Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

213 results about "Impact mill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Impact mills are one of two general classes of milling devices used to reduce the particle size of a material.

Process for producing particulate, water-soluble cellulose derivatives using a superheated gas mixture containing steam

The present invention relates to a new, particularly economical process for preparing particulate water-soluble cellulose derivatives. The process involves forming a feed composition of swollen and / or dissolved cellulose derivative, and water. The feed composition is contacted with a superheated gas mixture, in a sieve-free high rotational speed gas jet impact mill, and the cellulose derivative of the feed composition is converted into a solid state form of finely particulate particles. The superheated gas mixture, with which the feed composition is contacted, is selected from: (i) a superheated gaseous mixture of steam and an inert gas; and (ii) a superheated gas mixture of steam and air. The superheated gas mixture has a steam content of 40 wt. % to 99 wt. %, based on the total weight of the superheated gas mixture.

Owner:DOW GLOBAL TECH LLC

Conical-shaped impact mill

ActiveUS7861958B2Maximize efficiencyReduce the temperatureGrinding machine componentsCocoaRotational axisEngineering

Owner:LEHIGH TECH INC

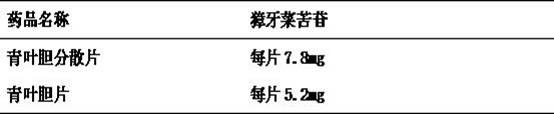

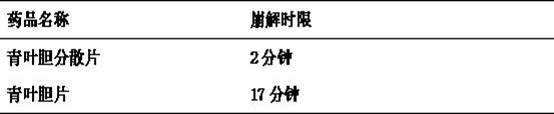

Swertia mileensis dispersible tablet and preparation method thereof

ActiveCN102600234AThe active ingredients are fully extractedHigh content of active ingredientsDigestive systemAntiviralsSwertia mileensisHigh energy

The invention discloses a swertia mileensis dispersible tablet and a preparation method thereof. The preparation method is characterized by comprising the following steps: extracting swertia mileensis by adopting a carbon dioxide supercritical extraction method; drying at reduced pressure; crushing the swertia mileensis into nano-paste by using a high-energy nano-impact mill; adding a functional auxiliary material to prepare the swertia mileensis dispersible tablet. By adopting the preparation method, the contents of effective components are remarkably improved, the disintegration time is remarkably shortened, the curative effect is remarkably superior to the swertia mileensis tablet, and a positive effect is obtained.

Owner:GUIPING PRODIVITY PROMOTION CENT

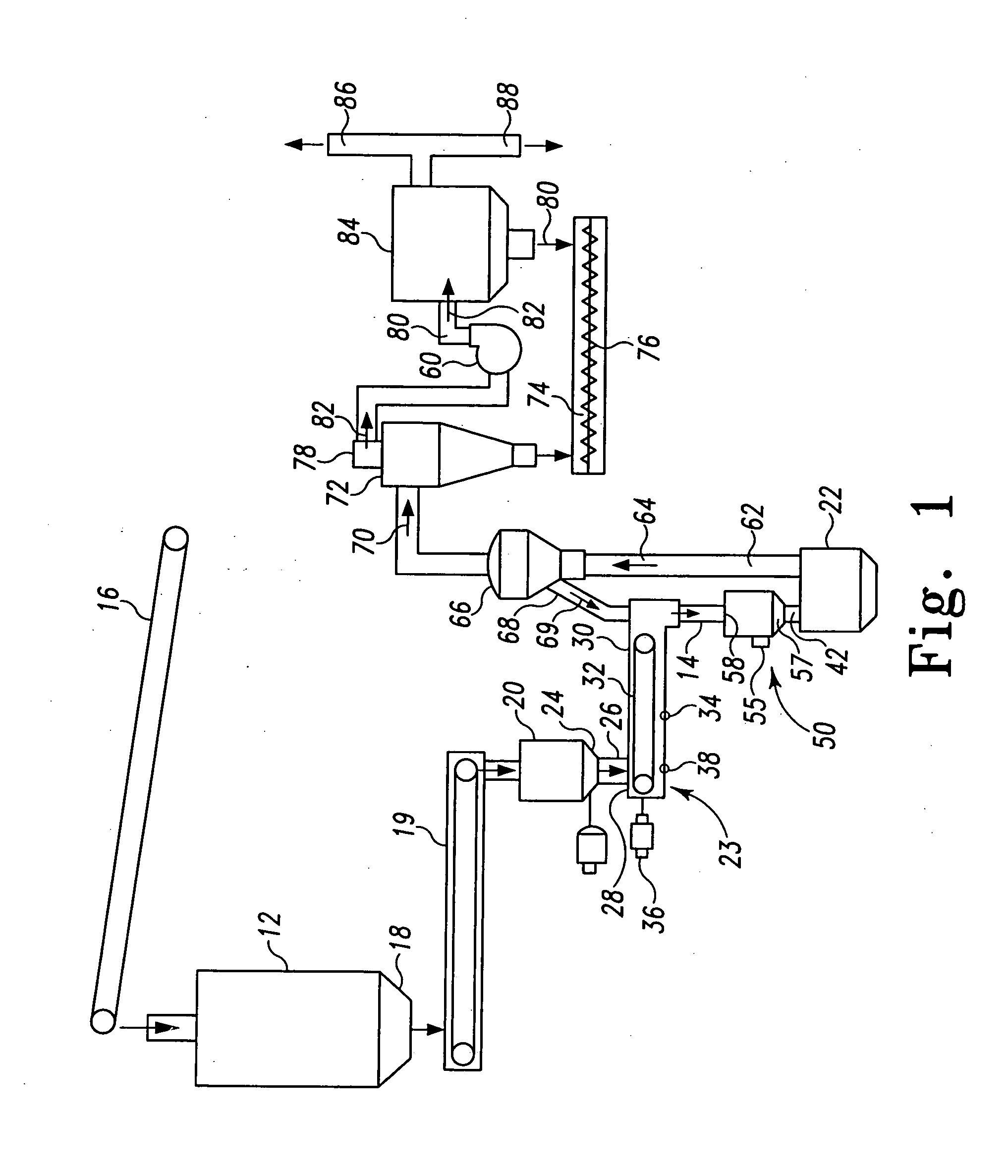

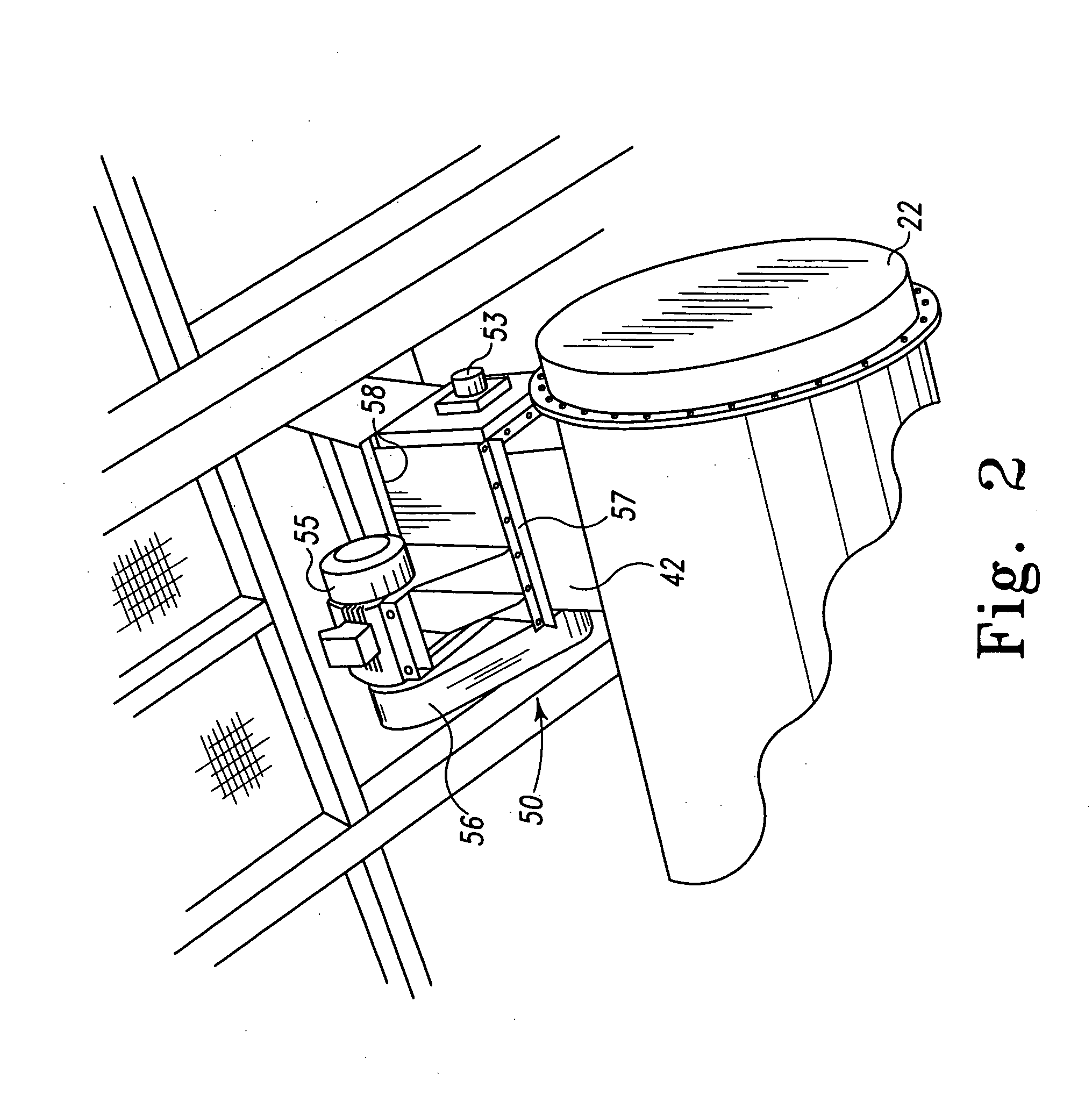

Method and apparatus for calcining gypsum

The subject invention relates generally to methods and apparatuses for calcining gypsum. The apparatuses and methods place a gypsum particle optimizer in close association with the impact mill so that all the gypsum supplied to the impact mill has to enter the gypsum particle optimizer prior to the gypsum entering the impact mill, and so that heat generated from the impact mill enters into the gypsum particle optimizer from the impact mill. The gypsum particle optimizer utilizes a rotor to disperse the gypsum throughout the gypsum particle optimizer so that the gypsum is exposed to the heat from the impact mill prior to entering the impact mill. The exposure to the heat removes free water from the gypsum prior to the gypsum entering the impact mill.

Owner:GOLD BOND BUILDING PROD LLC

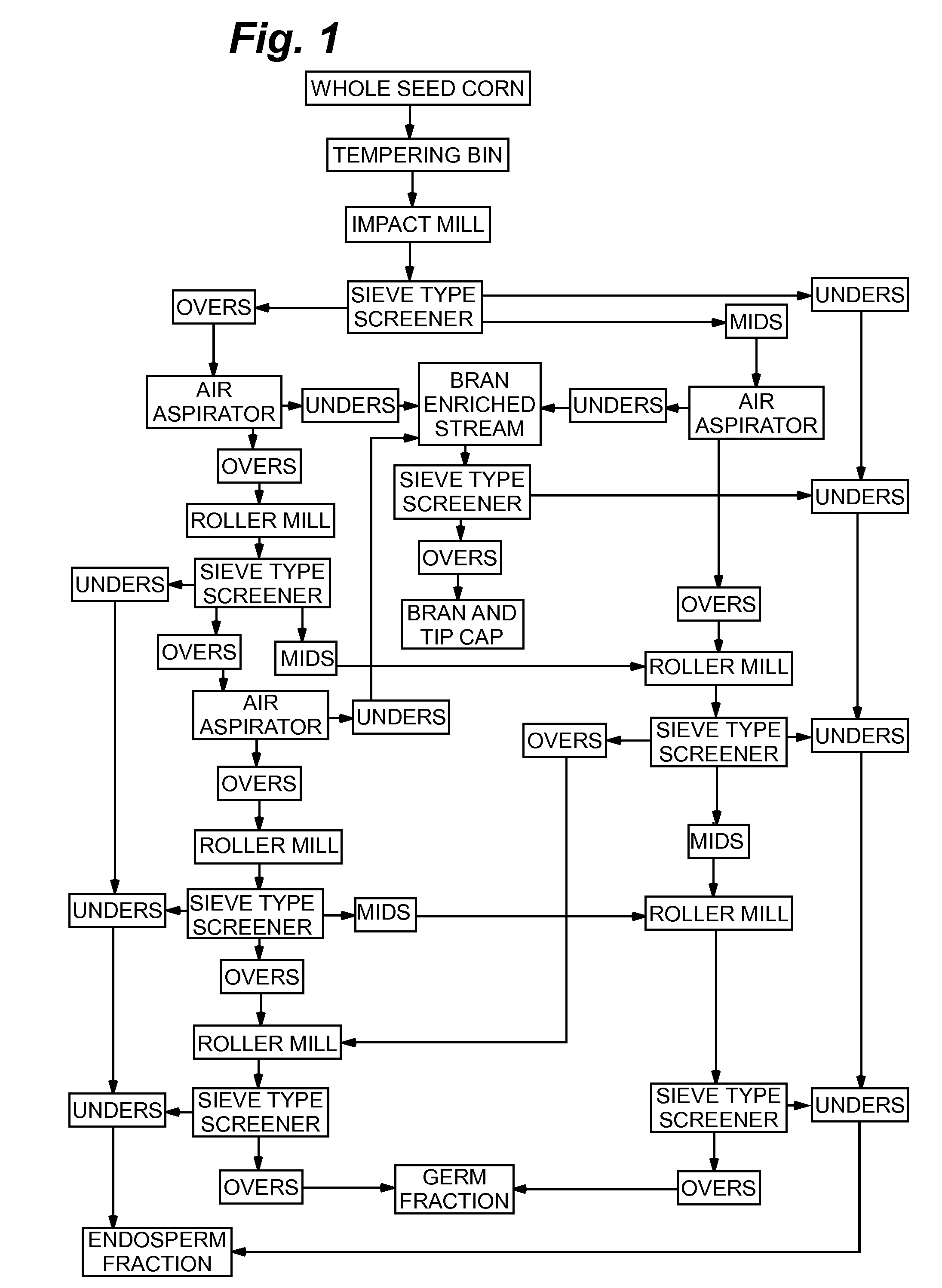

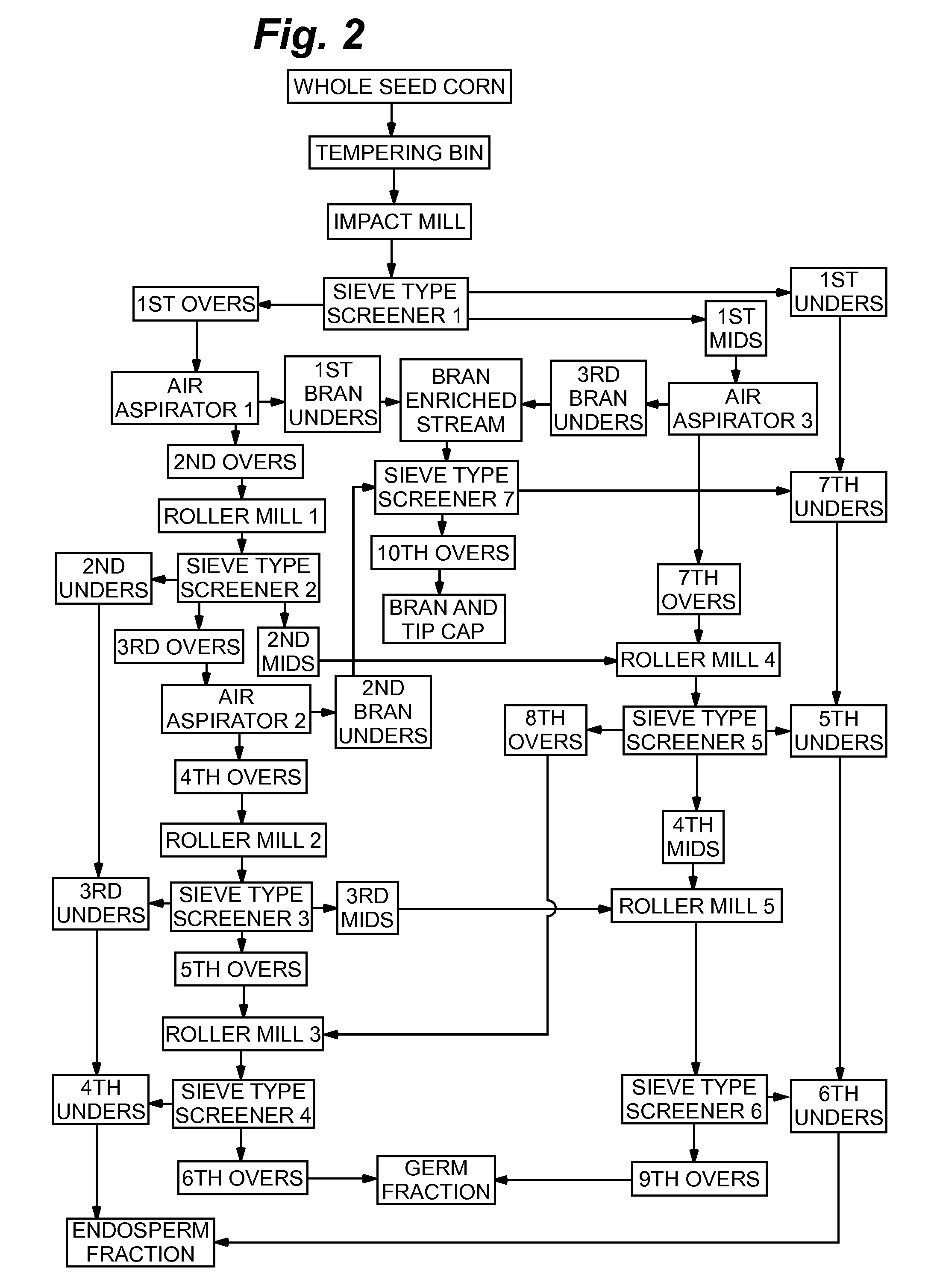

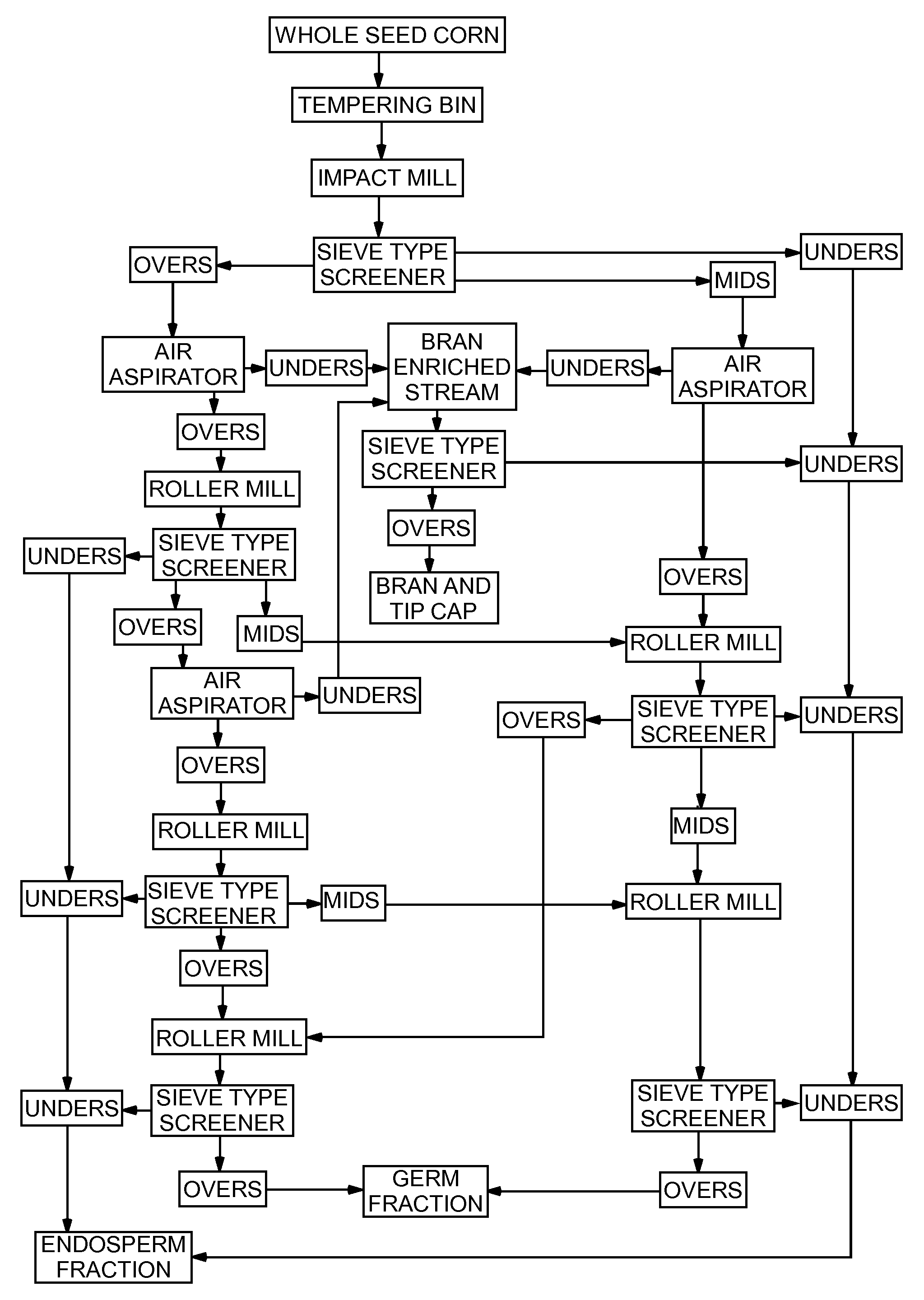

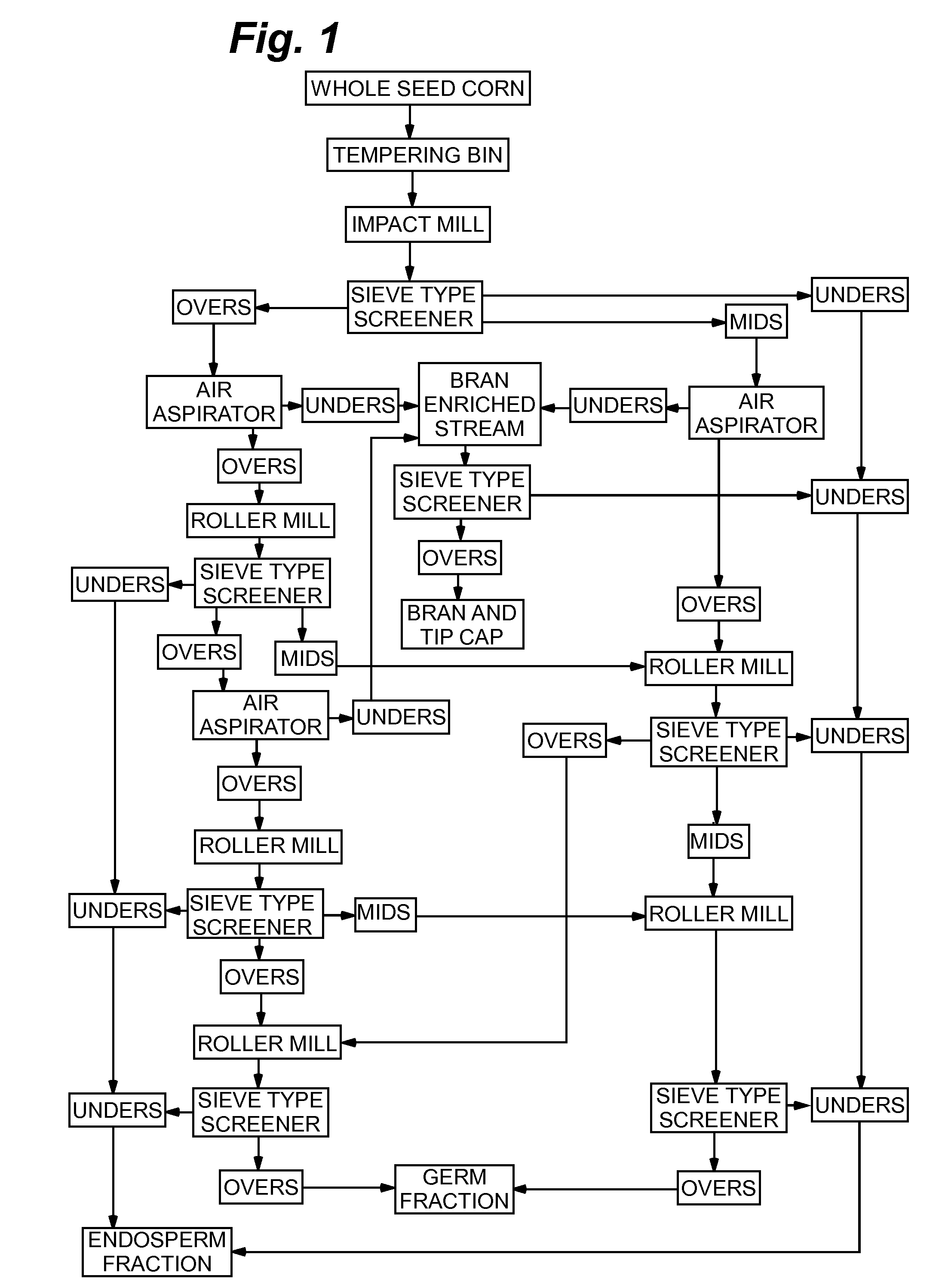

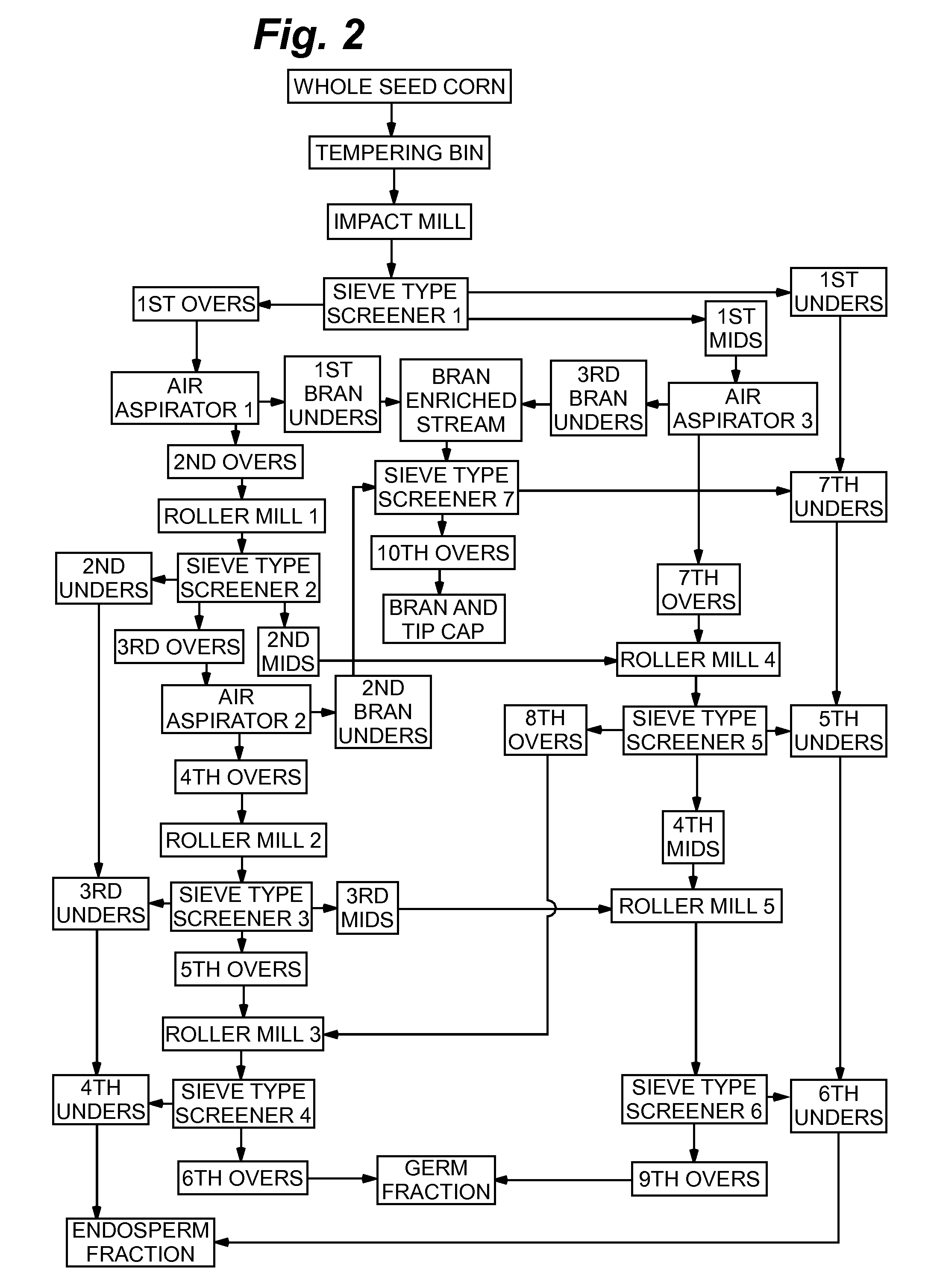

Dry Milling Corn Fractionation Process

A method for fractionating whole kernel corn into bran, germ and endosperm fractions. Corn (tempered or non-tempered) is processed through an impact mill and through a screener to divide the initial feed stream into two or more flows or substreams. The substreams or portions thereof may be further processed through a plurality of aspirators, roller mills and screeners to provide bran, germ and endosperm fractions of desired purity levels.

