Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86results about How to "Small temperature error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Temperature conversion method and a low-power high-precision integrated temperature sensor

ActiveCN104390715ASimple structureReduce power consumptionThermometers using electric/magnetic elementsUsing electrical meansCapacitanceEngineering

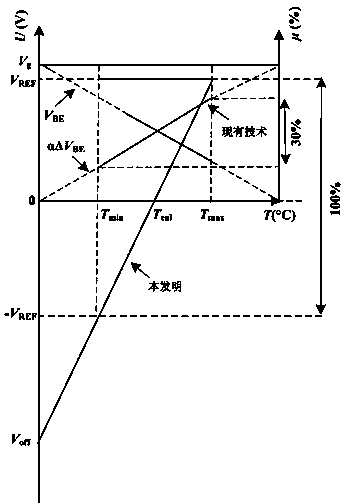

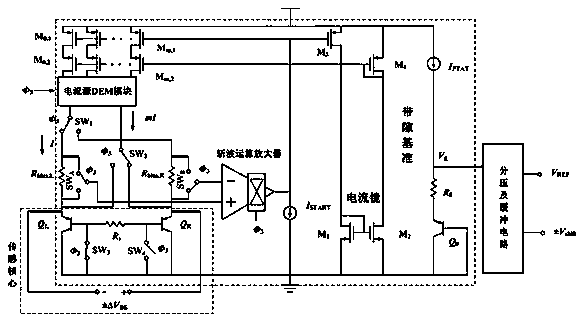

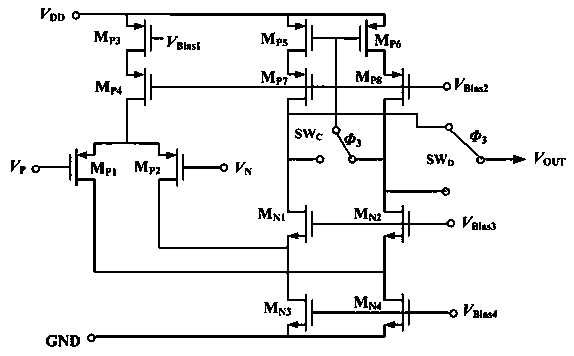

The invention relates to a temperature conversion method and a low-power high-precision integrated temperature sensor. The low-power high-precision integrated temperature sensor is composed of a band gap reference circuit with a sensing core, a positive and negative synchronous switch capacitor integral circuit, a current source and a sampling capacitor dynamic element matching module, a clock generating circuit, a divider and buffer circuit and a fully differential analog-to-digital converter. The sensing core circuit in the traditional technology and the band gap reference circuit are combined and integrated, so that the circuit structure is simplified; the current source dynamic element matching module is arranged and thus a base-emitter junction voltage difference in proportion to the absolute temperature is generated, wherein the polarity of the voltage difference changes alternately; with the novel positive and negative synchronous switch capacitor integral circuit, the improved temperature conversion function is completed and the dynamic range utilization rate of the analog-to-digital converter is improved; dynamic element matching is carried out on the sampling capacitor, thereby improving the integral accuracy; and the analog-to-digital converter is used for carrying out quantization processing on an effective temperature signal to provide a digital output. Therefore, the temperature error and circuit power consumption of the sensor can be effectively reduced; and the method and the sensor are suitable for the low-power high-precision temperature sensing application.

Owner:沈阳恒久安泰环保与节能科技有限公司

Super plastic forming method for plate type heat converter special titanium plate

InactiveCN101121178AHigh yield strengthEasy to processRoll mill control devicesFurnace typesPlate heat exchangerTitanium

The present invention relates to a superplastic forming method for the titanium plate specially used for the plate type heat exchanger, which belongs to the field of mechanical processing technology. The present invention comprises the following steps that spongy titanium is chosen to be the melted raw material; the spongy titanium is placed in a vacuum plasma smelting furnace to be directly cast into plate base; the plate base forms a plate of a thickness of 2.0 to 2.4 mm after the process of heating, hot rolling, acid and alkali washing; second heating, hot rolling and acid and alkali washing and annealing; the plate of a thickness of 2.0 to 2.4 mm after the annealing in the vacuum smelting furnace forms a titanium plate of a thickness of 0.5 to 0.6 mm after the process of cold rolling, cleaning, second annealing and cold rolling, acid and alkali washing and third annealing. The present invention adopts the process that the spongy titanium which contains oxygen, iron and nitrogen of comparatively high content is directly processed into the titanium plate base in the plasma smelting furnace and directly rolled into the plate without forging and pressing.

Owner:上海桦厦实业有限公司

Construction monitoring method for exchanging course of half/through arch bridge suspender

InactiveCN101016728AEnhanced identification of structural parametersSmall temperature errorBridge erection/assemblyBridge strengtheningRelative displacementStructural stress

The invention relates to a construction detection used in the hanger rod exchange of middle and lower arc bridges. The invention comprises that building arc bridge spatial reference limit model, analyzing the force state of bridge, simulating the whole construction, the construction uses arc bridge three-dimension position detection, bridge sink detection, displacement detection between arc rib and beam, hanger rod force detection, structural stress detection and long-time detection, then comparing the data of detection with the reference limit model, to correct the model, to be used in next reference limit model. The invention can confirm the flexibility less than theory value and confirm the hang force in design range, to improve safety or the like.

Owner:TONGJI UNIV +1

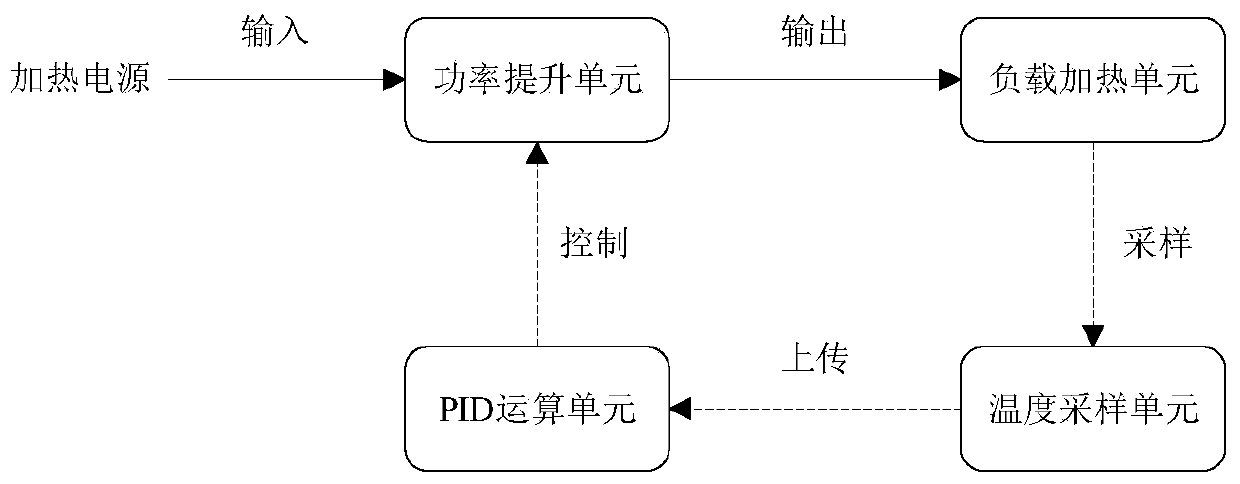

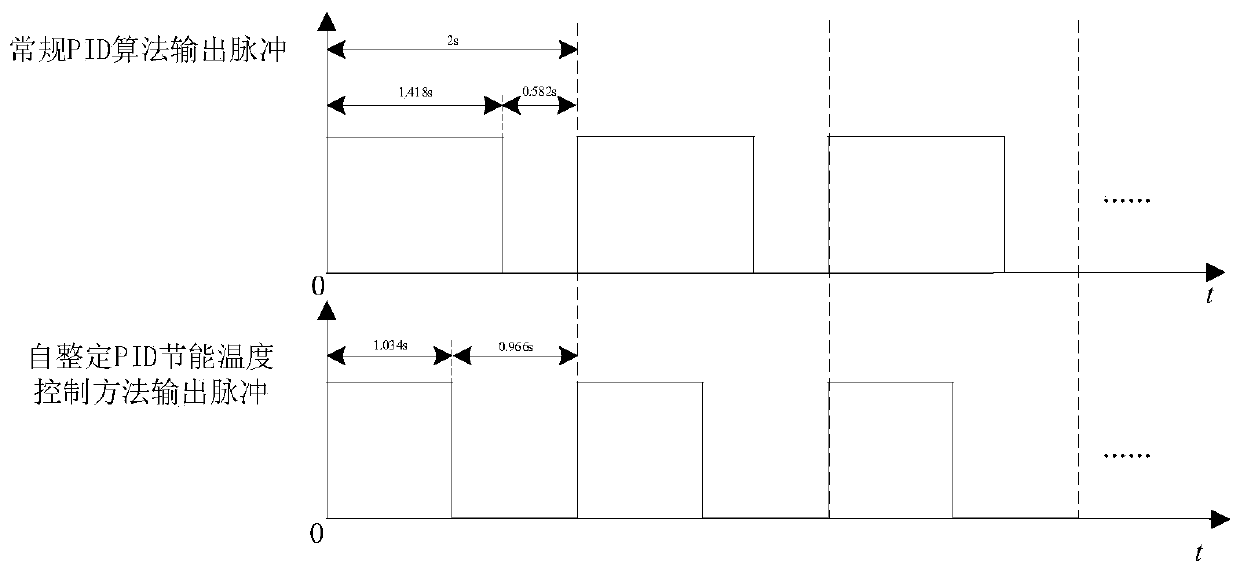

Self-tuning PID energy-saving temperature control method and module

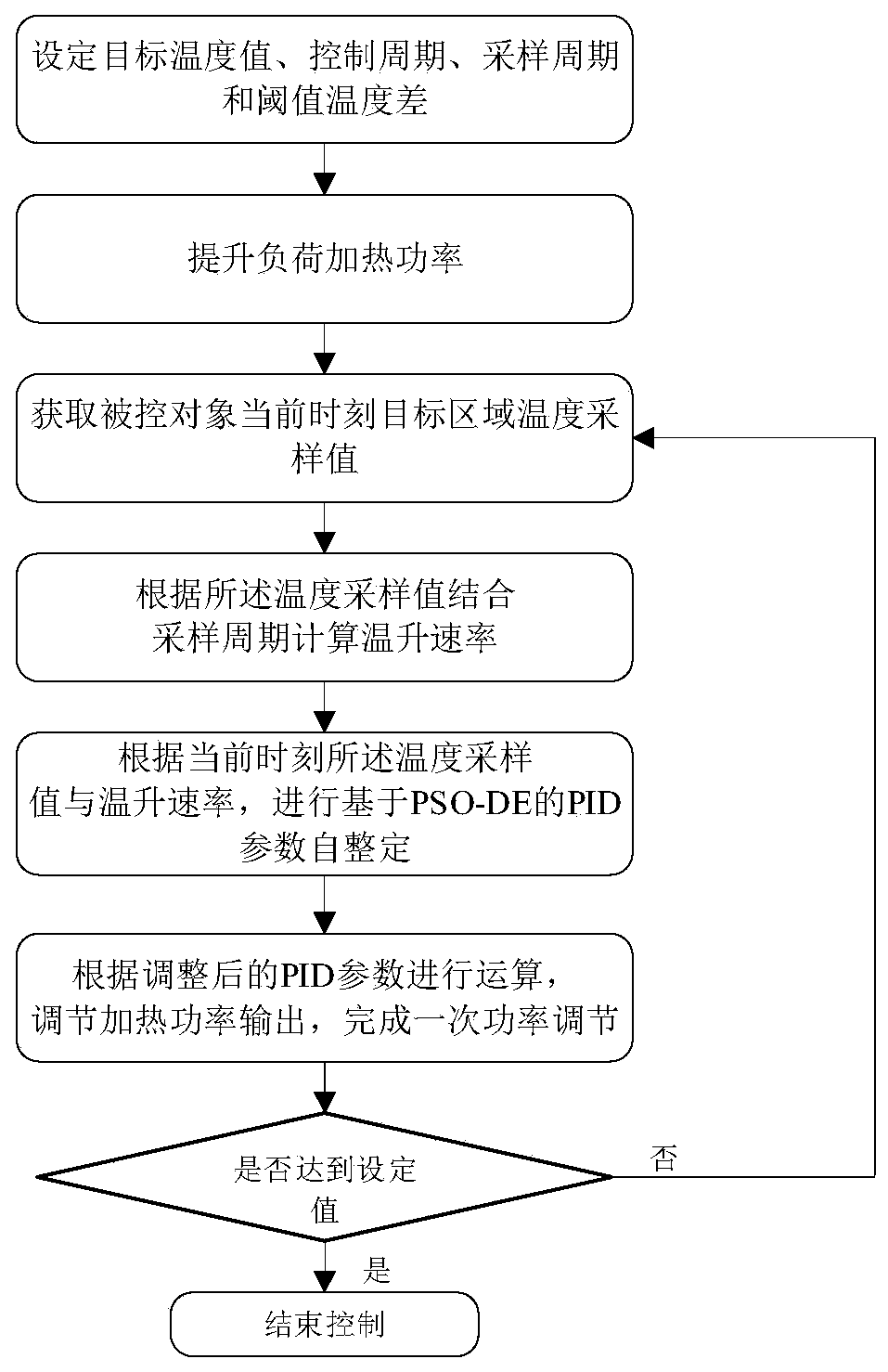

ActiveCN109839967ASmall duty cycleIncrease load heating powerTemperature control using electric meansEngineeringParticle swarm algorithm

The invention relates to a self-tuning PID energy-saving temperature control method. The method comprises the steps that a target temperature value, a control period, a sampling period and a thresholdtemperature difference are set first; load heating power is increased; the current regional temperature sampling value of a controlled object is acquired, and the sampling period is combined to calculate the temperature rise rate; a PSO-DE algorithm combining particle swarm optimization (PSO) and differential evolution (DE) is used to adjust and calculate PID control parameters; the duty cycle ofthe output pulse of a control period is adjusted according to the operation result; heating power output is adjusted, so that the sampled temperature sampling value is approximately equal to the actual temperature value of the controlled object; a temperature error caused by the heating inertia is reduced; heating power is accurately controlled; and the energy saving effect is obvious. A self-tuning PID energy-saving temperature control module comprises the self-tuning PID energy-saving temperature control method, can accurately control the heating power, and has an obvious energy-saving effect.

