Valve seat structure of fluid control valve

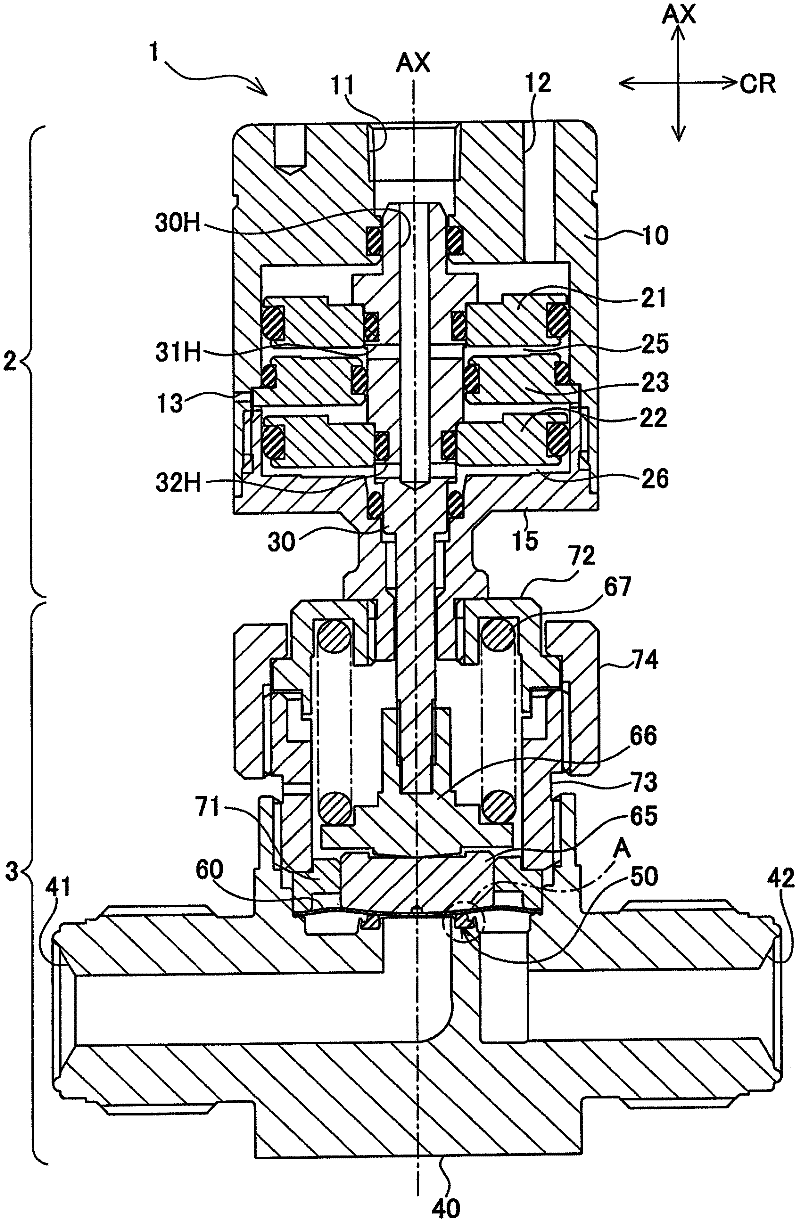

A technology for fluid control valves and valve seats, which is applied in the direction of lift valves, diaphragm valves, valve devices, etc., can solve the problem of uneven fluid flow, achieve the effect of suppressing flow fluctuations and reducing flow fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

