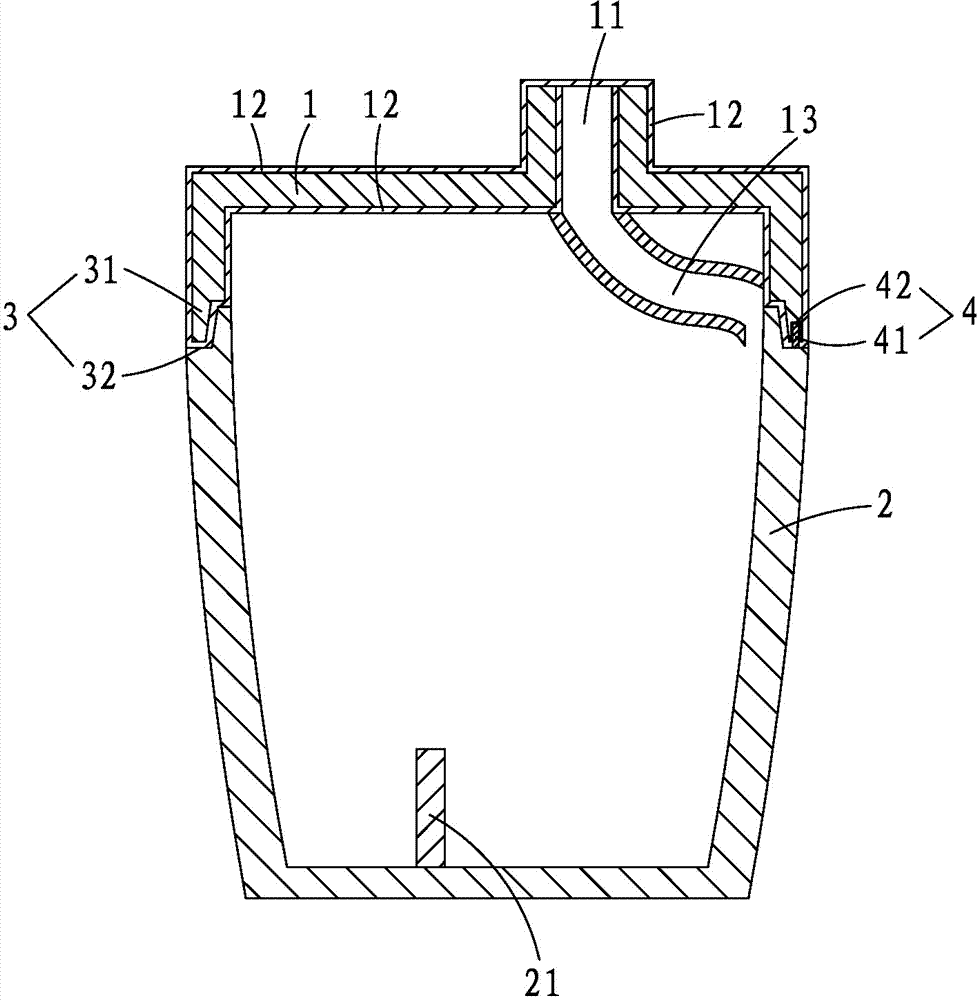

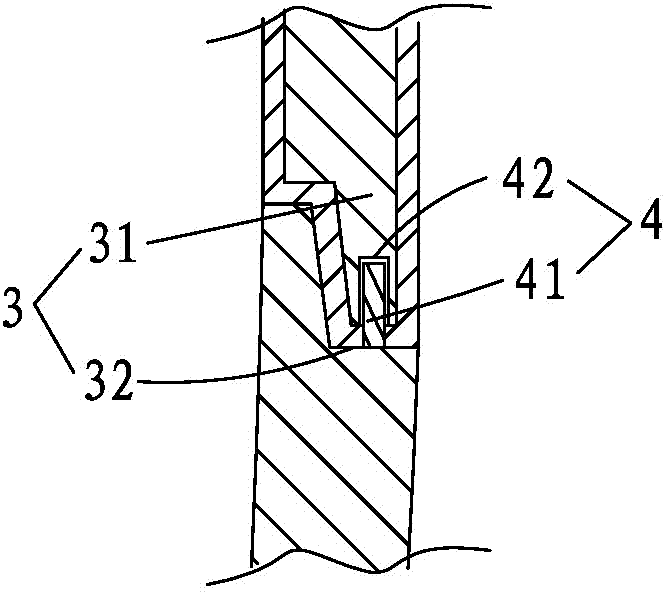

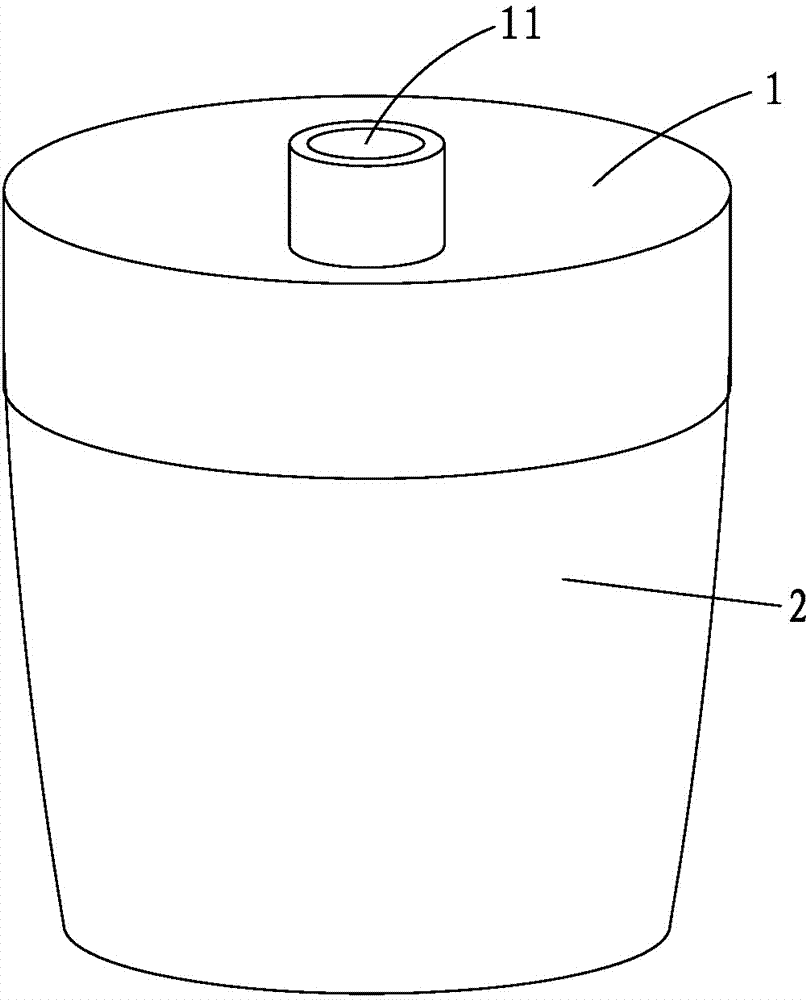

Nodularizing ladle cover

ActiveCN104275479AImprove high temperature resistanceExtended service lifeMelt-holding vesselsRefractoryEngineering

The invention provides a nodularizing ladle cover covering a nodularizing ladle. A cover body is provided with a sprue gate; the surface of each of the cover body and the sprue gate is provided with a layer of refractory material used to avoid direct contact between high-temperature molten iron and the material of the cover body and that of the sprue gate. The cover body is further provided with a guide channel used to link the inner wall of the sprue gate and that of the nodularizing ladle; the guide channel is used for guiding the high-temperature molten iron. The nodularizing ladle cover has the advantages that the cover body and the sprue gate are higher in high temperature resistance, spattering of the molten iron during pouring is prevented, service lives of the cover body and the sprue gate are prolonged, and operational safety is guaranteed.

