Pressure sensor with double redundancies and high reliability

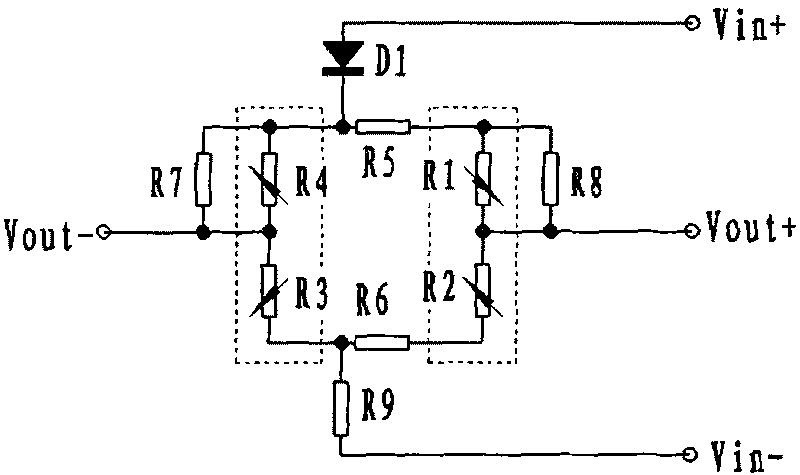

A pressure sensor, double redundancy technology, applied in the direction of fluid pressure measurement by changing ohmic resistance, can solve the problems of relatively large installation space, single measurement, measurement error, etc., to achieve small volume, small temperature error, frequency response high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Control attached figure 1 , its structure includes a pressure conversion joint 3, two silicon pressure sensitive cores 5, two silicon pressure sensitive core compensation circuits 8, a fixing bracket 9, four mounting screws 10, two electrical signal amplification processing boards 13, silicon pressure The connection lead 11 between the sensitive core compensation circuit and the electrical signal amplification processing board and the connection lead 15 between the electrical signal amplification processing board and the electrical connector, the stainless steel shell 14, the electrical connector 16, and the inner potting silicone 17; Between the two silicon pressure sensitive cores 5 and the pressure conversion joint 3, they are fastened by threads and then welded into a whole through the connecting weld 7. The two silicon pressure sensitive core compensation circuits 8 are respectively connected to the two silicon pressure sensitive cores. On the core body 5, the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com