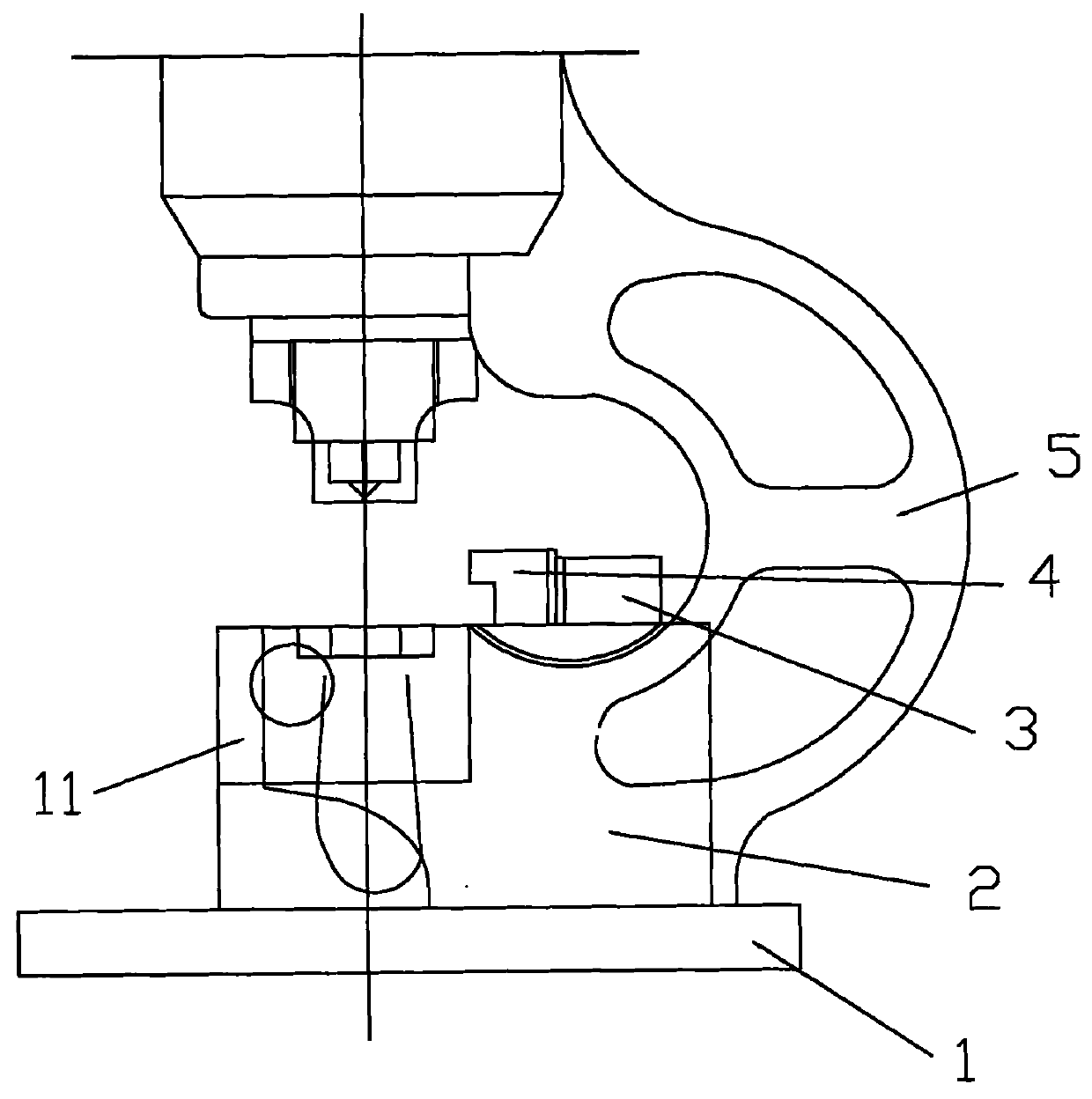

Portable bus hydraulic punching machine and punching method

A punching machine and portable technology, which is applied in the installation of busbars, switchgear, electrical components, etc., can solve the problems of shallow busbar contact surface, unsmooth bolt penetration, and inability to achieve symmetrical and consistent busbar connections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

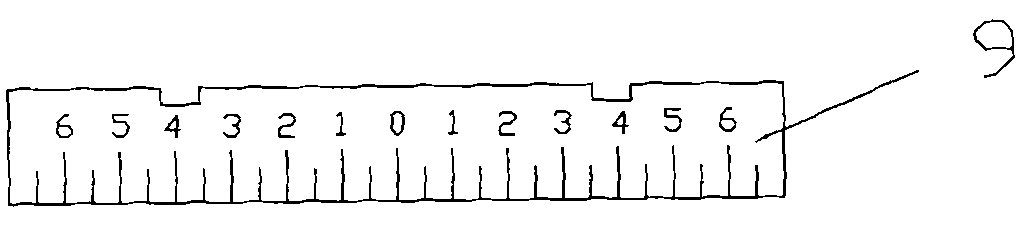

[0069] Taking the 100×10mm side of the busbar as a full circle, four round holes (50×4) need to be punched as an example to illustrate the vertical alignment method, such as Figure 6 , 7 As shown, the specific steps are as follows:

[0070] (1) Make a mark 100mm from the center of the first round hole;

[0071] (2) Use a steel square to draw a straight line perpendicular to the side of the busbar at the marked place;

[0072] (3) Align this straight line with the 100mm right side of scale 1 4, put the busbar and scale 1 4 inwardly and moderately close to the scale motherboard, and punch the first round hole;

[0073] (4) Align this straight line with the 50mm right side of scale 1 4, put the busbar and scale 1 4 inward and close to the scale motherboard, and punch the second round hole;

[0074] (5) Reverse the busbar (or reverse the hydraulic punching machine), align the straight line at the 100mm left side of the scale 4, and put the busbar and the scale 4 inward and mod...

Embodiment 2

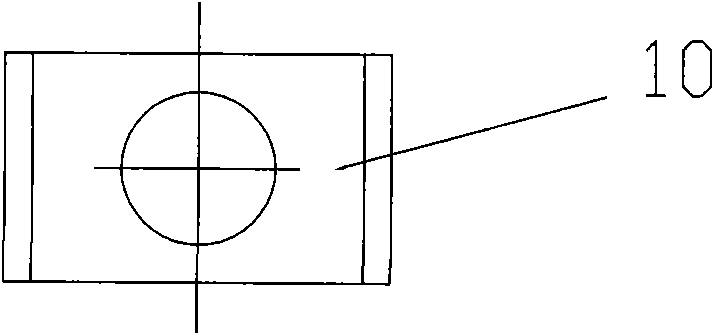

[0077] Take the 80×8mm copper expansion joint (the side is a straight side shape) that needs to be punched with a 40×4 round hole as an example to illustrate the plane alignment method, such as Figure 8 , 9 As shown, the specific steps are as follows:

[0078] Step 1: Make a mark at a distance of about 20mm from the outer edge of the copper expansion joint connecting the copper plate, and use a steel square to draw a straight line perpendicular to the side of the marked position;

[0079] Step 2: Based on the drawn straight line, align with the 0 point of the scale, and make the copper plate part and the scale two vertically close to the scale mother board, and punch the first round hole;

[0080] Step 3: Align the straight line with 40mm on the right side of the scale, put the copper plate part and the scale two inward and close to the scale mother plate vertically, and punch the second round hole.

[0081] Step 4: Reverse the copper expansion joint (or reverse the hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com