Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97 results about "Scarf joint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A scarf joint (also known as a scarph joint) is a method of joining two members end to end in woodworking or metalworking. The scarf joint is used when the material being joined is not available in the length required. It is an alternative to other joints such as the butt joint and the splice joint and is often favored over these in joinery because it yields a barely visible glue line.

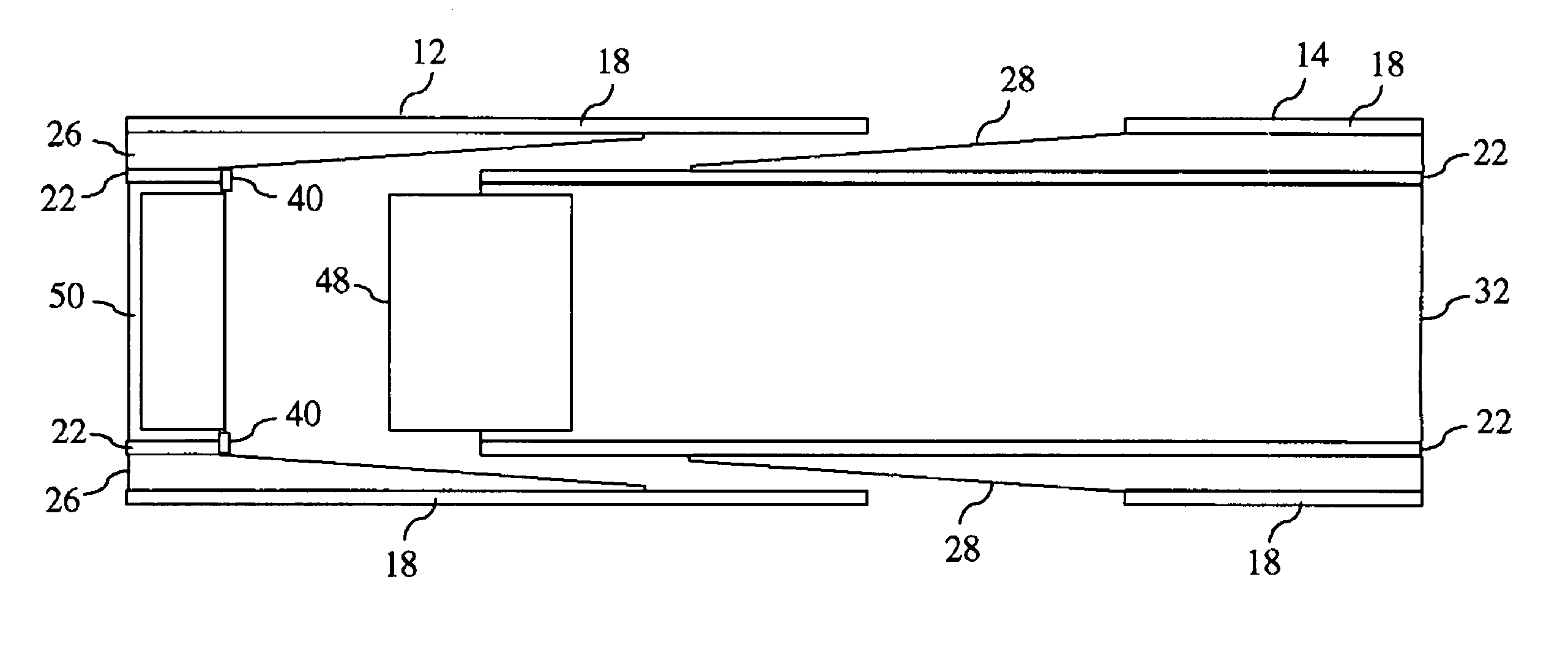

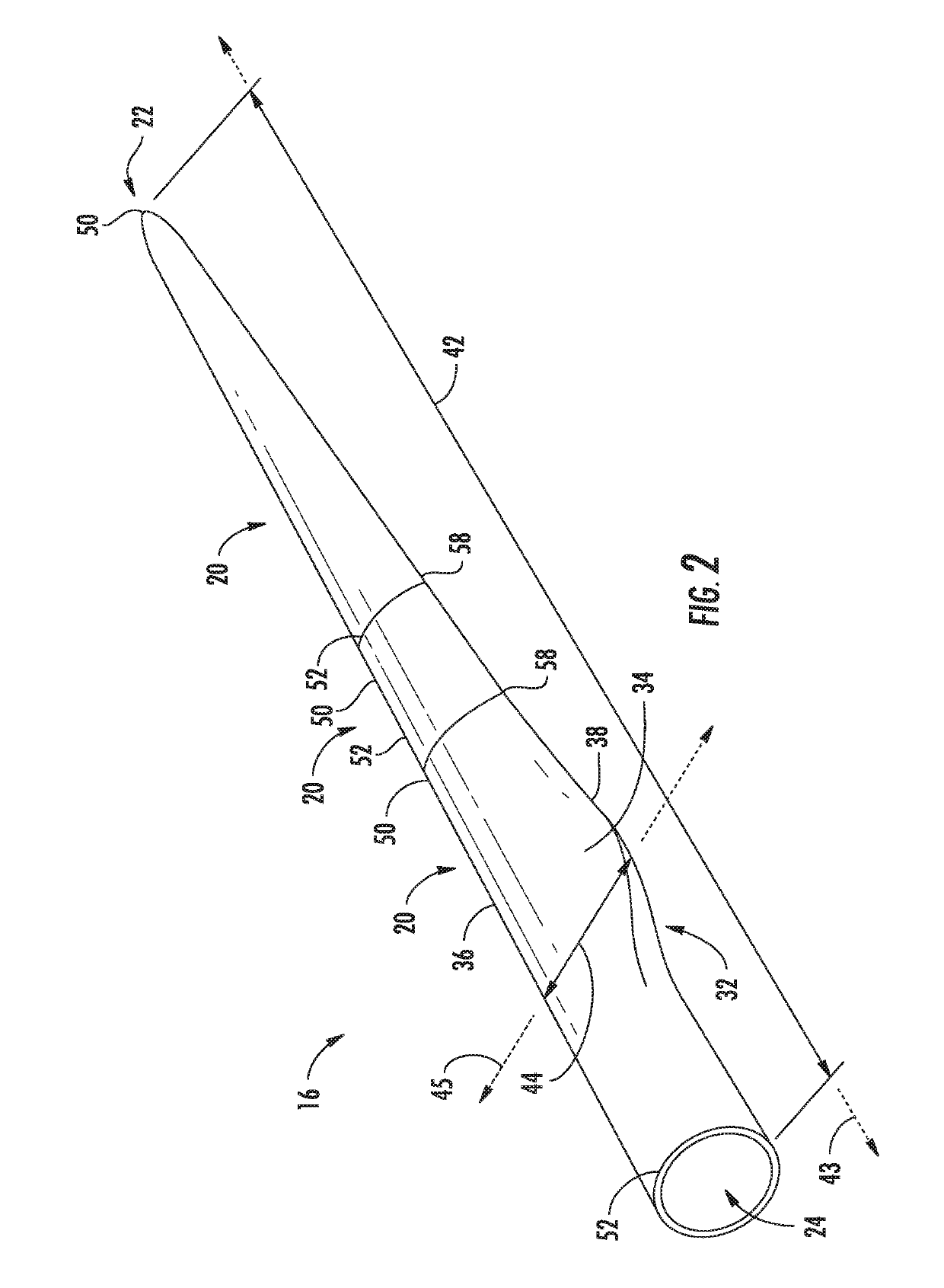

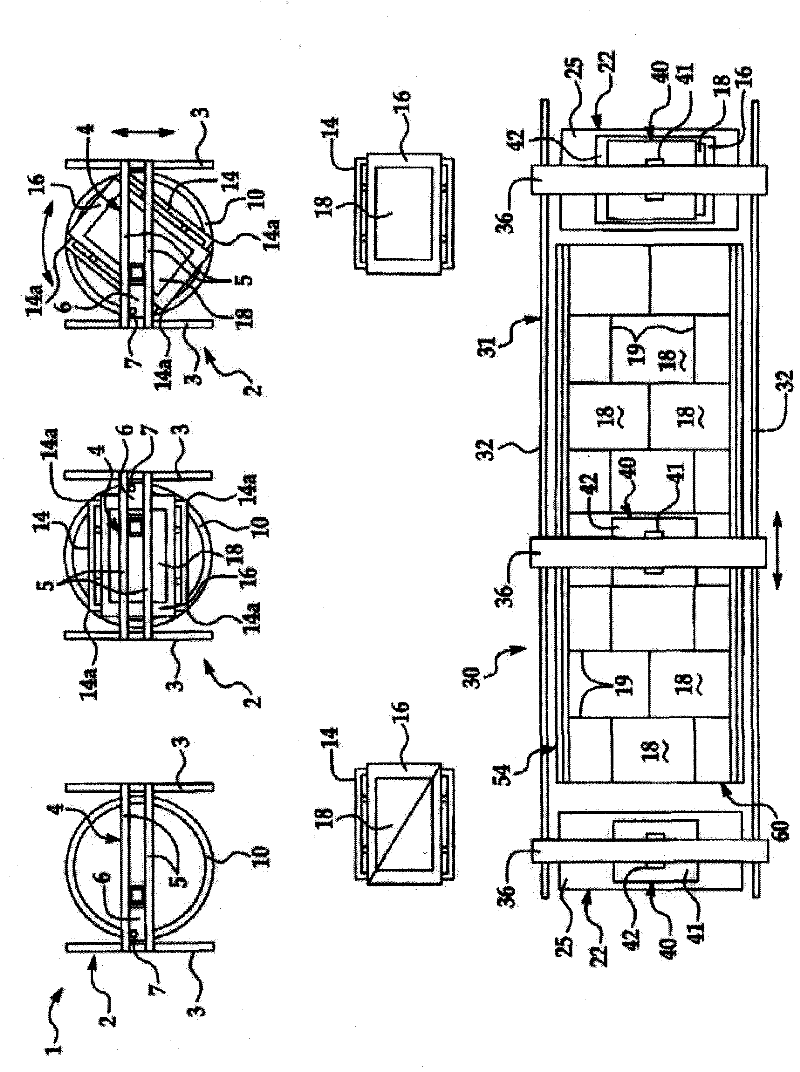

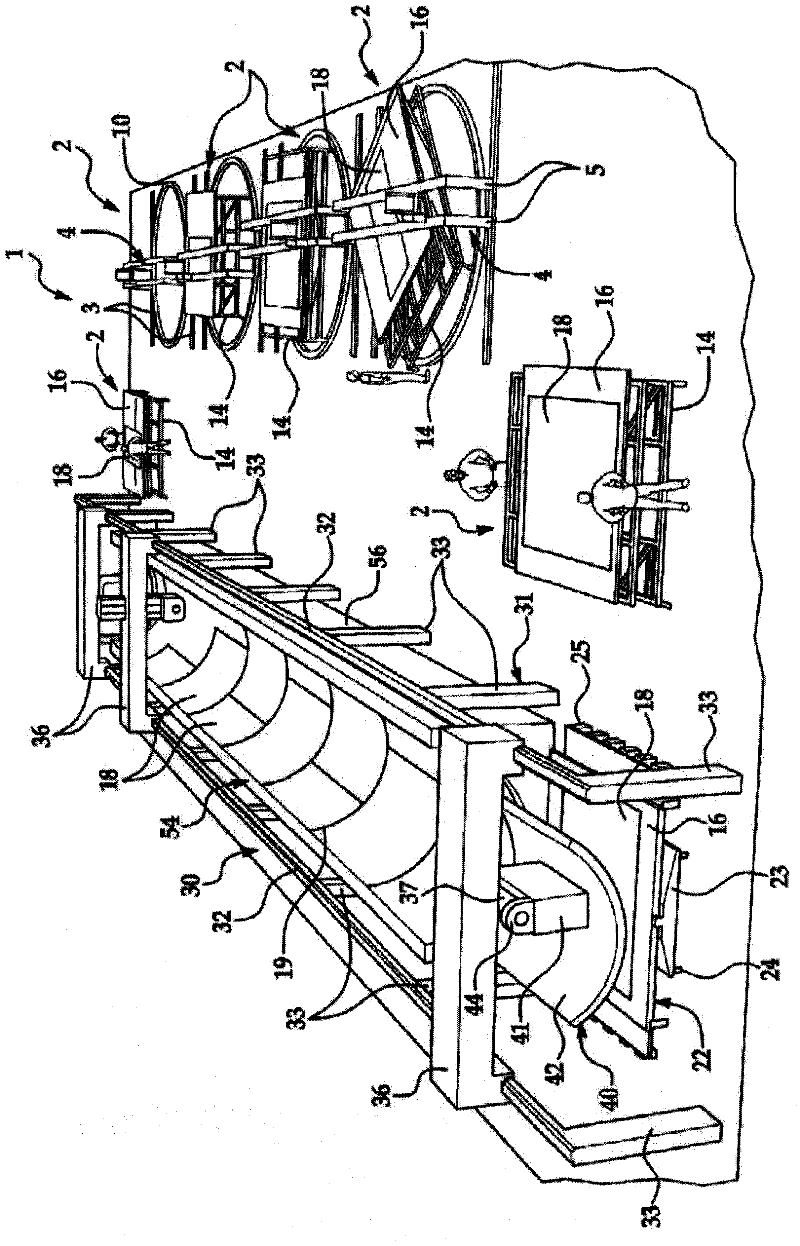

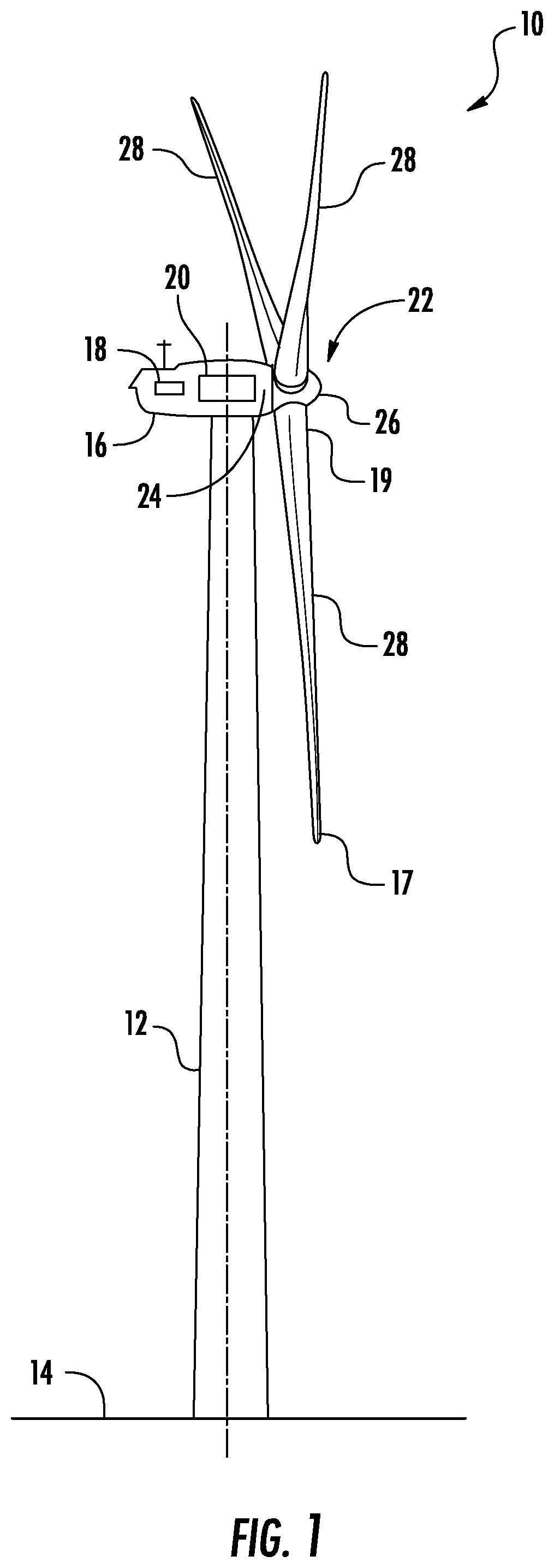

Method for assembling jointed wind turbine blade

A method of assembling a wind turbine blade comprises providing a first blade segment comprising at least two first spar cap segments; providing a second blade segment comprising at least two second spar cap segments; inserting the second blade segment into the first blade segment wherein a spar cap cavity is formed between each set of corresponding first and second spar cap segments; injecting an adhesive into the spar cap cavities to bond the blade segments together, wherein a scarf joint is formed between each set of corresponding first and second spar cap segments.

