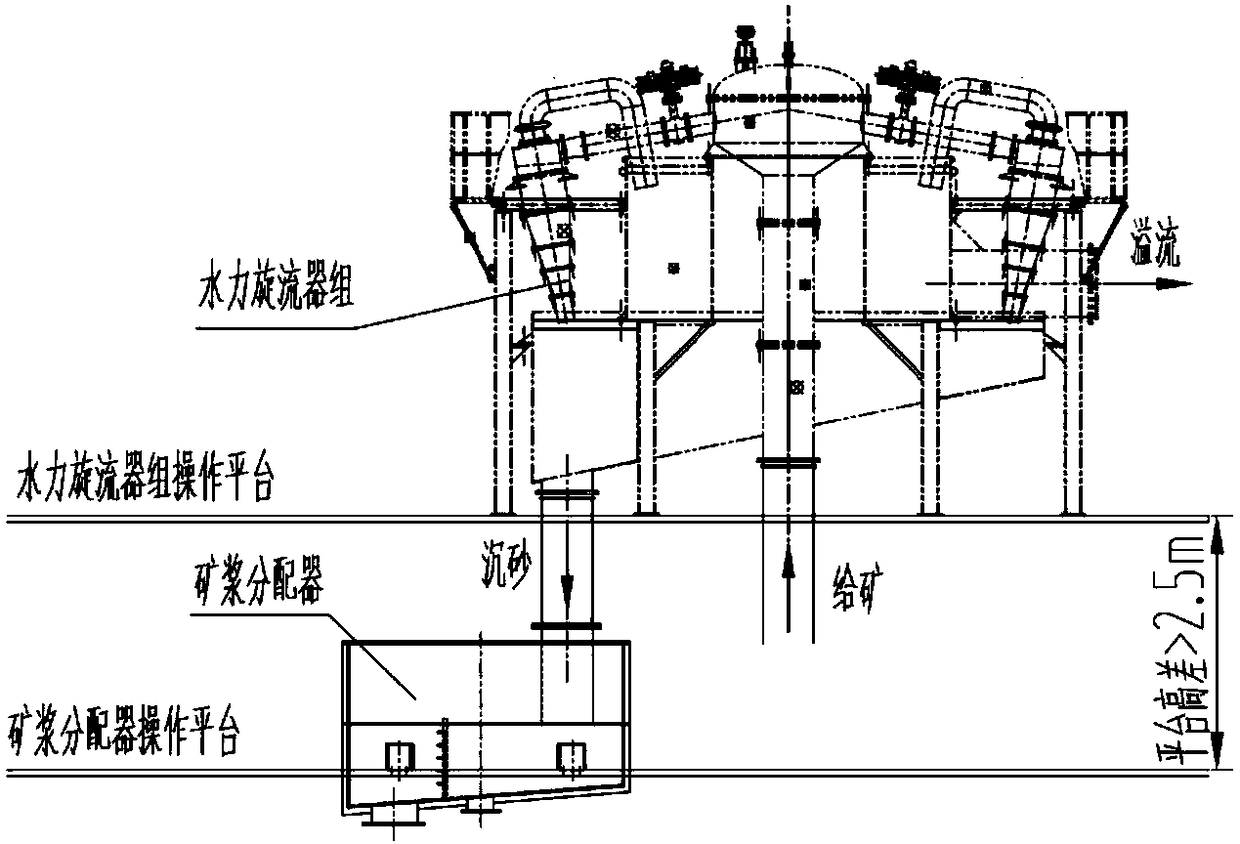

Hydrocyclone group

A hydrocyclone and cyclone technology, which is applied to cyclone devices, devices whose axial directions of cyclones can be reversed, etc., can solve the problem of increasing the amount of steel components, increasing construction investment, and increasing the height difference of the workshop. problems, to achieve the effect of improving efficiency, reducing construction investment, and reducing operation links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