Owner:CROWN IRON WORKS

Flour processing technology

InactiveCN104646087AIncrease powder yieldImprove completenessGrain treatmentsMaterials preparationWheat Brans

The invention relates to the field of food, in particular to a flour processing technology. The flour processing technology comprises the following steps of (1) material preparation; (2) clean wheat proportion; (3) wheat wetting; (4) grinding; (5) powder purification; (6) flour blending. According to the flour processing technology, the problem that some smaller particles in materials, which are processed by 9 reduction roller mills, 6 shelling mills and a purifier, are difficultly grinded sufficiently in a tail mill in the grinding process is solved. The flour processing technology has the advantages that the smaller particles are grinded more sufficiently by utilization of impact mills, so that the flour yield is improved, the integrity rate of wheat bran is improved at the same time, and the quality of flour and by-products are guaranteed.

Owner:山东津宜润德面业有限公司

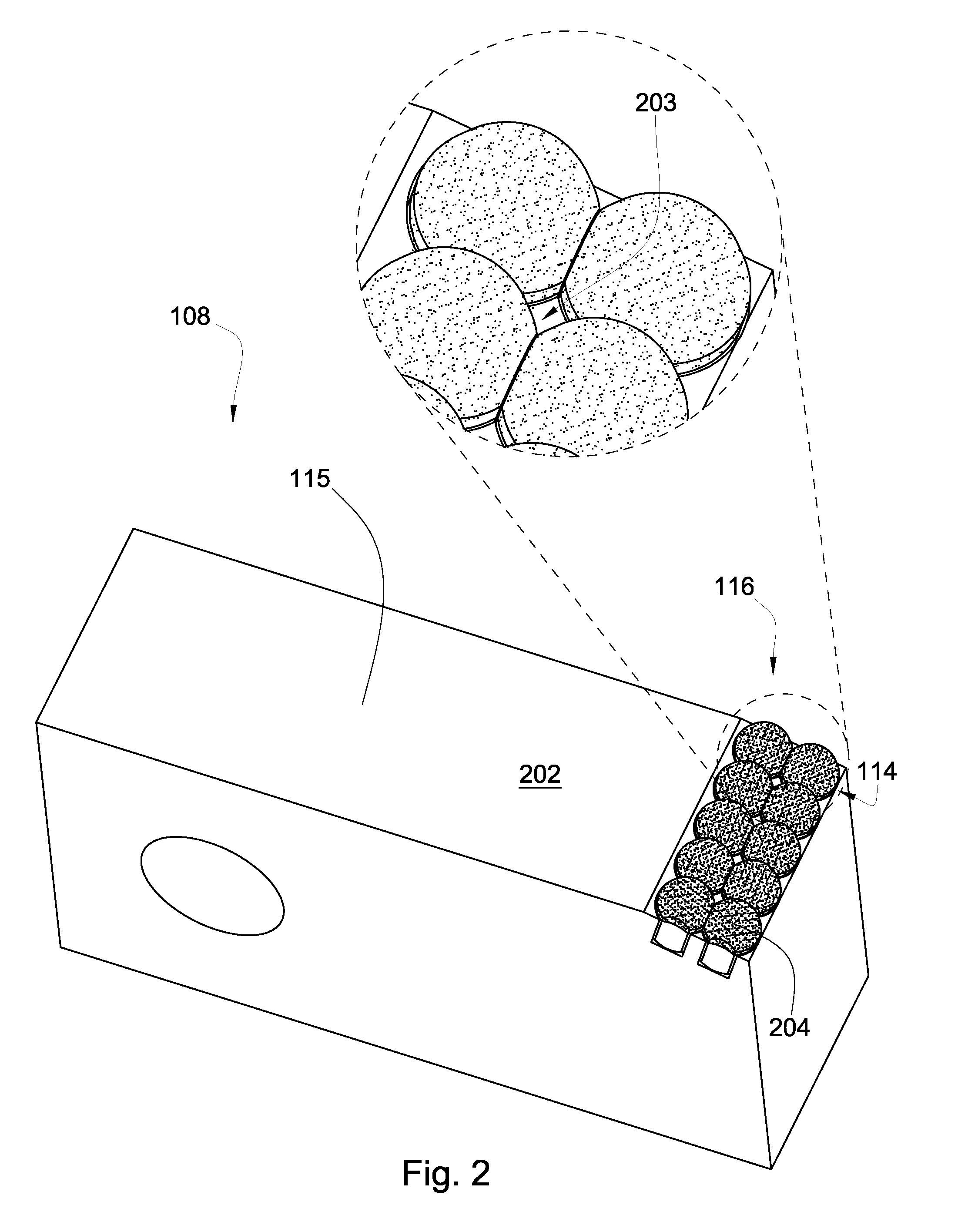

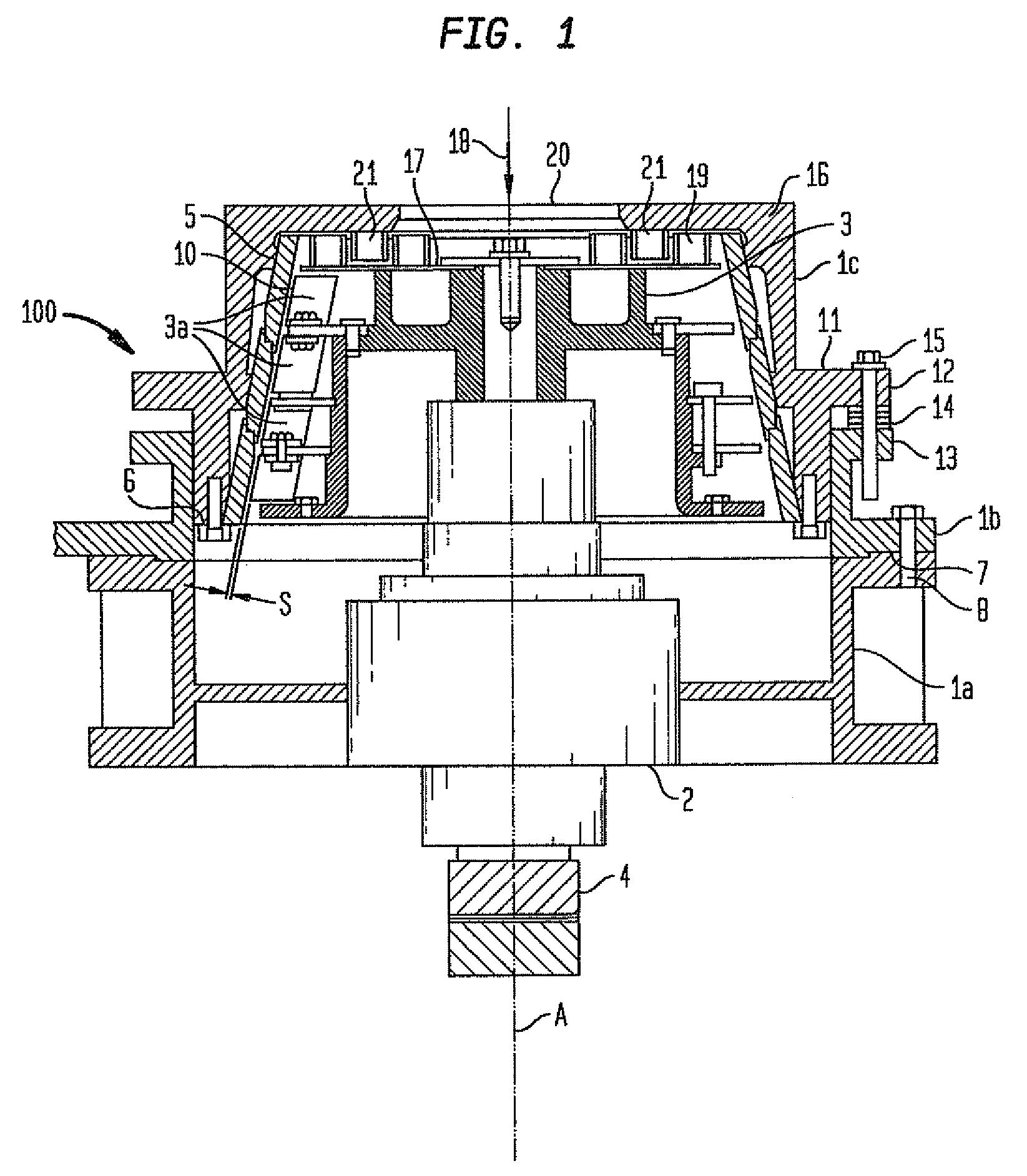

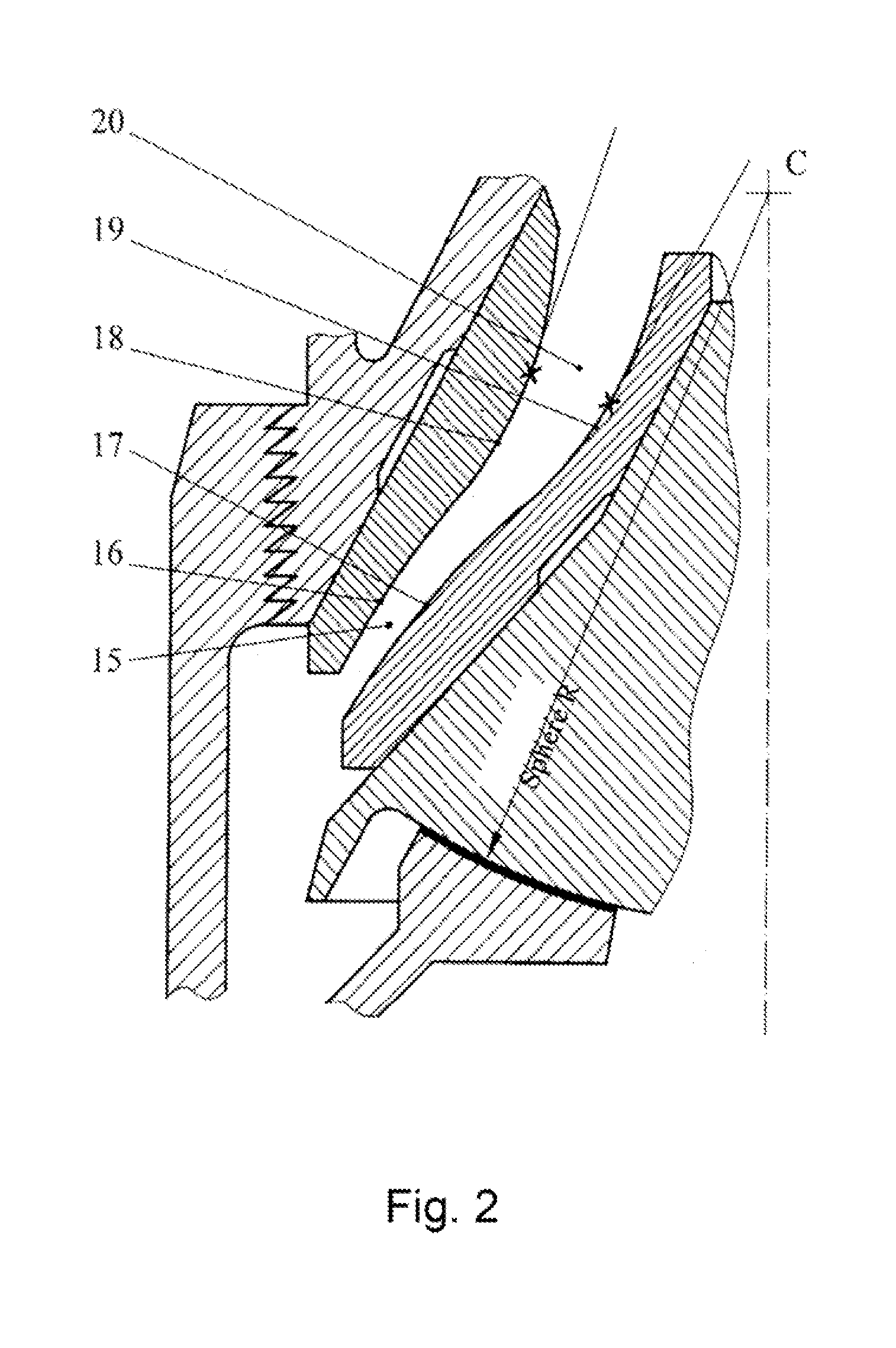

Rotary Impact Mill

In one aspect of the invention, a rotary impact mill has a milling chamber defined by a housing with an inlet, an outlet, and at least one wall. A plurality of impact hammers located within the milling chamber are fastened to and longitudinally disposed along a rotor assembly that is connected to a rotary driving mechanism. At least one of the impact hammers has a plurality of inserts arranged adjacent one another in a row and attached to a body of the hammer, wherein a first end of at least one insert is complementary to a second end of an adjacent insert.

Owner:NOVATEK IP

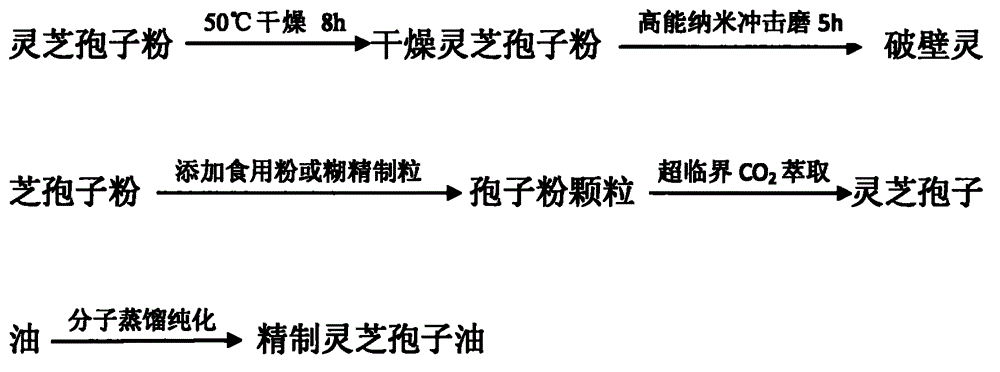

High-bioactivity ganoderma spore oil and supercritical preparation method thereof

ActiveCN102973616AReduce lossesOptimize the breaking processMetabolism disorderImmunological disordersSporeDistillation

The invention aims to disclose high-bioactivity ganoderma spore oil and a preparation method thereof, and belongs to the field of Chinese medicament. The method comprises the following steps: breaking walls of ganoderma spore powder by adopting a high-energy nano impact mill, performing dry granulation, supercritical CO2 extraction, molecular distillation and purification, and thus obtaining the ganoderma spore oil. The operation process of the method is carried out in an anhydrous environment, so that oxidation of the spore oil in the processing process is reduced, and the obtained product is stable in property; the freezing transparent test time of the ganoderma spore oil prepared by the method exceeds 5.5 hours; and the measured unsaturated fatty acid content is between 60 and 80 percent, the total triterpenoid content is 2 to 3 percent, the total ergosterol content is 2 to 5 mg / g, the ganoderic acid A content is more than 1 mg / g, the peroxide value is less than 5mmol / kg, and the acid value is less than 10 mg KOH / g.

Owner:厦门爱逸零食研究所有限公司

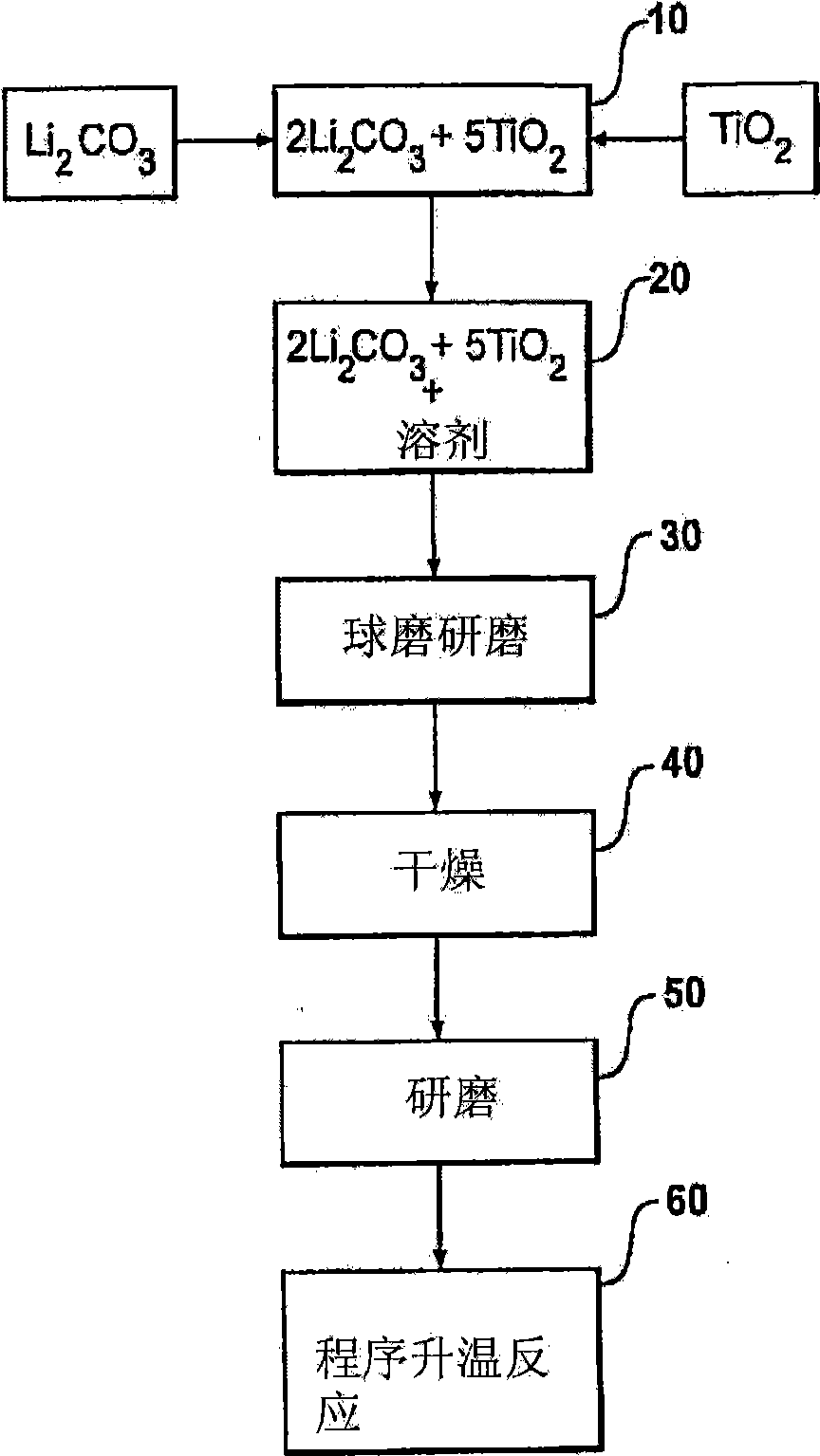

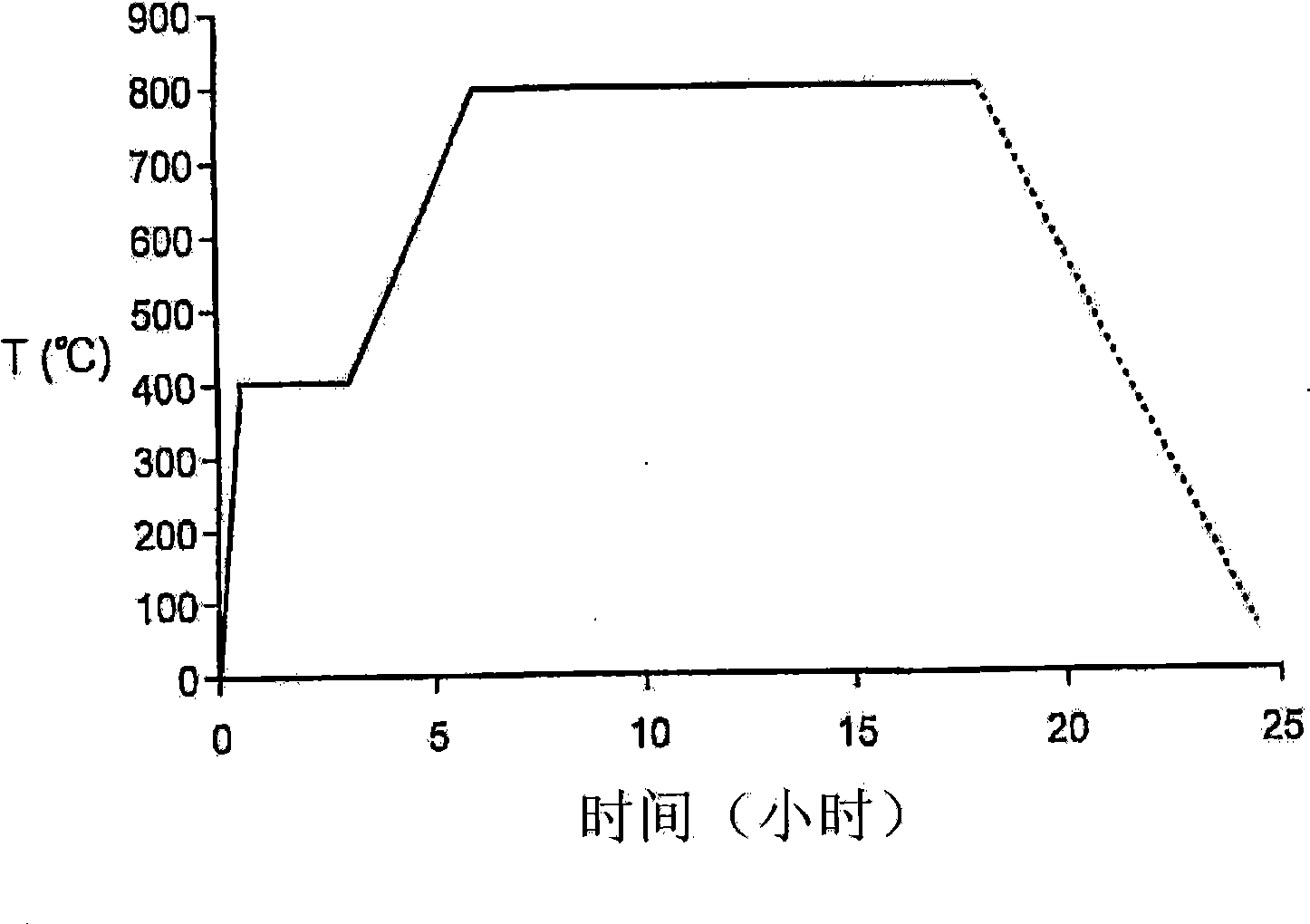

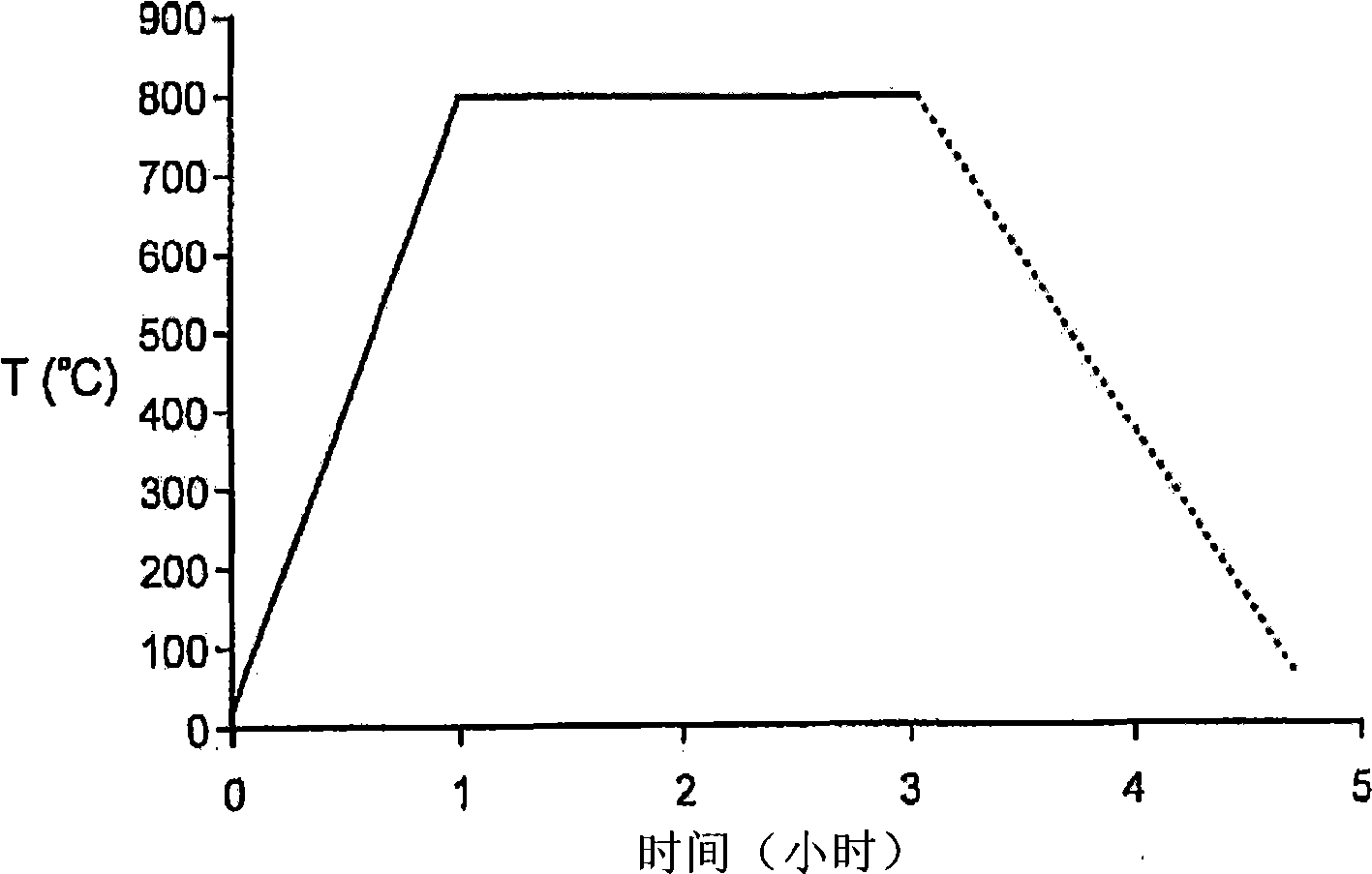

Alkali metal titanates and methods for their synthesis

Disclosed is a doped lithium titanate and its use as an electrode in a battery. Further disclosed is a method for making an alkali metal titanate, which method includes mixing an alkali metal compound and a titanium compound, impact milling the mixture, and heating the milled mixture for a time at a temperature, which is sufficient to convert the mixture to the alkali metal titanate. The alkali metal compound can be in the form of Li2CO3 and the titanium compound can be in the form of TiO2. A dopant may be included in the mixture.