Owner:GENERAL ELECTRIC CO

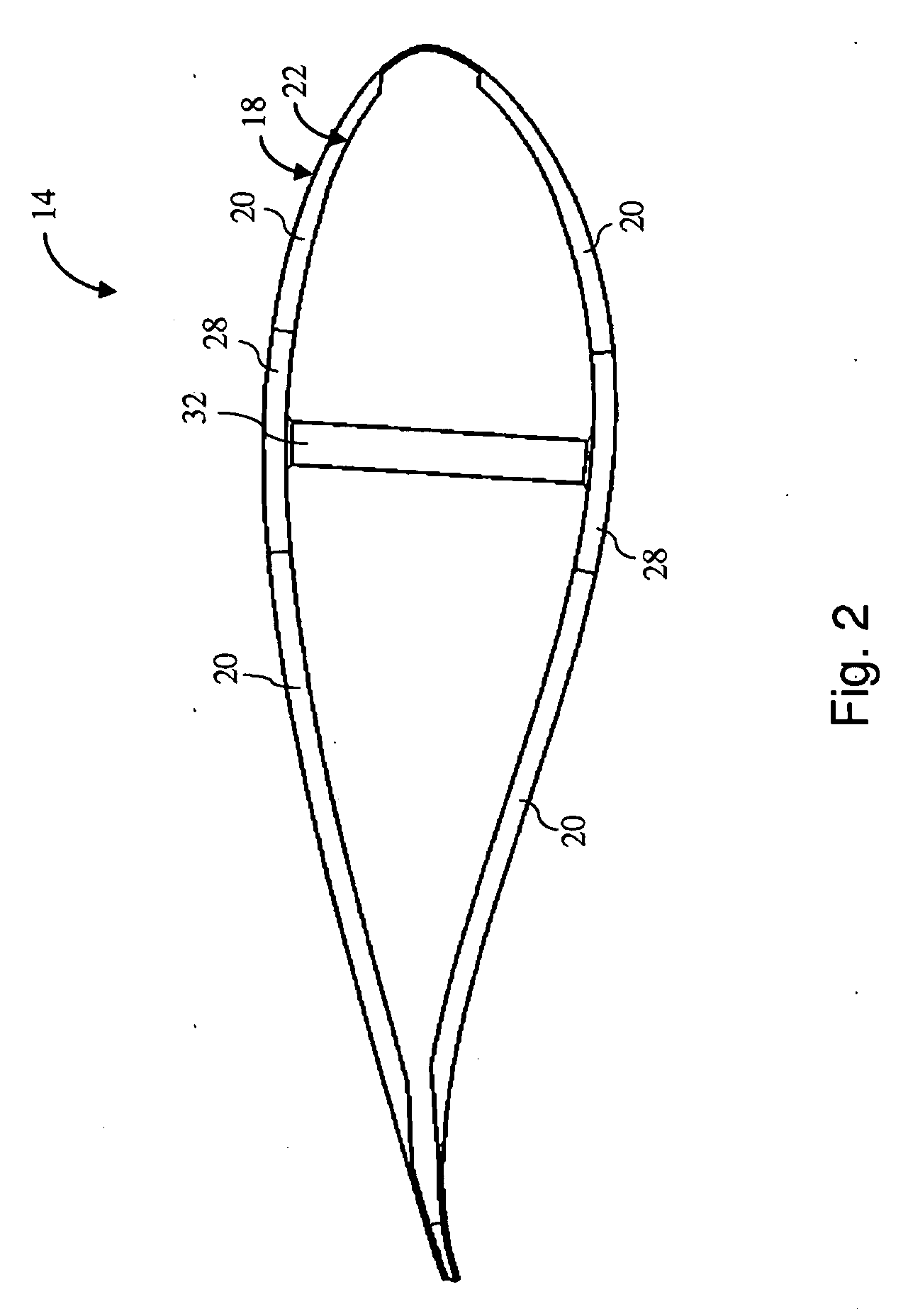

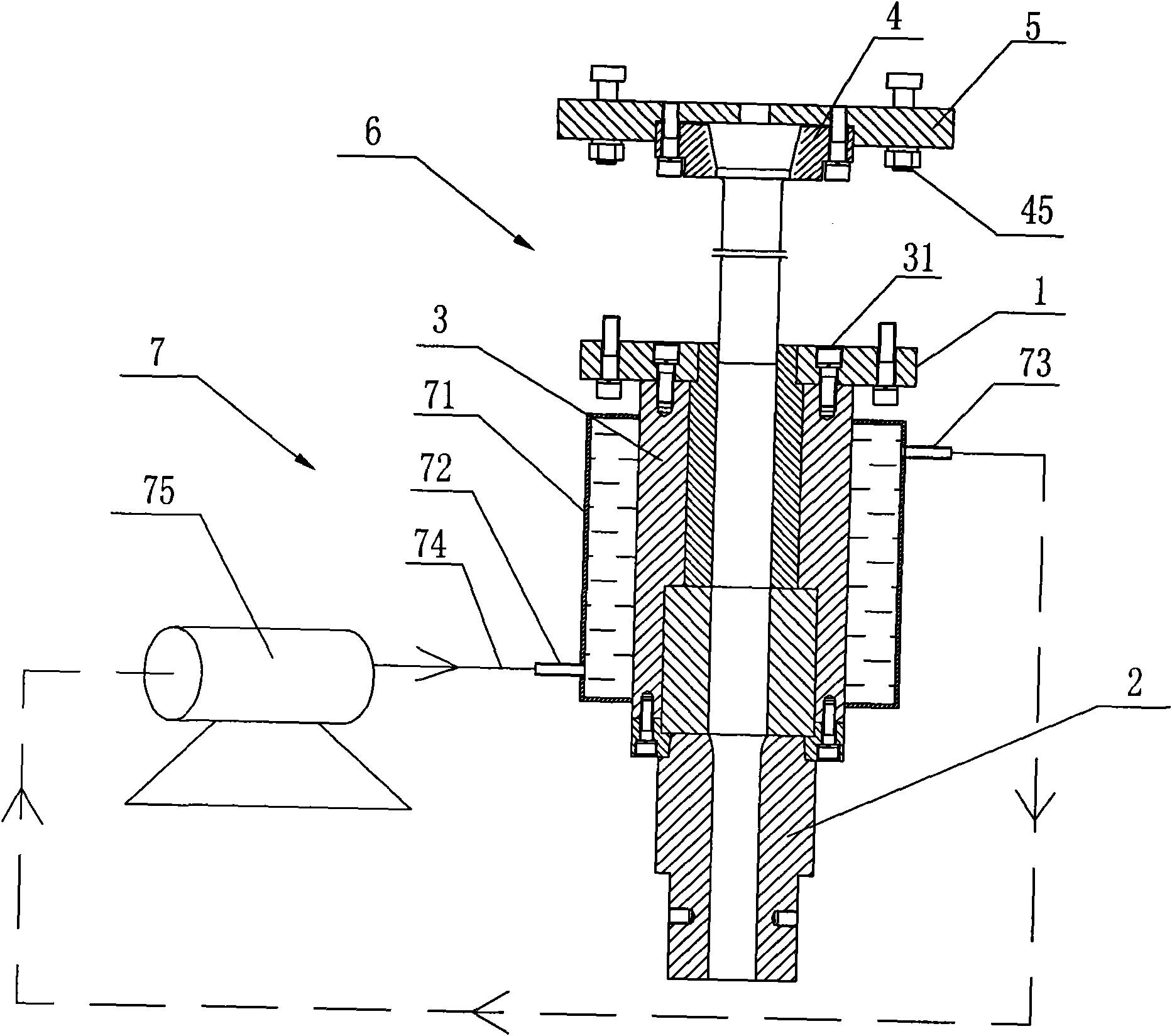

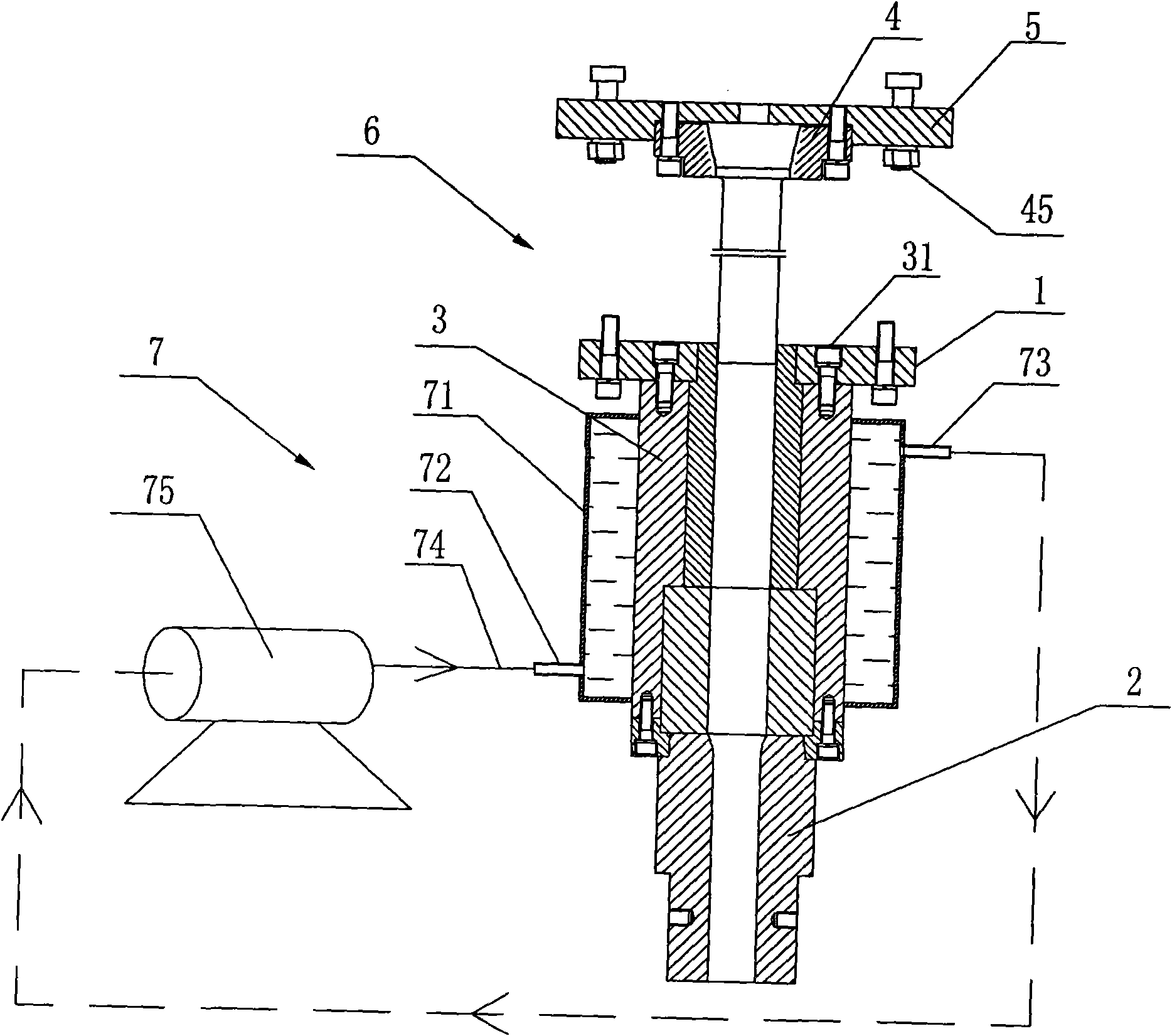

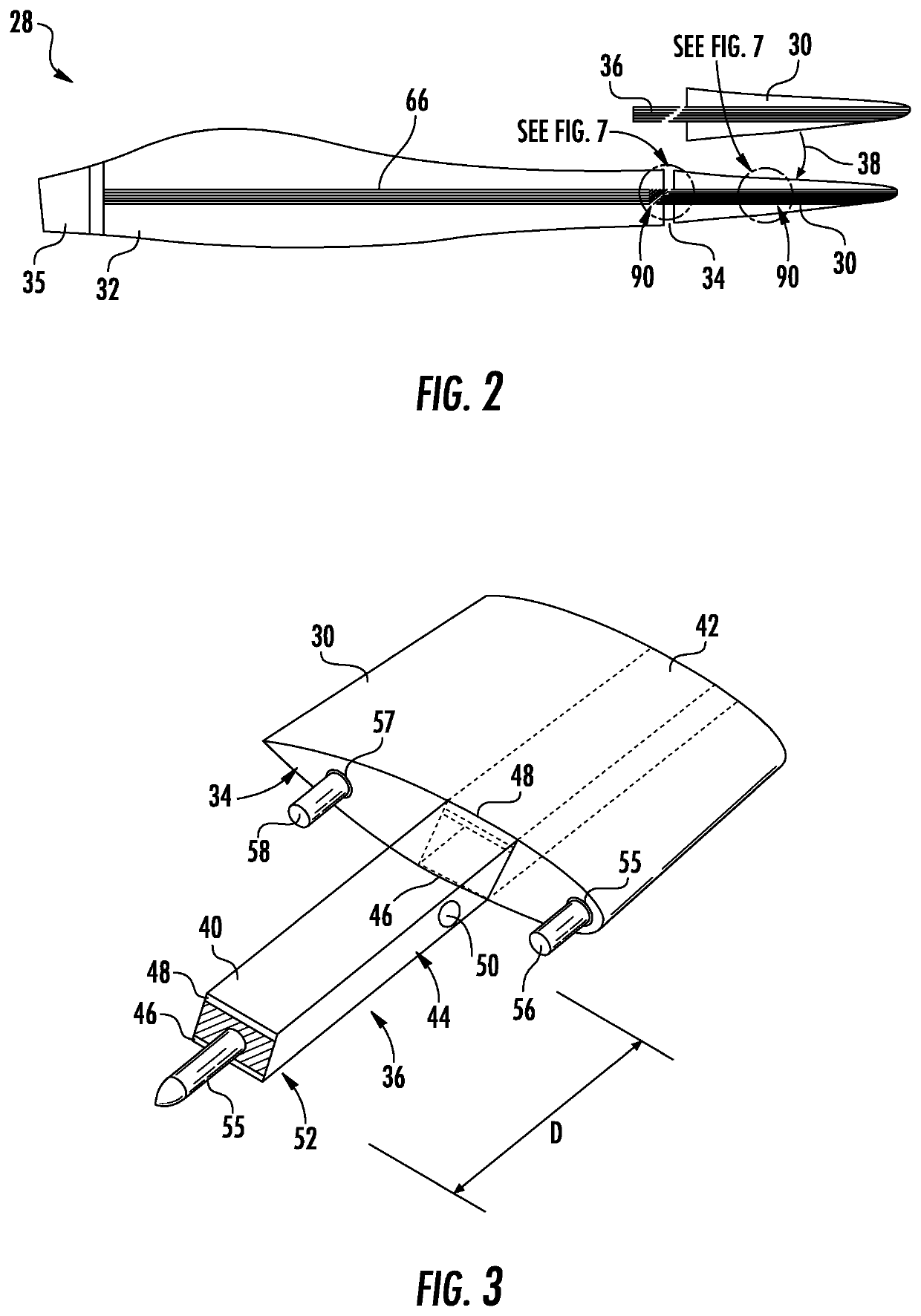

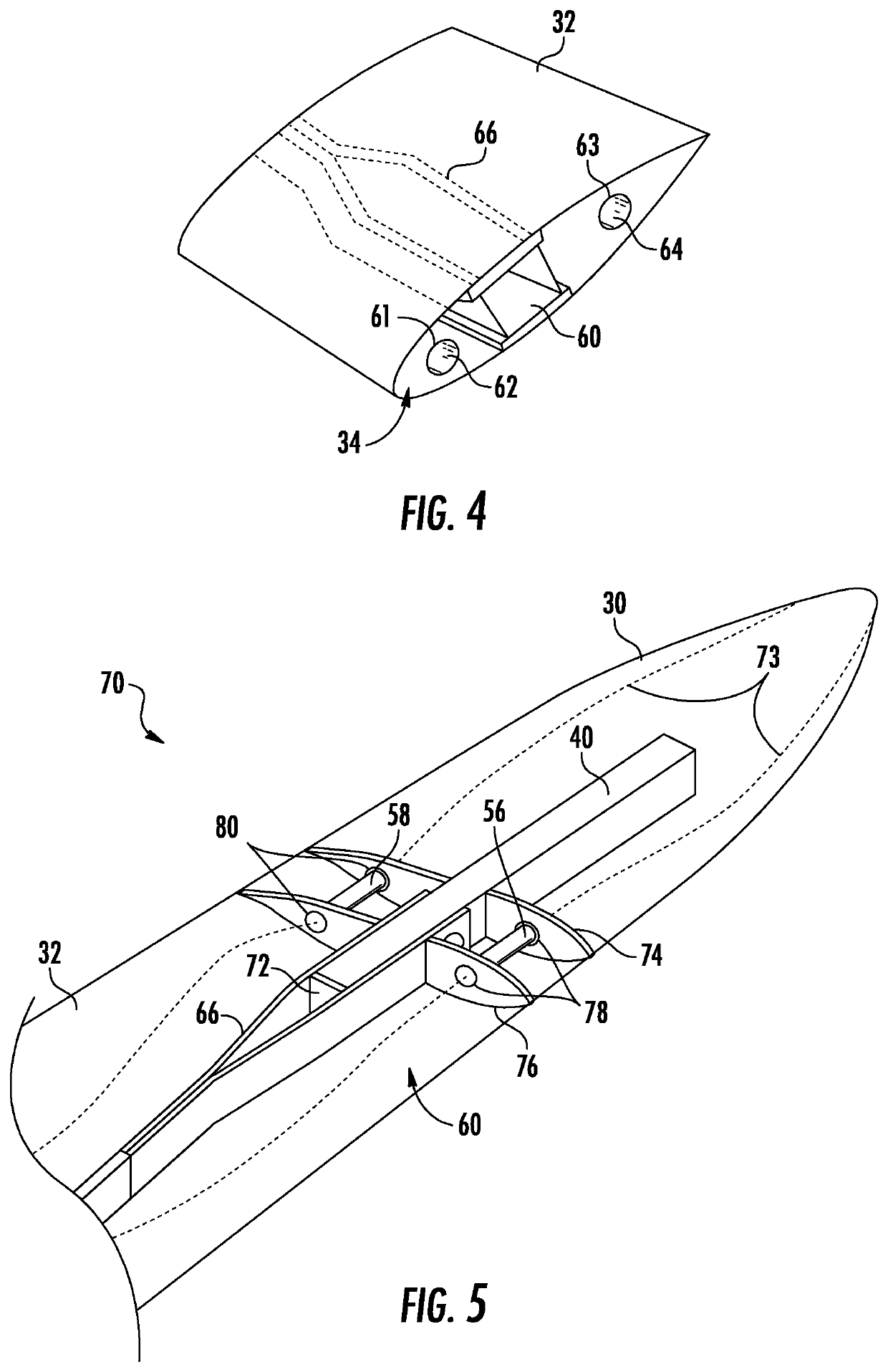

Multi-segment wind turbine blade and method for assembling the same

ActiveUS20090162208A1Easy alignmentEngine manufactureFinal product manufactureScarf jointTurbine blade

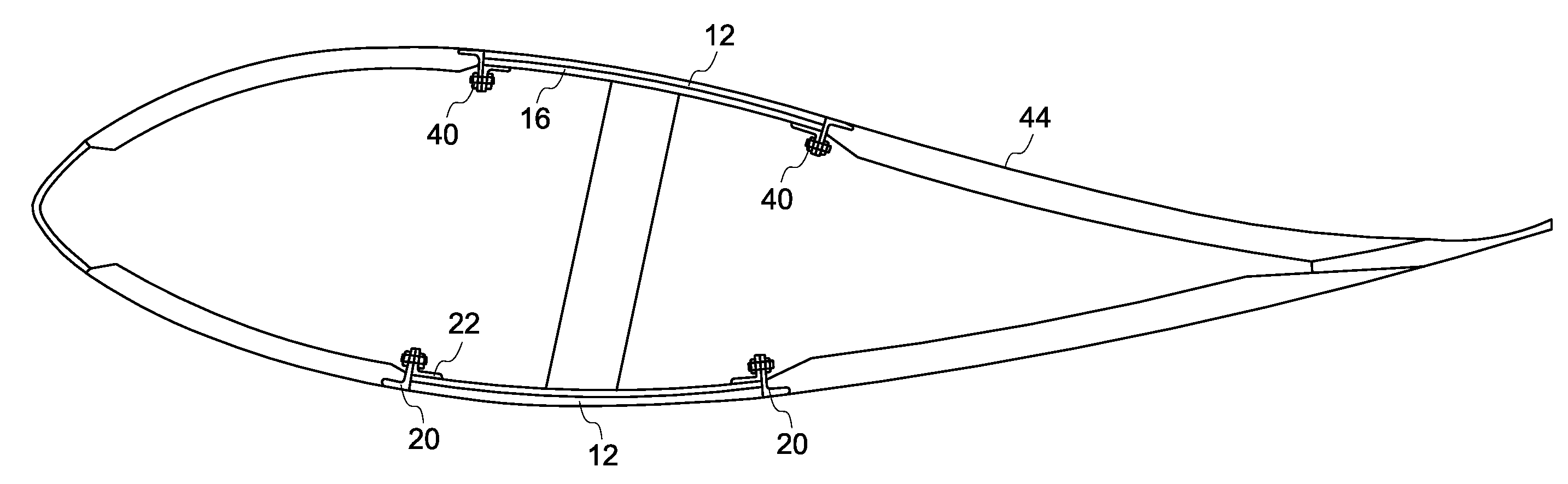

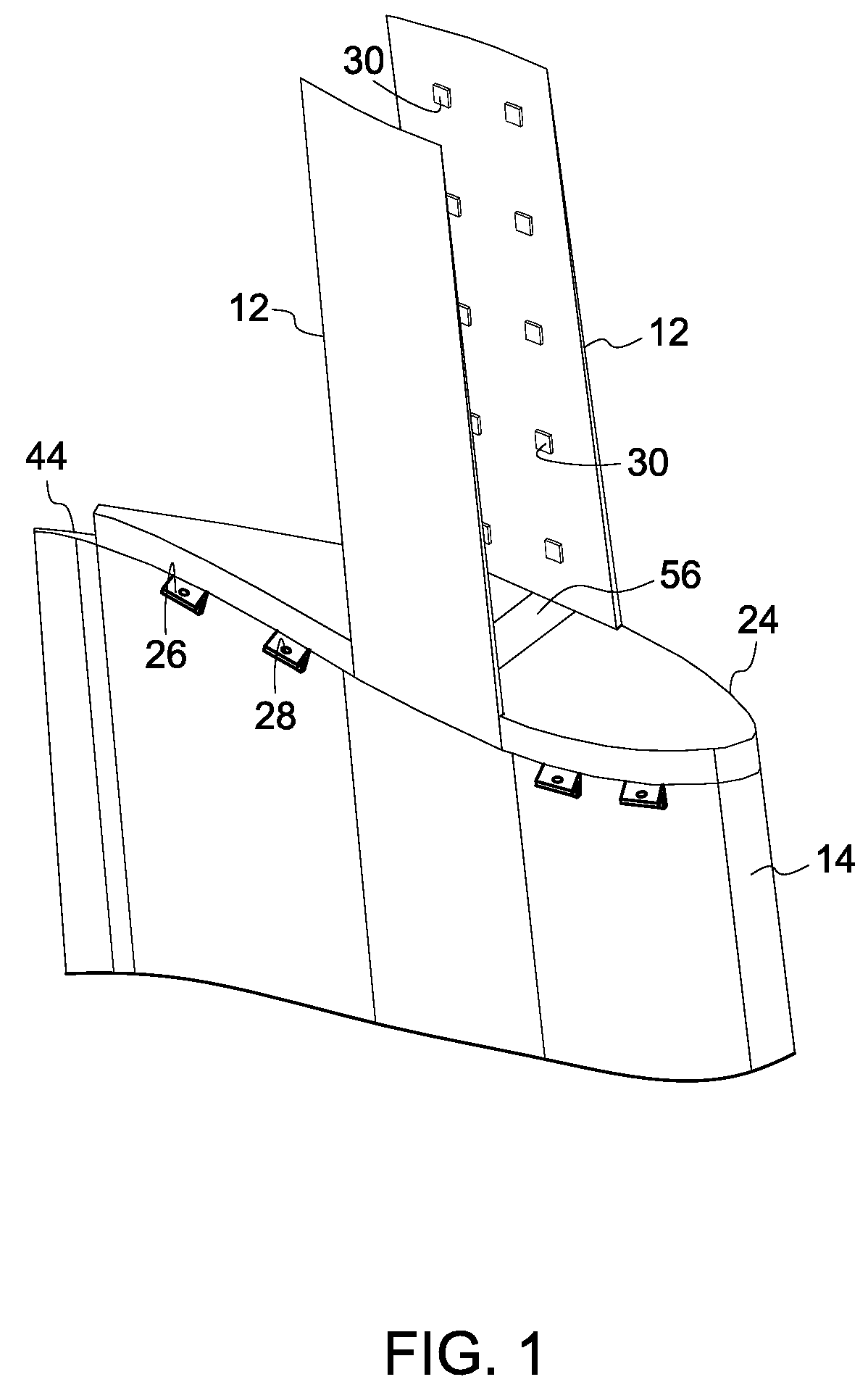

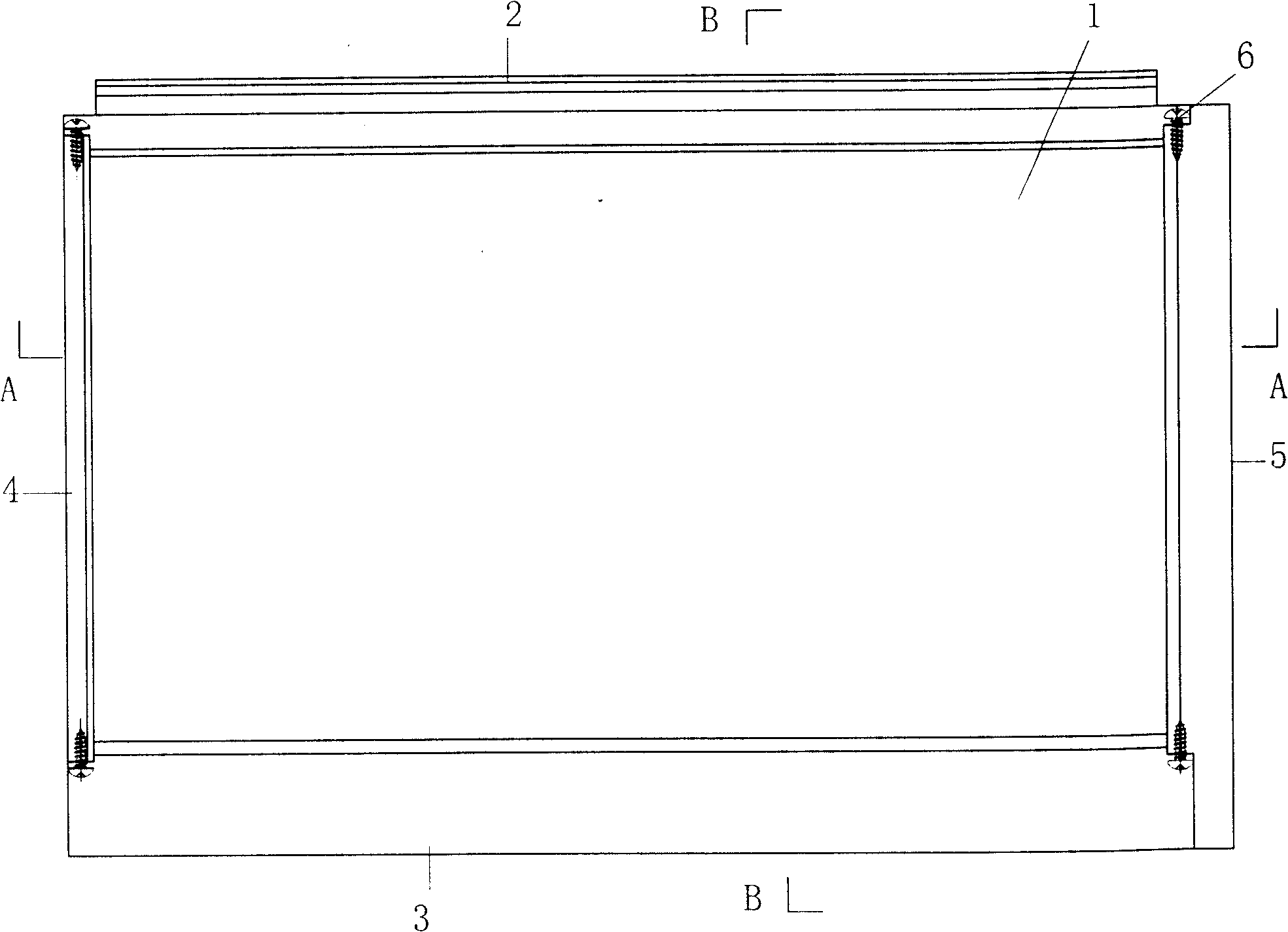

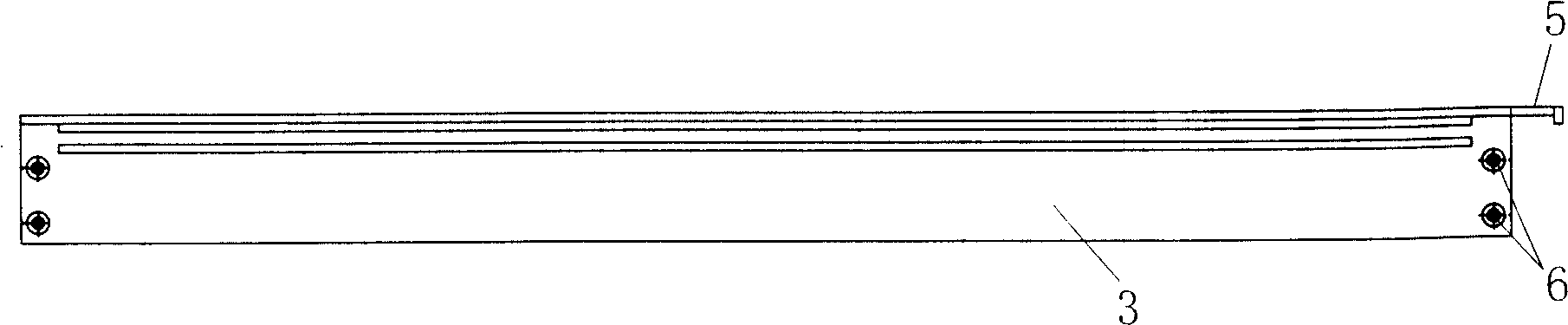

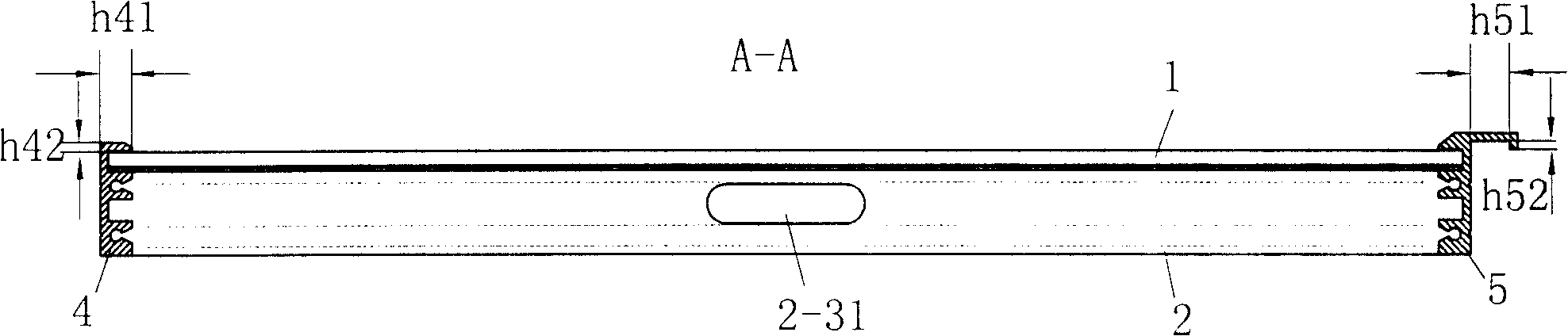

A multi-segment wind turbine blade comprises at least two blade segments. A first spar cap segment is attached to a first blade segment and a second spar cap segment is attached to a second blade segment. The first and second spar cap segments are configured to form a scarf joint. First and second spar cap brackets are attached in locations of the first and second spar cap segments, respectively, selected to facilitate alignment of the first and second spar cap segments at the scarf joint. At a field site, the first and second spar cap segments are bonded after fastening the first and second spar cap brackets.