Owner:广东国颂能源科技有限公司

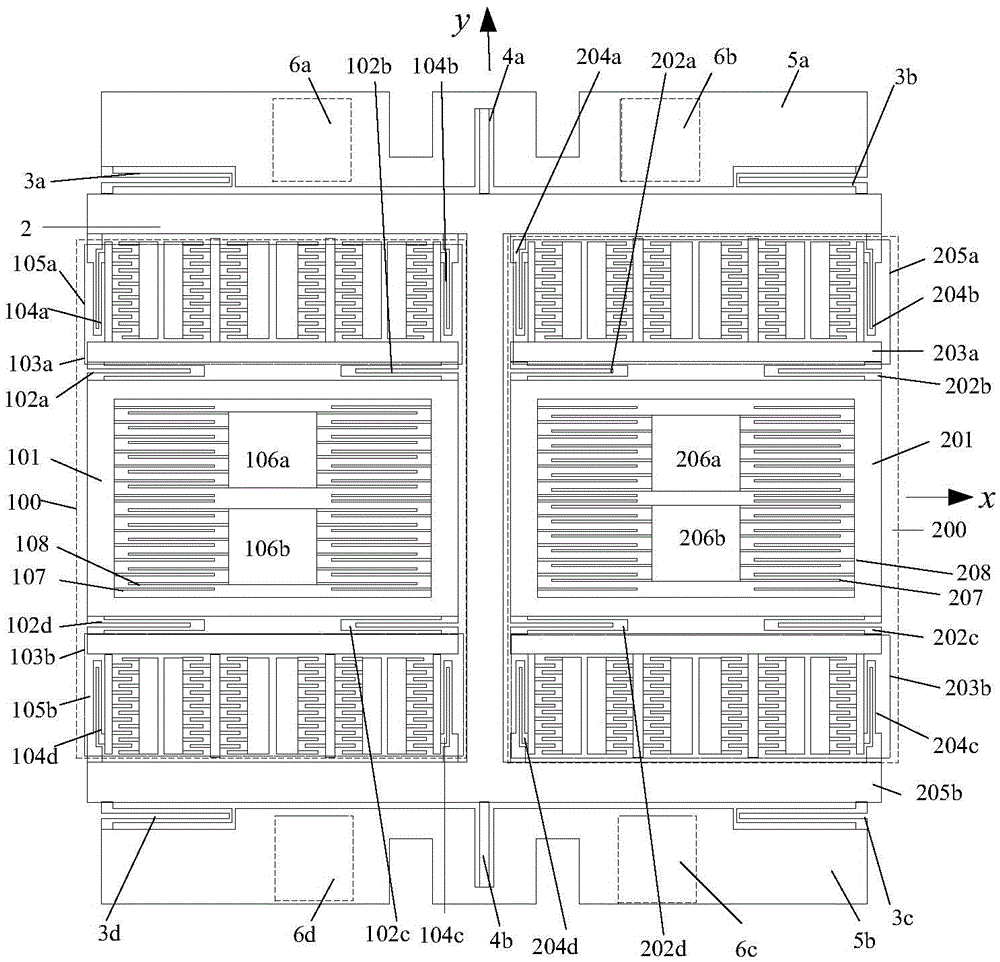

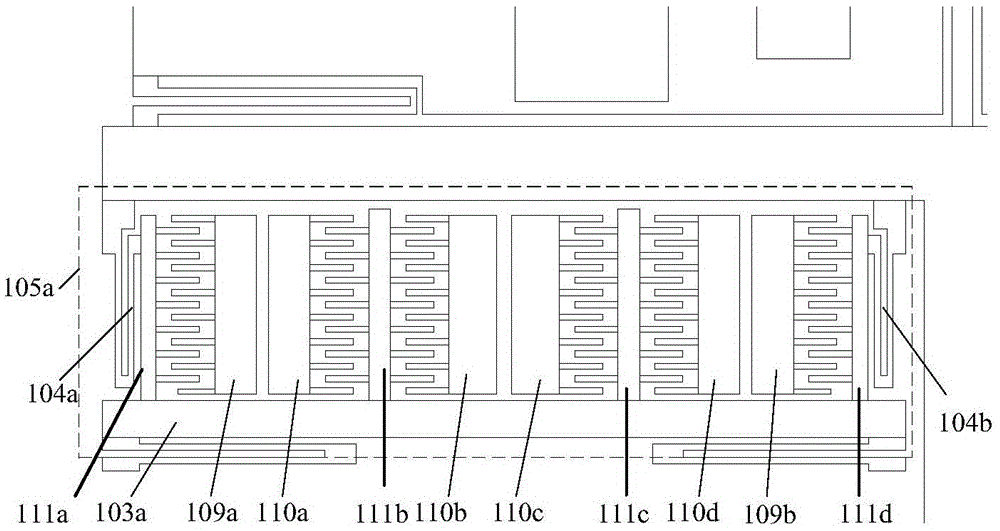

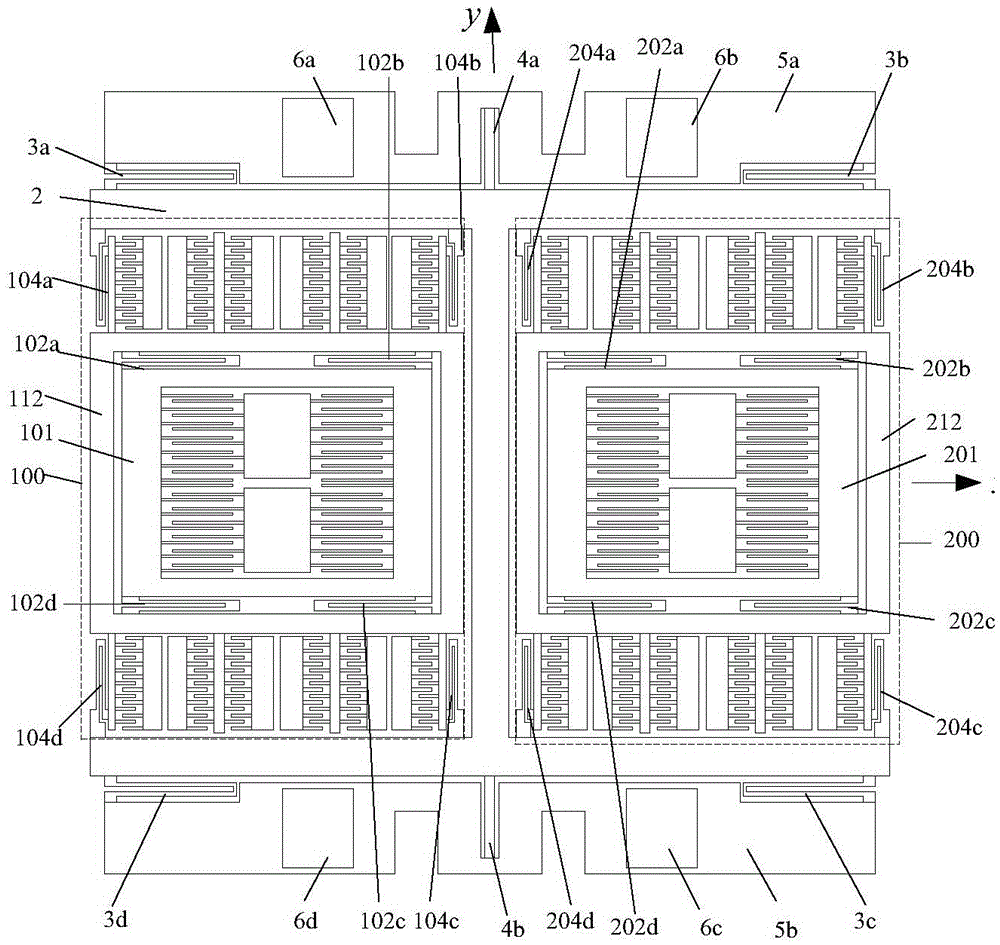

Silicon micromechanical vibrating gyroscope of I-shaped structure

ActiveCN105466406AImprove stabilityIncrease stiffnessSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesGyroscopeInter layer

The invention discloses a silicon micromechanical vibrating gyroscope of an I-shaped structure, which is used for measuring a measuring instrument vertical to the horizontal level of a base. The silicon micromechanical vibrating gyroscope is formed by upper-layer monocrystalline silicon, middle-layer monocrystalline silicon and lower-layer monocrystalline silicon, wherein the upper-layer monocrystalline silicon is a silicon micromachined gyroscope encapsulating cover plate with a signal input wire and a signal output wire; a gyroscope mechanical structure is formed on the middle-layer monocrystalline silicon; the lower-layer monocrystalline silicon is a gyroscope substrate provided with a fixed base; and the middle-layer monocrystalline silicon is sealed in a sealed cavity formed by the upper-layer monocrystalline silicon and the lower-layer monocrystalline silicon. The silicon micromechanical vibrating gyroscope is small in error, high in mechanical sensitivity, low in vibration sensitivity and low in temperature sensitivity, and can realize movement decoupling, violent vibration and detection output decoupling of a driving modal and a detection modal.

Owner:NANJING UNIV OF SCI & TECH

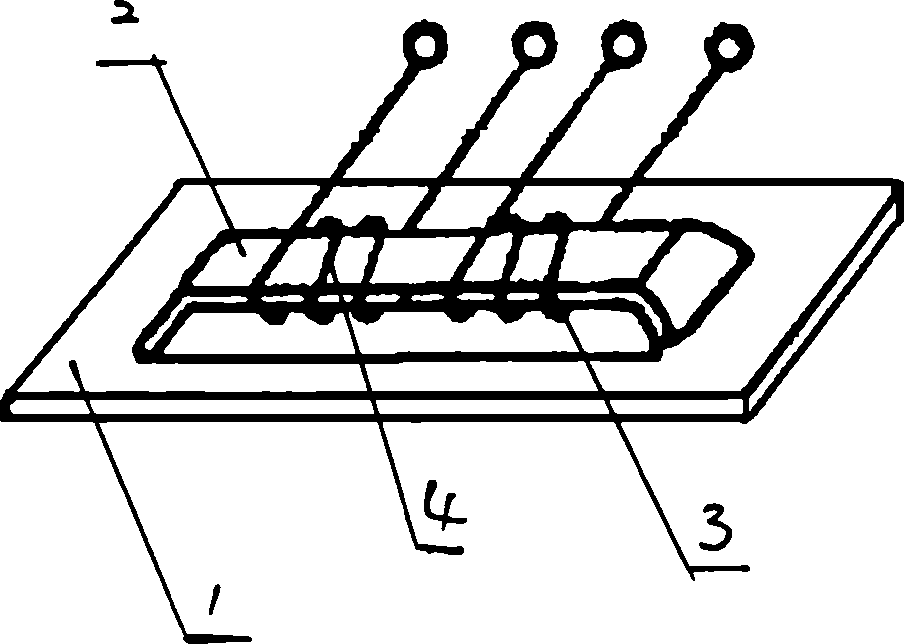

Strip-shaped jacketed oil-heat roller

ActiveCN102189743ASmall temperature errorEquilibrium Heat ReplacementRotary pressesPulp and paper industryBlind hole

The invention discloses a strip-shaped jacketed oil-heat roller, which comprises an inner pipe, an input shaft, an end cover, a partition plate, an inner cylinder, an outer cylinder, a strip, an inner ring plate, a ventilating pipe, a supporting shaft and a connecting pipe, wherein the input shaft is a hollow shaft, the jointing end of the input shaft and the connecting pipe is provided with a left radial hole and a right radial hole, and the inner pipe is inserted into the inner hole of the input shaft and connected with a step by crossing the left radial hole to form a bidirectional independent channel. The jointing end of the supporting shaft and the connecting pipe is provided with an axial blind hole channel which is communicated with the radial holes. The inner cylinder is connectedwith the input shaft and the supporting shaft through the inner ring plate, the baffle plate and the end cover; and a strip-shaped groove consisting of the strip is arranged in a jacket between the inner cylinder and the outer cylinder, and is communicated with an oil inlet cavity, an oil return cavity and the bidirectional independent channel through oil inlets at two ends of the wall of the inner cylinder and an oil return hole at one end of the wall of the inner cylinder. The strip-shaped jacketed oil-heat roller ensures that the error of a temperature on the surface of the roller is less than 5 DEG C through bidirectional equivalent heat exchange, thereby improving product quality. The invention is suitable for being matched with various specifications of rollers.

Owner:泰州科世茂工程设备有限公司

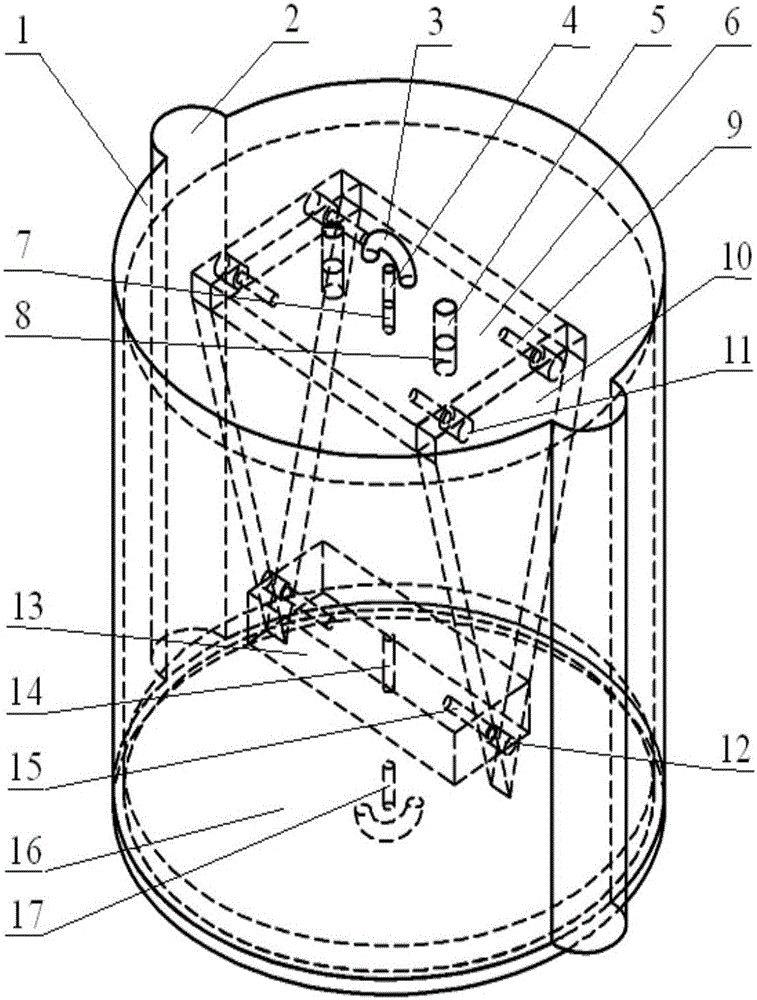

Distributed deformation measurement apparatus and method, fiber grating inclination angle sensor, and fiber grating inclination angle sensor structure

PendingCN105953751AImprove detection accuracySmall temperature errorUsing optical meansFiberEngineering

The invention discloses a distributed deformation measurement apparatus and method, a fiber grating inclination angle sensor, and a fiber grating inclination angle sensor structure. The fiber grating inclination angle sensor structure comprises a housing which is a hollow cylinder whose bottom end is open; a pair of constant-strength beams which are respectively disposed at opposite sides in the housing, wherein the opposite sides on the inner surfaces or the outer surfaces of the pair of constant-strength beams are provided with two fiber grating placement positions; and a weight which is arranged at the bottom of the housing and has two ends respectively fixed to the pair of constant-strength beams. According to the invention, since the fiber grating placement positions are arranged at the opposite sides, during deformation, one of the fiber grating placement positions is subjected to a positive strain effect and the other is subjected to a negative strain effect. Difference information of wavelength drift amounts of fiber gratings is taken as output signals, therefore, temperature errors in a detection process can be eliminated, and the detection precision of the fiber grating inclination angle sensor is improved.

