Circulating impact flour milling machine unit and circulating impact flour milling method by using circulating impact flour milling machine

A technology of impact mill and impact mill, applied in the direction of grain processing, etc., can solve the problems that the products cannot be divided into different particle sizes, the impact mill is easy to enter foreign objects, and the impact mill is easy to be damaged, etc. Promote application value, compact structure, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

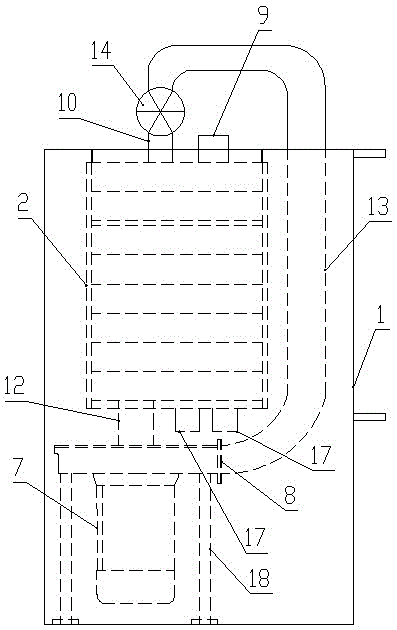

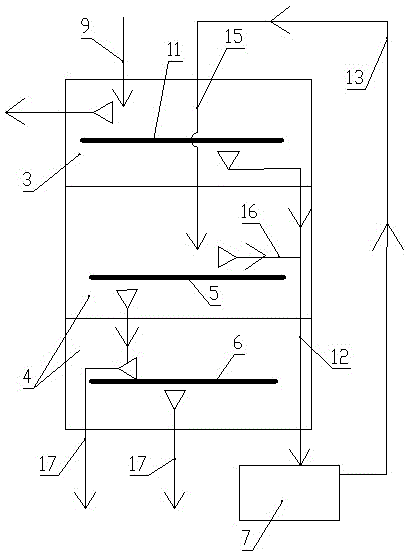

[0039] figure 2 The direction indicated by the middle arrow is the flow direction of the material. figure 2 The "△" with the tip pointing down in the middle indicates the undersize, and the "△" symbol with the tip pointing to the left or right indicates the oversize.

[0040] Such as figure 1 As shown in Figure 2, the circulating impact mill unit of the present invention includes a casing 1, a sieve 2 is installed in the casing 1, a cleaning bin 3 and a sieving bin 4 below the cleaning bin 3 are arranged in the sieve 2; The storage bin 4 is provided with a circulating screen 5 and a grading screen mechanism located below the circulating sieve 5, and the grading screen mechanism includes several grading screens 6;

[0041] The casing 1 directly below the sieve 2 is provided with an impact mill 7, and the discharge port 8 of the impact mill 7 is located on the top of the impact mill 7; The feed port 10; the feed port 9 of the sieve body communicates with the cleaning bin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com