Owner:GENERAL ELECTRIC CO

Method for assembling jointed wind turbine blade

Owner:LM WIND POWER US TECH APS

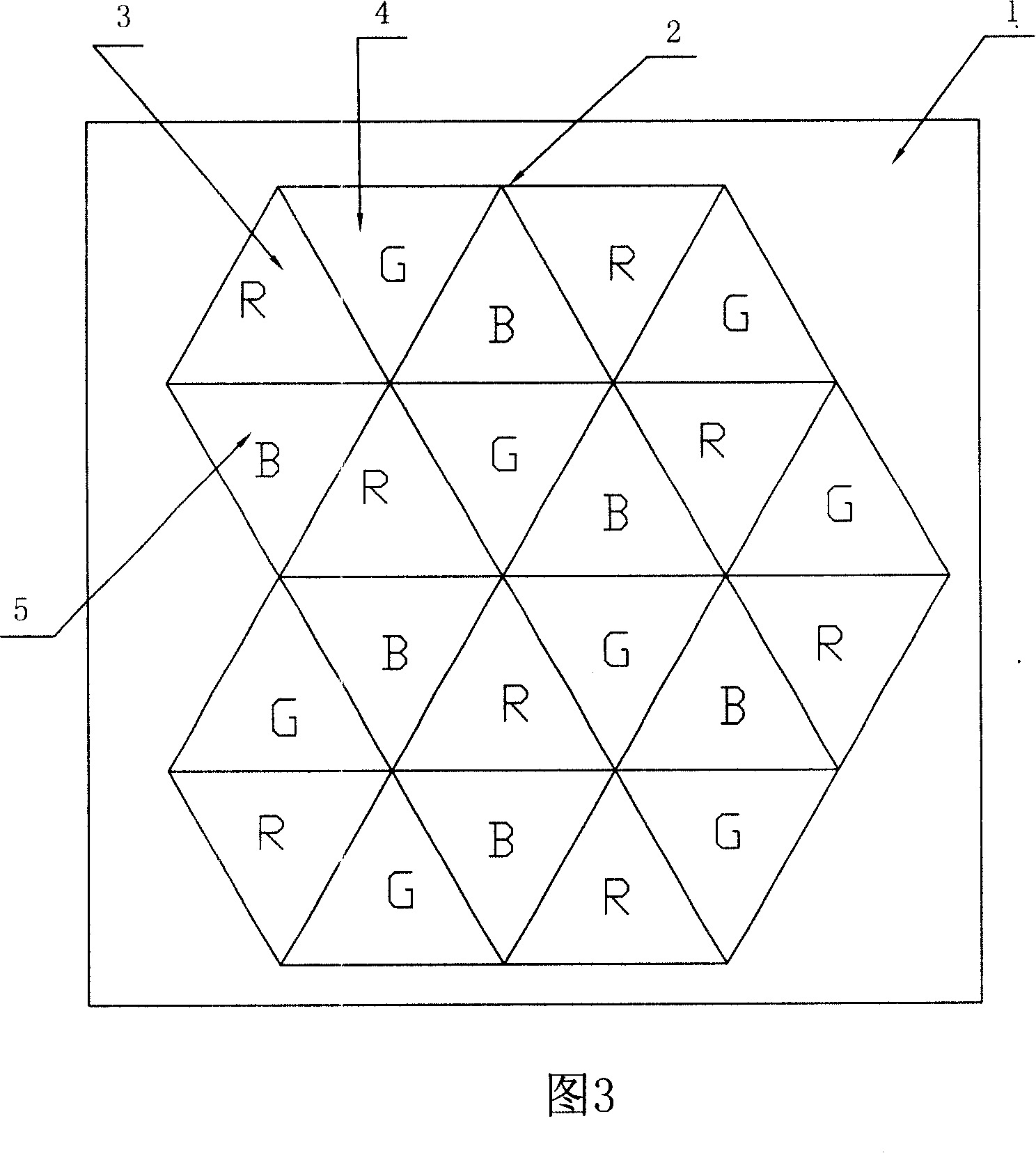

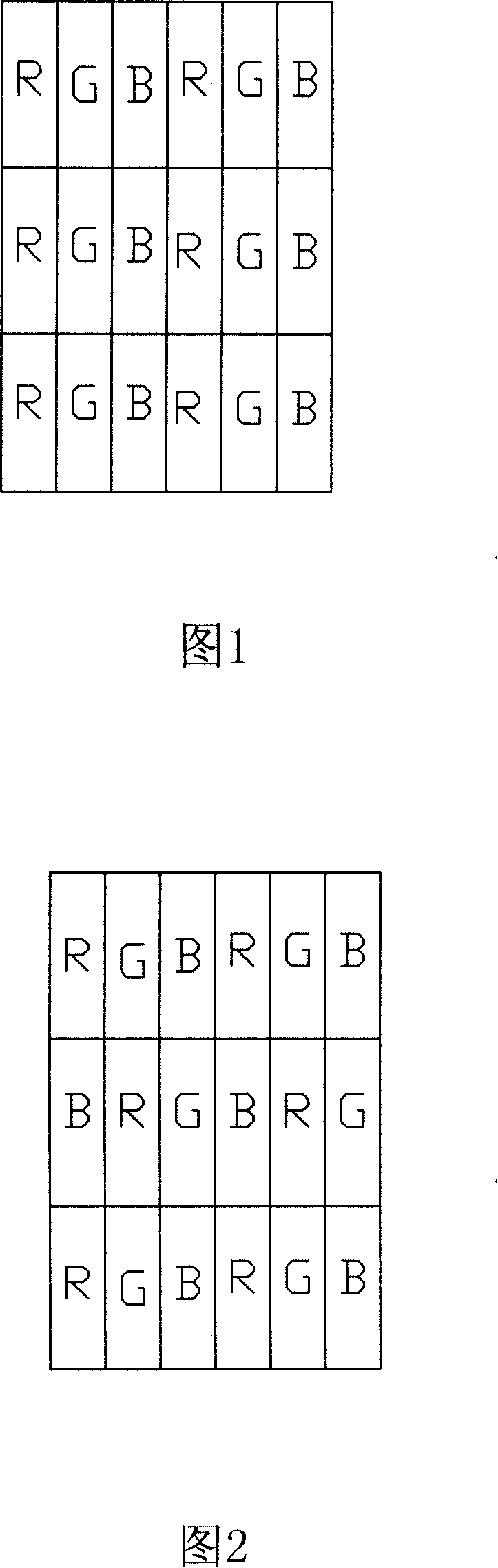

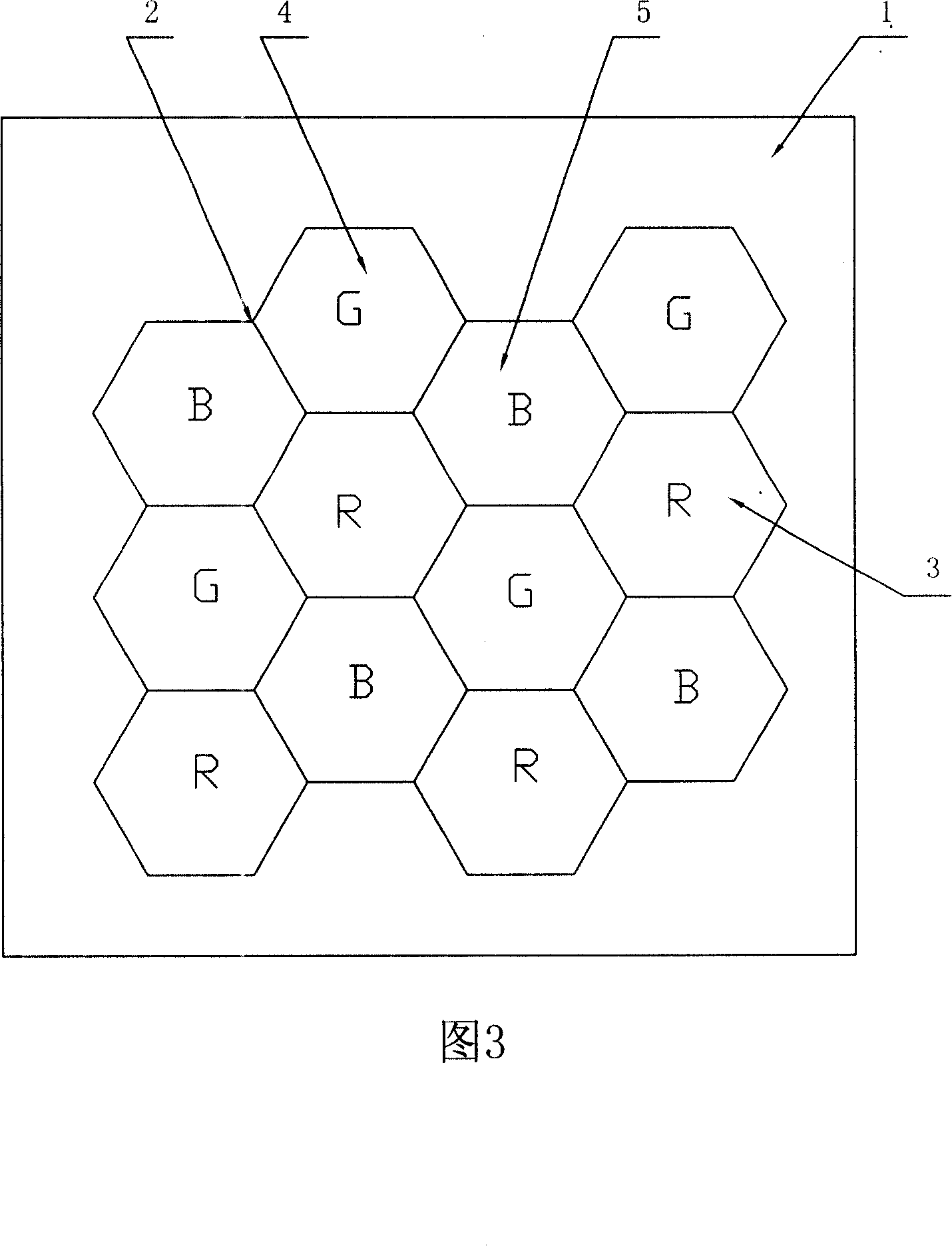

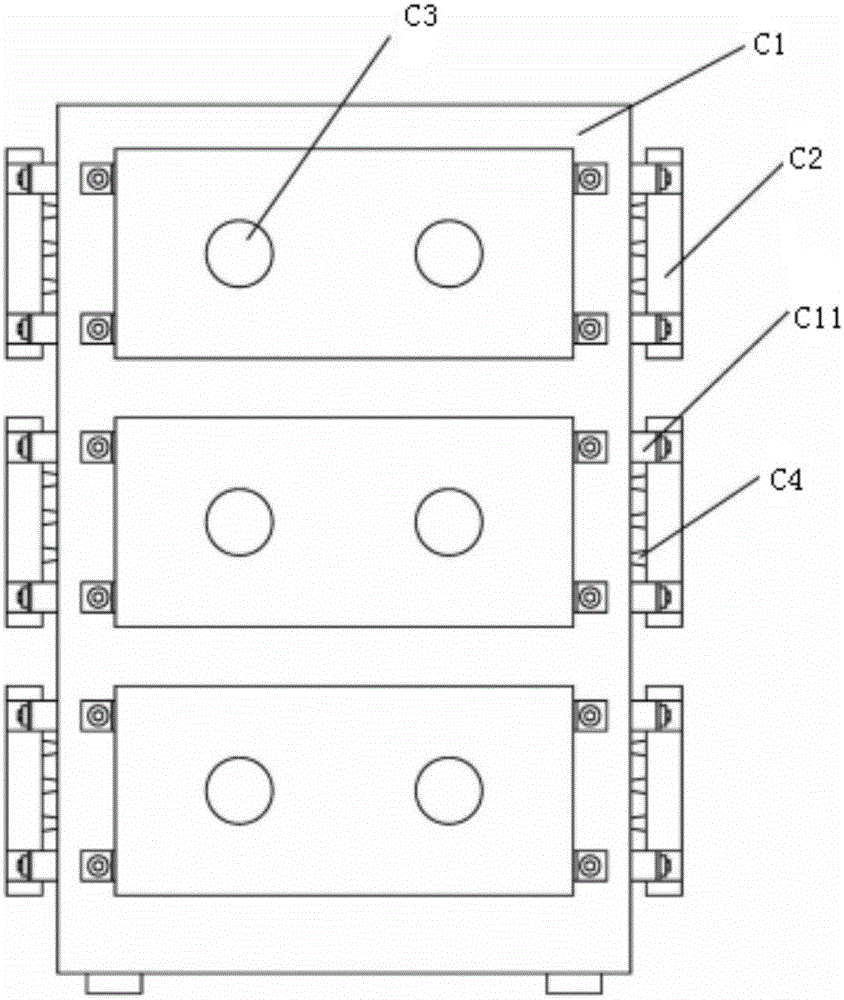

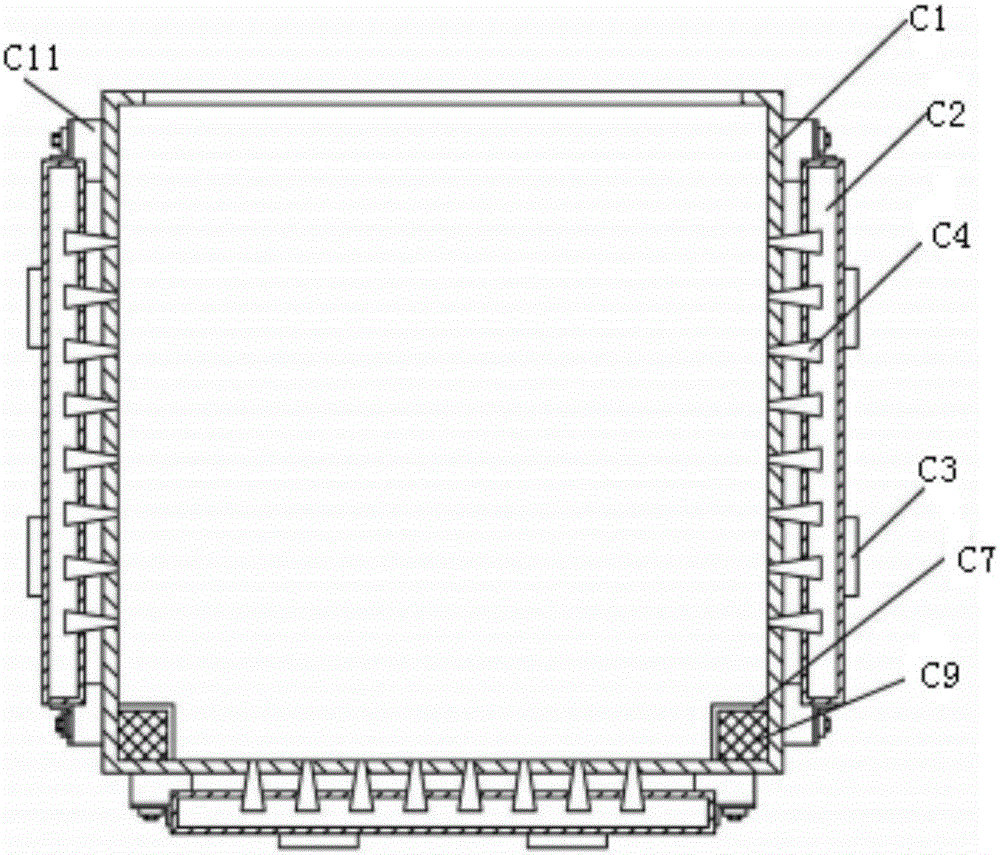

Structure of colorful spectral filter

InactiveCN101153932AScattered distributionOperableNon-linear opticsOptical elementsIsosceles trapezoidScarf joint

The present invention discloses a color filter structure which is provided with a transparent baseplate; a plurality of pixels are formed on the baseplate, wherein, each pixel is provided with a first color zone, a second color zone and a third color zone, in particular each pixel is an isosceles trapezoid; each two pixels are spliced to a regular hexagon; three identical regular triangles are in rabbet joint inside each isosceles trapezoid; three regular triangles respectively correspond to the first color zone, the second color zone and the third color zone, and after each two pixels are spliced to the regular hexagon on the transparent baseplate, with an arbitrary regular hexagon as the center, six regular hexagons spliced by other pixels in two are faveolately in scarf joint around. The color filter with the structure has good color display effect and can weaken sawtooth in the margin of image when the image is displayed obliquely.

Owner:BYD CO LTD

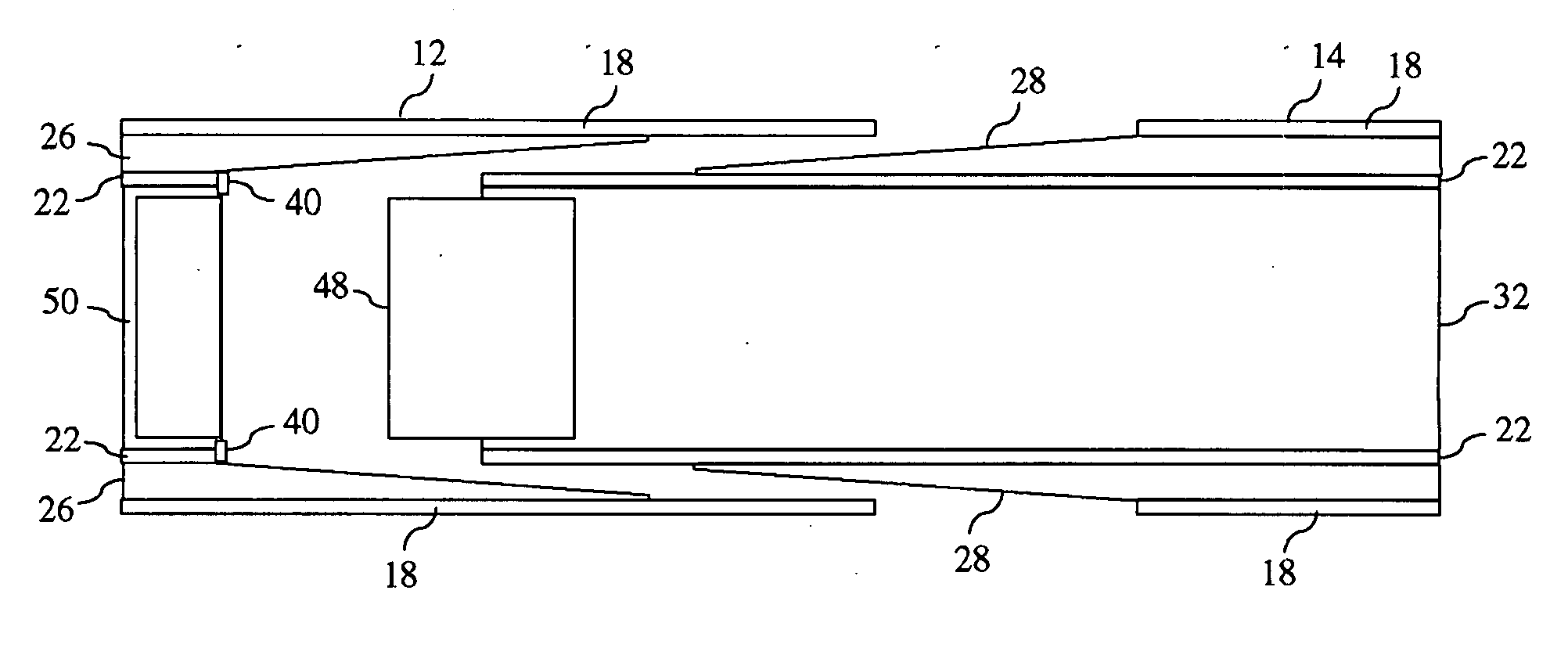

Multi-segment wind turbine blade and method for assembling the same

A multi-segment wind turbine blade comprises at least two blade segments. A first spar cap segment is attached to a first blade segment and a second spar cap segment is attached to a second blade segment. The first and second spar cap segments are configured to form a scarf joint. First and second spar cap brackets are attached in locations of the first and second spar cap segments, respectively, selected to facilitate alignment of the first and second spar cap segments at the scarf joint. At a field site, the first and second spar cap segments are bonded after fastening the first and second spar cap brackets.