Owner:福建丰力机械科技有限公司

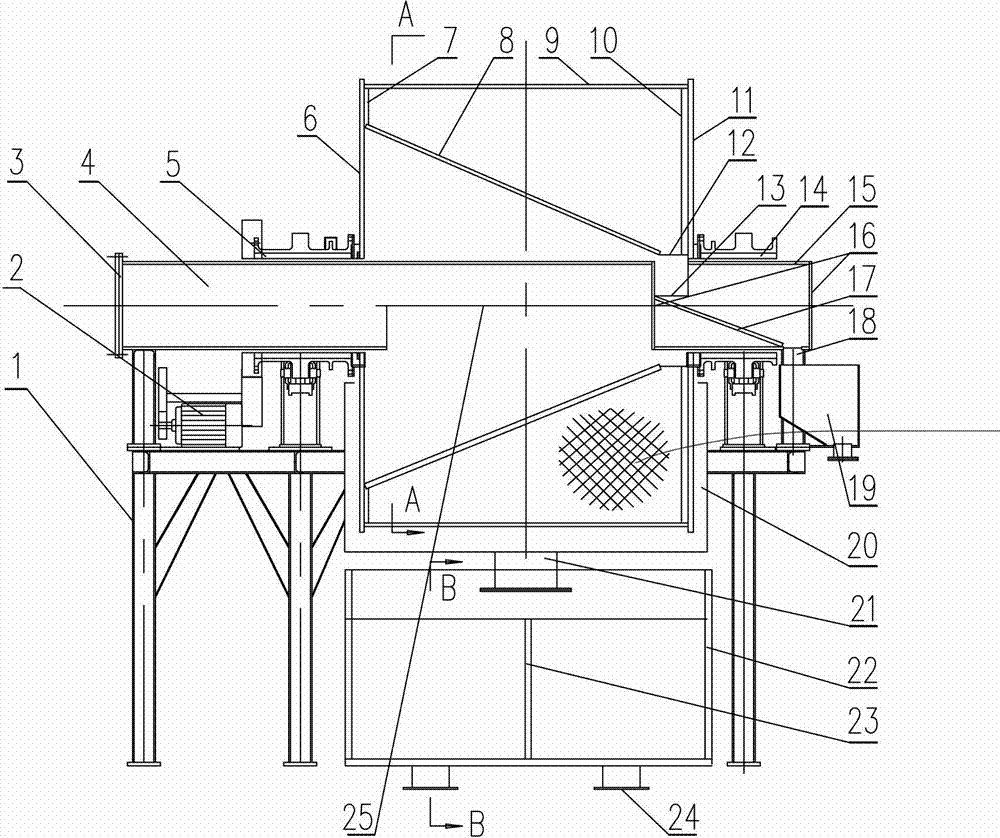

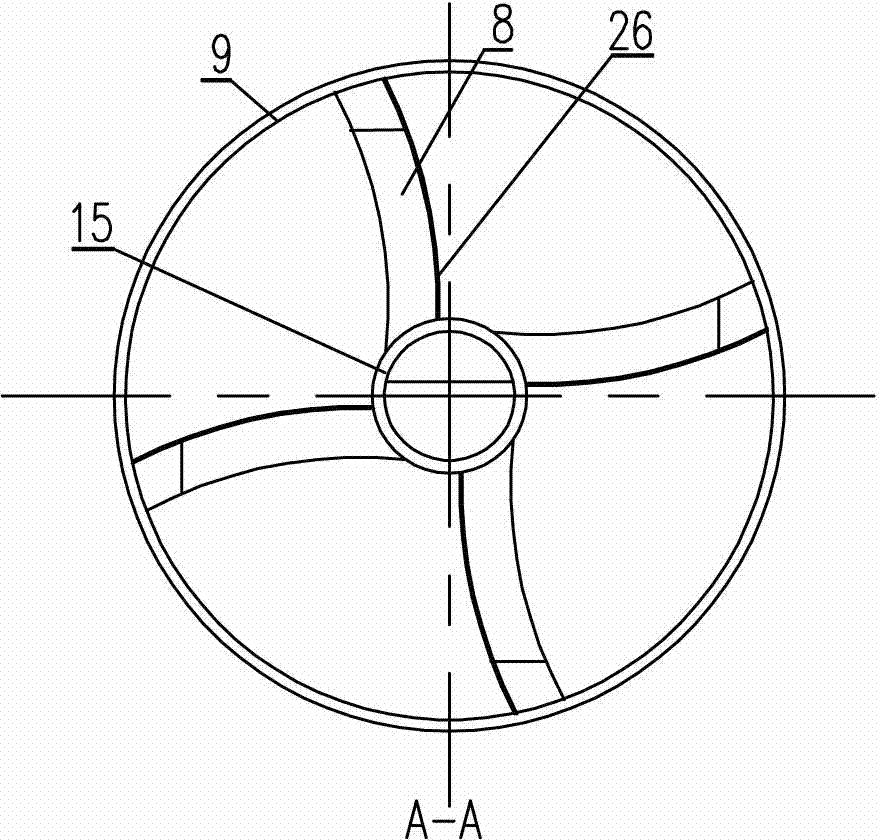

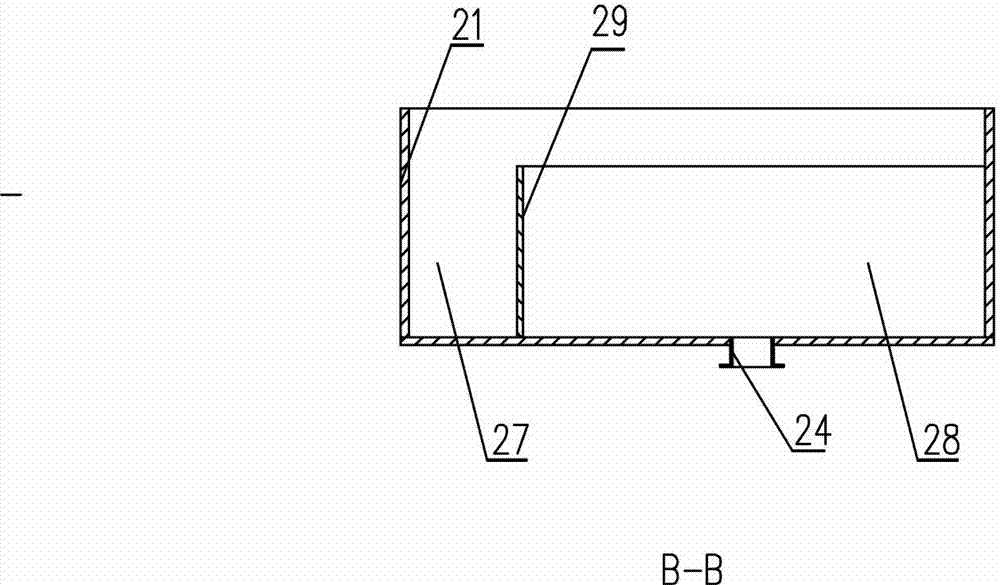

Slag removing drum screen capable of distributing pulp

ActiveCN102847674AGuaranteed normal operationThere is no problem of bringing out the pulpSievingScreeningDrive shaftSlag

The invention belongs to the technical field of slag removing equipment of beneficiation plants, and particularly relates to a slag removing drum screen capable of distributing pulp. The slag removing drum screen comprises a frame, a fixed feed tube, a drum screen body and a driving device, wherein the drum screen body consists of a cylinder, a left end plate, a right end plate, a hollow driving shaft and a hollow driven shaft, the hollow driving shaft is connected with the driving device, a group of filtering and slag discharging boxes are obliquely arranged in an inner space of the drum screen body, a pulp receiving box is arranged on the outer periphery of the lower half portion of the drum screen body, a pulp distribution box is arranged below the pulp receiving box, a central feed hole is arranged on the left end plate of the drum screen body, a central slag hole is arranged on the right end plate, one end of the fixed feed tube is connected with a feed connector, the other end of the fixed feed tube penetrates through the central feed hole to be connected with a slag discharge tube, and a slag receiving hopper is arranged below the slag discharge tube. The slag removing drum screen capable of distributing the pulp is reasonable in arrangement, simple to mount, convenient to use, less in maintenance and capable of distributing the pulp, removing slag in the pulp and protecting operation equipment at the lower segment, and production can be guaranteed to be smooth beneficially.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Dense-column narrow-span high-lower-layer type city-crossing overhead road

PendingCN105714632ALower requirementReduce thicknessRoadwaysClimate change adaptationRoad surfaceUrban area

The invention discloses a dense-column narrow-span high-lower-layer type city-crossing overhead road.The dense-column narrow-span high-lower-layer type city-crossing overhead road is a high-lower-layer overhead road constructed in the mode that narrow-span road slab beams are supported by densely-arranged stand columns.High-lower-layer small-car special channels are expanded between the stand columns below the road surface, safety rails and steps or ramps for upward and downward passing are arranged on the boundaries of the two sides of the overhead road, the road surface is connected with all intersecting ground roads through communication slopes, and a new traffic dispersion mode that the original traffic function is undertaken by the road surface, and car-type small vehicles pass through the urban area through high-lower-layer small-car special channels is formed.The dense-column narrow-span high-lower-layer type city-crossing overhead road is novel in structure, reasonable in arrangement and simple and rapid in construction, cost is saved, various construction modes and various roadway configurations can exist, the high-lower-layer small-car special channels can be located on the ground, buried in the ground in a half mode, shallowly buried in the ground or deeply buried into the underground, and two-layer or more-layer parallel or intersected arranging can be conducted.The dense-column narrow-span high-lower-layer type city-crossing overhead road is suitable for reconstruction and application of vehicle saturated roads, can be additionally constructed on existing common roads, and can also be constructed on a lower layer or an upper layer of an existing overhead road.

Owner:倪既民

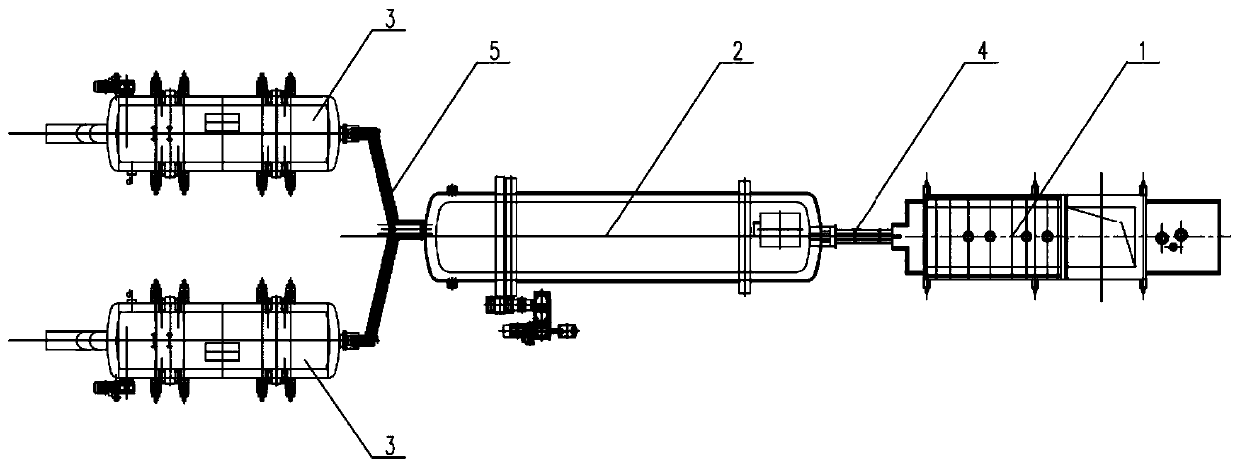

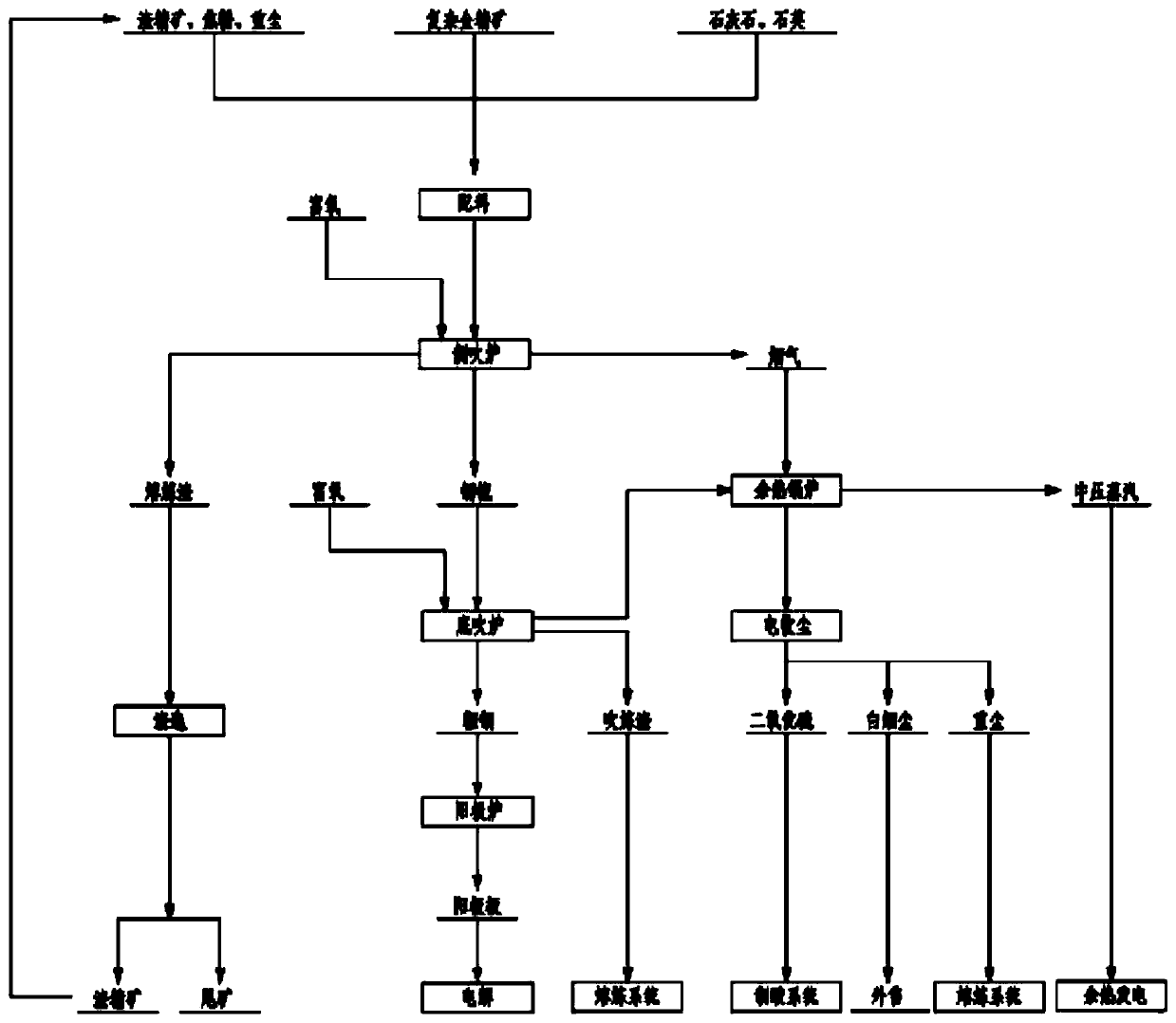

Continuous copper smelting system and continuous copper smelting method

InactiveCN111187920AReduce pollutionIncrease concentrationRotary drum furnacesCrucible furnacesFlue gasCopper

The invention discloses a continuous copper smelting system and a continuous copper smelting method. The continuous copper smelting system comprises a fixed side blowing smelting furnace, a rotary bottom blowing converting furnace and two anode refining furnaces; the side blowing smelting furnace is connected with the bottom blowing converting furnace through a copper matte launder; the bottom blowing converting furnace is connected with the anode refining furnaces through a blister copper launder; the side blowing smelting furnace, the bottom blowing converting furnace and the anode refiningfurnaces are arranged in a stepped mode; and a feeding end of the copper matte launder is connected with the side blowing smelting furnace through a siphon discharge pipe. The side blowing smelting furnace is used for smelting to produce high-grade copper matte, the high-grade copper matte is smelted into blister copper after being subject to bottom blowing smelting by using the bottom blowing converting furnace, and the anode refining furnaces are used for refining the blister copper to produce qualified anode plates. The full-thermal continuous production can be achieved, the SO2 concentration contained in the generated flue gas is high, the pollution to the environment is small, the comprehensive utilization level of resources is high, and the comprehensive energy consumption is low.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