Owner:A123 SYSTEMS LLC

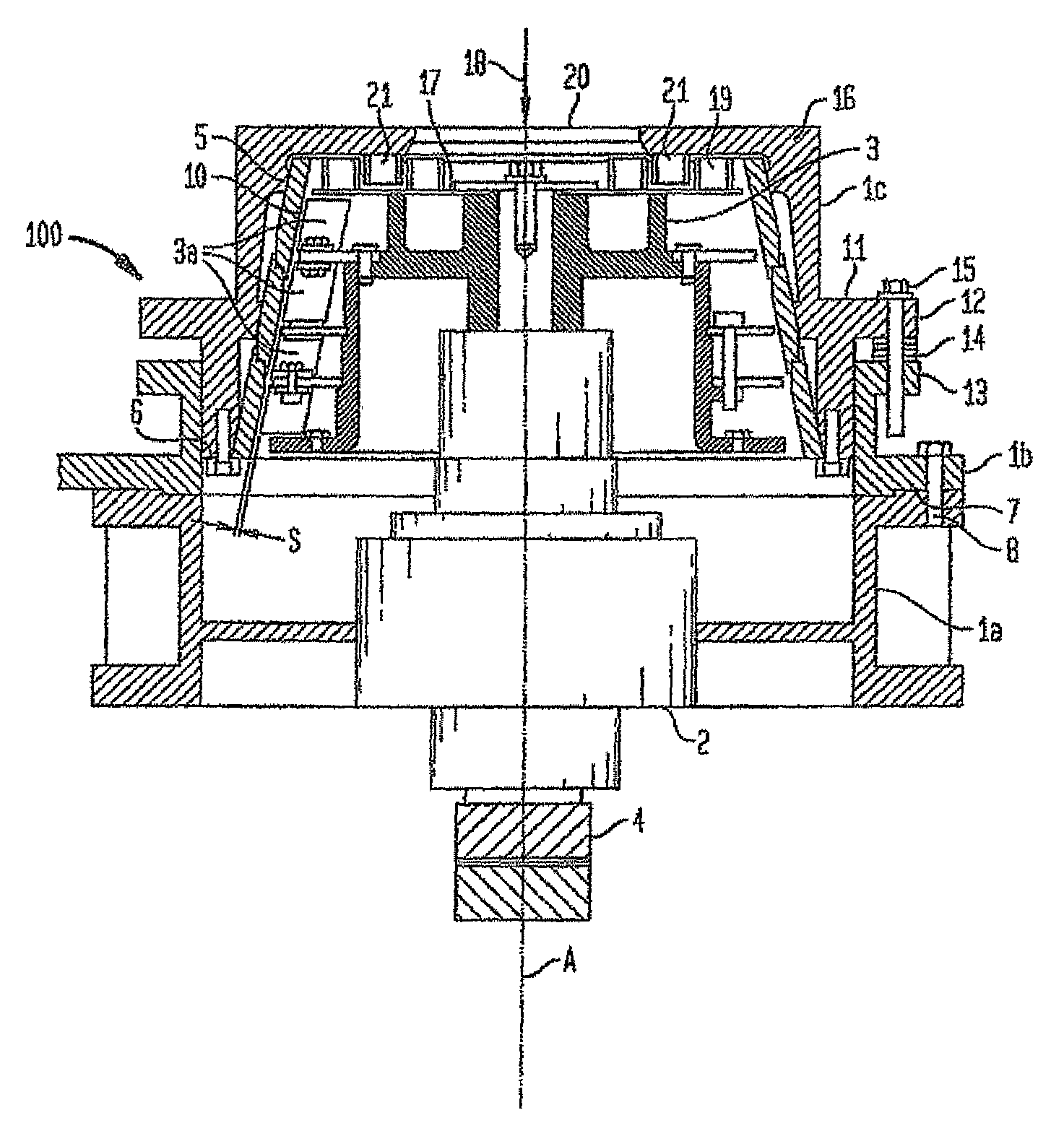

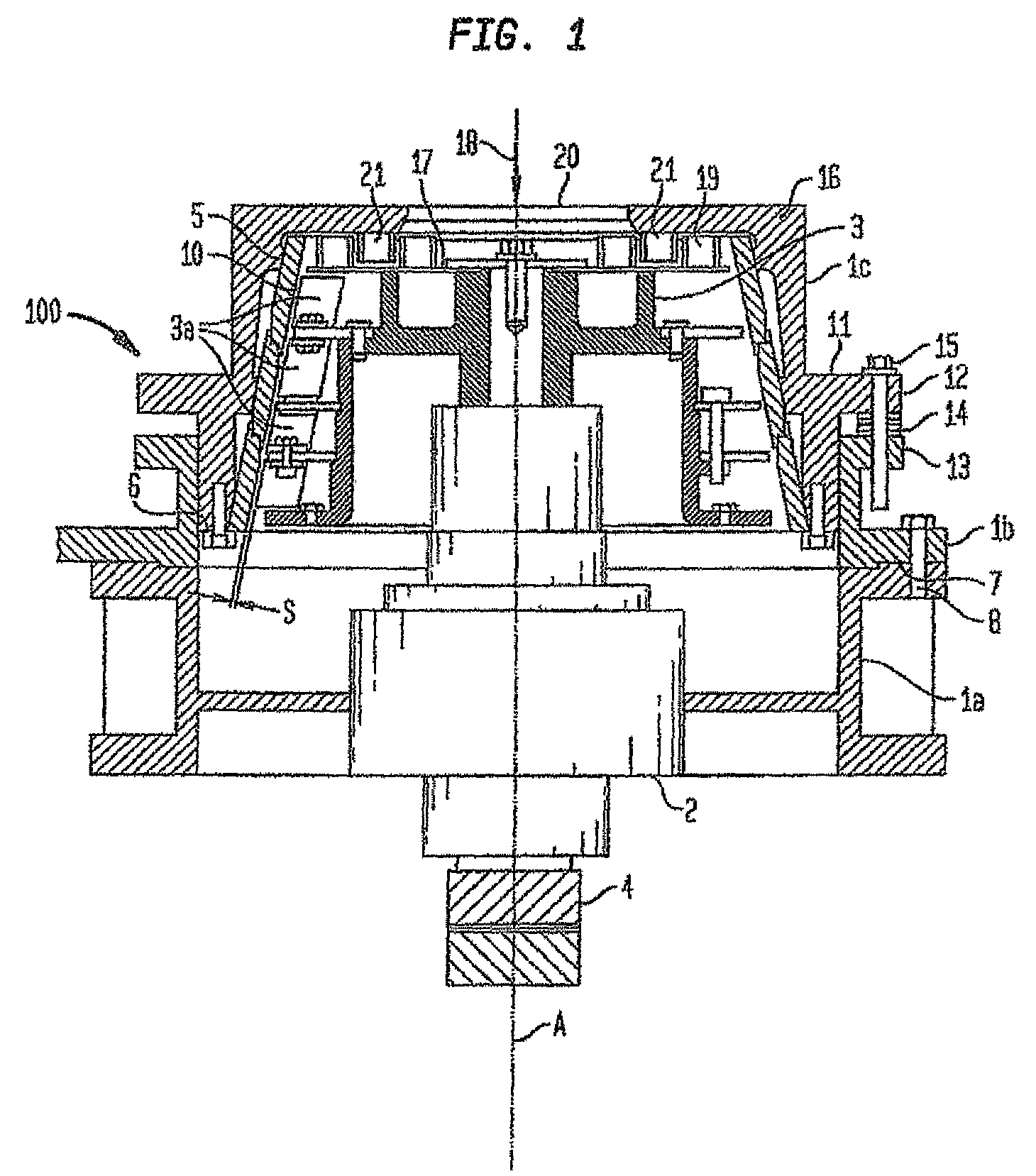

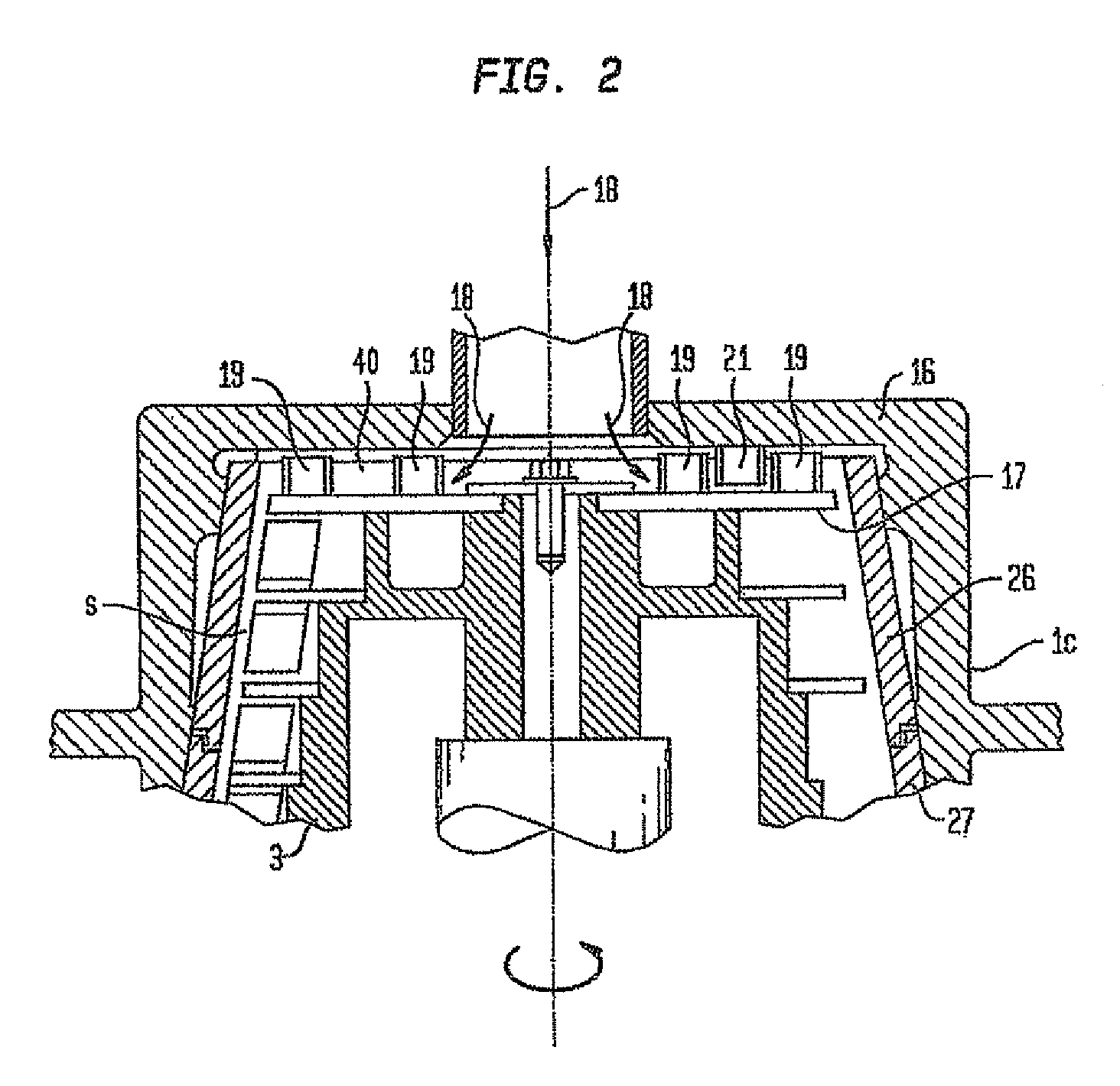

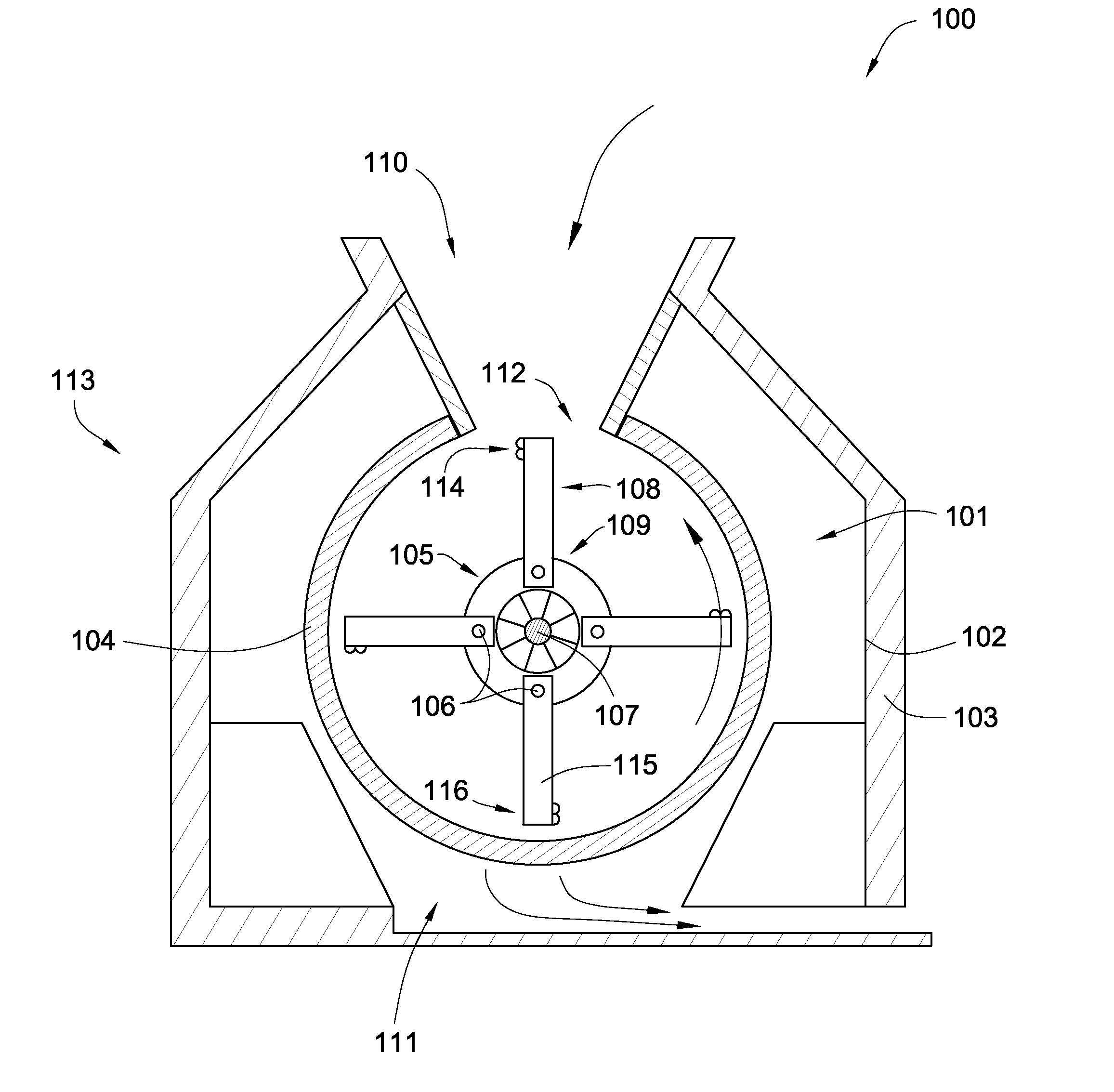

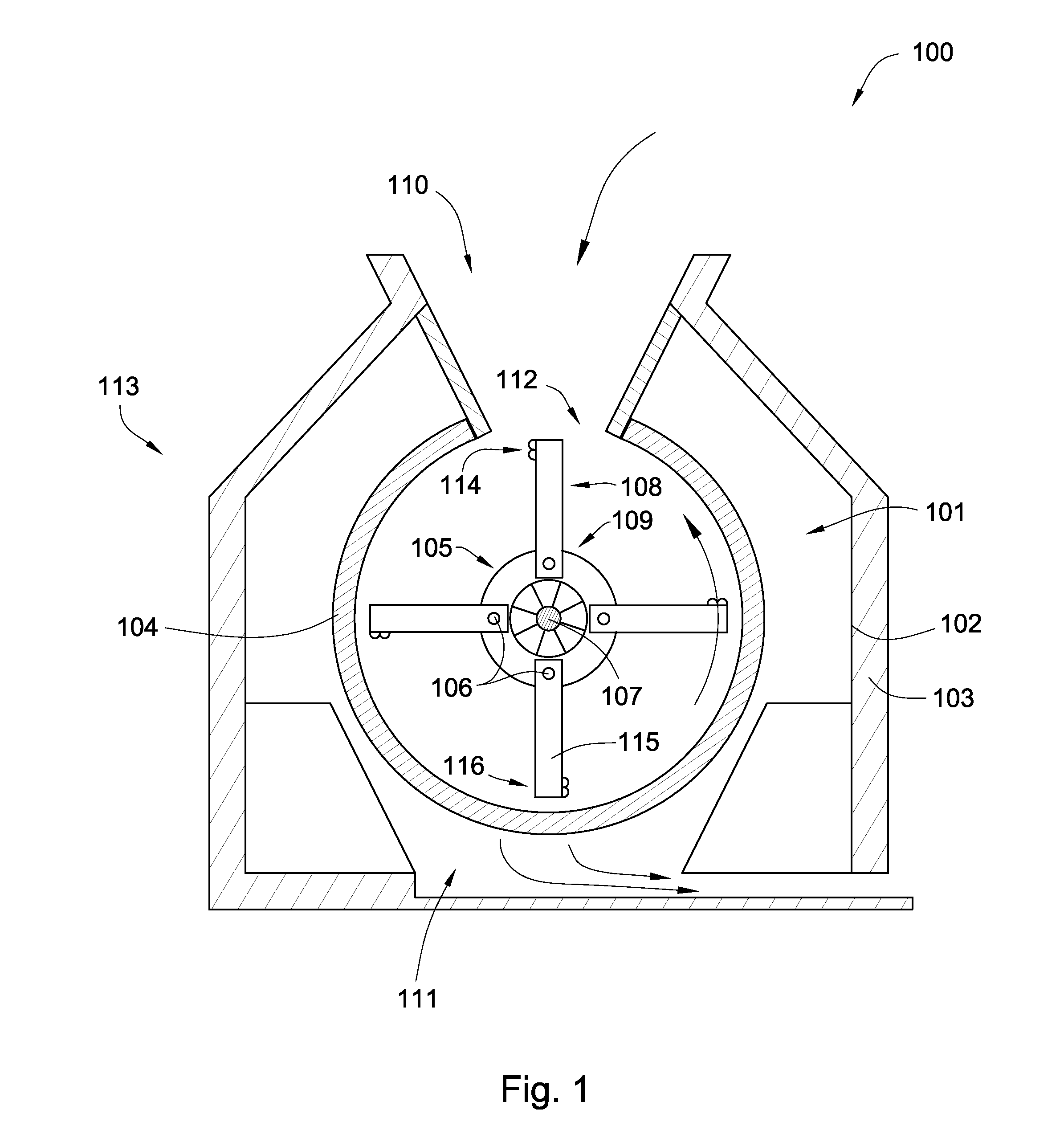

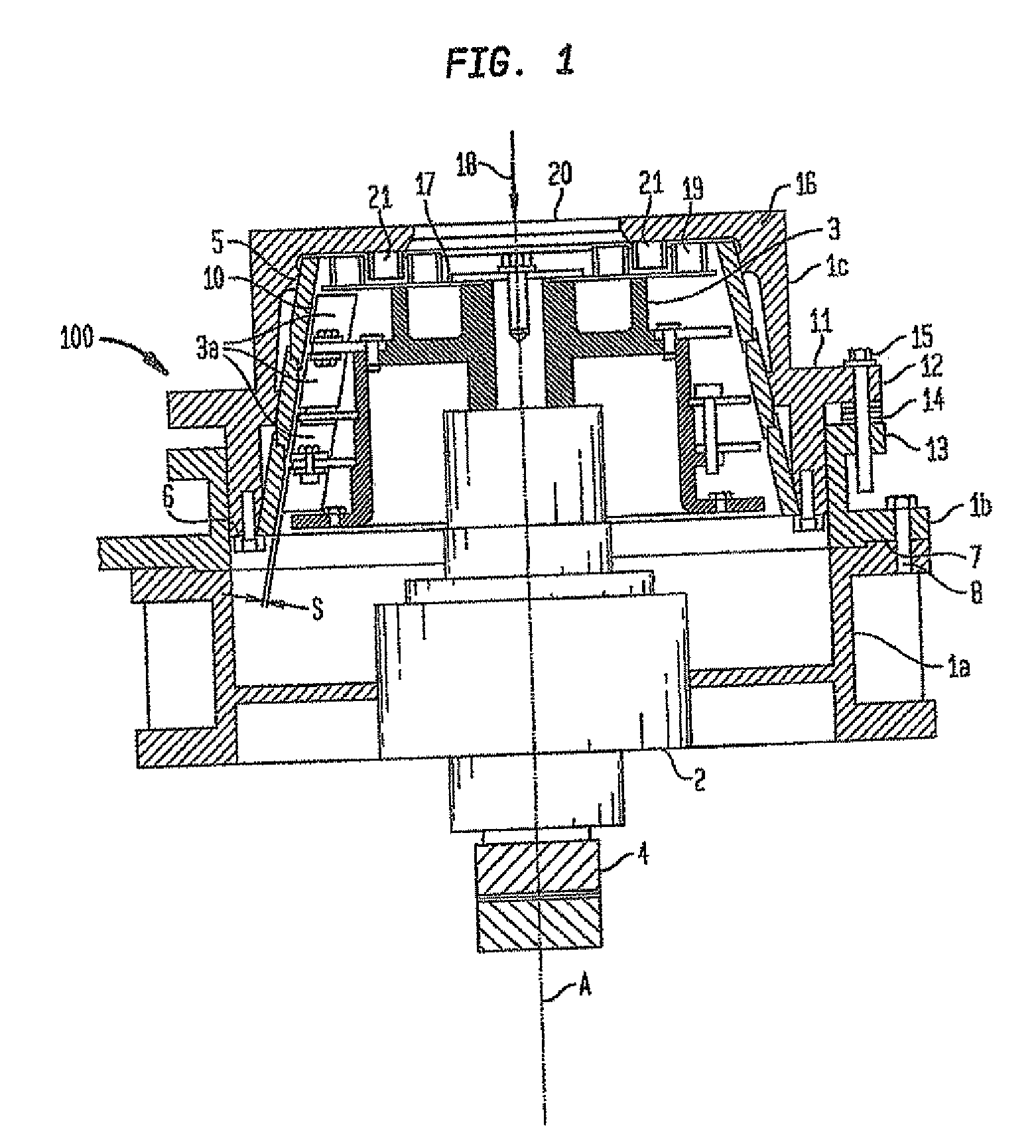

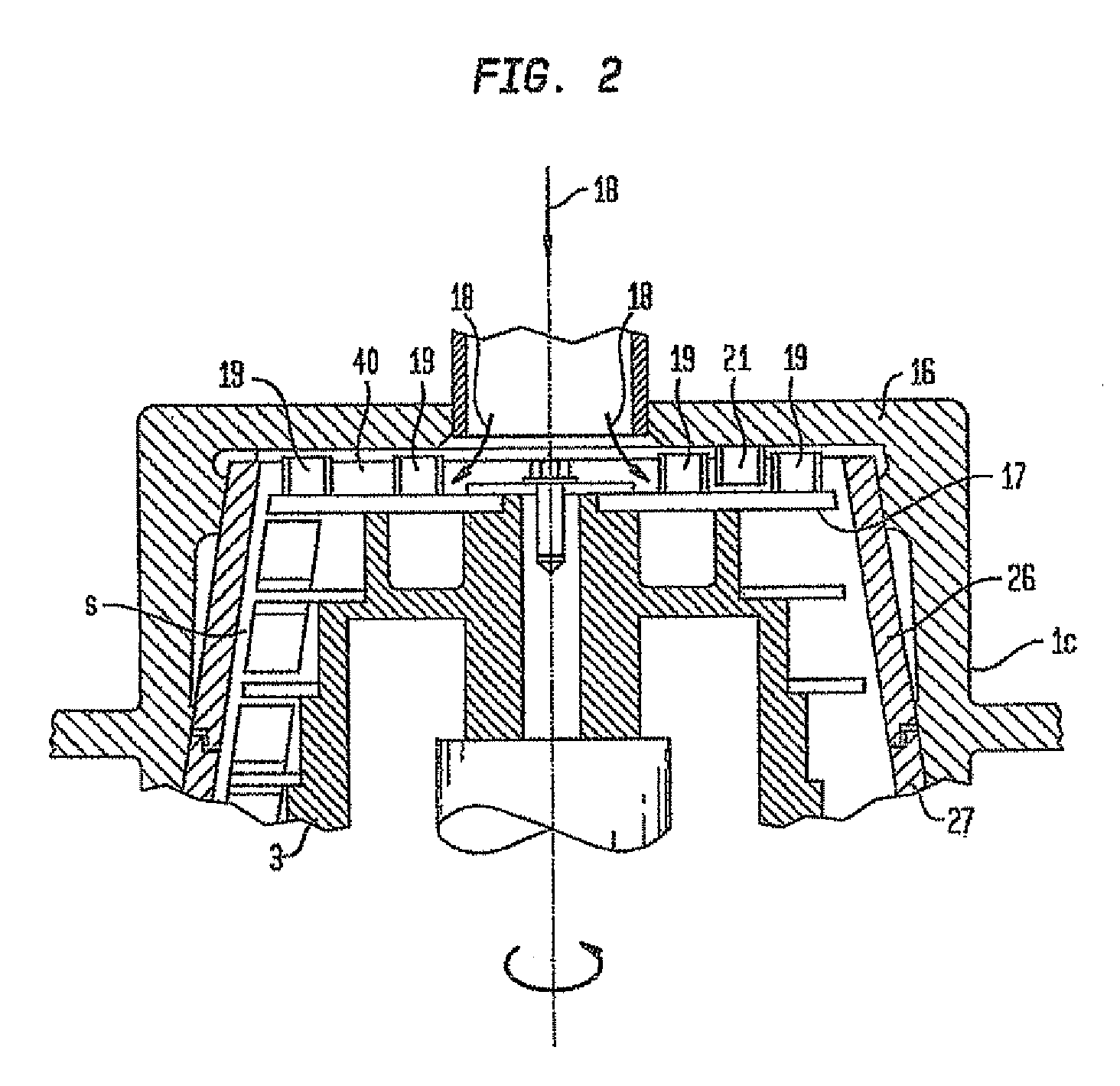

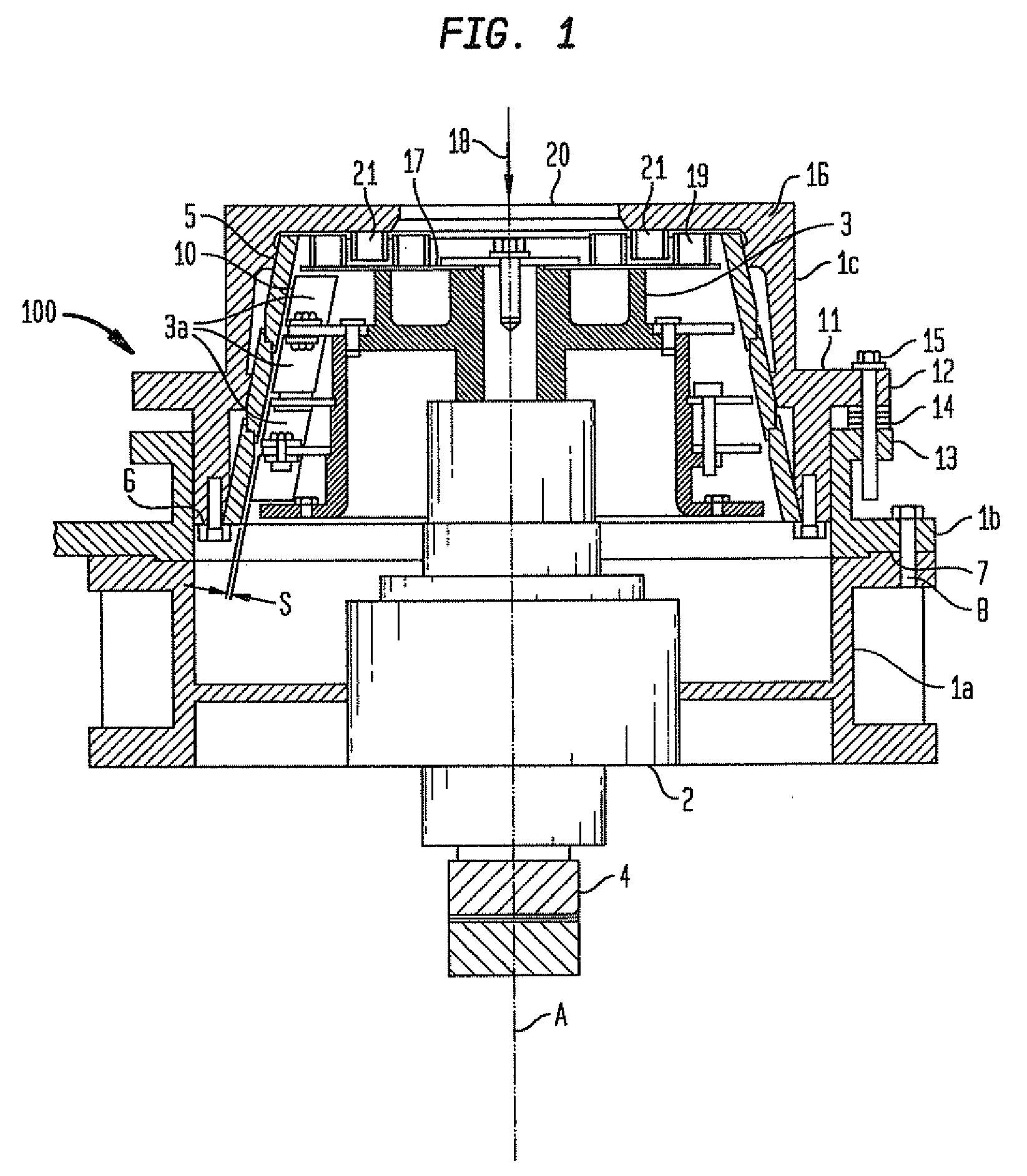

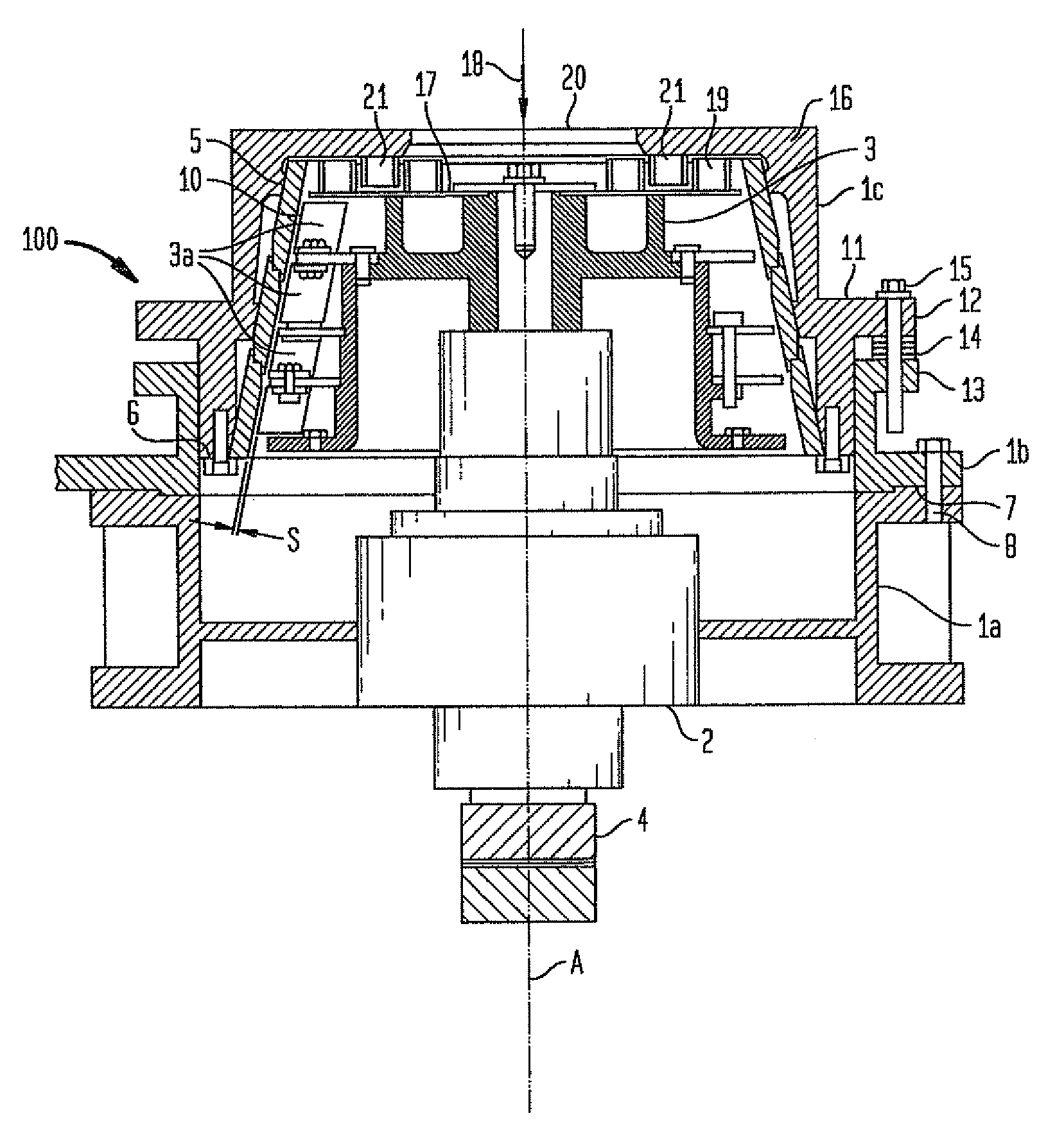

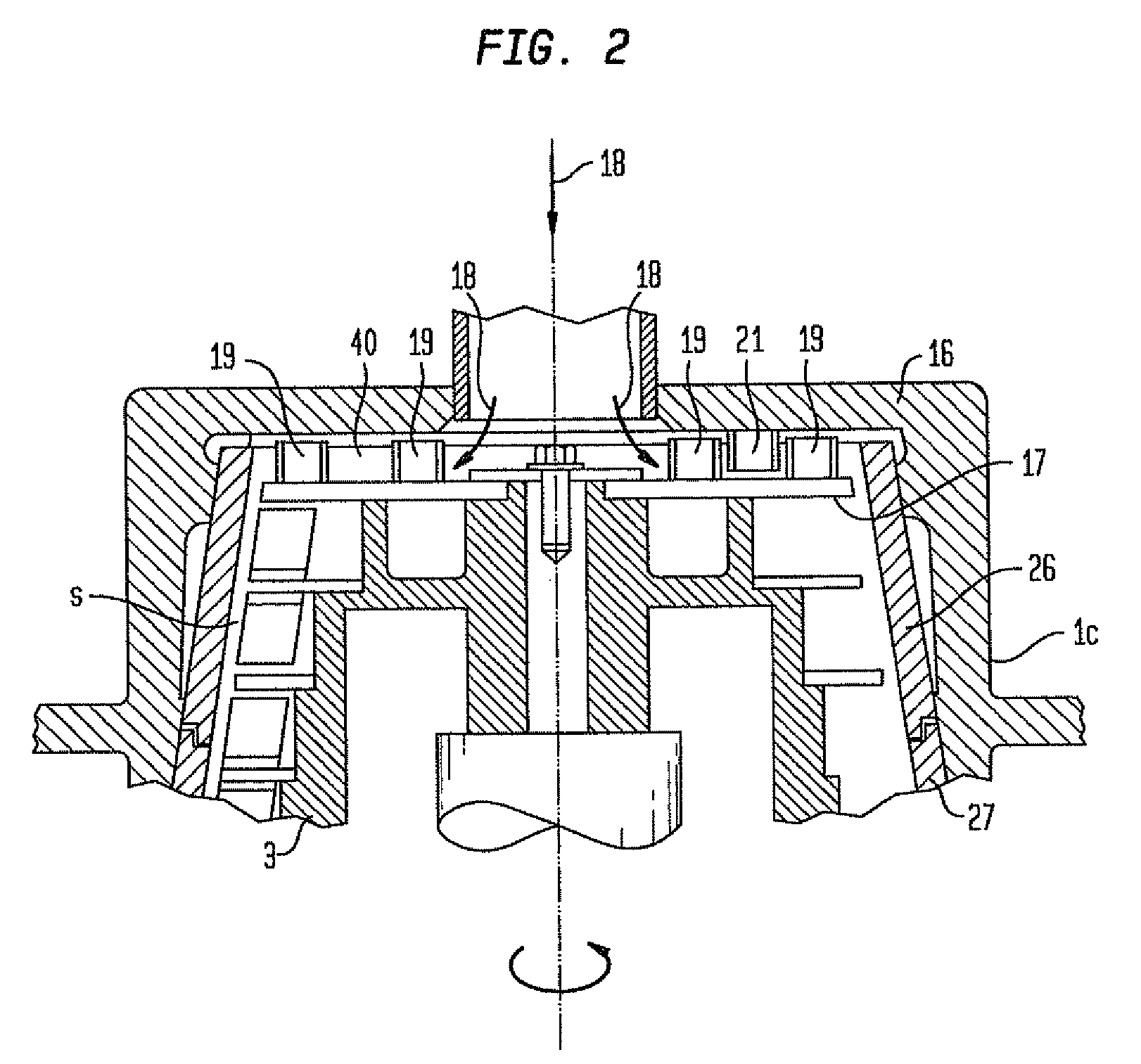

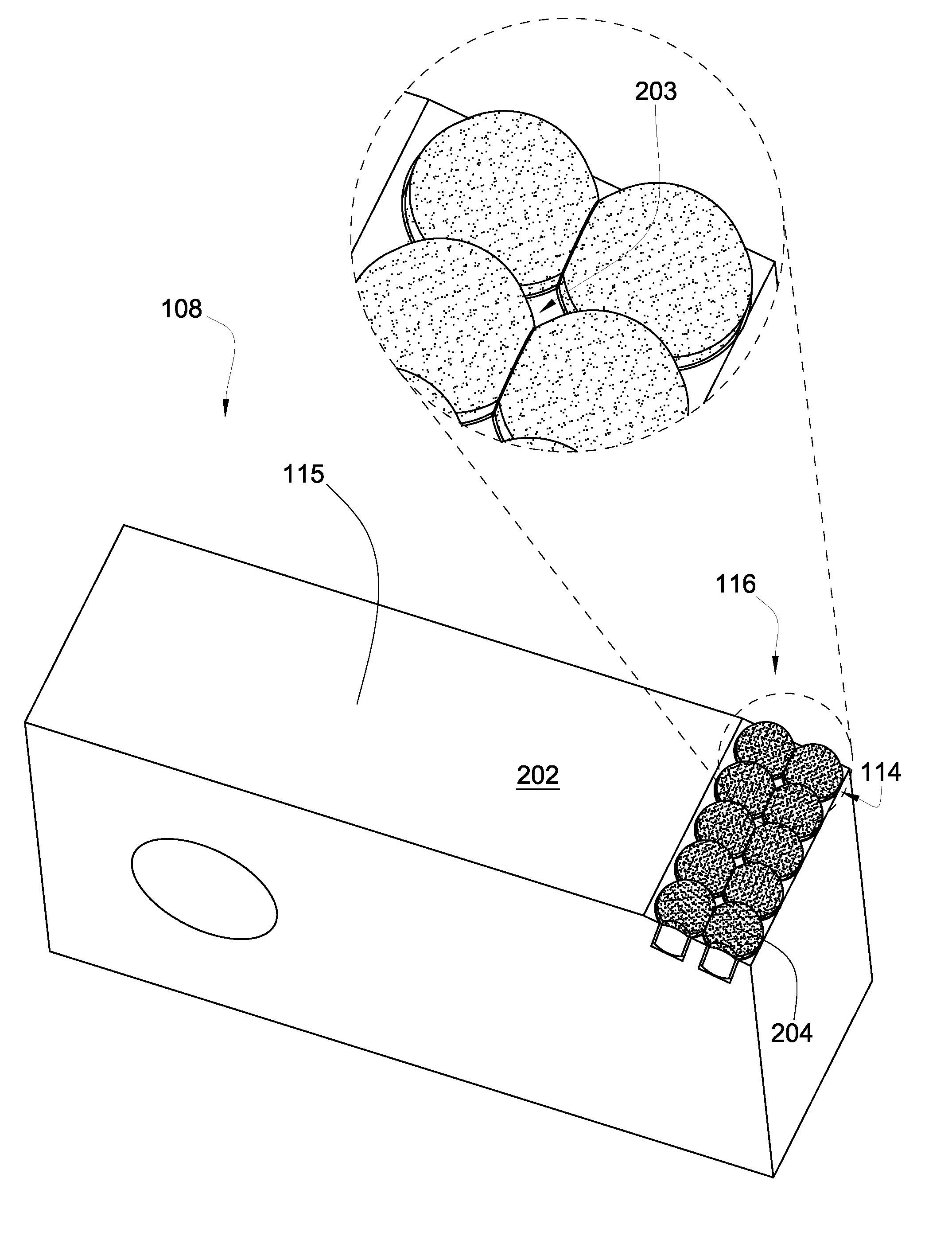

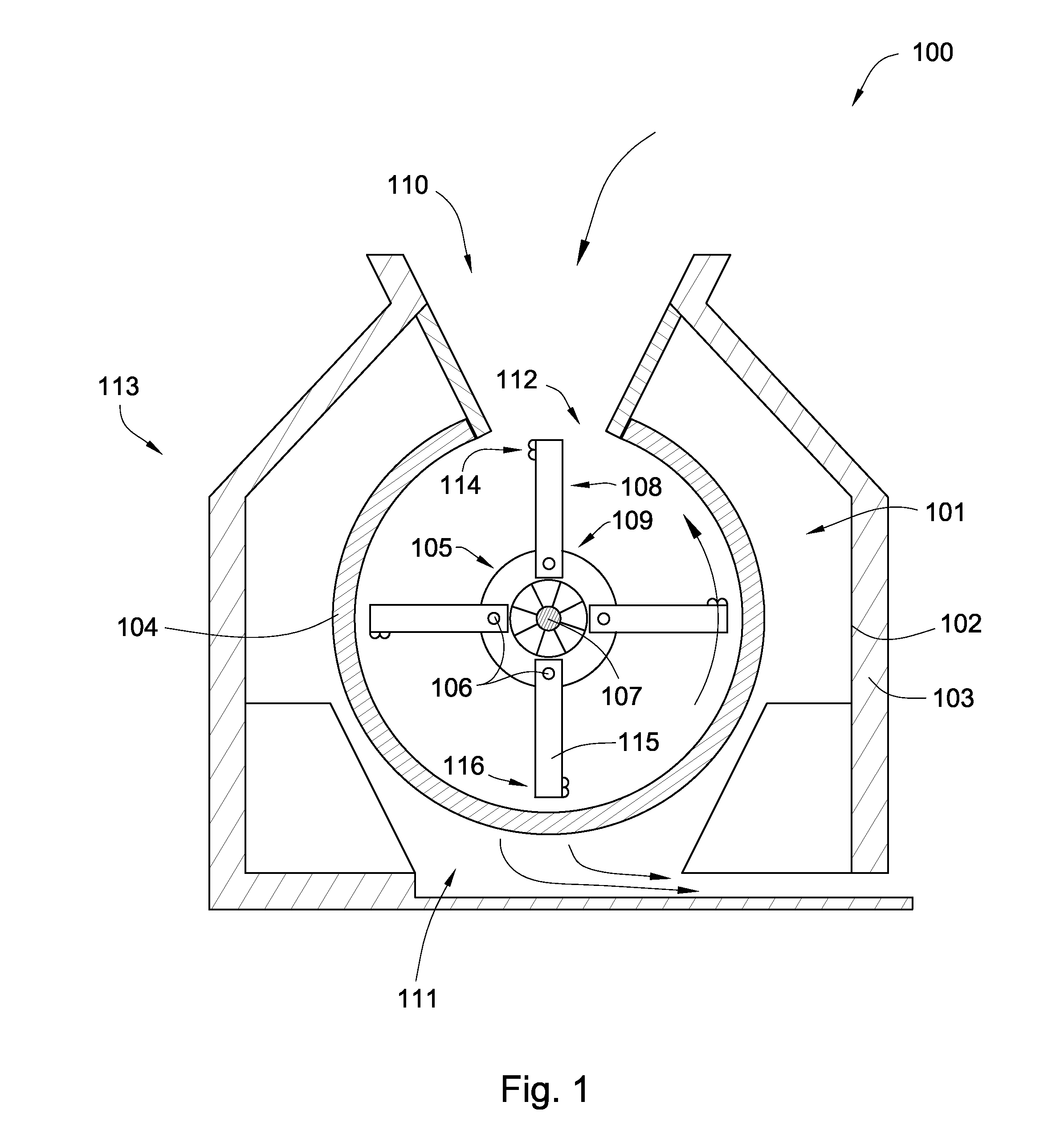

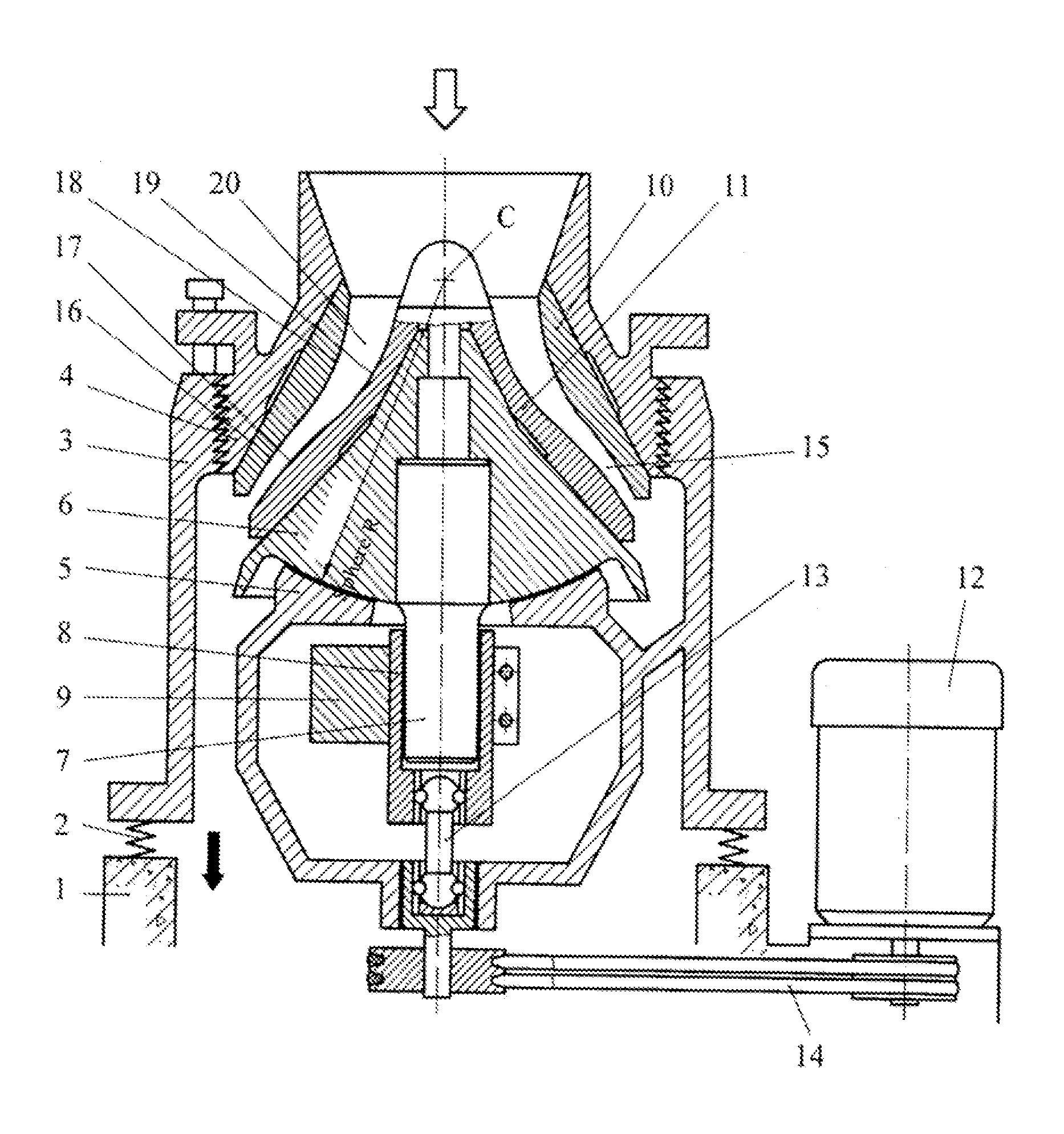

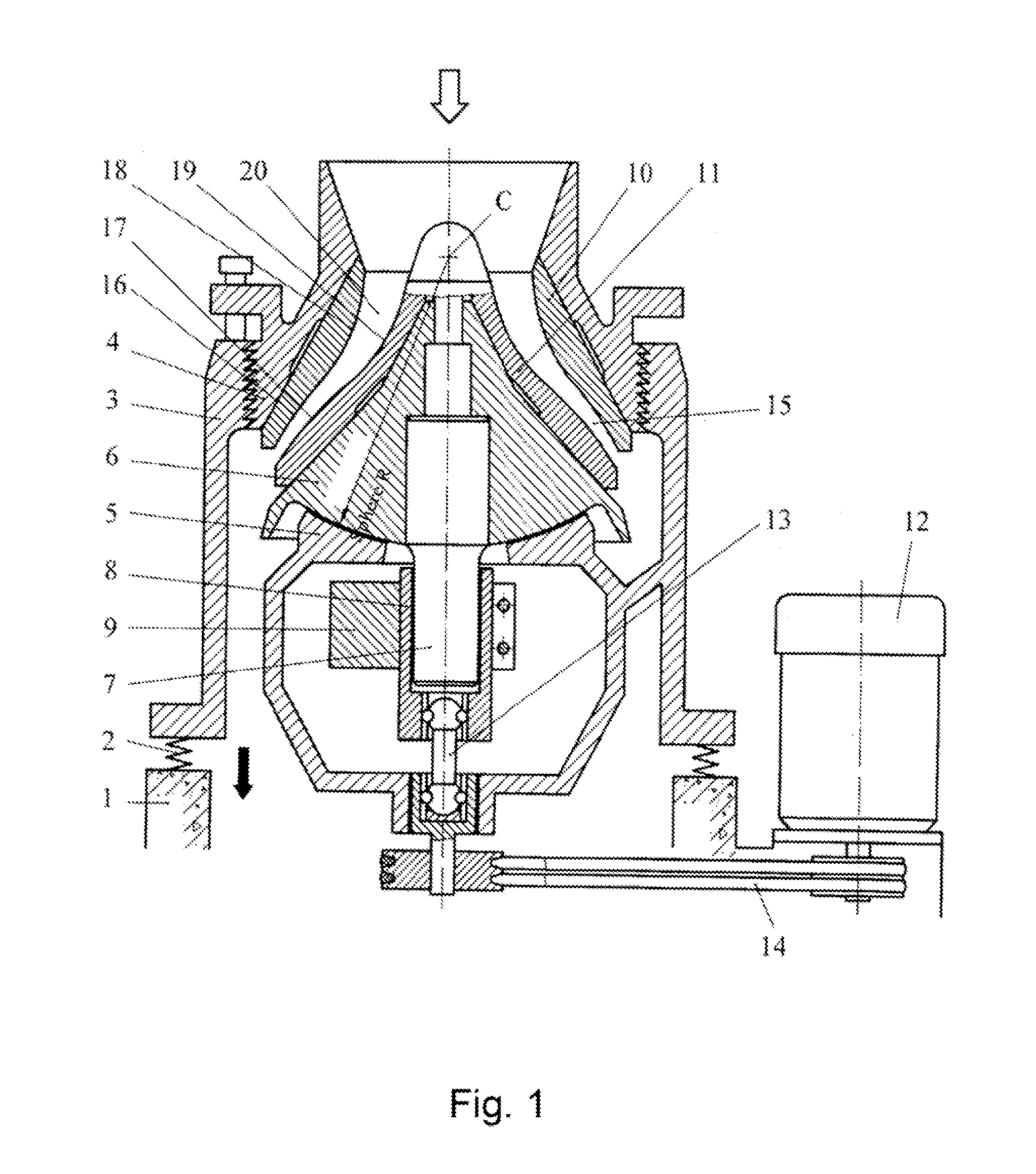

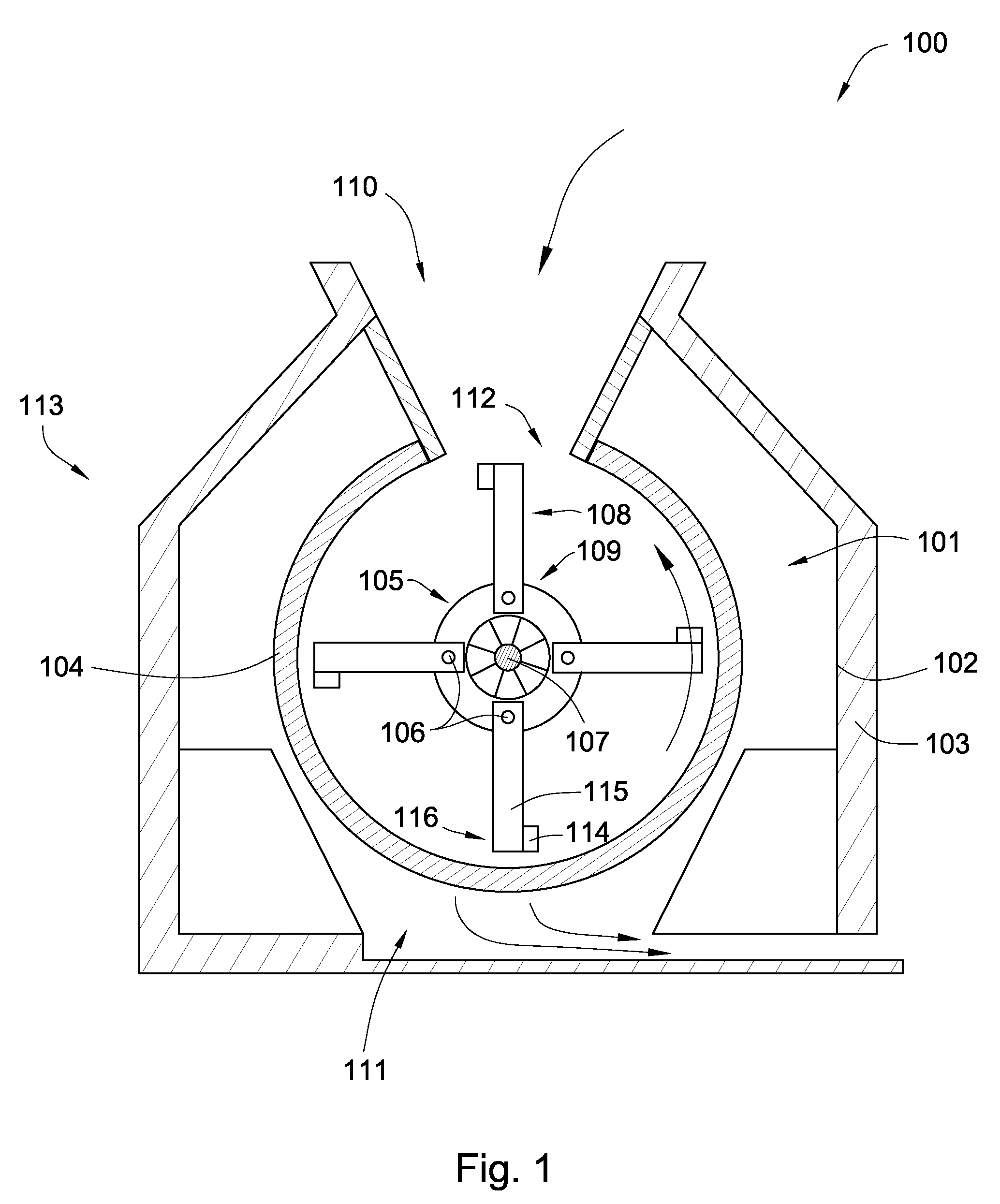

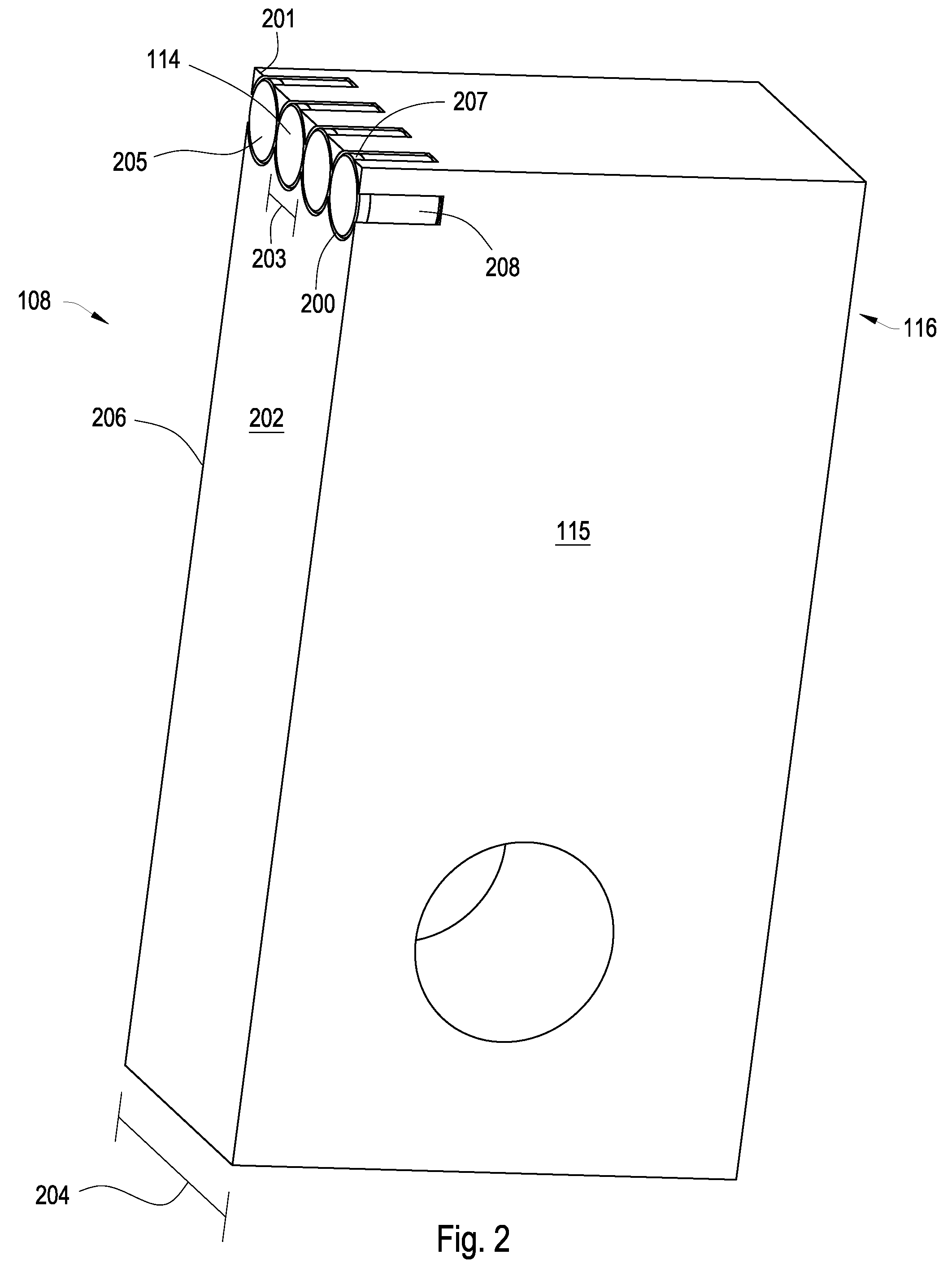

Conical-Shaped Impact Mill

ActiveUS20090134257A1Mitigate belt slippageReduce excessive noiseGrinding machine componentsCocoaRotational axisEngineering

An impact mill including a base portion on which is disposed a rotor rotatably mounted in a bearing housing, the rotor having an upwardly aligned cylindrical surface portion coaxial with the rotational axis. The impact mill is provided with a mill casing within which is located a conical track assembly which surrounds the rotor to form a conical grinding path. The mill casing is provided with a downwardly aligned cylindrical collar which may be axially adjusted to set a grinding gap between the rotor and the mill casing. The rotor is provided with a plurality of impact knives complementary with a plurality of impact knives disposed on the inside top surface of the mill casing. The conical track assembly can be a series of assembled conical sections or one unit with varied number of serrations in either a vertical or sloped configuration. This flexibility allows for greater compatibility with the feedstock being milled.