Owner:GE INFRASTRUCTURE TECH INT LLC

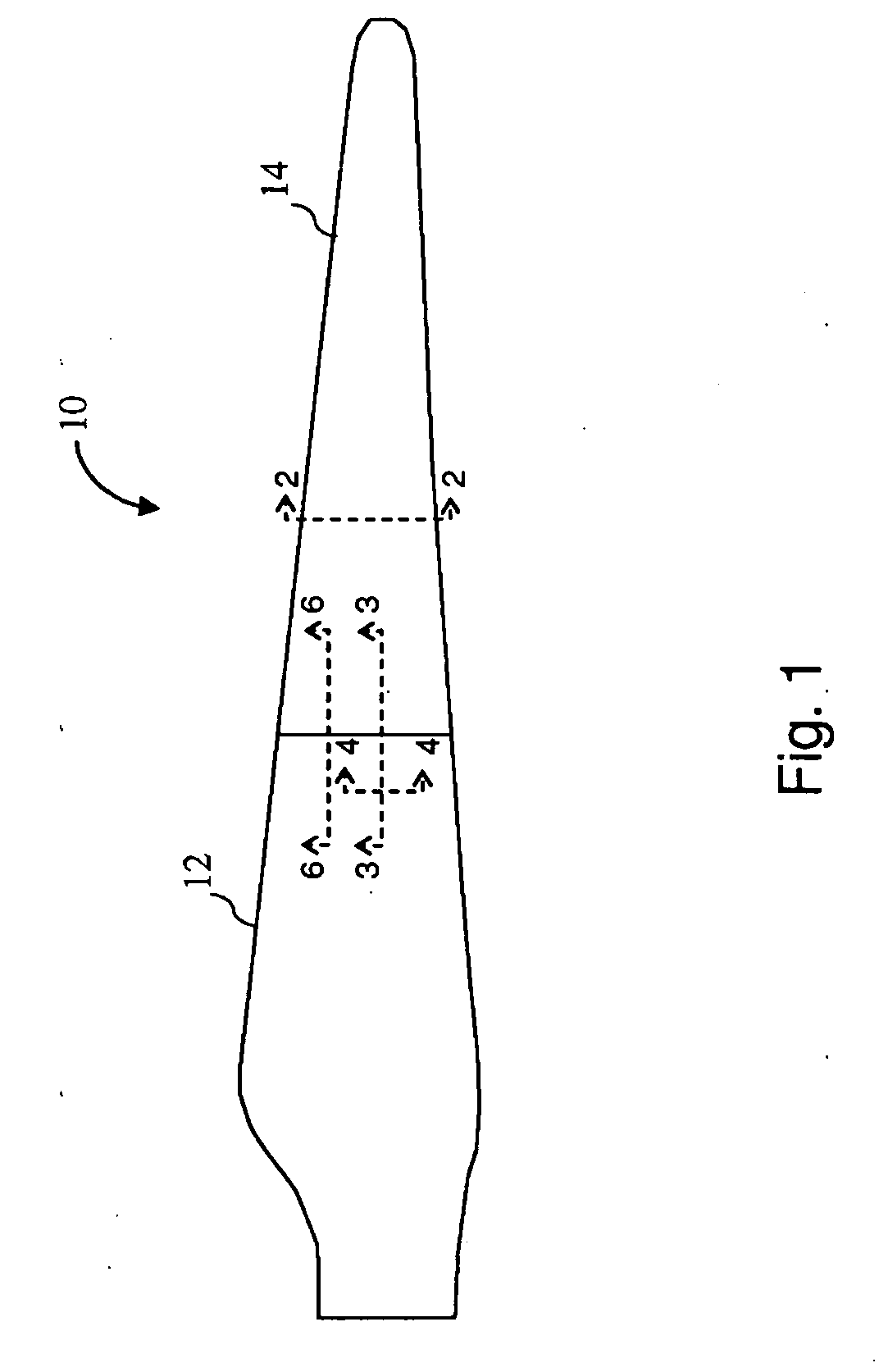

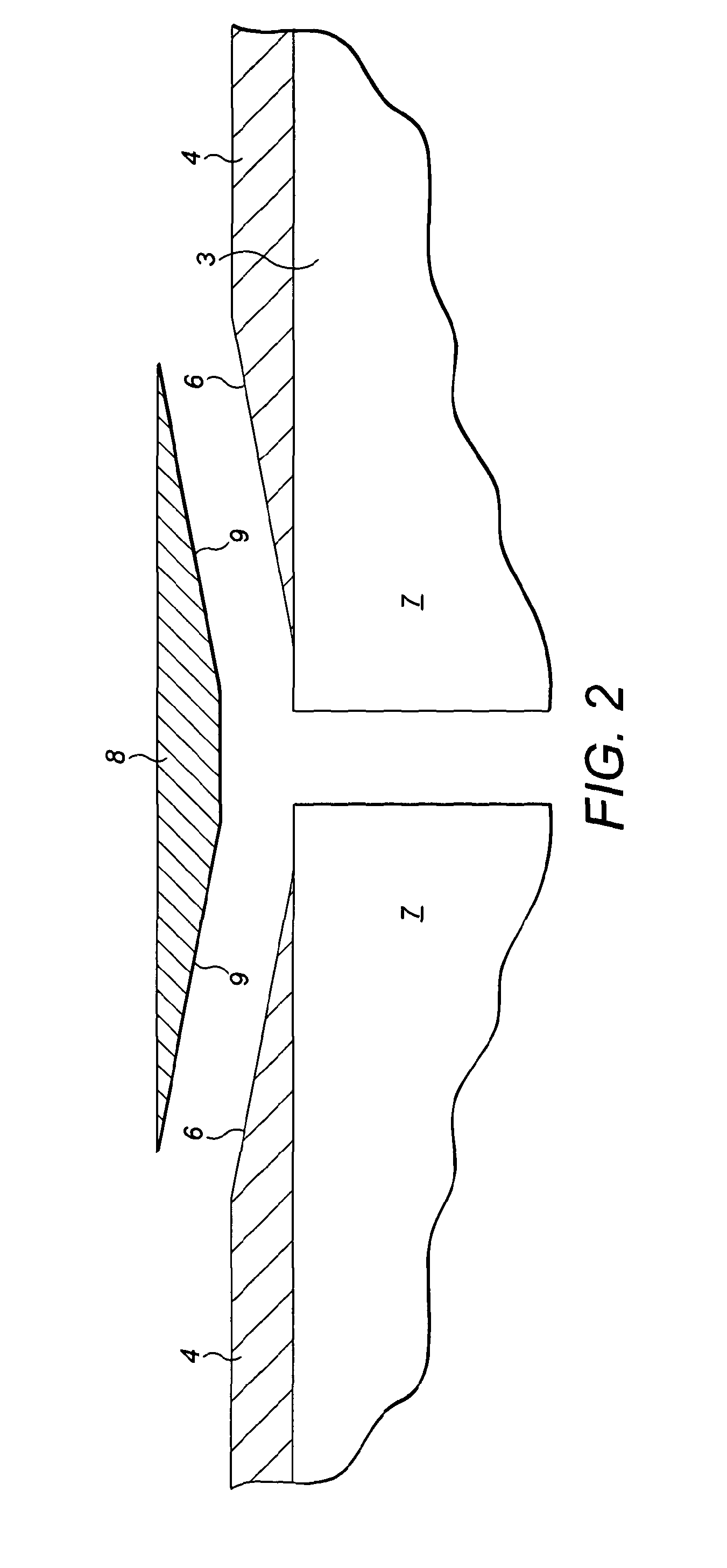

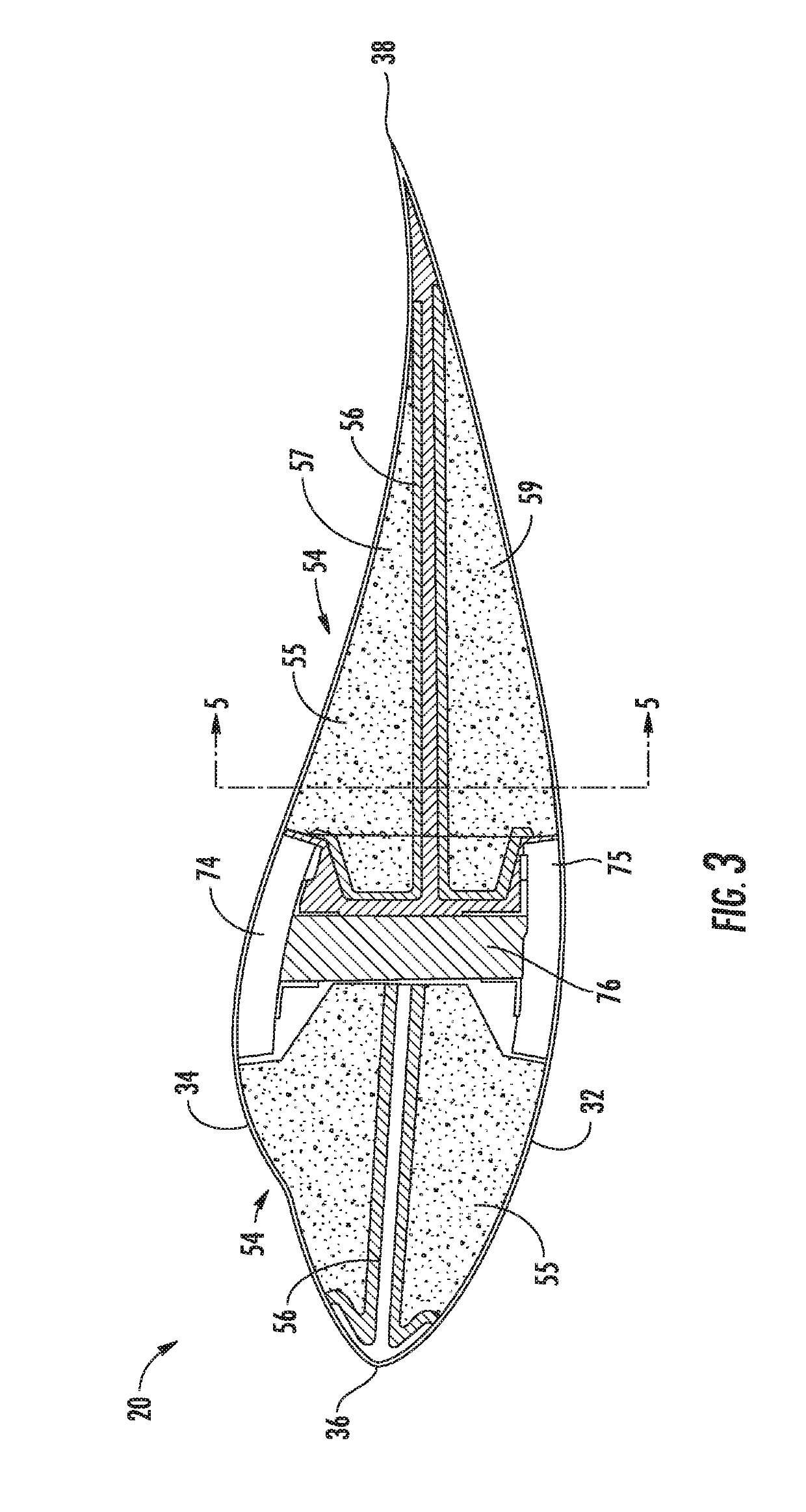

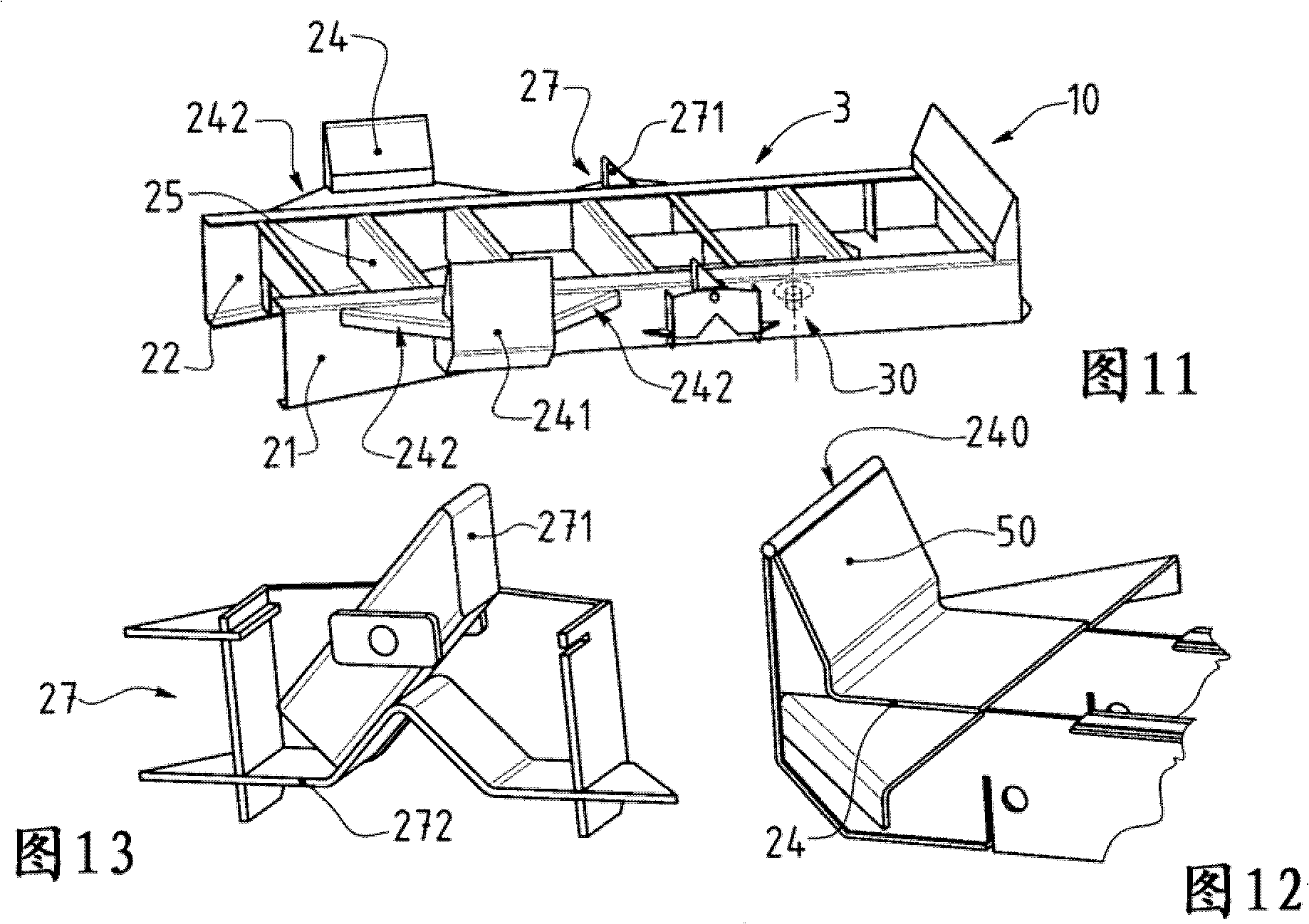

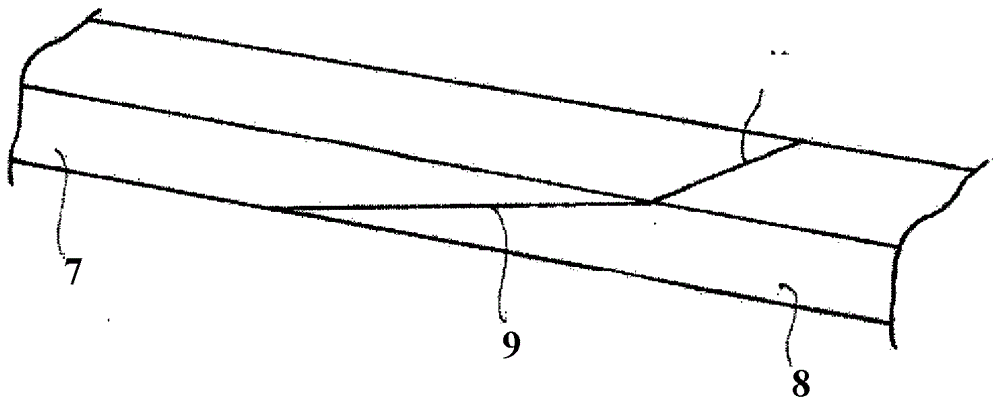

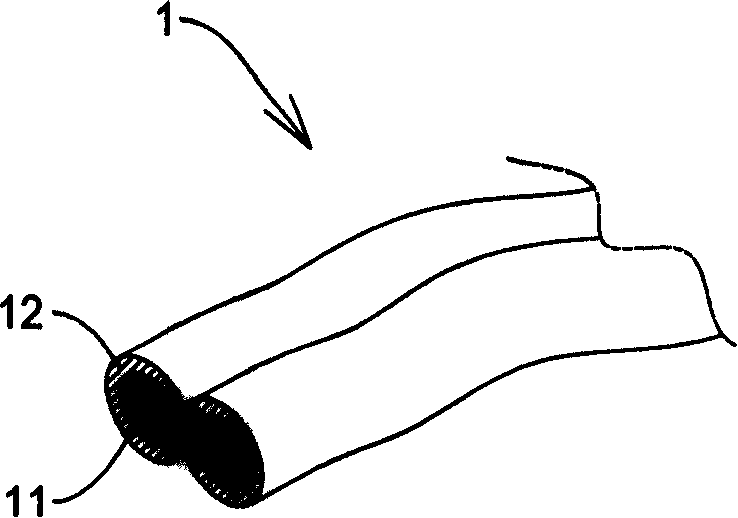

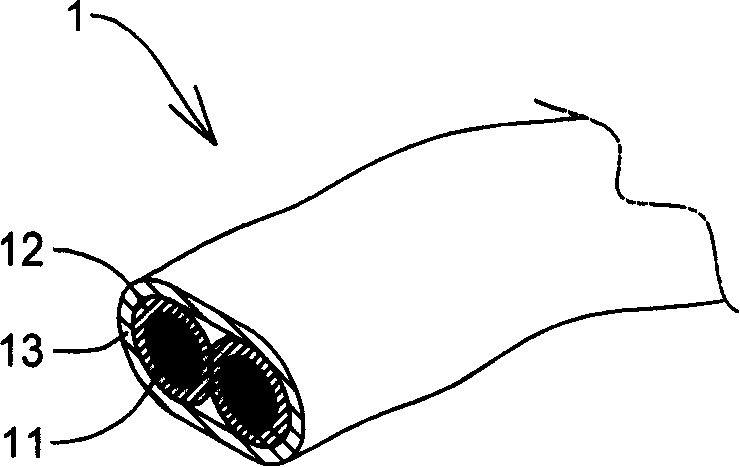

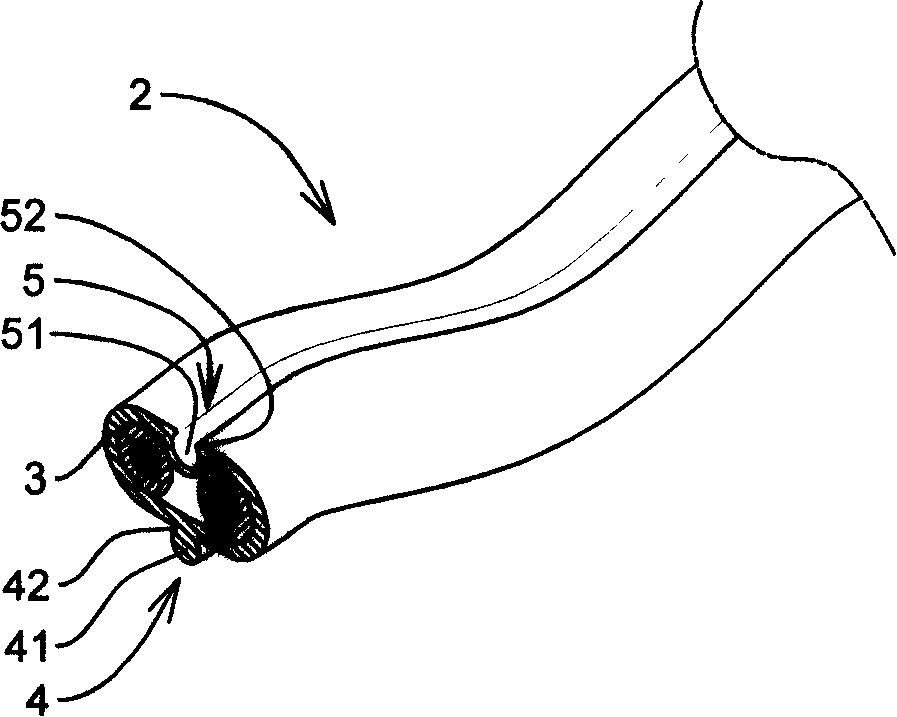

Wind turbine blade

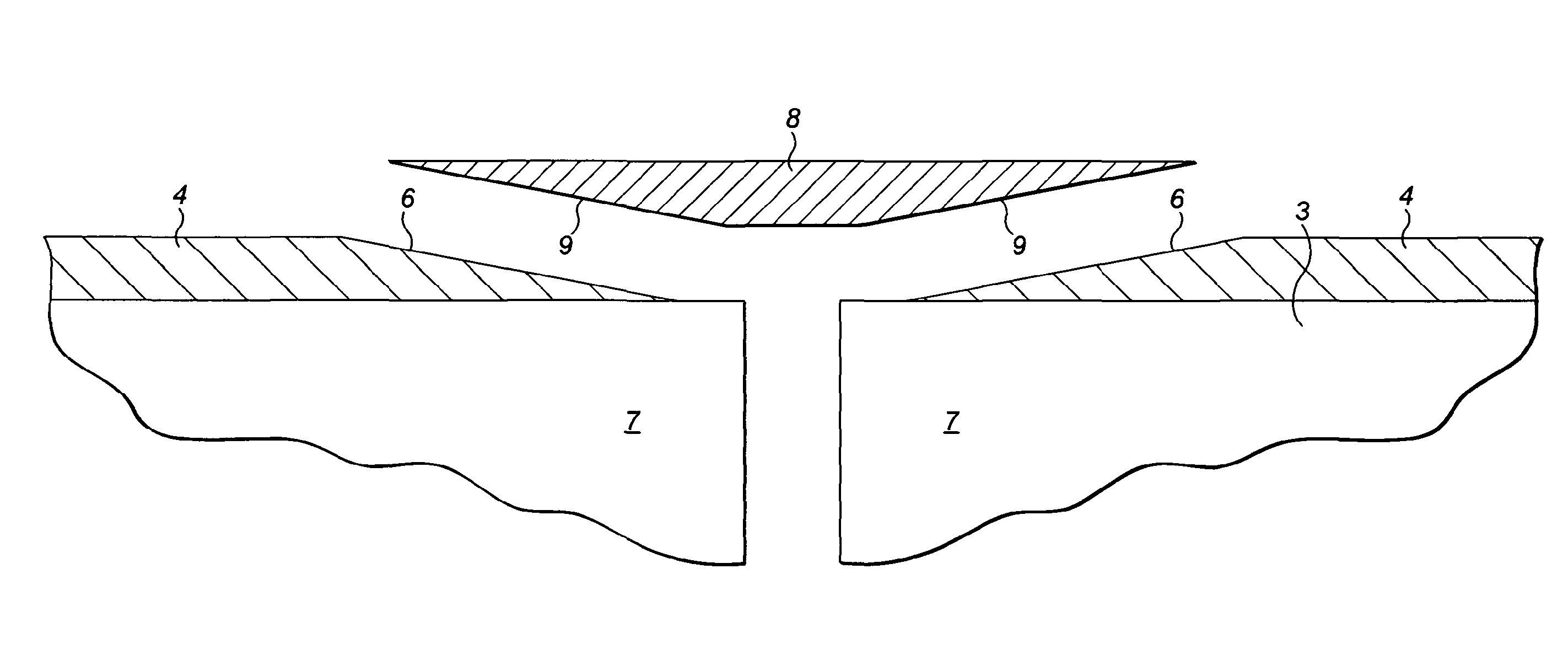

ActiveUS8764401B2Simplifies assembly process and reliabilityEasy to handlePropellersPump componentsScarf jointTurbine blade

A wind turbine blade comprising an aerodynamic fairing supported along at least a portion of its axial length by a spar (12). The spar comprises at least two spar segments (12) joined end-to-end at an interface (9), each spar segment comprising a shear web (3) with a spar cap (4) on each side. The outer face (6) of each spar cap tapers inwardly towards the interface such that its depth is reduced towards the interface creating a recess on each side of the interface formed by the tapered faces of adjacent spar caps. A respective connection piece (8) is sized to fit into each recess. Each connection piece (8) is sized to fit into each recess. Each connection piece (8) being fixed to the tapered faces of adjacent spar caps to form a double scarf joint.

Owner:BLADE DYNAMICS LTD

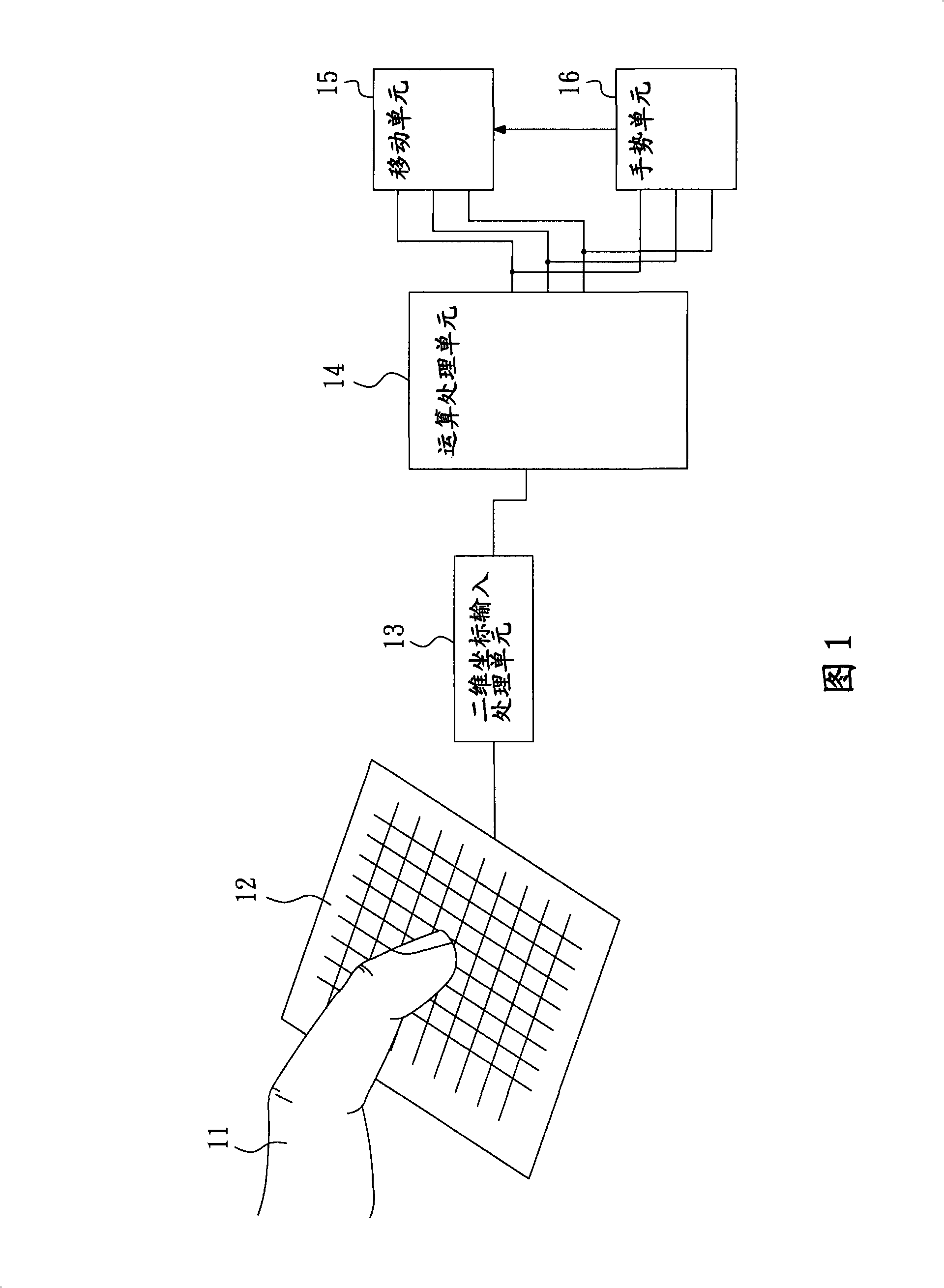

Input device of capacitive touchpad

InactiveCN101339470AImprove the problem that the moving distance is relatively shortImproved Capacitive Sensing DifferenceInput/output processes for data processingPolyesterCapacitance

The invention relates to a capacitance type touch control panel input device for user holding to produce capacitance inductor of capacitance type touch control panel. The capacitance type touch control panel comprises: a conductive pen head, made of conductive material for contacting capacitance type touch control panel; a pen body, one end of which connects or deploys conductive pen head; and a connection part, between pen head and pen body, for user holding capacitance inductor producing a capacitance type touch control panel with conductive pen head. The invention comprises conductive pen head, pen body of relative big area for contacting user palm and for user holding, and finger touchable pen body; conductive pen head and connection part can be scarf joint in pairs. The conductive pen head can uses polyester as inside filler of pen head, uses metal material as clad, or uses mixed polyester and metal material as pen head conductive material to increase contact surface with capacitance type touch control panel, thereby resolving problem of relative short moving distance resulting from relative large area of finger for contacting capacitance type touch control panel, and capacitance inducted variation resulting from sweating of hand.

Owner:ELAN MICROELECTRONICS CORPORATION

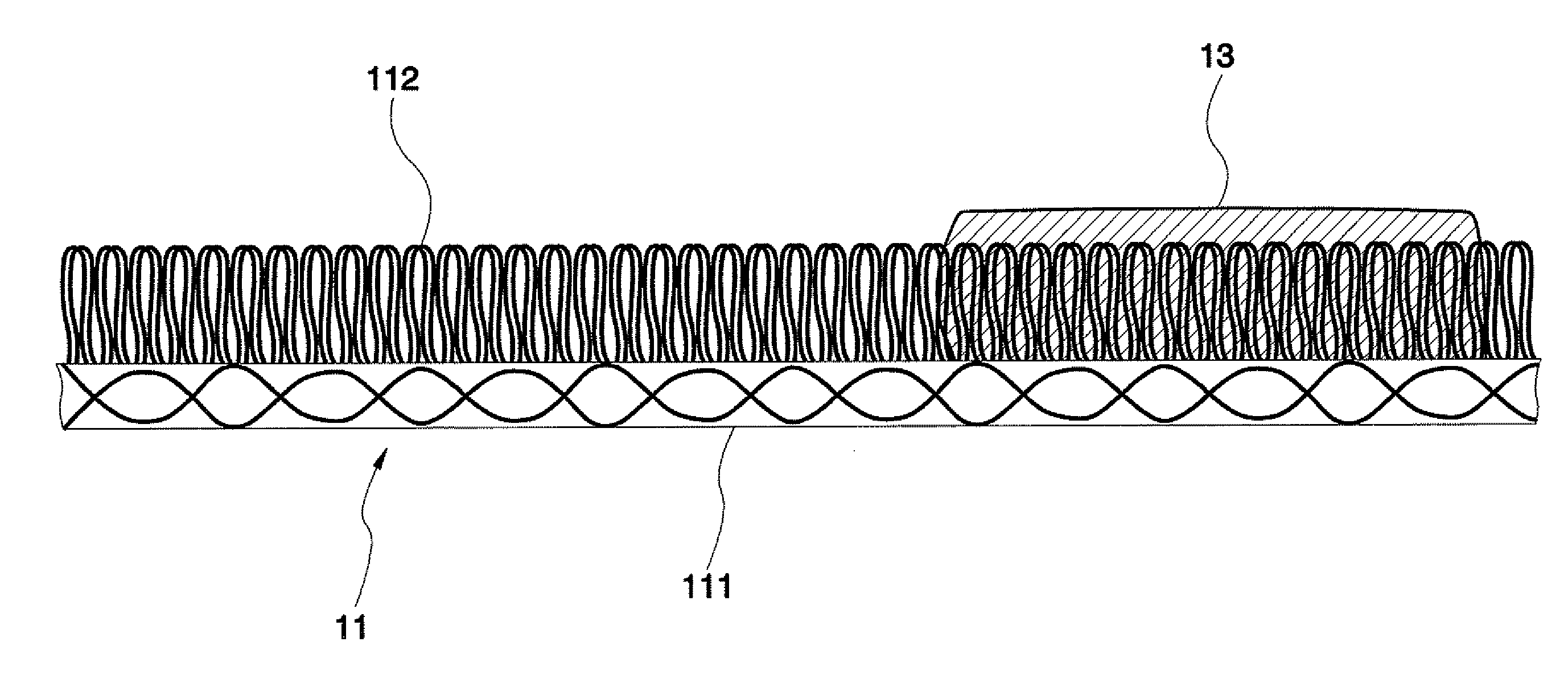

Anti-skid exercise mat

InactiveUS20100260963A1Preferable absorptionPreferable of functionSynthetic resin layered productsAbsorbent padsFiberPerspiration

An anti-skid exercise mat includes a foam member having a predetermined thickness, a fabric layer located on at least one side of the foam member, and at least one soft plastic material disposed on a predetermined area of a surface of the fabric layer and at least penetrating into the fabric layer for a predetermined depth for scarf joint and adhesive connection with fibers of the fabric layer. Accordingly, the anti-skid exercise mat has preferable anti-skid and perspiration-absorptive functions during the whole course of exercising.

