Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

595 results about "ELASTIC ADHESIVE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Elastic adhesive wound dressing for control of bleeding and for dressing bleeding wounds

Owner:RICHARD NAIMER

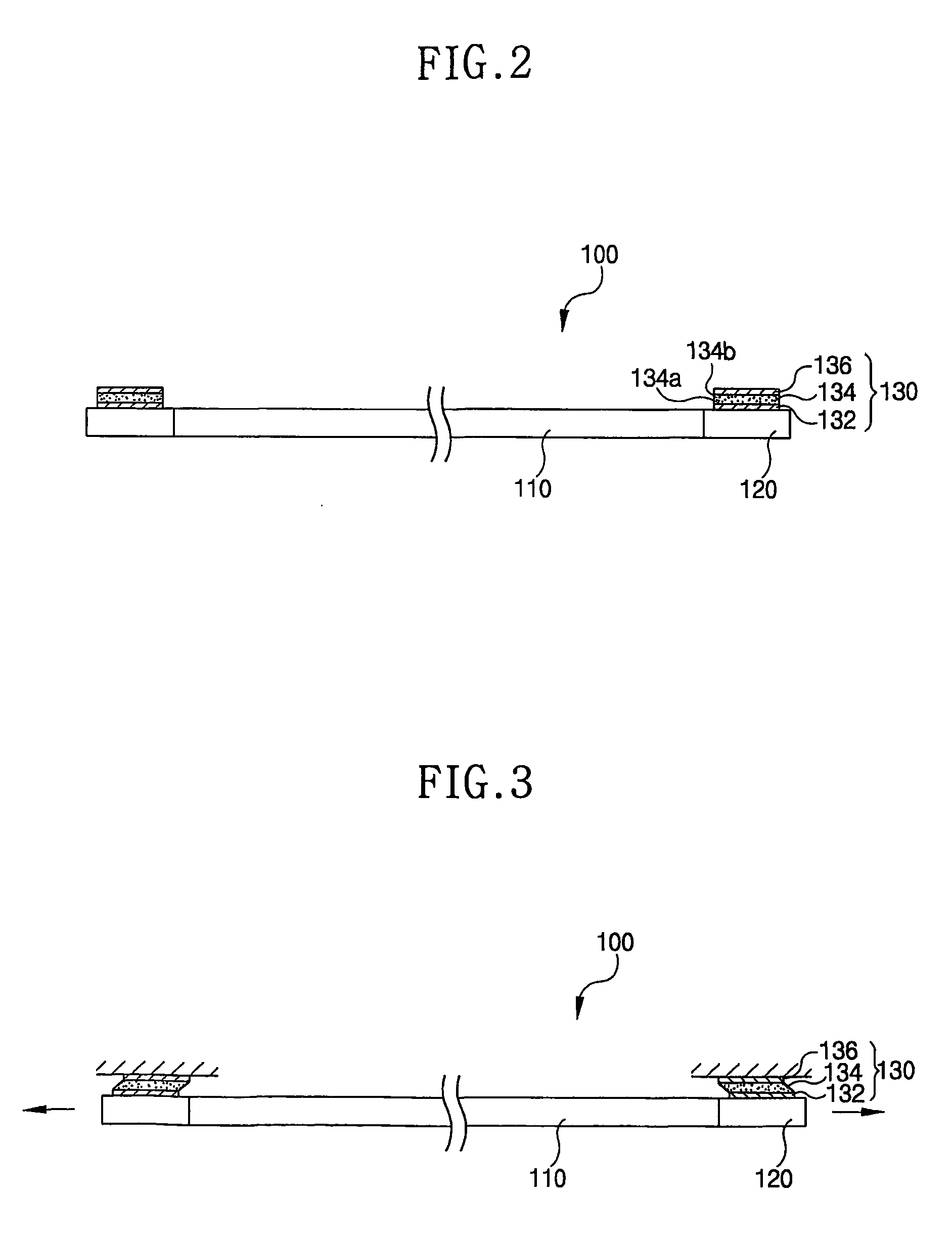

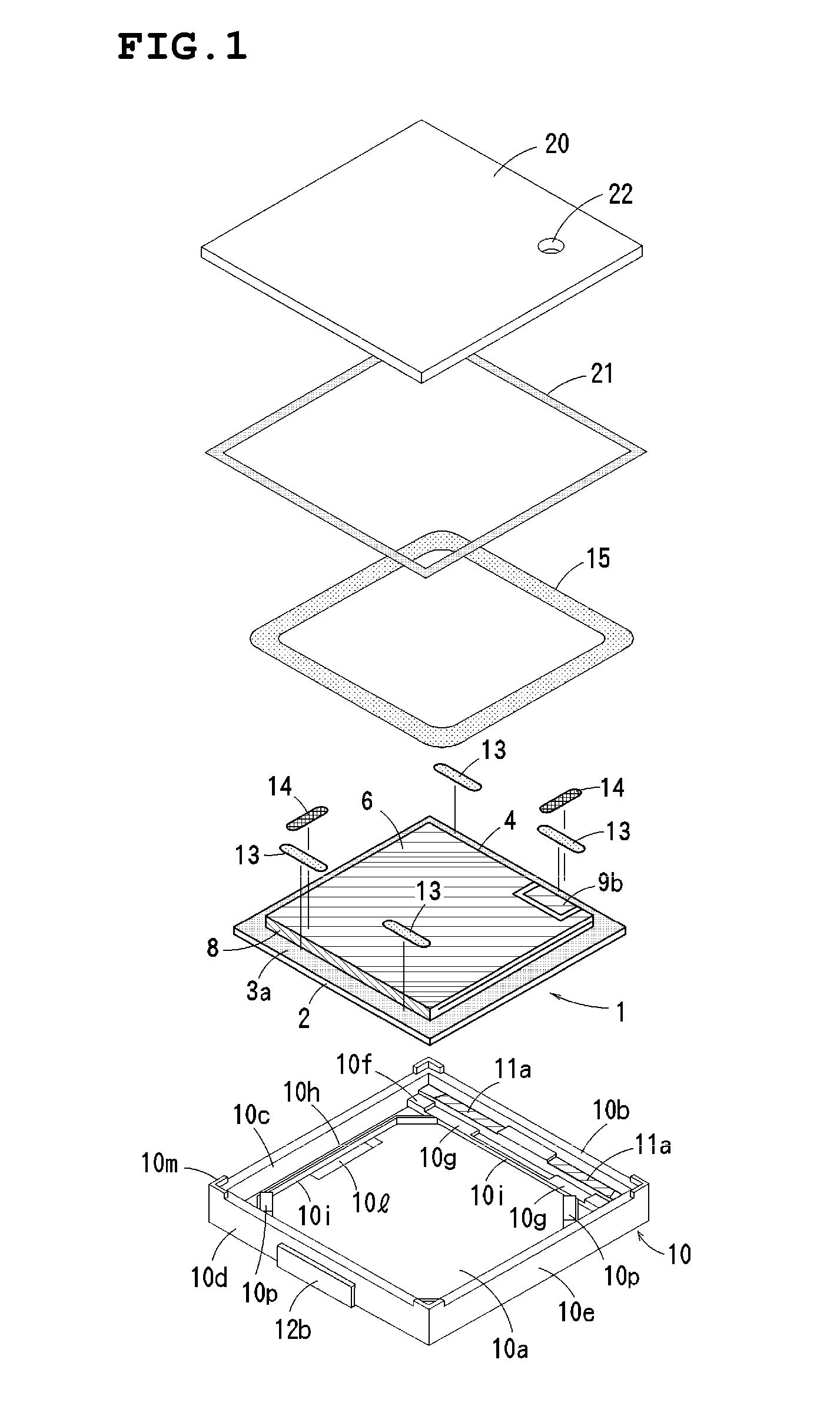

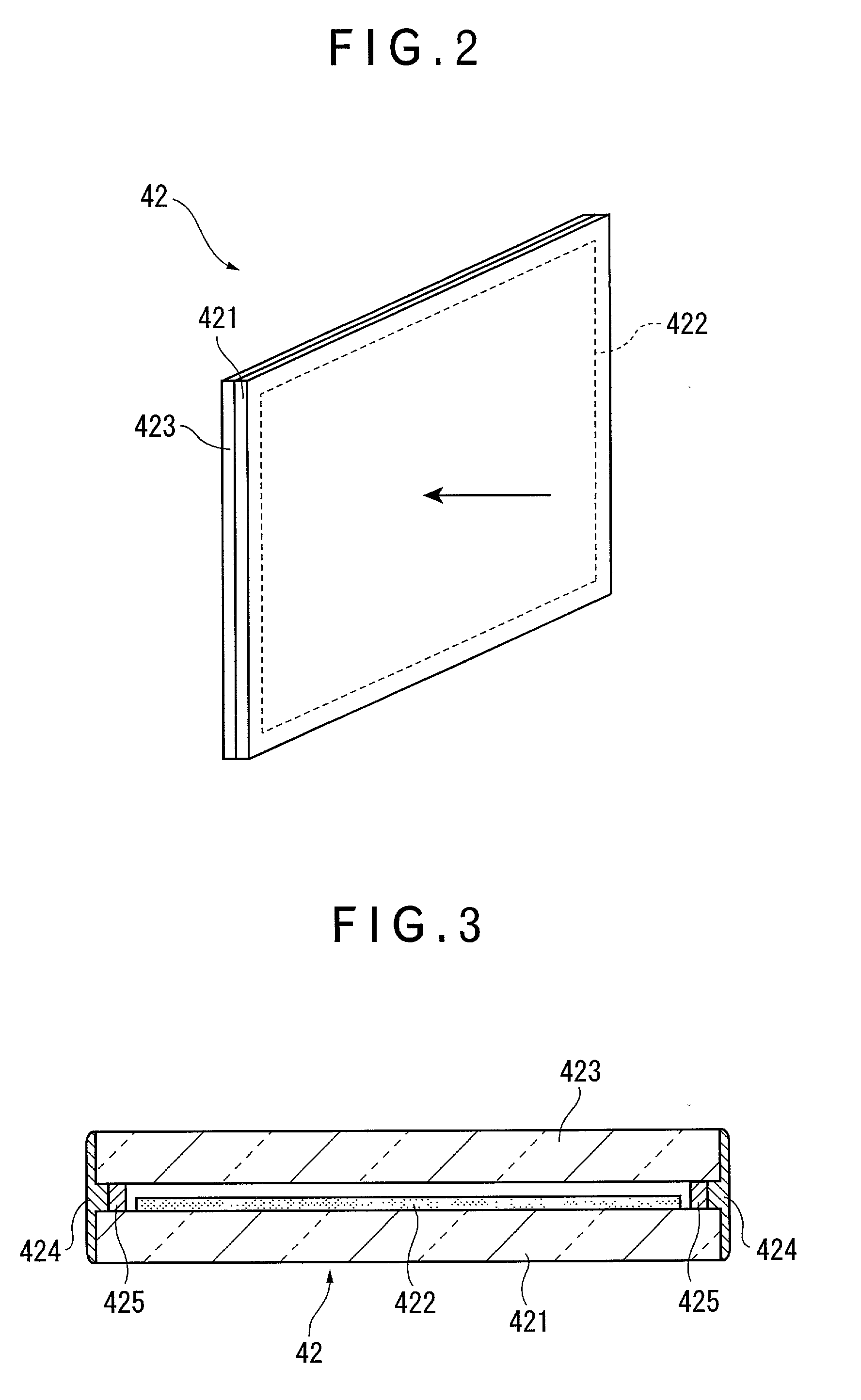

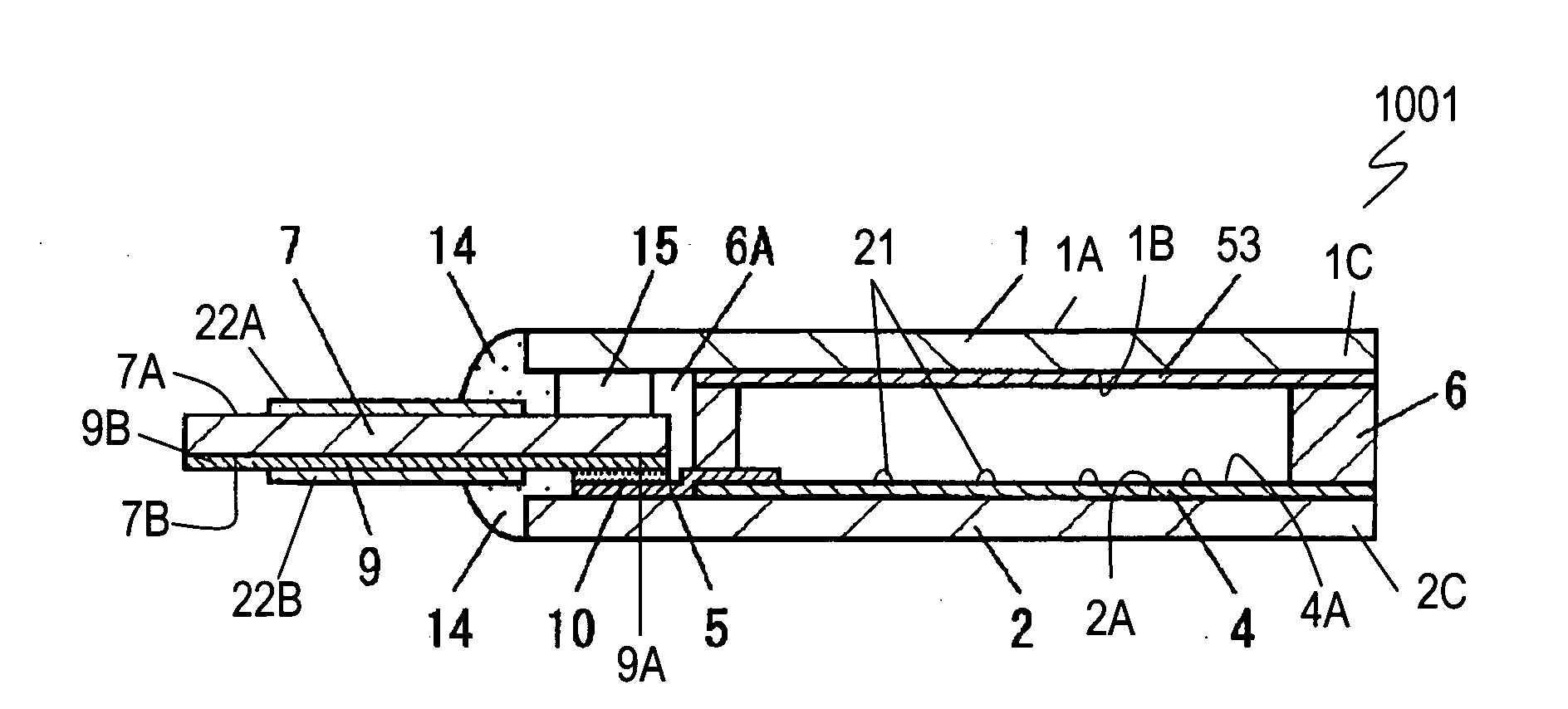

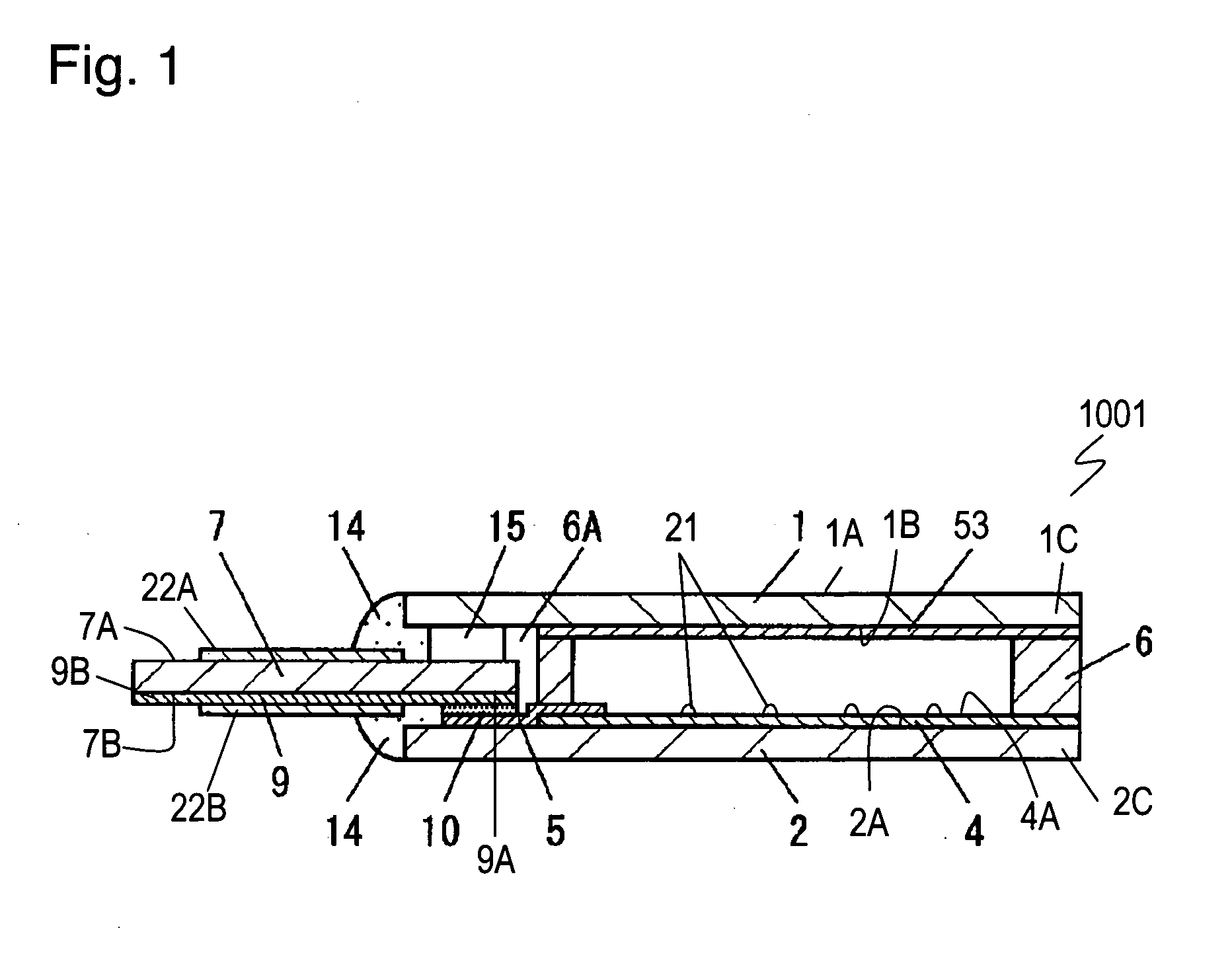

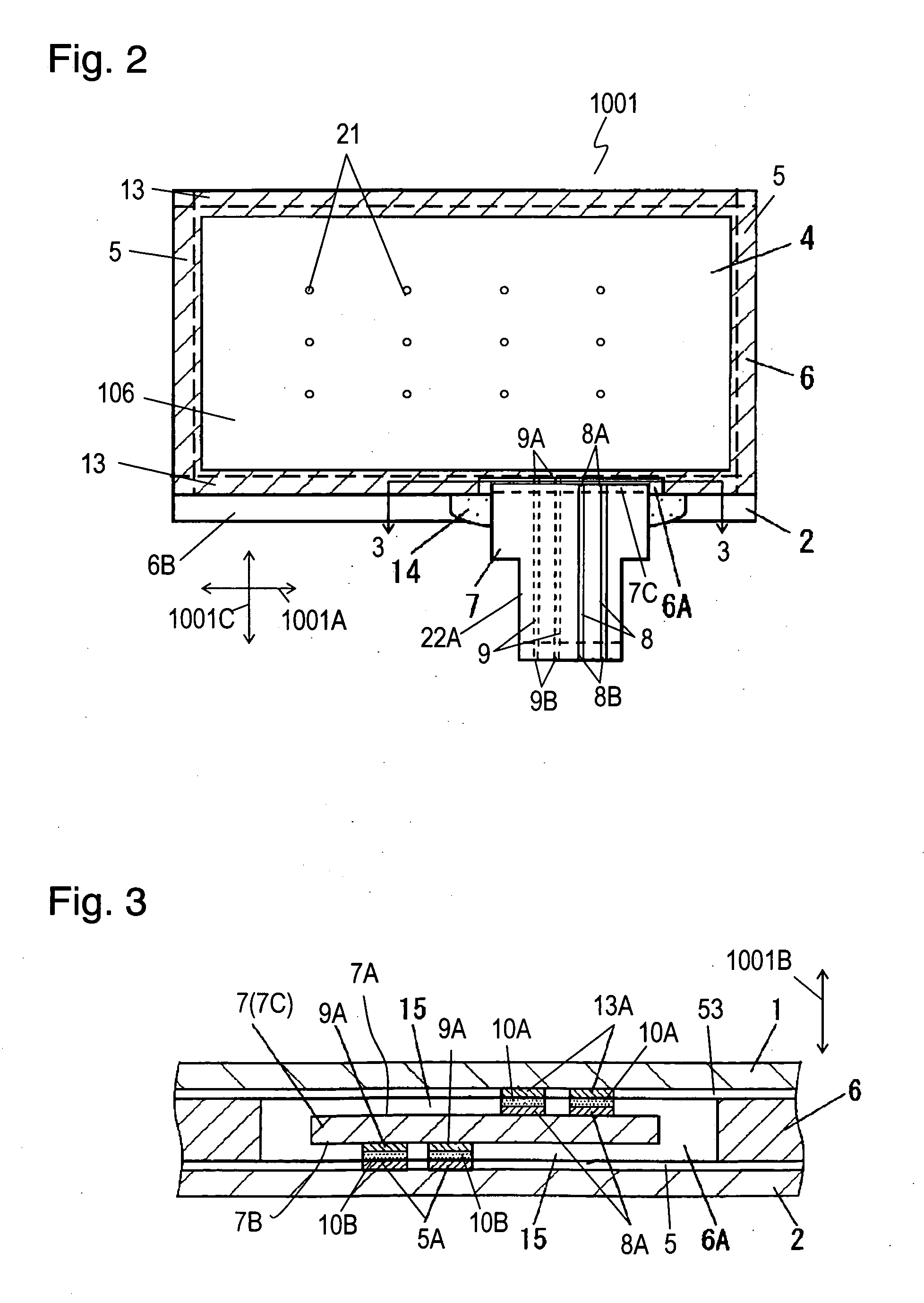

Backlight assembly using the same and liquid crystal display device

InactiveUS7224416B2Preventing an optical sheet from being wrinkled or scratchedMechanical apparatusElongate light sourcesOptical propertyLiquid-crystal display

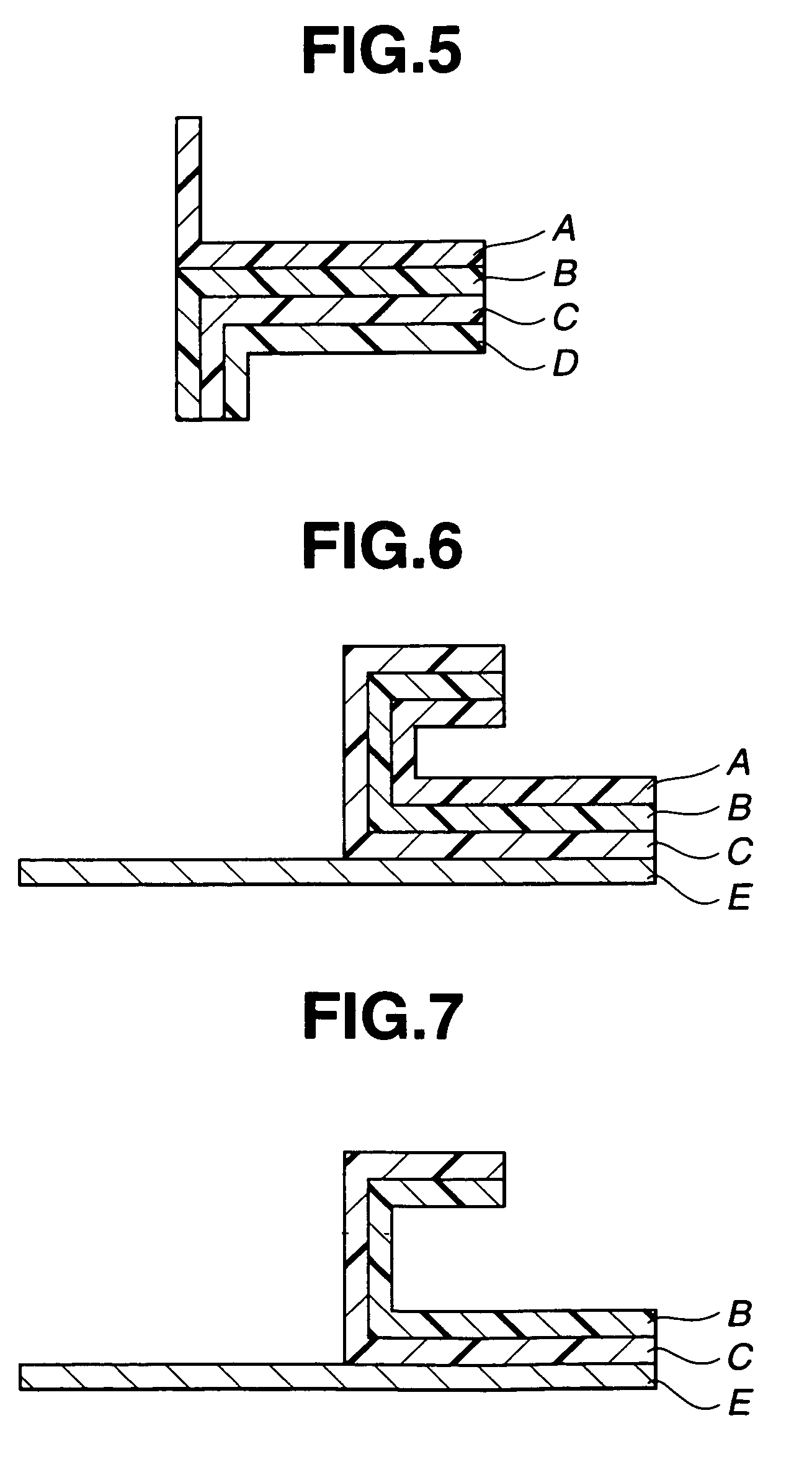

There are provided a backlight assembly (700) and an LCD device (1000) using the same. The backlight assembly (700) has an optical sheet (100) for improving light efficiency and optical properties thereof and an elastic adhesive member (130) disposed on the optical sheet (100). When the optical sheet (100) deforms with heat, the elastic adhesive member (130) may be expanded or contracted corresponding to deformation of the optical sheet (100) and absorb impact applied to LCD device. Accordingly, the backlight assembly (700) may prevent the optical sheet (100) from being wrinkled or scratched, thereby preventing display quality of the LCD device from being deteriorated.

Owner:SAMSUNG DISPLAY CO LTD

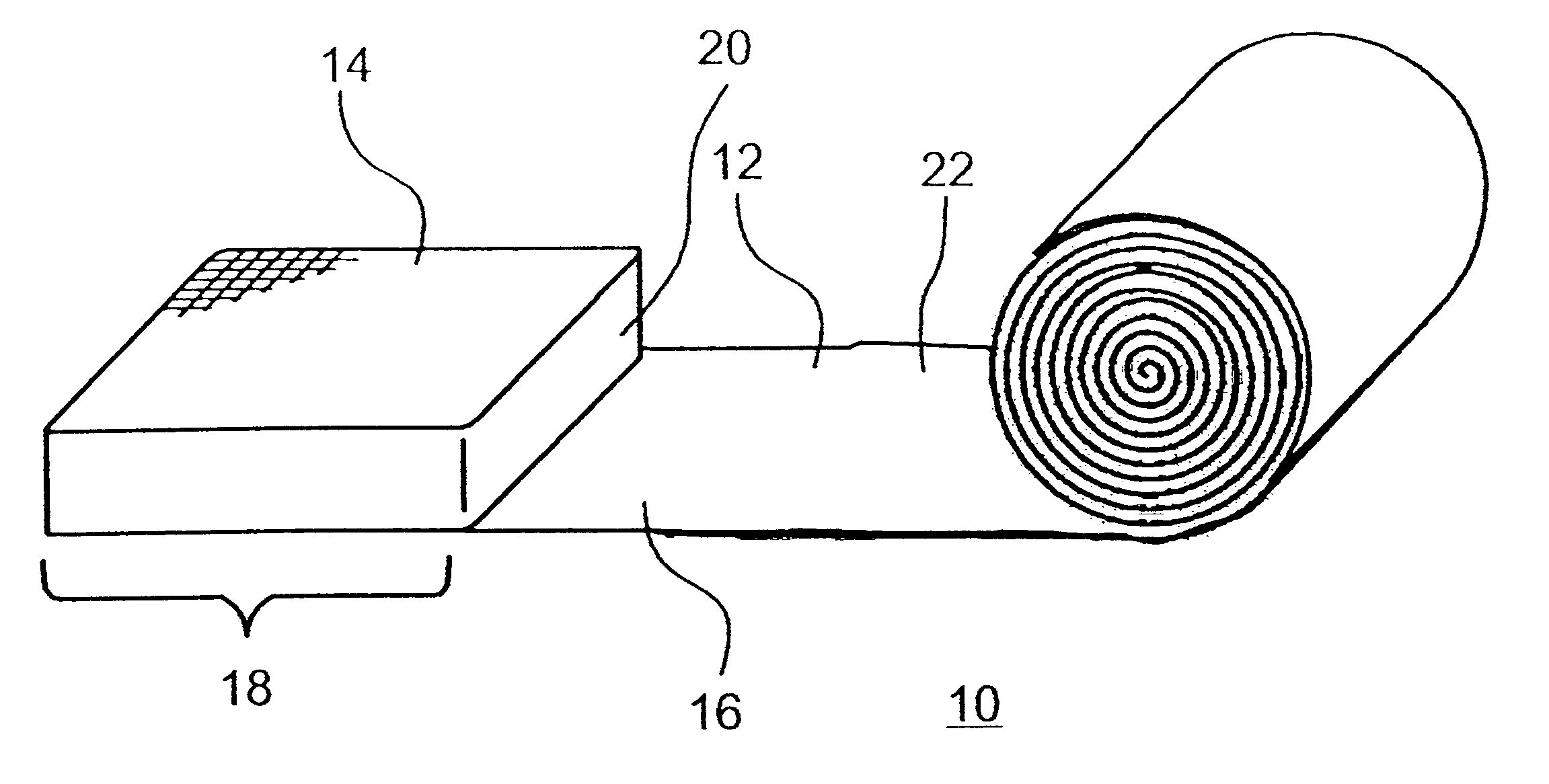

Reusable elastic adhesive sheet redetachable without residue or damage

InactiveUS7175898B2Large stretchCellulosic plastic layered productsSpecial surfacesPressure sensitiveChemistry

A single-sidedly or double-sidedly pressure-sensitively adhesive, elastic adhesive sheet comprising at least one layer of a pressure-sensitive adhesive, and having a maximum stretchability of more than 200% and a recovery of more than 60% after stretching to ⅔ of its maximum elongation, said pressure-sensitive adhesive (PSA) being based on a