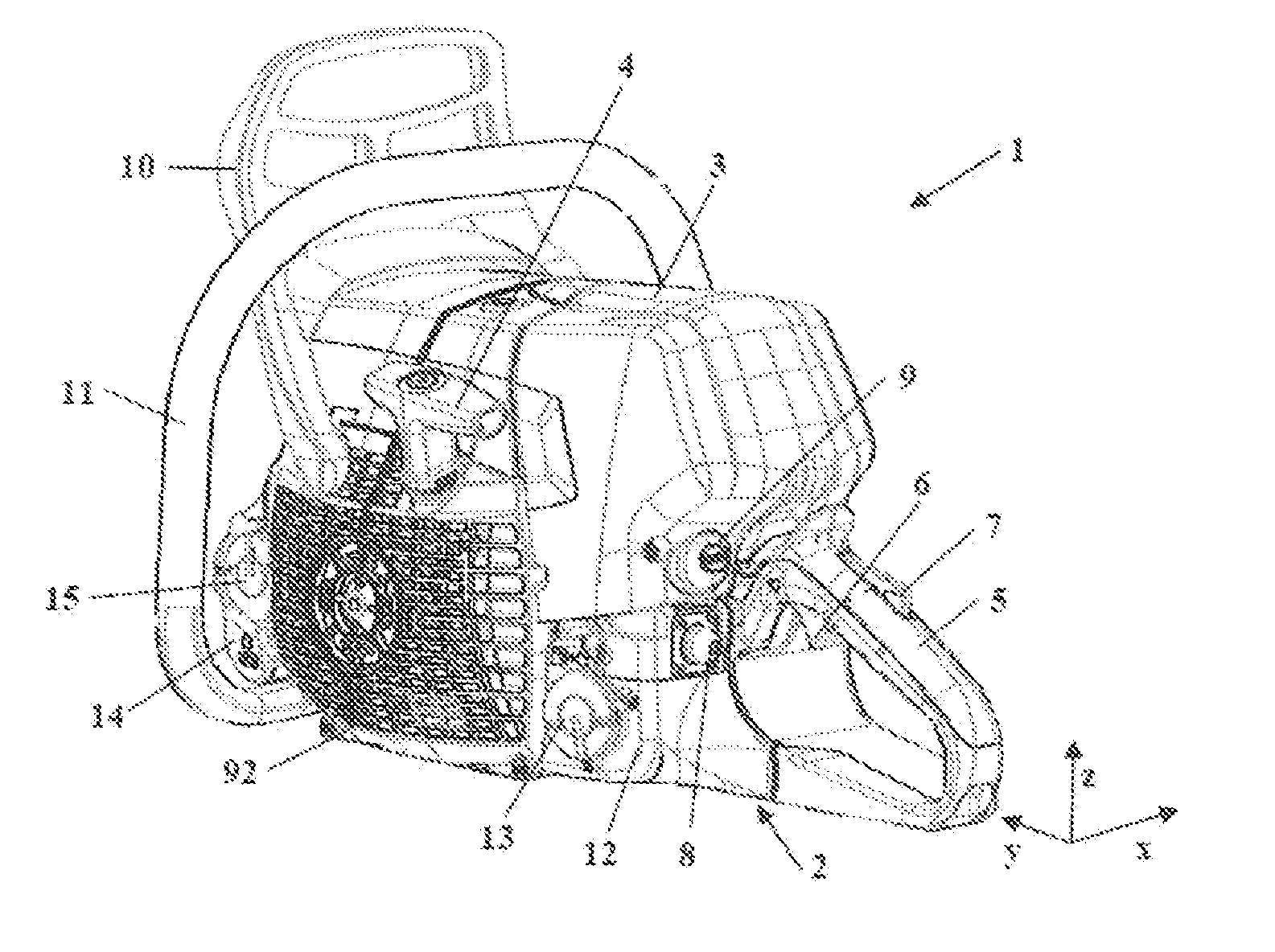

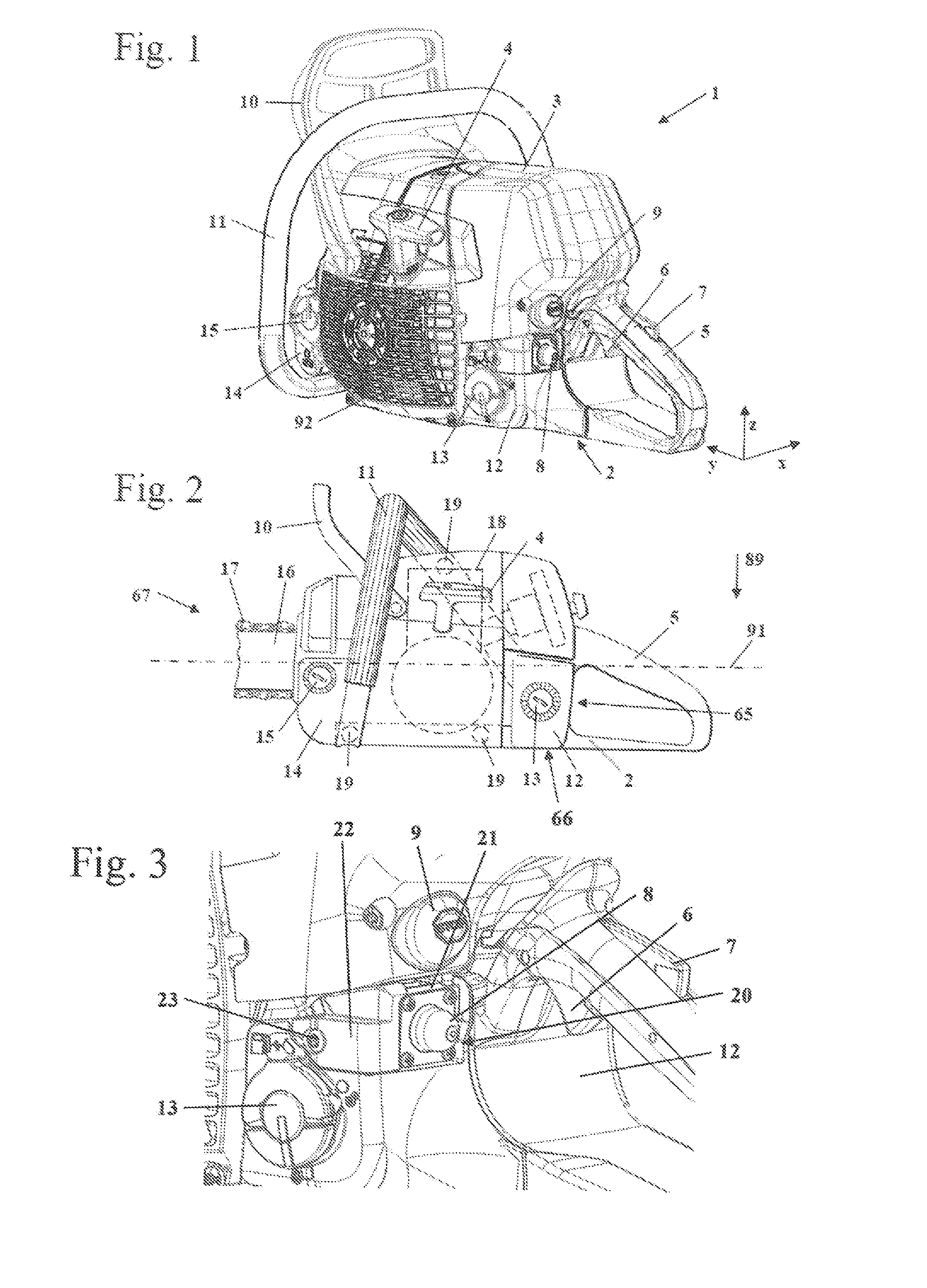

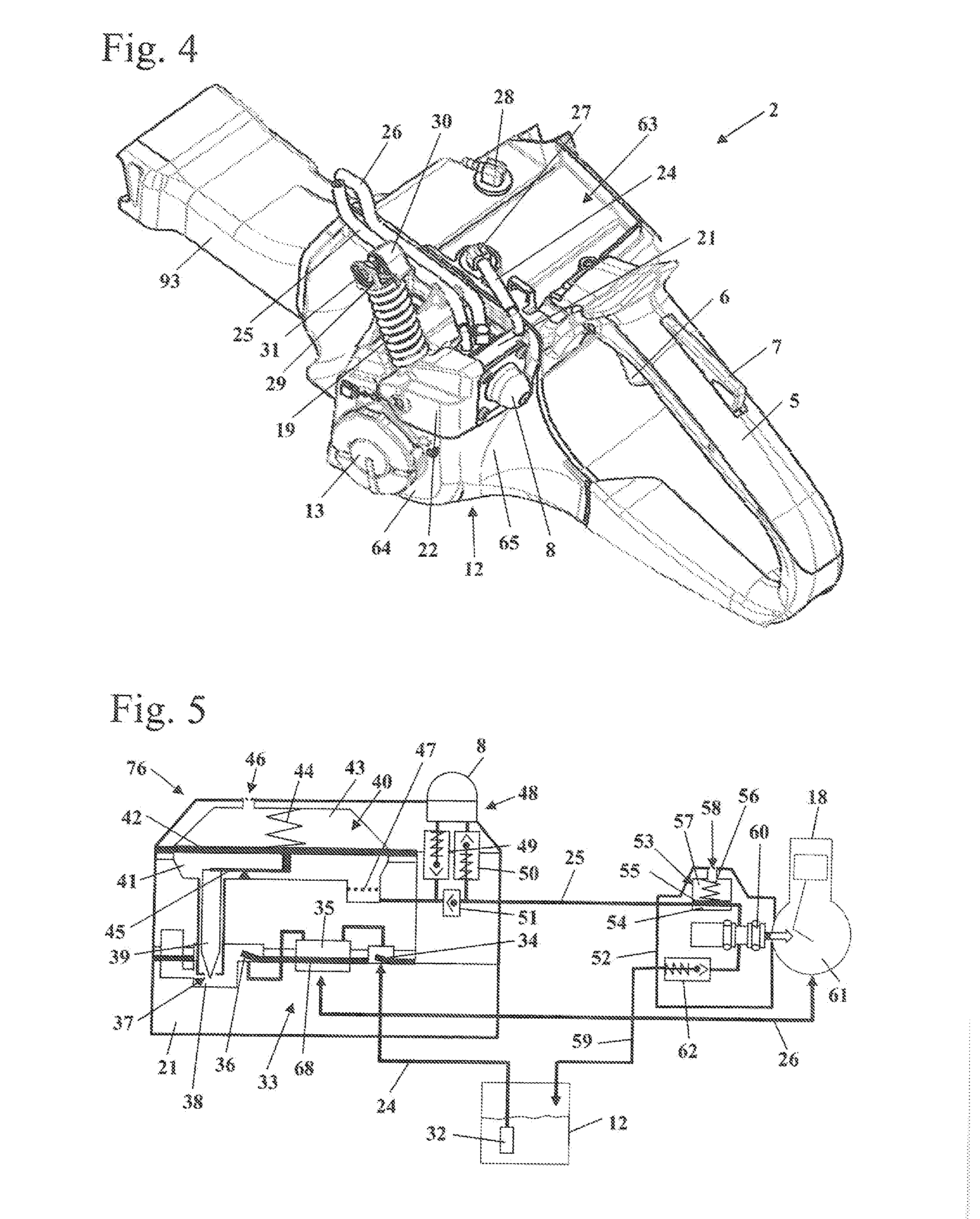

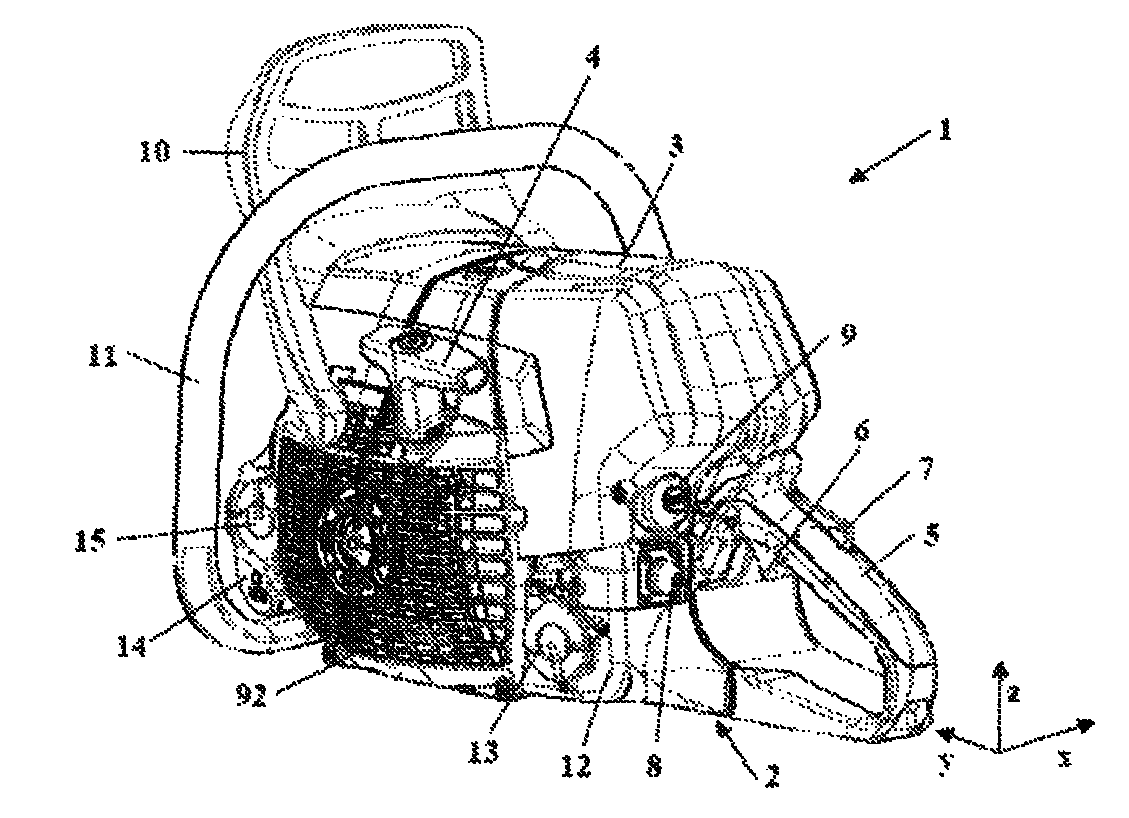

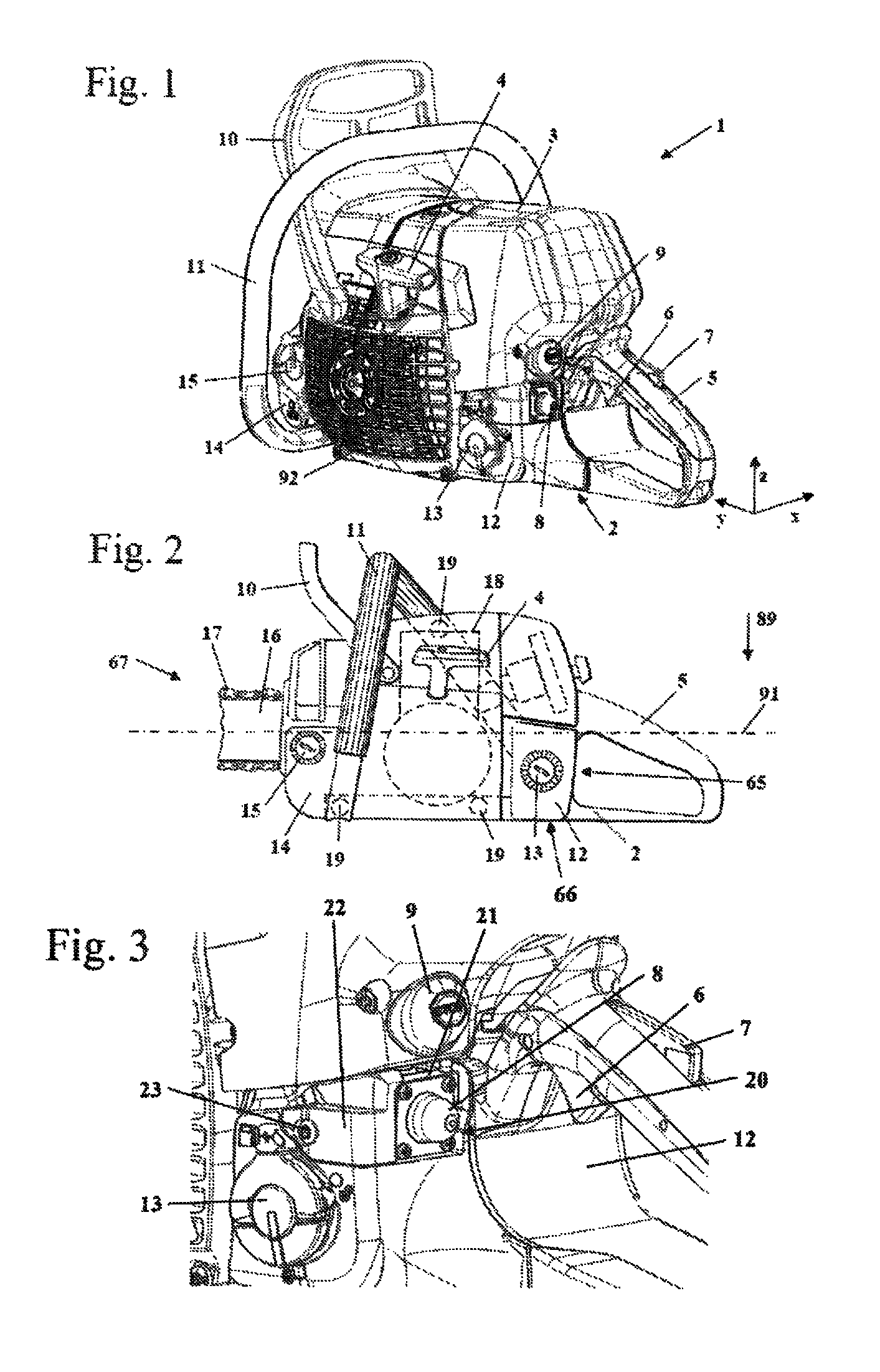

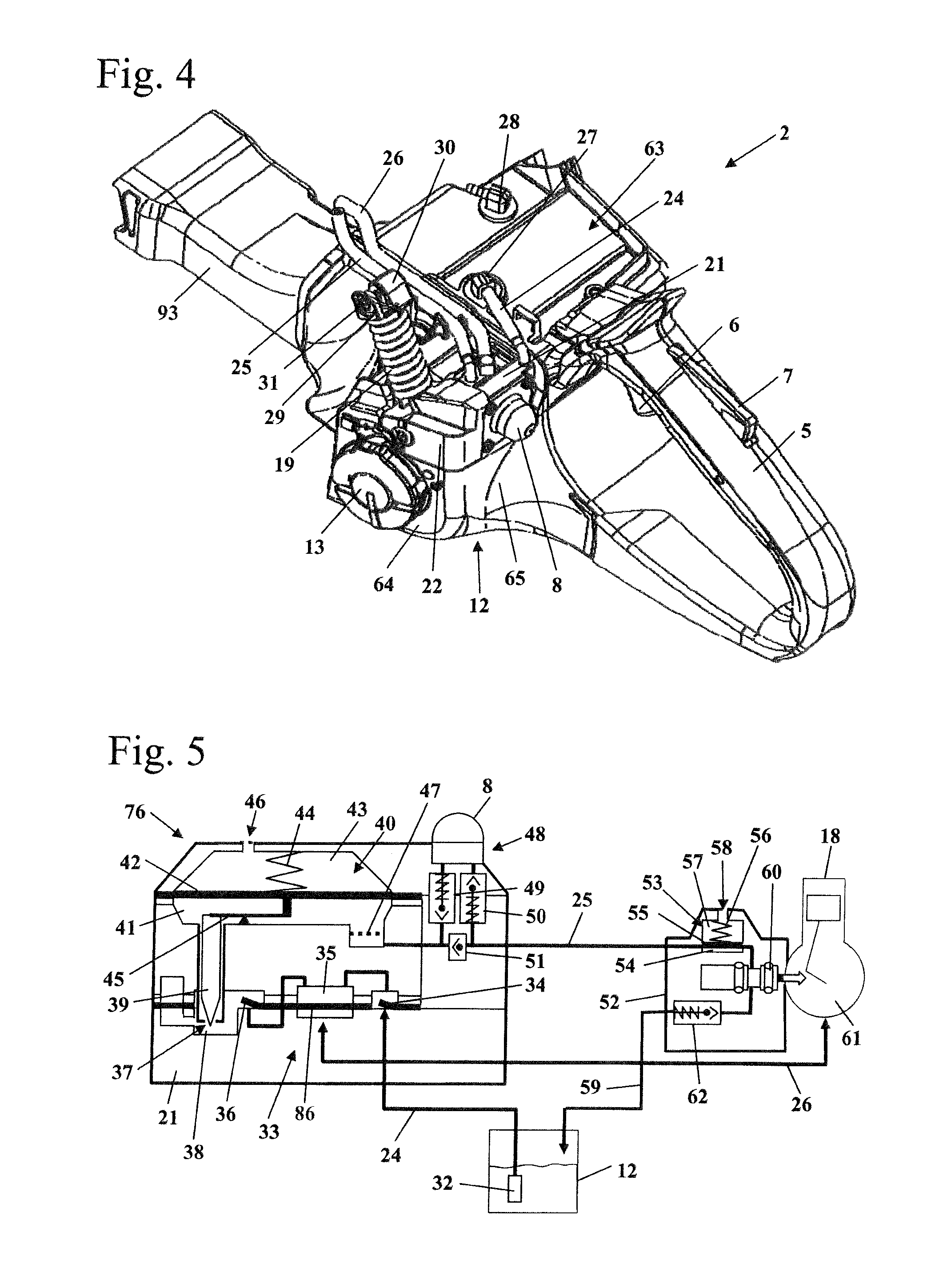

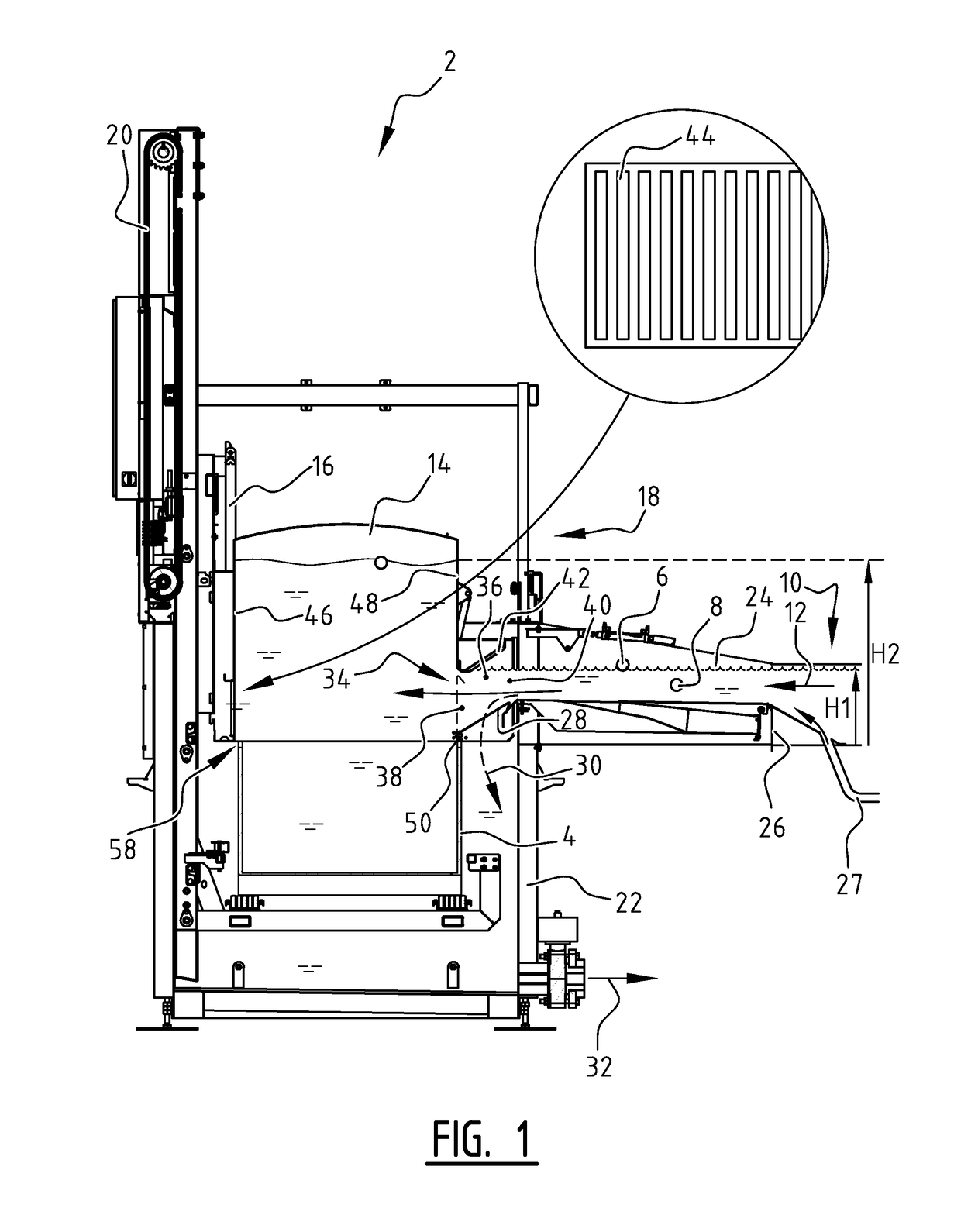

Work apparatus having a fuel pump

ActiveUS20130276724A1Simple designReduce in quantityMachines/enginesLiquid fuel feedersFuel tankInternal combustion engine

A work apparatus has an internal combustion engine for driving a work tool of the work apparatus and a fuel pump which is driven by the engine and delivers fuel from a fuel tank to the engine. The work apparatus has a feed pump which is to be actuated manually by the operator. The fuel pump and the feed pump form one component which is arranged outside the fuel tank. The fuel tank has a tank wall which delimits the tank interior. An advantageous arrangement arid satisfactory cooling of the component are achieved if the component is arranged at least partially on the tank wall.

