Continuous copper smelting system and continuous copper smelting method

A technology for copper smelting and furnace smelting, which is applied in crucible furnaces, electric furnaces, rotary drum furnaces, etc., can solve the problems of high copper grade in smelting slag, high raw material requirements, and large amount of refractory materials, and achieves high comprehensive utilization of resources. The effect of high SO2 concentration and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

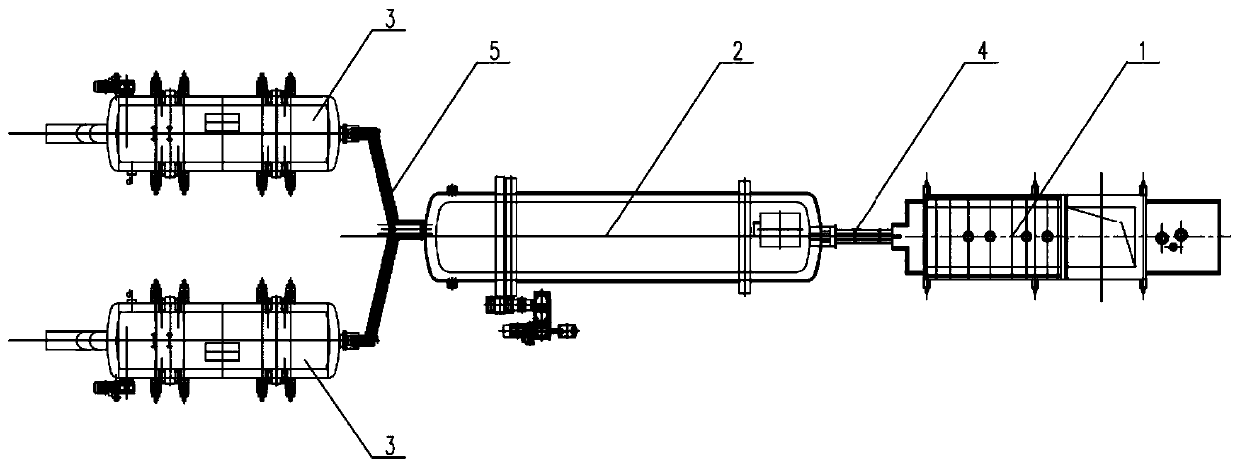

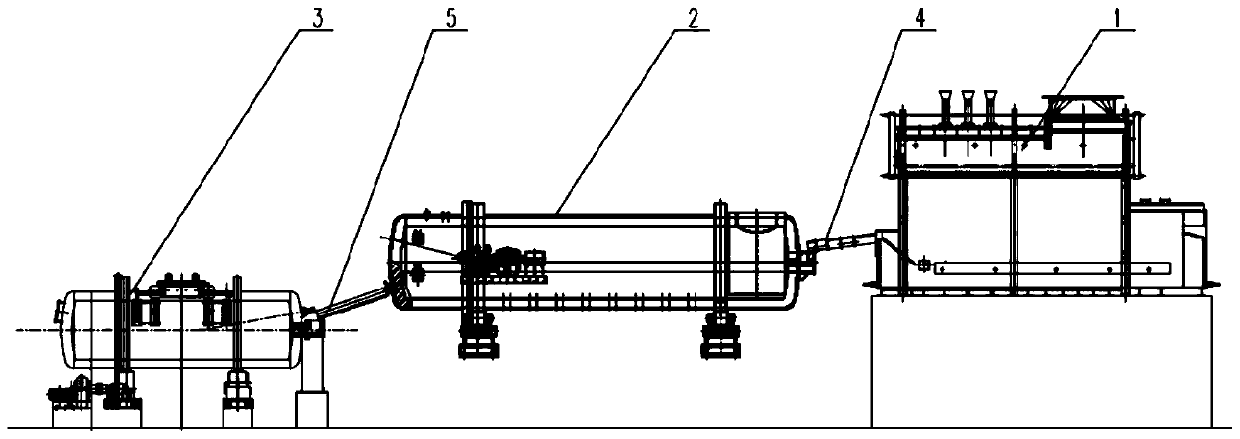

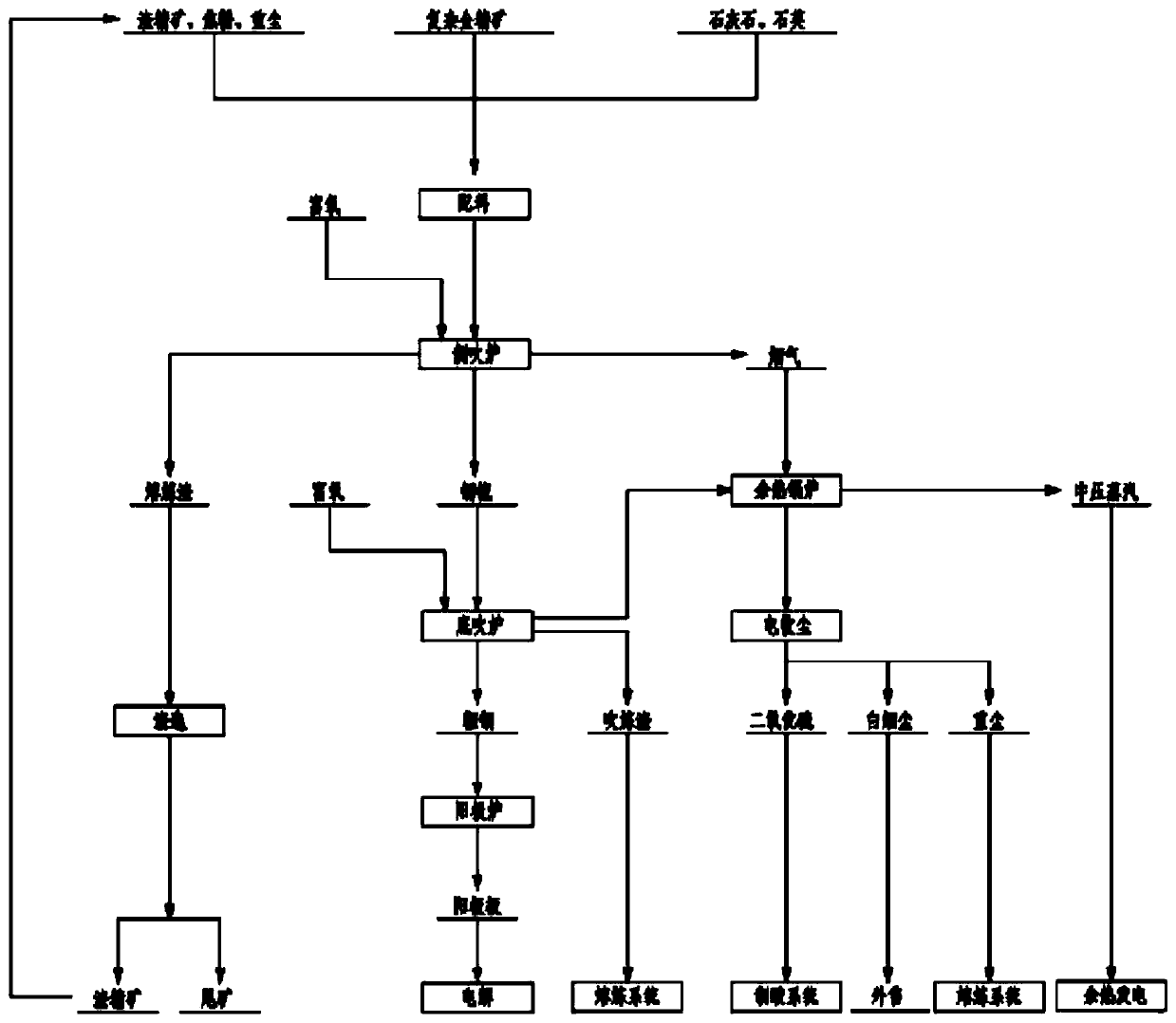

[0058] Include the following steps:

[0059] Copper sulfide concentrate, flux, slag concentrate, blowing slag and returned flue dust are uniformly fed into the furnace by the belt feeder after batching; Oxygen-enriched air is blown into the eye, and the smelting reaction is carried out in the furnace to generate copper matte and smelting slag;

[0060] The copper matte enters the bottom-blown converting furnace continuously from the launder through the siphon port, and the matte grade can be stabilized at 70% to 71%;

[0061] The smelting slag flows into the smelting slag bag through the overflow port, and the copper content of the smelting slag can be controlled at 1-1.5%;

[0062] The copper matte feed port of the bottom-blowing converting furnace is set at the center of the end of the furnace body. The oxygen lance at the bottom sends oxygen-enriched air into the furnace for blowing. The blowing temperature is controlled at ~1200°C, and blister copper containing Cu>98% an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com