Owner:WUHAN UNIV OF SCI & TECH

Non-consumable electrode arc hot wire additive manufacturing wire temperature detection control device and method

InactiveCN110524092ASimple structureExtended temperature detection rangeArc welding apparatusTemperature controlPower flow

The invention discloses a non-consumable electrode arc hot wire additive manufacturing wire temperature detection control method and device; the device comprises a temperature acquisition control device, a hot wire power supply and a welding power supply, and the temperature acquisition control device comprises an infrared temperature sensor, a hot wire temperature acquisition instrument, a hot wire temperature control instrument and a display. The infrared temperature sensor is fixed to a non-consumable electrode welding gun and connected with the display through the hot wire temperature acquisition instrument , and the hot wire temperature control instrument and the display are both connected with the hot wire power supply. The method has the following steps: comparing a difference deltaT' between a preset temperature T0 and the acquired temperature T1 with a preset difference delta T in the display via the hot wire temperature control instrument, and adjusting the heating current of the hot wire power supply in time to stabilize the heating temperature of the wire at the preset temperature; according to the method and device, the stable detection and control of the wire temperature in the plasma arc hot wire additive manufacturing process can be realized, and the stability of a stacking process and the forming size precision and quality of an additive member are effectivelyimproved.

Owner:NANJING UNIV OF SCI & TECH

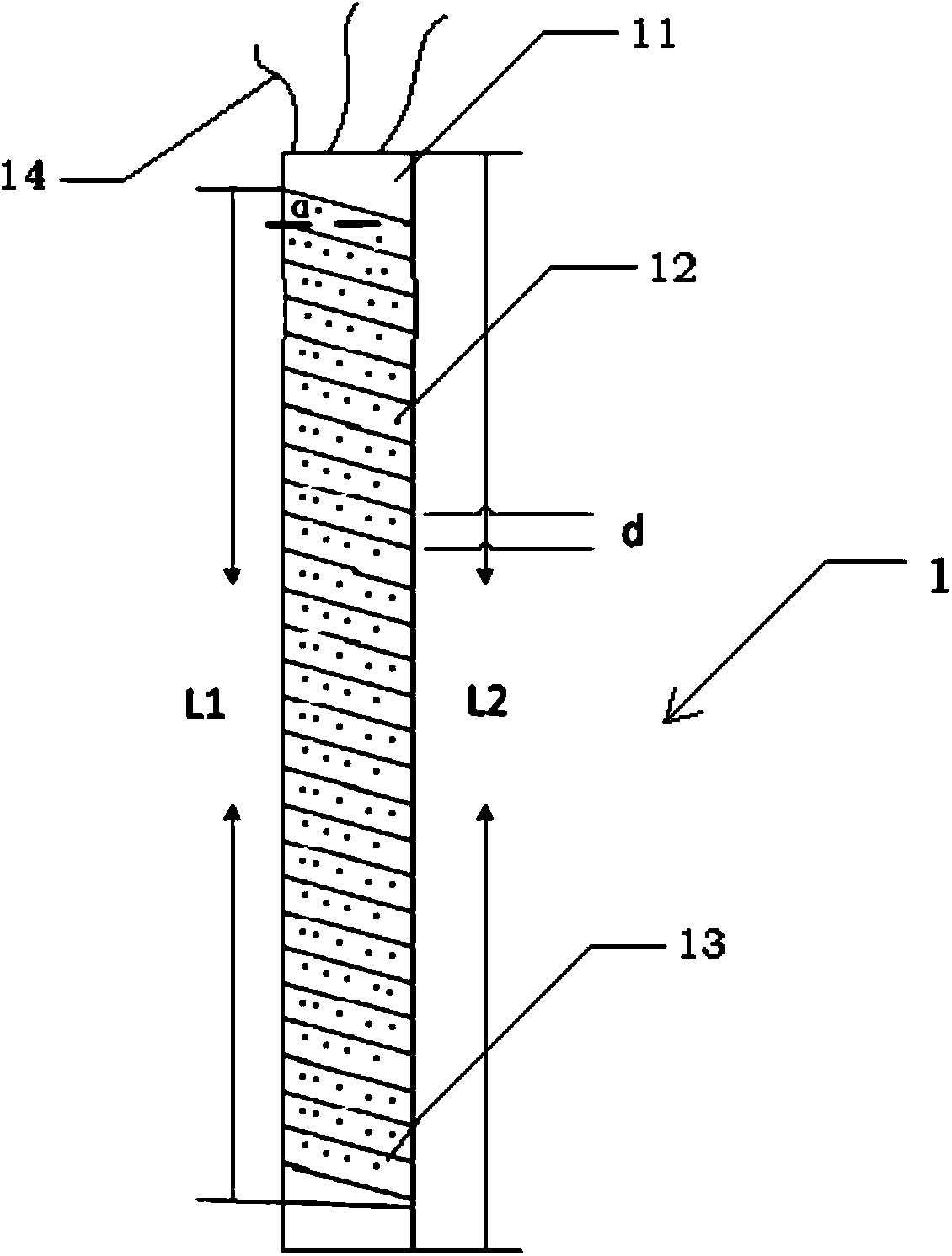

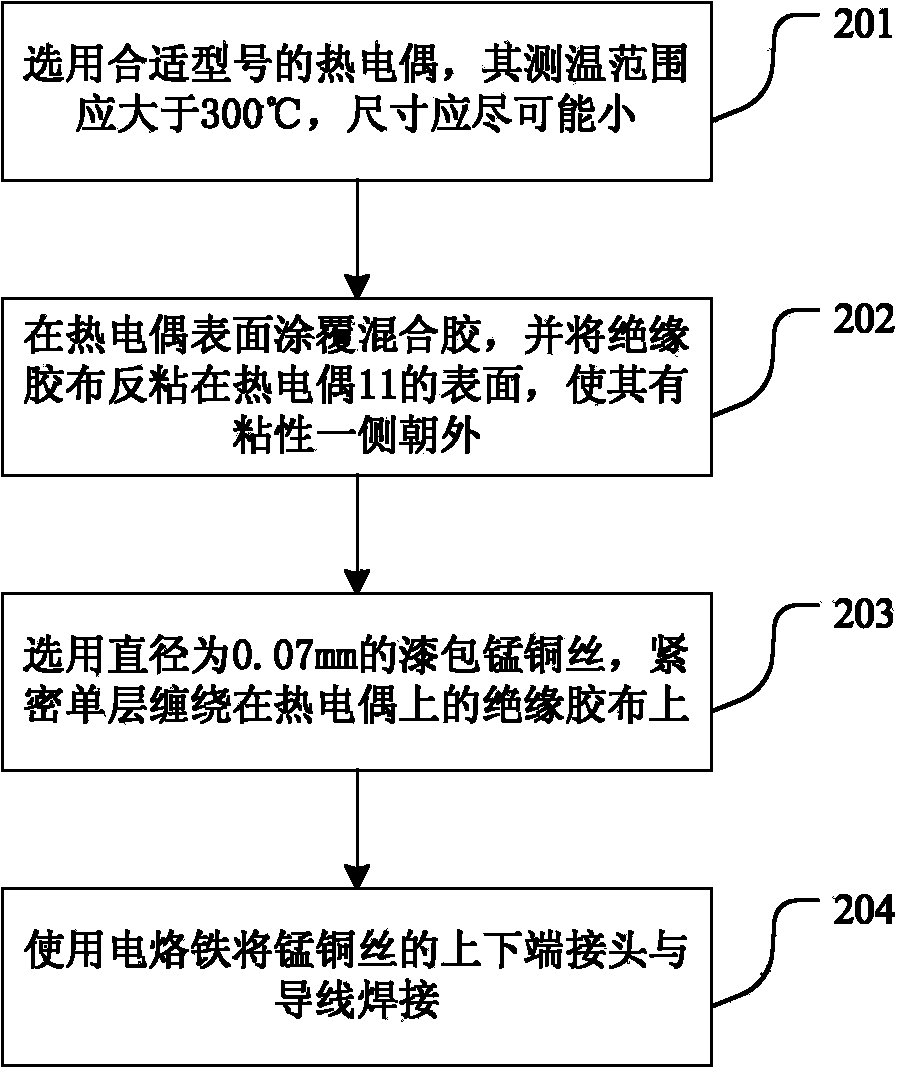

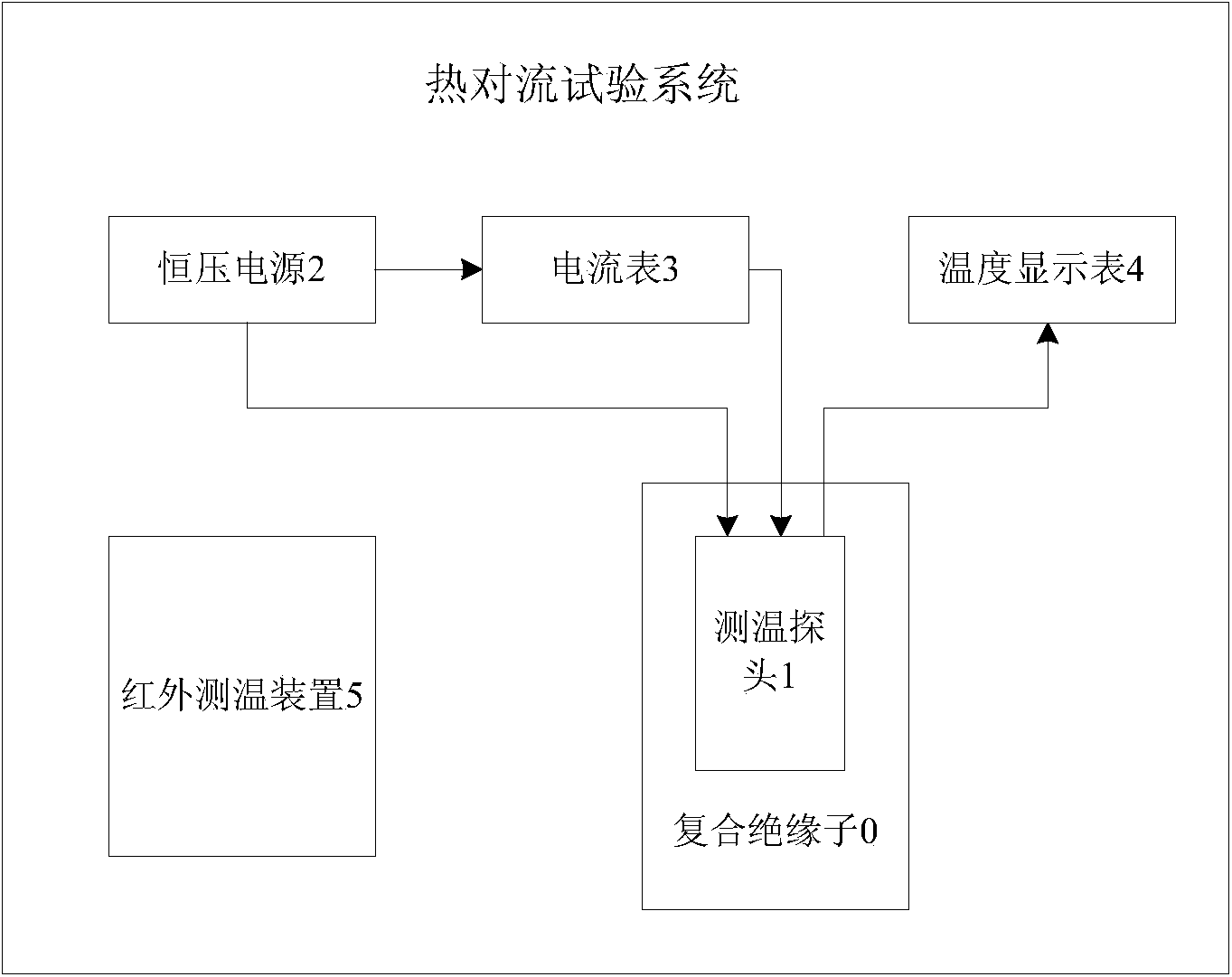

Heat convection testing method and system for composite insulator including artificial defect

InactiveCN103941126AReduce the chance of damageAvoid disconnectionThermometer detailsThermometers using electric/magnetic elementsInternal temperatureEngineering

The invention provides a heat convection testing method and a system for a composite insulator including an artificial defect. The testing method comprises the steps of fixedly embedding a temperature measuring probe in the composite insulator and enabling the temperature measuring probe to be located on the junction face of a silicone rubber sheath and an epoxy resin core rod; adopting a direct current constant voltage source to perform power supply for the resistance defect of the composite insulator; utilizing the temperature measuring probe to perform real-time detection on the internal temperature of the composite insulator in the power supply process, recording the internal defect temperatures under different currents and using an infrared temperature measurement device to shoot and record the surface temperature distribution situation of the composite insulator; and performing compilation and analysis on recorded data to obtain the relation of the outer surface temperature rise and internal actual temperature rise of the composite insulator. The temperature measuring probe improvable in temperature and a special fixing method are adopted, reliable connecting strength, insulating strength and heating power can be achieved, and the measurement accuracy is finally ensured.

Owner:SHENZHEN POWER SUPPLY BUREAU

Pressure sensor with double redundancies and high reliability

InactiveCN101718606AReduce volumeReduce weightFluid pressure measurement using ohmic-resistance variationWhole bodySilica gel

The invention relates to a pressure sensor with double redundancies and high reliability, which comprises a pressure conversion joint, two silicon pressure sensitive cores, two compensation circuits of the silicon pressure sensitive cores, two electric signal amplification processing boards, a stainless steel shell, an electric connector and potting silica gel, wherein the two silicon pressure sensitive cores are welded in the pressure conversion joint; the two compensation circuits of the silicon pressure sensitive cores are respectively connected with the two silicon pressure sensitive cores through connecting cables; the two electric signal amplification processing boards are respectively connected with output signals of the two compensation circuits of the silicon pressure sensitive cores; processing signals of the electric signal amplification processing boards are transmitted out from the aerial electric connector through the output ends of the circuits; the pressure conversion joint, the stainless steel shell and the aerial electric connector are welded into a whole body; and the silica gel is potted in the whole body. The invention has the advantages of small volume, light weight, full stainless steel watertight structure, pressure resistance, salt mist prevention, electromagnetic interference resistance, overpressure impact resistance, high frequency response, high comprehensive precision, small temperature error and the like.