Owner:FENG SHEN PAO LAN

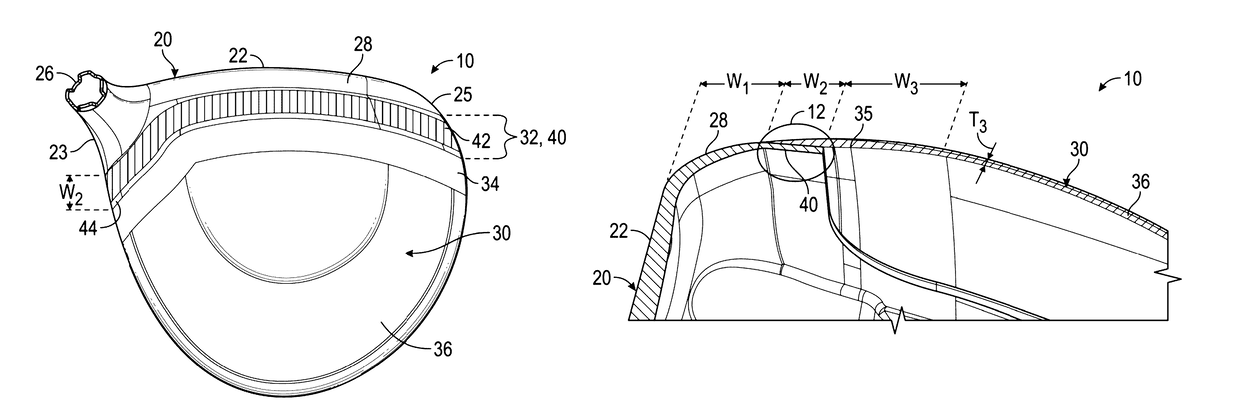

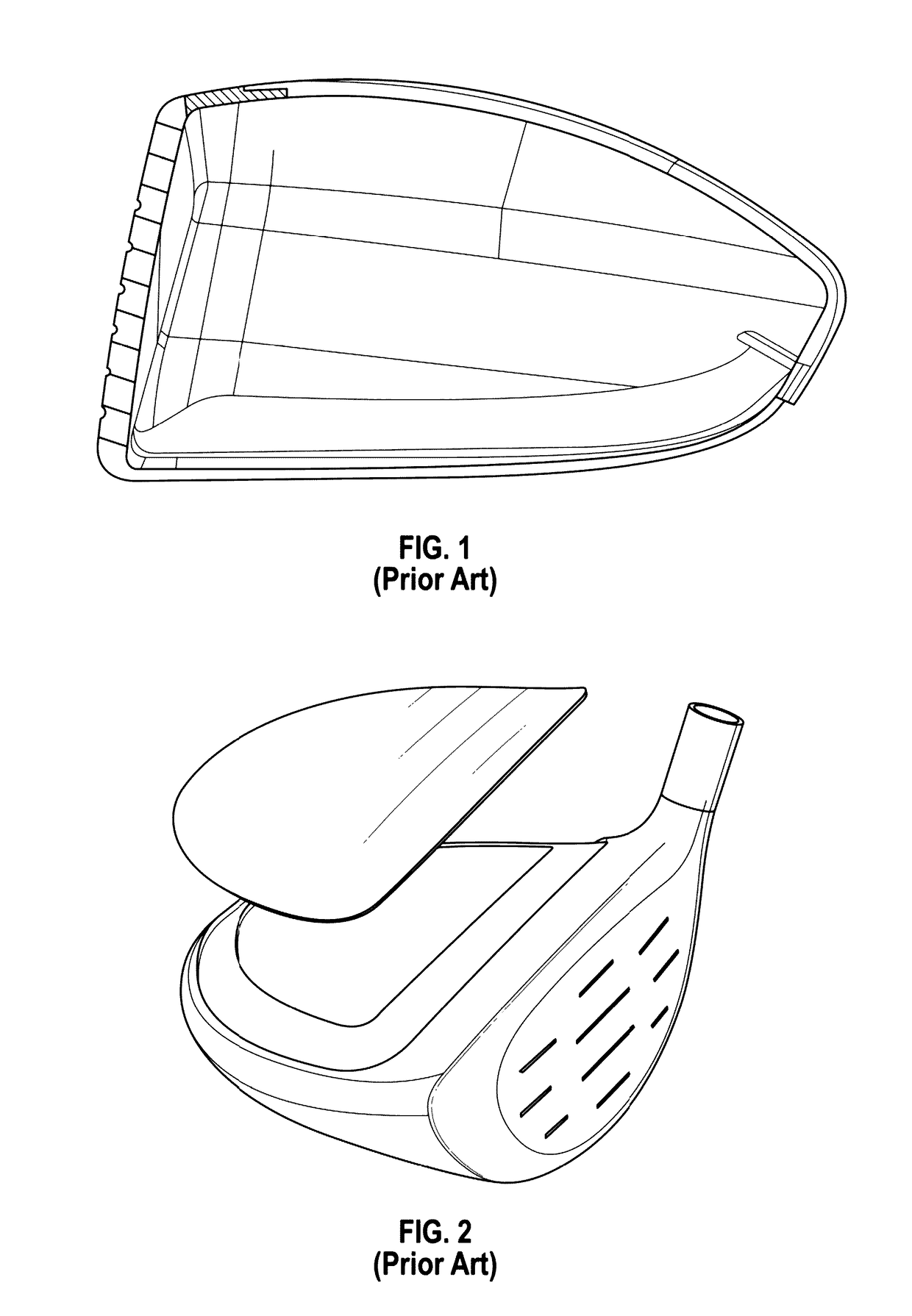

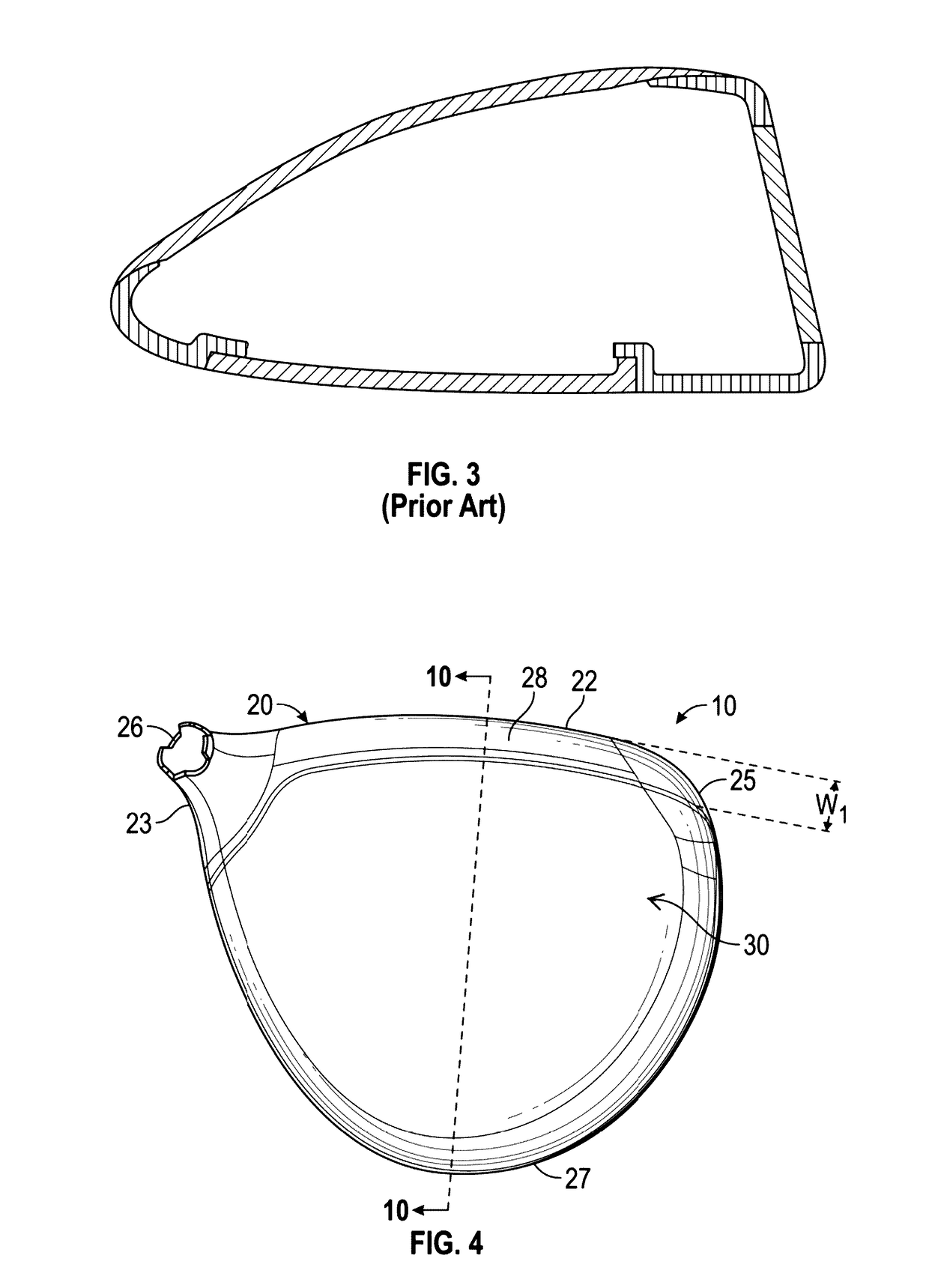

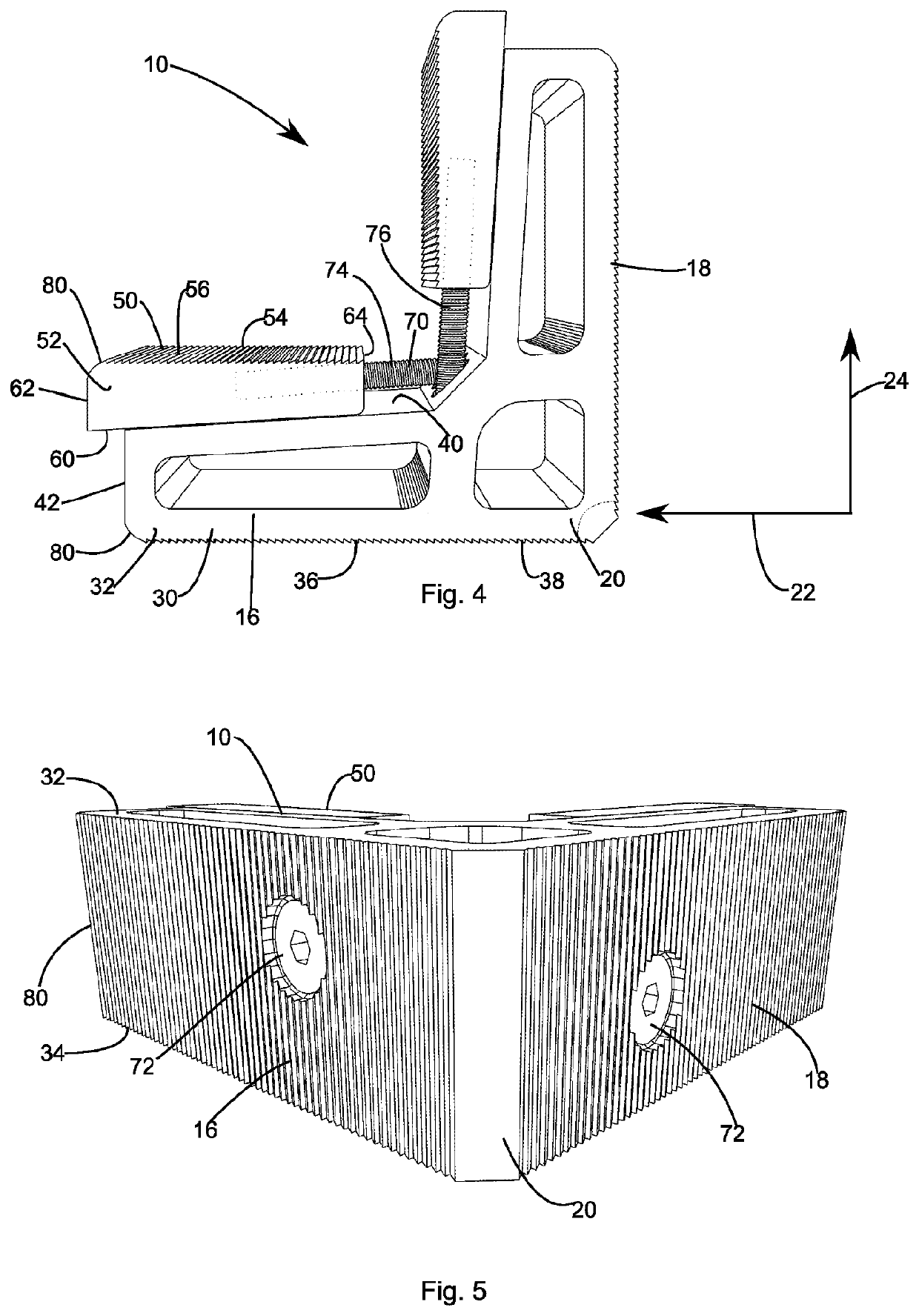

Multiple-material golf club head with scarf joint

A multiple-material golf club head with an improved scarf joint between the crown and the body is disclosed herein. The golf club preferably is a driver that has a metal body comprising a striking face, a sole, a return portion, a front flange, and a rear flange, and a composite crown having a scarf joint region, a transitional thickness region directly behind the scarf joint region, and a constant thickness region directly behind the transitional thickness region. The thickness distribution along the crown, in combination with the tapered edge of the scarf joint and its intersection with the front flange, greatly reduces the stress placed on critical portions of the club head and improves overall golf club head durability.