chemically crosslinked polyurethane, wherein the starting materials for the chemically crosslinked polyurethane include at least one isocyanate-reactive substance having a functionality of more than 2.0, in an amount of at least 5% by weight, based on the weight of the polyurethane composition, where the molecular weight of at least one of the starting materials used to form the polyurethane is being greater than or equal to 1000, at least one difunctional polyisocyanates are being used to form the polyurethane, and the ratio of maximum tensile stress to stripping stress is of said elastic adhesive sheet being more than 1.2, and the tensile stress at an elongation of 200% is being not more than 2.0 N / mm.sup.2.

Owner:TESA SE

Ultralight high-elastic rubber sole material and preparation method thereof

InactiveCN103205026AIncrease elasticityImprove bending resistanceSolesSpecific gravityButadiene-styrene rubber

The invention discloses an ultralight high-elastic rubber sole material and a preparation method thereof. The ultralight high-elastic rubber sole material comprises the following raw materials in parts by weight: 40-60 parts of natural rubber, 30-40 parts of synthetic rubber, 10-20 parts of SEBS (Styrene-Butadiene-Styrene Block Copolymer) rubber, 10-20 parts of synthetic EVA (Ethylene Vinyl-Acetate Copolymer), 30-40 parts of ultralight white carbon black, 6-10 parts of naphthenic oil, 3-5 parts of high-activity zinc oxide, 3-5 parts of activating agents, 2-3 parts of vulcanization accelerators, 1-2 parts of stearic acid, 2-3 parts of diethylene glycol and 1-3 parts of anti-aging agents. The preparation method of the ultralight high-elastic rubber sole material comprises four steps. The ultralight high-elastic sole rubber prepared through the method disclosed by the invention has the advantages of scientificity in formula, low cost, simple preparation process and lighter specific gravity of the sole material and effectively enhances the elasticity and bending resistant degree of a sole.

Owner:南平市天时雨投资合伙企业(有限合伙)