Owner:李维平 +2

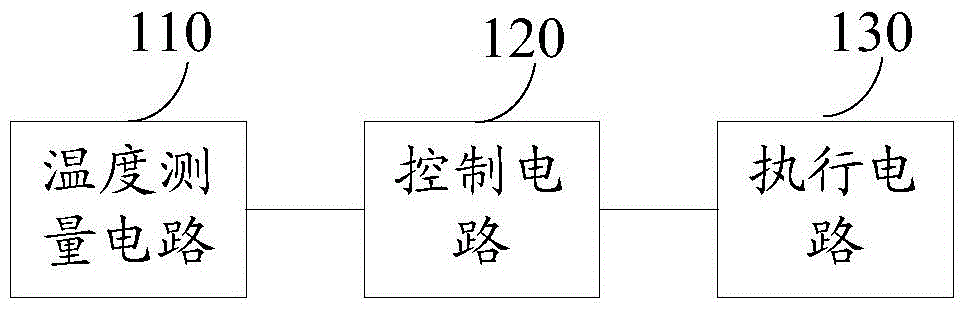

Temperature control system

ActiveCN105652919AHigh precisionImprove accuracyTemperatue controlHeating timeTemperature measurement

The invention relates to a temperature control system comprising a temperature measuring circuit, a control circuit, and an execution circuit. The temperature measuring circuit is used for carrying out periodic measurement on a temperature of a target object, generating a voltage signal, and outputting the signal. The control circuit connected with the temperature measuring circuit is used for receiving the voltage signal, obtaining a current temperature value of the target object based on the voltage signal, and setting heating time based on a preset target temperature value and the current temperature value, wherein the heating time is less than or equal to a measurement period of the temperature measuring circuit. The execution circuit connected with the control circuit is used for controlling a heating device to carry out heating according to the heating time, thereby realizing temperature adjustment of the target object. The temperature control system can detect the temperature of a target object periodically and set the conduction time of the heating device within the measurement period based on the detection time, thereby realizing temperature adjustment. The output is adjusted correspondingly with the temperature change of the target object, so that the temperature adjustment precision is improved and the temperature error is reduced.

Owner:SHENZHEN COMEN MEDICAL INSTR

Optical distance measuring device and manufacturing method therefor

InactiveCN101078771AReduce light transmission lossLow refractive indexElectromagnetic wave reradiationRefractive indexFirst light

The present invention provides an optical distance measuring device and manufacturing method therefor. In the optical distance measuring device of the invention, a second optical path is formed by a transparent resin formed in a region where a light emitting element and a second light receiving part are connected directly to each other. As the temperature increases, the length of the optical path increases while its refractive index decreases, so that the optical path length itself becomes generally constant. Therefore, the length of the second optical path can be kept generally constant independently of temperature. Further, a first light receiving part for a first optical path and a second light receiving part for the second optical path 18 are formed in one identical light receiving element. Therefore, characteristic variations of the first light receiving part and the second light receiving part due to temperature can be reduced. This optical distance measuring device can achieve high distance measuring accuracy even under environments of intense temperature changes.

Owner:SHARP KK

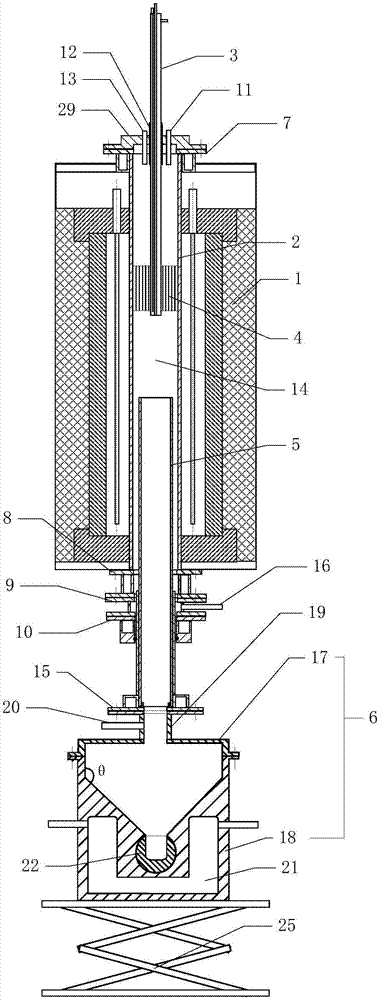

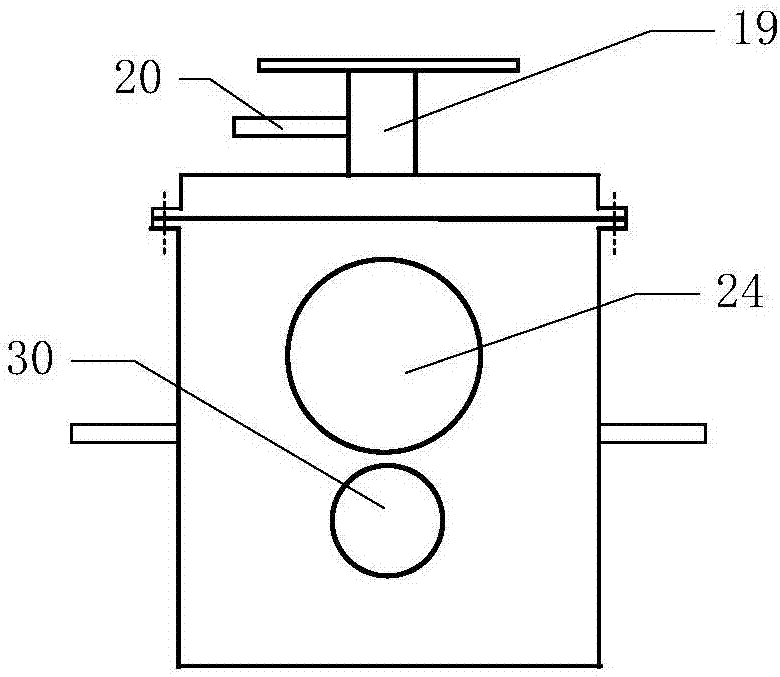

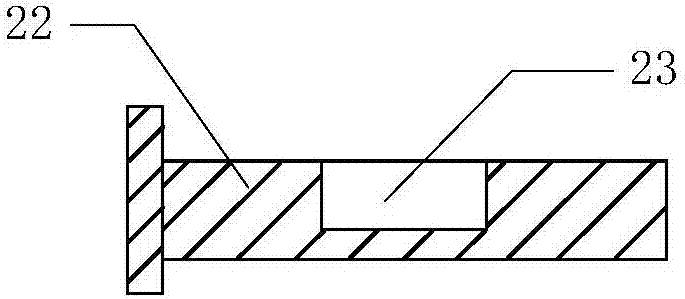

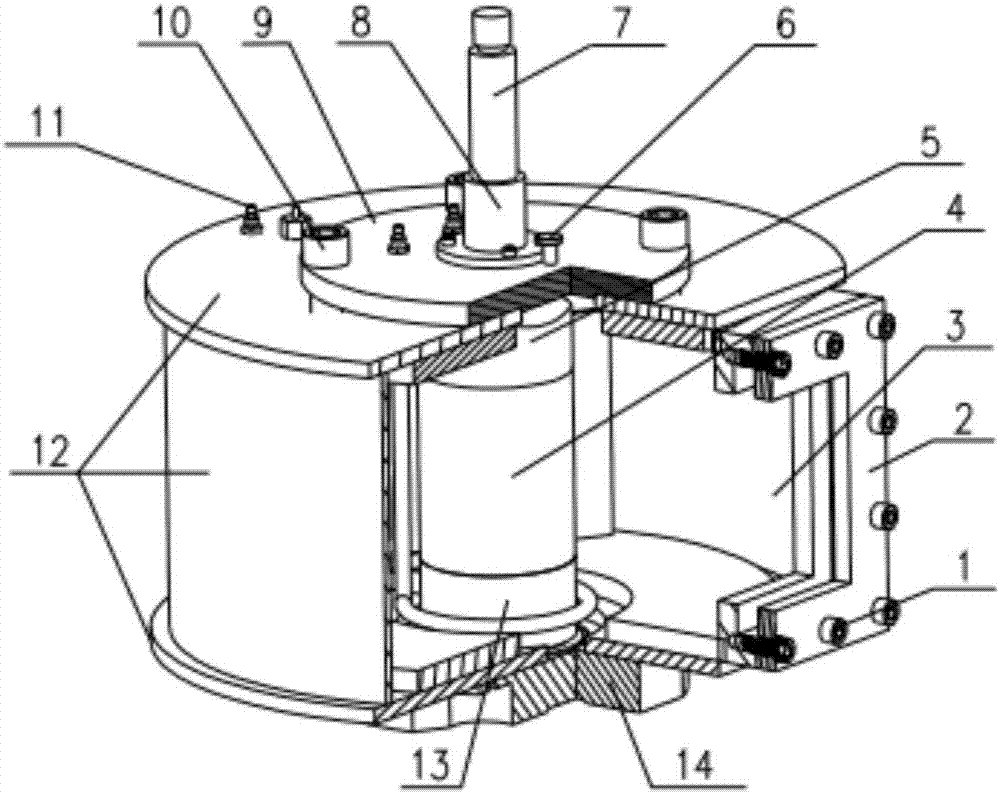

Force-thermal coupling loading system for superconducting materials under ultra-low varying temperature environment

InactiveCN106018071AReliable experimental conditionsWide temperature rangeStrength propertiesHuman–machine interfaceEngineering

A force-thermal coupling and loading system for superconducting materials under an ultra-low varying temperature environment comprises a testing machine, a refrigerator, a heating unit and a temperature control unit, wherein the testing machine is an electronic universal testing machine; the electronic universal testing machine uses a cooled cryostat which is in a double vacuum mode; the inside of the cooled cryostat is connected with a vacuum pump through a vacuum pipe assembly; an observation window is further formed in the front of the cooled cryostat; the refrigerator is mounted on the back of the cooled cryostat; refrigeration is carried out in a multi-stage refrigerating head mode; the heating unit comprises a heater, a temperature controller and a temperature sensor; and the temperature control unit comprises an intelligent PID (proportion integration differentiation) regulating and controlling unit, a central arithmetic unit and a human-machine interface (HMI). The force-thermal coupling loading system can be used for testing the performance of the superconducting materials under the ultra-low or varying temperature environment, and has the advantages of large temperature range, small temperature errors, good testing precision, high stability and good simplicity in operation.

Owner:LANZHOU UNIVERSITY

Amorphous alloy strain gauge

InactiveCN1888841AHigh measurement sensitivitySmall temperature errorForce measurement by measuring magnetic property varationMagnetic polesStrain gauge

The middle of amorphous alloy thin strip heaves to one side and forms arch bridge type magnetic pole of a kind of amorphous alloy strain gauge. The bridge of magnetic pole parallel winds along the body of amorphous alloy thin strip and the height of heave is h, 0<h<0.5mm.There are excitation loop and measure loop enlace on the pole side by side and the magnetic field intensity is 0.01-0.05A / mm of the excitation loop. The amorphous alloy strain gauge adheres strongly on surface to measuring material so it takes distortion with measuring work piece along the portrait at the same time. It arouses the change of iron core magnetism conductance and inductance value to finish the test of piece. It utilizes well soft magnetism characteristic and steady temperature capability of amorphous alloy, so it is fit for testing tiny force and displacement with high testing sensitivity. Its temperature error is small and testing circuit is easy to be used in abominable condition with long using life.

Owner:HUAIHAI INST OF TECH

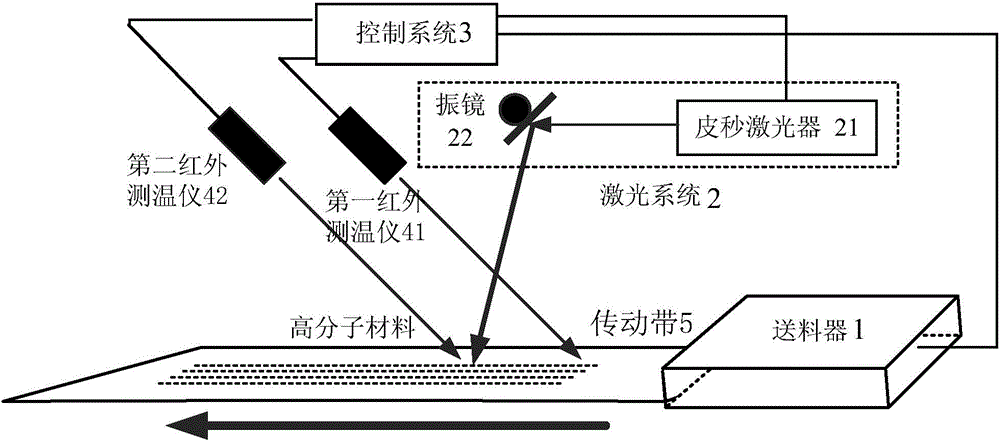

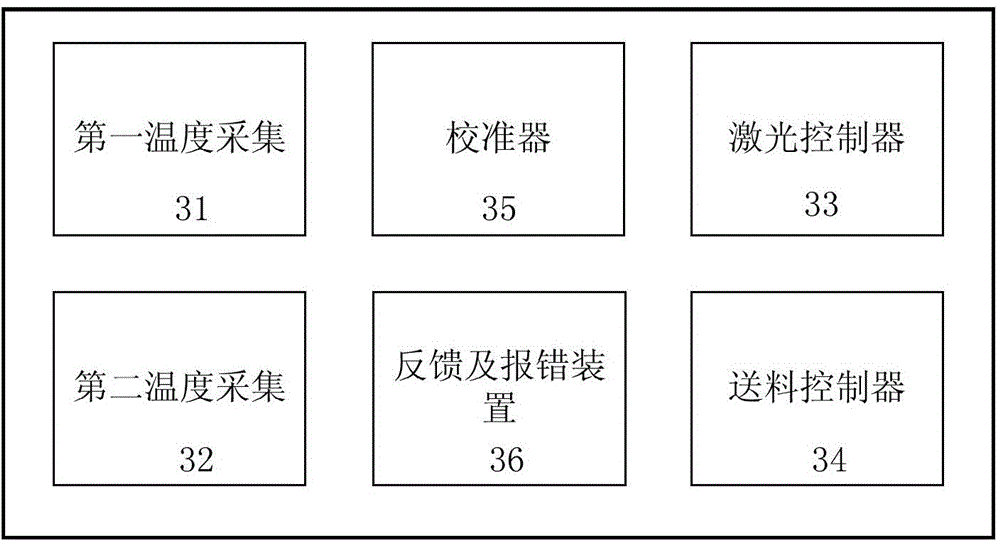

Precise temperature control system for 3D printing of high-molecular material by picosecond laser

