Manufacturing method for titanium alloy large-specification ring piece with basket-weave microstructure

A technology of mesh basket structure and manufacturing method, applied in metal rolling, manufacturing tools, metal rolling and other directions, can solve the problem of not giving full play to the needs of durability and creep performance, shorten the holding time, improve the comprehensive performance, The effect of lasting resistance increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

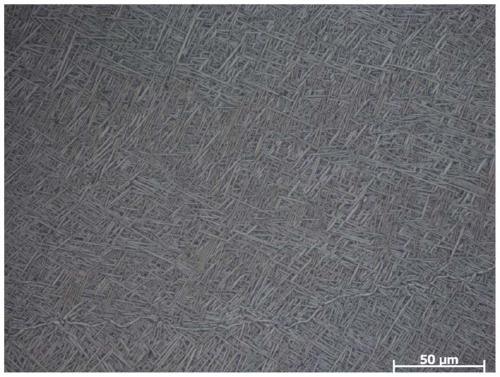

Embodiment 1

[0036] The raw material is Ф300×400mm TC17 titanium alloy bar. The weight percentages of the alloy components are Al: 5.00%, Cr: 4.01%, Zr: 1.98%, Mo: 3.81%, Sn: 2.00%, Fe: 0.06% , C: 0.02%, H: 0.005%, O: 0.056%, N: 0.006%, the balance is Ti and other unavoidable impurity elements, the β phase transformation point of the alloy ingot detected by metallographic method is 905℃; bar structure It is a two-state structure, the volume fraction of the primary α phase is about 40%, and the low-magnification structure is fuzzy crystals.

[0037] The preparation process of the ring is as follows:

[0038] 1) Preparation of ring-rolled billet: heat the billet to 875°C, and perform upsetting and punching on a hydraulic press in turn after holding the temperature for 240 minutes to obtain a ring billet with an outer diameter of 410mm, an inner diameter of 130mm, and a height of 200mm. The upsetting deformation is 50%, the deformation rate is 0.067s -1 ; Reshape the blank after punching;

[0039]...

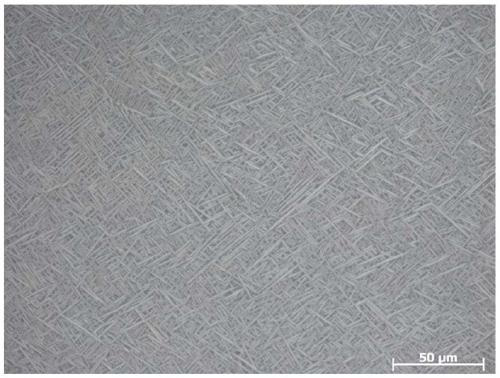

Embodiment 2

[0045] The raw material is made of TC17 titanium alloy bar with a specification of Ф300×500mm. The weight percentages of the alloy components are Al: 5.05%, Cr: 3.98%, Zr: 2.00%, Mo: 3.86%, Sn: 1.98%, Fe: 0.05% , C: 0.017%, H: 0.008%, O: 0.07%, N: 0.005%, the balance is Ti and other unavoidable impurity elements, the β phase transformation point of the alloy ingot detected by metallographic method is 905℃; bar structure It is a two-state structure, the volume fraction of the primary α phase is about 40%, and the low-magnification structure is fuzzy crystals.

[0046] The preparation process of the ring is as follows:

[0047] 1) Ring-rolled billet preparation: The billet is heated to 875°C, and then upset and punched in a hydraulic press after 240 minutes of holding time to obtain a ring billet with an outer diameter of 470mm, an inner diameter of 130mm, and a height of 200mm. The upsetting deformation is 60 %, the deformation rate is 0.08s -1 ; Preferably, the blank is shaped aft...

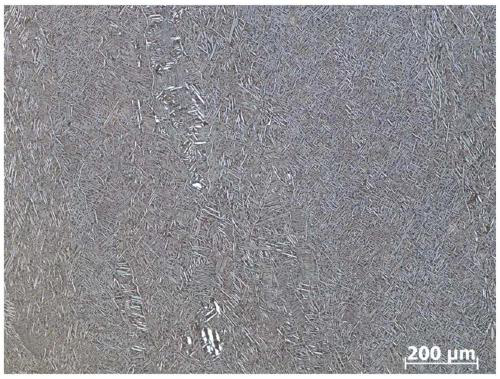

Embodiment 3

[0054] The raw material is Ti6246 titanium alloy bar with a specification of Ф300×400mm. The weight percentage of each component of the alloy is Al: 6.1%, Sn: 2.0%, Zr: 4.01%, Mo: 6.02%, Fe: 0.04%, C: 0.005% , H: 0.006%, O: 0.07%, N: 0.005%, the balance is Ti and other unavoidable impurity elements, the metallographic method detects the β phase transition point of the alloy ingot is 937℃; the bar structure is a dual-state structure, The volume fraction of primary α phase is about 40%, and the low-magnification structure is fuzzy crystals. The preparation process of the ring is as follows:

[0055] 1) Preparation of ring-rolled billet: heat the billet to 907°C, hold for 240 minutes and then perform upsetting and punching in a 2000t hydraulic press to obtain a ring billet with an outer diameter of 410mm, an inner diameter of 130mm and a height of 200mm. The upsetting deformation is 50%, the deformation rate is 0.07s -1 ; Preferably, the blank is shaped after punching;

[0056] 2) H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com