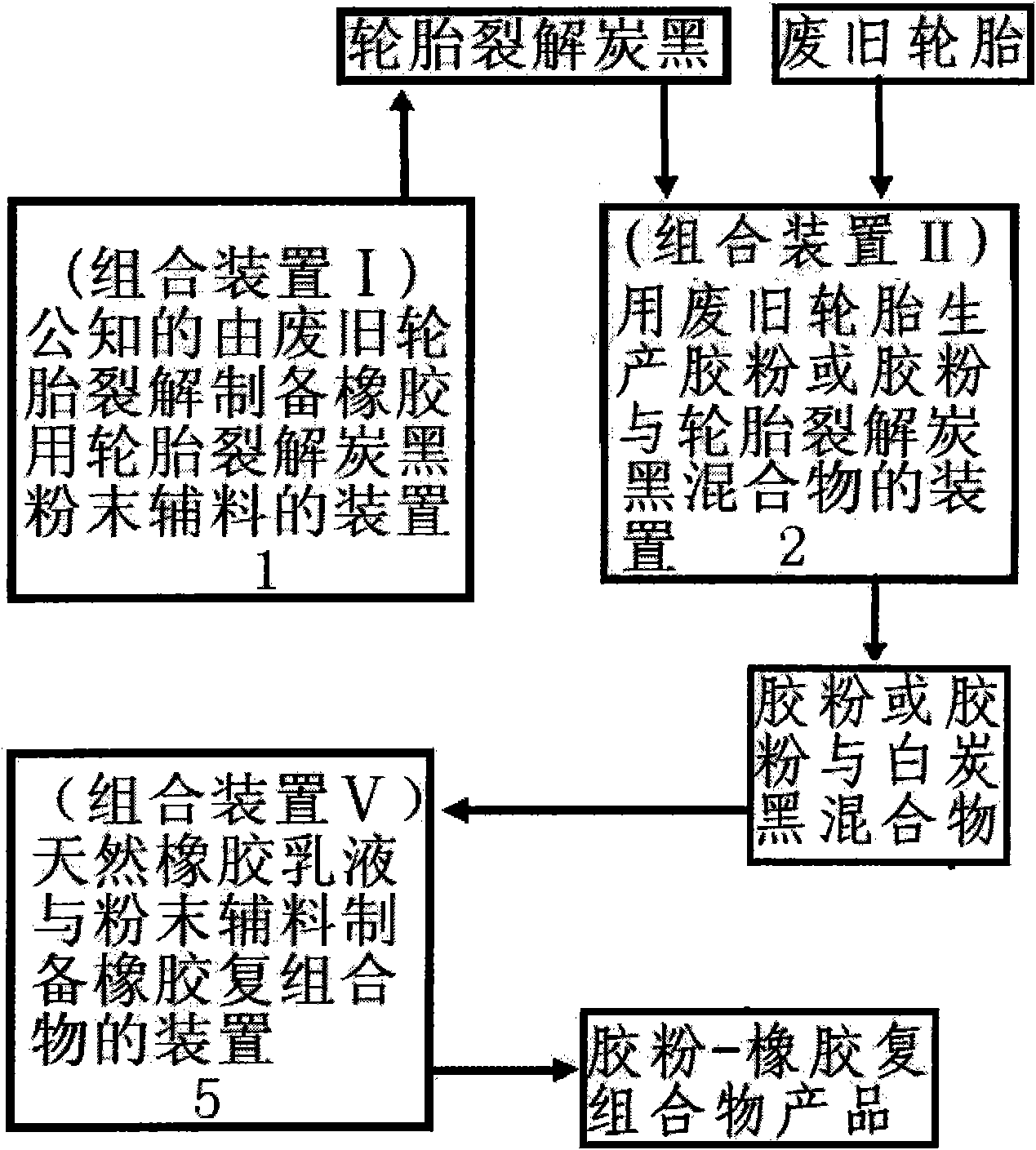

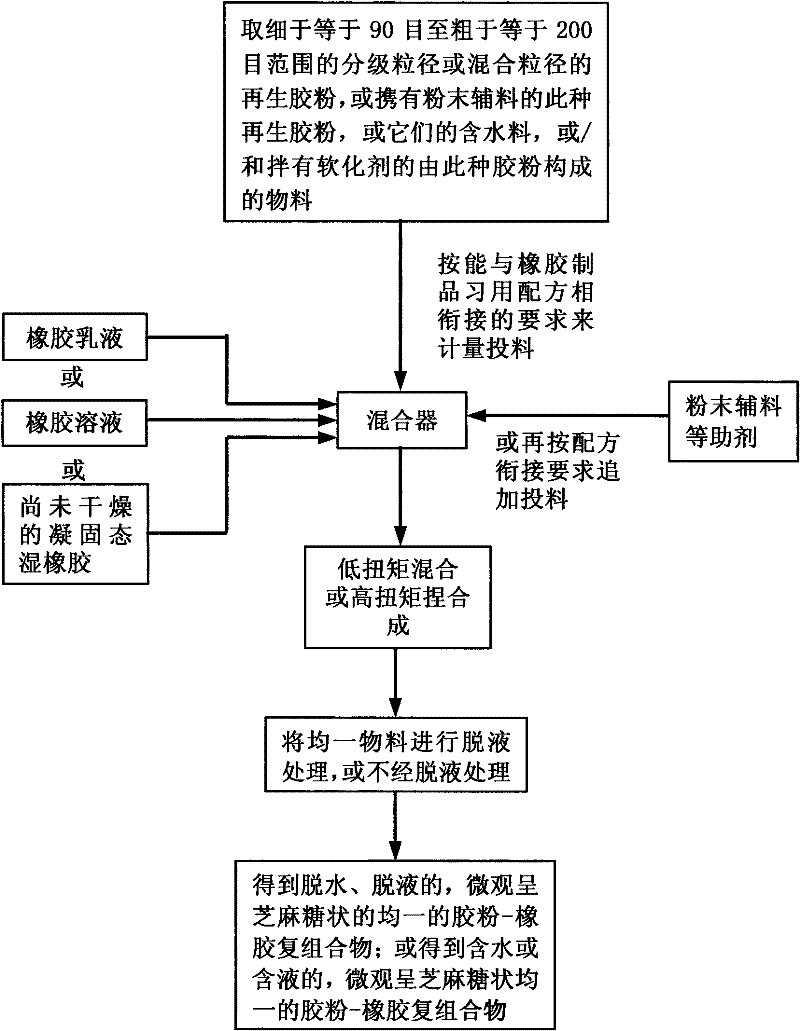

Latex mixing or solution mixing preparation method of rubber powder-rubber compound composition

The invention provides a latex mixing or solution mixing preparation method of a rubber powder-rubber compound composition, comprising the following steps of: mixing rubber powder, or rubber powder containing powder accessories, or sizing agent containing water or materials containing softening oil with rubber latex, or solution or undried solidified rubber to obtain rubber powder-rubber compound composition intermediate products, and then carrying out liquid removing treatment to obtain solid-state rubber powder-rubber compound composition products. The technical scheme provided by the invention obviously saves energy compared with the treatment process of kneading high-elasticity rubber micelle by utilizing the glue powder in the traditional rubber product industries, and greatly enhances the efficiency compared with the wet rubber drying process of the traditional rubber manufacturing. The provided rubber powder-rubber compound composition products enables up course, middle course and lower course of a rubber industrial chain to be tightly spliced, and then the entire industrial chain can receive the benefits of energy saving, emission reduction and synergia.

Owner:上海橡源驰晨环保科技发展有限公司

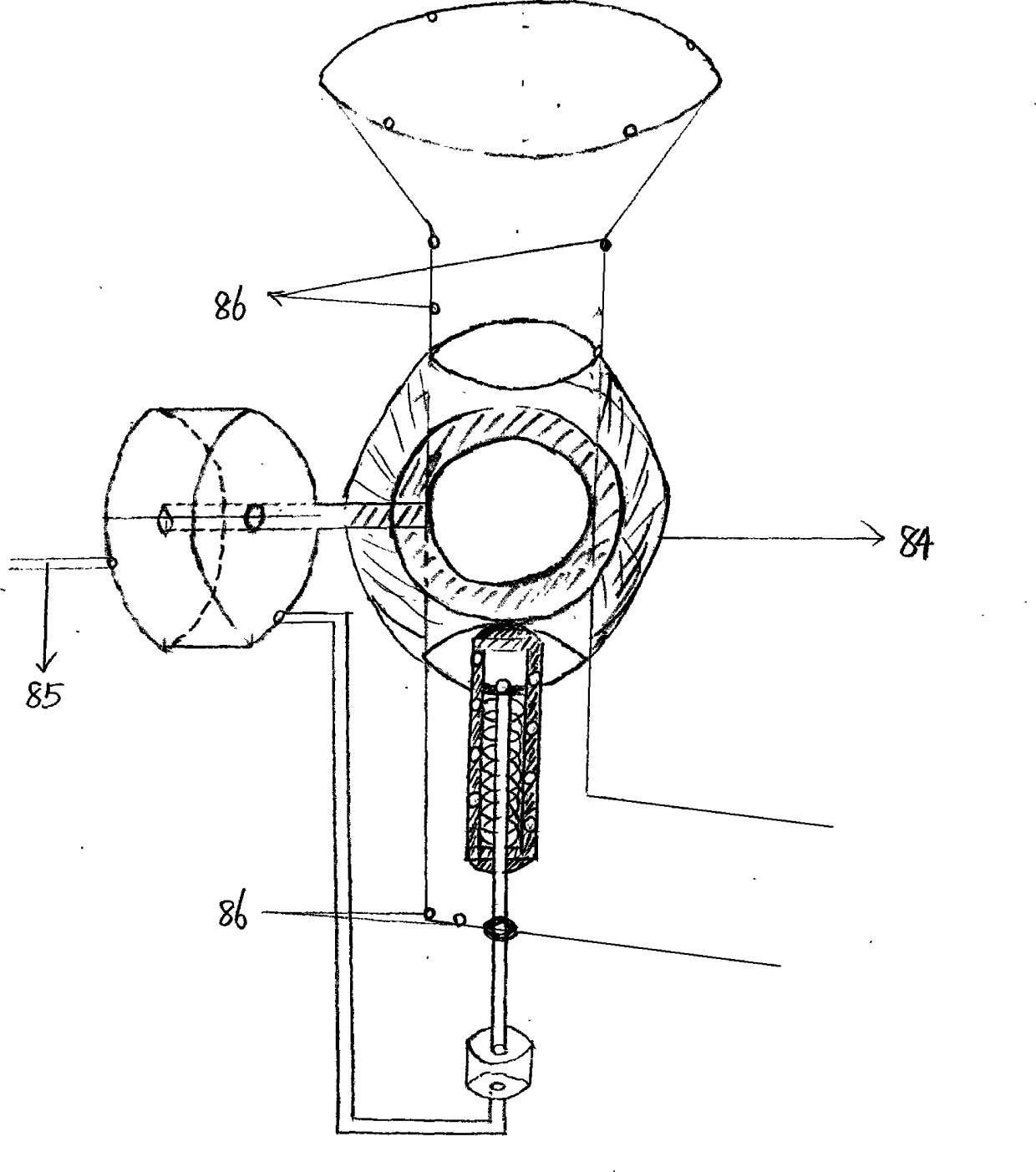

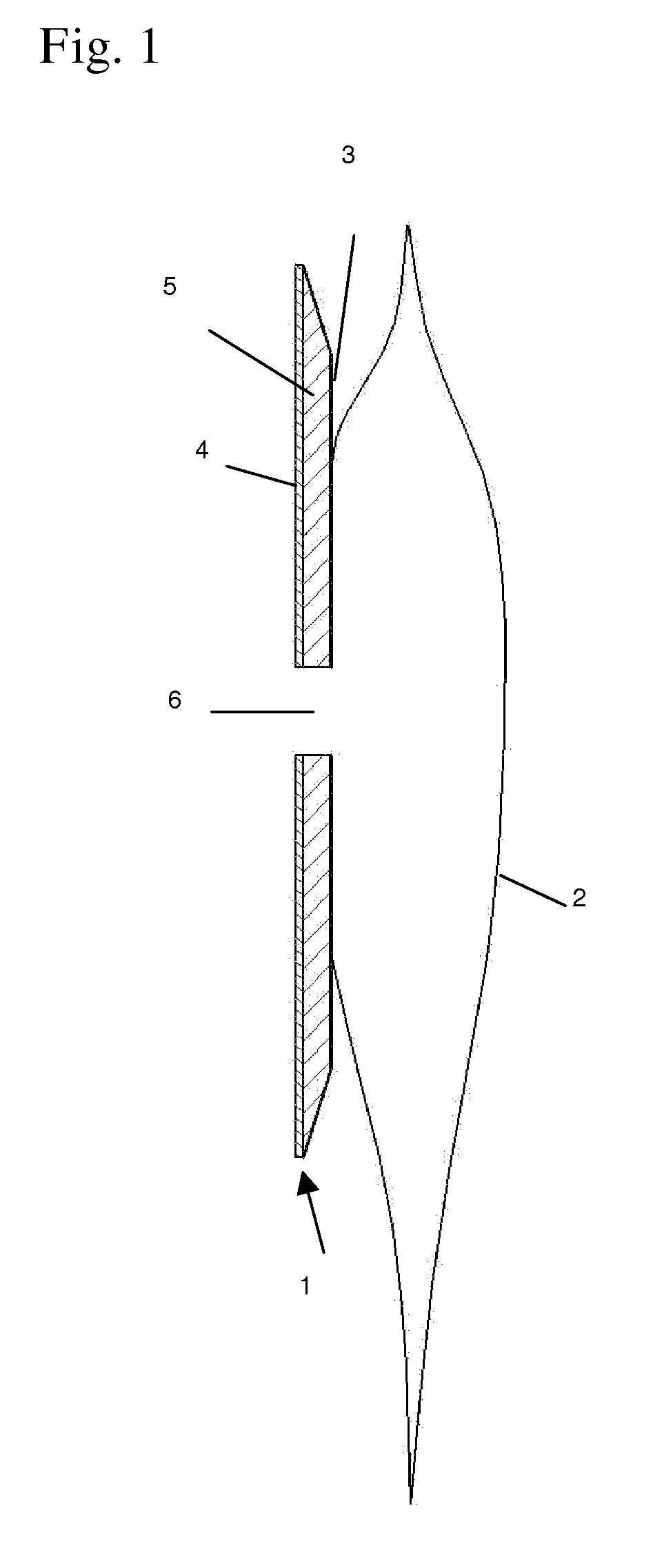

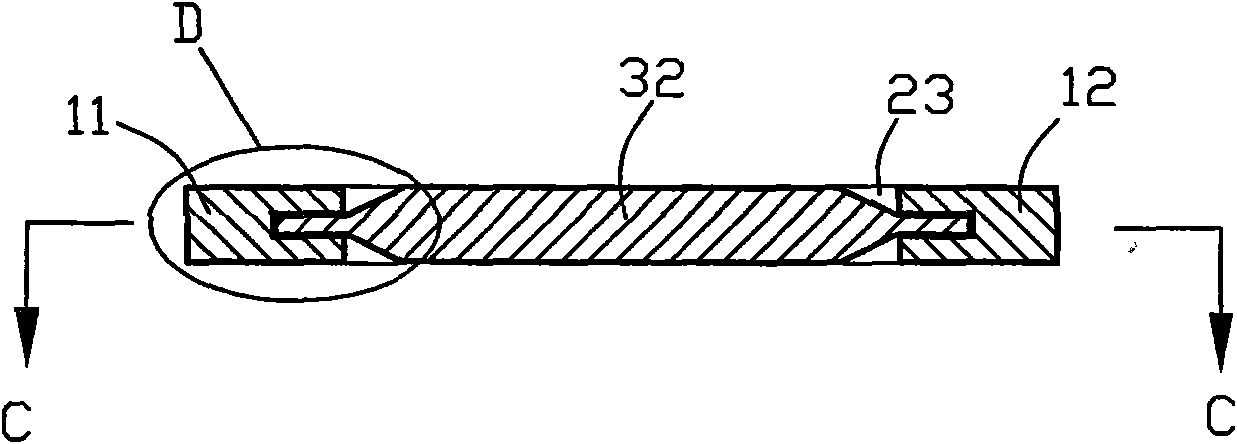

Piezoelectric electroacoustic transducer

ActiveUS20090015108A1Avoid crackingPrevents an excessive curvature of a piezoelectric diaphragmPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive transducersTransducerEngineering

Owner:MURATA MFG CO LTD

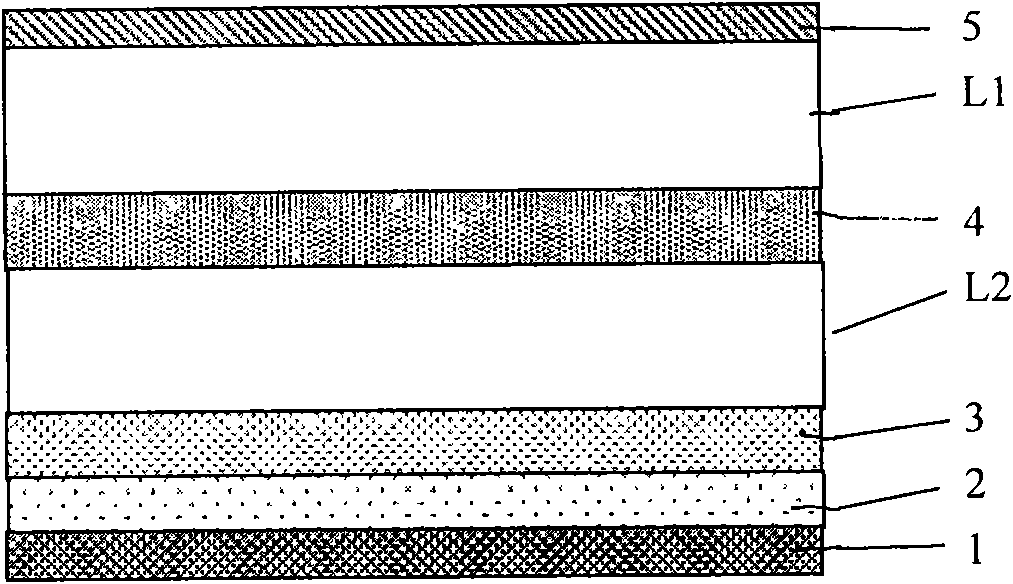

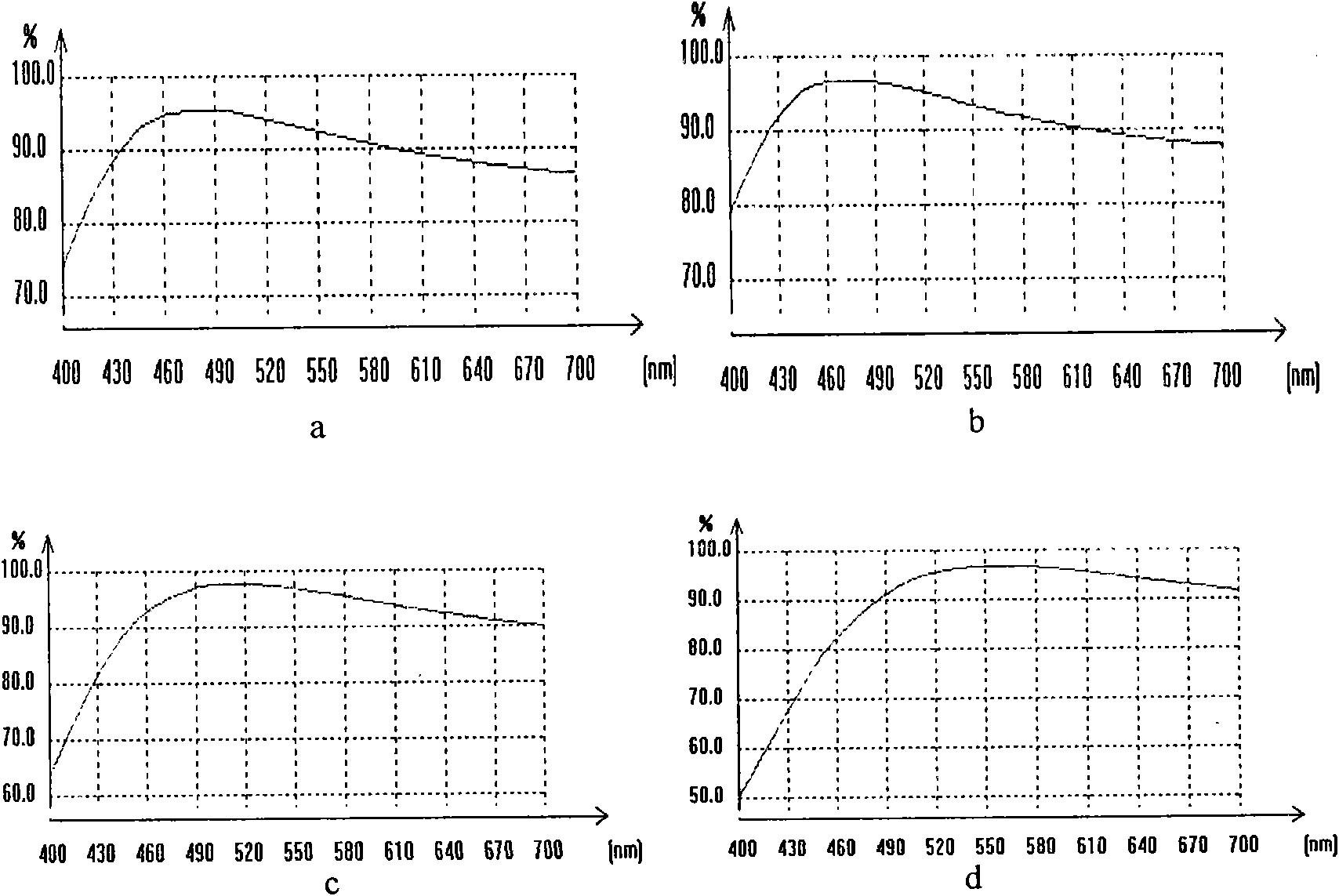

Compound conducting film and touch screen using same

InactiveCN101581800AGood light transmissionImprove performanceLayered productsCoatingsElectrical resistance and conductanceDielectric

The invention discloses a compound conducting film which comprises a first flexible transmitting base layer L1 with an upper surface and a lower surface, a second flexible transmitting base layer L2 with an upper surface and a lower surface, an elastic adhesive layer positioned between the first flexible transmitting base layer L1 and the second flexible transmitting base layer L2, inorganic dielectric film systems of at least two layers of dielectric films formed by sequentially staggering high-index inorganic dielectric films and low-index inorganic dielectric films and settled in sequence on the lower surface of the second flexible transmitting base layer L2 , and a transparent conducting film layer positioned at the outermost layer of the film system, wherein the thickness of the transparent conducting film layer meets the value being 3-10mm required by a square resistance, at least two dielectric film systems consisting of the high-index inorganic dielectric and both the low-index inorganic dielectric are settled by adopting a vacuum magnetron sputtering method so that optical interference film systems with whole transmittance rate reaching more than 80 percent is formed. The invention also provides a touch screen using the compound conducting film.