Owner:LEHIGH TECH INC

Conical-shaped impact mill

ActiveUS20080245913A1Mitigate belt slippageReduce excessive noiseGrinding machine componentsCocoaRotational axisSprocket

An impact mill including a base portion on which is disposed a rotor rotatably mounted in a bearing housing, the rotor having an upwardly aligned cylindrical surface portion coaxial with the rotational axis. The impact mill is provided with a mill casing within which is located a conical track assembly which surrounds the rotor to form a conical grinding path. The mill casing is provided with a downwardly aligned cylindrical collar which may be axially adjusted to set a grinding gap between the rotor and the mill casing. The rotor is provided with a plurality of impact knives complementary with a plurality of impact knives disposed on the inside top surface of the mill casing. In addition, the impact mill can be formed of separated conical sections. Finally, power is transmitted to the rotor of the impact mill by a synchronous sprocketed belt, accommodated by a sprocketed drive sheave, wherein the belt is in communication with a power source.

Owner:LEHIGH TECH INC

Rotary Impact Mill

In one aspect of the invention, a rotary impact mill has a milling chamber defined by housing with an inlet, an outlet, and at least one wall. A plurality of impact hammers located within the milling chamber are fastened to and longitudinally disposed along a rotor assembly connected a rotary driving mechanism. At least one of the impact hammers has a body with a first hardness. The impact hammer also has a wear resistant insert bonded to the body, wherein the wear resistant insert comprises a hard surface with a second hardness greater than the first hardness.

Owner:NOVATEK IP

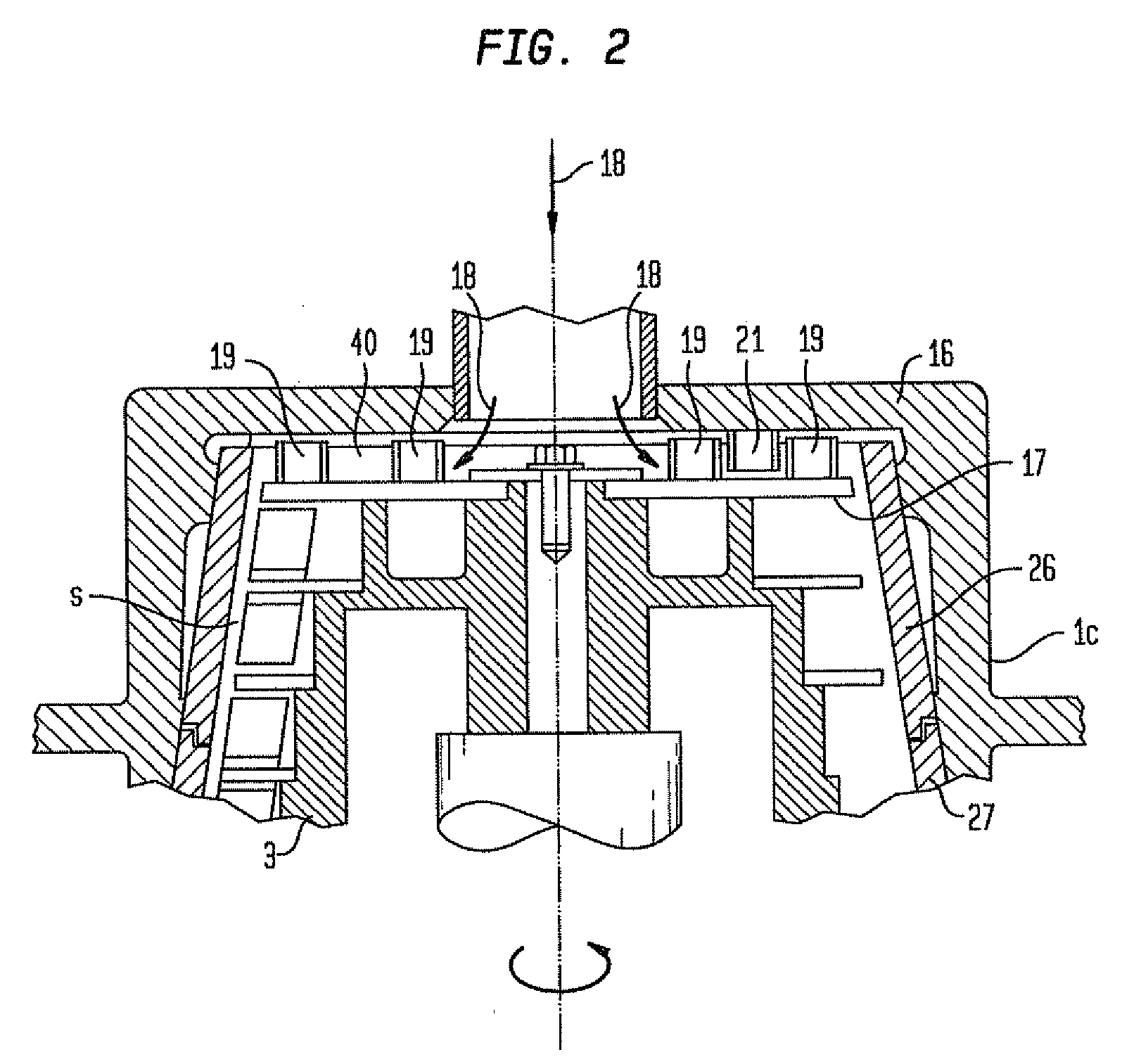

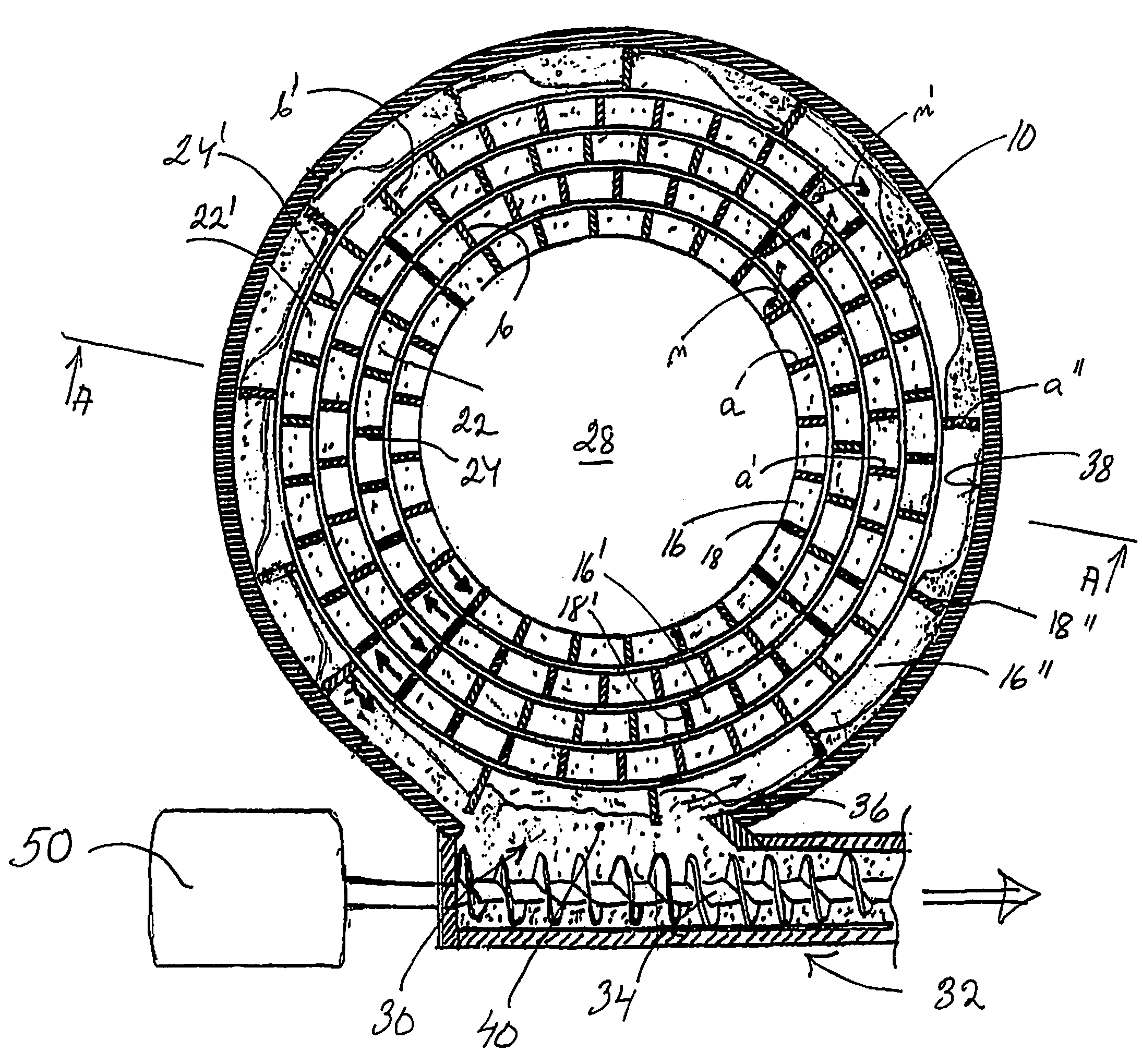

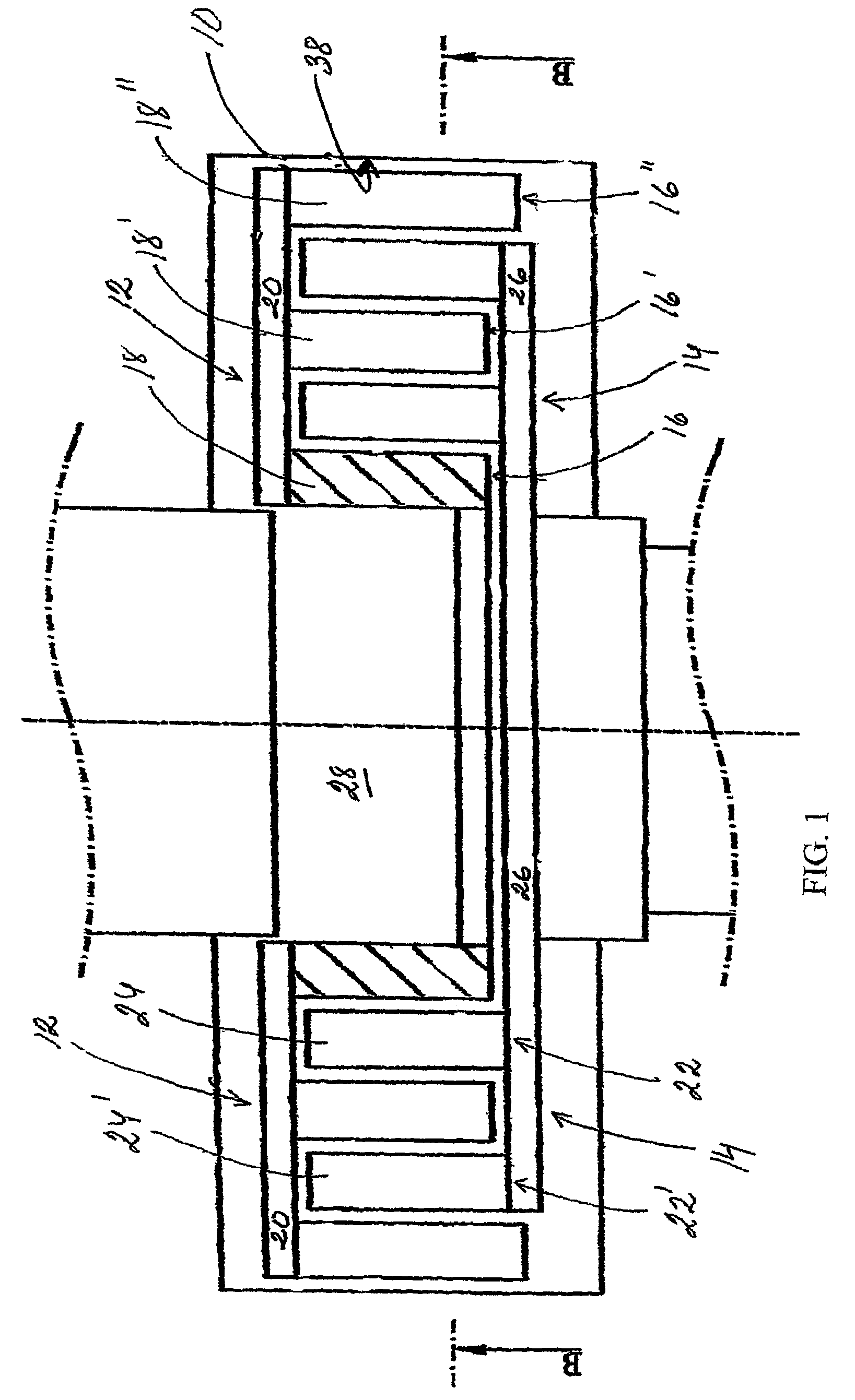

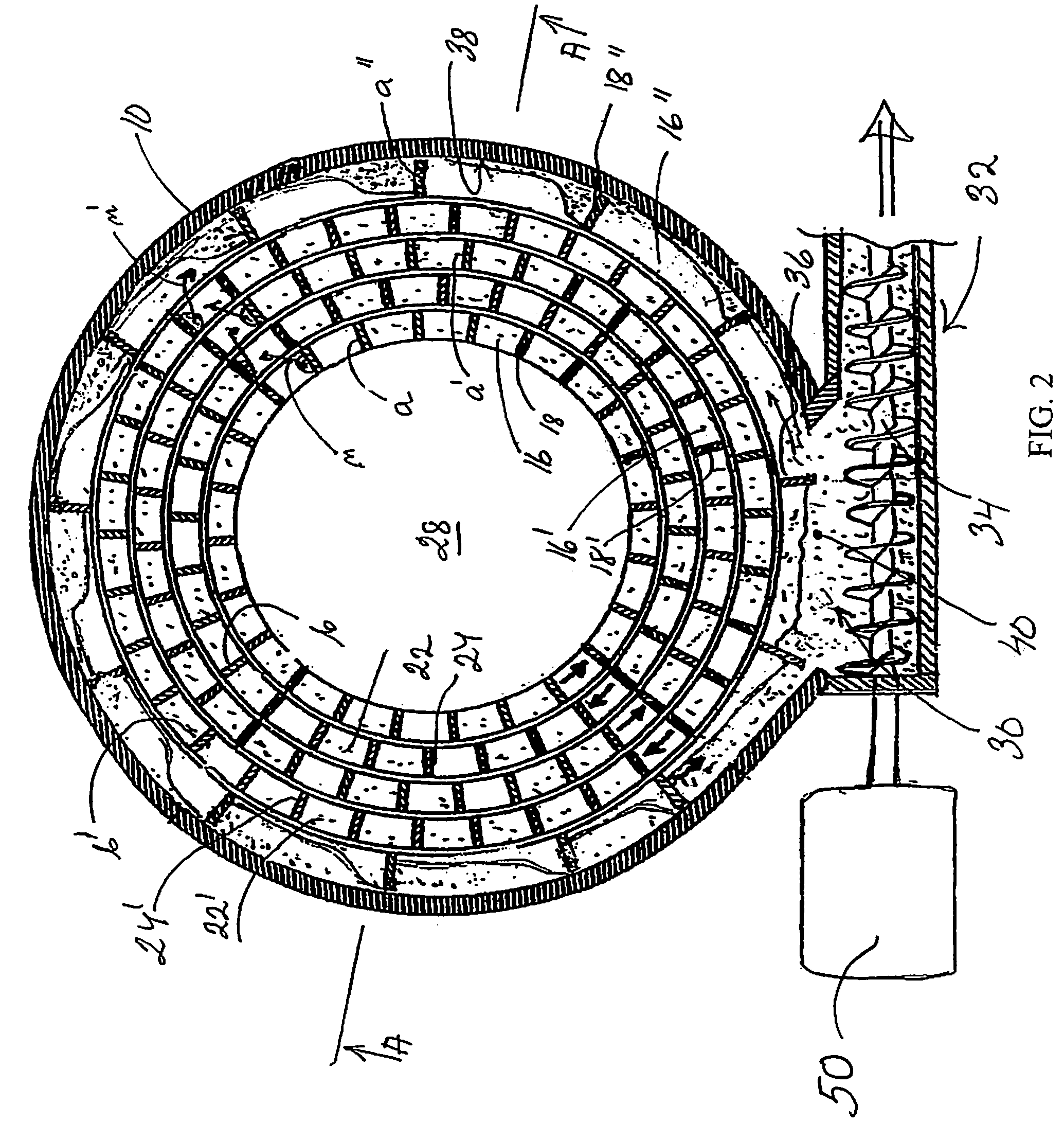

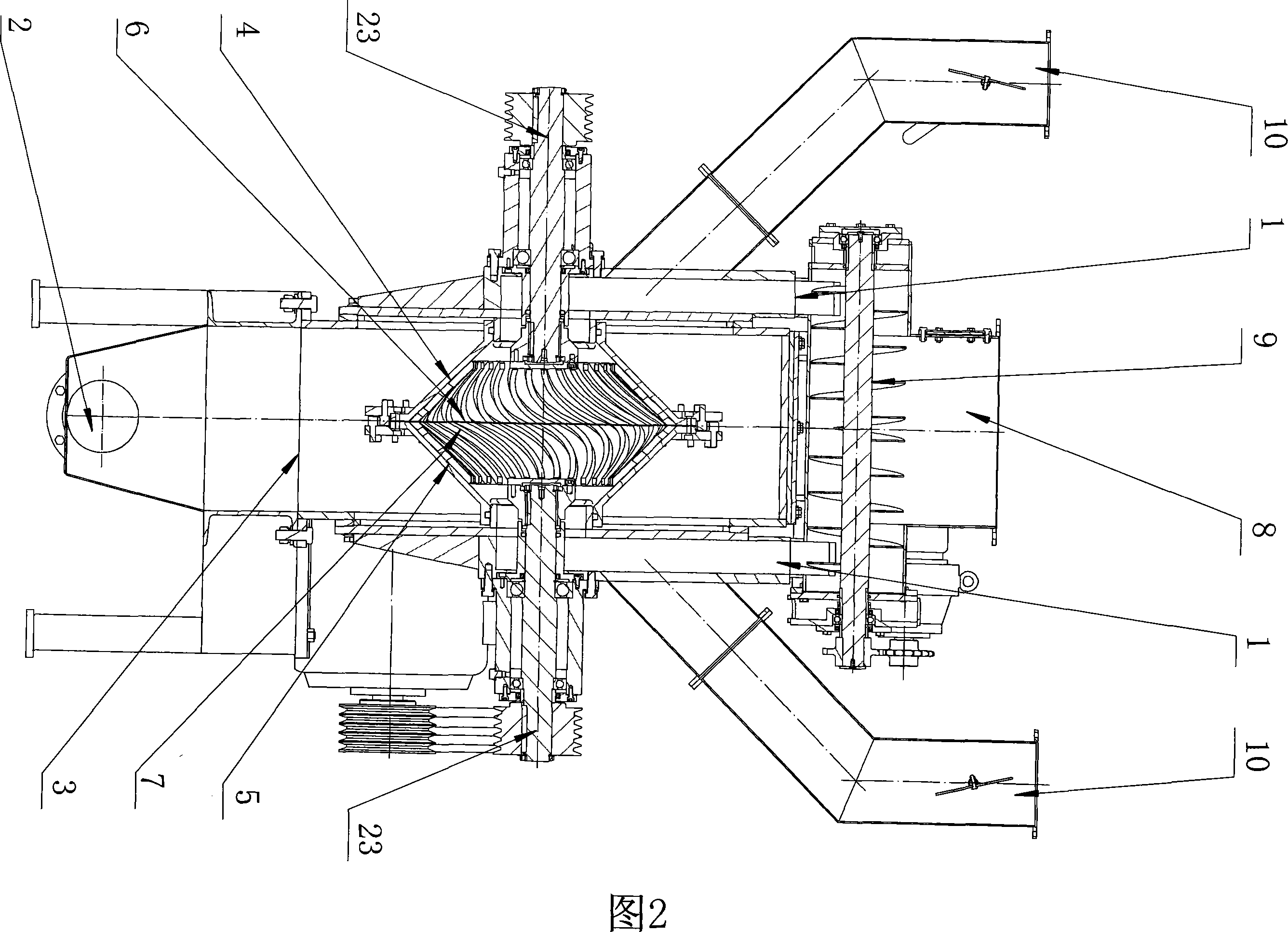

Method and apparatus for treating materials or mixtures of materials

InactiveUS7748653B2Longer handling timeEffective treatmentGrain treatmentsPaper material treatmentMaterials scienceImpact mill

A method and apparatus for treating materials or material mixtures in a treatment apparatus operating on the principle of the double-action impact mill, which includes a discharge conveyor (34), such as a discharge screw. A material layer (40) is maintained between the discharge opening and the discharge conveyor, using the material exiting the outermost ring (16″) of the treatment apparatus through the discharge opening (30), which layer prevents free discharge of the material to be treated from the treatment apparatus.

Owner:FRACTIVATOR OY

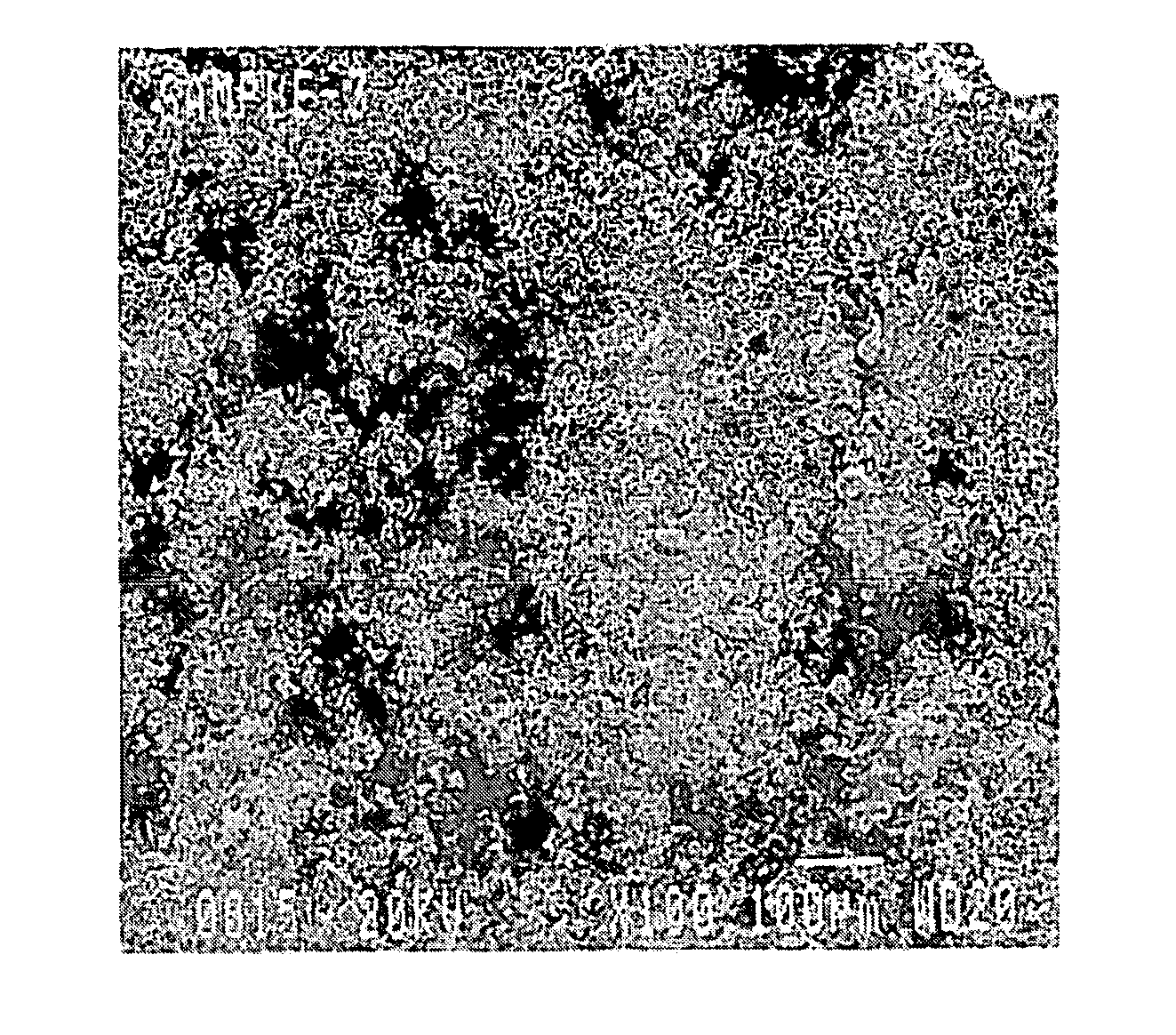

Tantalum powders and methods of producing same

ActiveUS20040252445A1Large specific surface areaIncrease capacitanceLiquid electrolytic capacitorsCapacitor electrodesCapacitanceNiobium

Methods of forming tantalum powders and other valve metal powders are described. The method involves high impact milling a starting powder in a fluid medium and optionally a milling media using a high energy mill. The methods of the present invention have the ability to reduce DC leakage and / or increase capacitance capabilities of valve metal powders when formed into capacitor anodes. The methods of present invention further reduce the milling time necessary to form high surface area valve metal powders and leads to reducing contaminant levels in the valve metal powders. The process is particularly well-suited for forming metal flakes, such as tantalum or niobium flakes, of high purity.

Owner:GLOBAL ADVANCED METALS USA

Method and device for disintegration of organic material and use of the device

InactiveUS7314190B2Improve efficiencyFast decompositionWaste water treatment from animal husbandryWaste water treatment from animal processingOrganic matterPre treatment

