Self-balancing slurry harrowing and soil flatting operation machine for paddy field

A self-balancing, operating machine technology, applied in the direction of agricultural machinery and tools, agricultural, agricultural machinery, etc., can solve the problems that the operation cannot meet the predetermined requirements, the balance of the left and right horizontal directions of the whole machine cannot be controlled, and the operation efficiency is low. Consistent effect of rotary tillage depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

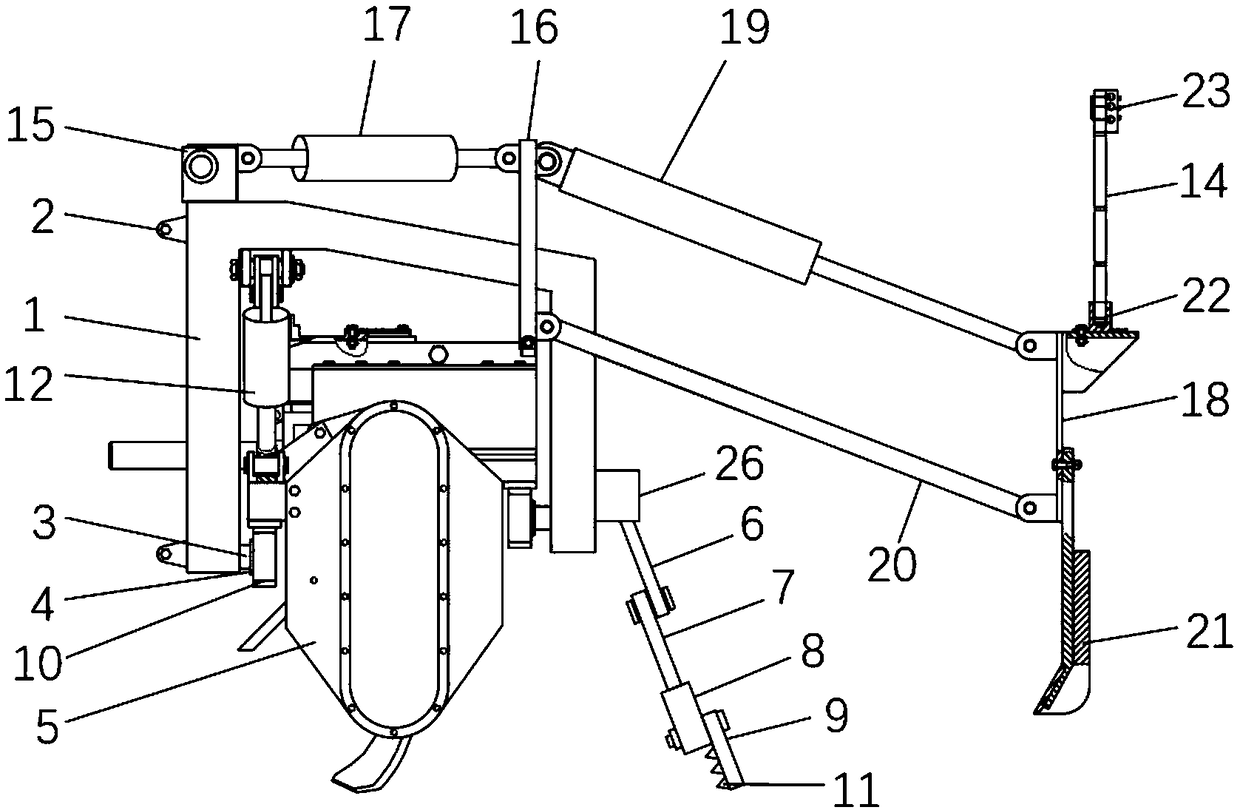

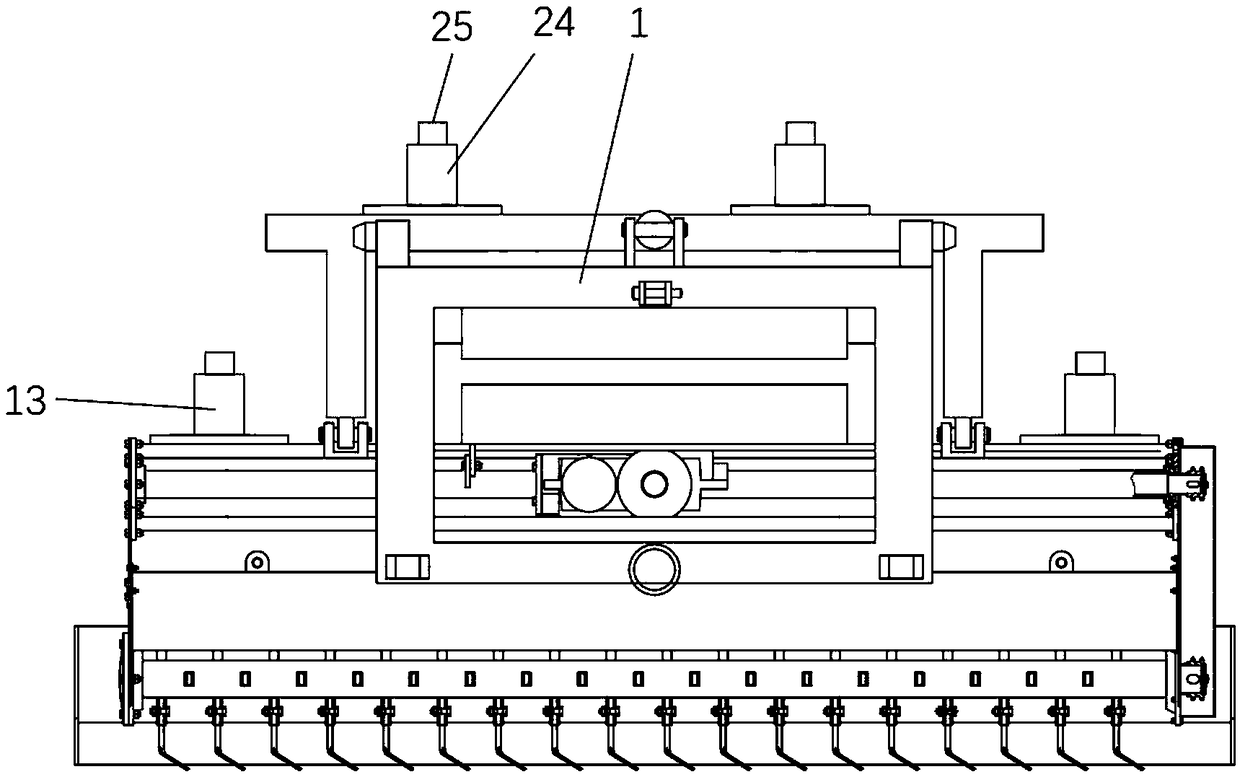

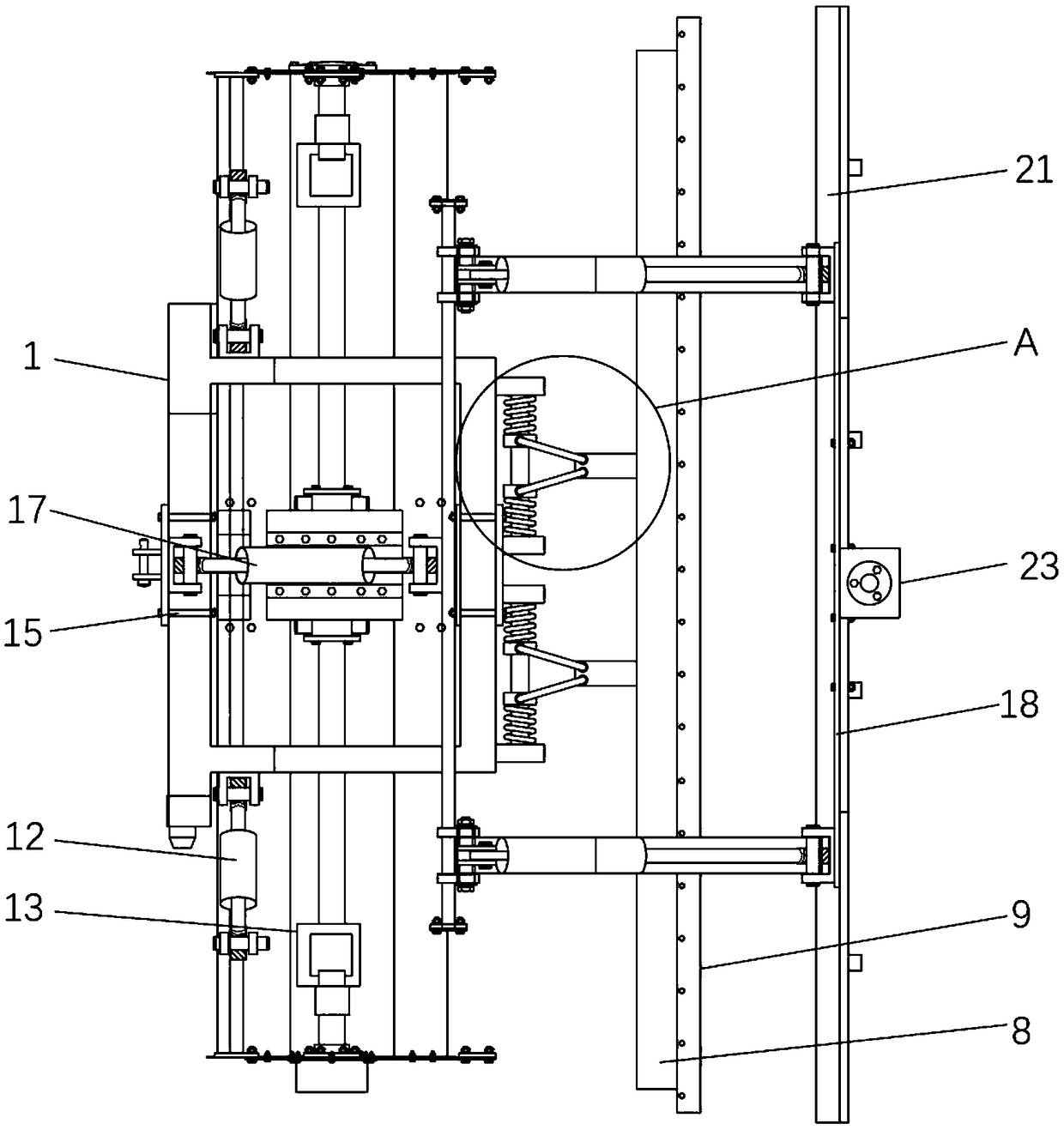

[0022] refer to Figure 1-4 , a self-balancing paddy field raking and leveling machine, comprising a rotating bracket 1, a raking machine 5, a bearing seat 10 is installed under the middle part of the front beam of the raking machine 5, and a three-point suspension 2 is welded to the front end of the rotating bracket 1 and connected to a tractor The rotating shaft 3 is welded in the middle of the front and rear beams below the rotating bracket 1, and each rotating shaft 3 is interference-fitted with a tapered roller bearing 4. The tapered roller bearing 4 is installed in the bearing housing 10. The tapered roller bearing mainly It is used to bear combined radial and axial loads, mainly radial loads. Compared with angular contact ball bearings, it has larger load capacity and lower limit speed. The tapered roller bearing can bear the axial load in one d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com