Owner:ANDREAS STIHL AG & CO KG

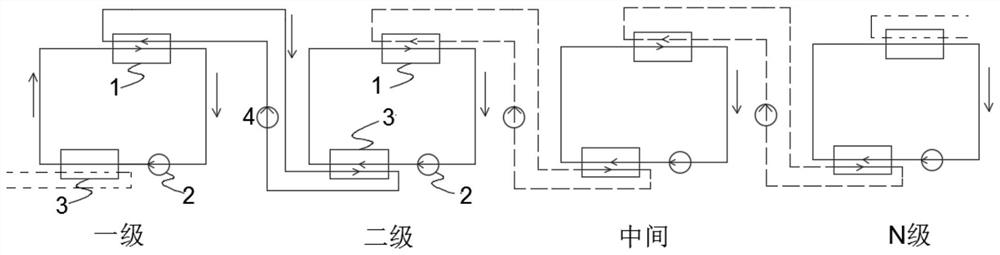

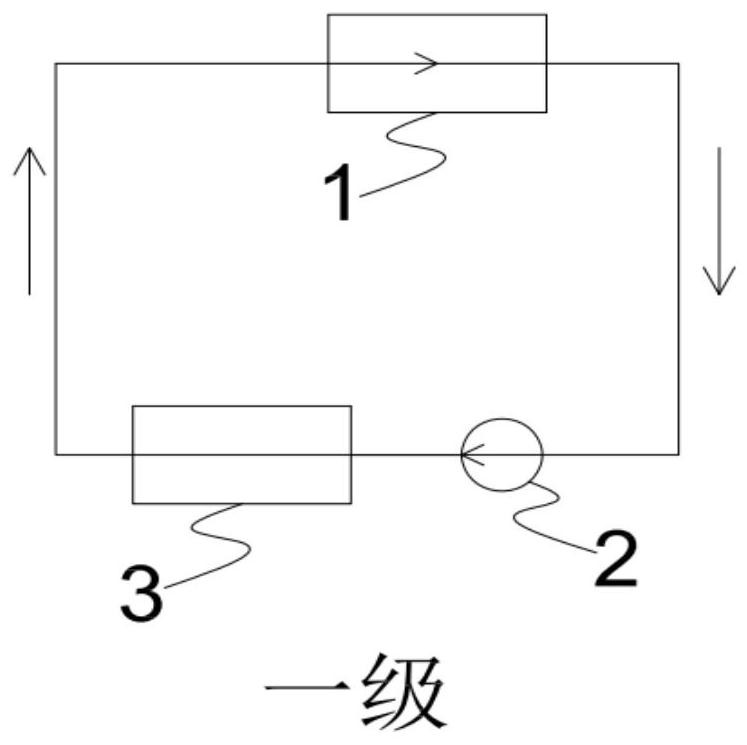

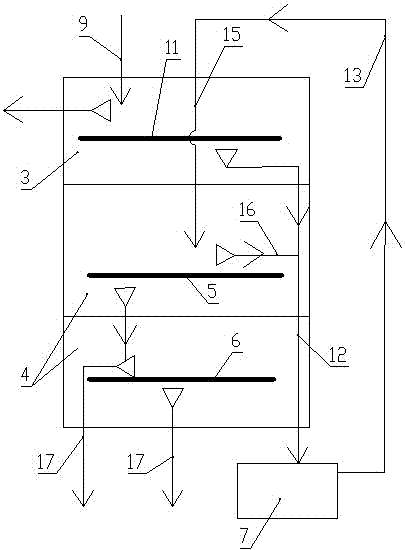

Overlapped gravity field work applying method and used device

ActiveCN111636940ALarge temperature differenceReduce the position gapCombination enginesCompression machines with cascade operationEngineeringCirculating pump

The invention discloses an overlapped gravity field work applying device. The overlapped gravity field work applying device is at least composed of two stages of gravity field work applying subsystems; an interstage circulating system is arranged between the adjacent two stages of gravity field work applying subsystems, and each interstage circulating system comprises an interstage circulating pump (4); each stage of gravity field work applying subsystem comprises a high-level condenser (1), a low-level liquid turbine (2) and a low-level evaporator (3); and a heat absorption channel of the high-level condenser (1) of the previous stage of gravity field work applying subsystem, a heat releasing channel of the low-level evaporator (3) of the next stage of gravity field work applying subsystem and the interstage circulating pumps (4) are sequentially connected to form a closed cycle. The invention further provides an overlapped gravity field work applying method using the device. According to the overlapped gravity field work applying device, the position drop required by the system work is reduced, and the application range is wider; and through the overlapped circulation, the temperature difference of the evaporators and the condensers is enlarged under the condition of the certain position drop.

Owner:ZHEJIANG SCI-TECH UNIV

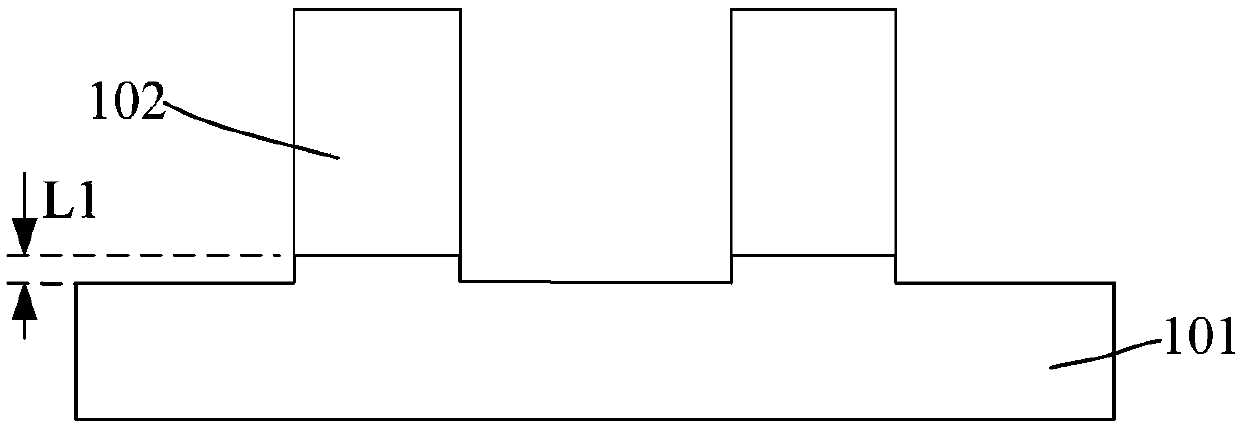

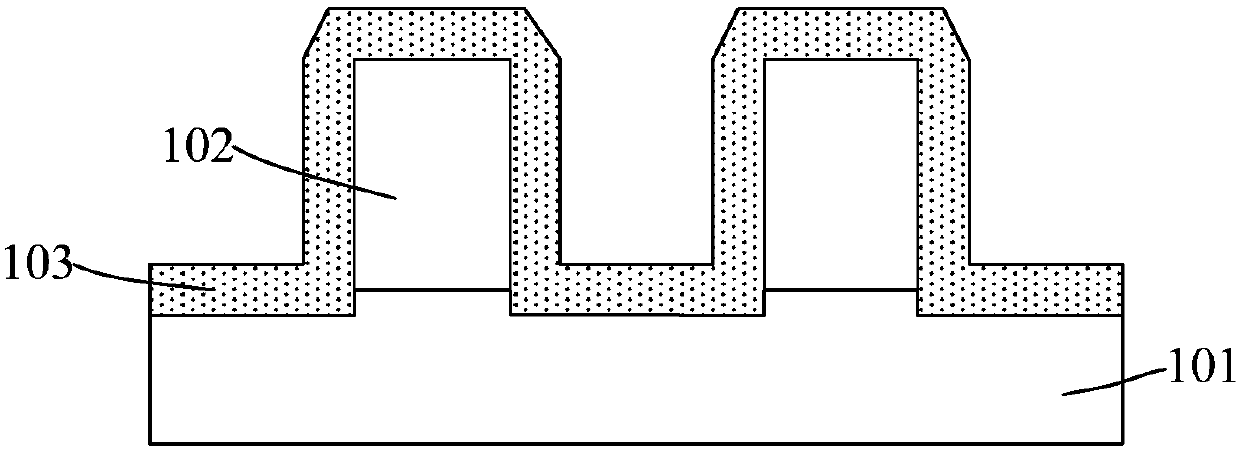

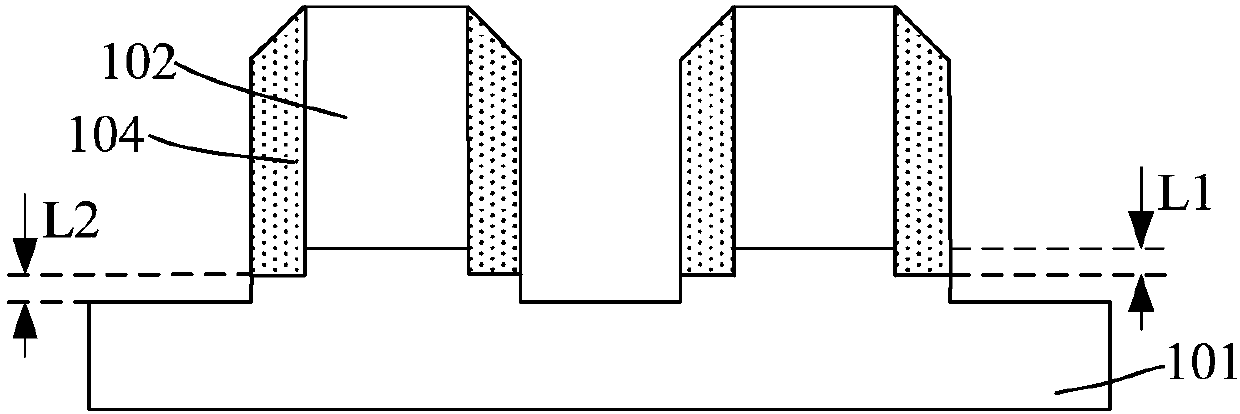

Double patterning method

ActiveCN107785252AQuality improvementSmall height differenceSemiconductor/solid-state device manufacturingSurface levelEngineering

The invention discloses a double patterning method. The method comprises steps: lateral wall layers are formed on the top part and the side wall of a core layer and the substrate in a second area; a sacrificial layer is formed on the lateral wall layer in a second sub area; the top part of the sacrificial layer and the top part of the lateral wall layer are subjected to planarization processing toexpose the top part of the core layer; a first etching process is adopted to etch the sacrificial layer and the core layer, and thus, the top part of the remaining core layer is flush with the top part of the remaining sacrificial layer in the second sub area; a second etching process is adopted to etch and remove the remaining core layer, the lateral wall layer in the second sub area is also etched and removed, and the first area substrate and the second sub area substrate are exposed; and with the lateral wall layer in a first sub area as a mask, the substrate is etched to form a target pattern. The surface height difference between the remaining substrates at two sides of the target pattern can be reduced, and the formed target pattern quality is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Work apparatus having a fuel pump

ActiveUS9181864B2Small height differenceEasy to assembleFuel injection apparatusMachines/enginesFuel tankInternal combustion engine