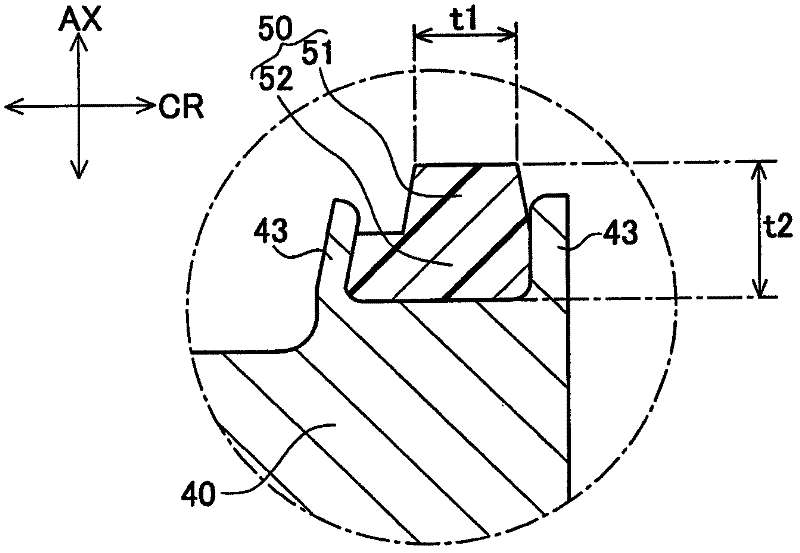

Embodiment 1

[0100] Embodiment 1 is the second wall thickness t2 such as figure 2 In the case of the valve seat member 50 shown in the shape of t2=1.25t1, specifically, for example, if the wall thickness (first wall thickness) of the valve seat portion 51 is set to t1=1.2 (mm), the valve seat member 50 A case where the height (second wall thickness) t2 = 1.5 (mm).

[0101] In Embodiment 1, the gas control valve 1 is in the closed state. After the valve is opened, the high-temperature gas continues to flow from the input port 41 through the valve chamber to the output port 42 for a long time. When a predetermined time has elapsed after the valve is opened, The stroke St of the diaphragm valve element 60 and the valve seat portion 51 of the valve seat member 50 when fully open and the Cv value at this time were measured.

[0102] Figure 5 It is a table about the relationship between the time after valve opening and the flow rate of flowing high-temperature gas comparing the valve seat st...

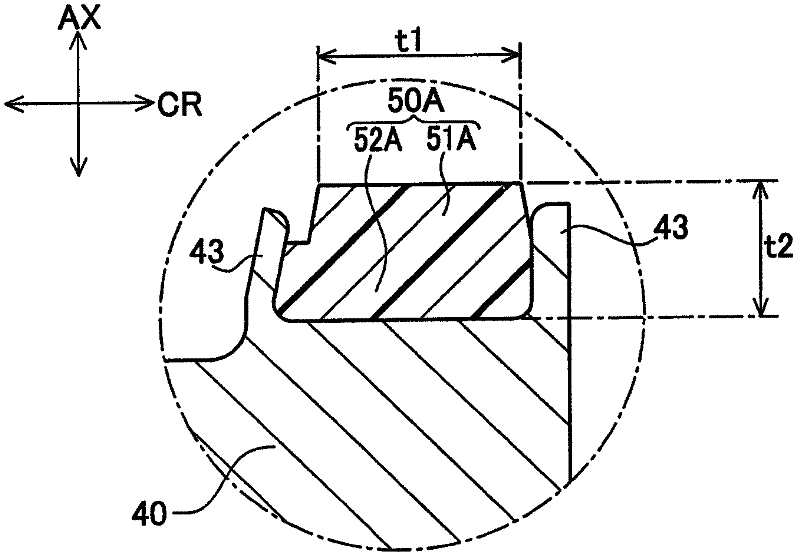

Embodiment 2

[0121] Same as Example 1, such as image 3 As shown, in the valve seat member 50A of the second embodiment, the fixed portion 52A is disposed between the grip portions 43, 43, and the grip portion 43 on the radially inner side in the radial direction CR and the grip portion 43 on the radially outer side face each other. The direction of caulking is carried out, thereby clamping along the radial direction CR and being fixed to the valve body 40 .

[0122] In this example, if image 3 As shown in the shape of the valve seat member 50A, when the second wall thickness t2 is t2=0.63t1, specifically, for example, if the wall thickness of the valve seat portion 51A is t1=2.2 (mm), the height of the valve seat member 50A is It is t2=1.5 (mm). In this case, the sinking amount of the valve seat portion 51A is 0.13 mm, and the restoring amount of the valve seat portion 51A is 0.10 mm.

[0123] In addition, as a modified example of Embodiment 2, Figure 4 An explanatory diagram showin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com