Owner:TOPGOLF CALLAWAY BRANDS CORP

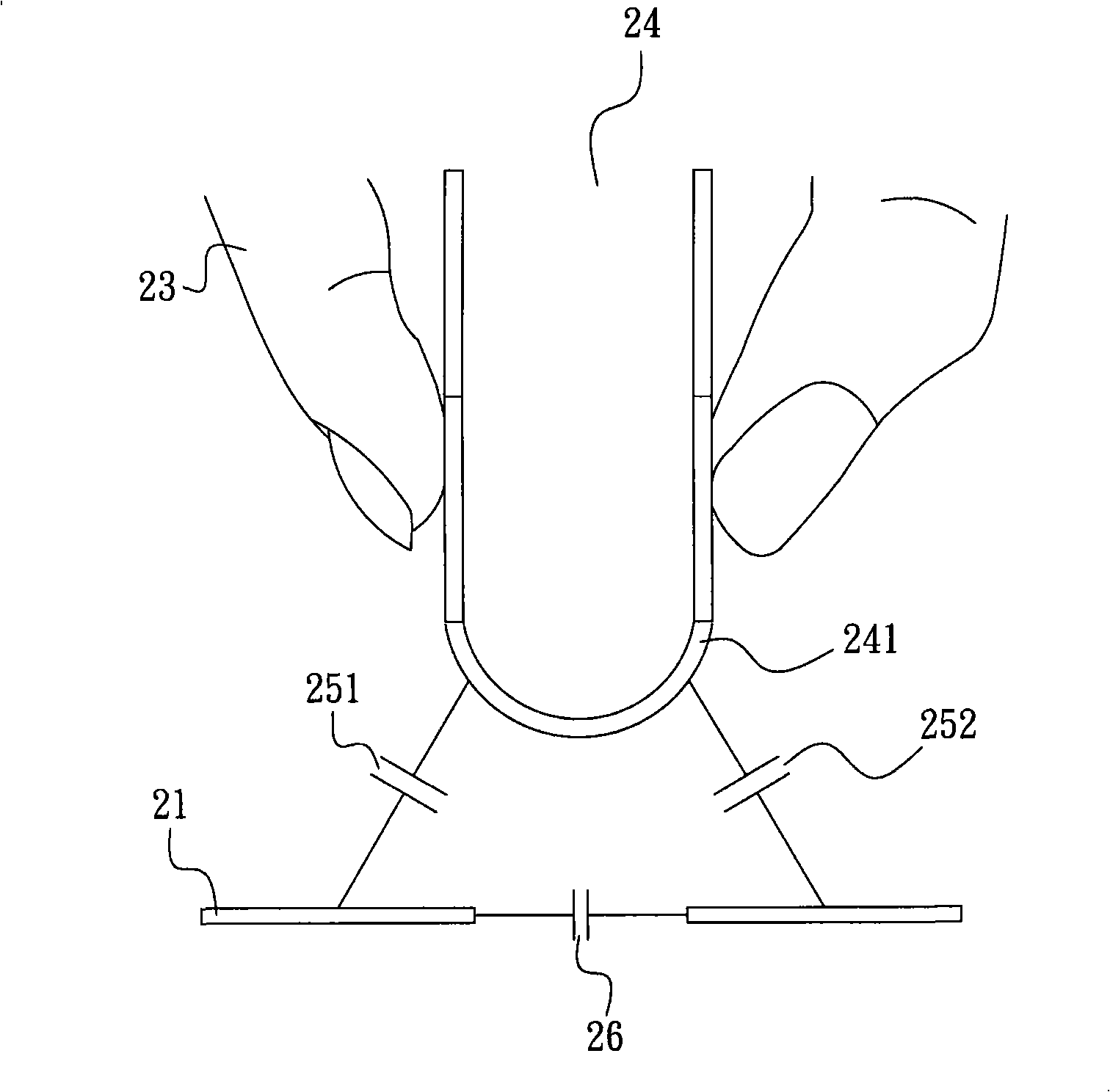

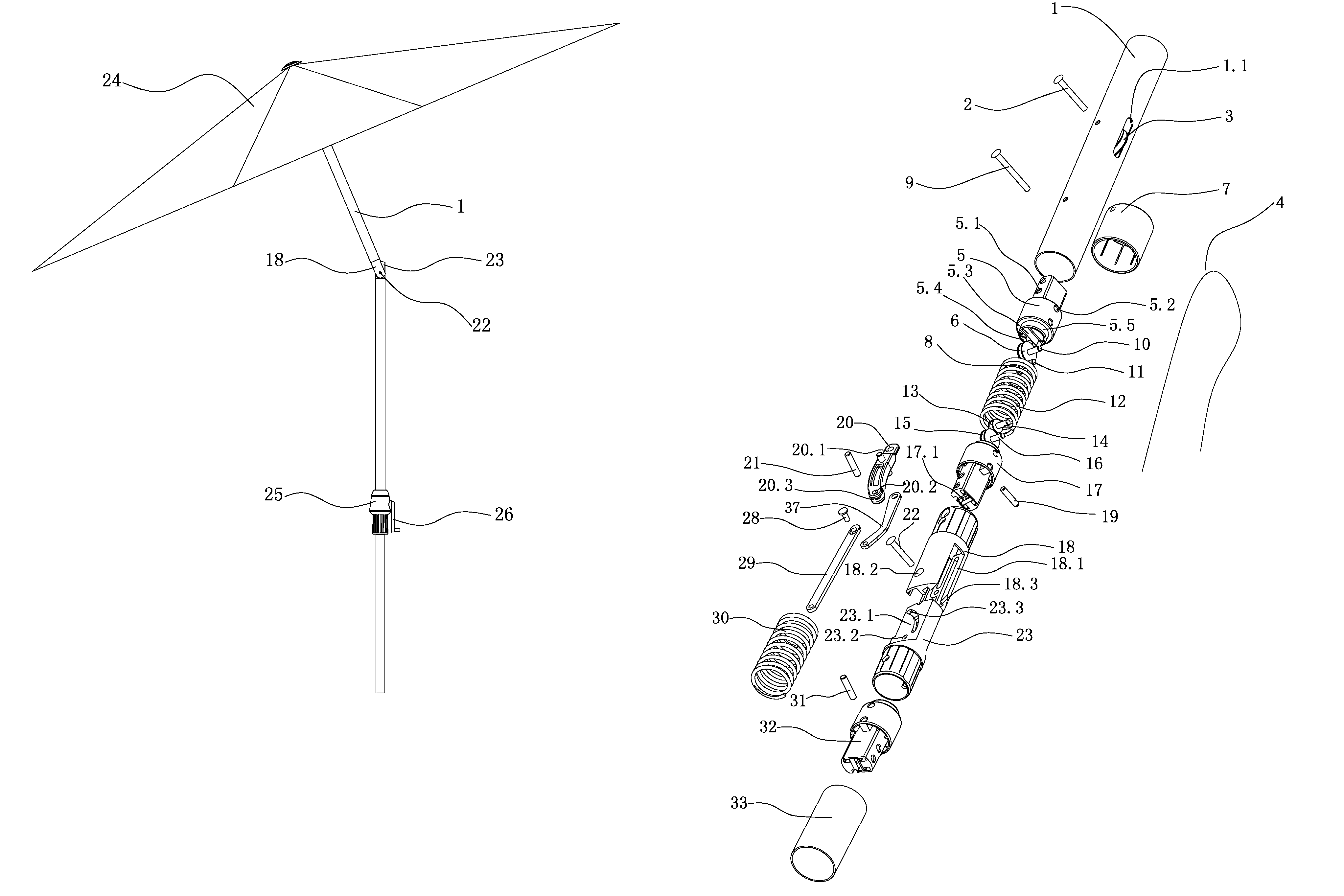

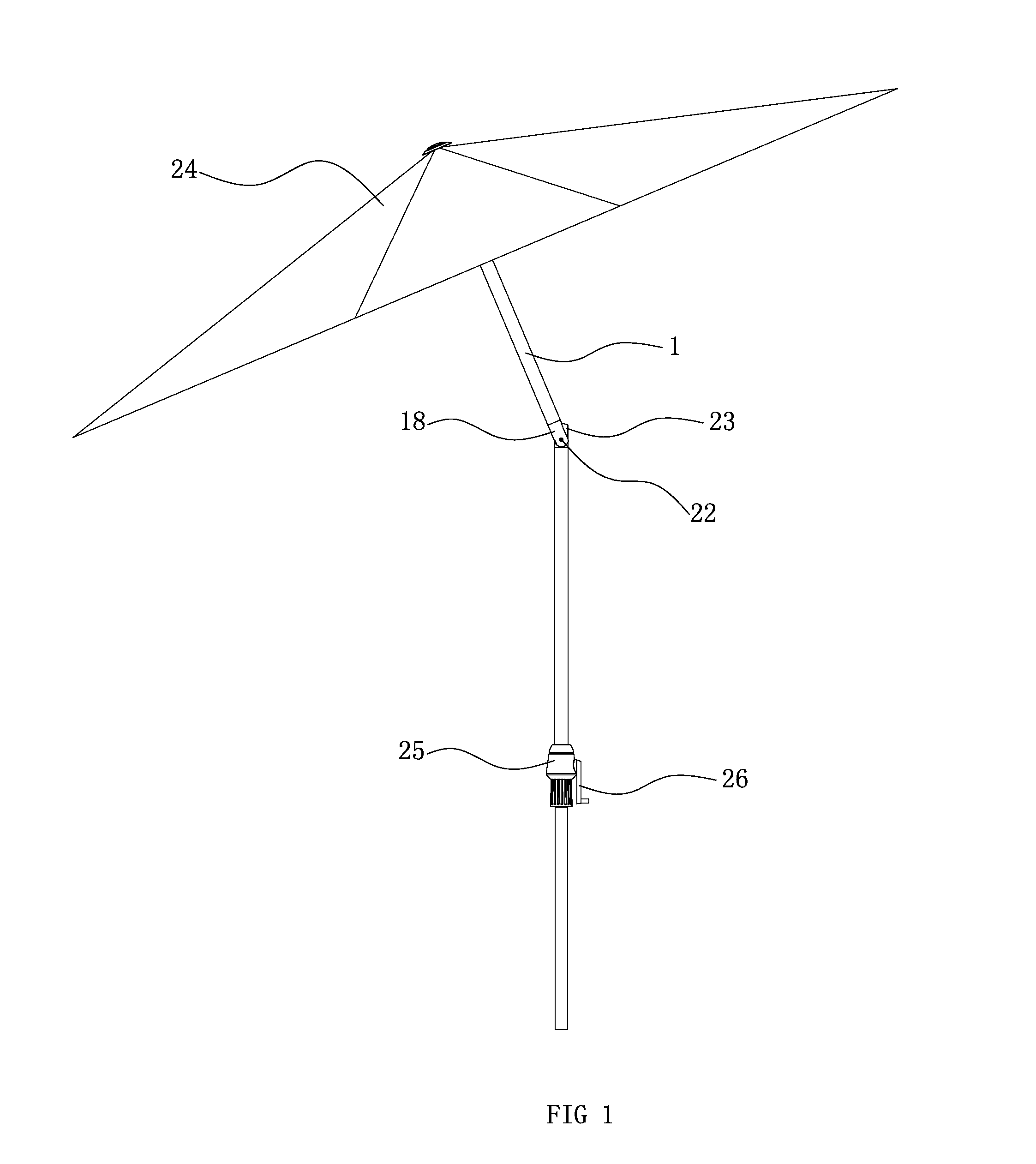

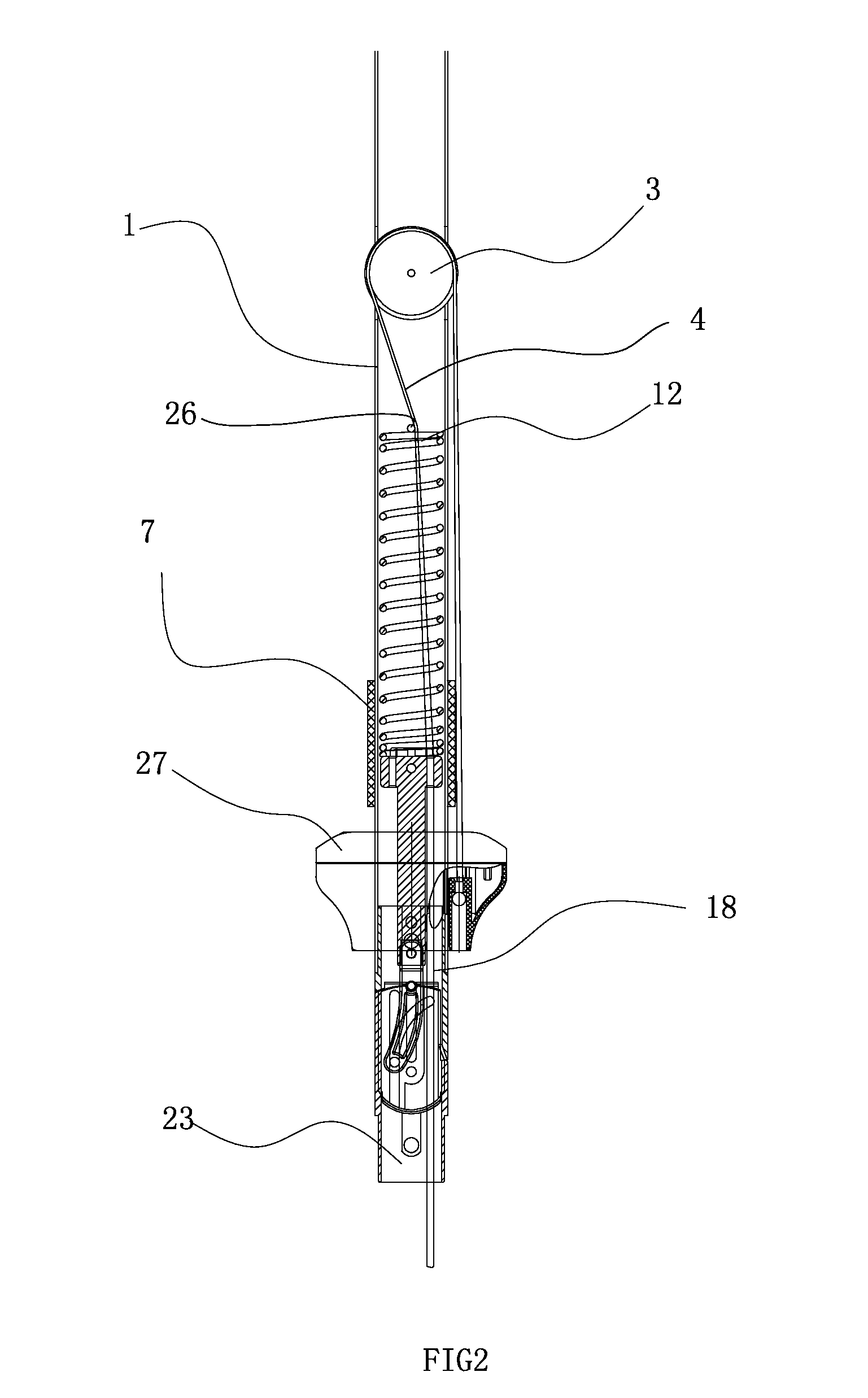

Auto bending structure of sunshade

Owner:PHAETON MFG LLC

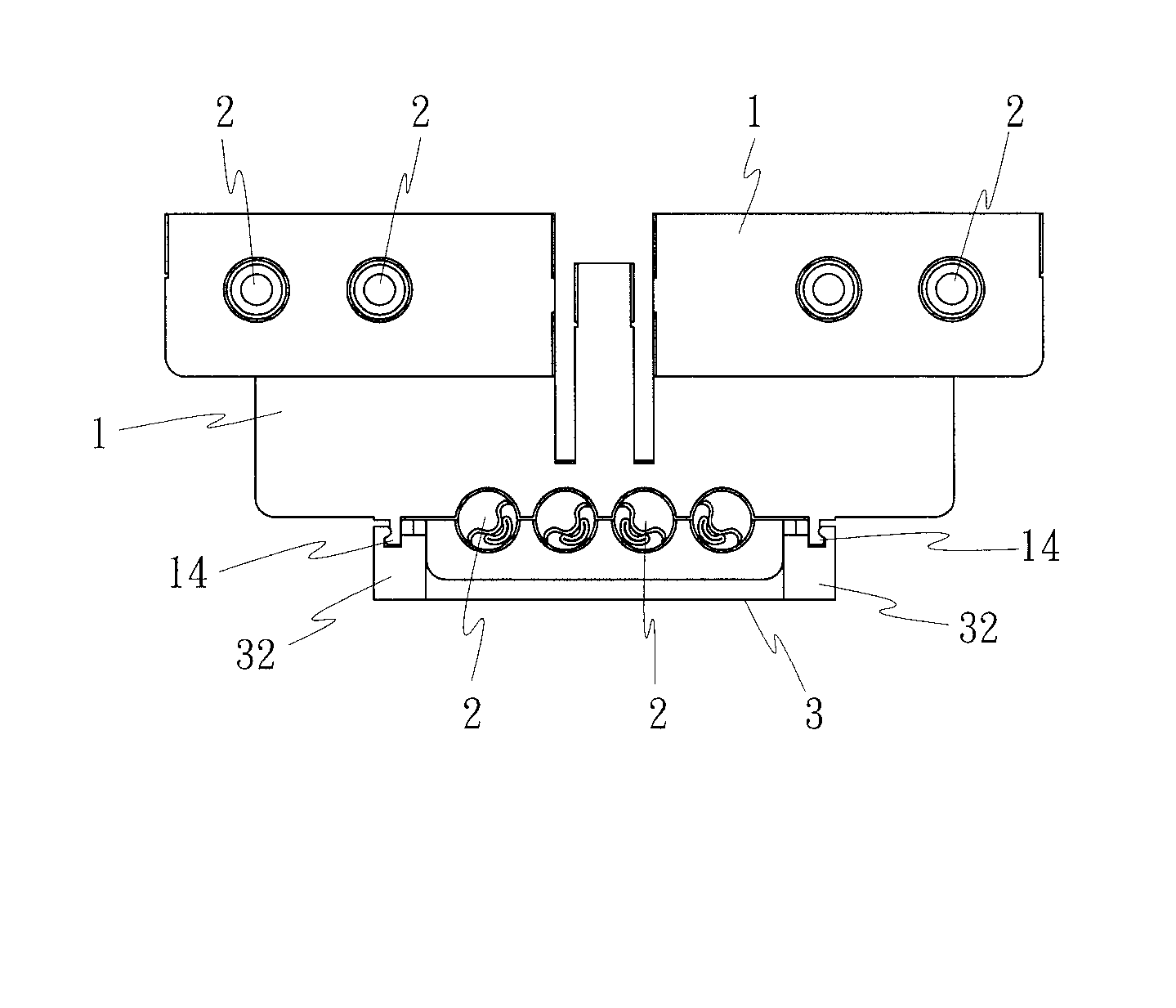

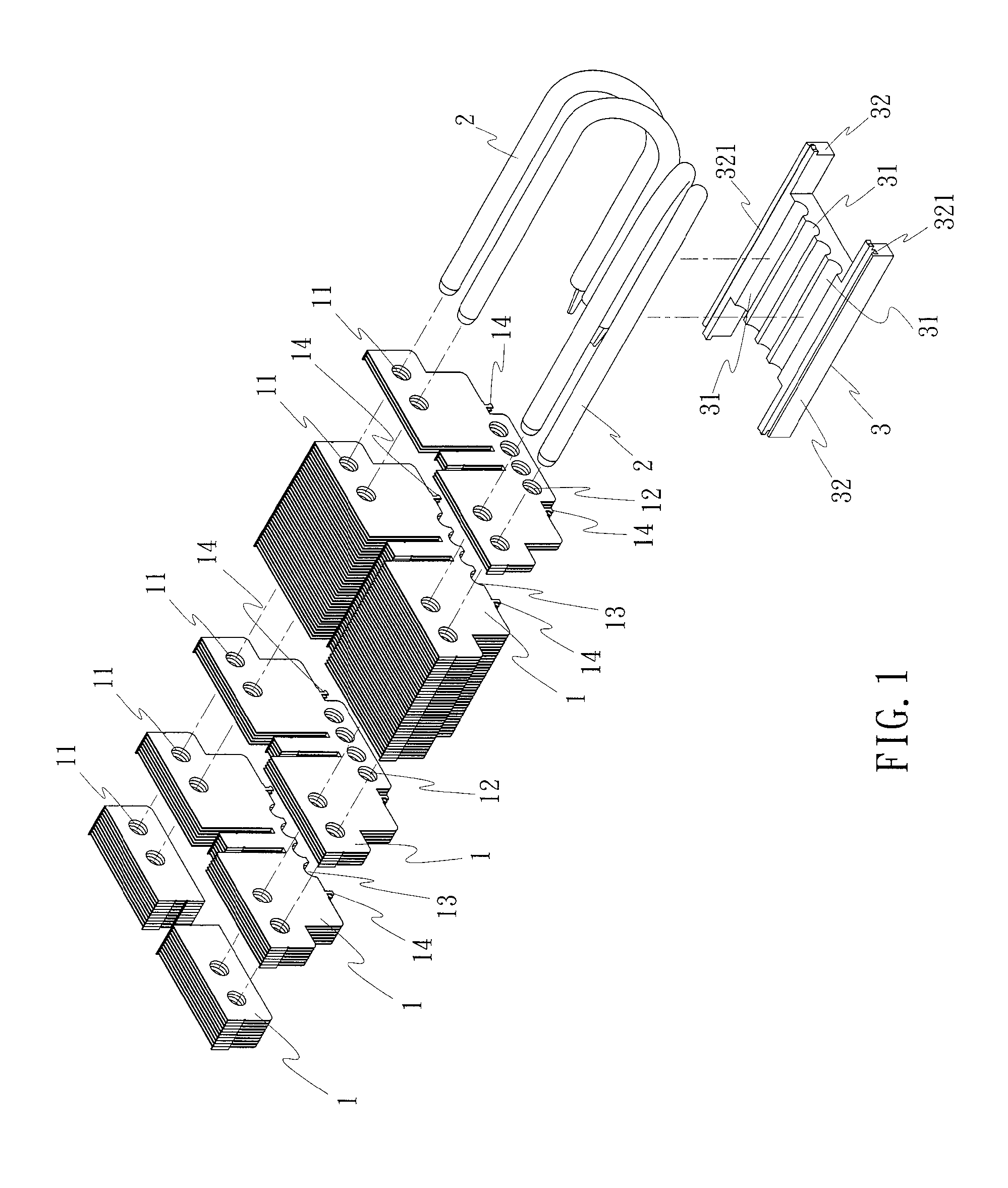

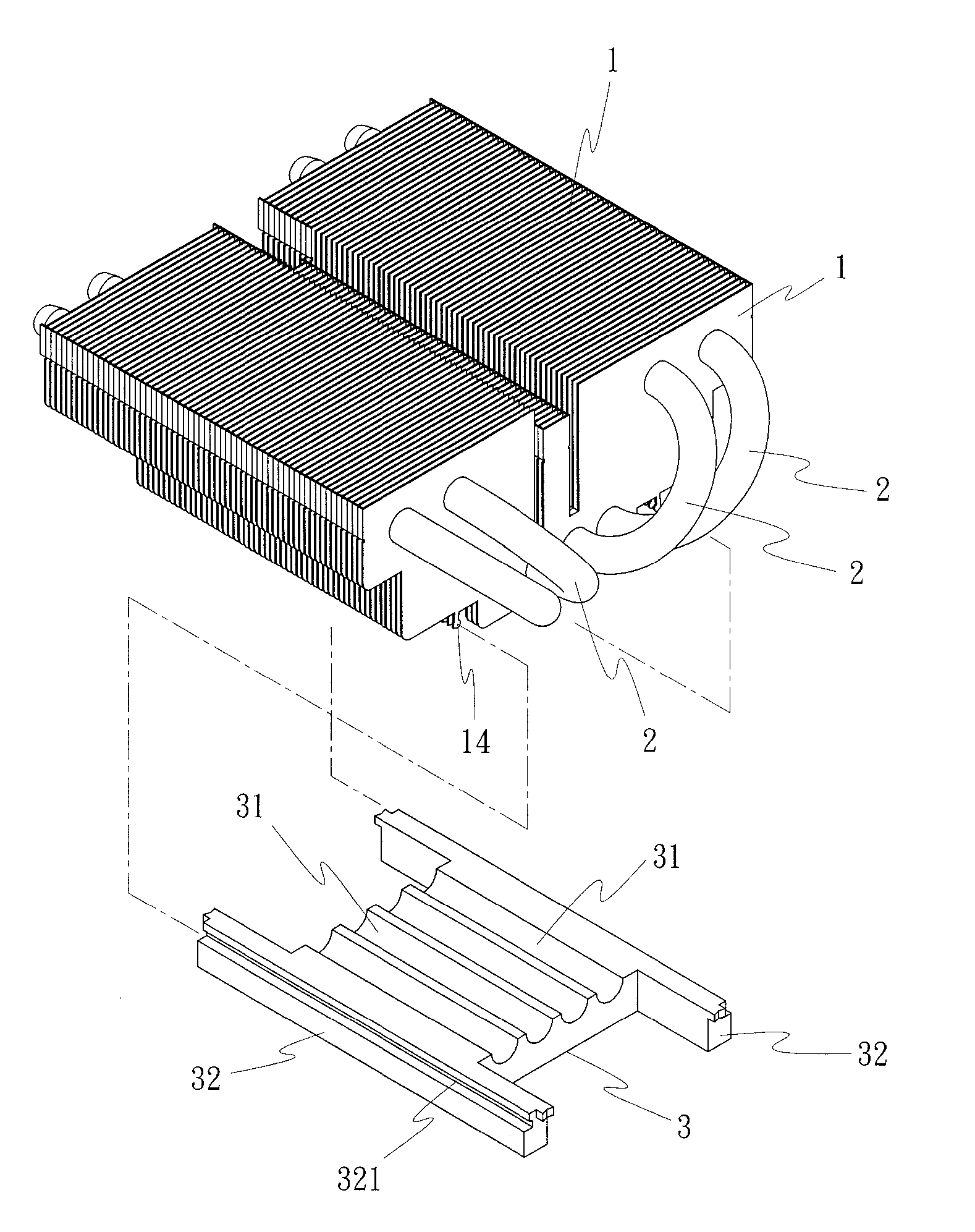

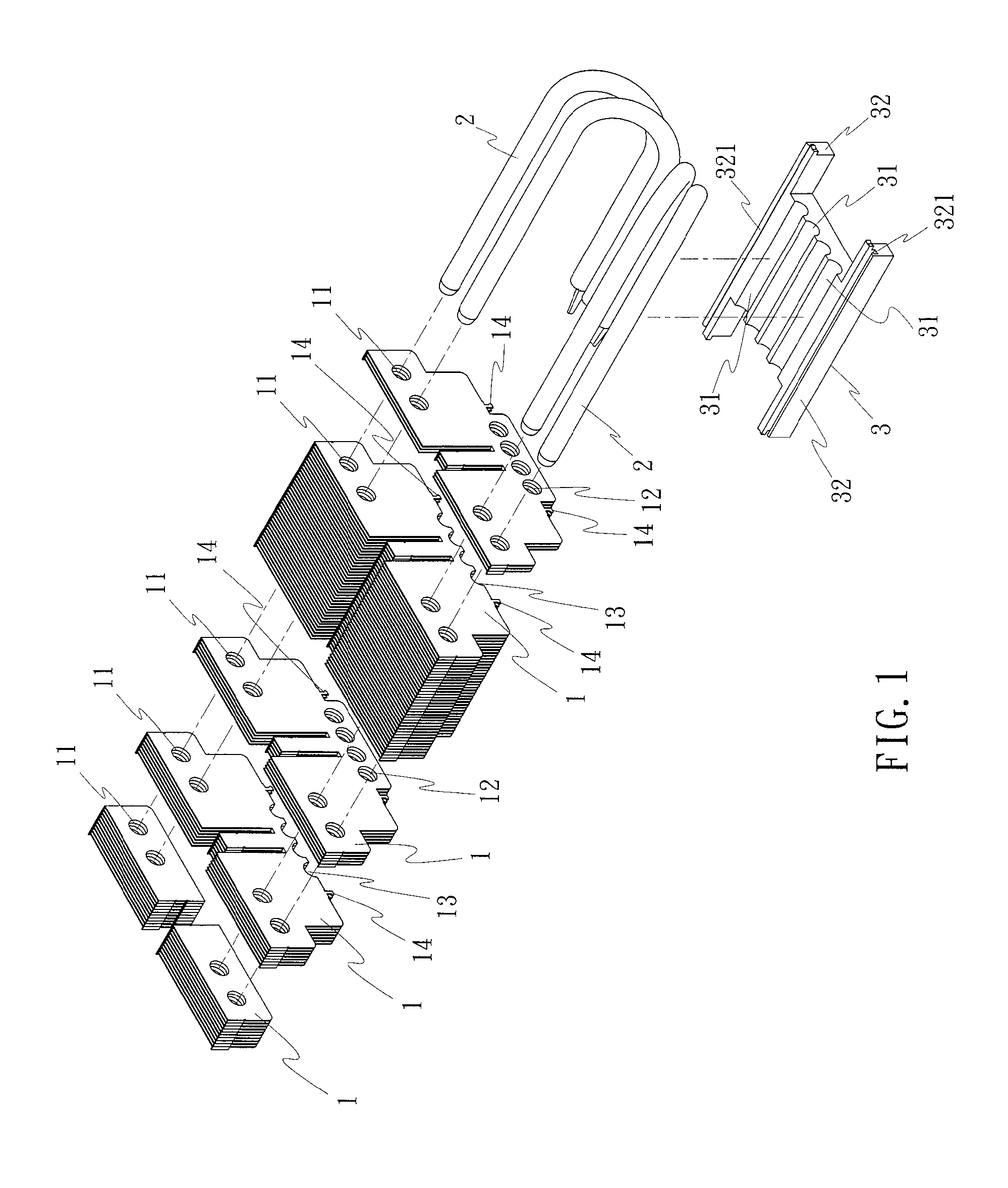

Combination cooler module

A combination cooler module is disclosed, which includes a plurality of radiating fins that are arranged in a stack, a plurality of heat tubes inserted through the radiating fins, and a heat conductive base affixed to the radiating fins by means of a dovetail joint, hook or scarf joint and disposed in contact with the heat tubes.

Owner:KUO HUA SHOU

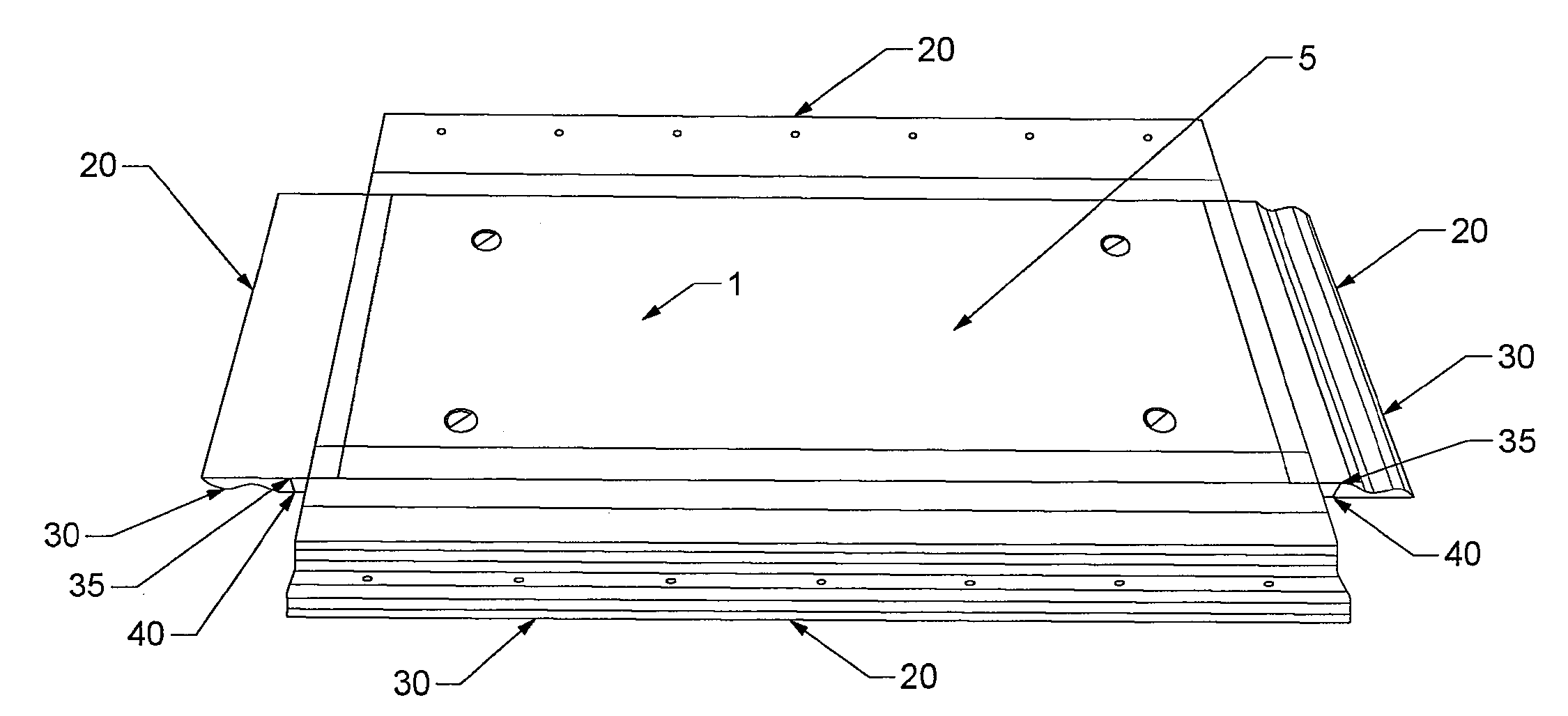

Multi-purpose panels with a modular edge

InactiveUS20090016817A1Easy transferStiffness and weightIn situ pavingsCovering/liningsMortise and tenonScarf joint

A panel for use in constructing a mat or a road and method for same is provided. The panel can include a wafer having at least three sides operatively coupled to an edge having a complementary profile for overlapping and attaching to another edge coupled to another wafer. The edge can be attached to the wafer using a scarf joint or a mortise and tenon joint. The complementary profile can include a lap joint, a tapered lap joint, an S-shaped lap joint or a modified lap joint for use with fasteners for attaching two edges together.

Owner:ACCUFORM CANADA

General photovoltaic building member

InactiveCN100424305CReduce construction costsSimple structureSolar heating energyRoof covering using slabs/sheetsBuilding integrationScarf joint

Owner:TRINA SOLAR CO LTD

Method of joining blade sections using thermoplastics

A segmented rotor blade for a wind turbine includes a first rotor blade segment, a second rotor blade segment, at least one thermoplastic material, and an internal pressure source. The first rotor blade segment includes a first joint end. The second rotor blade segment includes a second joint end. The first and second joint ends are arranged together in an end-to-end orientation so as to form at least one scarf joint. The at least one thermoplastic material is arranged at each of the first and second joint ends. The first and second joint ends of the first and second rotor blade segments are bonded together via thermoplastic welding of the at least one thermoplastic material. The internal pressure source provides pressure to the scarf joint during the thermoplastic welding. The internal pressure source remains within the rotor blade after thermoplastic welding is complete.

Owner:GENERAL ELECTRIC CO

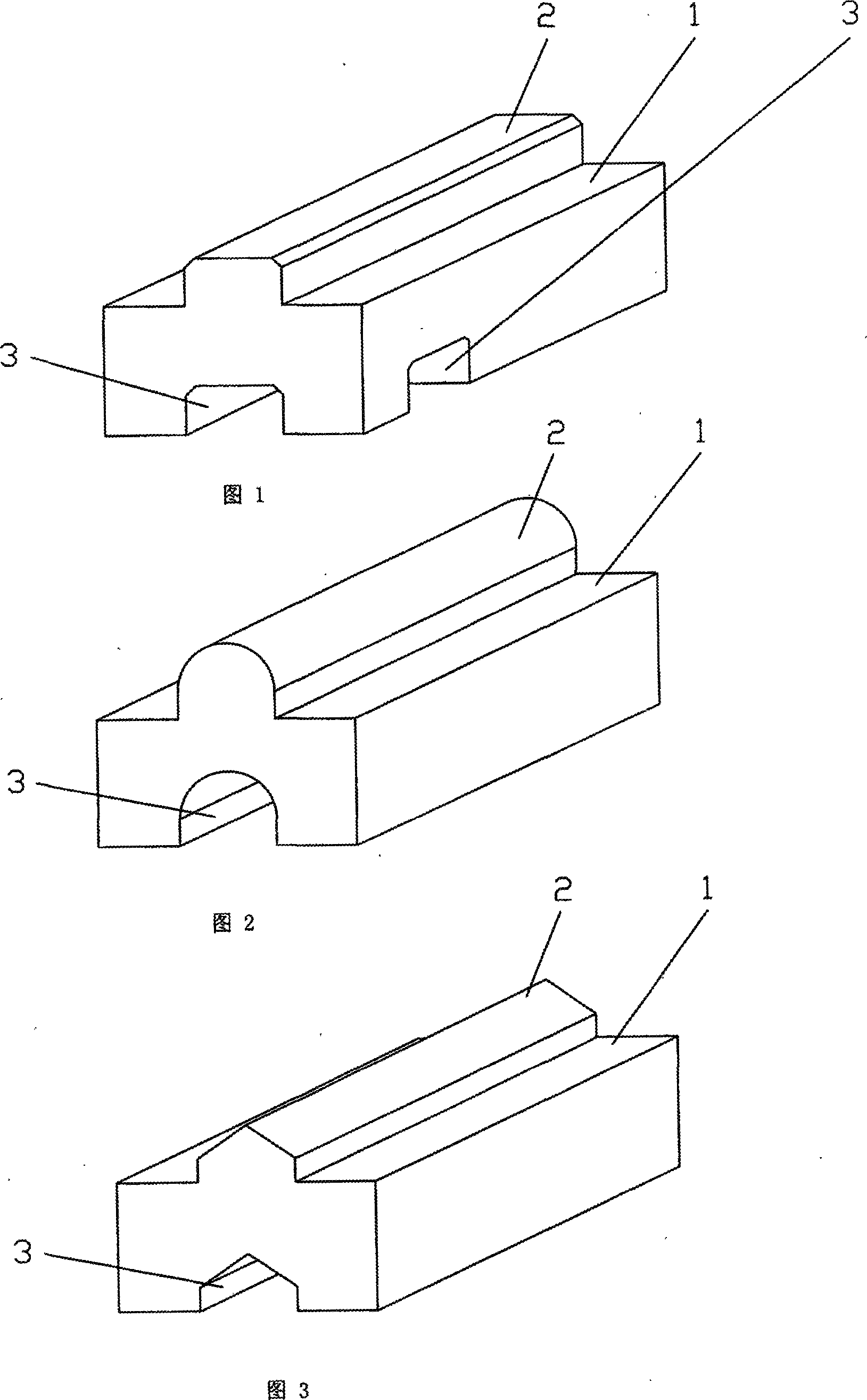

Positioning embedded bricklaying

InactiveCN101122154AIncrease bonding surfaceHigh bonding strengthArtificial islandsCoastlines protectionPull forceBrick

The invention relates to a positioning inlaid brick which comprises a brick body. At least one convex body in straight line shape, crisscross shape, Character ''Jing'' shape or boss shape is made on at least one end face of the brick body, and at least one groove in straight line shape, crisscross shape, Character ''Jing'' shape or boss shape is made on the corresponding end face of the brick body; adjacent bricks are scarf jointed by convex bodies and corresponding grooves. The invention can effectively enlarge the bonding face between adjacent bricks, improve the bonding strength between bricks, so as to improve the strength of the wall. Scarf joint between the convex bodies and the grooves can play a good role of positioning, improve the longitudinal pulling force and lateral pushing force of the wall, to make the vertical and horizontal lines as well as plane effect of wall building have good effect; scarf joint of the convex bodies and the grooves also can effectively save the bonding materials, which can not only improve the wall engineering quality, but also reduce the engineering construction cost; and scarf joint of the convex bodies and the grooves is applicable to all burning-free bricks, burnt bricks, hollow bricks, solid bricks, half-hollow bricks and stone bricks.

Owner:何荣灿

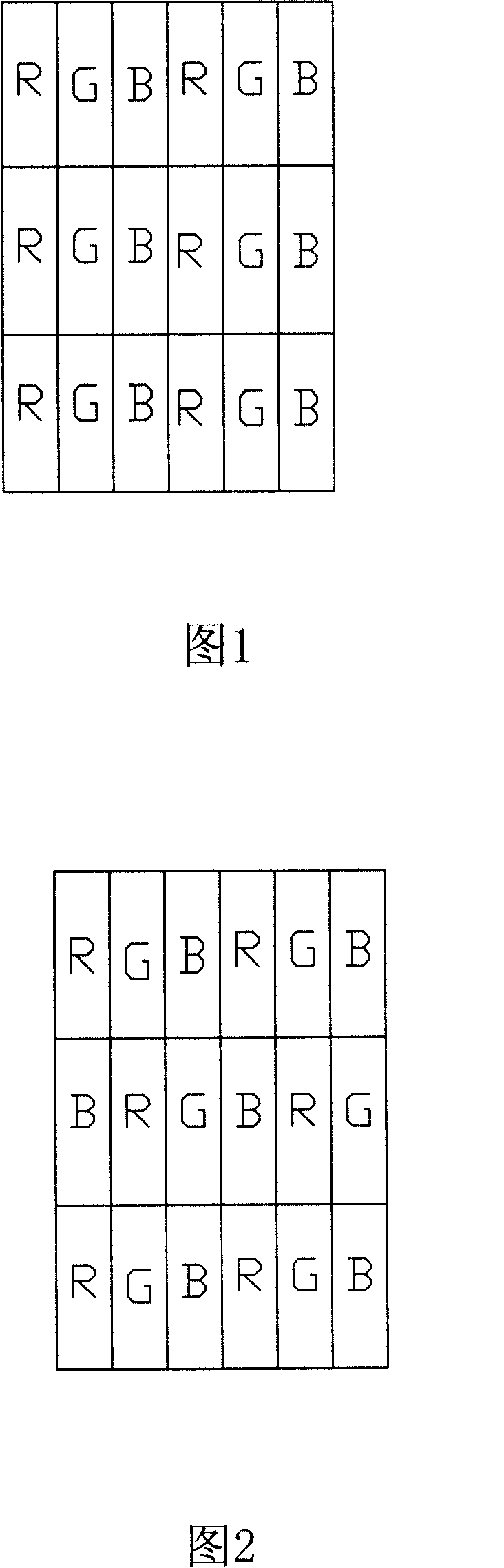

Colorful spectral filter

InactiveCN101153931AScattered distributionOperableNon-linear opticsOptical elementsScarf jointSpectral filtering

The present invention discloses a color filter which is provided with a transparent baseplate; a shading zone is formed on the baseplate and a plurality of pixels are also distributed on the baseplate, wherein, each pixel is provided with a first color zone, a second zone and a third zone, in particular the first color zone, the second color zone and the third color zone of each pixel are centrosymmetric hexagons, and with an arbitrary first color zone as the center on the transparent baseplate, six mutually spaced second color zones and third color zones are faveolately in scarf joint around. The color filter with the structure has good color display effect and can weaken sawtooth in the margin of image when the image is displayed obliquely.