Owner:ANDREAS STIHL AG & CO KG

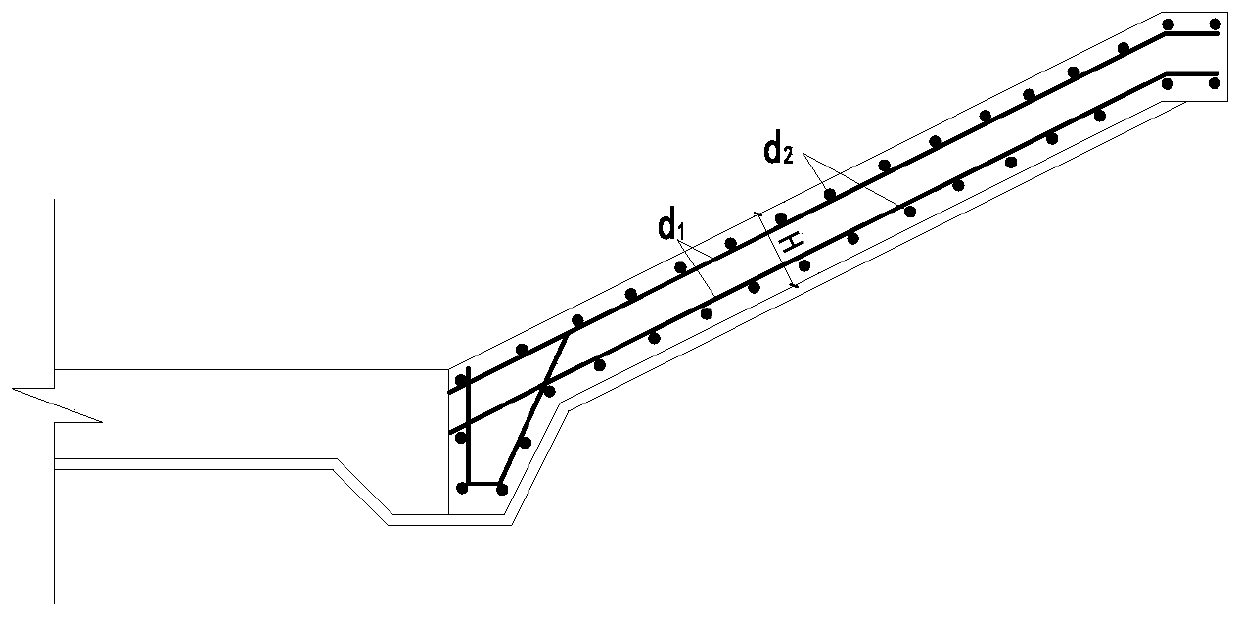

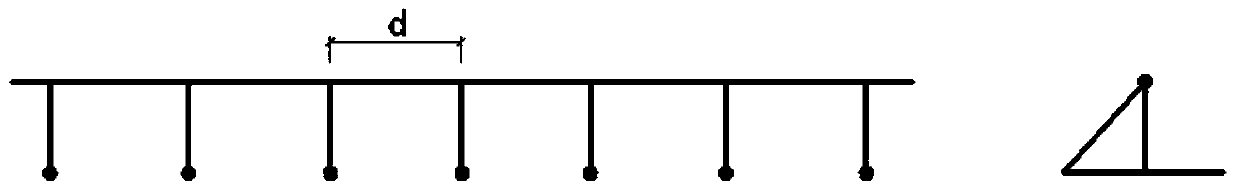

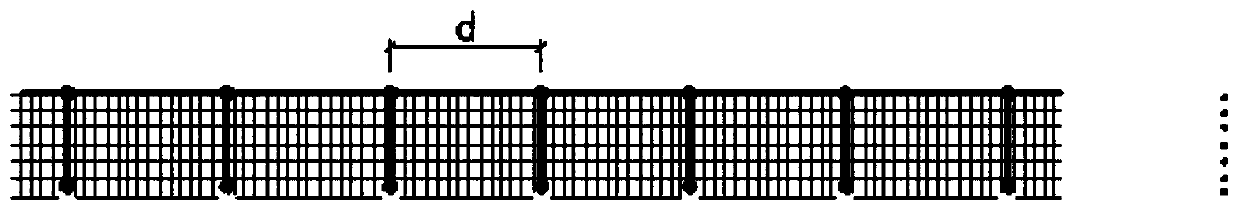

Large-angle high-thickness slope surface concrete pouring graded grid

The invention discloses a large-angle high-thickness slope surface concrete pouring graded grid. The large-angle high-thickness slope surface concrete pouring graded grid is composed of meshes and a supporting mounting system; the supporting mounting system is paved along the slope surface, and galvanized electrowelding steel wire gauze is adopted in the meshes; and the width of the graded grid isslope surface concrete thickness minus the thickness of an upper protective layer and a lower protective layer and the diameter of an upper layer of steel bars and a lower layer of the steel bars, aninterval of the meshes placing is determined through the galvanized steel wire mesh theory maximum ash blocking quantity water level and a perpendicular distance from a slope surface intersection tothe meshes, so that the meshes better block ash, and the concrete slope slipping phenomenon is controlled. According to a field slope surface structure, the limitation of concrete pouring slump limitand the pouring procedure of concrete, the concrete is poured in two layers, and vertical partition meshes are arranged and pouring is carried out by dividing left and right parts of each layer. Whenthe concrete is poured, pouring phenomena of large area and high pressure do not exist, and the slope surface is stable. The problems of increased operating personnel operating quantity, slow construction speed, low efficiency, prolonged construction period and the like are solved.