Owner:甘国工

Room-temperature curing high-temperature-resistant organic silicon rubber material as well as preparation method and application of room-temperature curing high-temperature-resistant organic silicon rubber material

ActiveCN109593465AHigh strengthSimple formula designFireproof paintsNon-macromolecular adhesive additivesRubber materialRoom temperature

The invention provides a room-temperature curing high-temperature-resistant organic silicon rubber material as well as a preparation method and application of the room-temperature curing high-temperature-resistant organic silicon rubber material. The rubber material is low in cost, capable of realizing room temperature curing, resistant to high temperature and good in process performance, tensileproperty and adhesive property. The room-temperature curing 350-DEG C high-temperature-resistant organic silicon rubber material is composed of double components, wherein the component A is used as abasic rubber material and mainly comprises basic rubber, namely hydroxy-terminated polysiloxane containing different functional groups, precipitated white carbon black pretreated by using a certain amount of treating agent, an optional amount of silicon resin and a certain amount of matched high-temperature-resistant additive; and the component B is formed by matching a polysilazane room-temperature curing agent with a certain amount of catalyst. The room-temperature curing 350-DEG C high-temperature-resistant organic silicon rubber material is simple and convenient in construction process andis an ideal matrix material for preparing an elastic adhesive sealing material and an elastic thermal protection coating.

Owner:INST OF CHEM CHINESE ACAD OF SCI

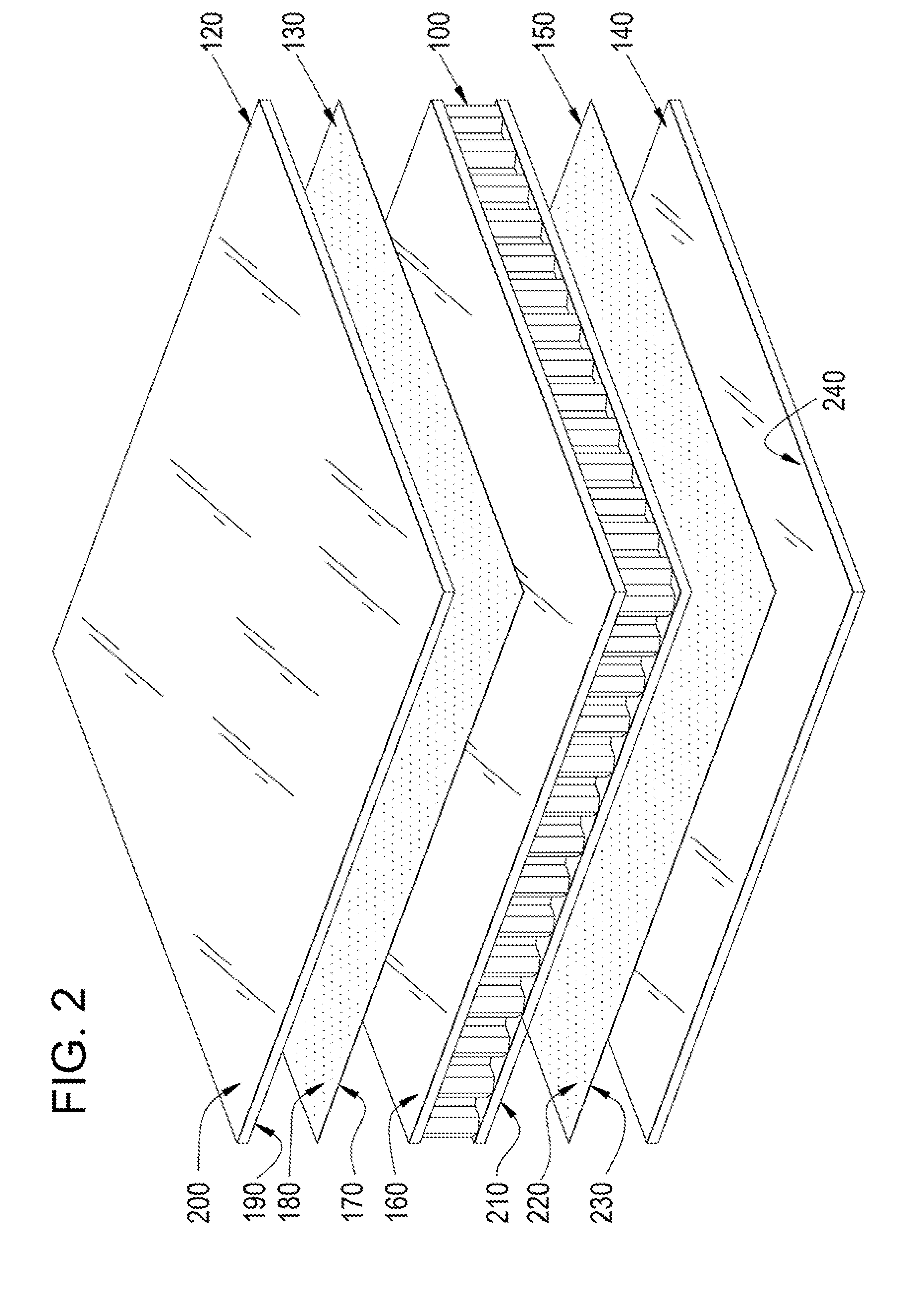

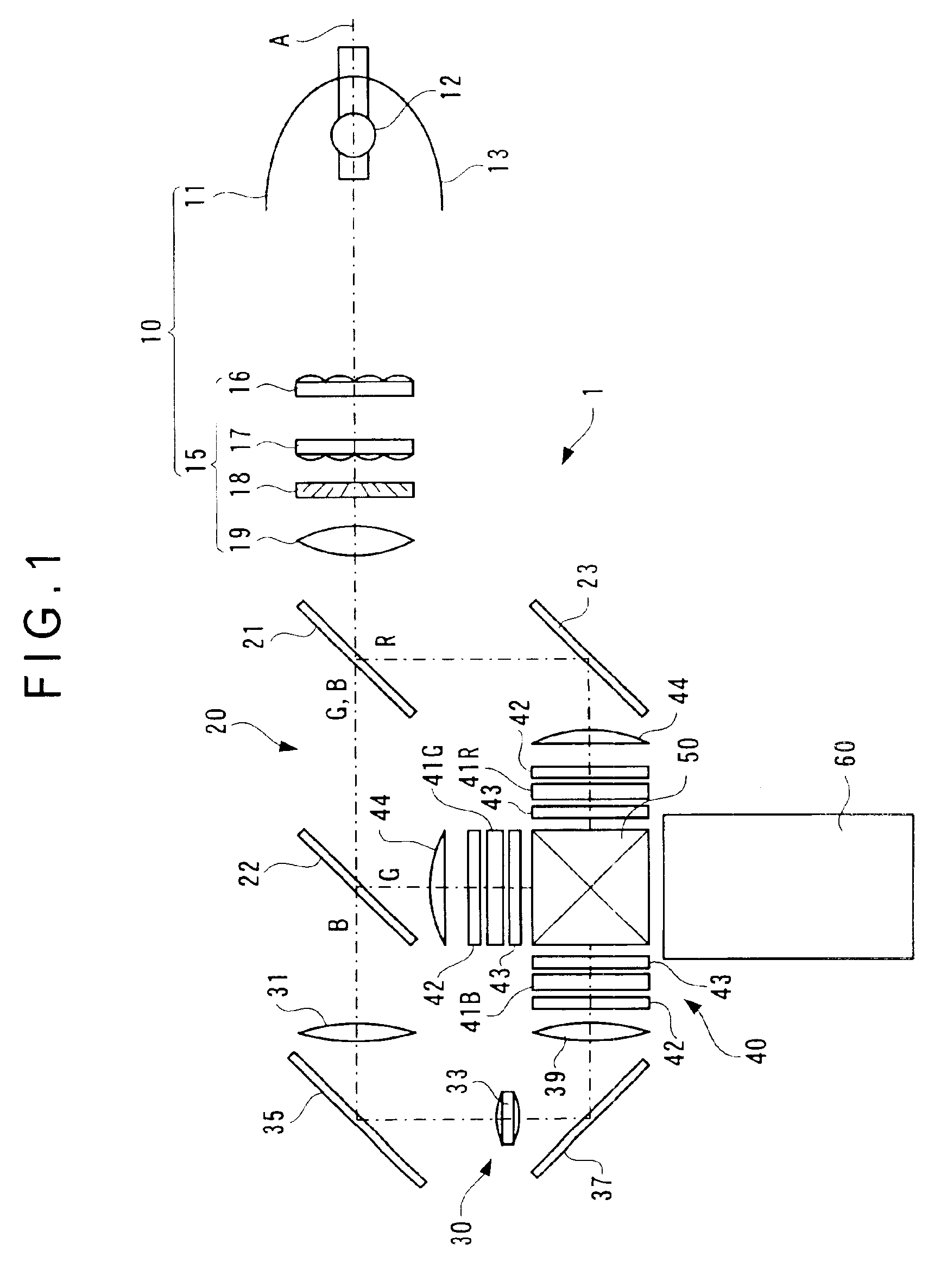

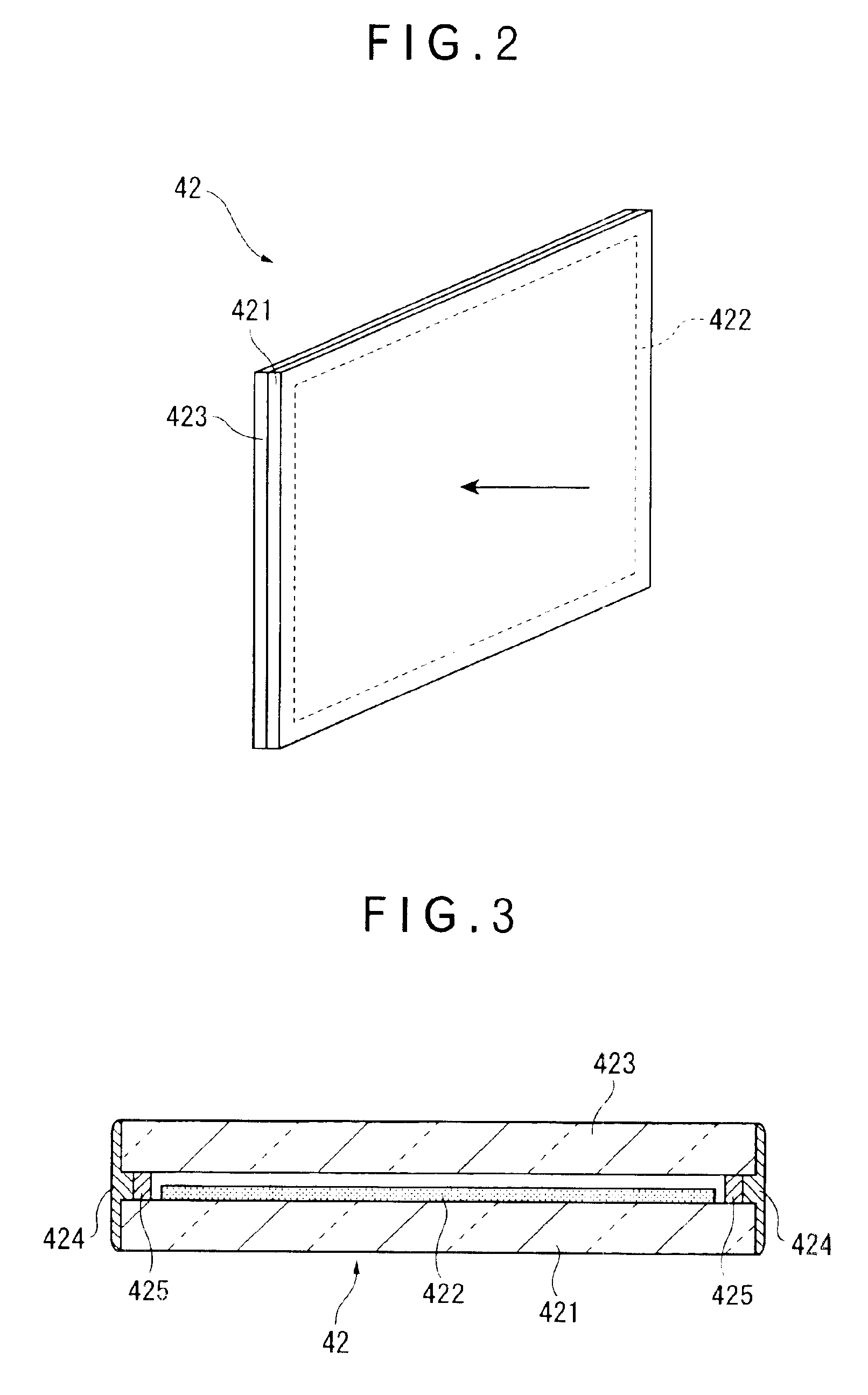

Polarizer and optical device using the polarizer

A polarizer for converting incident light beam into a linear polarization light beam has a base plate of a material of low linear expansion coefficient, high thermal conductivity or low photoelastic constant, a birefringent portion formed by arranging minute metal concave tread on a surface of light-emission side of the base plate in stripe, and a protection plate covering the birefringent portion and made of the same material as the base plate, the base plate and the protection plate being bonded by an elastic adhesive on the periphery thereof so that the birefringent portion is sealed and enclosed by the protection plate and the elastic adhesive.

Owner:SEIKO EPSON CORP

Specular coatings for composite structures

Disclosed herein is a method for bonding dissimilar materials using an elastic adhesive to permit the bond to withstand variations in temperature and pressure. The use of elastic adhesive accommodates previous problems associated with large differences in thermal expansion coefficient between dissimilar materials, and provides a thermally and chemically stable materials combination that withstands large thermal shock loads, such as may be experienced in a space environment. Also disclosed herein is a method for attaching a coating to a structure. In particular applications, the coating may be (1) specular (greater than 98% specularity); or (2) RF reflective for use in applications including but not limited to high frequency satellite communications.