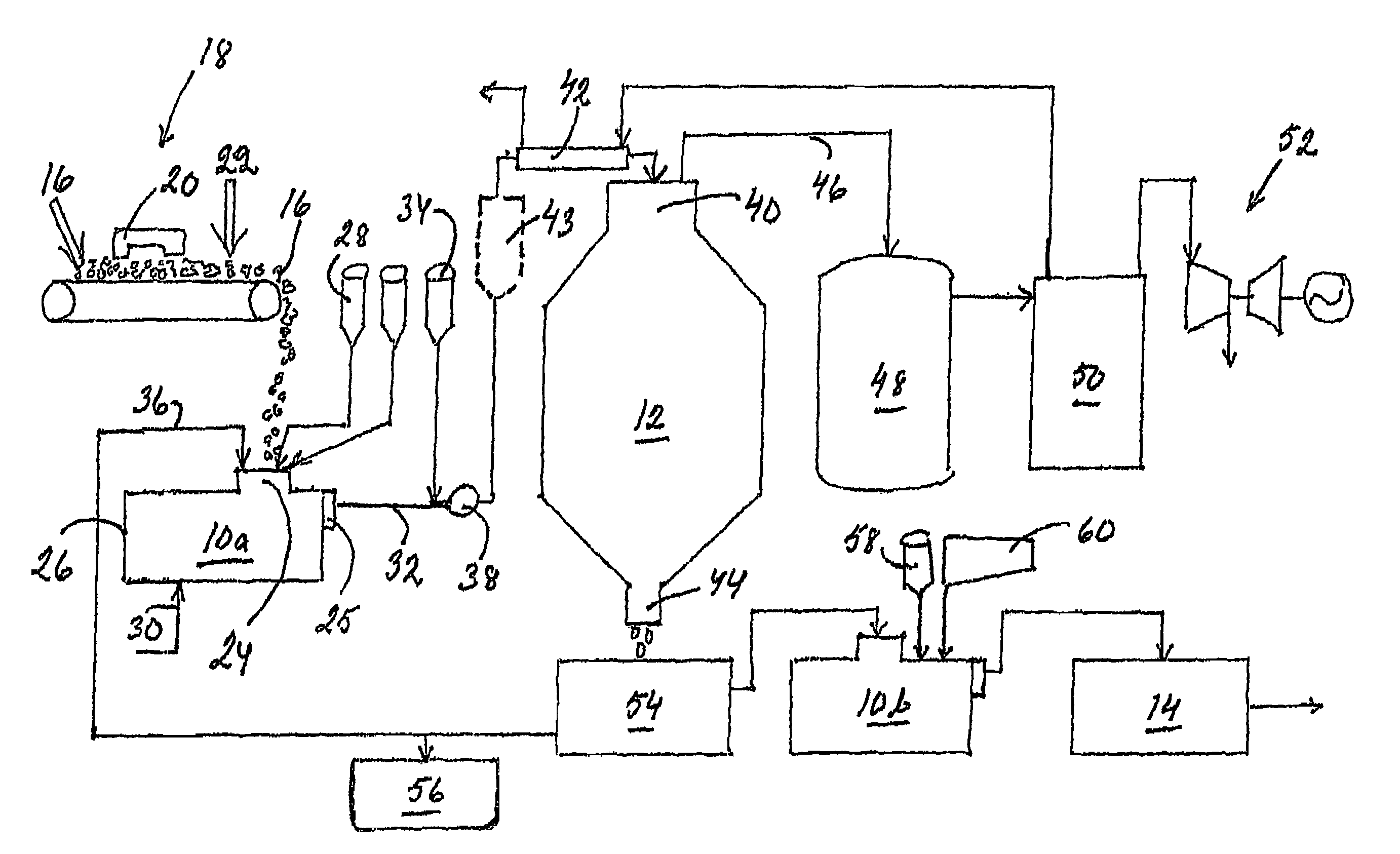

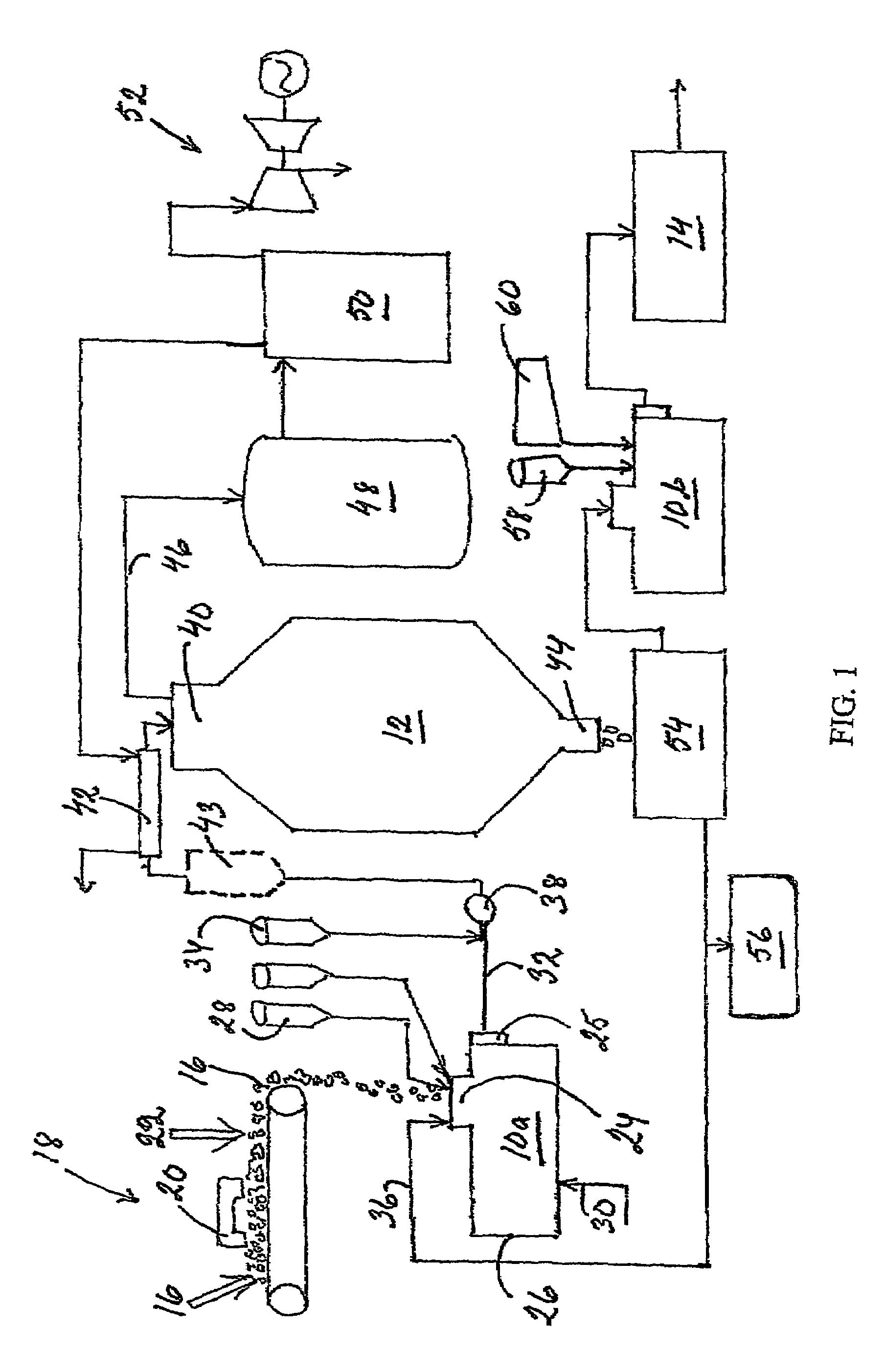

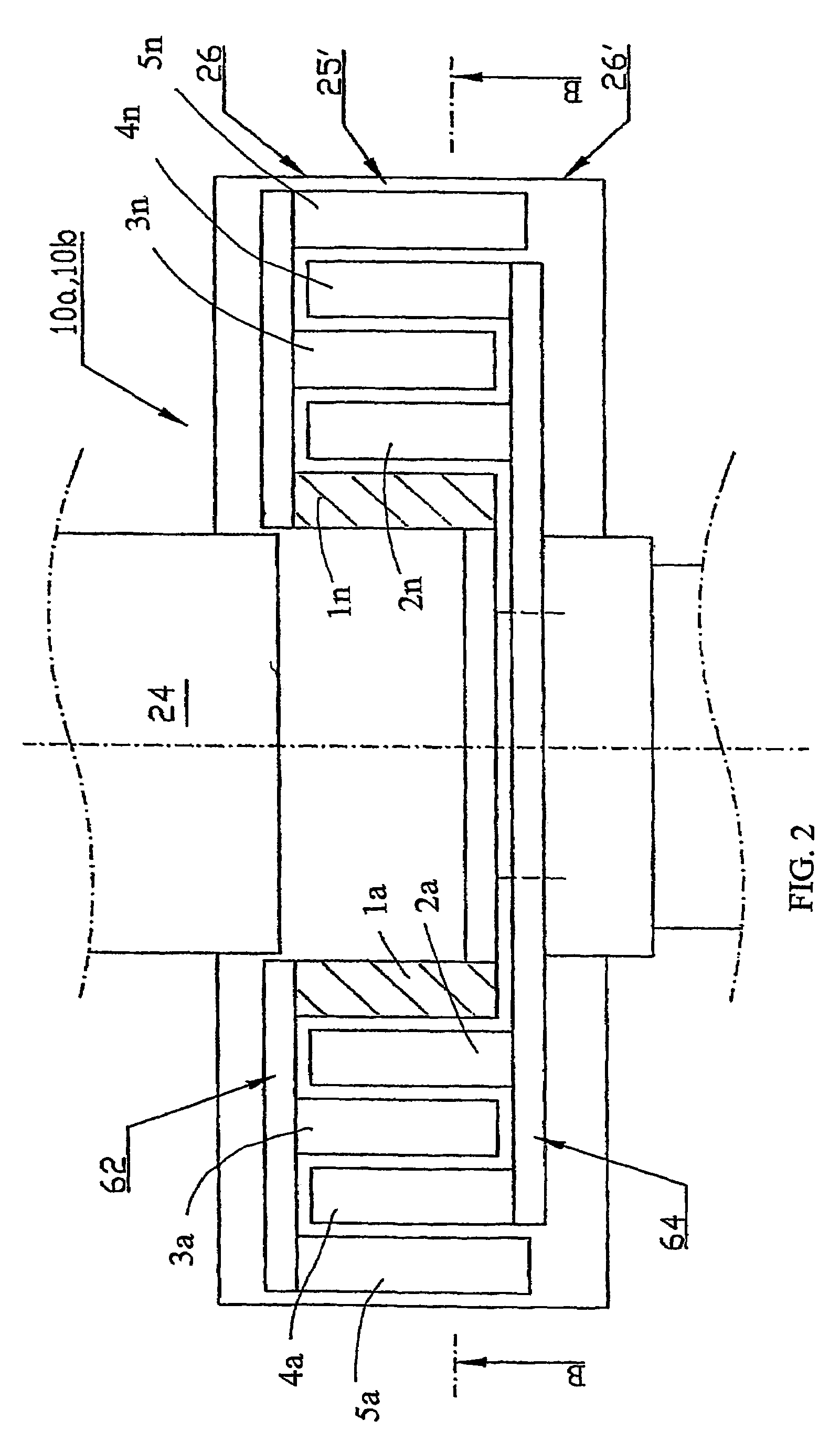

A method and apparatus for biological and / or chemical decomposition of waste containing organic matter. The method includes waste pretreatment in which waste is fragmented and homogenised in a pretreatment apparatus (10a, 10b) operating on the principle of a multi-ring double action impact mill. The apparatus has either two rotors (62, 64) or a rotor and stator disposed inside a housing (26), which rotors and / or stator are equipped with blades having impact surfaces, and which form one or more rings (1,2,3, . . . ) coaxial with the rotor. The waste is fed into the housing through the hub of rings formed by the blades, and travels by the effect of a rotor or rotors, to the outer ring of the ring (7) formed by the outermost blades, and further to the discharge opening (25, 27′) at the outer ring.

Owner:FRACTIVATOR OY

Tantalum powders and methods of producing same

ActiveUS7142408B2Large specific surface areaIncrease capacitanceLiquid electrolytic capacitorsCapacitor electrodesCapacitanceNiobium

Methods of forming tantalum powders and other valve metal powders are described. The method involves high impact milling a starting powder in a fluid medium and optionally a milling media using a high energy mill. The methods of the present invention have the ability to reduce DC leakage and / or increase capacitance capabilities of valve metal powders when formed into capacitor anodes. The methods of present invention further reduce the milling time necessary to form high surface area valve metal powders and leads to reducing contaminant levels in the valve metal powders. The process is particularly well-suited for forming metal flakes, such as tantalum or niobium flakes, of high purity.

Owner:GLOBAL ADVANCED METALS USA

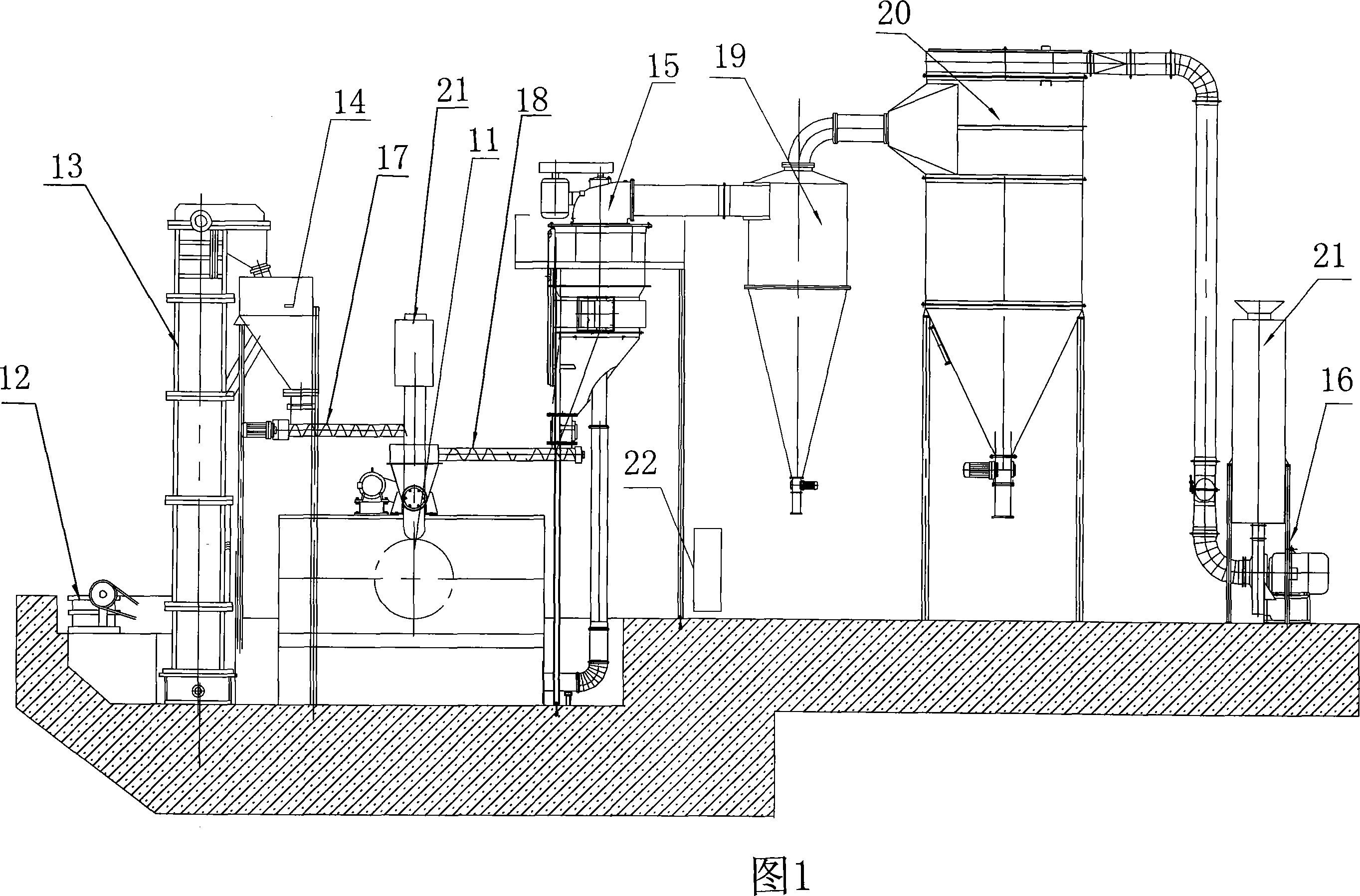

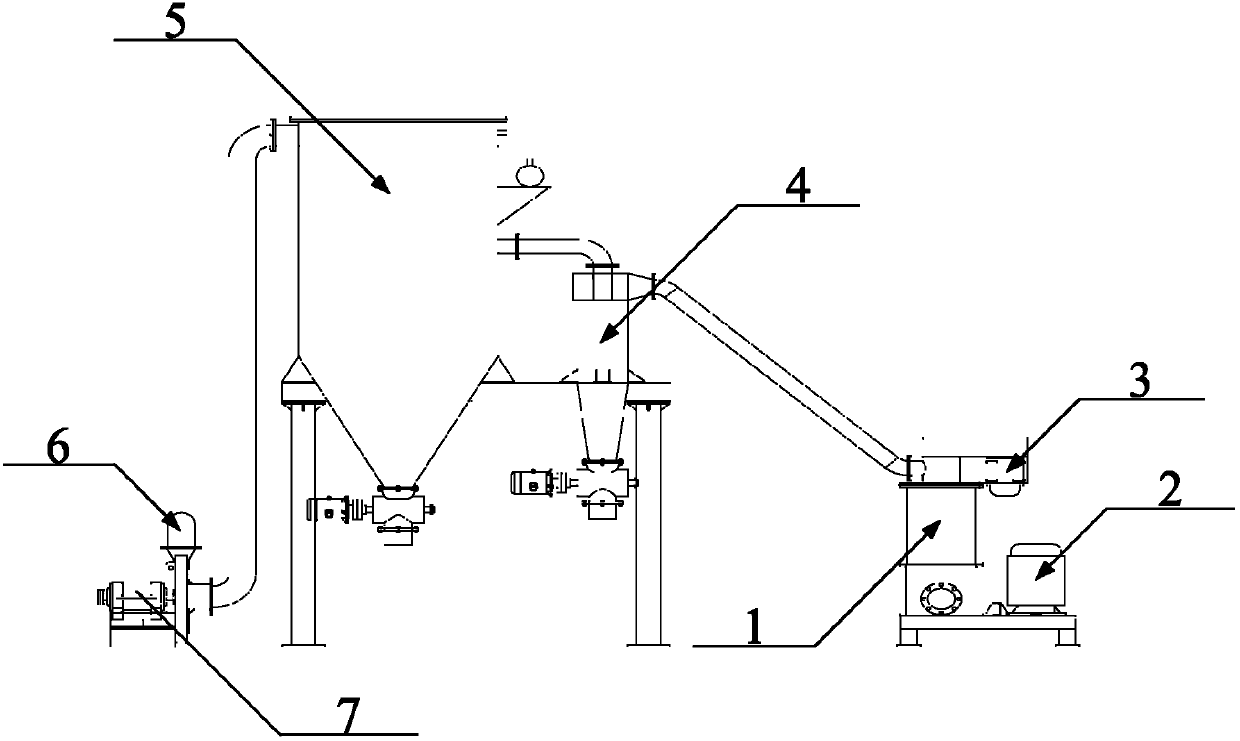

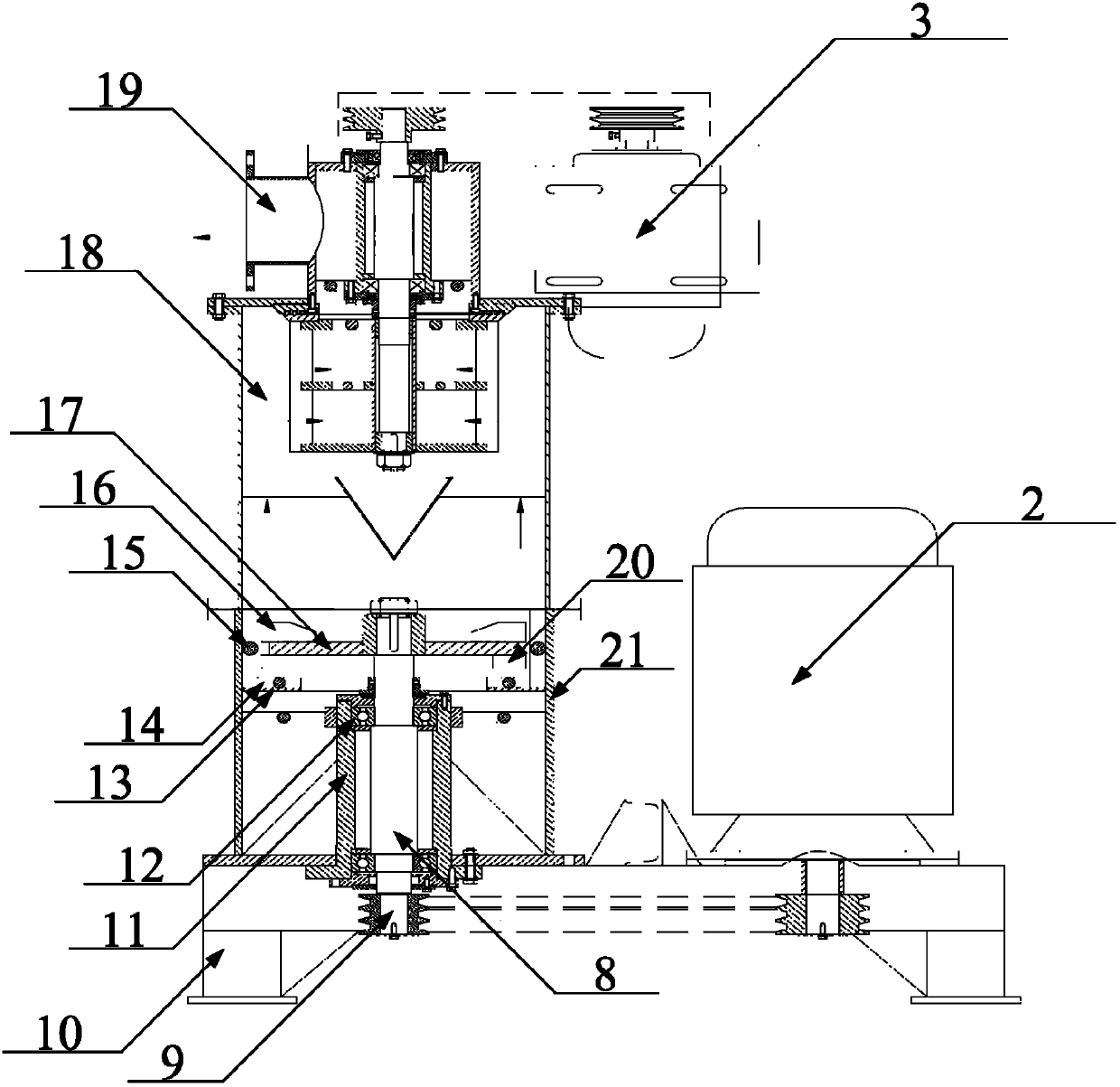

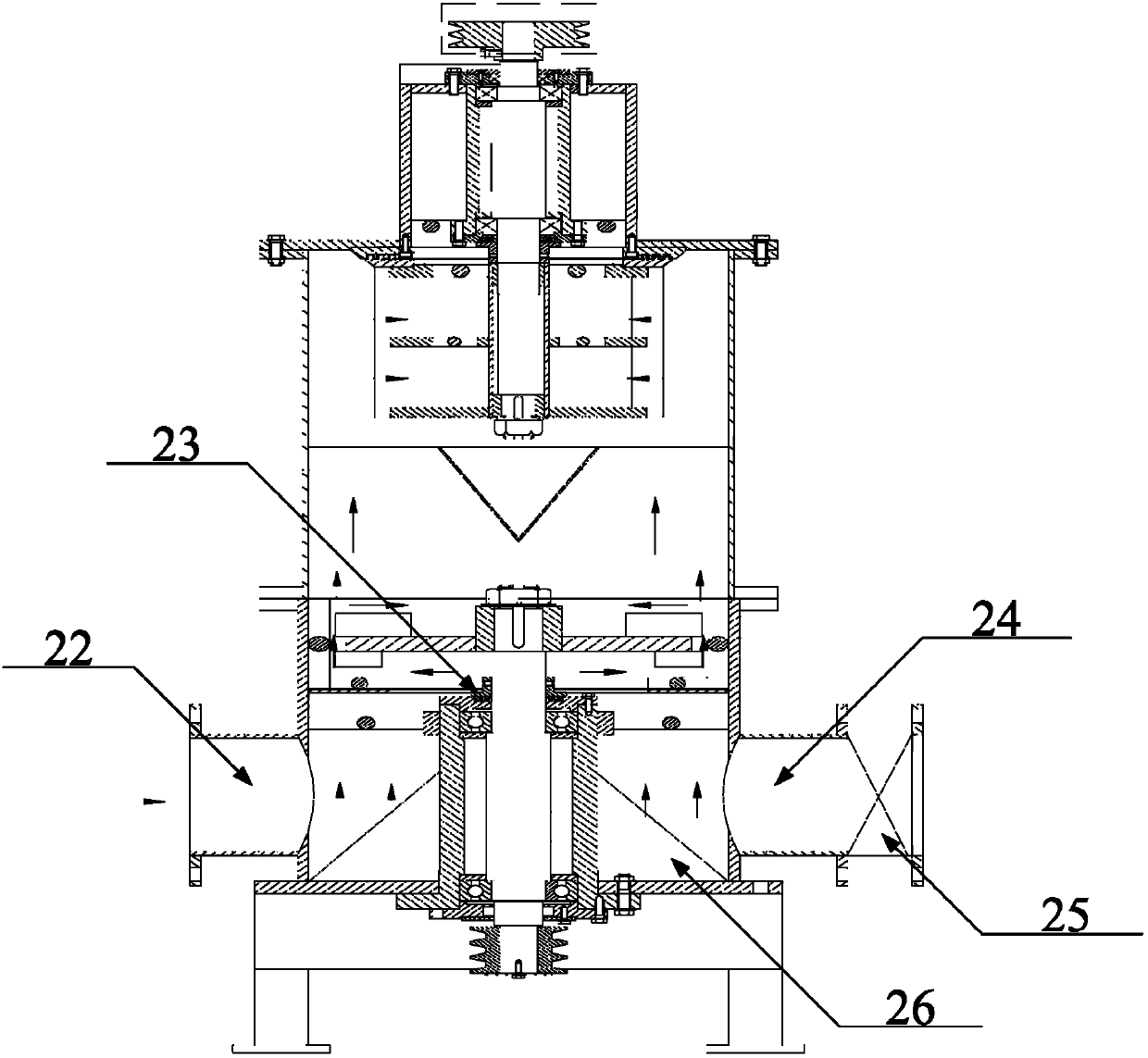

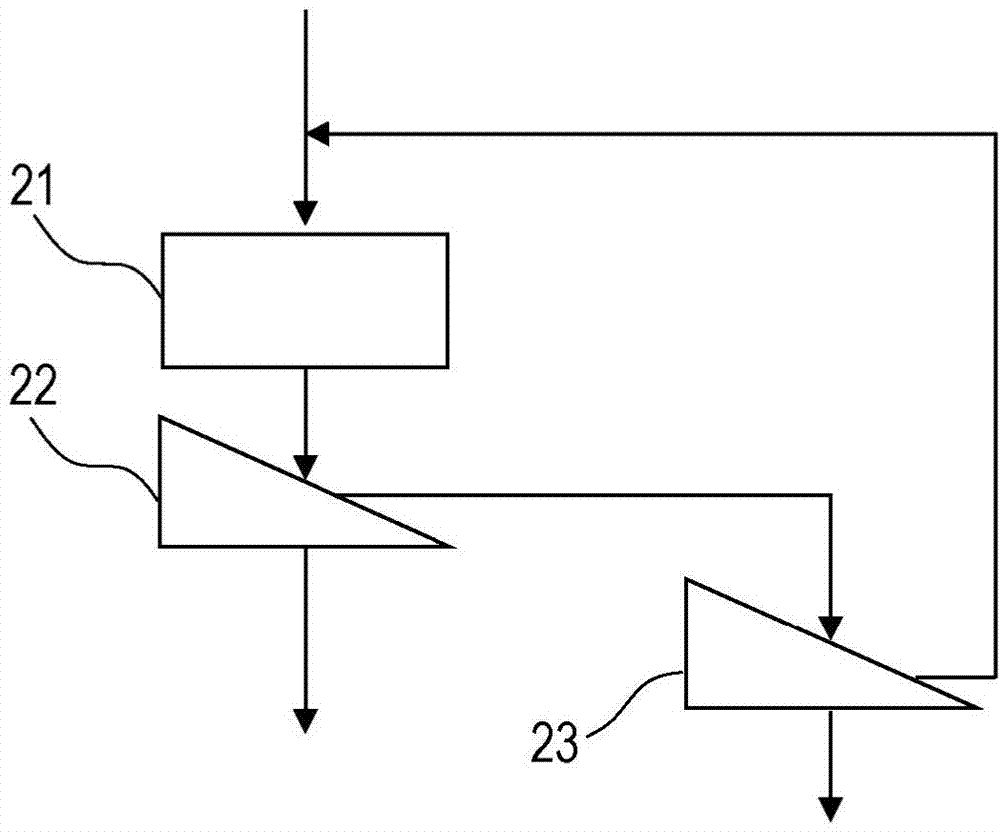

Micronizing impact grinder and the powder processing system thereof

ActiveCN101081374ACompact two-stage crushing structureImprove crushing efficiencyGrain treatmentsMechanical impactEngineering

The present invention discloses one impact mill for crushing ore into fine powder, and the impact mill has one casing, two coaxial nailed discs in opposite rotation directions, and two coaxial cones set separately inside the cavities inside the nailed discs and provided with spiral accelerating slots in opposite directions to form one first crushing area and one second crushing area. Through crushing in these two crushing area, the produced powder may reach the powder size of D97 not greater than 3 micron. The impact mill of the present invention has the functions of both airflow mill and mechanical impact mill. The present invention discloses one powder producing system with the impact mill comprising one crusher, one elevator, one storage hopper, one grader, one cyclonic collector, one bag type collector and one induced draft fan. The powder producing system capable of producing powder of different sizes has low power consumption and high efficiency.

Owner:桂林鸿程矿山设备制造有限责任公司

Conical-shaped impact mill

ActiveUS7900860B2Maximize efficiencyReduce the temperatureGrinding machine componentsCocoaRotational axisEngineering

An impact mill including a base portion on which is disposed a rotor rotatably mounted in a bearing housing, the rotor having an upwardly aligned cylindrical surface portion coaxial with the rotational axis. The impact mill is provided with a mill casing within which is located a conical track assembly which surrounds the rotor to form a conical grinding path. The mill casing is provided with a downwardly aligned cylindrical collar which may be axially adjusted to set a grinding gap between the rotor and the mill casing. The rotor is provided with a plurality of impact knives complementary with a plurality of impact knives disposed on the inside top surface of the mill casing. In addition, the impact mill can be formed of separated conical sections. Finally, power is transmitted to the rotor of the impact mill by a synchronous sprocketed belt, accommodated by a sprocketed drive sheave, wherein the belt is in communication with a power source.