Owner:BEIJING TIANHENG CONSTR

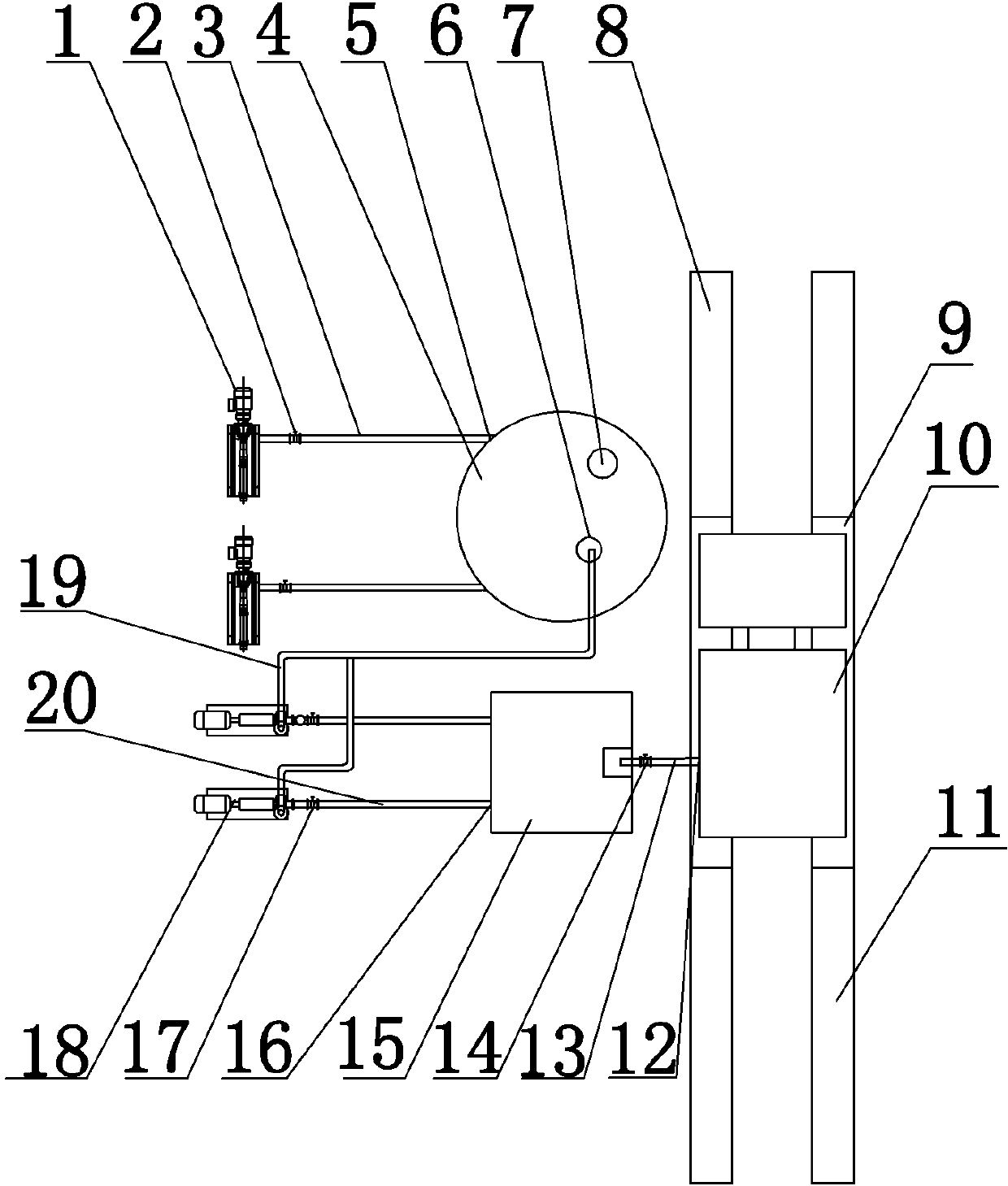

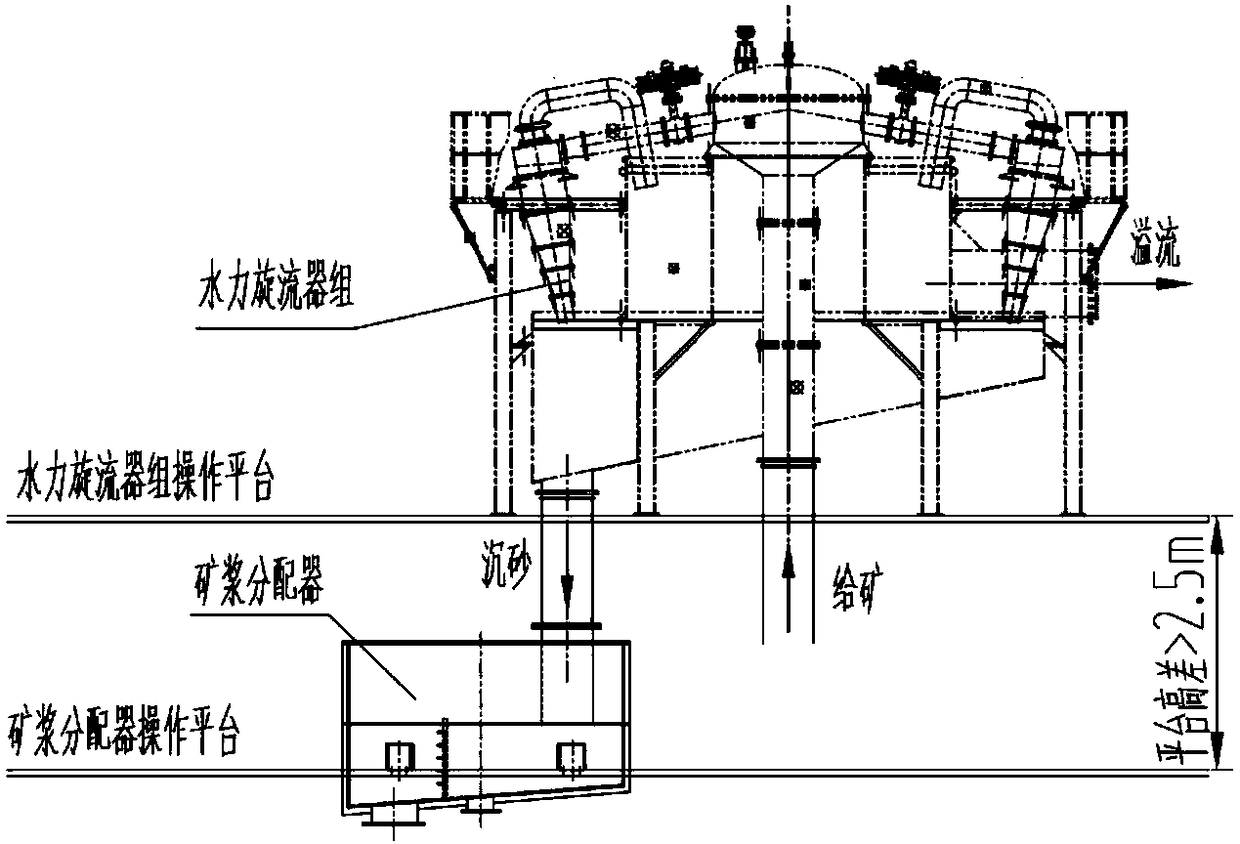

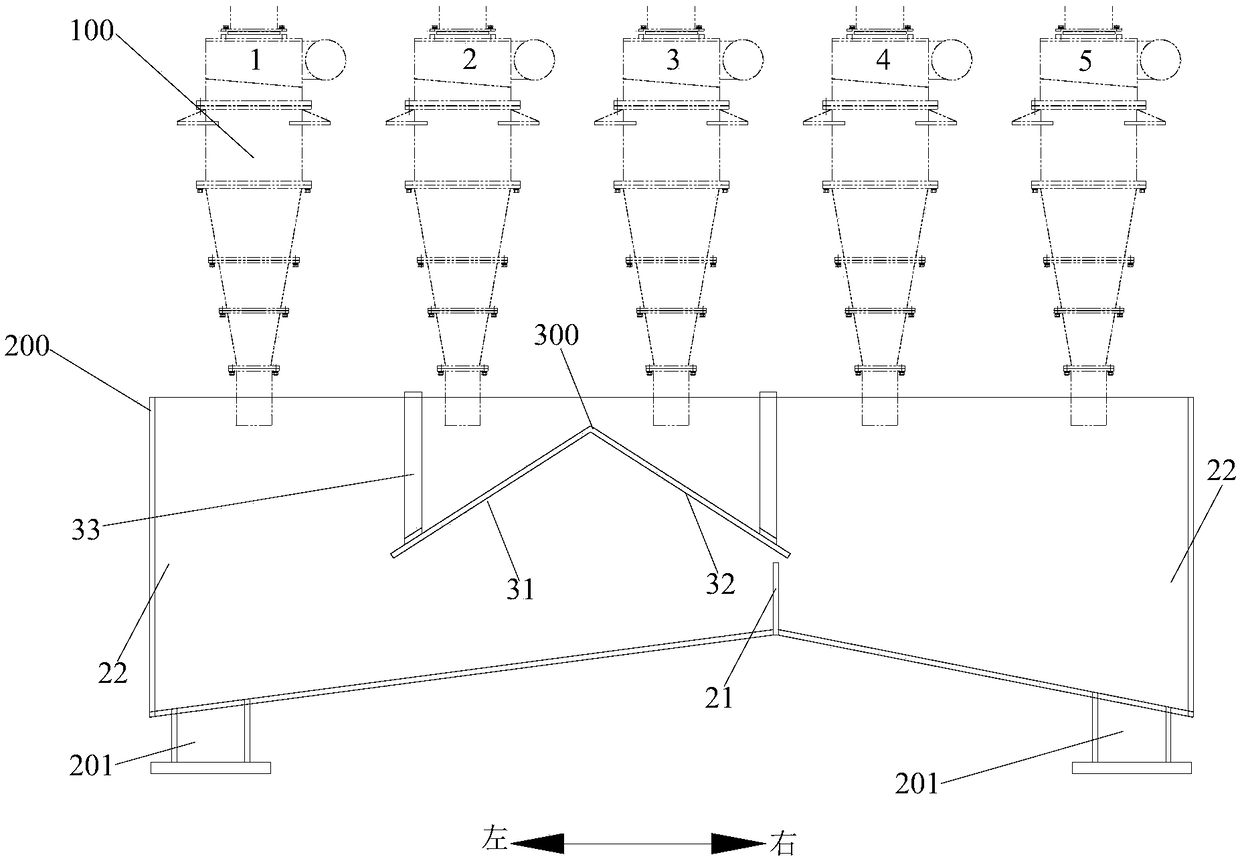

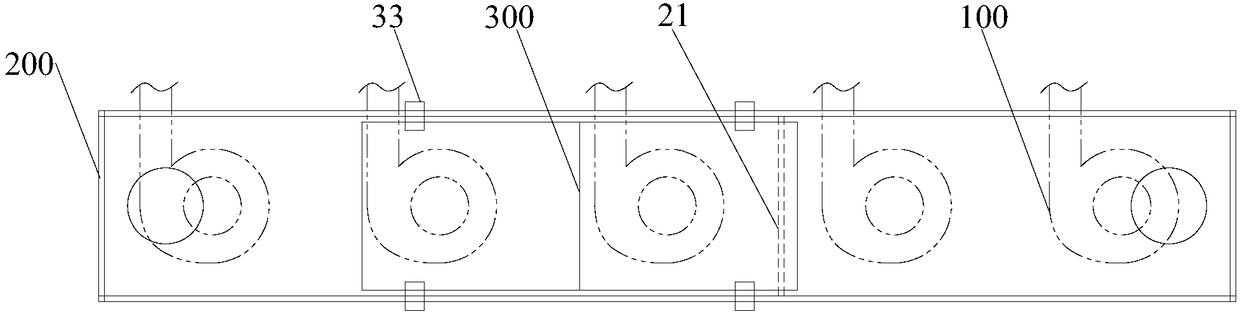

Hydrocyclone group

PendingCN108212564ASmall height differenceSave construction investmentReversed direction vortexConfiguration designHeight difference

The invention discloses a hydrocyclone group, which comprises a plurality of hydrocyclones, a sand setting box and a movable ore pulp distributor moving along the layout direction of the plurality ofhydrocyclones, wherein the sand setting box is arranged below the plurality of hydrocyclones for containing sand setting ore pulp which flows out of the plurality of hydrocyclones; a fixed baffle is arranged in the sand setting box to divide the lower part of the inner cavity of the sand setting box into at least two separated sand setting chambers; in addition, the sand setting box is provided with at least two set sand outlets corresponding to the sand setting chambers; the ore pulp distributor is arranged in the sand setting box and is positioned between the fixed baffle and one part of hydrocyclones for distributing the set ore pulp to at least two sand setting chambers at a ratio. Therefore, the hydrocyclones have an ore pulp distribution function, so that an ore pulp distributor operation platform is omitted in plant configuration design, the height difference of a whole ore grinding factory is lowered, and investment is lowered.

Owner:CHINA ENFI ENGINEERING CORPORATION

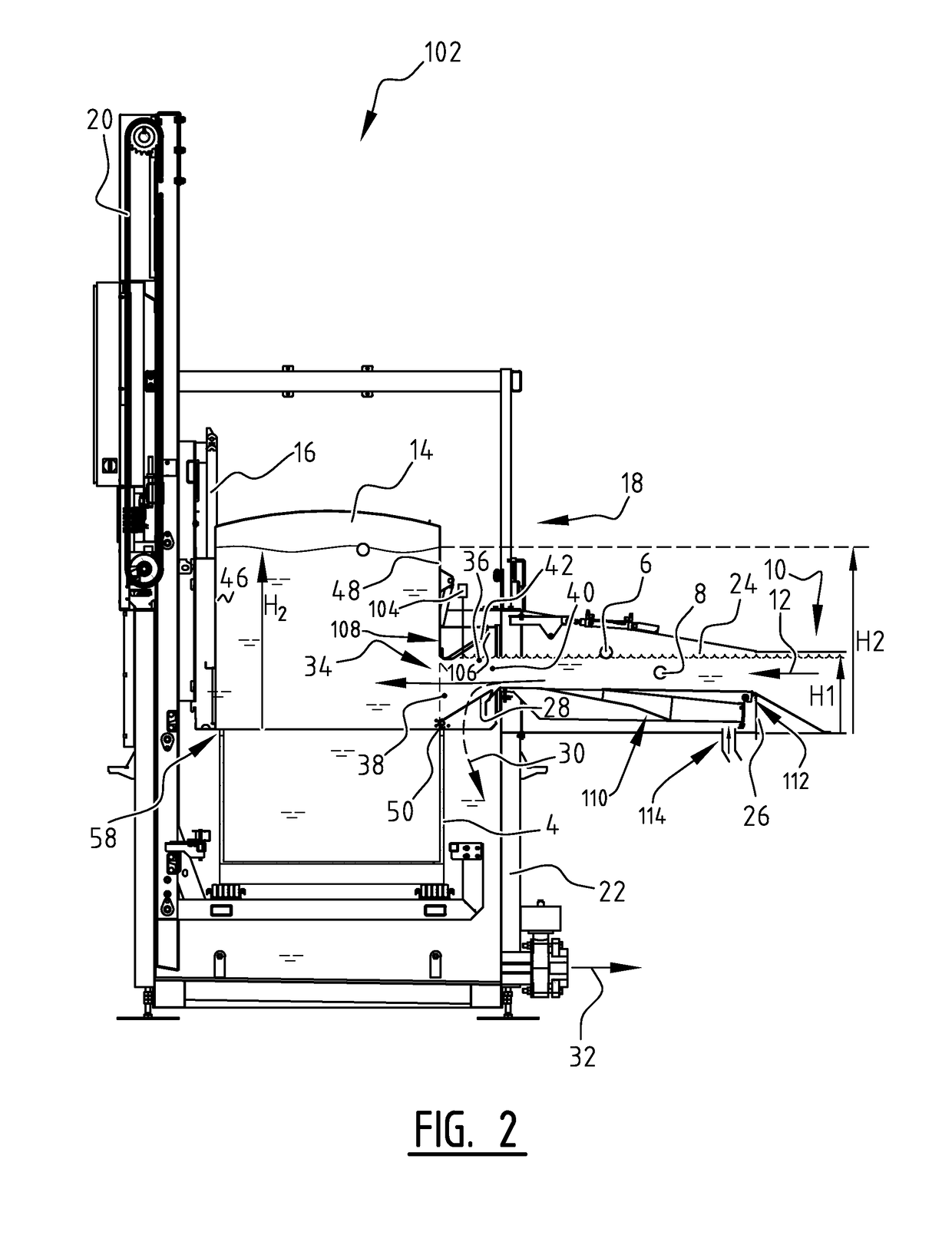

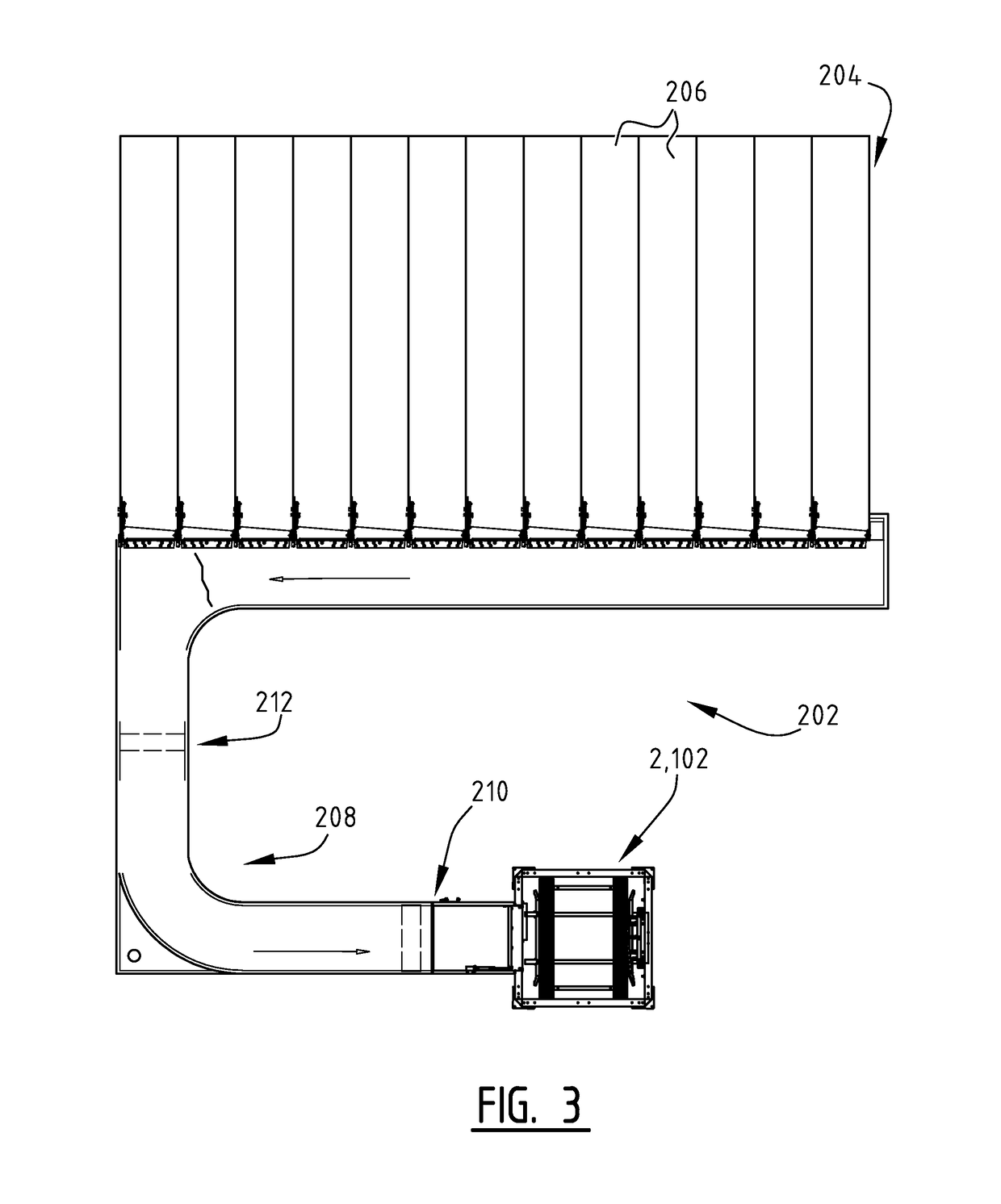

Filling device and method for filling a container with products floating and/or suspended in an aqueous liquid

ActiveUS10138011B2Small heightSmall height differencePackaging under special atmospheric conditionsLiquid materialPEARVacuum chamber

A filling device and method for filling a container with floating and / or suspended products, in particular for apples and pears. The device has a frame provided with a supply tank fillable with aqueous liquid, and a vacuum chamber for realizing an underpressure in at least a part of the supply tank; immersion means operatively connected to the frame for the purpose of placing the container into or removing the container from the supply tank; and feeder for feeding to the supply tank the aqueous liquid in which the floating and / or suspended products are entrainable. The feeder includes a flow tube or flow channel with which the floating and / or suspended products are carriable into the vacuum chamber.