Owner:NASA

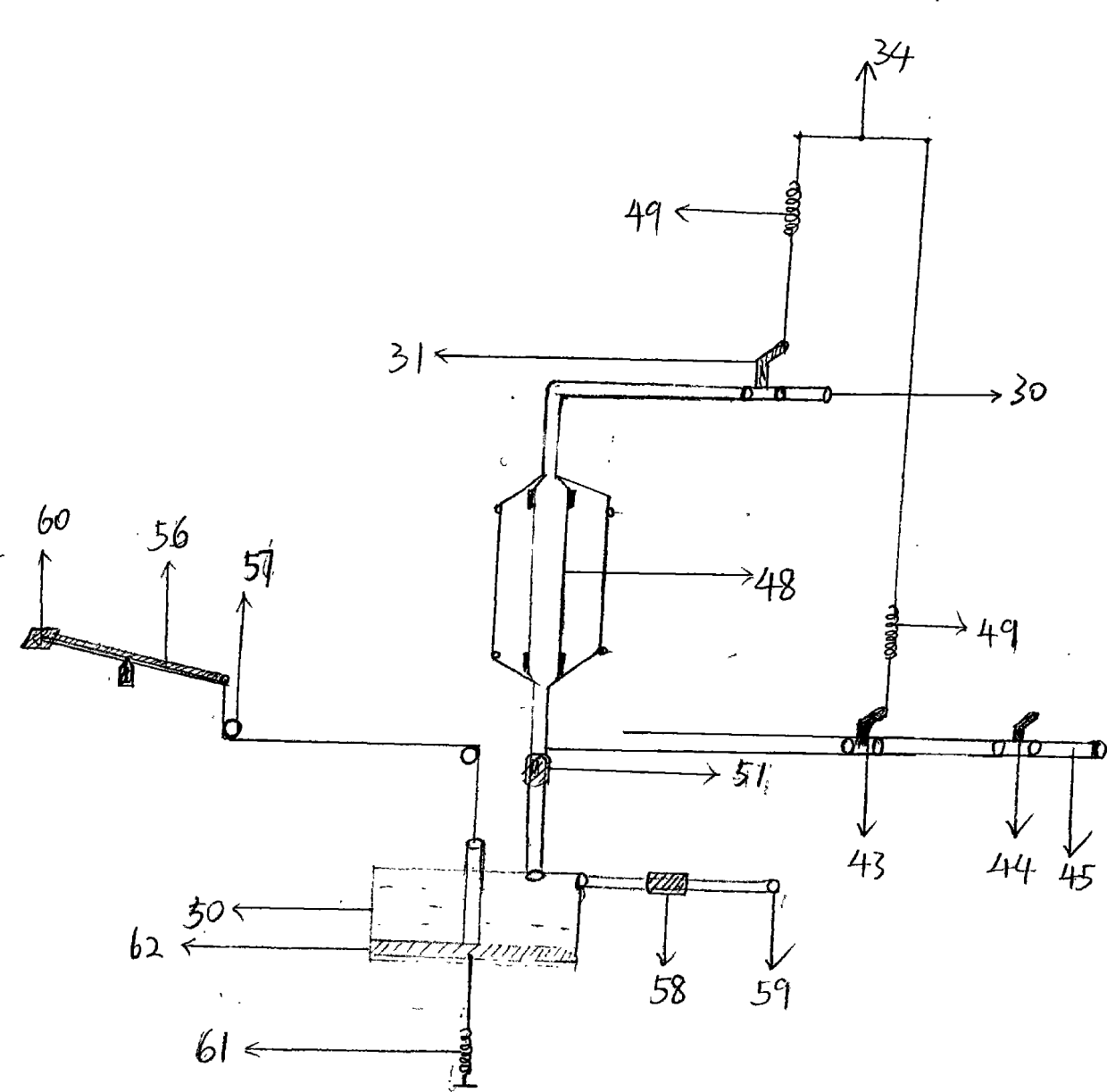

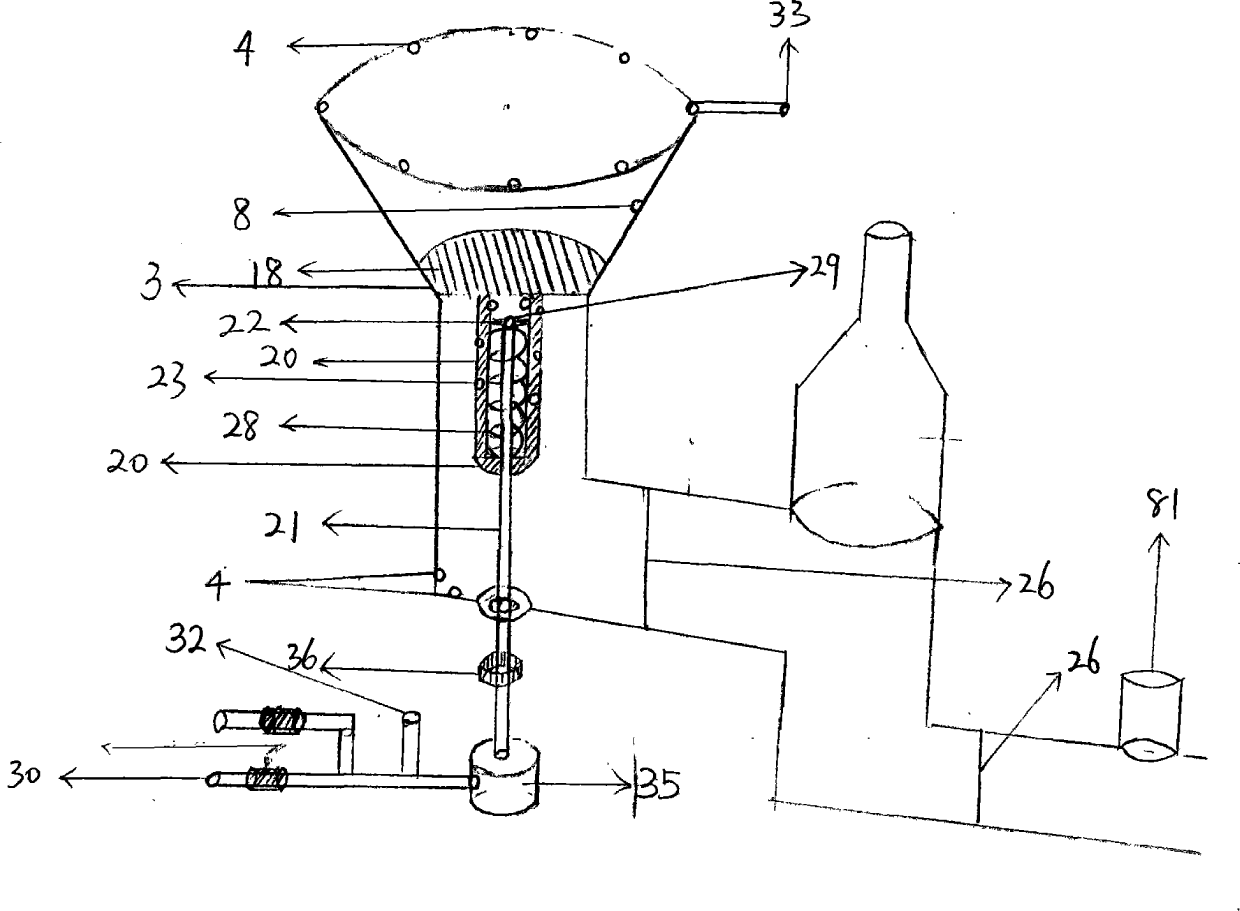

Water-saving, non-blocking, clean and sanitary automatic toilet

ActiveCN102817409APower saving control systemIncrease flexibilityWater closetsFlushing devicesPistonSpray nozzle

The invention discloses a water-saving, non-blocking, clean and sanitary automatic toilet which uses the human gravity switching force. A toilet cover is automatically closed and opened, so the toilet can flush automatically after being used. A lower opening of the toilet is separated in a piston or ball valve manner so as to circulate with the air in a lower pipeline. Compared with the sealing effect of the traditional water lock, the toilet has excellent effect and saves water. The toilet piston can move downwards (upwards) and rotate; an upper opening, a lower opening and a passage turning of the toilet are provided with fixing spray nozzles; a spray shaft pipe of the toilet is provided with a spray nozzle which is capable of rotating along the shaft; the water of the toliet is added by the tap water or is finished by pedalling; the spraying process is finished by recycling an elastic glue pipe; the pressure of cleaning stream of the toilet is greater than that of the traditional toilet; the toilet saves water; and the spray nozzles of the toilet has a sleeve structure. The toilet can be cleaned by the water steam; and a steam pot is provided with a heating passage which is communicated with the toilet ring. The structure of the connection passage ball valve of the toilet is controlled by the spraying pressure. The inner wall of the upper part of the toilet is provided with a camera.

Owner:ZHEJIANG KEZHUDA MACHINERY TECH CO LTD

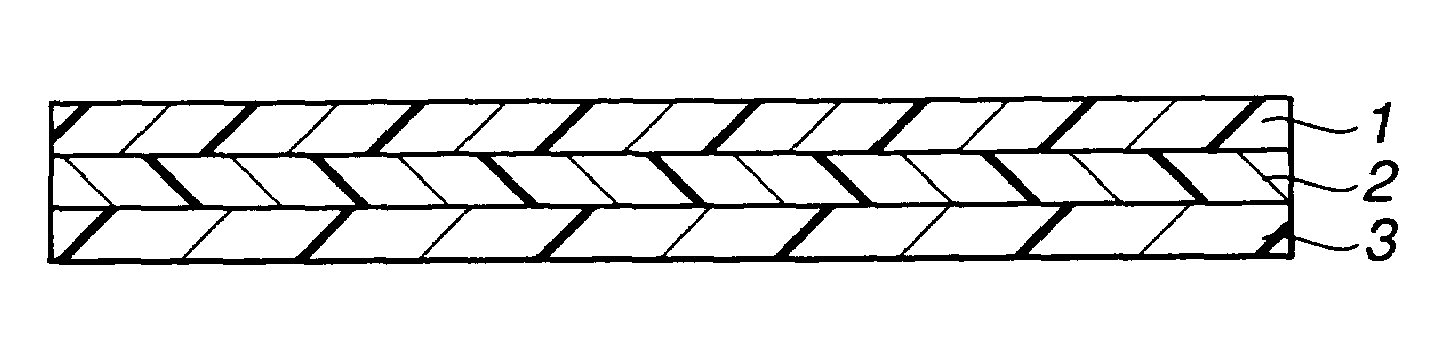

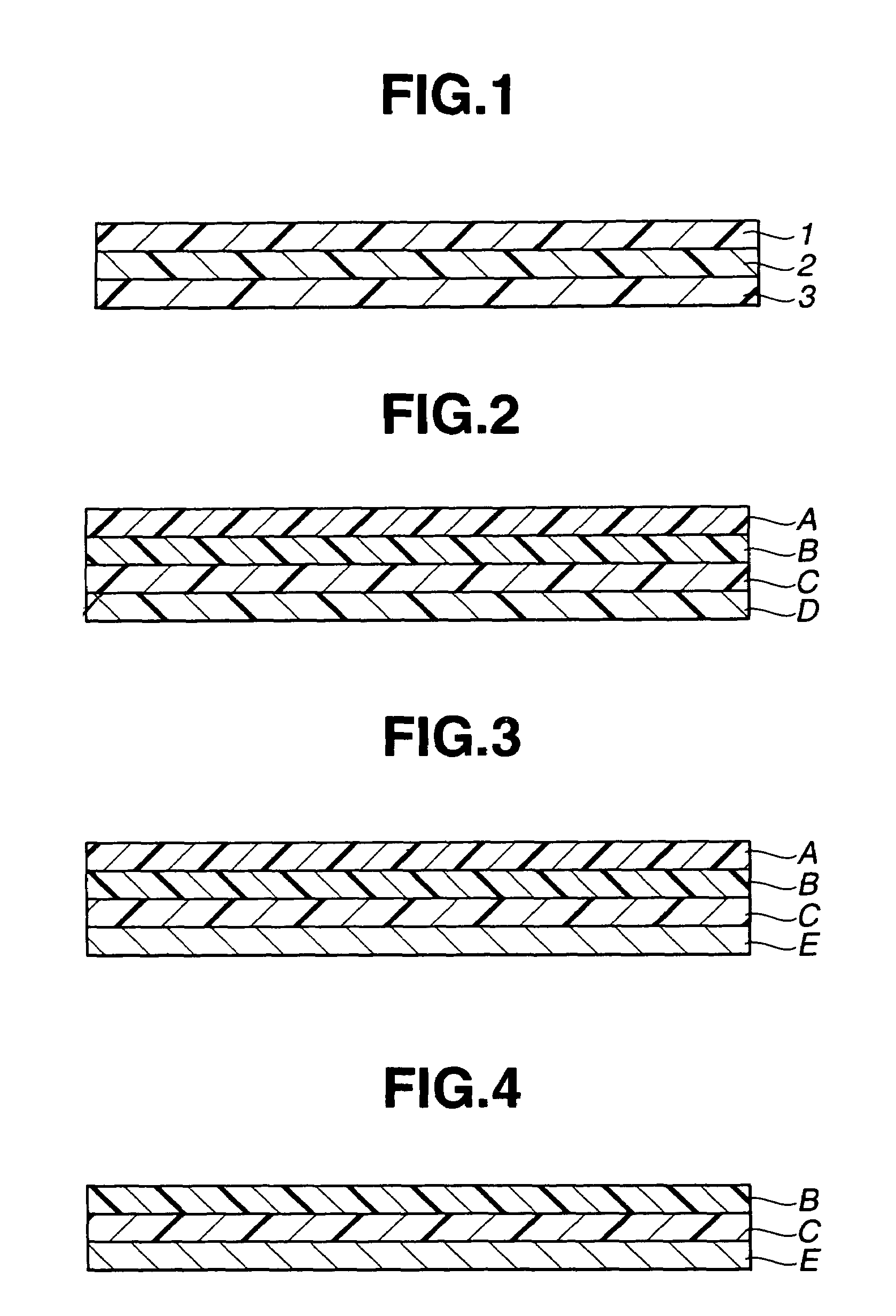

Method for the surface treatment of a fluorine resin, method for making a laminate, and a laminate

InactiveUS6972068B1Excellent in initial bonding property and storage stabilityReliably madeLamination ancillary operationsLayered product treatmentPolyresinEthylene-vinyl acetate

The invention relates to a laminate, which has at least a portion where a fluorine resin and a crosslinking elastic adhesive body such as of an ethylene-vinyl acetate copolymer or the like are directly bonded together and which is used as a window material of buildings or mainly used as an outdoor electric member and also to a method for making the laminate. More particularly, the invention provides a surface-treating method of a fluorine resin suited to impart bonding properties to a fluorine resin for the laminate, to a laminate having a good property of bonding between the fluorine resin and the crosslinking elastic adhesive body, and also to a method for making such a laminate as mentioned above.