Owner:BYD CO LTD

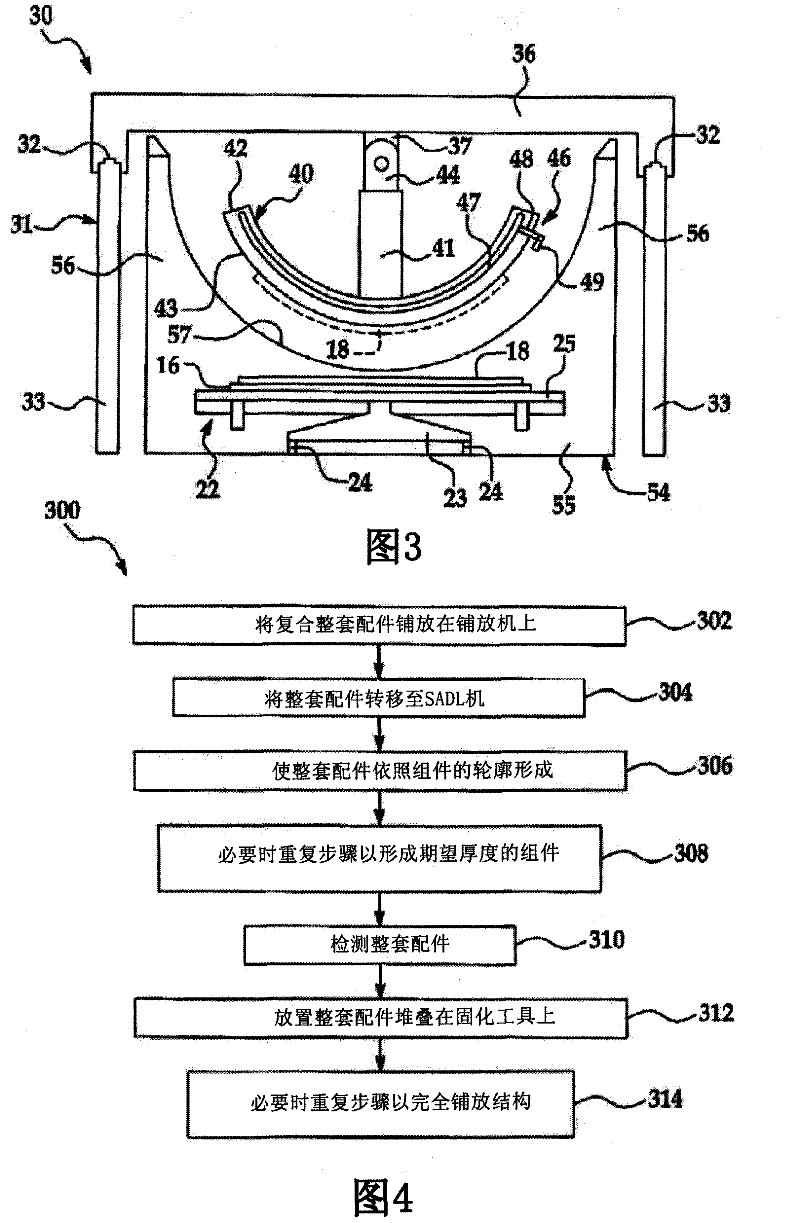

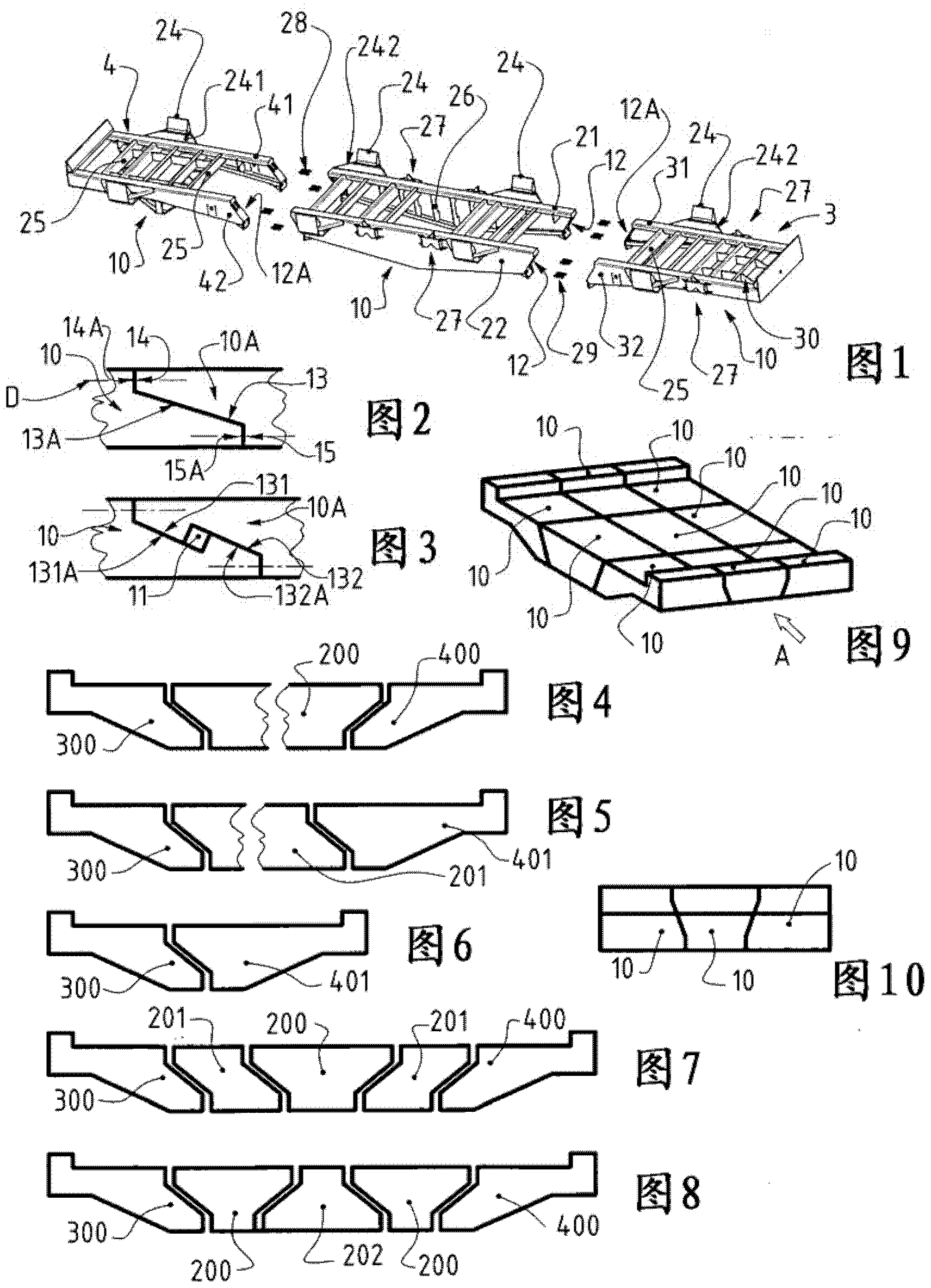

Method of fabricating structures using composite modules and structures made thereby

ActiveCN102196962AHigh placement rateLow costLayered productsEfficient propulsion technologiesScarf jointComposite laminates

A large scale composite structure is fabricated by forming a plurality of composite laminate modules (208d, 208e) and joining the modules together along their edges (210) using scarf joints.

Owner:THE BOEING CO

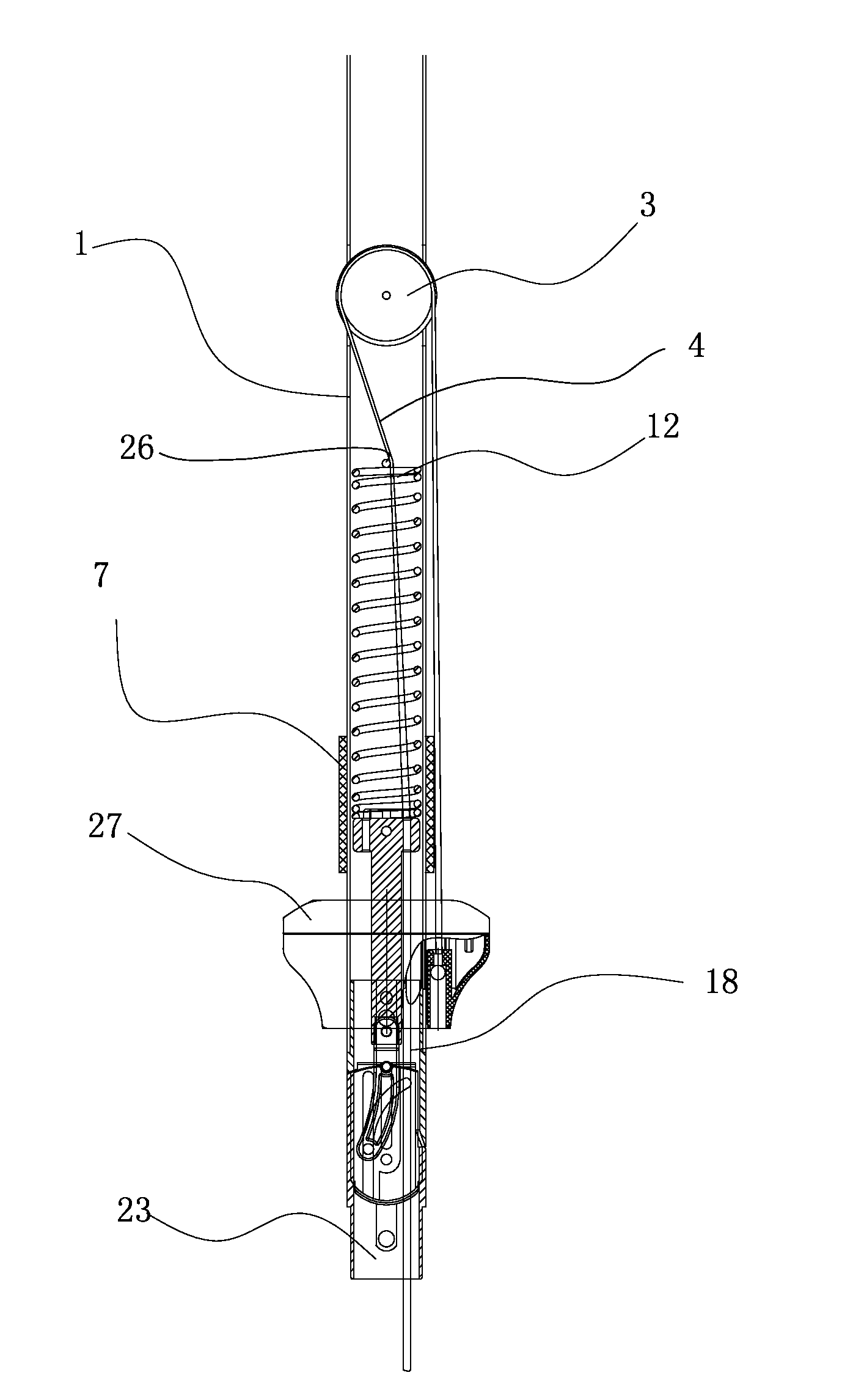

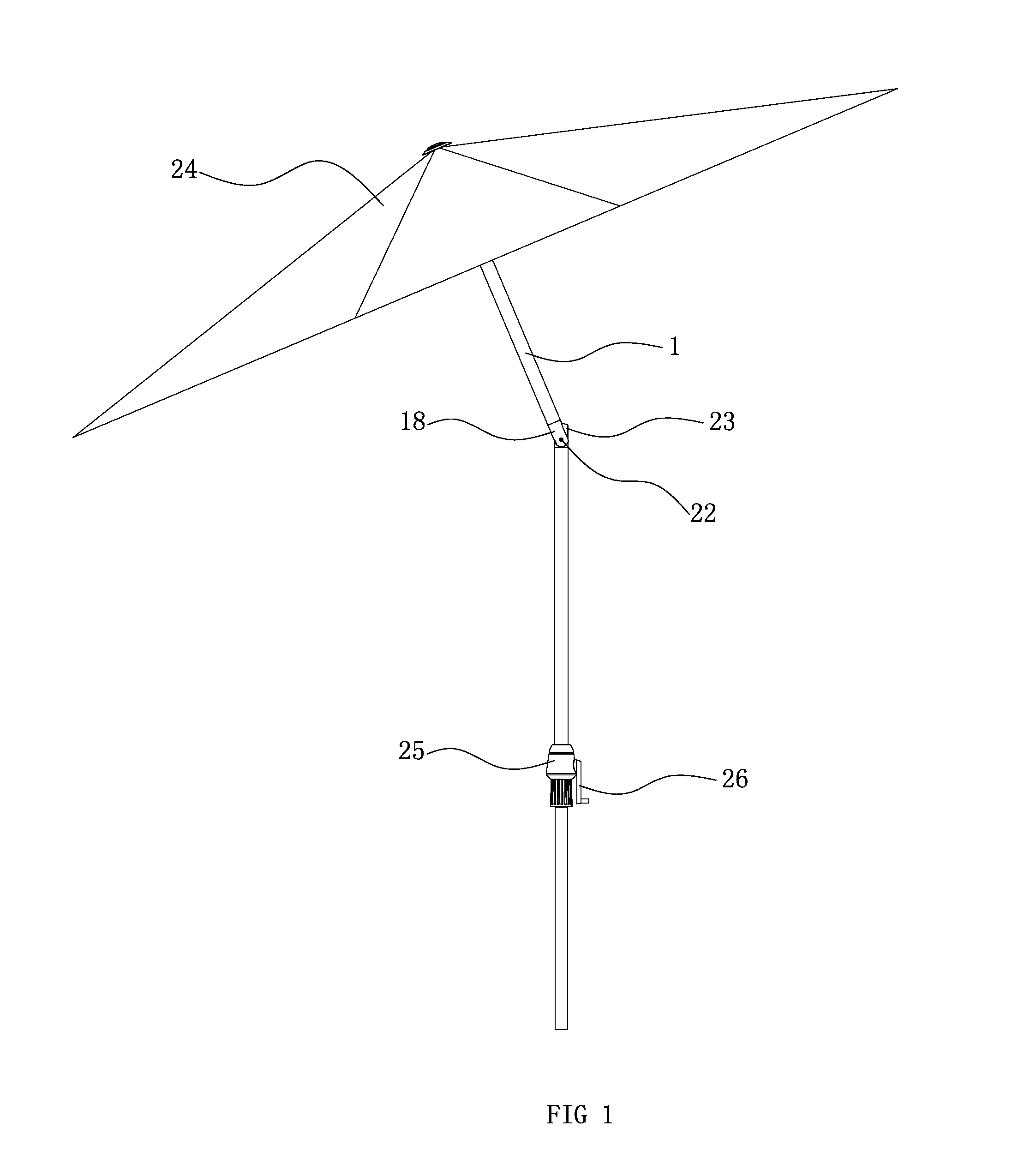

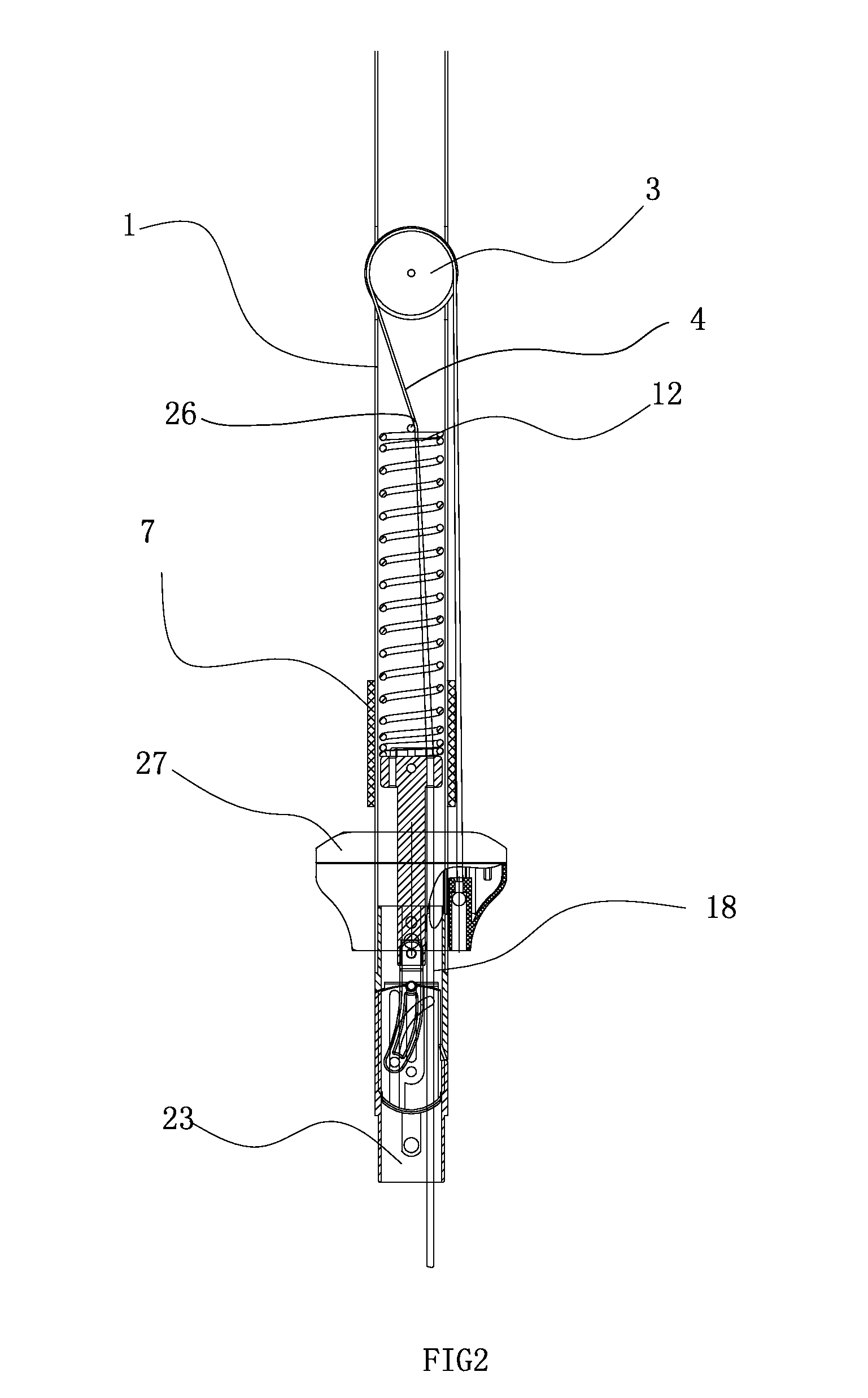

Auto Bending Structure of Sunshade

An auto bending structure of sunshade comprising an upper section of bending and a lower section of bending movably riveted featuring that: a sliding rod is provided in the pivotally connected upper section of bending and lower section of bending, through holes are provided on the top and bottom of said sliding rod, the through hole on the bottom of said sliding rod is provided with a guide pin, an arc groove for said guide pin to slide on is provided on the scarf joint part of the lower section of bending, linear groves corresponding to said arc groove for said guide pin to slide on are provided on both sides of said groove of the upper section of bending, a sliding sleeve with a through hole on the bottom is provided on the top of said sliding rod, said through hole on the bottom of said sliding sleeve corresponds to the through hole on the top of said sliding rod, correspondingly, the upper section of umbrella stem is provided with a linear groove on the outer wall and is surrounded by a ring, which is connected with the sliding rod and the sliding sleeve with the connecting pin, which slides in the linear groove to make the ring cooperate with the lower nest moving up and down and pulled by the umbrella string; the present invention is advantageous in simpler structure and lower production cost.

Owner:PHAETON MFG LLC

Combination cooler module

InactiveUS20070169918A1Semiconductor/solid-state device detailsSolid-state devicesScarf jointHeat sink

A combination cooler module is disclosed, which includes a plurality of radiating fins that are arranged in a stack, a plurality of heat tubes inserted through the radiating fins, and a heat conductive base affixed to the radiating fins by means of a dovetail joint, hook or scarf joint and disposed in contact with the heat tubes.

Owner:KUO HUA SHOU

Scarf joint method of Canarium album ReauschRaeusch

The invention discloses a scarf joint method of Canarium album ReauschsRaeusch. The method sequentially comprises the following steps of: selecting stock trees, selecting scions, carrying out scarf joint, fixing, managing after scarf joint, and managing the grafted trees which are subjected with to scarf joint for a long term. The scarf joint method of the Canarium album Reaaeuschs has the following advantages of: 1, improving the survival rate, wherein the survival rate of the grafted trees is improved to above 90% from the current 30-50%; 2, realizing dwarfing, wherein the height of the fruit-bearing trees are is descended to below 5 meters from 10 meters; 3, realizing close planting, wherein the plantings at every mu are increased to 30 plants from 12 plants; 4, realizing early bearing, wherein the trial period after planting is decreased to 4 years from 7 years, and the startup time is decreased to 6 years from 10 years; 5, realizing high yield, wherein the yield is improved to 1500 kilograms, but the traditional planting yield per mu is 600 kilograms; and 6, realizing high quality, wherein, comparing with seedling cultivation, a fine variety generation is cultivated through scarf joint with unseparated properties, and fine variety performance can be kept.

Owner:福州市经济作物技术站

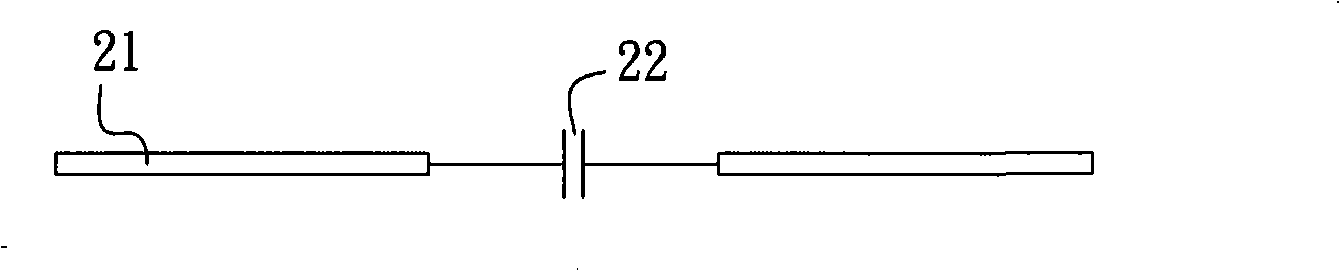

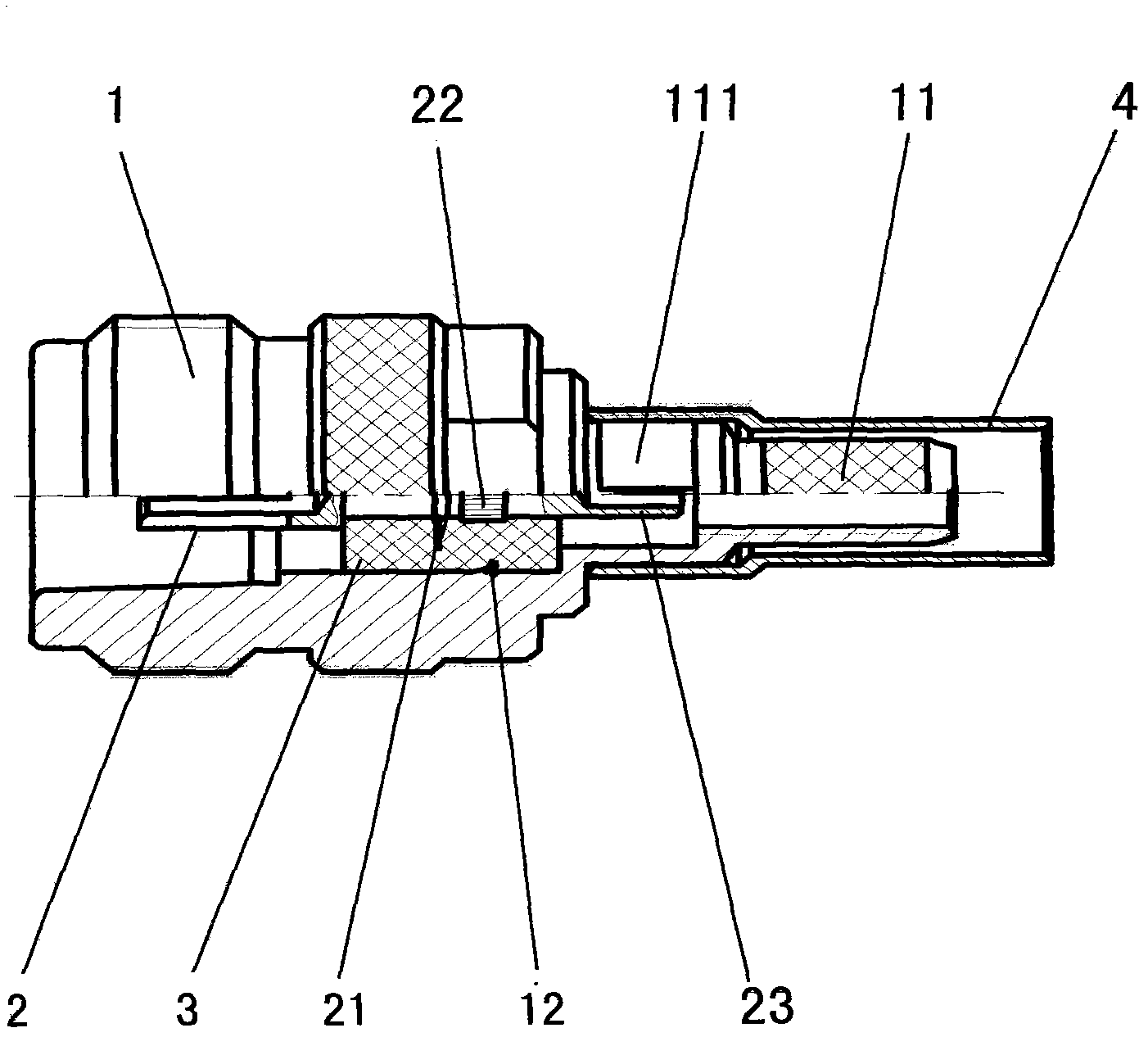

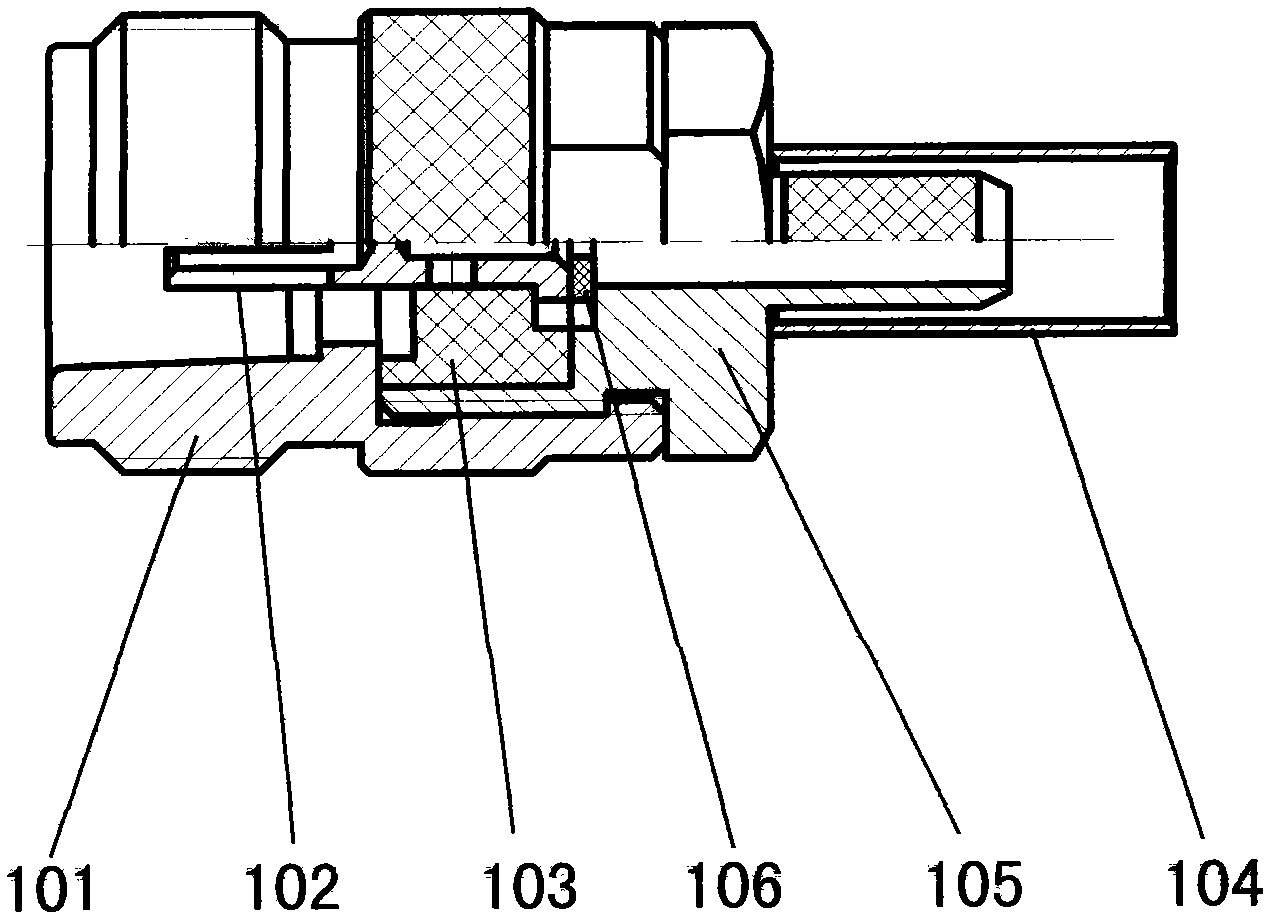

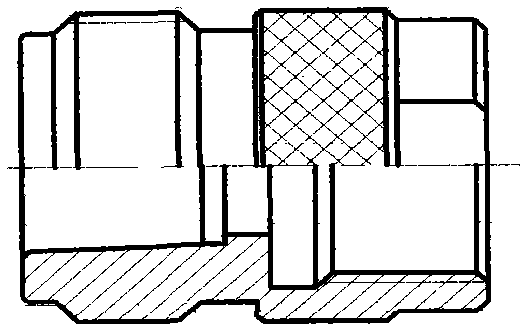

Crimping radio frequency coaxial connector

InactiveCN102136644AEasy to useShedding no longer occursCoupling contact membersCouplings bases/casesElectrical conductorScarf joint

The invention discloses a crimping radio frequency coaxial connector, belonging to the radio frequency coaxial connectors. Aiming at the problems that the similar connector is complex in operation and sometime falls off when in use, the adopted technical scheme is as follows: the crimping end of a connecting sleeve is designed into a tubular crimping head with a larger external diameter of the neck and a smaller external diameter of the head, wherein the tubular crimping head is provided with steps and integrated with the connecting sleeve body into a whole; a welding operation window is designed at the neck of the tubular crimping head of the connecting sleeve; a ring-shaped bulge the cross section of which is in a wedge tooth shape is designed on a scarf joint insulation sleeve of the cavity in the connecting sleeve; a ring-shaped bulge the cross section of which is in a wedge tooth shape is designed on the scarf joint insulation sleeve on the periphery of an inner conductor; a ring-shaped bulge the surface of which is provided with axial horizontal streaks is arranged on the scarf joint insulation sleeve of the periphery of the inner conductor; and the tubular welding end of the inner conductor is designed into a semi-tubular inclined opening. After the coaxial connector is on trial, we can find that the number of the components is reduced to 4 from 6; the crimping working procedures are reduced to 5 from 12; the falling-off condition does not occur in using; the electric property is improved; and the voltage standing wave ratio is reduced to 1.15 / 3GHz from 1.25 / 3GHz.