Owner:LEHIGH TECH INC

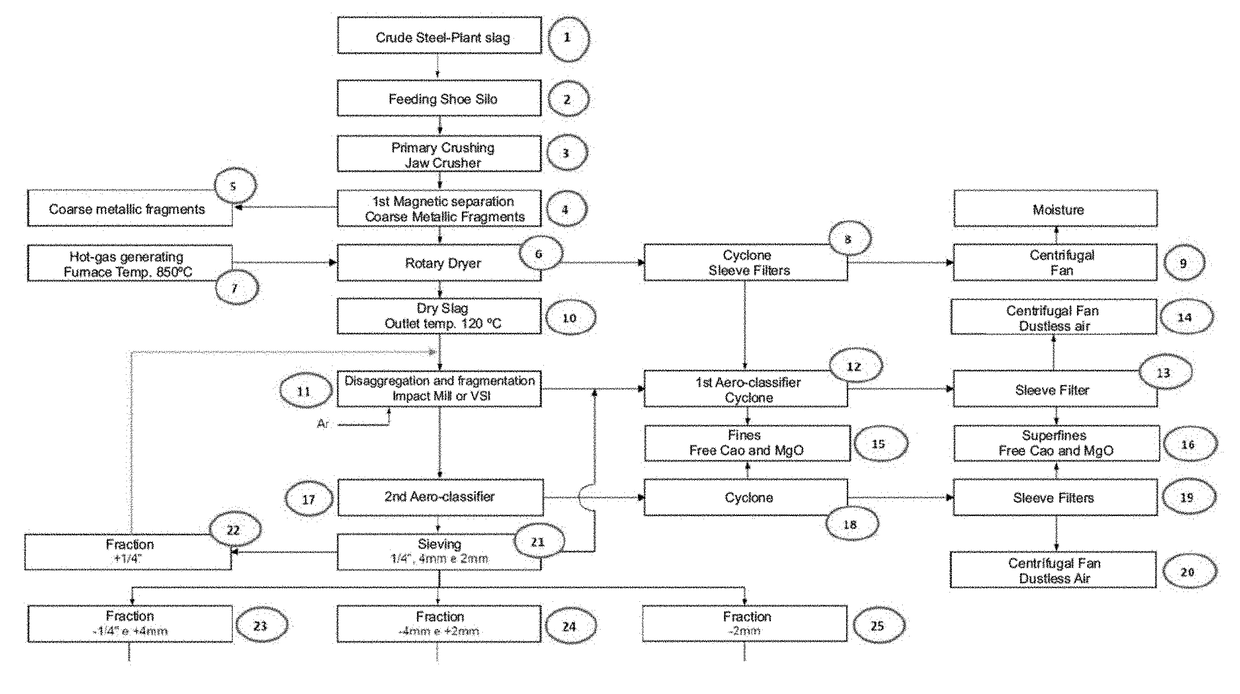

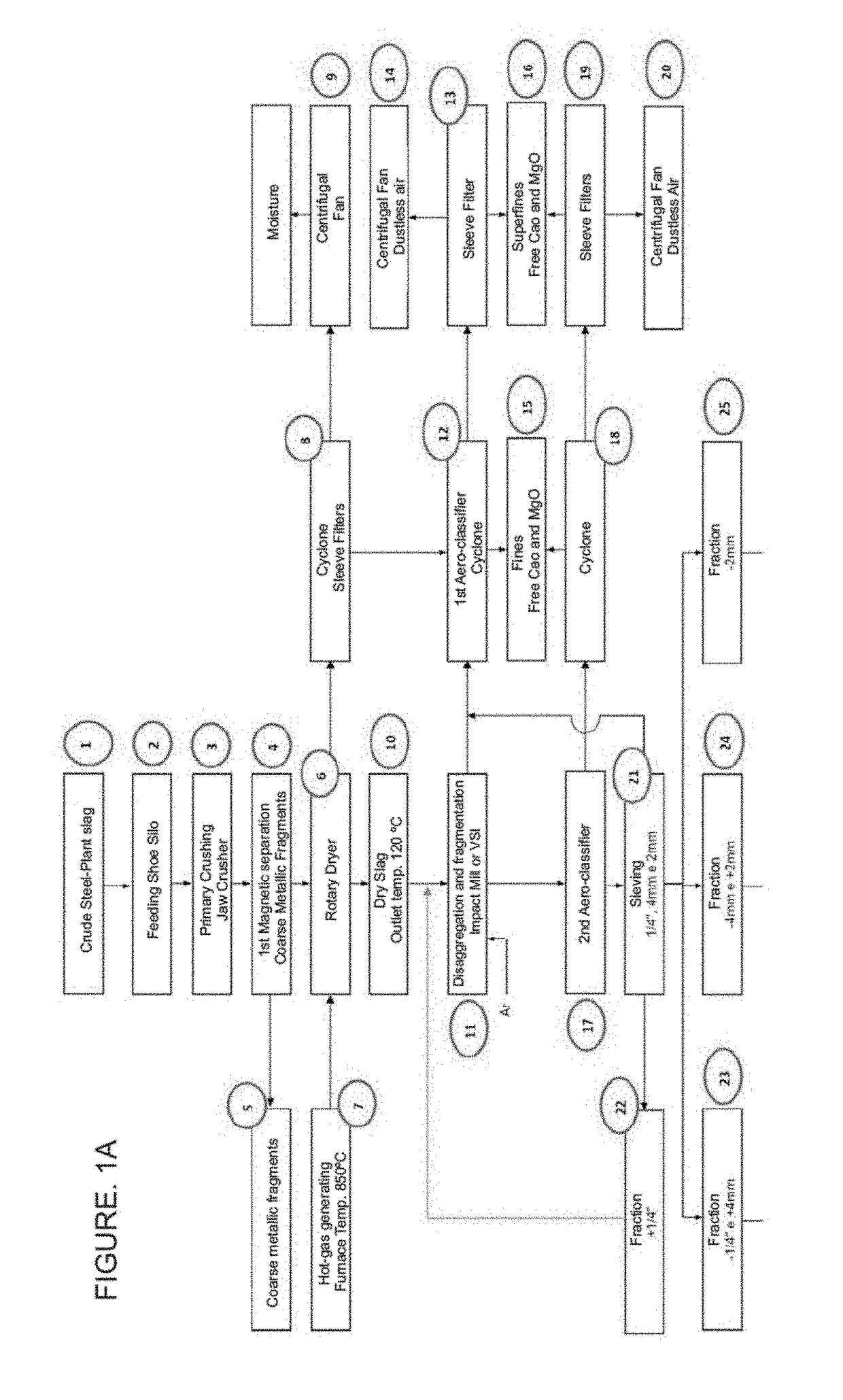

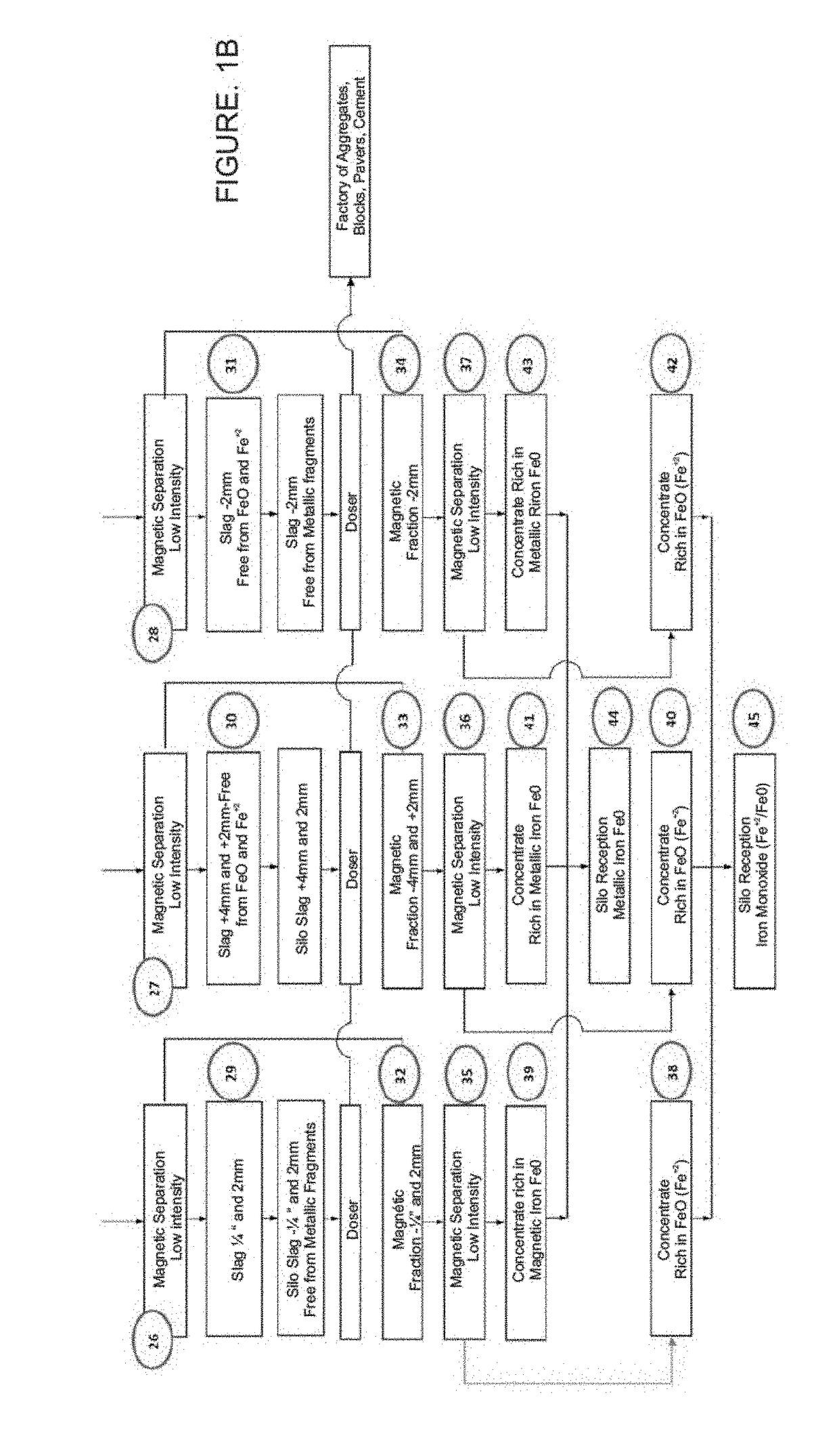

Process and system for eliminating the potential for ld and eaf steel slag expansion

The present invention relates to a process and to a system for eliminating the expandability of steel-plant slag, which comprises a primary crusher (3) to reduce the fragments according to their granulometry; a magnetic separator (4) to remove metallic fragments bigger than a determined granulometry (5); a rotary dryer (6) to dry slag free from bigger metallic fragments; an impact mill (11) to disaggregate and fragment slag particles that are bigger than a predetermined granulometry; a classifier (12) for aero-classification and drag of fine and superfine particles; a cooler (17) for cooling slag particles bigger than a predetermined granulometry by means of heat exchange and removal of the fine and superfine particles that were not collected by the impact mill (11); a vibrating sieve (21) provided with two or more decks (23, 24, and 25) with screens of predetermined sizes; low-intensity magnetic separators (26, 27 and 28), with generation of non-magnetic slag fractions free from metallic iron and from iron monoxide, and of magnetic fractions composed by metallic iron and iron monoxide; and low-intensity magnetic separators (35, 36 and 37) to reprocess the magnetic fractions with generation of concentrate with high metallic iron contents and a product with high concentration of iron monoxide.

Owner:ROLTH DO BRASIL IND COMML E SERVICOS LTDA

Ultrafine grinding system

The invention discloses an ultrafine grinding system. The ultrafine grinding system comprises a grinding main body, wherein the grinding main body is also connected with a grinding motor and a classification electrode, and is also connected with a vortex cyclone collector, a pulse belt-type deduster as well as a high-pressure draught fan sequentially; the high-pressure draught fan is also provided with a silencer; the grinding main body comprises an ultrafine impact mill which is arranged on the lower end and is connected with the grinding motor through a belt wheel; and a classification machine is also fixed on the upper end of the ultrafine impact mill, and is connected with the classification motor through a belt wheel. According to the ultrafine grinding system disclosed by the invention, a structure for charging materials from a lower opening is adopted, so that materials are effectively re-grinded; the grinding efficiency is improved; the device energy consumption is lowered; further the cost required for production is saved; meanwhile, a shaping effect is generated for the materials; and the development in the industry is improved further.

Owner:四川坤森微纳科技股份有限公司

Dry milling corn fractionation process

A method for fractionating whole kernel corn into bran, germ and endosperm fractions. Corn (tempered or non-tempered) is processed through an impact mill and through a screener to divide the initial feed stream into two or more flows or substreams. The substreams or portions thereof may be further processed through a plurality of aspirators, roller mills and screeners to provide bran, germ and endosperm fractions of desired purity levels.

Owner:CROWN IRON WORKS

Rotary impact mill

Owner:NOVATEK IP

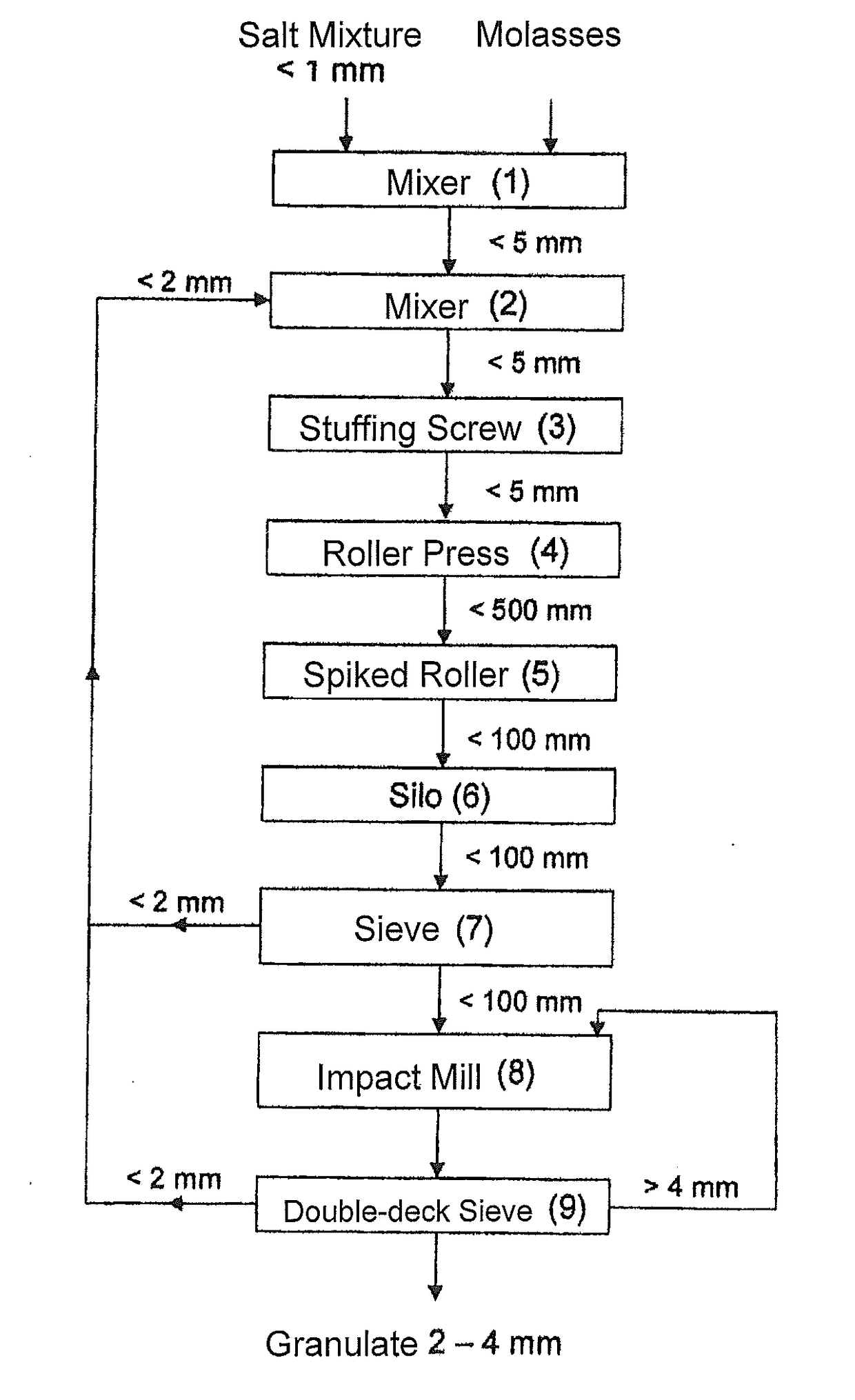

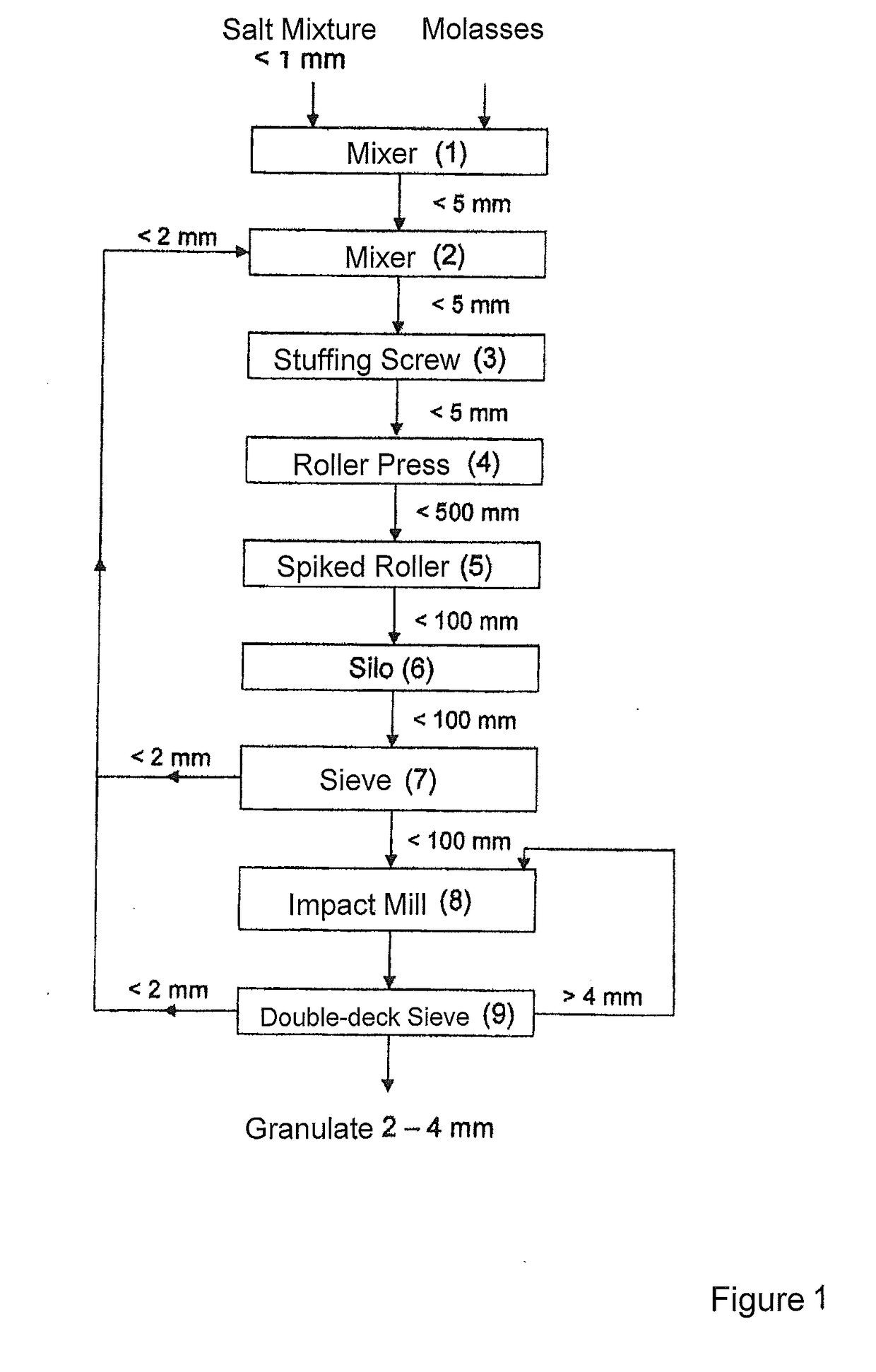

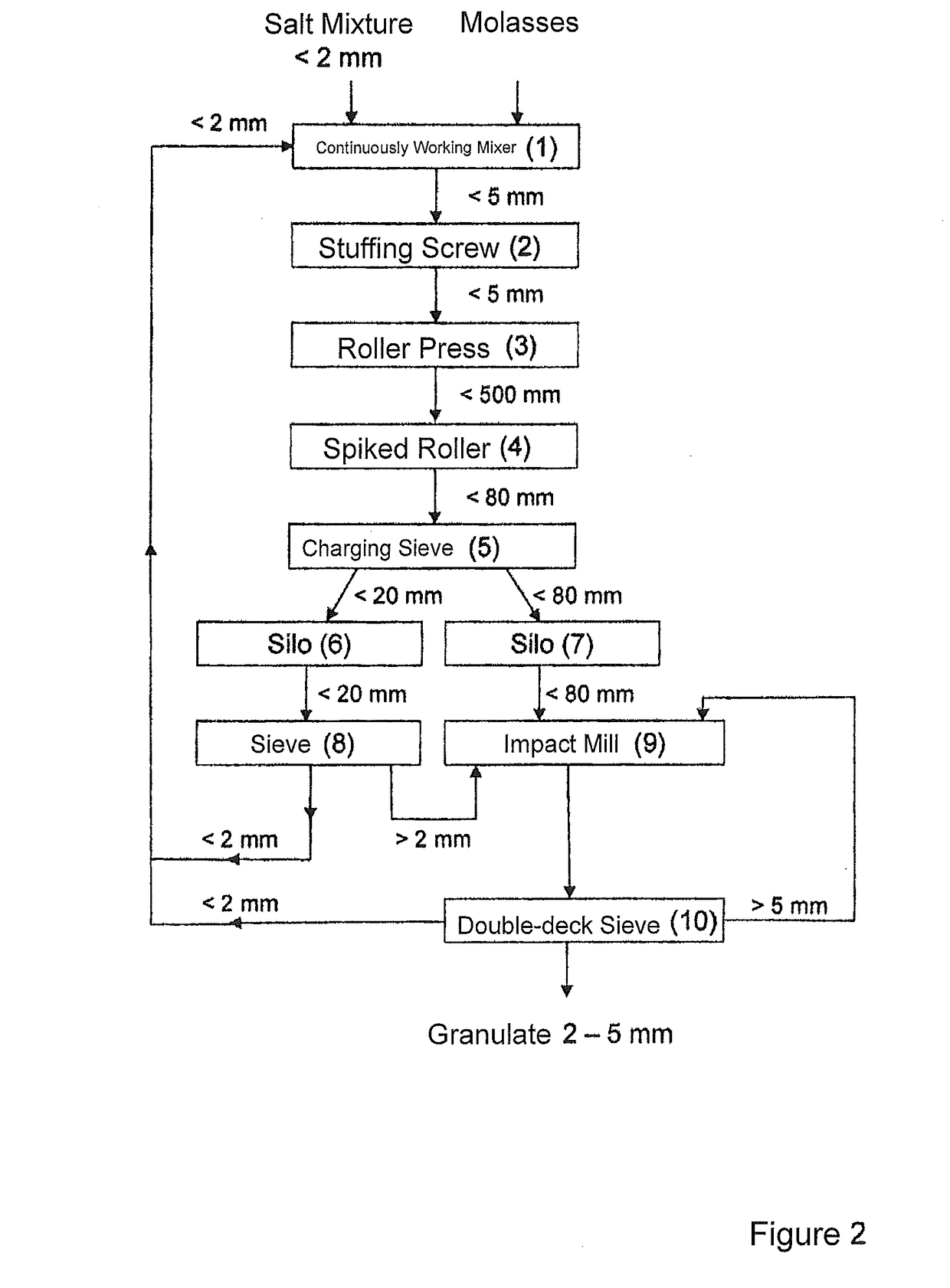

Press-granulating process of non-ductile salts

InactiveUS20170129823A1Reduce generationIncrease food productionGranulation by pressingGrain treatmentsArcaniteSugar

Process of press-granulating non-ductile salts and salt mixtures, such as kieserite (MgSO4.H2O), langbeinite (K2SO4.2MgSO4), polyhalide (K2SO4.MgSO42CaSO4.2H2O), arcanite (K2SO4) and anhydrite (CaSO4) for preparing stable, storable granulate, by pressing a mixture of fine grains of salt and a viscous, sugar-containing additive, such as molasses having a total sugar content in the dry matter of from 47 to 55%, by roller pressing at pressures up to 260 bar. The press scraps initially obtained, which are ductile, are solidified by maturing of the material at temperatures between 20 and 40° C. and maturing times of 3 to 8 hours prior to crushing them in impact mills and sieving.

Owner:KAPS STEPHAN +2

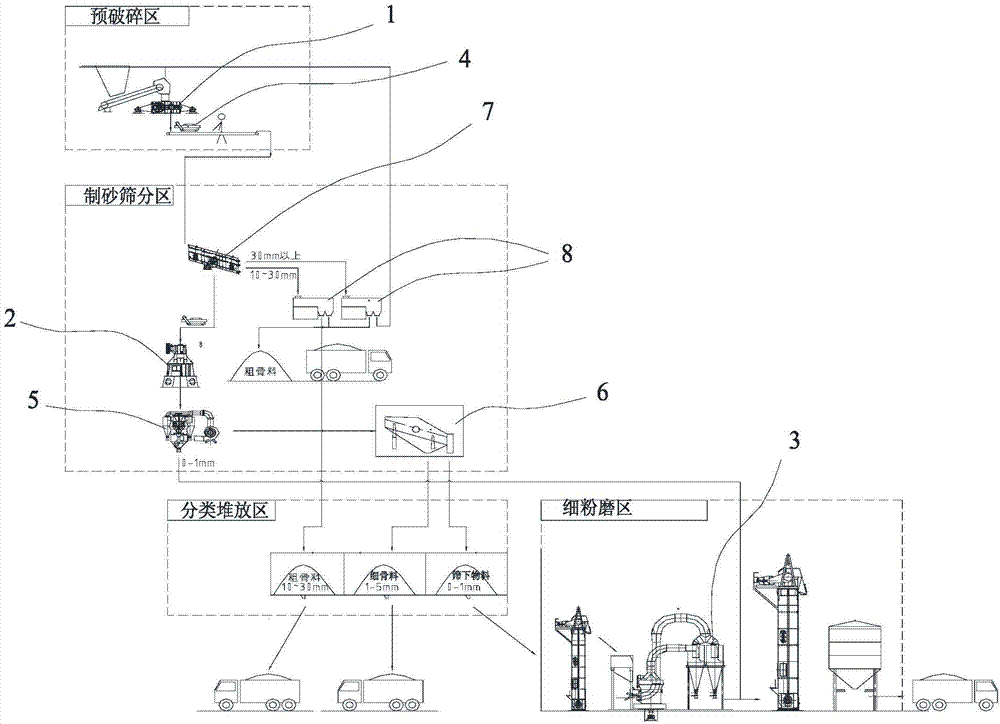

Production process for recycling premixed concrete solid waste residues

ActiveCN103693875AEfficient separationCurb Over GrindingSolid waste managementProcess engineeringCrusher

The invention discloses a production process for recycling premixed concrete solid waste residues. The production process comprises the following steps: S1. crushing the concrete solid waste residues into blocks with the grain diameters of 0-30 mm by adopting a toothed roll crusher; S2. screening the blocks with the grain diameters of 0-30 mm, and separating to form coarse aggregates with the grain diameters of 10-30 mm and screen underflow with the grain diameters of 0-10 mm; S3. stacking the coarse aggregates for storage, delivering the screen underflow with the grain diameters of 0-10 mm into a conical ball mill or an impact mill, and crushing into a mixture with the grain diameter of 0-5 mm; S4. screening the mixture, and separating to form fine aggregates with the grain diameters of 1-5 mm and screen underflow with the grain diameters of 0-1 mm; and S5. stacking the fine aggregates for storage, and delivering screen underflow with the grain diameters of 0-1 mm into an ultrafine mill, and milling into active ultrafine powder with the grain diameter of 0-0.025 mm. According to the production process disclosed by the invention, the separation efficiency and recovery rate of the coarse aggregates, the fine aggregates and the active ultrafine powder in the concrete solid waste residues can be improved, and meanwhile, the total energy consumption of the production process can be reduced.