The invention provides a system for realizing 3D printing of a high-molecular material by a picosecond laser. The system comprises a laser system, a control system, an infrared temperature measuring device and a feeding device. Temperature difference with the latest 3D printing job temperature is compensated through calibration, feedback and laser power control. The temperature difference can be accurately controlled within + / - 0.5 DEG C. The high-molecular material can be effectively prevented from warping and nonuniform processing phenomena during 3D printing process.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

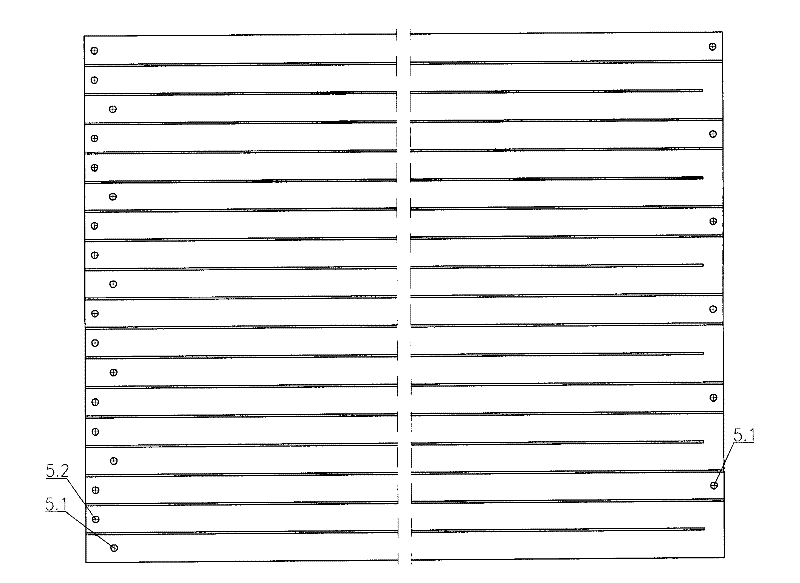

Optical fiber ring for optical fiber gyro and optical fiber ring processing method

The invention provides an optical fiber ring for optical fiber gyros. The optical fiber ring comprises a optical fiber sensitive ring, a magnetic shielding film, a heat storage layer, a magnetic shielding case and a thermal insulation layer which are sequentially arranged from inside to outside. The magnetic shielding case comprises a magnetic shielding base and a magnetic shielding cover laminated on the magnetic shielding base. The magnetic shielding case is a closed structure. A pigtail of the optical fiber sensitive ring sequentially penetrates through the magnetic shielding film and the magnetic shielding case to be connected with a Y waveguide pigtail of an optical fiber gyro system. The heat storage layer is composed of a heat storage material. The invention further provides an optical fiber ring processing method. According to the optical fiber ring for optical fiber gyros and the optical fiber ring processing method, by adopting the wrapping method for the optical fiber sensitive ring as well as the heat storage layer and the heat insulation layer on the structure, the influence of the temperature on the fiber sensitive ring is reduced, and the gyro temperature performanceis improved. The magnetic shielding film and the magnetic shielding case are combined to form a double-layer magnetic shielding structure, so that the influence of the external magnetic field on theoptical fiber sensitive ring is effectively reduced, and the environment adaptability of the optical fiber ring on the temperature and the magnetic field is improved.

Owner:HUNAN AEROSPACE ELECTROMECHANICAL EQUIP & SPECIAL MATERIAL INST

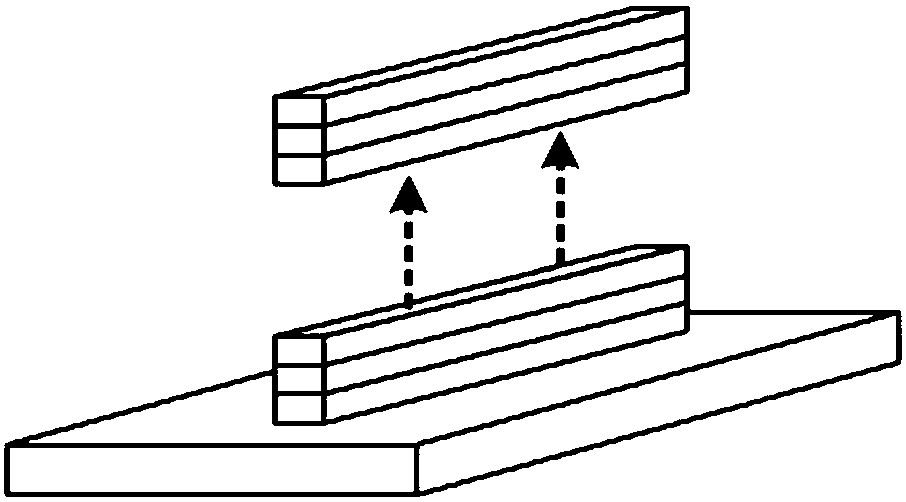

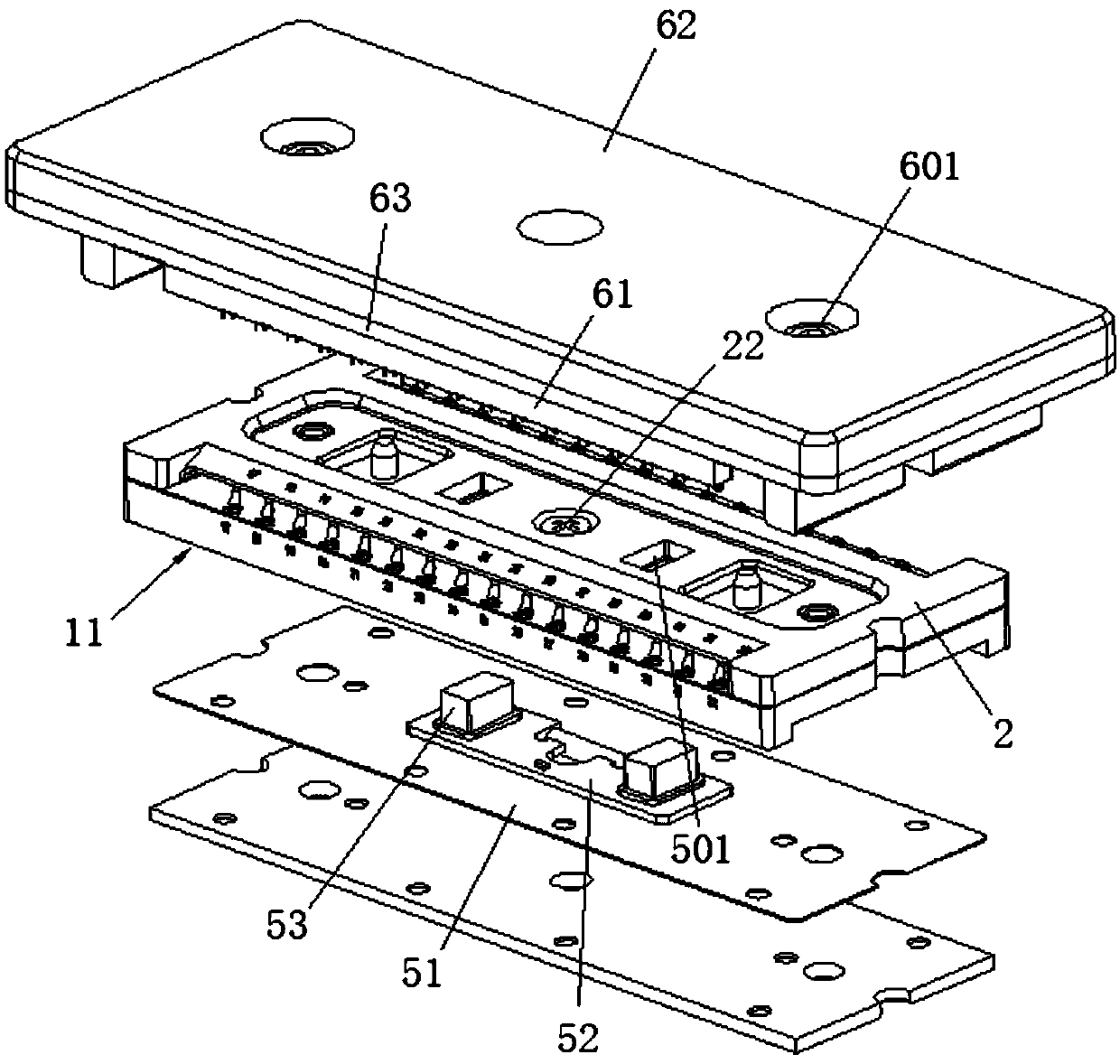

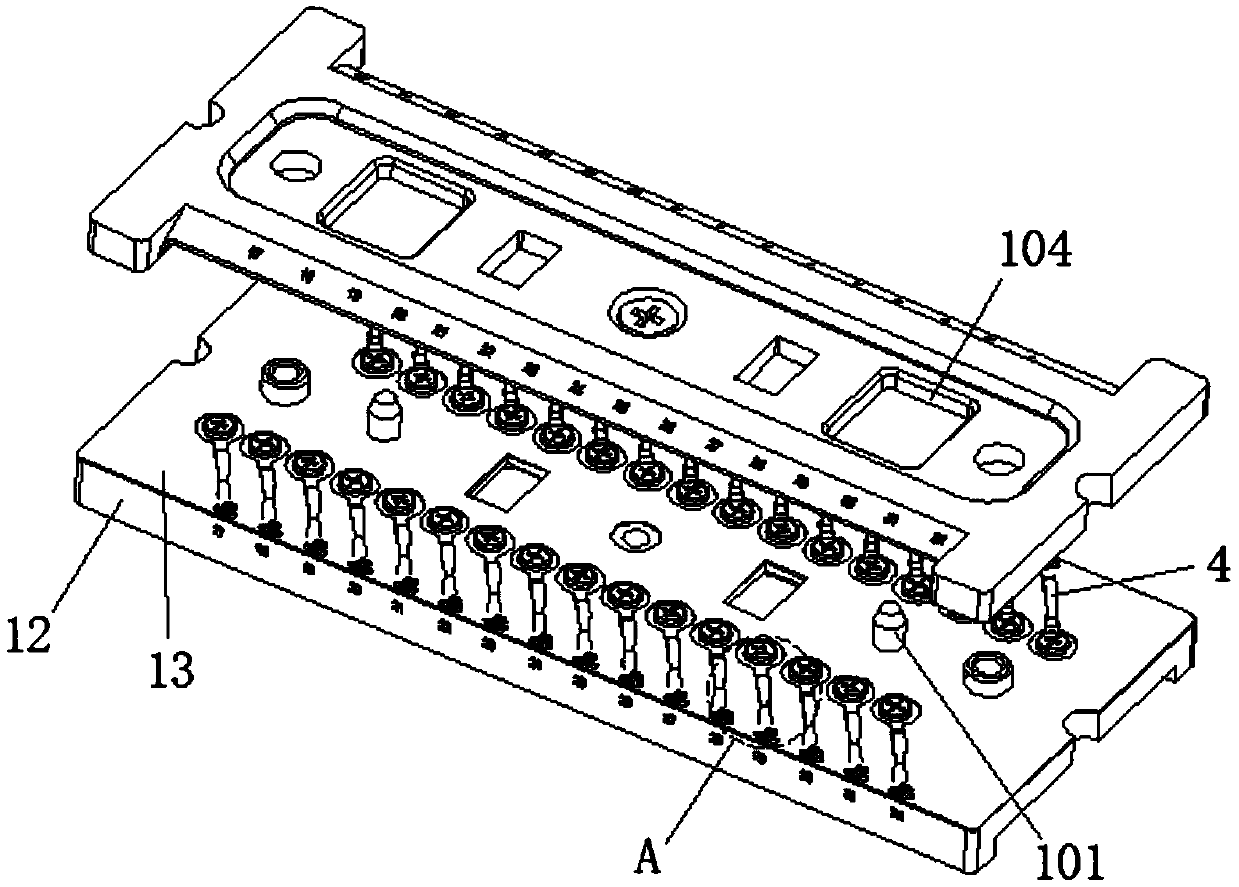

Integrated fixture of laser chip

PendingCN109596867AStable pressureGuaranteed extrusion strengthWork holdersMeasurement instrument housingEngineeringControl circuit

The invention discloses an integrated fixture of a laser chip. The integrated fixture comprises a chip positioning seat for loading chips, a test module and a heat module; the chip positioning seat comprises base shrapnel and a shrapnel gland; multiple positioning slots for the embedding of the chips are formed on an upper surface of the base; the shrapnel comprises a connecting part, a deformation part and a positioning part arranged on the base; each positioning lost is provided with a positioning right angle, and a right angle positioning gap is formed at the end part of the positioning part, and the shrapnel gland and the deformation part are in extrusion contact; multiple pins corresponding to the chips are arranged at a lower surface of a PCB board, the pins contact with the chips bypenetrating a cover plate, and connecting contacts are arranged at two ends of the PCB board; the heating module comprises a heating plate and a control circuit board. The integrated fixture disclosed by the invention has the advantages of being strong in applicability and convenient for use.

Owner:STELIGHT INSTR CO LTD

Constant-temperature stirring tank

InactiveCN103432929AAvoid wastingAvoid damageRotary stirring mixersMixer accessoriesEngineeringWell control

The invention relates to a novel stirring tank. The stirring tank comprises a tank body, a tank cover, a feeding opening, a discharging opening, a drain outlet, a stirring shaft, a bearing, a sleeve, stirring teeth, a scraper, a clamping sleeve, heating liquid or cooling liquid inlet, a heating liquid or cooling liquid outlet and a temperature controller, wherein the stirring tank is configured to drive the stirring teeth and the scraper connected to the stirring teeth to rotate so as to stir the materials through the stirring shaft connected to the bearing and remove material liquid adhered to the tank wall during stirring; the temperature of the material liquid can be well controlled in a small range through the cooperation between the temperature controller and the clamping sleeve. Through the stirring tank disclosed by the invention, the stirring process is optimized, simultaneously the waste and degeneration of the materials are avoided and the production efficiency and the product quality are improved.

Owner:天津隆雷科技有限公司

Polyethylene corrugated pipe and expansion molding process thereof

The invention discloses a polyethylene corrugated pipe and an expansion molding process thereof, and relates to the field of plastic pipeline molding methods. According to key points of the technicalscheme, the expansion molding process includes the following steps that S1, the corrugated pipe is fed onto an expansion mold; S2, the flaring end is heated by an annular far-infrared heating part; S3, heating does not exceed the critical temperature of melting, and after softening, the end needing to be expanded is flared through the expansion mould; S4, cooling molding is conducted; S5, air is fed into the inner wall of the pipe through an air blowing system in a contact adsorption state; and S6, demolding is conducted. The polyethylene corrugated pipe and the expansion molding process thereof have the technical effects that 1, the annular far-infrared heating part is used for heating, heating equipment with glycerin used as a heating medium is avoided, and thus the situations that the glycerin is mixed with water inevitably, the decomposition temperature of the glycerin is lowered, and a large amount of smoke is produced to pollute the environment are avoided; and 2, by changing theheating form and controlling the temperature difference, the axial shrinkage ratio of the corrugated pipe is well controlled, use of the large heating equipment is avoided, and 50% of electricity issaved compared with the large heating equipment.