Owner:DE GREEFS WAGEN CARROSSERIE & MACHINEBOUW

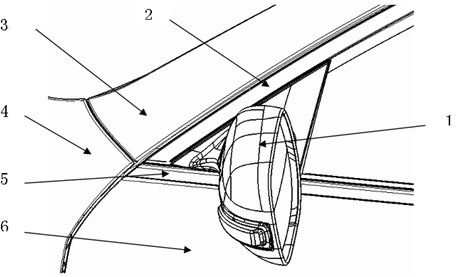

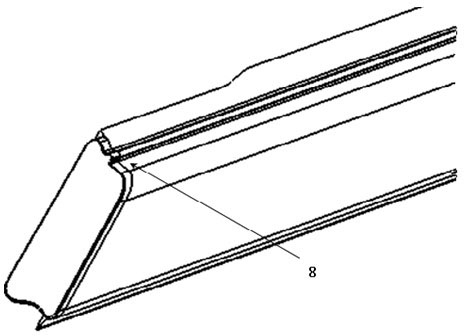

Automobile front door triangular window bright strip system

InactiveCN102424023ASmall height differenceGood lookingVehicle componentsEngineeringHeight difference

The invention discloses an automobile front door triangular window bright strip system which comprises a front door window frame decoration bright strip subassembly, a front door outer holding strip subassembly and a front door triangular window bright strip subassembly, wherein the front door window frame decoration bright strip subassembly and the front door outer holding strip subassembly are in positioning connection with a front door triangular window bright strip assembly respectively. The front door triangular window bright strip subassembly comprises a bright strip body, an injection upper bracket, an injection lower bracket and a mounting clip, wherein the bright strip body is punched into a '<' shape, the injection upper bracket is connected to an oblique side of the bright strip body, the injection lower bracket is connected to a horizontal side of the bright strip body, and the mounting clip is in positioning connection with one end of the injection lower bracket; the front door window frame bright strip subassembly is clamped on an oblique stretching structure of the front door triangular window bright strip subassembly; and the front door outer holding strip subassembly is clamped on a horizontal stretching structure of the front door triangular window bright strip subassembly. In the invention, as the front door triangular window bright strip subassembly is added, height difference between the small side wall and the front door window frame bright strip subassembly can be reduced, and the vortex wind noise also can be reduced.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Powder feeding device and method for broadband laser cladding additive manufacturing

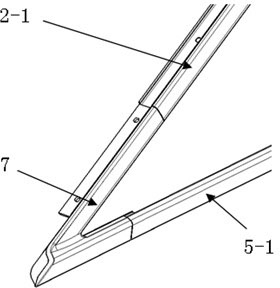

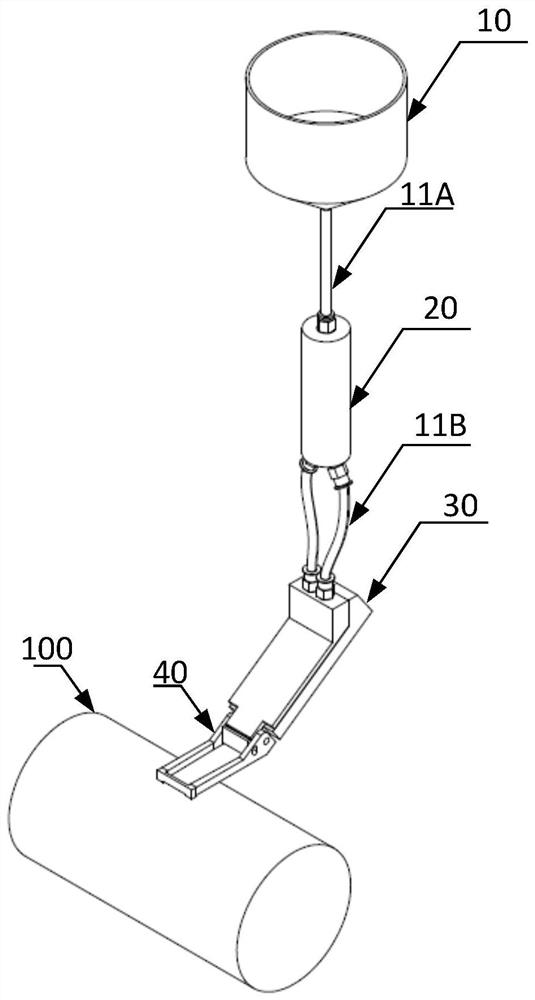

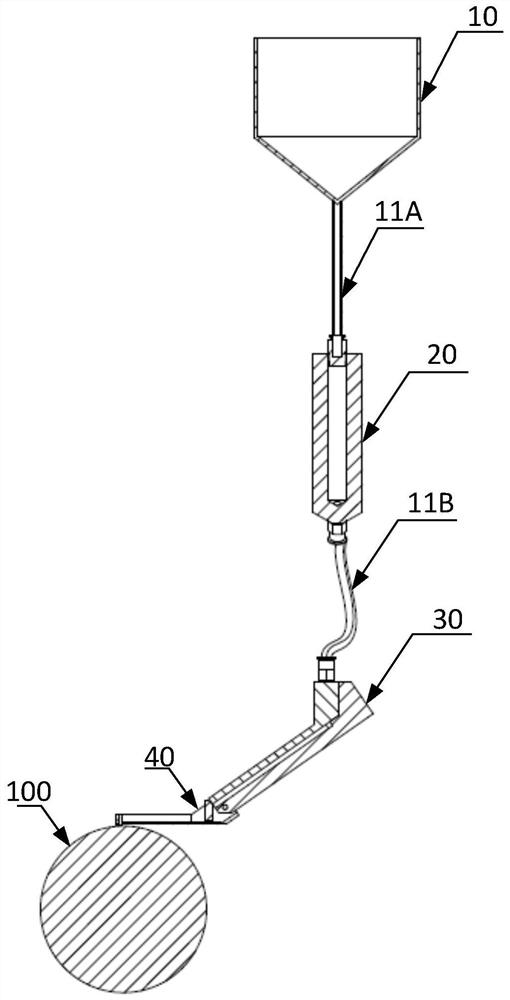

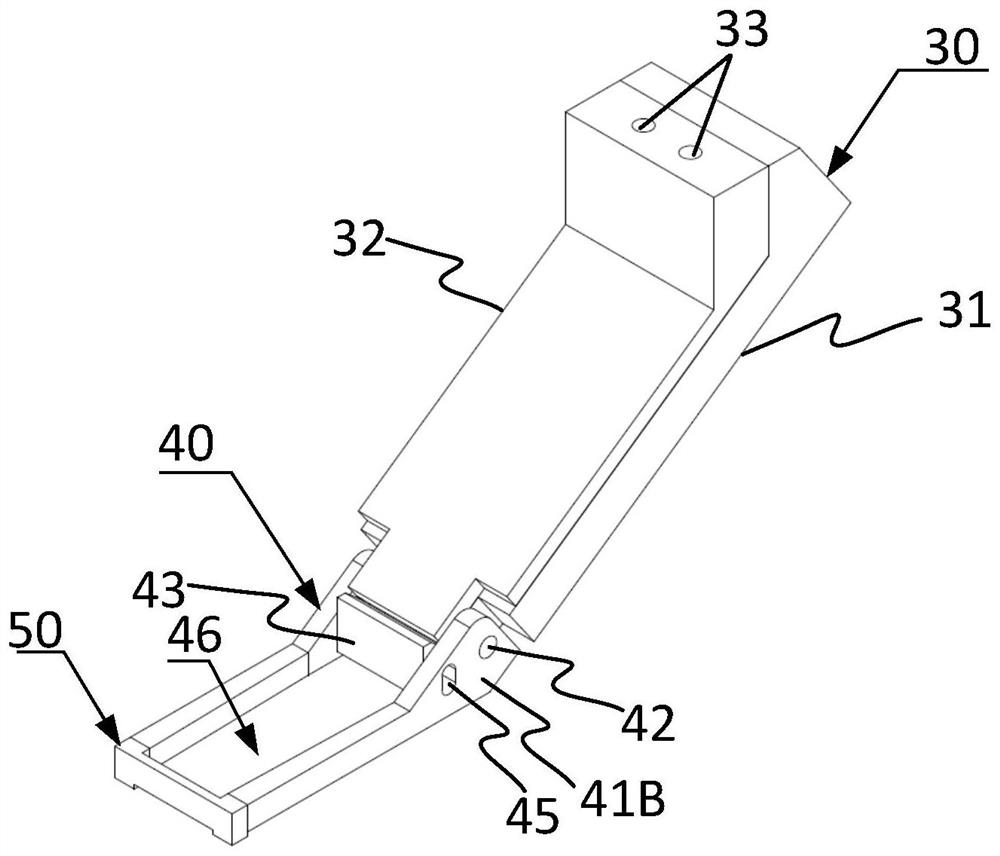

PendingCN113894292ATiled evenlySpread powder evenlyAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringStructural engineering

The invention relates to the technical field of laser additive manufacturing, and provides a powder feeding device and method for broadband laser cladding additive manufacturing. A pressure relief device is arranged between a broadband powder feeding nozzle and the surface of a base material, the pressure relief device and the broadband powder feeding nozzle form a certain angle, and the pressure relief device is installed at the position below a first powder outlet of the broadband powder feeding nozzle. The pressure relief device is used for conducting pressure relief treatment on the powder flowing out of the first powder outlet. The pressure relief device comprises a first-stage pressure relief mechanism and a second-stage pressure relief mechanism which are arranged in a cascade connection mode, the first-stage pressure relief mechanism is used for conducting pressure relief on the powder flowing out of the first powder outlet, and the second-stage pressure relief mechanism is arranged at the tail end of the first-stage pressure relief mechanism and used for conducting secondary pressure relief on the powder subjected to pressure relief through the first-stage pressure relief mechanism. Therefore, the problems of poor uniformity during laser cladding, poor flatness after cladding and large machining allowance caused by non-uniform and uneven powder feeding of lateral preset powder for laser broadband cladding at present are solved.

Owner:NANJING ZHONGKE RAYCHAM TECH

Circular impact mill unit and cycle impact mill method using impact mill

InactiveCN105149045BAvoid damageEliminate the phenomenon of mixing in finished productsGrain treatmentsForeign matterEngineering

The invention discloses a circulating impact pulverizing unit and method. The unit includes a casing, a screen is installed in the casing, a cleaning bin and a screening bin are arranged in the screen, and a circulating screen and a grading screen are arranged in the screening bin. There is an impact mill in the casing, and the top of the sieve is provided with a sieve body feed port and a circulating feed port; the cleaning bin is provided with a cleaning screen for separating impurities; the discharge port of the impact mill is connected to the mill. The discharge pipe of the pulverizer, the discharge pipe of the pulverizer extends upward and is connected with a discharger after being bent; the circulating feeding port is connected with a screening feeding channel, and a circulating discharging channel is arranged above the circulating screen, and the circulating The discharging channel is communicated with the feeding channel of the pulverizer; the grading screen mechanism is connected with a number of sieve discharge pipes at each grading screen. The invention occupies less area, has low cost and low energy consumption, can avoid the damage of large foreign objects, can process cyclically and continuously discharge materials, avoid that the pulverized materials fail to meet the particle size requirements, and divide the processed materials into different particle sizes. Finished product sent.

Owner:王毅

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com