Owner:BRIDGESTONE CORP

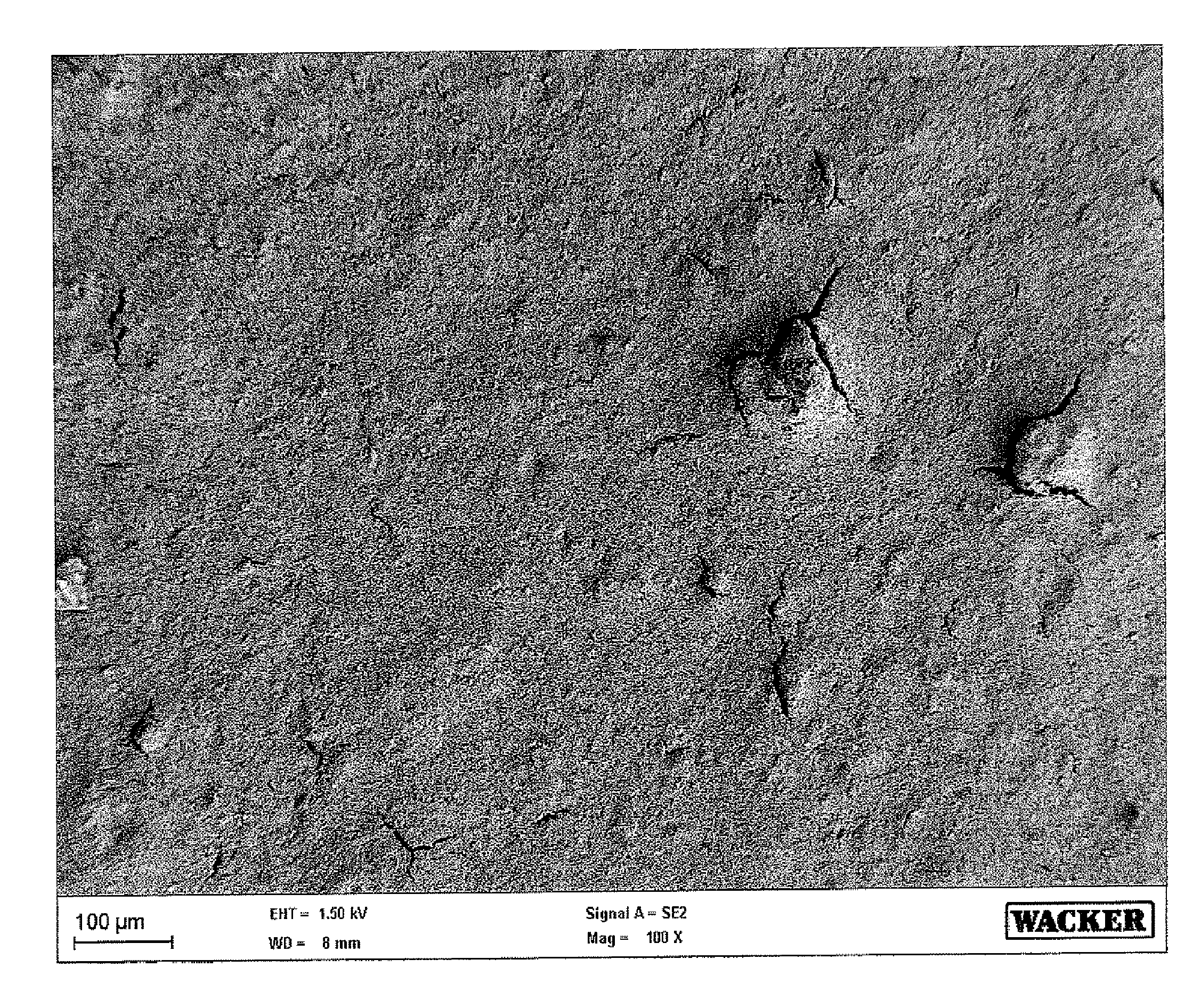

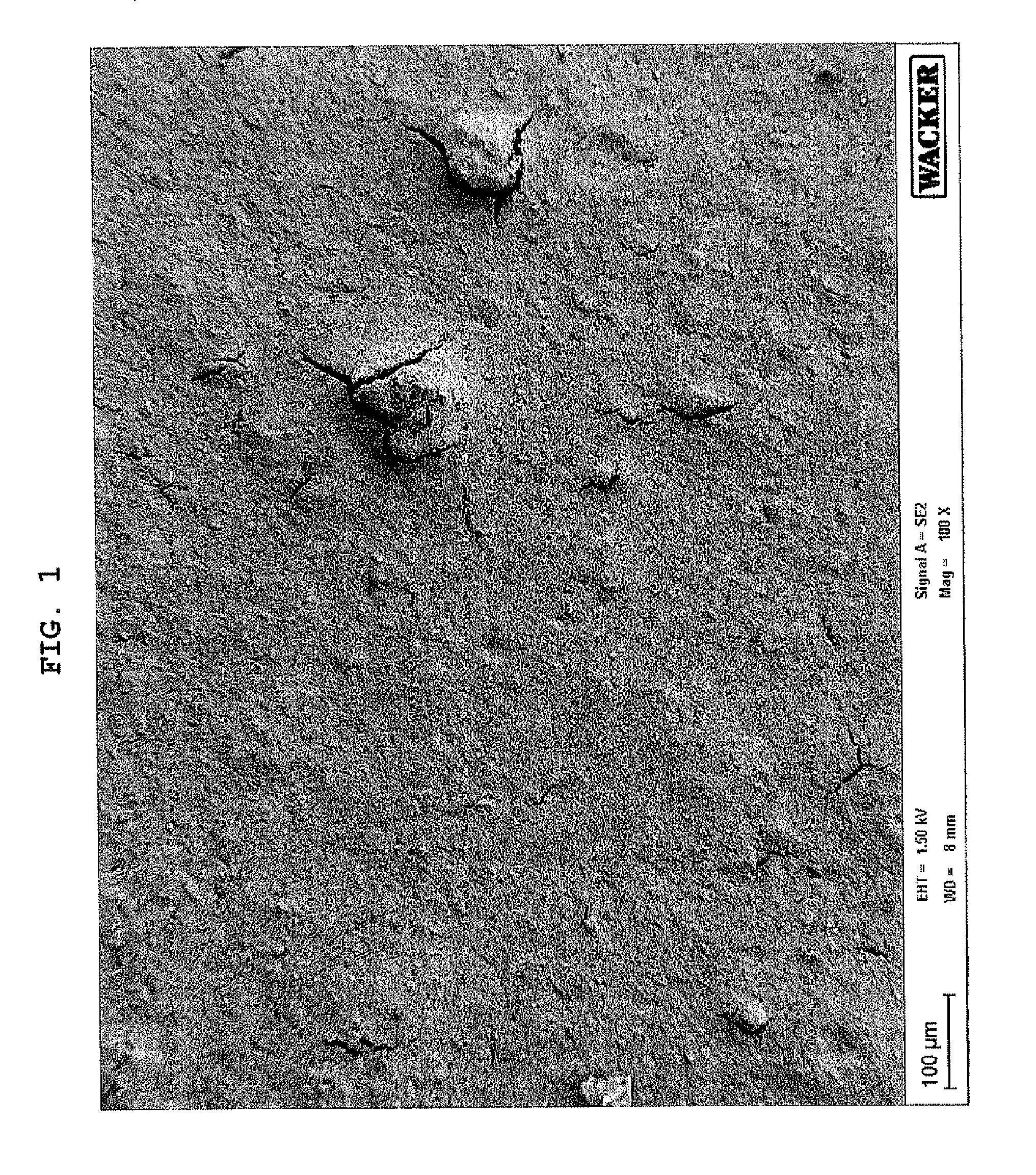

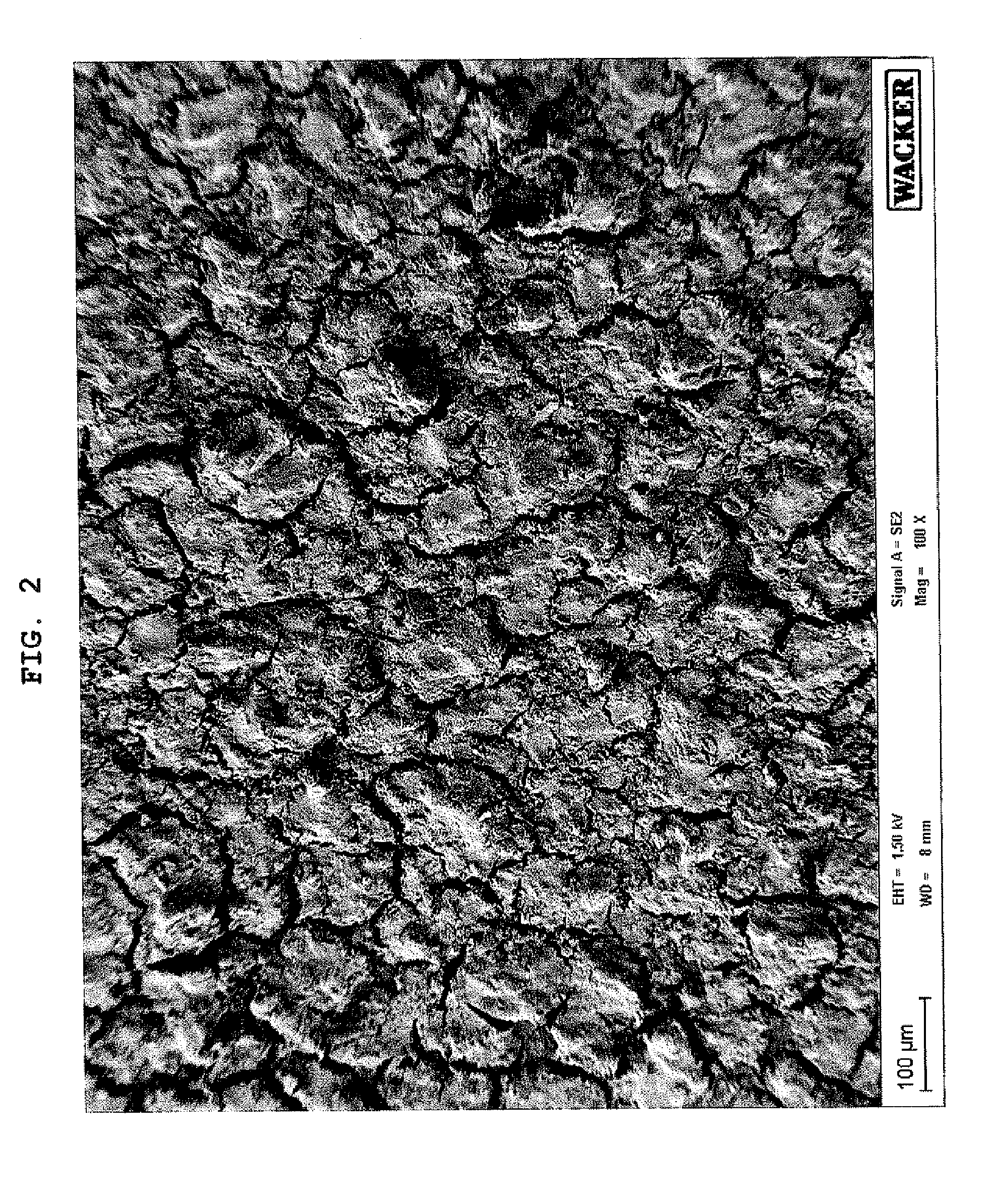

Highly Hydrophobic Coatings

InactiveUS20110263751A1Stable structureGood conditionLayered productsRecord information storageFine particulatePolymer chemistry

The invention relates to a suspension comprising: fine-particulate particles in an amount of 0.01-50 wt %, wherein the particles have a fractal mass dimension Dm of less than or equal to 2.8, —fluid-elastic adhesive in an amount of 101-1000 parts by weight based on 100 parts of particles.

Owner:WACKER CHEM GMBH

Body waste collecting device

InactiveUS20100191201A1Eliminates or-atSoft and flexible attachmentSurgical adhesivesPharmaceutical delivery mechanismCross-linkEngineering

Owner:COLOPLAST AS

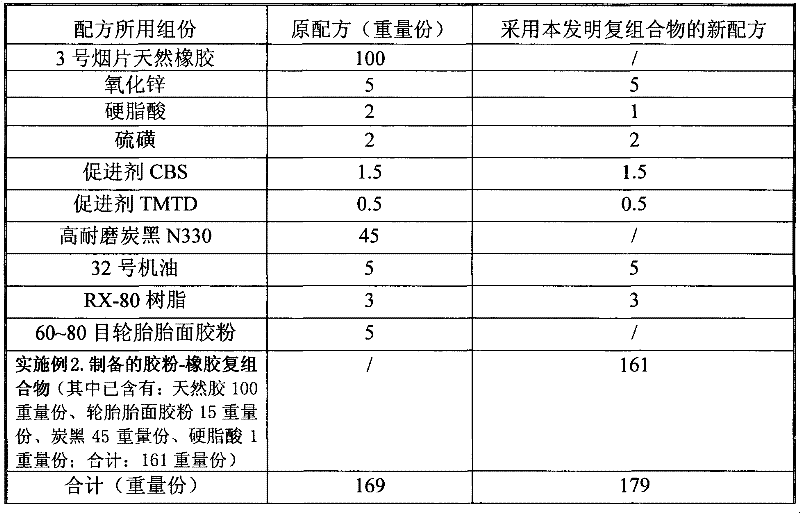

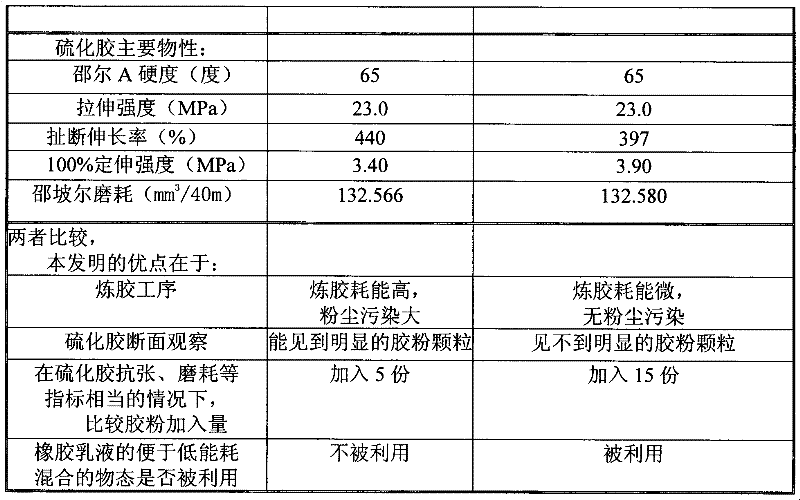

Preparation method of composition used for rubber product, and product thereof

The invention discloses a preparation method of a composition used for a rubber product, and a product thereof. The method comprises steps that: under normal temperature, reclaimed rubber particles are mechanically crushed into reclaimed rubber powder with mixed sizes or graded sizes of no more then 90 meshes and no less than 200 meshes, or the reclaimed rubber powder with powdery auxiliary materials, or a watery material thereof, and / or a material composed of the rubber powder mixed with a softener; the material obtained in the previous step is mixed with a rubber emulsion or a rubber solution or a coagulated wet rubber phase which is not dried; the mixture is processed through a liquid removing treatment, such that a solid rubber powder-rubber composite product is obtained; or the mixture is not processed through the liquid removing treatment, such that a rubber powder-rubber composite product containing water or liquid is obtained. Compared to a processing technology in current rubber industries wherein rubber powder is masticated into high-elasticity rubber balls, the method provided by the invention is substantially energy saving. Compared to a wet rubber drying process in the current rubber industries, the method provided by the invention has greatly improved efficiency. With the provided composite product, upstream, middle stream and downstream of a rubber industrial link can be tightly combined, and benefits such as energy saving, discharge reducing, and efficiency enhancing can be provided.

Owner:陈汇宏 +1

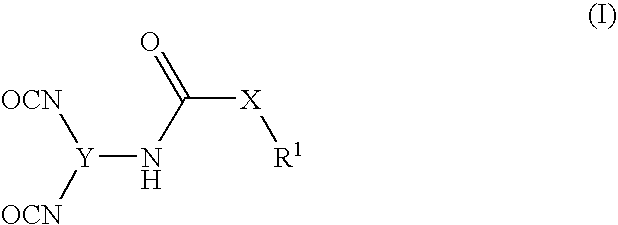

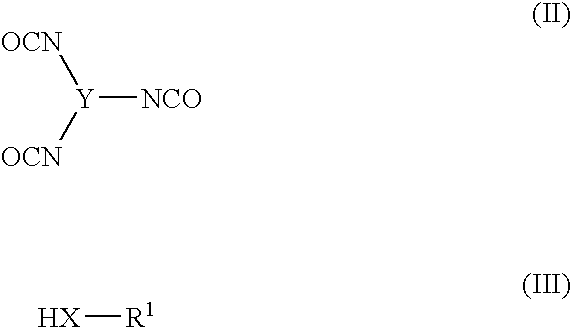

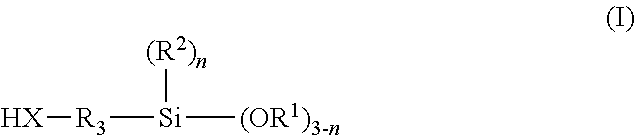

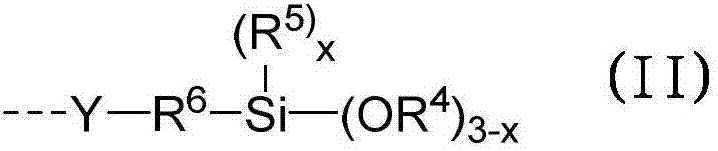

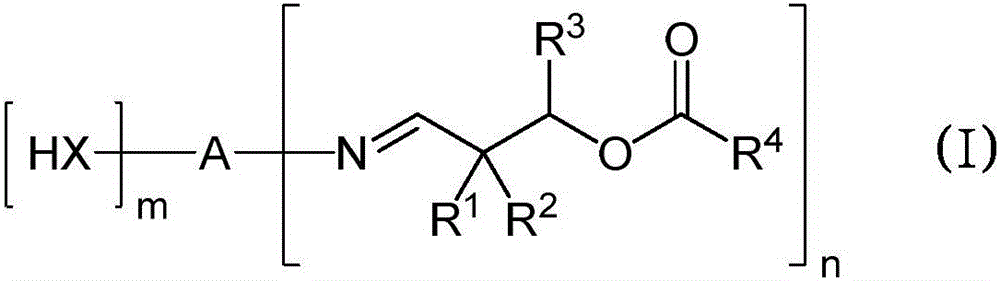

Adducts containing isocyanate groups and composition adhering effectively to painted substrates

InactiveUS20070055038A1Improve adhesionEffective adhesionOrganic chemistryPolyureas/polyurethane adhesivesExtensibilitySealant

The present invention relates firstly to adducts of the formula (I) which are obtainable from the reaction of an oligomeric aliphatic polyisocyanate and a compound of the formula HX—R1. Secondly the invention relates to one-component or two-component compositions which comprise such adducts of the formula (I). The adducts of the formula (I) find a use as adhesion promoters and are suitable in particular for use in elastic adhesives and sealants. The cured one-component or two-component compositions exhibit excellent paint adhesion in tandem with high extensibility.