Owner:杭州亿通塑胶实业有限公司

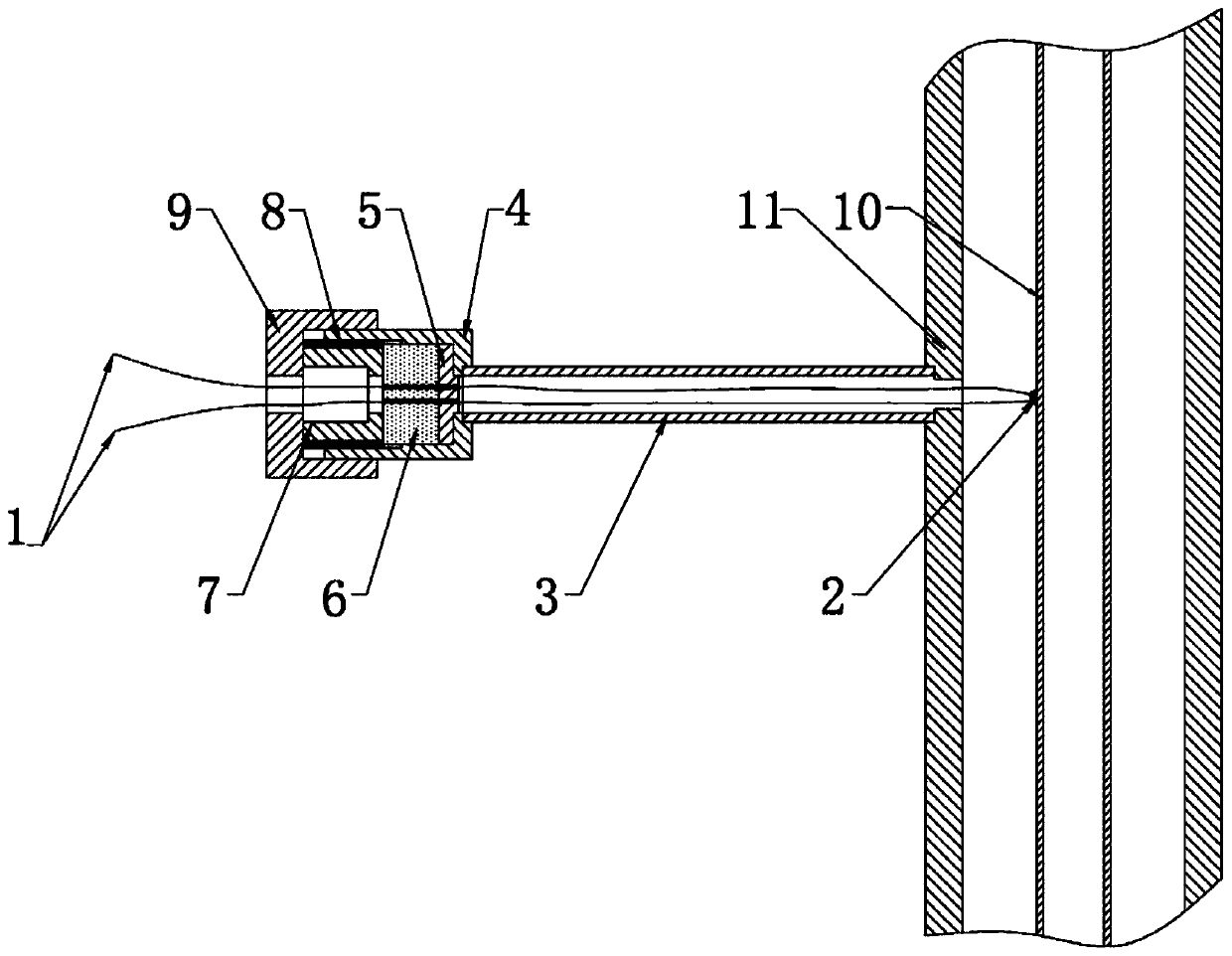

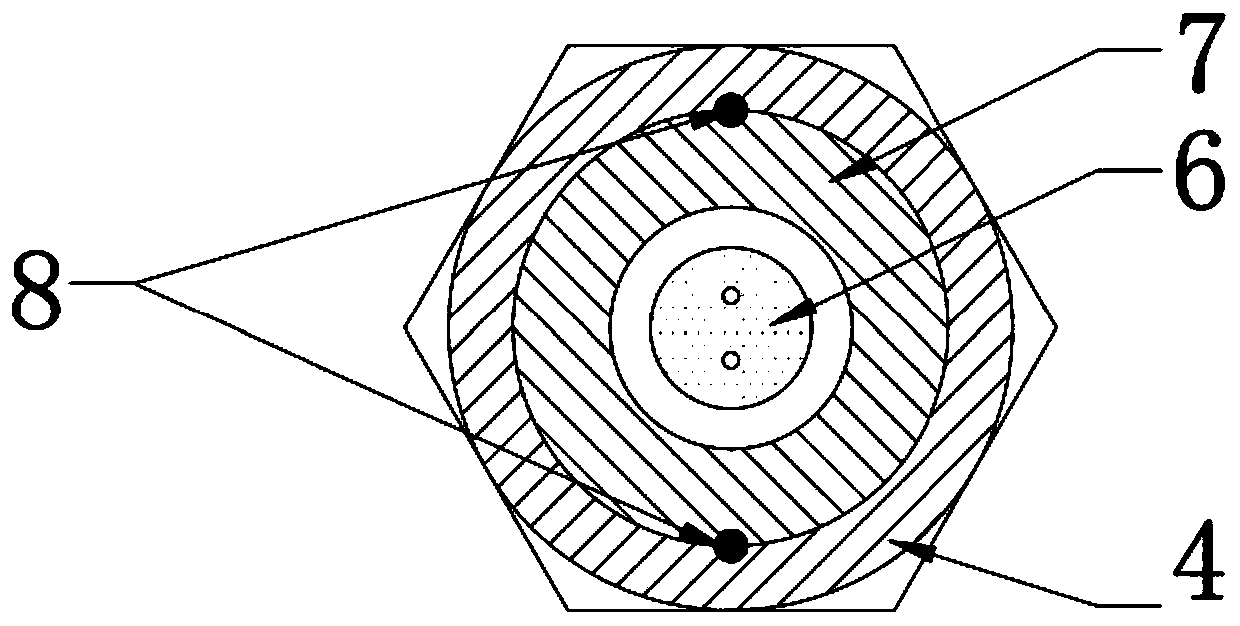

Device and method for measuring temperature of outer wall of supercritical water-cooled reactor coolant channel inner pipe

ActiveCN110648772AHigh measurement accuracyFast diameterThermometer detailsNuclear energy generationEngineeringThermocouple device

The invention relates to a device and a method for measuring the temperature of the outer wall of a supercritical water-cooled reactor coolant channel inner pipe. The problems of slow response, largemeasurement error and high measurement point arrangement difficulty of a traditional wall surface temperature measurement method are solved. The temperature measuring device comprises a sealing unit and a temperature measuring unit; the sealing unit comprises a guide pipe, a base, a bottom extrusion pad, a sealing pad, a top extrusion pad and an extrusion nut; one end of the guide pipe is fixedlyconnected with the outer wall of a coolant channel outer pipe and is communicated with the coolant channel outer pipe, and the other end of the guide pipe is fixedly connected with the base; the bottom extrusion pad, the sealing pad and the top extrusion pad are sequentially arranged in the base from inside to outside, and are pressed in the base through the extrusion nut; the sealing pad is madeof a nonmetallic elastic sealing material; and the temperature measuring unit comprises at least one thermocouple, one end of the thermocouple is fixed to the outer wall of the coolant channel inner pipe, and the other end of the thermocouple sequentially penetrates through the coolant channel outer pipe, the guide pipe, the base, the bottom extrusion pad, the sealing pad, the top extrusion pad and the extrusion nut and then is led out.

Owner:XI AN JIAOTONG UNIV +1

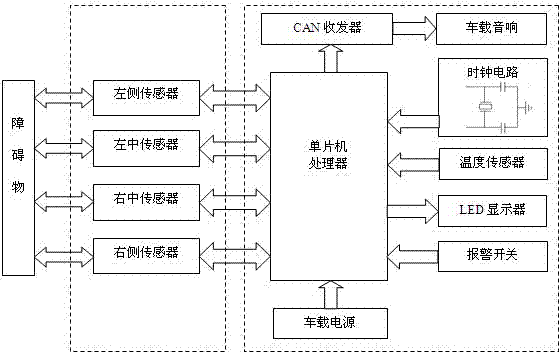

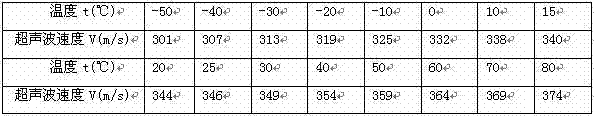

Accurate positioning method for automobile

InactiveCN104267404AAccurate distanceRich in featuresProgramme control in sequence/logic controllersBus networksDisplay deviceUltrasonic velocity

The invention relates to the field of automobiles, in particular to an accurate positioning method for an automobile. The accurate positioning method for the automobile includes the steps that a standard barometric pressure value and a common temperature range are selected; then all values corresponding to temperature and ultrasonic velocity are obtained within the common temperature range through an experiment under the standard barometric pressure value; then the temperature and the ultrasonic velocity are fitted to obtain a temperature and speed function relation; finally, signals of ultrasonic sensors and a temperature sensor are transmitted to a vehicle-mounted controller, the vehicle-mounted controller works out current ultrasonic velocity through the temperature and velocity function relation according to the signal of the temperature sensor, and then the signals of the ultrasonic sensors are combined with the current ultrasonic velocity to obtain the distance between the installation position points of the ultrasonic sensors and the position of an obstacle. The distance from the obstacle can be detected more accurately through the ultrasonic sensors, alarm sound can have more features, a better function can be achieved, the distance from the obstacle can be directly displayed on a displayer inside a vehicle, and therefore a driver learns about the position of the obstacle more visually.

