Micronizing impact grinder and the powder processing system thereof

A technology of impact mill and processing system, applied in grain processing and other directions, can solve the problems of easy wear and tear of machinery, high feeding requirements, mechanical grinding equipment can not meet the requirements of high mesh fineness and high-efficiency powder material production, etc. The effect of preventing contamination and improving crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

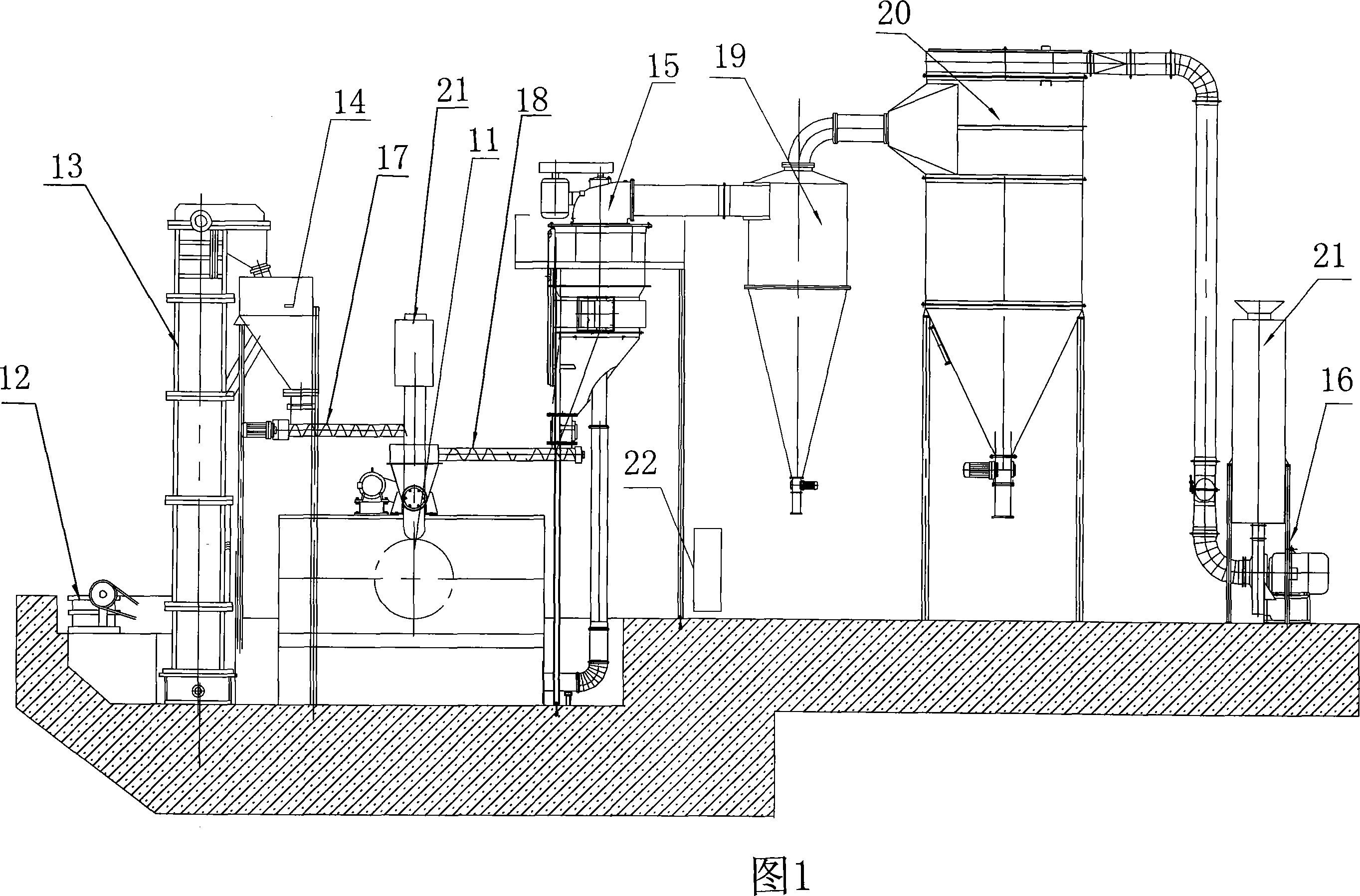

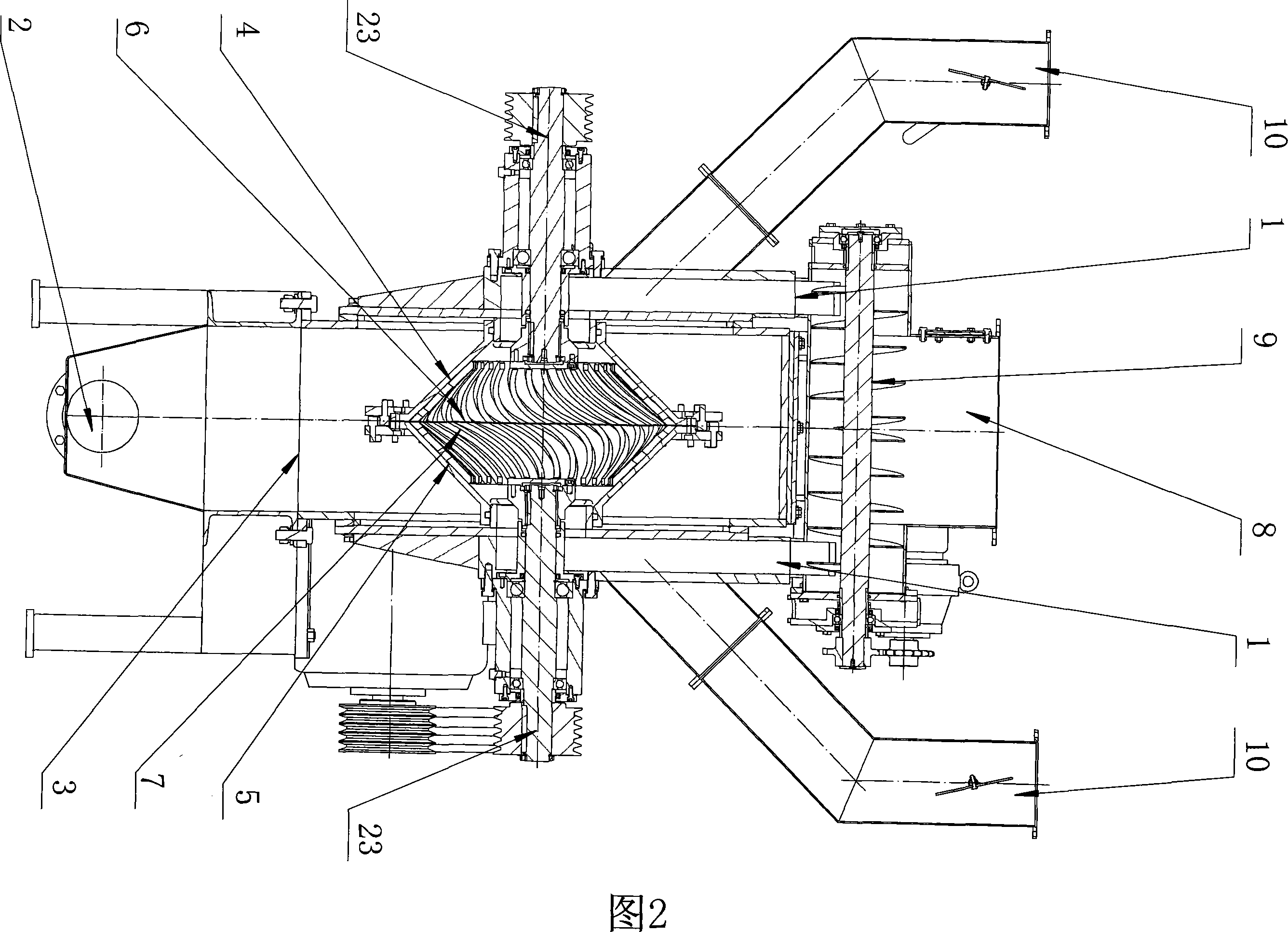

[0030] In the embodiment shown in Figure 1, the vertical casing 3 of the micropowder impact mill 11 of the present invention is fixedly installed on the frame, and the bearing positions on the left and right sides of the casing 3 are horizontally arranged with a rotating shaft 23. One shaft end of the rotating shaft 23 stretches into the casing 3, and the other shaft end of the rotating shaft 23 is coaxially fixed to the belt pulley, and is connected with the belt pulley of the motor mounted on the frame by a belt. Both sides of the casing 3 are also provided with a vertical feeding interface 1, the side of the feeding interface 1 is connected to the air duct 10, and the bottom opening of the feeding interface 1 is connected to the casing through the shaft side gap between the rotating shaft 23 and the casing 3. 3 are connected, and the discharge interface 2 of the casing 3 is located at the bottom of the casing 3 .

[0031] As shown in Figure 1, the shaft ends of the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com