Owner:SIKA TECH AG

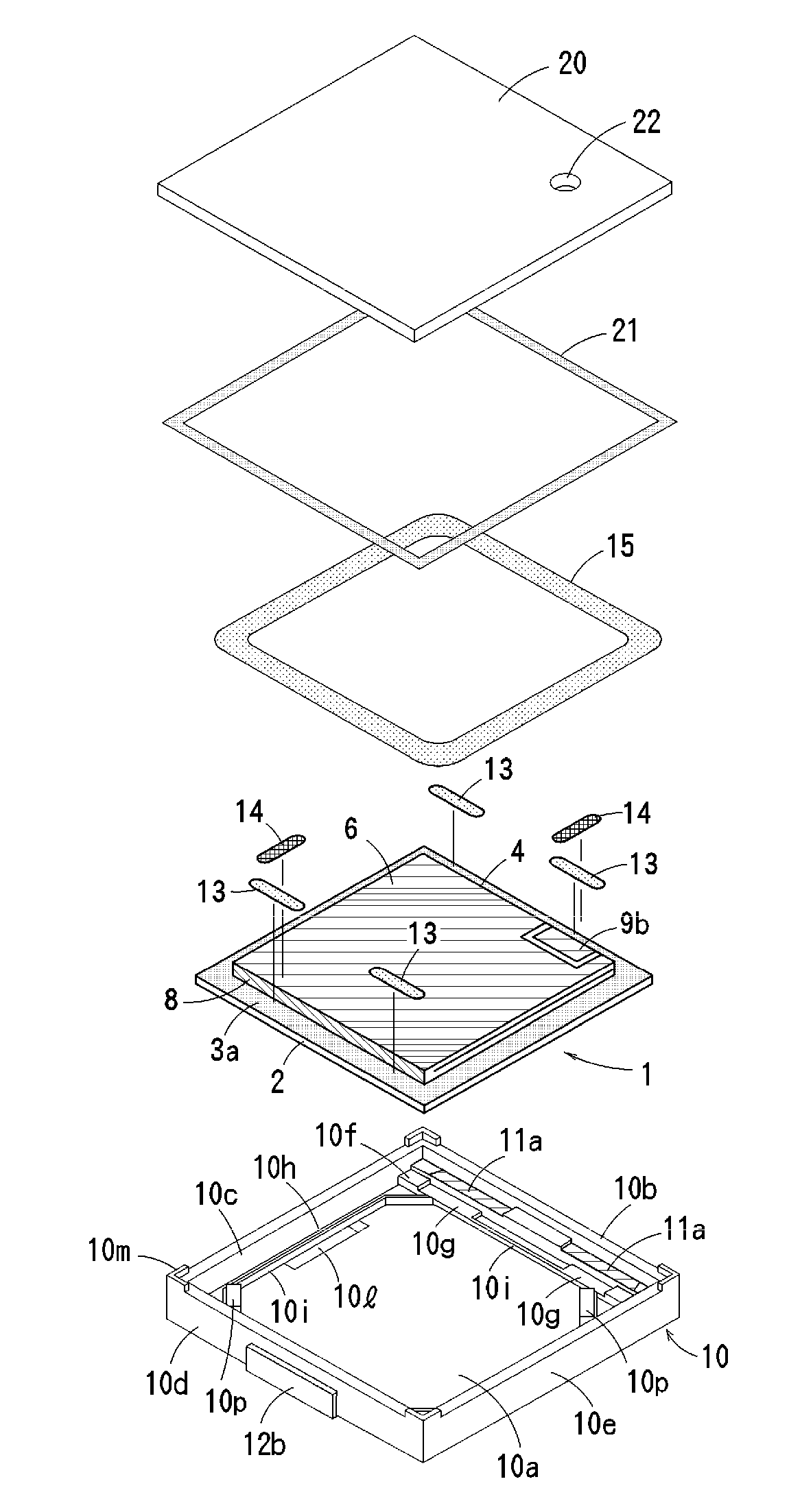

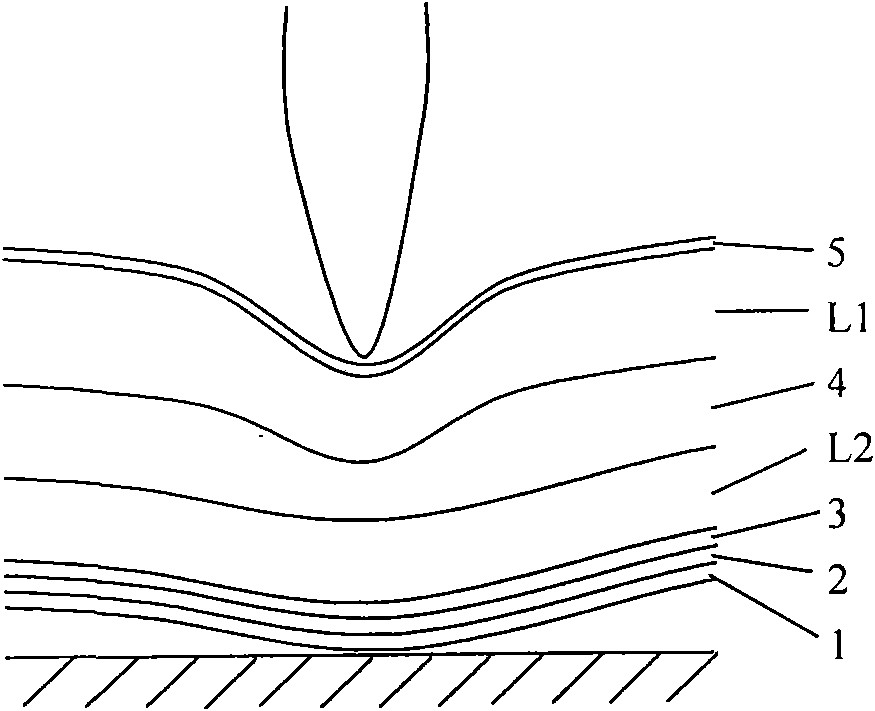

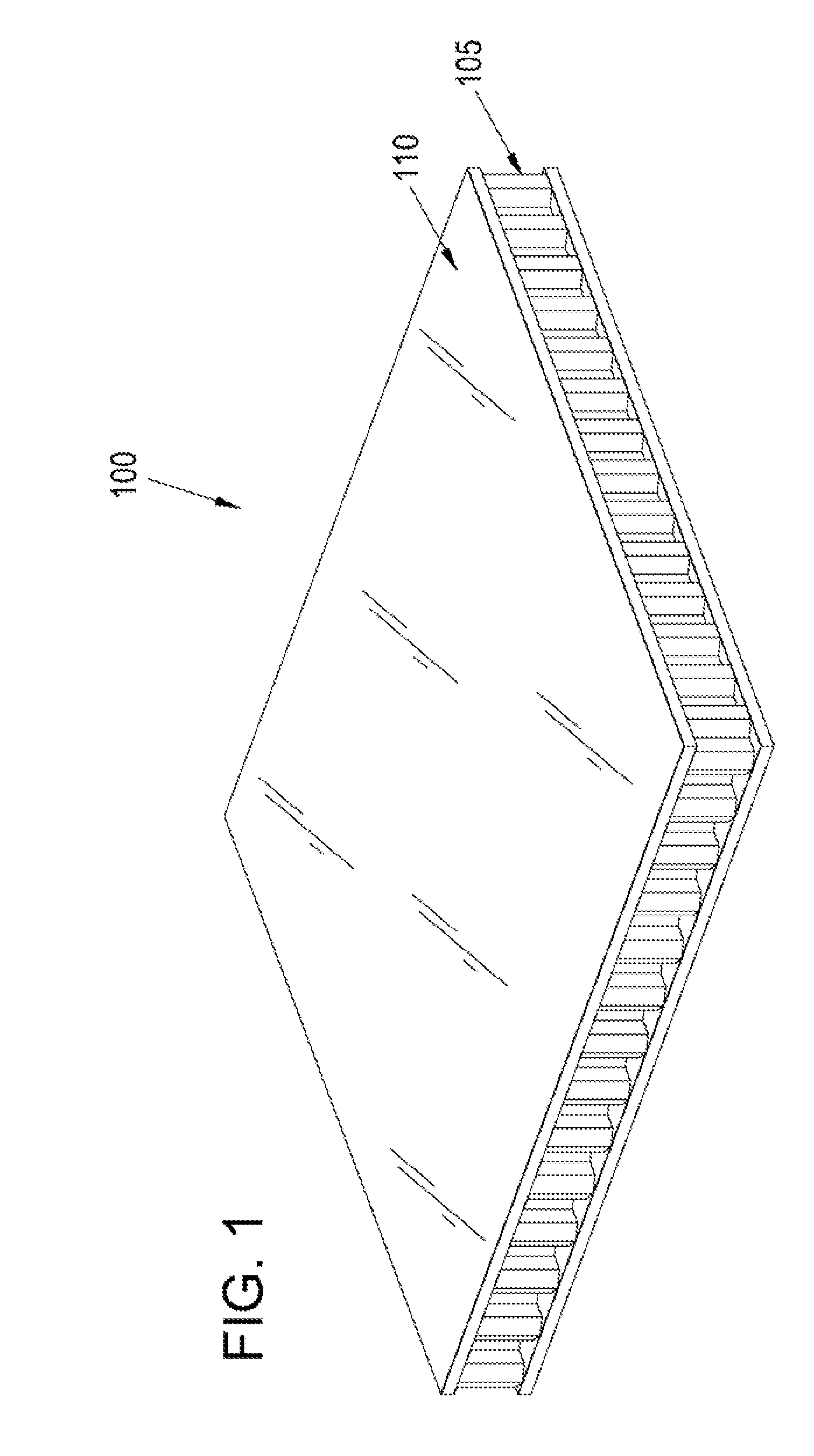

Touch panel

A touch panel includes a light-transmissible upper board, an upper resistor layer on a lower surface of the upper board, a light-transmissible lower board, a lower resistor layer provided on an upper surface of the lower board and facing the upper resistor layer with a predetermined distance, a spacer having a substantial frame shape between an outer periphery of the lower surface of the upper board and an outer periphery of the upper surface of the lower board, upper electrodes extending from both ends of the upper resistor layer, lower electrodes extending from both ends of the lower resistor layer, a wiring board, and wiring patterns on the wiring board. The spacer has a cutout portion provided therein. The upper and lower electrodes have portions located at the cutout portion of the spacer. The wiring board has an end located at the cutout portion. The wiring patterns are connected to the portions of the upper electrodes and the portions of the lower electrodes, respectively. An elastic adhesive seals the cutout portion of the spacer. This touch panel allows the wiring patterns to be connected electrically to the electrodes stably, and insulates between the wiring patterns and between electrodes, thus being reliable.

Owner:PANASONIC CORP

A fabric enhanced composite vascular prosthesis

ActiveCN101007186ASolve permeabilityResolve blood compatibilityPharmaceutical containersMedical packagingEngineeringMaterials processing

The invention discloses a fabric reinforced composite artificial vessel to transplant into human body in the biological medical material manufacturing domain, which is composed of anticoagulant layer, reinforced fabric layer and elastic adhesive layer, wherein the reinforced fabric layer and elastic adhesive layer constitute the frame of artificial vessel; the reinforced fabric layer is buried in the elastic adhesive layer; the anticoagulant layer is set on the inner surface of artificial vessel frame of reinforced fabric layer and elastic adhesive layer, which forms blood flow channel; the anticoagulant layer and elastic adhesive layer are blending bulk of polyurethane or hyper-fine protein powder and polyurethane with grafted sulfuric group on the surface with micro-hole on the inner part.

Owner:WUHAN YONGSEN BIOTECH

Solid wood door leaf and manufacturing method thereof

InactiveCN101638969ANo crackingThere will be no whitening phenomenonWood working apparatusDoor leavesSolid woodMechanical engineering

The invention relates to a solid wood door leaf and a manufacturing method thereof. The solid wood door leaf comprises a door leaf outer frame and at least a door closure plate inlaid in the door leafouter frame, wherein the door leaf outer frame is formed by assembling at least two door vertical beams in horizontal arrangement and at least two crosspieces in vertical arrangement, at least a doorclosure plate assembly port is formed, an assembly groove assembled at the edge of the door closure plate through scarf joint is formed at the periphery of the door closure plate assembly port, the door vertical beams, the crosspieces and the door closure plate are respectively covered with a paint later, an unpainted adhesive position is respectively left at the bottom of the assembly groove andat the periphery of the door closure plate, and the door closure plate, the door vertical beams and the crosspieces are cemented into a whole at the adhesive positions in an elastic adhesive mode. The door vertical beams, the crosspieces and the door closure plate are not easily deformed in the use process, and the phenomena of painted surface break and whiteness exposure do not occur, ensuring that the door leaf outer frame and the door closure plate are tightly bonded in an adhesive mode and can not be tightly bonded because of paint.

Owner:QUANZHOU JIASEN WOOD

Polarizer and optical device using the polarizer

A polarizer for converting incident light beam into a linear polarization light beam has a base plate of a material of low linear expansion coefficient, high thermal conductivity or low photoelastic constant, a birefringent portion formed by arranging minute metal concave tread on a surface of light-emission side of the base plate in stripe, and a protection plate covering the birefringent portion and made of the same material as the base plate, the base plate and the protection plate being bonded by an elastic adhesive on the periphery thereof so that the birefringent portion is sealed and enclosed by the protection plate and the elastic adhesive.

Owner:SEIKO EPSON CORP

Two-component composition

ActiveUS20170292050A1Reduce the smellHigh strengthPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsHeat resistanceRoom temperature

A two-component composition, containing at least one silane-group-containing polymer that is liquid at room temperature, at least one epoxide liquid resin, at least one polyetheramine, and at least one aminosilane or mercaptosilane. The composition has low odor, cures quickly and without blistering at room temperature, and, when cured, forms a tough elastic material of high strength, high adhesive force, and good thermal resistance that has no tendency toward yellowing or substrate discoloration. The composition is excellently suitable as a tough elastic adhesive for structural adhesive joints in the field of construction and in industrial production.

Owner:SIKA TECH AG

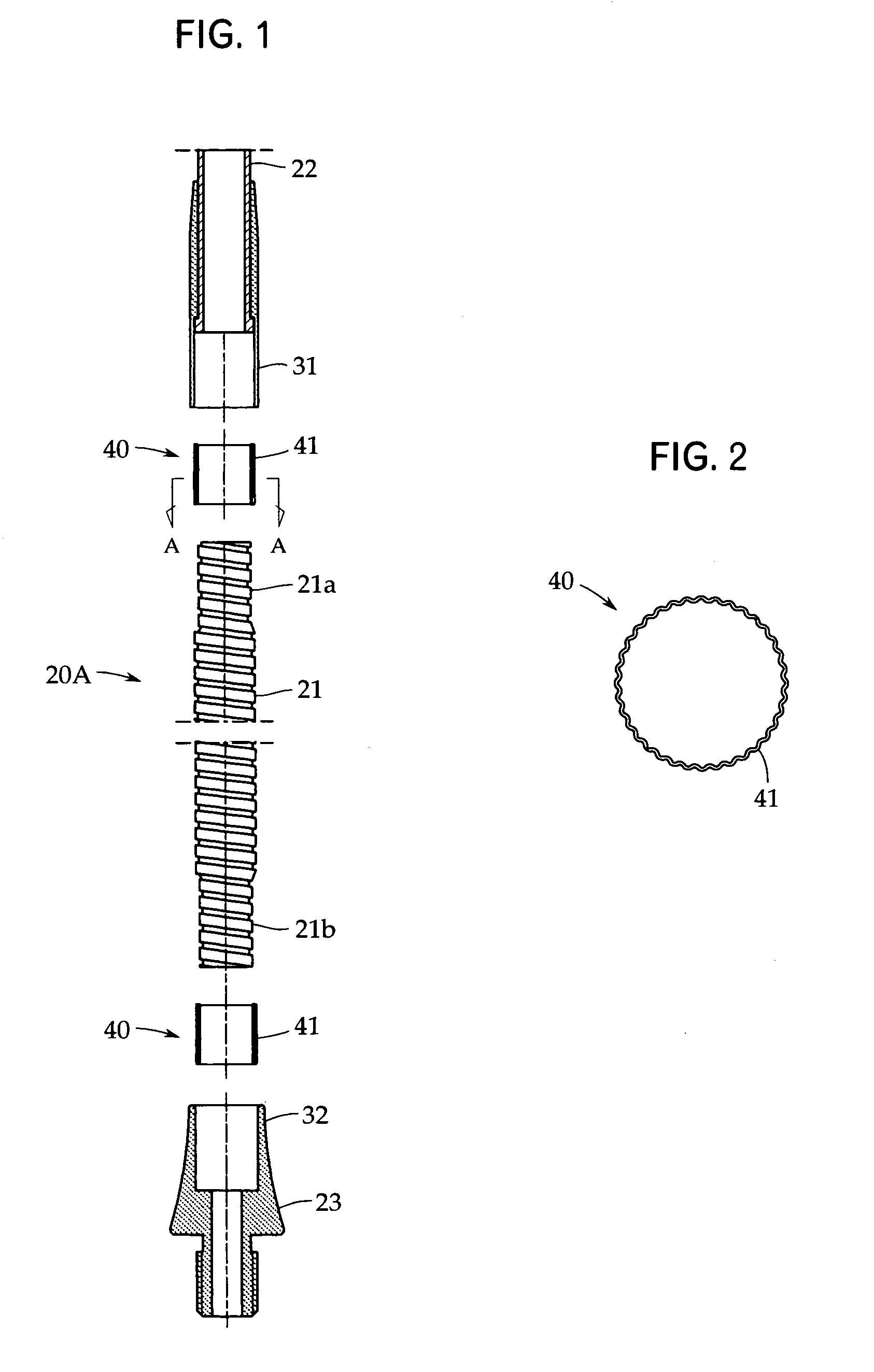

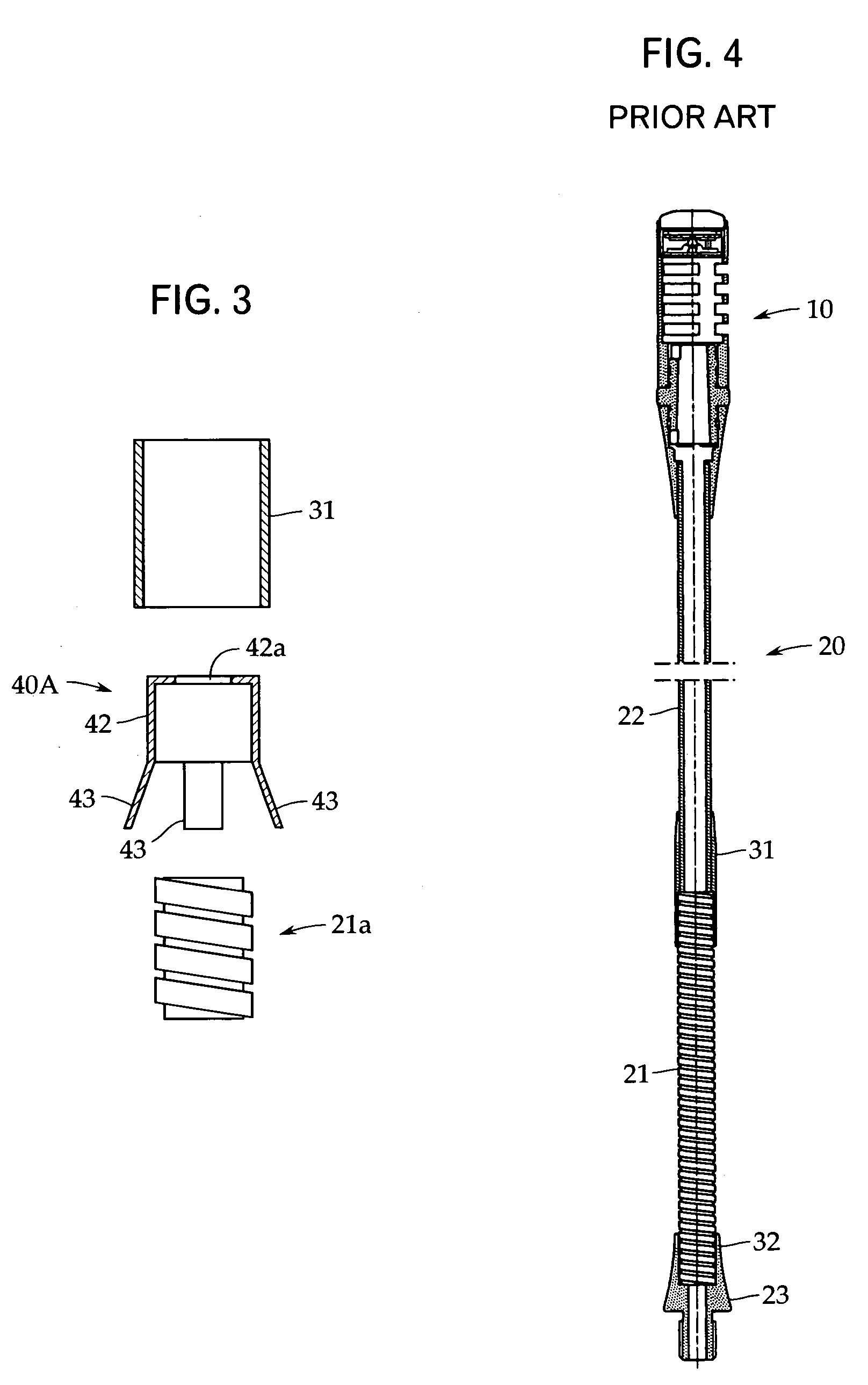

Microphone

ActiveUS7330559B2Lower on-resistanceImprove continuityPiezoelectric/electrostrictive microphonesAdjustable jointsElectrical resistance and conductanceMetallic materials

In a gooseneck microphone device in which a microphone unit is supported by a column partially including a flexible pipe, the conductive resistance in a connecting portion of the flexible pipe is low, so that stable continuity can be secured for a long period of time, and vibrations are damped in the connecting portion of the flexible pipe. In connecting an end portion 21a of the flexible pipe 21 to a support pipe 22 via a connector 31, a spacer 40 (for example, a metallic mesh sheet 41) formed of a metallic material having electric conductivity and spring-like elastic restoring force is interposed in the connecting portion, and the flexible pipe and the connector are bonded to each other by an elastic adhesive which has elasticity even after being cured.