Owner:广东嘉阳工程材料有限公司

Production process for preparing nanometer coal powder by using puffing and mechanical crushing

InactiveCN103232874AWide range of usesReduce consumptionSolid fuelsNanotechnologyChemical treatmentChemical industry

The present invention provides a production process for preparing nanometer coal powder by using puffing and mechanical crushing. The production process comprises: carrying out a low temperature puffing treatment on selected coal particles under gas protection, crushing through a ball mill, carrying out jet mill crushing while carrying out chemical treatments such as alkali washing, acid washing, water washing and solvent extraction on the coal particles, and finally adopting a high energy nanometer impact mill to prepare the required coal nanometer particles. Compared with the production process in the prior art, the production process of the present invention has the following characteristics that: puffing and mechanical crushing are combined during the nanometer coal powder production process while the coal particle chemical treatments are performed during crushing, such that the prepared coal particles are fine, energy consumption during the production process is reduced, and the prepared nanometer coal powder has wide uses, can be used for compounding a novel fuel base material, can be separately adopted as a fuel or a fuel additive, can be adopted to replace carbon black products, and can further be separately adopted as a chemical industry intermediate.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

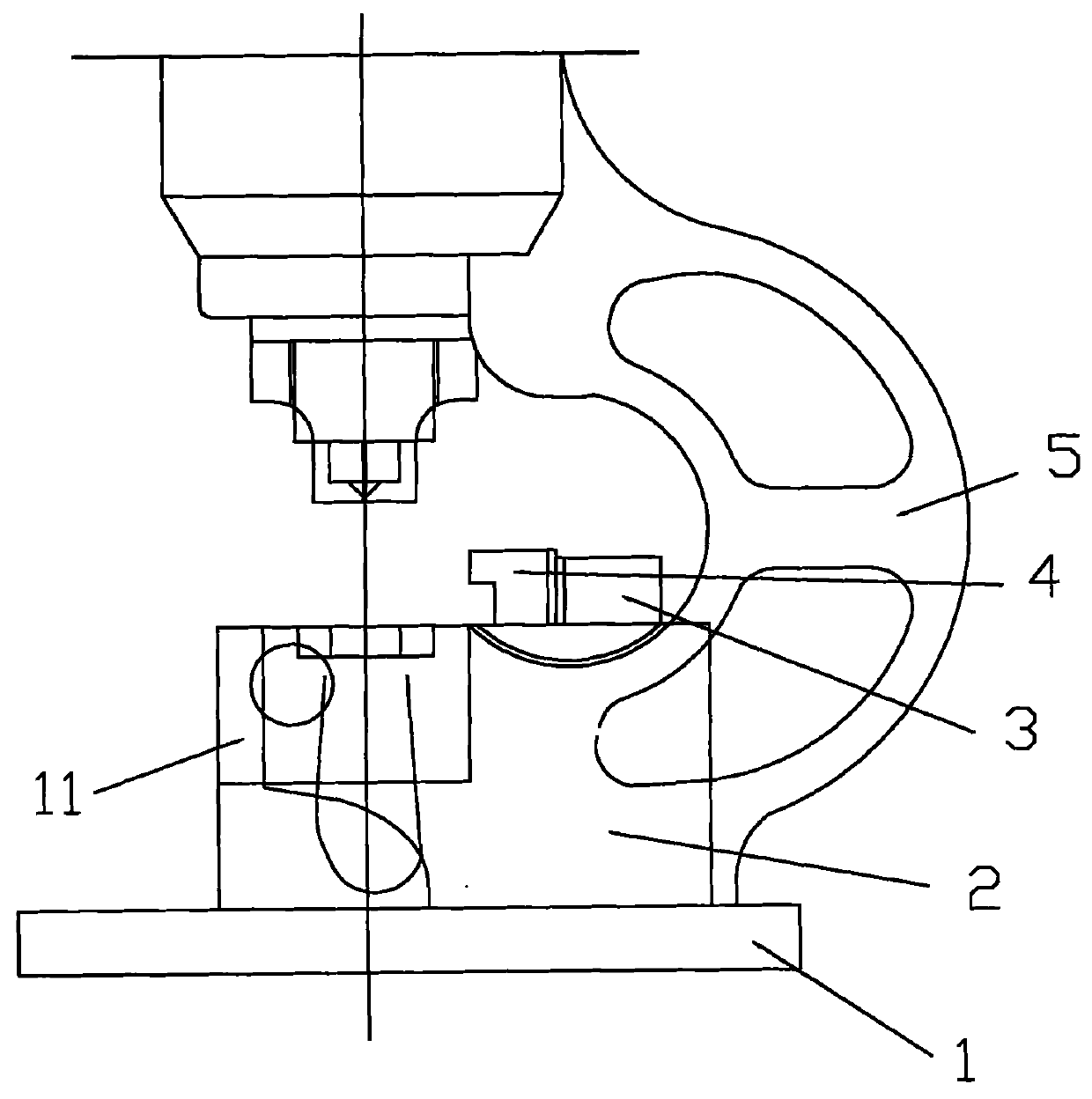

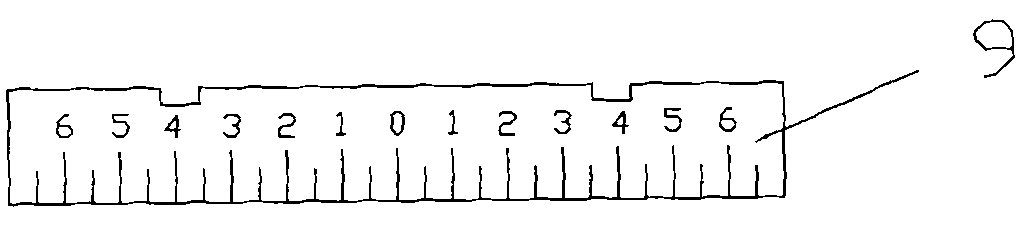

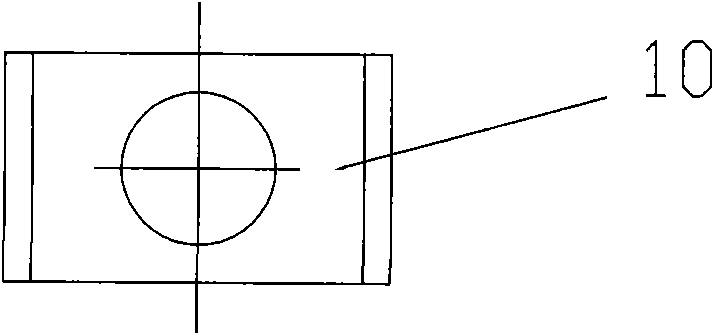

Portable bus hydraulic punching machine and punching method

InactiveCN101997277ASolving problems under stressReduce the error factorBus-bar installationSwitchgearPunchingVertical alignment

The invention discloses a portable bus hydraulic punching machine and a punching method. The hydraulic punching machine at least comprises a hydraulic punching machine main body, a hydraulic punching machine bottom plate, a scale mother blank side bracket, a movable scale set I, a movable scale set II, a scale mother blank for positioning scales, and a protective upright post; a perforated fixed hydraulic punching machine and the scale mother blank side bracket are arranged on the hydraulic punching machine bottom plate; after supporting and accurately positioning the scale mother blank, the scale mother blank side bracket properly prolongs the length of the scale mother blank to the positive direction of the hydraulic punching machine main body, and keeps the height of the scale mother blank accordant with the punching plane of a hydraulic punching machine static impact mill; the scale mother blank is provided with two inverse trapezoidal positioning tenons for accurately positioningthe scale set I or the scale set II; and the scale set I is used for a vertical alignment method, and the scale set II is used for a planar alignment method. The portable hydraulic punching machine punches a bus based on the punching requirement of a bus connection form by using a scale I or a scale II with graduation as a reference of a bus punching circle center.

Owner:JIAXING ELECTRIC POWER BUREAU +1

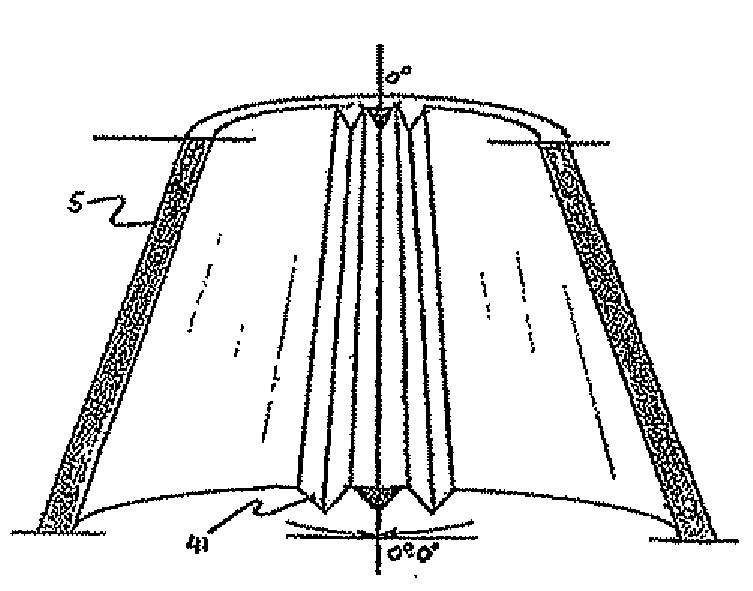

Parabolic vibratory impact mill

InactiveUS20150129696A1High grinding ratioSlow down material flowGrain treatmentsEnergy expenditureMechanical engineering

A parabolic vibratory impact mill is proposed which comprises a housing having an outer cone, an inner cone and a power-operated vibrator. The shells of the cones have working surfaces in the form of parabolic generatrices: in the bottom part, the concavity of the parabolae is oriented toward the axis of the mill; in the top part, the convexity of the parabolae is oriented toward the axis of the mill. Conditions are created for the autogenous grinding of large pieces in the top part and small pieces in the bottom part, wherein the material partially decelerates in the transition region between the top parabolae and the bottom parabolae, providing for the metered feeding of the bottom region. The advantageous vertical distribution of the load in the grinding chamber provides a grinding ratio of 30 with little wear on the shells and low energy expenditure.

Owner:TRANSMICRON

Rotary impact mill

In one aspect of the invention, a rotary impact mill has a milling chamber defined by housing with an inlet, an outlet, and at least one wall. A plurality of impact hammers located within the milling chamber are fastened to and longitudinally disposed along a rotor assembly connected a rotary driving mechanism. At least one of the impact hammers has a body with a first hardness. The impact hammer also has a wear resistant insert bonded to the body, wherein the wear resistant insert comprises a hard surface with a second hardness greater than the first hardness.

Owner:NOVATEK IP

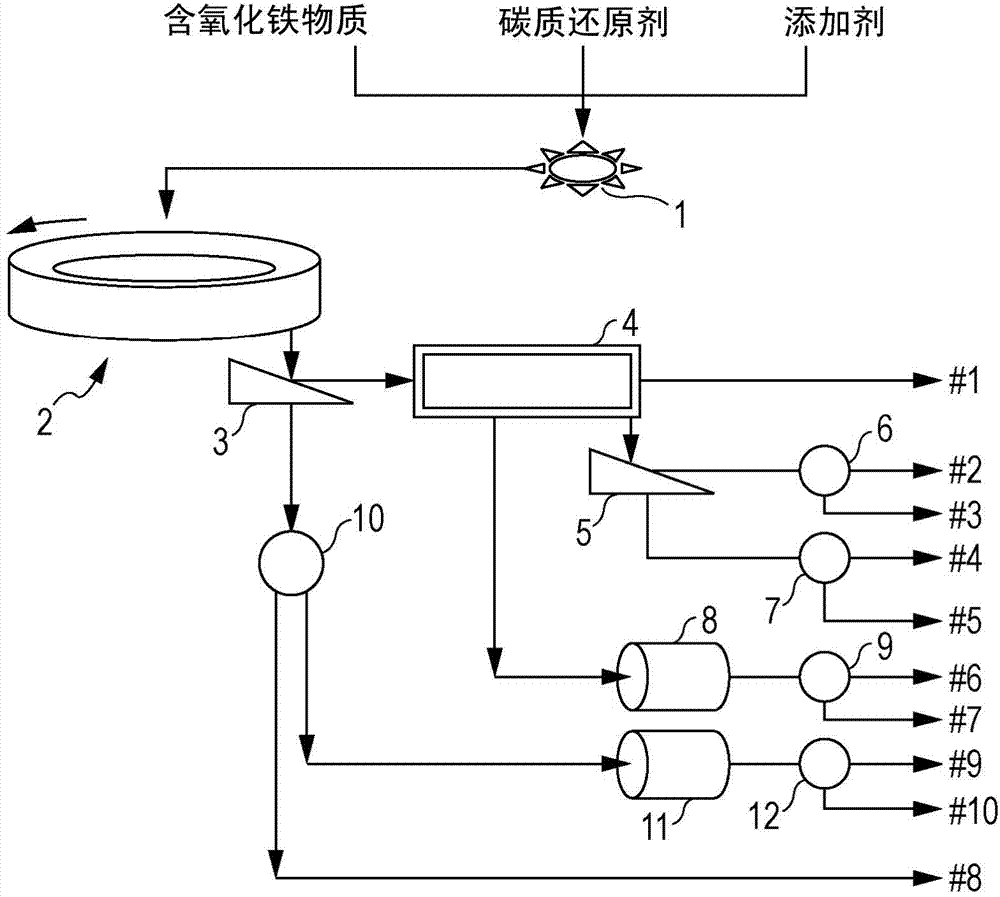

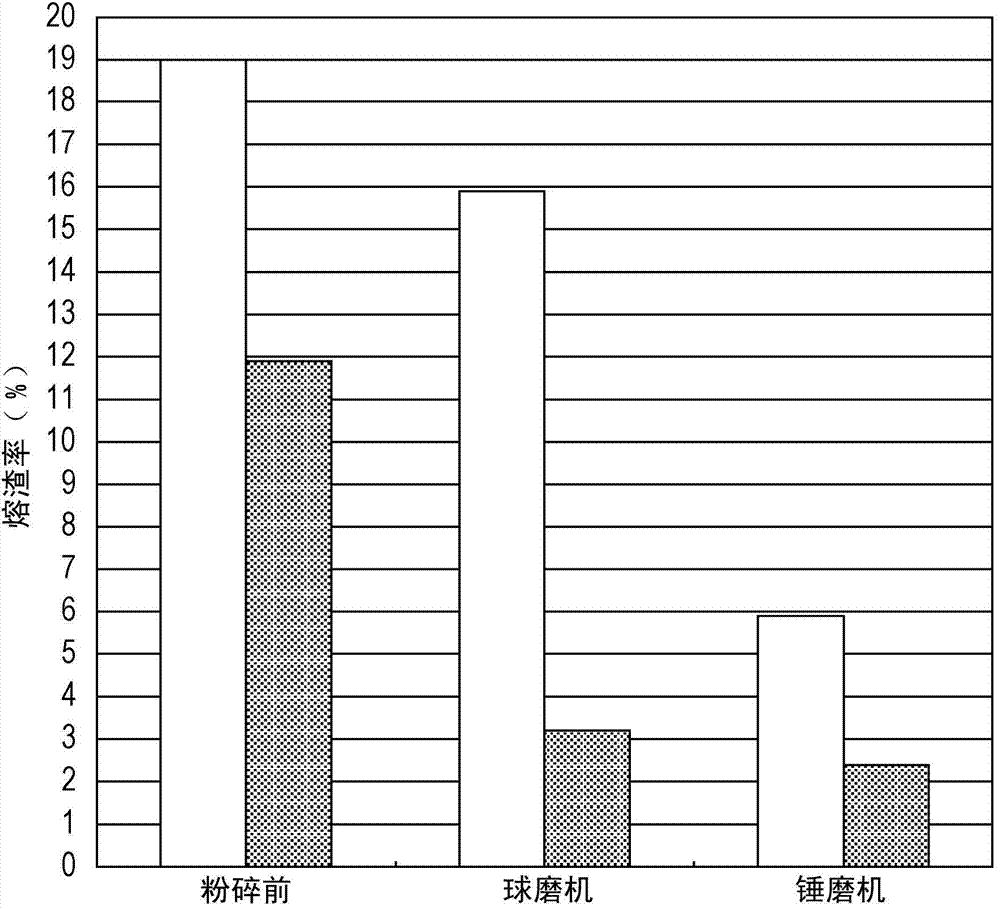

Method for producing metallic iron

InactiveCN104508151AEfficient recyclingEfficient separationProcess efficiency improvementMagnetic separationSlagHeating furnace

The first purpose of the present invention is to provide a method for producing metallic iron, whereby, in the production of metallic iron by heating an agglomerate, which comprises an iron oxide-containing material and a carbonaceous reducing agent, in a movable hearth type heating furnace, metallic iron can be efficiently collected from a reduced product containing metallic iron and a slag, said reduced product being obtained by heating the agglomerate. The method for producing metallic iron according to the first embodiment of the present invention comprises: a step for forming an agglomerate of a mixture which comprises an iron oxide-containing material and a carbonaceous reducing agent; a step for introducing the obtained agglomerate into a movable hearth type heating furnace and reducing the same by heating; a step for milling a reduced product containing metallic iron and a slag, said reduced product being discharged from the movable hearth type heating furnace, using an impact mill; and a step for selecting and collecting the metallic iron using a separator.

Owner:KOBE STEEL LTD

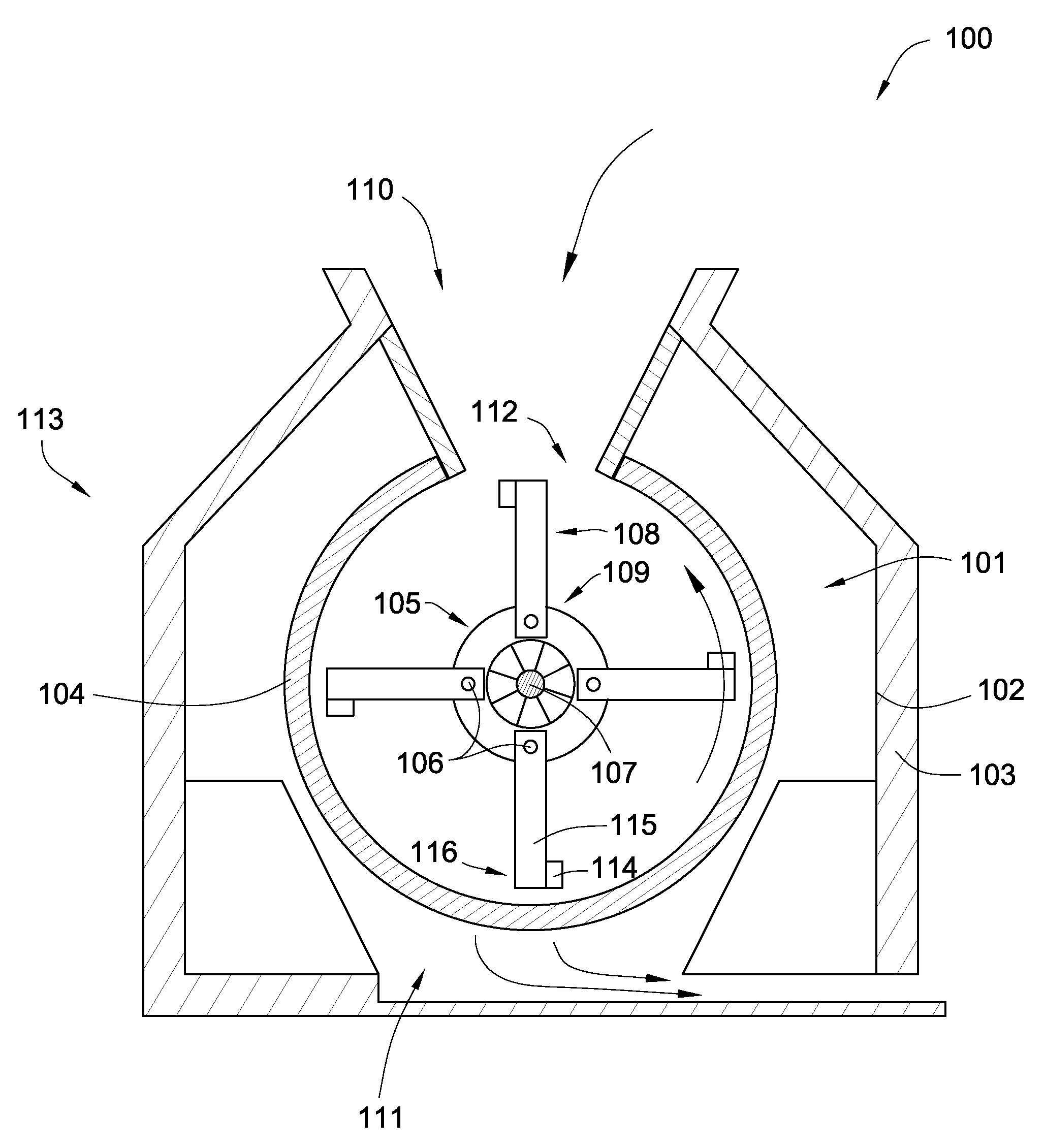

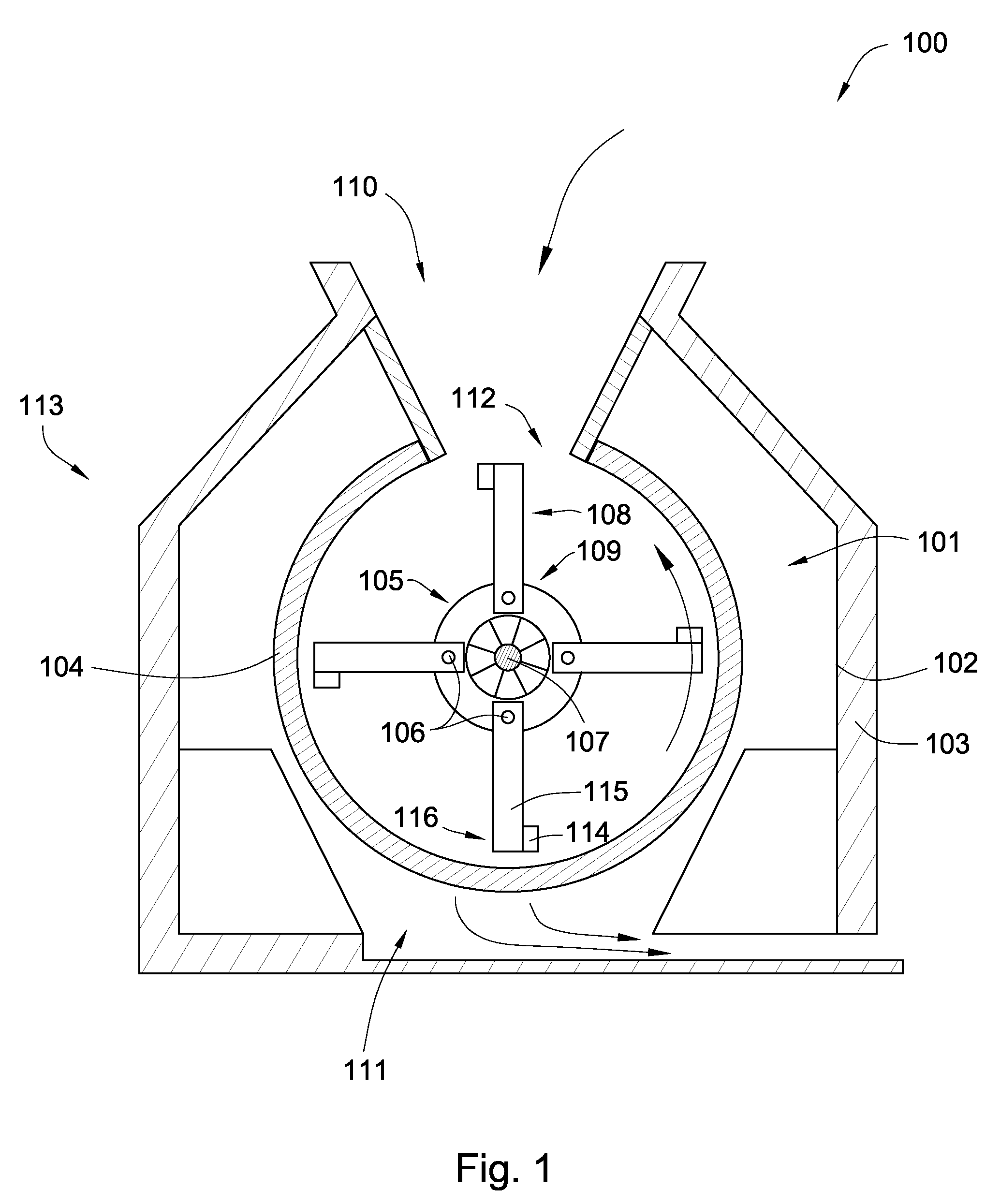

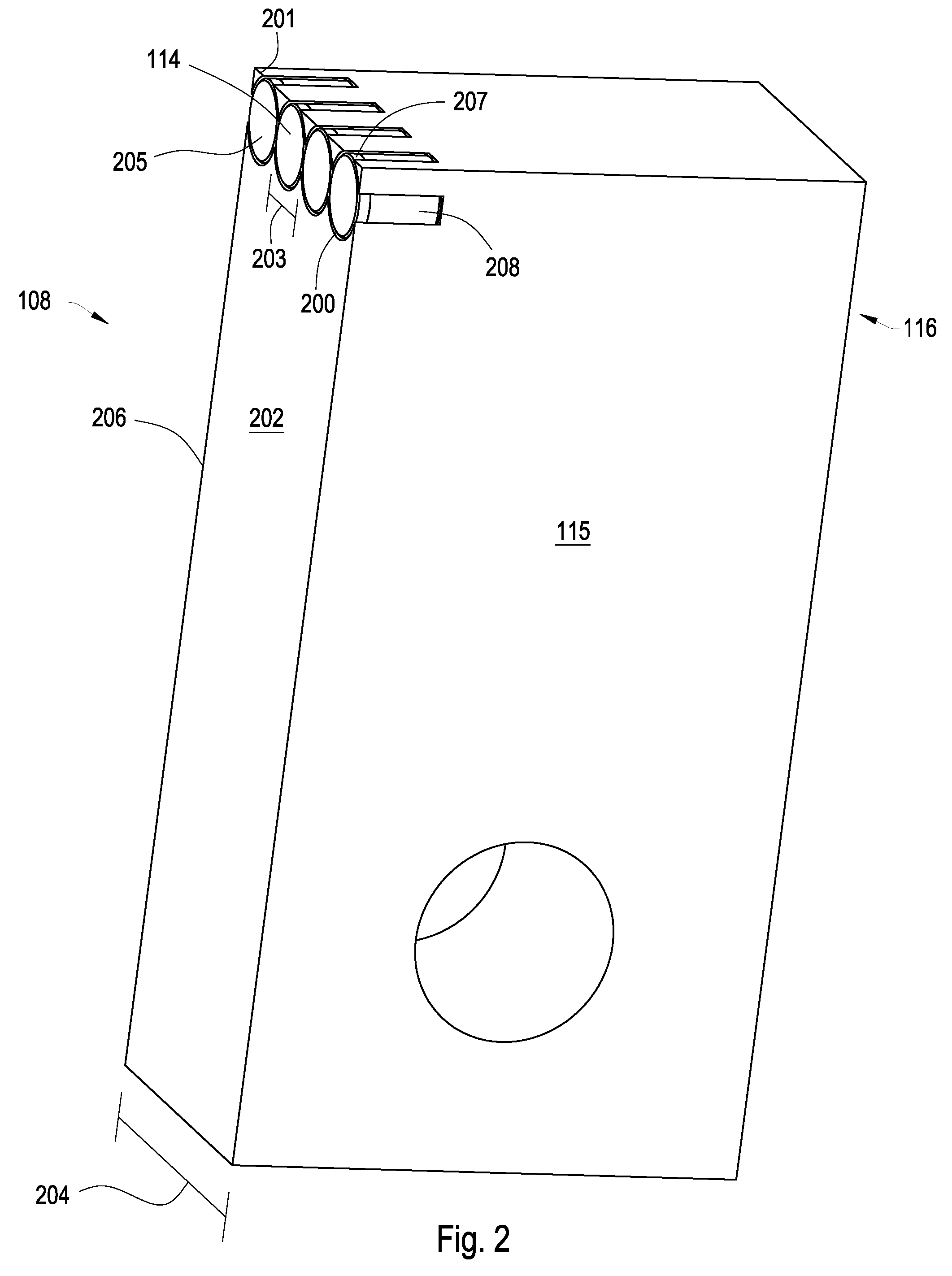

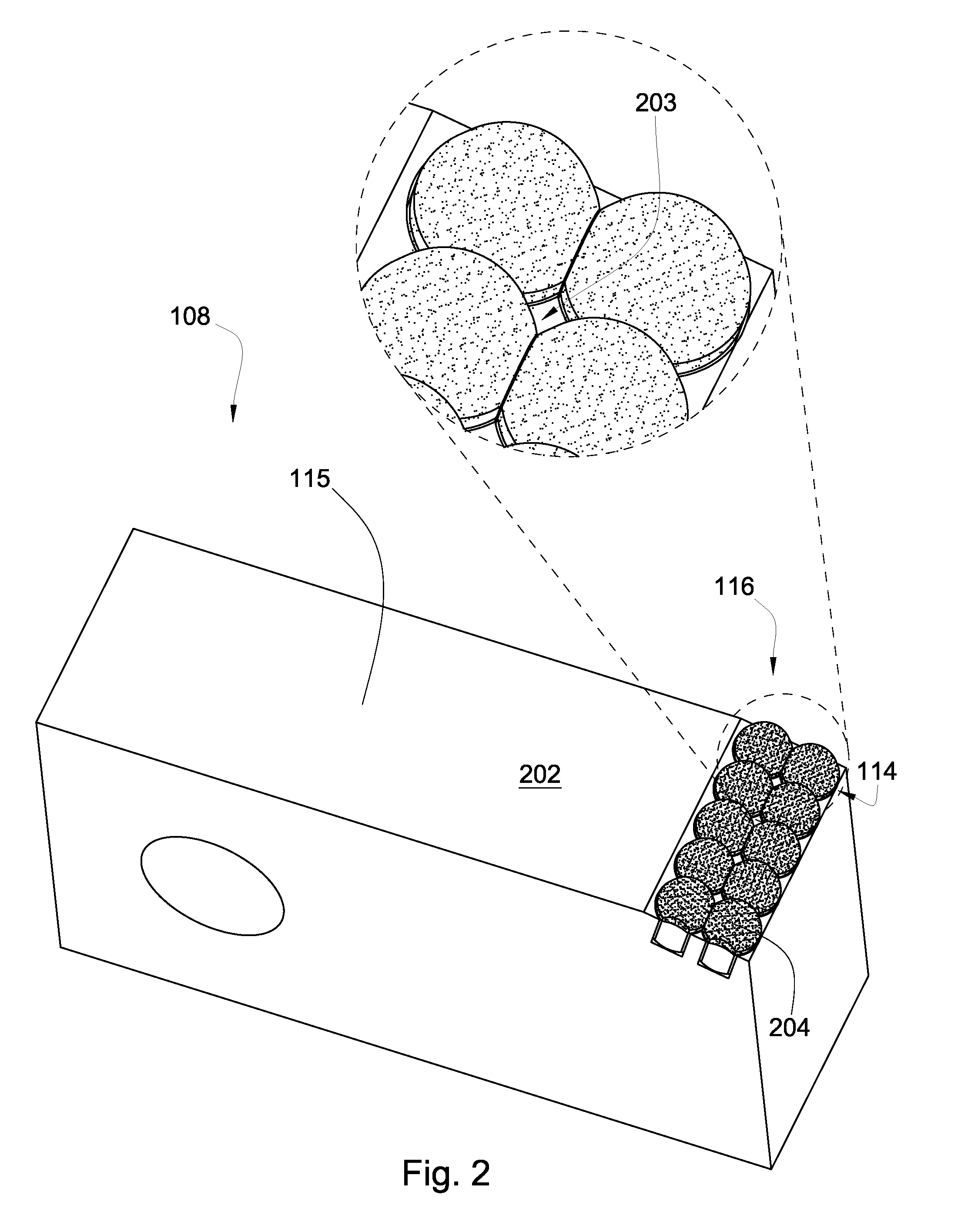

An impact mill and a residue processing system incorporating same

PendingUS20210022289A1Reduce mass flow rateShorten speedMowersThreshersRotational axisThermodynamics

An impact mill (10) has an inlet (12) for material to enter the mill, an impact mechanism (16, 50) arranged to rotate about a rotation axis and being operable to pulverise the material after entering through the inlet, and an outlet (154) for discharge of pulverised material. Blockage sensors (Bj), vibration sensors V, torque sensors Tn, temperature sensors and proximity sensors may be selectively incorporated into the mill.

Owner:SEED TERMINATOR HLDG PTY LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com