Owner:SAIC MOTOR

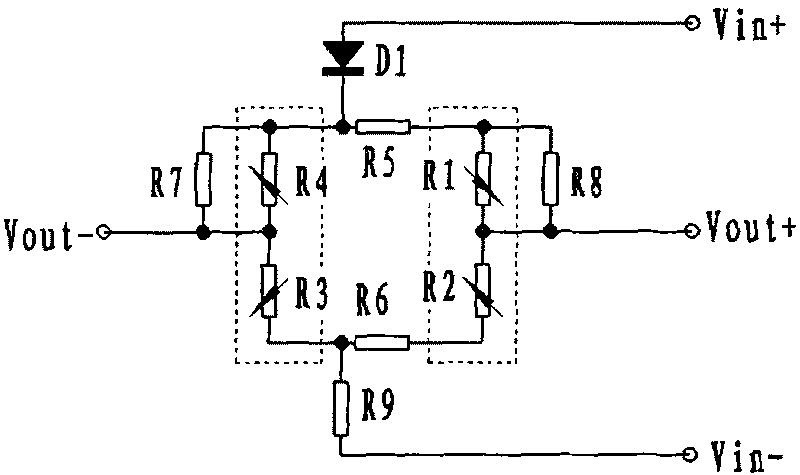

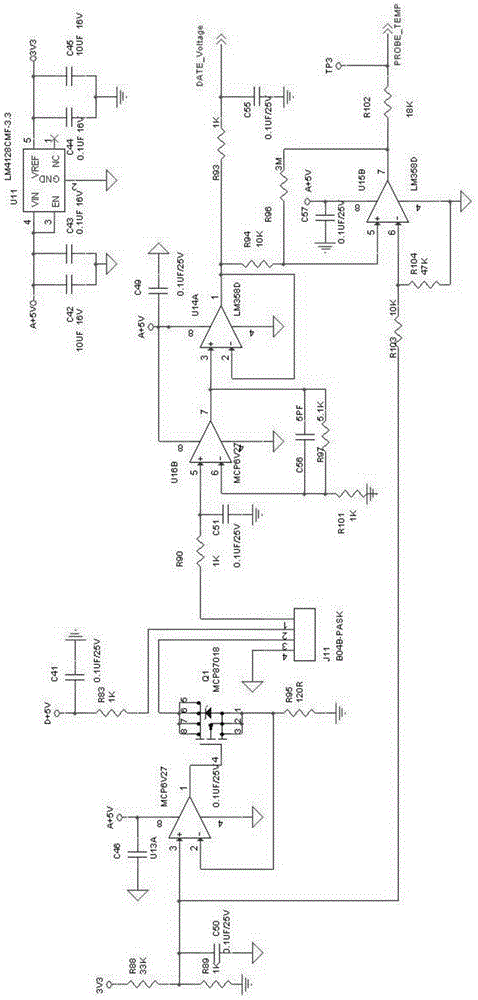

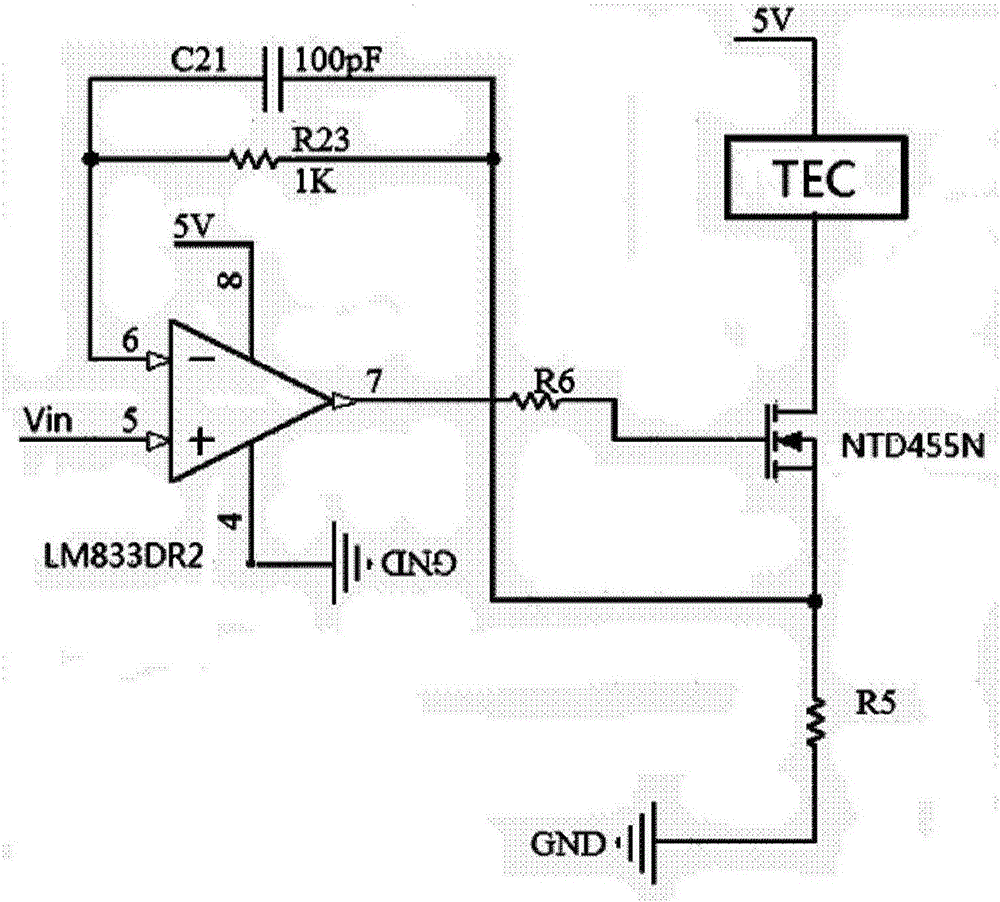

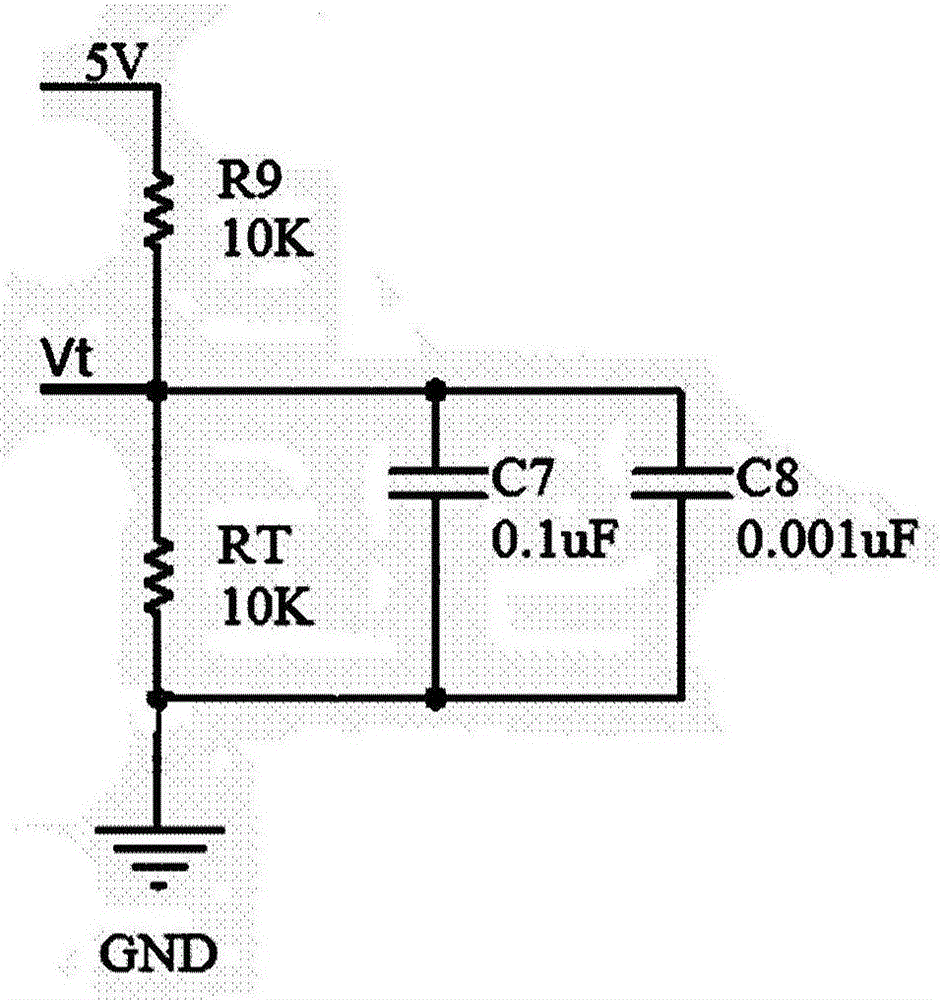

Temperature control circuit based on thermoelectric cooler and quantum cascade laser employing temperature control circuit

InactiveCN105843274AEasy to installExtended service lifeLaser detailsSemiconductor laser structural detailsTemperature controlThermoelectric cooling

A temperature control circuit based on a thermoelectric cooler comprises a temperature acquisition module for detecting the temperature of an area to be detected and outputting temperature signals, a controller for controlling the thermoelectric cooler according to the temperature signals inputting by the temperature acquisition module, and the thermoelectric cooler for cooling. The invention also discloses a quantum cascade laser employing the temperature control circuit. The temperature control precision of the temperature control circuit is less than or equal to 0.1 DEG C. The temperature control circuit when used in combination with a small air-cooling device can replace a conventional water cooling system, and realizes temperature control of the quantum cascade laser under a room temperature working state, thereby substantially reducing the size of the cooling system. No mechanical oscillation is needed, which facilitates stable work of the system. The temperature control circuit is small in size, convenient for installation, ling in service lifetime, simple for operation and free of noises, and is especially applicable to temperature control of a portable laser system.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Tester for rapidly testing heat-insulation property of fabric

InactiveCN109507232AThe test results were close toEnsure structural unityMaterial heat developmentEngineeringPerformance index

The invention relates to a tester for rapidly testing a heat-insulating property of a fabric, and belongs to the technical field of textile measurement. The tester mainly comprises two heating plates,a temperature acquisition and control module and an air flow generation module, and the two heating plates are placed on the same horizontal plane. The tester for rapidly testing the heat-insulatingproperty of the fabric is reasonable in structure and convenient to operate and use. By the tester for rapidly testing the heat-insulation property of the fabric, the heat-insulation property of the fabric can be tested rapidly, the heat-insulation index of the fabric can further be tested in an open environment, and the theoretical basis is provided for researching and evaluating heat transfer performance indexes of the fabric.

Owner:WUHAN TEXTILE UNIV

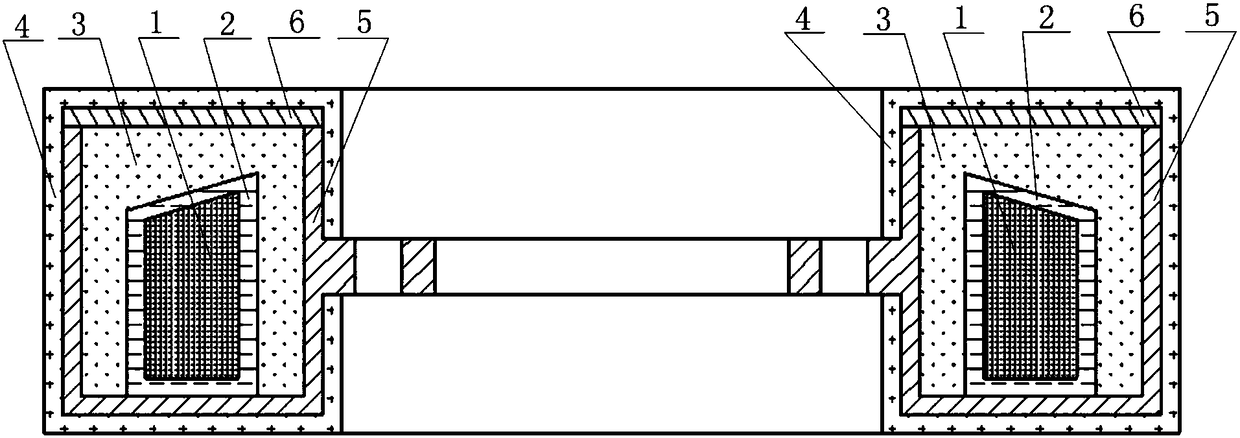

All electric melting insulator glass furnace

The invention discloses an all electric melting insulator glass furnace, comprising a molten pool (11), an allocation pool (6) and a feed path (7), wherein, the molten pool is mainly composed of an external wall (3), an insulating layer (4), a lining (5), a furnace top (8) and a furnace bottom (10); the lower part of the molten pool is connected with the allocation pool by a liquid flowing opening (9) and an upper liquid flowing path (12); the allocation pool is connected with the feed path; a charging opening (1) is arranged above the molten pool; electrodes (2) are respectively arranged in the molten pool, the liquid flowing opening, the upper liquid flowing path and the allocation pool at intervals; and the molten pool is vertically arranged, and the cross section of the inner cavity of the molten pool (11) is of an annular regular hexagon structure. The glass furnace does not generate toxic and harmful gas and dust pollution, is favorable for environment protection, and achieves quick, even and pollution-free melting state, thus improving quality such as insulating properties, mechanical strength and the like of a glass insulator, improving the melting rate of a melting furnace, lowering production cost, increasing economic benefit, and being more favourable for environment protection.

Owner:三瑞科技(江西)有限公司

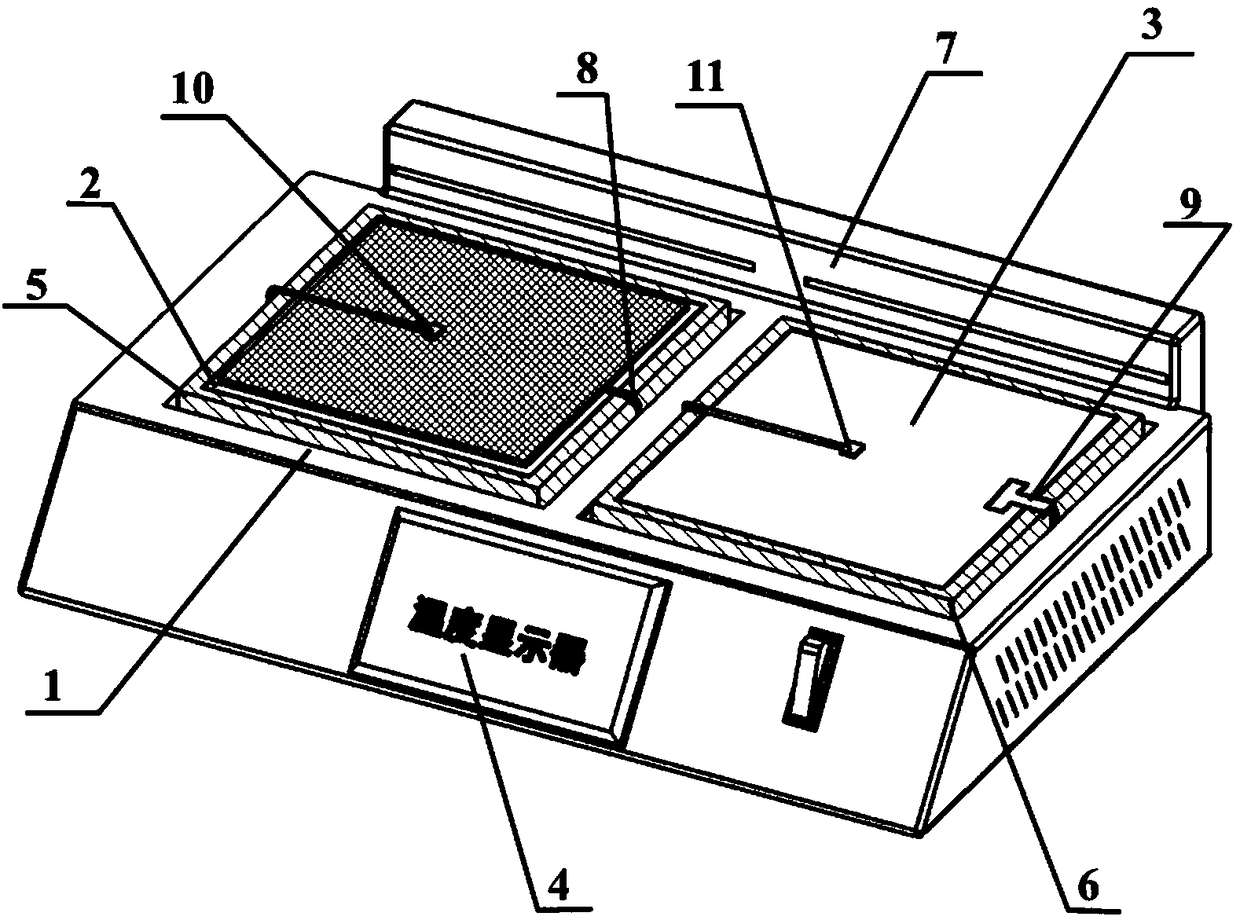

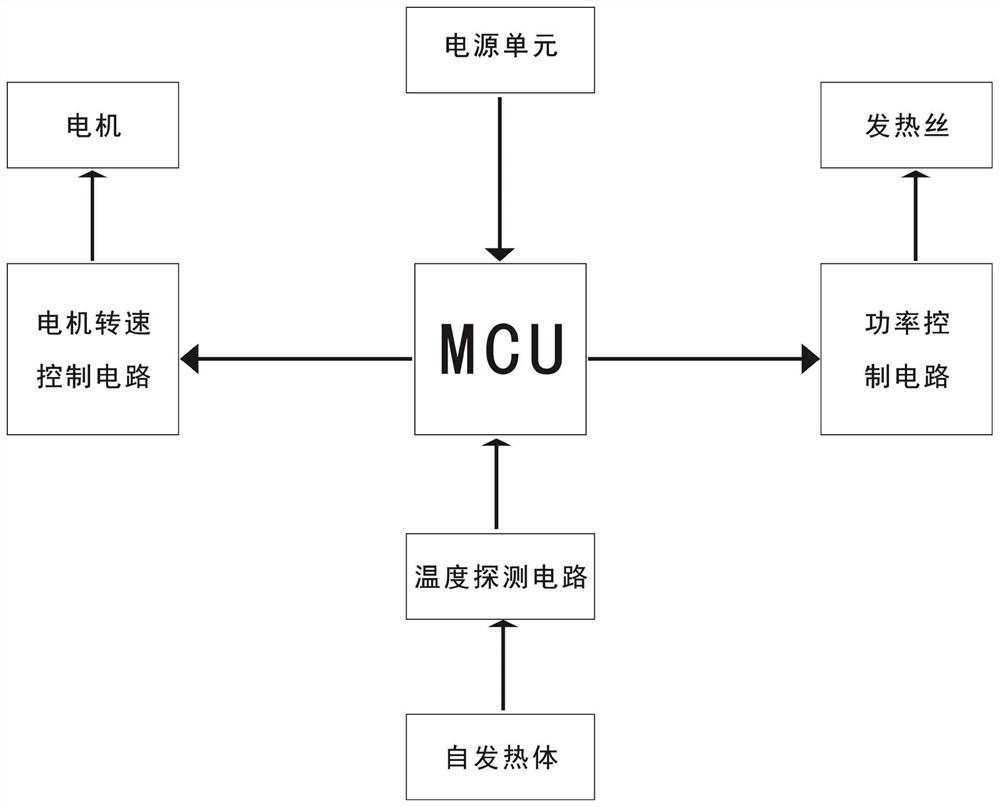

Constant temperature control method of hair dryer

InactiveCN112120382ARealize high-precision constant temperature controlSmall temperature errorAuxillary controllers with auxillary heating devicesHair dryingTemperature controlControl power

The invention relates to the technical field of hair dryers, and discloses a constant temperature control method of a hair dryer. The hair dryer comprises an air duct, a handle and a self-heating body, the resistance value of the self-heating body changes along with the change of the temperature of the self-heating body, and the self-heating body is arranged in the air duct. A fan, a motor and a heating wire are arranged in the air duct. A main board is arranged in the handle, and a temperature detection circuit, a control unit and a power control circuit are arranged on the main board. The temperature detection circuit measures the resistance value of the self-heating body and feeds back a resistance value signal to the control unit, and the control unit controls heating of the heating wire through the power control circuit according to the received resistance value signal so that air blown out of the air outlet of the air duct can be in a constant-temperature state. Through the powercontrol circuit, heating of the heating wire can be controlled, and air blown out of the air duct is in a constant-temperature state. The self-heating body is arranged in the air duct and deviates from the high-temperature environment of the air outlet, installation is convenient and time-saving, the temperature error of the self-heating body is small, the feedback sensitivity is high, and high-precision constant-temperature control over the hair dryer is achieved.