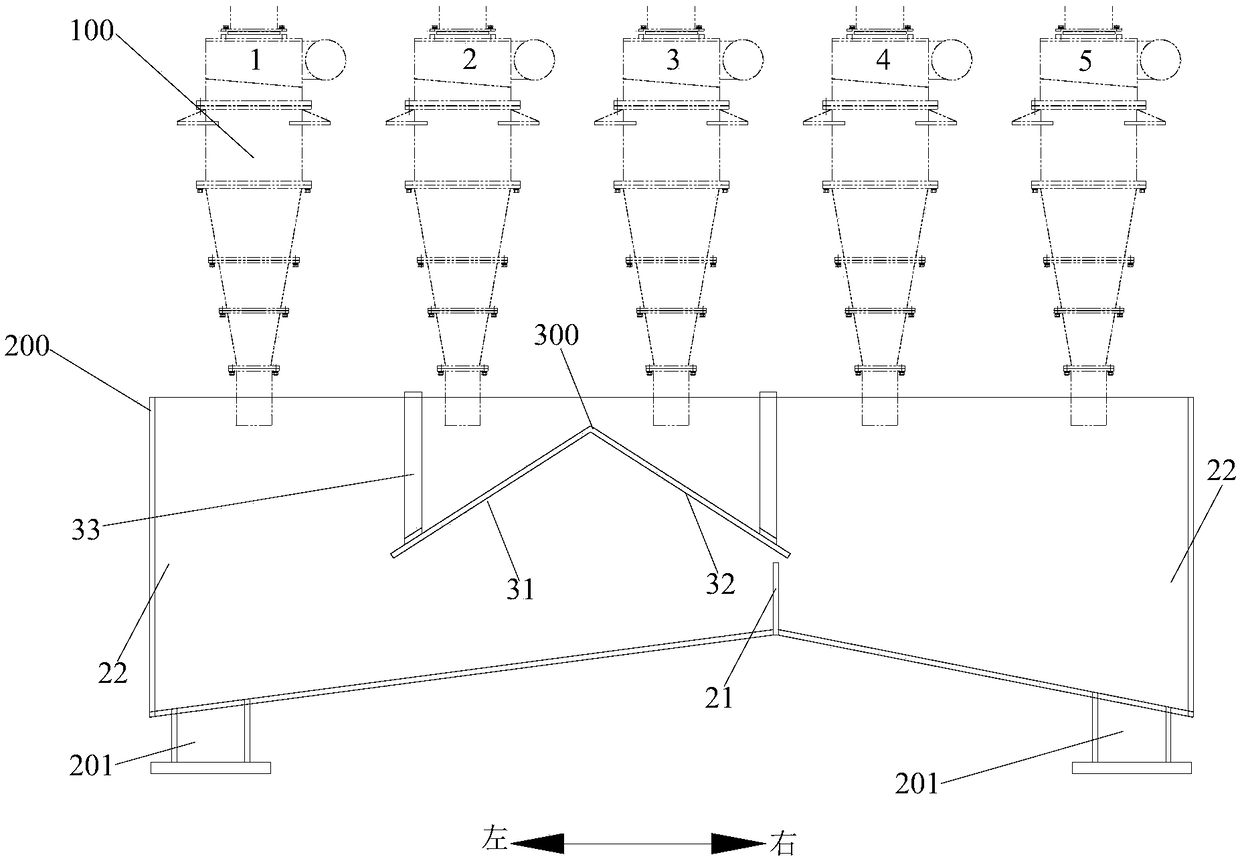

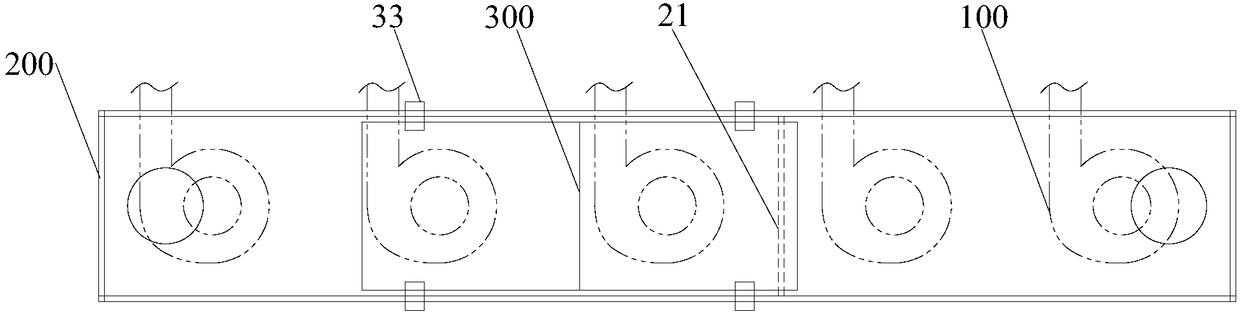

[0043] by figure 2 For example, the group of hydrocyclones is arranged linearly, and the grit chamber is formed into a long strip extending along the direction of arrangement of multiple cyclones, and there are 5 hydrocyclones, which are marked as 1 from left to right No., No. 2, No. 3, No. 4 and No. 5, of which 3 are in operation and 2 are in standby, and assuming that the process requires that the distribution ratio of grit and slurry in the hydrocyclone group is 1:2, of which figure 2 As shown, the left grit outlet distributes 2 / 3 of the grit slurry, and the right grit outlet distributes 1 / 3 of the slurry. figure 2 As shown in the running status of No. 1, No. 2 and No. 3 cyclones (No. 4 and No. 5 standby), the slurry distributor moves between No. 2 and No. 3 cyclones. At this time, the grit-set slurry in No. 1 cyclone Directly enter the left grit chamber of the grit chamber, the grit slurry in the No. 2 cyclone enters the left grit chamber in the grit chamber through th...

Embodiment 2

[0045] refer to Figure 4 , the hydrocyclone group is arranged in a ring, and the grit box forms a ring extending along the arrangement direction of multiple cyclones (the bottom of the grit box is a ring structure inclined to one side), and has 10 Cyclone, of which 6 are running and 4 are standby, the fixed baffle is installed in the form of a plug-in plate, and there are 3 installation slots, which can be installed in different positions to change the flow direction of the upper cyclone grit chamber; the bottom of the grit chamber Two grit outlets are arranged at intervals at the lowest part of the part, and the fixed baffle between the two grit outlets is fixed by welding. The outlet is discharged; the slurry distributor can move along the circumference on the two walls of the grit box to adjust the grit flow direction of the upper cyclone to a greater extent. Assuming that the process requires the grit distribution ratio of the hydrocyclone group to be 1:2, the inner grit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com