Owner:AUDIO-TECHNICA

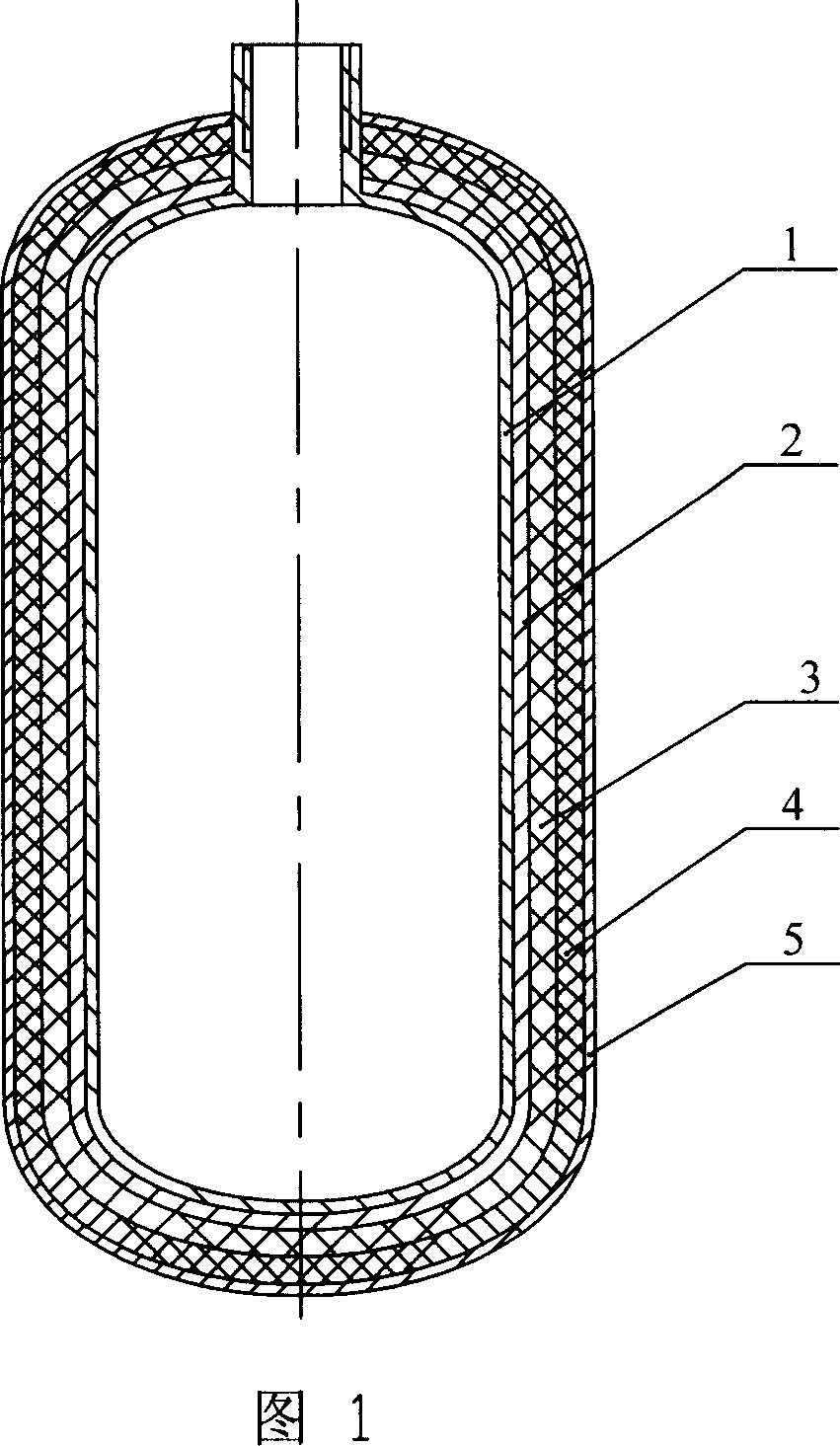

High pressure nitrogen storage bottle made of kevlar fiber and carbon fiber mixed composite material and its preparation method

InactiveCN1948817AOptimized structural formFree from mechanicalPressure vesselsNitrogen gasHigh pressure

The invention relates to a nitrogen cylinder and its preparation method, in which, on the outside surface of the lining is bonded an adhesive layer and the outside surface of the adhesive layer is bonded to the inside surface of the inner structure layer of carbon fibre composite; the inside surface of the outer structure layer of Kevlar fibre composite is wound on the outside surface of the inner structure of the outer structure layer is wound an outer protective covering. The method consists in: coating an elastic adhesive layer on the outside surface of the lining; overlying a spiral and toroidal wound inner structure layer, an outer structure layer and an outer protective covering; curing and then getting the present inventive nitrogen cylinder.

Owner:HARBIN INST OF TECH

Water-based polyurethane elastomer applied to sports ground

ActiveCN102504515AImprove mechanical propertiesMeet construction requirementsPolyurethane elastomerPolymer science

The invention discloses a water-based polyurethane elastomer applied to a sports ground, which includes the following raw materials: by weight parts, 50 to 80 parts of water-based polyurethane resin, 3 to 15 parts of water-based color paste, 1 to 25 parts of inorganic filler, 10 to 60 parts of elastic rubber powder, 1 to 10 parts of auxiliaries and 0 to 10 parts of hardener. The water-based polyurethane elastomer applied to the sports ground has excellent mechanical performance, drying time therefor can meet the construction requirement and the preparation method and the process thereof are environment-friendly.

Owner:GUANGDONG BOSHENG NEW MATERIAL TECH CO LTD

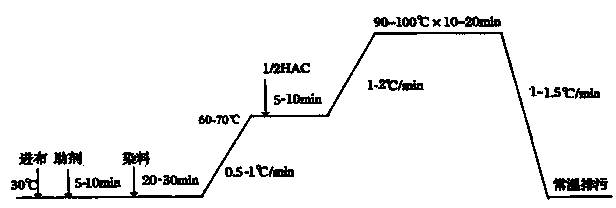

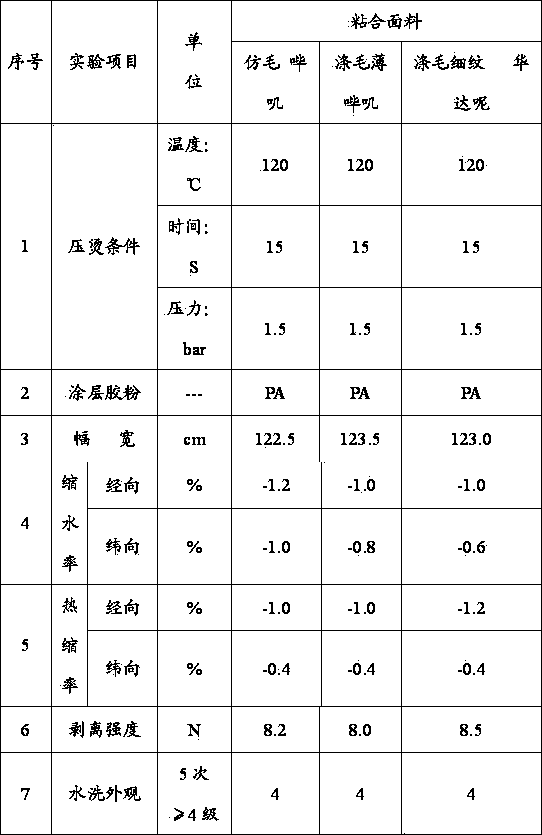

Production process of thin nylon elastic adhesive-bonded interlining

ActiveCN103462263AImprove performanceRaise the gradeLiquid surface applicatorsFibre typesCooking & bakingInterlining

The invention relates to a production process of thin nylon elastic adhesive-bonded interlining. The production process includes the following steps: 1, grey cloth inspecting; 2, cloth turning, print and end stitching; 3, loosening and dyeing; 4, shaping and finishing; 5, coating; and 6, inspecting, wherein the step of coating includes the following processes: unwinding, J-shaped cloth containing box, LG deviation corrector, pasting by a scraper, spreading hotmelt adhesive powder, blowing and sucking powder, edge-detecting, baking, cooling, coating-forming, and coiling. By adopting the production process, product grade can be effectively increased, performance of lining cloth is greatly improved, and the thin nylon elastic adhesive-bonded interlining is preciser in coating process, good in water washing and dry washing effect, low in formaldehyde content and more comfortable to wear, and has wider market prospect and market value.

Owner:JIHUA 3502 PROFESSIONAL GARMENT

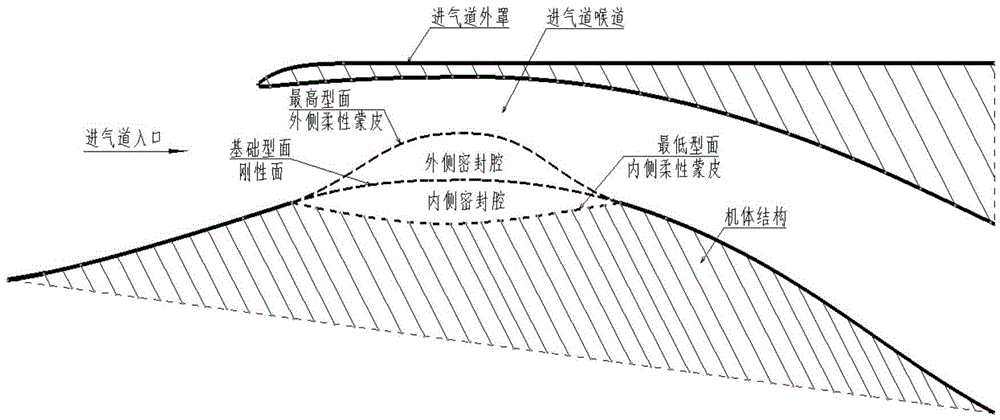

Structural design method for internal balance self-adaptation bump air inlet channel

ActiveCN104590570AExcellent aerodynamic performanceExcellent featuresPower plant air intake arrangementsAviationInlet channel

The invention belongs to the technical field of aviation structural design, and relates to a structural design method for an internal balance self-adaptation bump air inlet channel. The structural design method comprises the steps that a deformed region is selected on a bump molded surface of the air inlet channel; flexible skin is formed by compositing elastic adhesive films and high-elastic fibers; an outer side sealing cavity is formed between the basic molded surface of the air inlet channel and the outer side flexible skin, and an inner side sealing cavity is formed between the basic molded surface of the air inlet channel and the inner side flexible skin; the initial shape of the flexible skin is consistent with the basic molded surface of the internal balance self-adaptation bump air inlet channel; the air inlet channel is provided with a deformation driving device. Under the control of the deformation driving device, the shape of the flexible skin of the internal balance self-adaptation bump air inlet channel can be changed. According to the structural design method, the problem that the molded surface of a conventional bump air inlet channel cannot be adjusted is solved, the air inlet channel have the best pneumatic performance and the inlet engine compatibility characteristics under different flight states, and the good engineering applicability is achieved.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

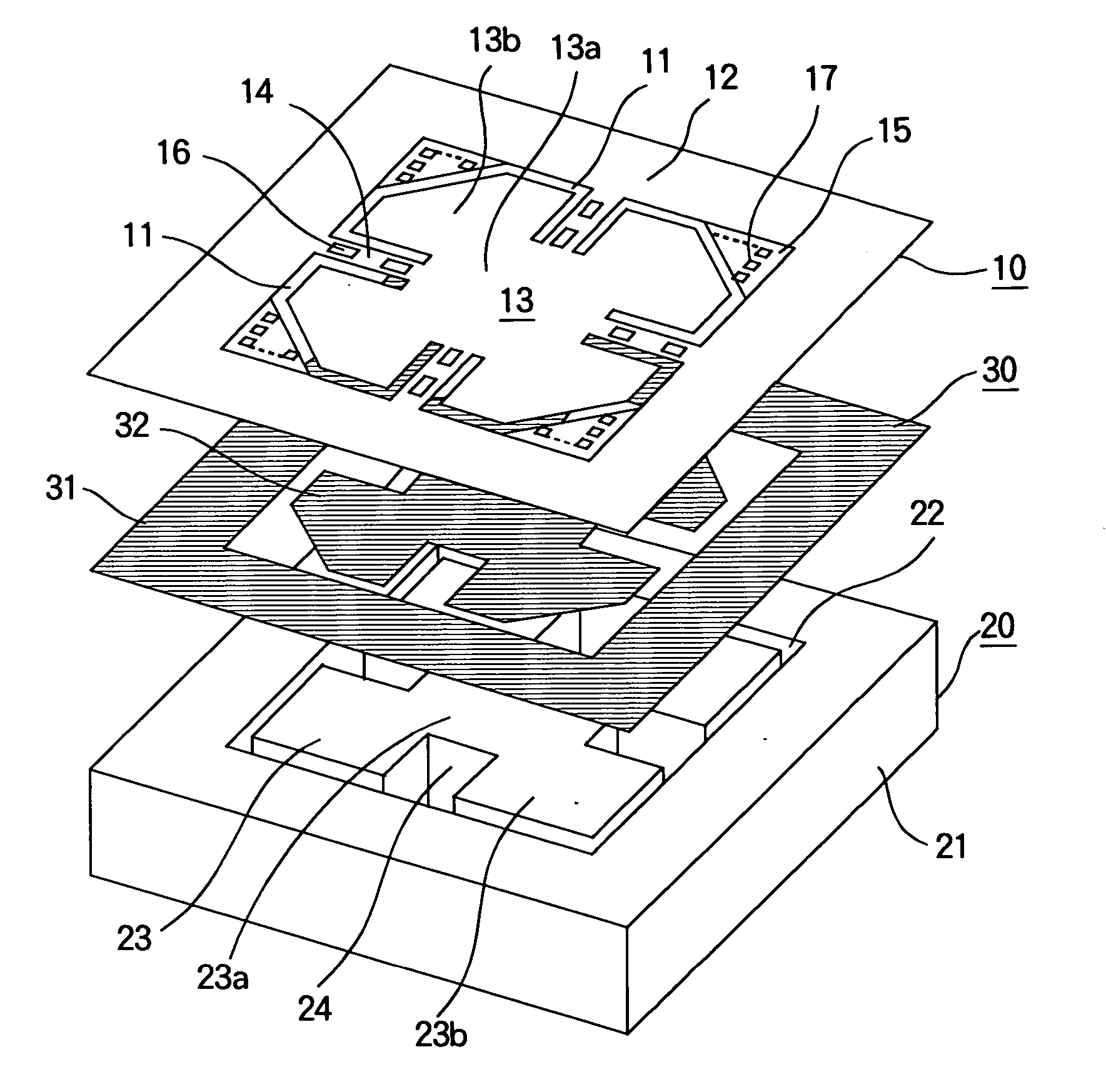

Acceleration sensor manufactureable by simplified method

InactiveUS20060130580A1Easy to manufactureReduce manufacturing costAcceleration measurement using interia forcesLinear/angular speed measurementClassical mechanicsAcceleration Unit

An acceleration sensor has a mass movably linked to a peripheral attachment section to which at least one stopper is attached to stop the motion of the mass in a certain direction. In the absence of acceleration, the mass rests at a distance from a first surface of the stopper. A quantity of a curable elastic adhesive on a second surface of the stopper absorbs impact of the mass on the first surface, enabling the acceleration sensor to survive mechanical shock. The curable elastic adhesive may adhere to the cover of a package in which the acceleration sensor is enclosed. The curable elastic adhesive may be applied as a drop or swath from a dispenser, which simplifies the manufacturing process and reduces the manufacturing cost.

Owner:LAPIS SEMICON CO LTD

Method for making adhesive elastic bandage

ActiveCN1568916AImprove ductilityImprove tensile strengthBandagesEngineeringADHESIVE ELASTIC BANDAGE

The invention relates to a making method of an adhesive elastic bandage, comprising steps of: 1) daubing a layer of adhesive agent on an inelastic backing cloth material; 2) arranging spandex threads in longitude direction, and layering them on the backing cloth material; 3) overlaying another layer of backing cloth material on the top layer; 4) extruding each layers in step 1), 2), and 3), to imbed the spandex threads between the two layers of backing cloth materials; 5) drying the composite backing material formed in step 4) by using baking oven, to make the two layers of inelastic backing cloth materials formed into elastic backing cloth composite material via compounding of adhesive agent and spandex threads; 6) fully immersing into adhesive agent, daubing a layer of composite adhesive agent on the backing cloth material, extruding and drying for a second time, and thus forming elastic adhesive cloth. The invention has the beneficial effects of self-adhesion, no adhesion to other things, good ductility, high tension stress, free of lock seaming, good air permeability, moderate self-adhesiveness, easy opening, arbitrary fixing, free of falling-off, and arbitrary tearing.

Owner:NANJING 3H MEDICAL PROD CO LTD

Two-component composition

ActiveCN107108836AHigh strengthEasy to stretchPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsEpoxyPolymer science

The invention relates to a two-component composition, containing at least one silane-group-containing polymer that is liquid at room temperature, at least one epoxide liquid resin, at least one polyetheramine, and at least one aminosilane or mercaptosilane. The composition has low odor, cures quickly and without blistering at room temperature, and, when cured, forms a tough elastic material of high strength, high adhesive force, and good thermal resistance that has no tendency toward yellowing or substrate discoloration. The composition is excellently suitable as a tough elastic adhesive for structural adhesive joints in the field of construction and in industrial production.

Owner:SIKA TECH AG

Two-component polyurethane adhesive having a long open time

ActiveCN106103525AExtended opening hoursImprove mechanical propertiesPolyureas/polyurethane adhesivesPolyurethane adhesiveSolvent free

The present invention relates to a two-component composition comprising a polymer-polyol, optionally further polyols, an aldimine of the formula (I), a zirconium (IV) catalyst and, in the second component, diphenylmethane diisocyanate. The composition is particularly suitable as a solvent-free, low-odor elastic adhesive. The composition has a particularly long open time, a low density and a high level of final strength and cures quickly and without complications.

Owner:SIKA TECH AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com