Overlapped gravity field work applying method and used device

A gravity field and cascading technology, which is applied in the direction of steam engine devices, combined engines, lighting and heating equipment, etc., can solve the problems of high position drop requirements and reduced practical feasibility, so as to achieve wide application range and reduce height difference , The effect of reducing the position drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

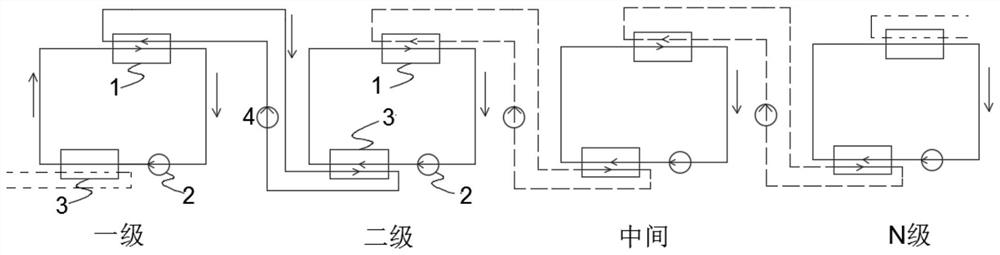

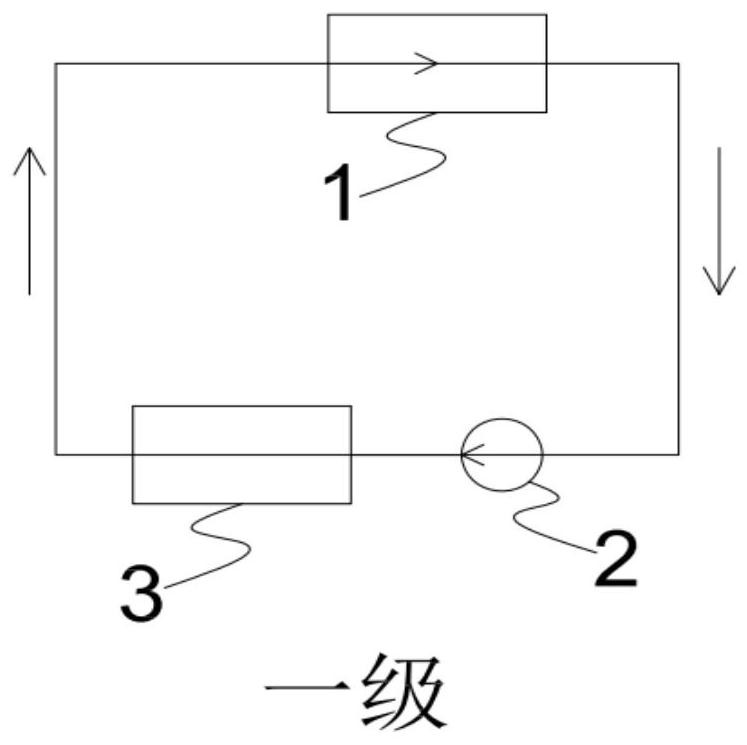

[0048] Embodiment 1, the square circulation method of the cascading gravity field acting device, its mode of operation is as follows:

[0049] 1.1. In the gravitational field work subsystem of the same level:

[0050] The gas-liquid mixture with low dryness flowing out from the condensation heat release channel of the high-level condenser 1 flows adiabatically to the inlet of the low-level liquid turbine 2 under the joint action of gravity and pressure difference. As the height decreases in the gravitational field, the gravity The potential energy decreases, the pressure gradually increases, and the temperature rises; therefore, an ultra-high pressure liquid working fluid enters the low-level liquid turbine 2, and its liquid pressure can be released to do work externally, and at the same time the pressure is reduced to high pressure, becoming a high-pressure working medium; the high-pressure working medium continues to flow into the low-level evaporation The evaporating and he...

Embodiment 2

[0058] Embodiment 2, cascade type gravitational field acting device square, triangular circulation method, its mode of operation is as follows:

[0059] 2.1. In the gravitational field work subsystem of the first level (first level):

[0060] 1.1 with embodiment 1.

[0061] 2.2. In the gravitational field work subsystem of the same level except the first level:

[0062] The low-temperature and low-pressure saturated (or supercooled) liquid working medium flowing out from the condensation heat release channel of the high-level condenser 1 flows adiabatically to the inlet of the low-level liquid turbine 2 under the joint action of gravity and pressure difference. small, the gravitational potential energy decreases, the pressure gradually increases, and the temperature rises; therefore, an ultra-high-pressure liquid working fluid enters the low-level liquid turbine 2, releases its liquid pressure and can do work externally, and at the same time the pressure decreases to a high p...

Embodiment 3

[0068] Embodiment 3, the triangular cycle method of the cascading gravity field work device, its mode of operation is as follows:

[0069] 3.1. In the gravitational field work subsystem at the same level:

[0070] 2.2 with embodiment 2.

[0071] 3.2. In the interstage circulation system:

[0072] 1.2 with embodiment 1.

[0073] 3.3, same as 1.3 of embodiment 1.

[0074] The cycle state of the refrigerant at each stage in Embodiment 3 is represented as a triangular cycle feature on the T-S diagram.

[0075] Take the two-stage cycle as an example; the calculation parameters of embodiment 3 are shown in Table 2 (for 1kgR22). The design conditions are: the average temperature of the high-temperature heat source is 65°C, and the average temperature of the low-temperature heat source is 10°C. The difference between the high level and the low level is 164.2 meters. The evaporation temperature of the first-level low-level evaporator is 60°C, and the working fluid is R22. The ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com