Owner:SHENZHEN ACME ELECTRIC APPLIANCE CO LTD

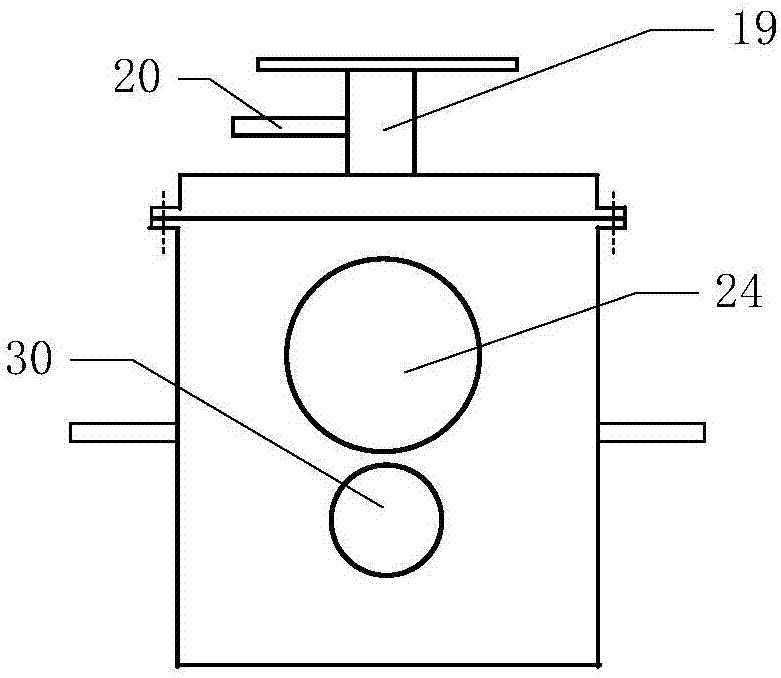

Experiment apparatus used for researching reaction of fine ore during motion

ActiveCN106918686ASmall temperature differenceIsothermal experiment results are accurateEarth material testingHearthTemperature difference

The invention relates to an experiment apparatus used for researching reaction of fine ore during motion. The experiment apparatus comprises a tubular vertical furnace, a reacting furnace pipe is arranged in a hearth of the tubular vertical furnace, a filling tube is stretched into the reacting furnace pipe from the top of the tubular vertical furnace in a slide and sealing mode, a discharge hatch is movable at the position in the reacting furnace pipe; a material receiving pipe is stretched into the bottom of the tubular vertical furnace in the slide and sealing mode, a material receiving port is movable at the position in the reacting furnace pipe; a constant-temperature area with adjustable position and / or length is provided between the discharge hatch and the material receiving port, the ore powder is introduced into the constant-temperature area through the discharge hatch of the filling tube, and then is introduced into the material receiving pipe through the material receiving port after being reacted. The ore powder is subjected to a reaction during a movement process in the constant-temperature area, the temperature difference of the constant-temperature area is little through adjustment and selection.

Owner:NORTHEASTERN UNIV

Multifunctional pressure chamber for realizing image measurement and temperature control

The invention relates to a multifunctional pressure chamber for realizing image measurement and temperature control, a pitch sample is put on a sample base, a linear bearing is cooperated with a pressure rod, and the pressure rod uniformly transmits the force to the pitch sample through a sample cap. Tempered glass is fixed in a tempered glass fixed plate to form a visible window, and a camera shoots the experimental variation on whole surface of the pitch sample through the visible window; an illuminating lamp provides stable illumination; two mirrors are fixed to a mirror bracket behind the pitch sample, the mirror bracket is adjusted, and the two mirrors form an angle of 120 degrees. A heating wire is fixed in a pressure chamber cavity, and hot water is added; a temperature sensor is fixed to an upper plate of the pressure chamber cavity, a probe of the sensor suspends in the pressure chamber cavity to directly measure the water temperature, a water temperature value is fed back to the heating wire through an outside PID control system, and the water temperature is controlled. According to the invention, the experimental sample whole surface observation can be realized through the visible window, the water temperature control is realized, and the temperature error in the measurement process is small; and the chamber has advantages of low cost, simple structure and high experimental accuracy.

Owner:SUZHOU H C SOIL & WATER SCI & TECH CO LTD +1

Thermal insulation plate

InactiveCN101176612AAdd timing functionHandy handleTable equipmentsInequality problemThermal insulation

The invention discloses a heat insulation disc, comprising a heat generating plate formed by rigidly folding the plate. The invention is characterized in that the heat generating plate is sleeve-jointed with a kettle support, which can hold and support at least two kettles, two handle seats in parallel are connected with each side end of the heat generating plate with threads respectively, and a stainless steel handle is sleeve-arranged between the two handle seats arranged at the same side; an elastic adhesive leg component is arranged at the bottom of each handle seat; at least two groups of heating wires separately matched with the kettles for heat supply are bound and fixed to the inner top surface of the heat generating plate; a PCB board for controlling and adjusting the temperature of the heating wires is fixed in the internal cavity of the heat generating plate. The invention has the advantages that: as a temperature sensor is employed for feedback, the error between the set temperature and the actual temperature is small and the control precision is high; as the heating wires are separately matched with the kettles and the kettles can be controlled and adjusted separately, the energy can be saved; the invention is convenient for operation and can be controlled automatically due to the electronic timing function added to the program inside the PCB board; and as the adhesive legs employ spring structure, the problem that the bottom of the product in the prior art is not smooth and other problems are solved.

Owner:NINGBO WUJI ELECTRIC APPLIANCE

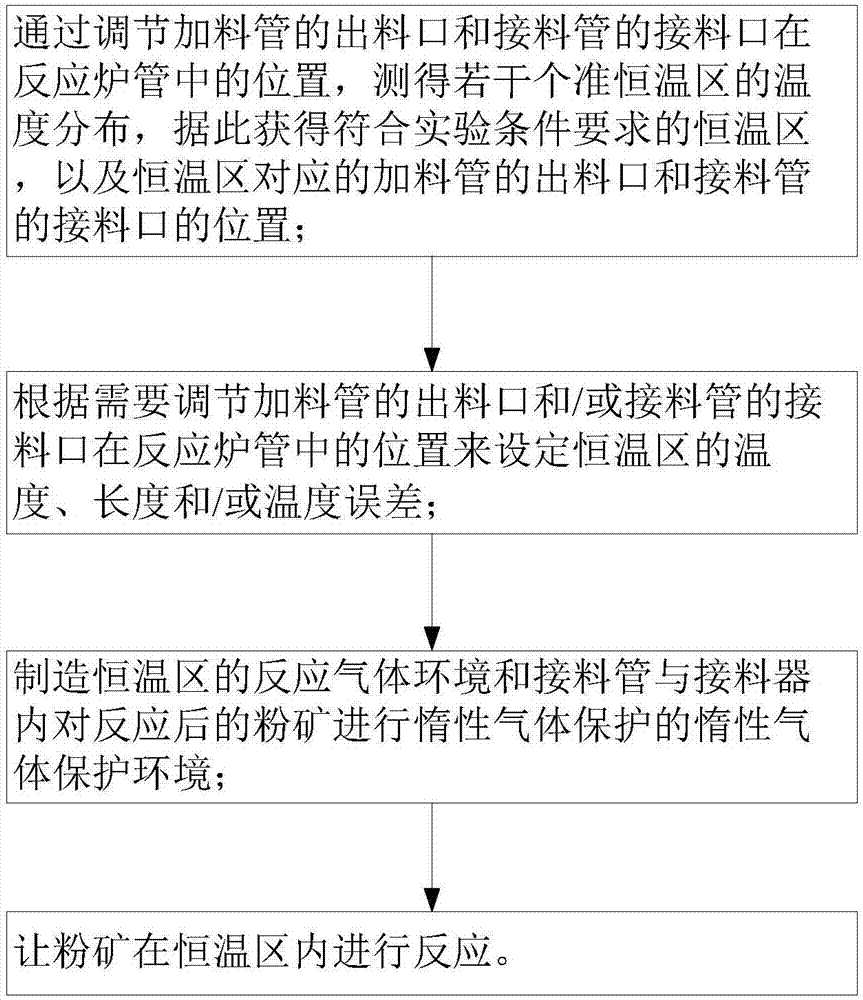

Experimental method for studying the reaction of fine ore in motion

ActiveCN106908359ASmall temperature differenceIsothermal experiment results are accurateMaterial analysisExperimental methodsEngineering

The invention relates to an experimental method for studying the reaction of fine ore in motion. The method comprises the following steps of: S1. adjusting the position of a discharge port of a feed pipe and a collecting port of a collecting pipe in a reactor pipe to obtain the temperature distribution of a number of quasi-constant temperature zones, then according to the experimental requirements, selecting constant temperature zones and the position of the discharge port of the feed pipe and the feed-collecting port of the feed-collecting pipe that the constant temperature zones correspond to; S2. According to the needs, adjusting the position of the discharge port of the feed pipe and / or the feed-collecting port of the feed-collecting pipe in the reactor pipe,so as to set the temperature, length and / or temperature error of the constant temperature zones; and S3. ensuring the fine ore is reacted in the constant temperature zones. The experimental method for studying the reaction of fine ore in motion has the advantages of implementing all reactions of fine ore in the constant temperature zones, and making the temperature difference of the constant temperature zones smaller through adjustment and selection.

Owner:NORTHEASTERN UNIV

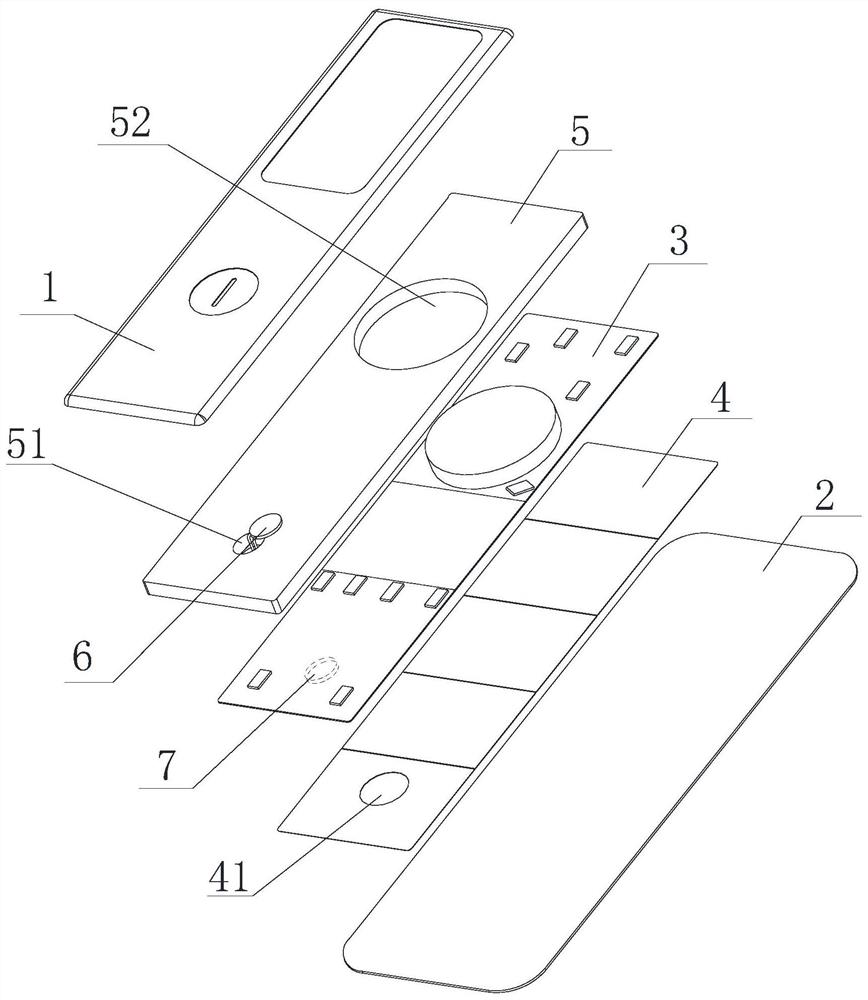

Body temperature prediction method, body temperature continuous monitoring method and dual-temperature-measurement body temperature patch

PendingCN111947801ASimple structureReasonable layoutThermometer detailsThermometers using electric/magnetic elementsMonitoring dataProcess engineering

According to the invention, the body temperature of a human body can be accurately measured within 3.5 minutes at the soonest; and the matching degree of monitoring data and real data is high in continuous monitoring use process. According to the body temperature continuous monitoring method and the dual-temperature-measurement body temperature patch, the controller starts to collect and store thetemperature information uploaded by the main temperature sensor at set intervals in the set time; and the controller compares and judges a temperature rise curve formed by each temperature information value acquired within a set time with each group of standard temperature rise curves pre-stored in a database. The invention has the advantages that: 1, double temperature sensors are adopted, the main temperature sensor monitors the temperature of the oxter epidermis, and the auxiliary temperature sensor assists in monitoring the temperature of the oxter gap and is used for calibrating the temperature error caused by the main temperature sensor due to non-clamping, so that the temperature measurement precision of the invention is improved;.

Owner:HANGZHOU CENTURY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com