Owner:镇江市胜超电子有限公司

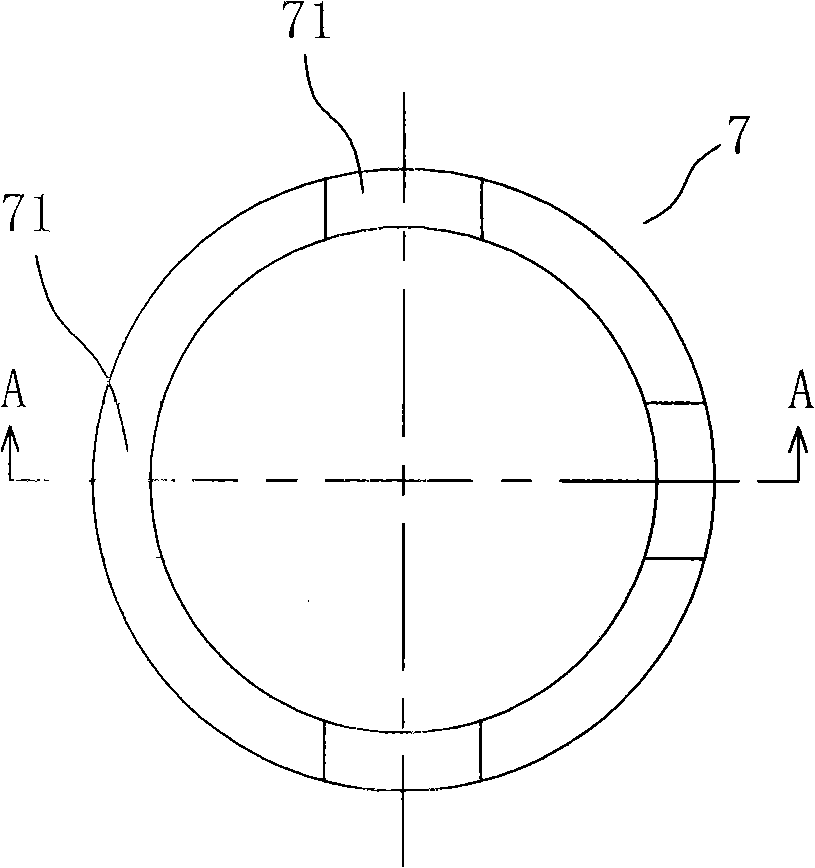

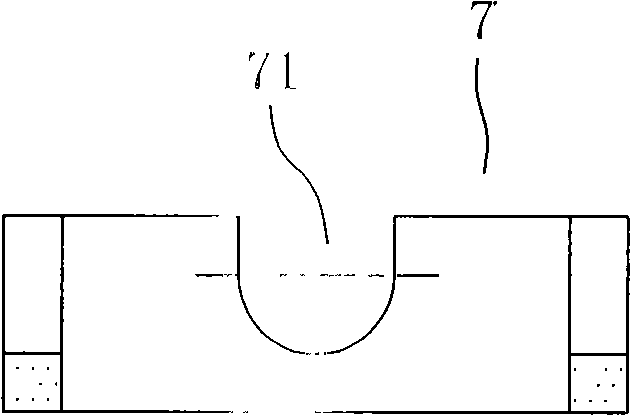

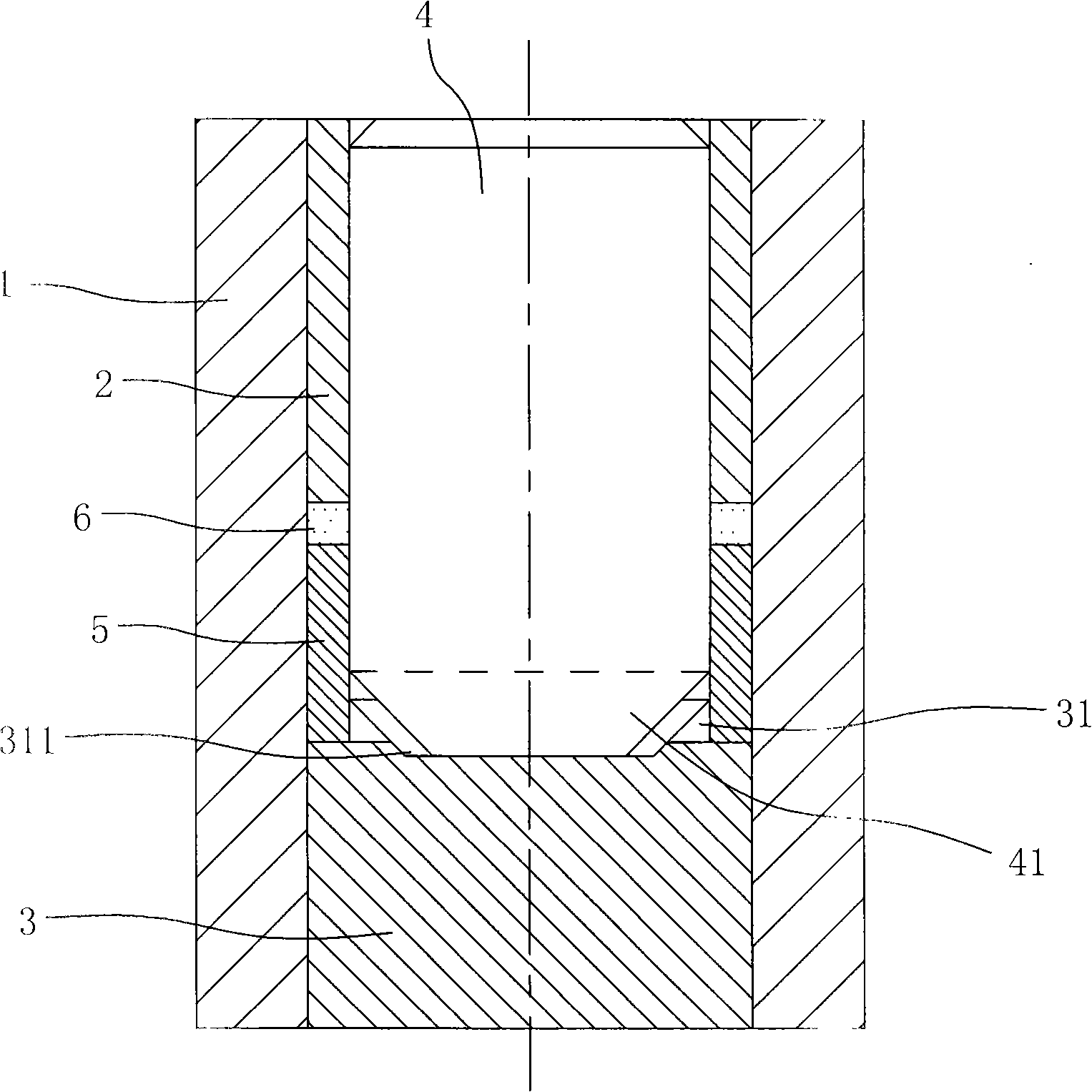

Diamond thin wall drill tool-tip sintering forming die

InactiveCN101357401AEasy to assemble and disassembleExtended service lifeDrill bitsOpen waterScarf joint

The invention discloses a mould for sintering a cutter head of a thin-wall diamond bit. The die comprises a concave die with an up-and-down communicated center hole, of which the inside diameter is equal to the external diameter of the cutter head, a lower pressure head which can be movably matched in the center hole of the concave die in an up-and-down way, a mould core which is sheathed in the center hole of the concave die arranged above the lower pressure head and of which the external diameter is equal to the inside diameter of the cutter head, a center concave hole which is not communicated and arranged on the middle part of the top surface of the lower pressure head and of which the size is equal to the external diameter of the mould core, wherein, the lower end part of the mould core is inserted in the central hole of the lower pressure head and is supported on the low pressure head; a moulding cavity is formed between the mould core and the concave mould. The die also comprises a plurality of arc-shaped plate molding inserting blocks, of which the thickness is equal to that of the moulding cavity, scarf joints which are equidistantly arranged on the top surface of the lower pressure head, wherein, each scarf joint is embedded with the moulding inserting block, the lower part of the moulding inserting block is embedded into the middle part and the upper part of the scarf joint and then extends into a moulding cutter head water tank of the moulding cavity. The mould realizes one-step sintering and moulding of the cutter head of the thin-wall diamond bit and the open water tank on the cutter head can be sintered directly. Therefore, the mould has long service life and convenient disassembly and assembly.

Owner:泉州众志金刚石工具有限公司

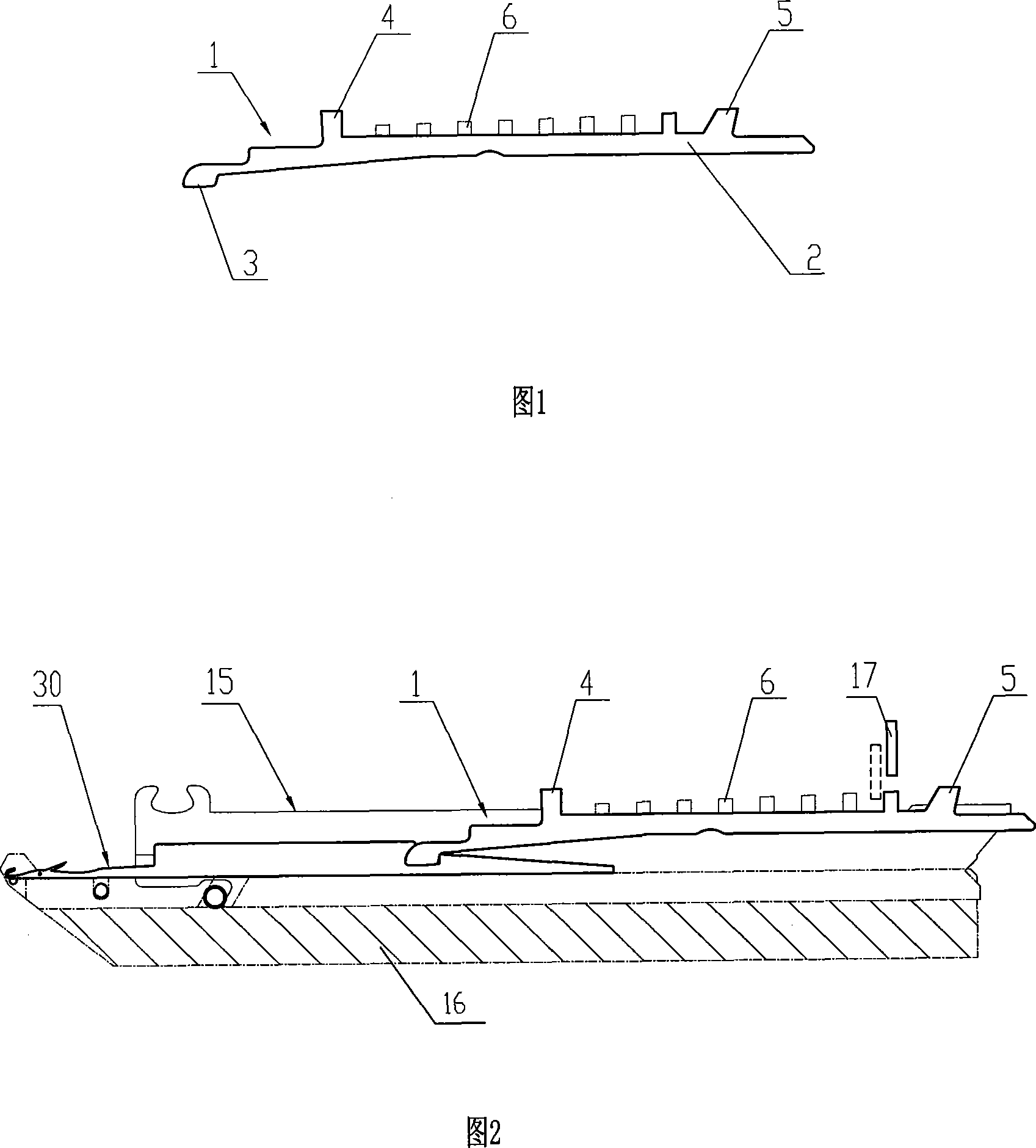

Needle jack having needle selecting function

The invention relates to a jack with the function of selecting needle, comprising a planar laminar basal; wherein, a scarf joint for connecting with knitting needle is arranged at the front of the basal; a front needle butt and a back needle butt for triangle pushing are arranged on the top of the basal. The needle selecting tooth for selecting needle is arranged between the front needle butt and the back needle butt. The jack with the function of selecting needle has the advantages of reducing the number of the assistant stitch that just one assistant stitch is needed, reducing the length of the needle slot, which reduces the size of the whole machine and consumables greatly, and simplify the head controlling the assistant stitch, such as no pressing device is needed which not only reduces the manufacturing cost, but also makes the needle work more stably and reliably.

Owner:冯加林 +1

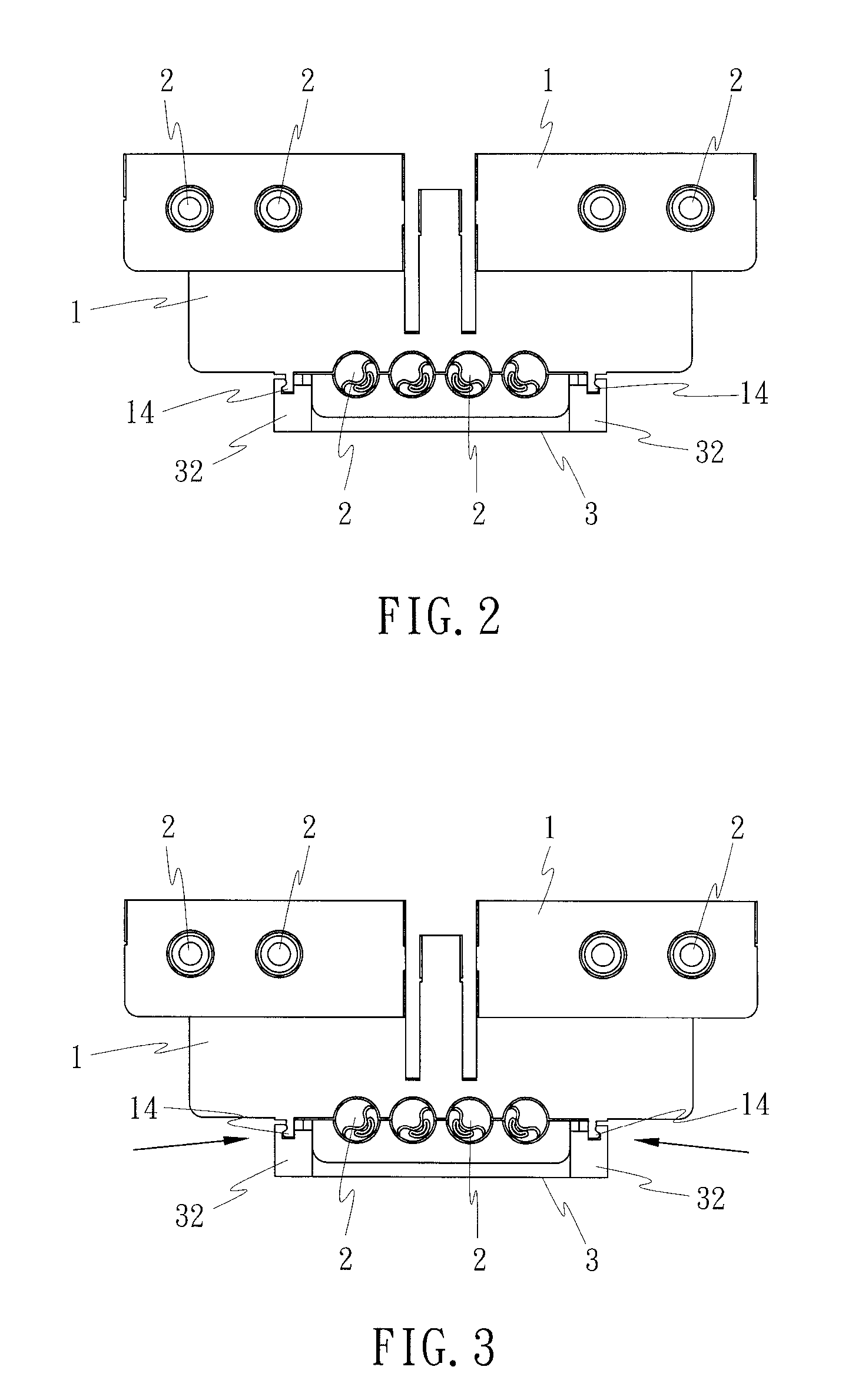

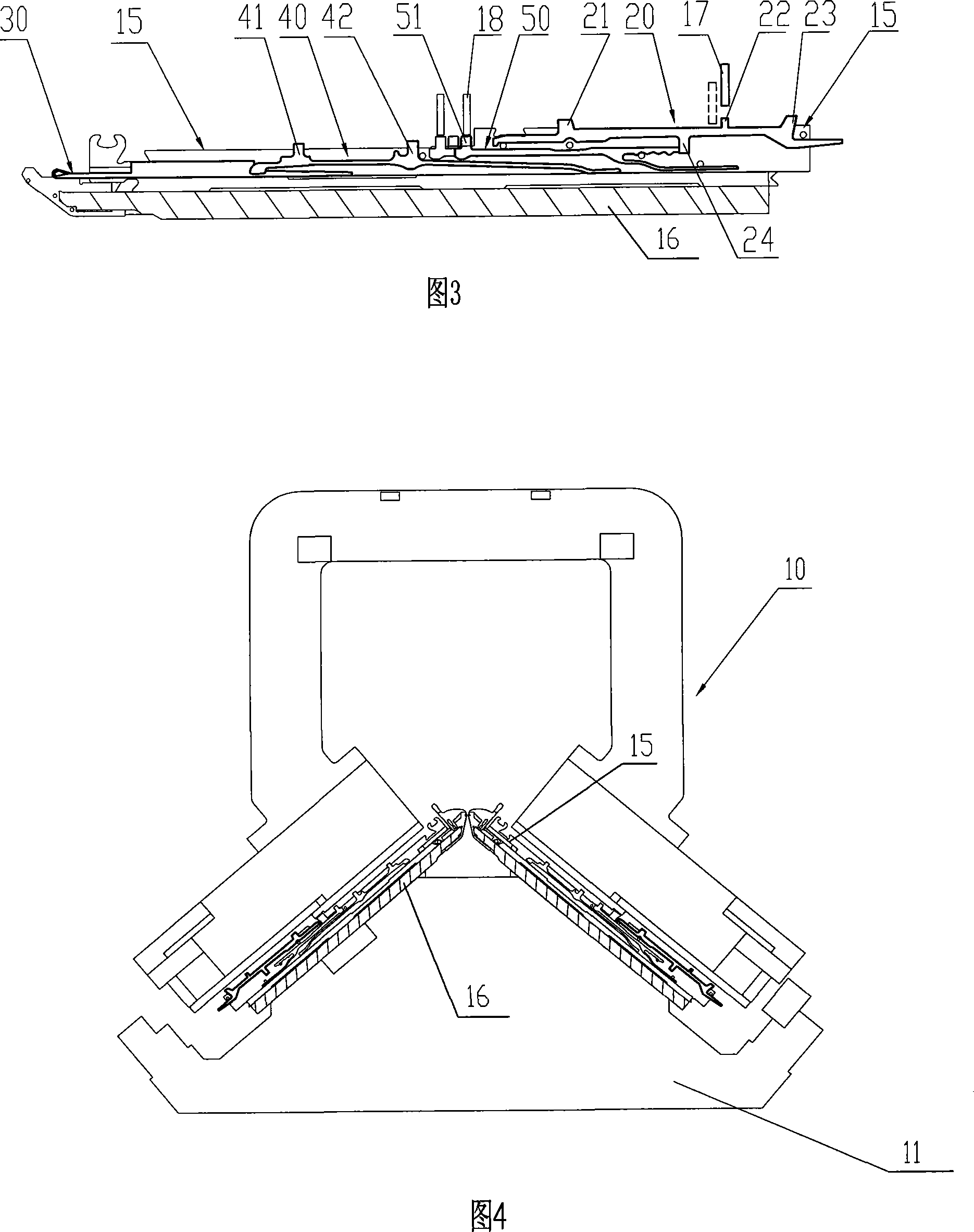

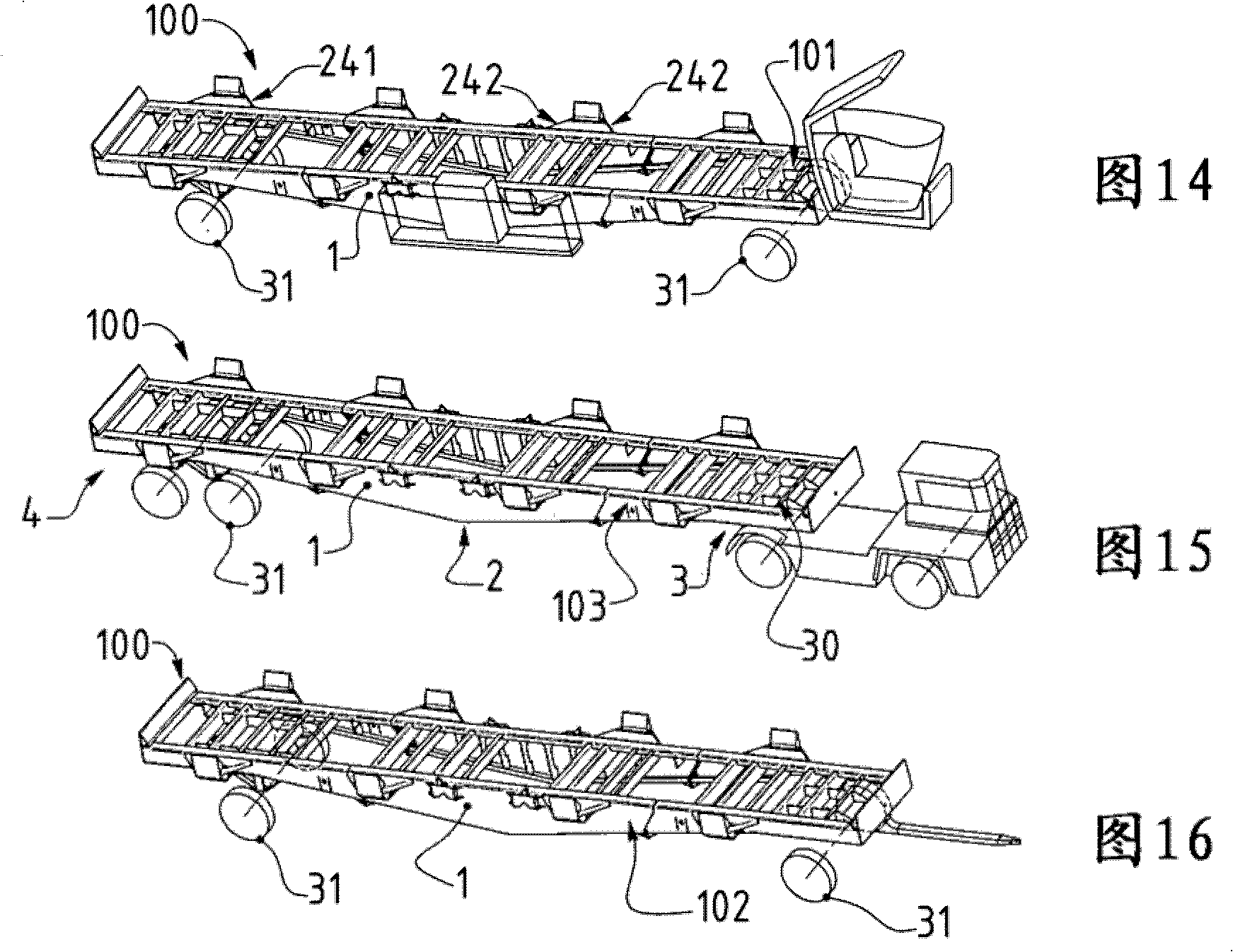

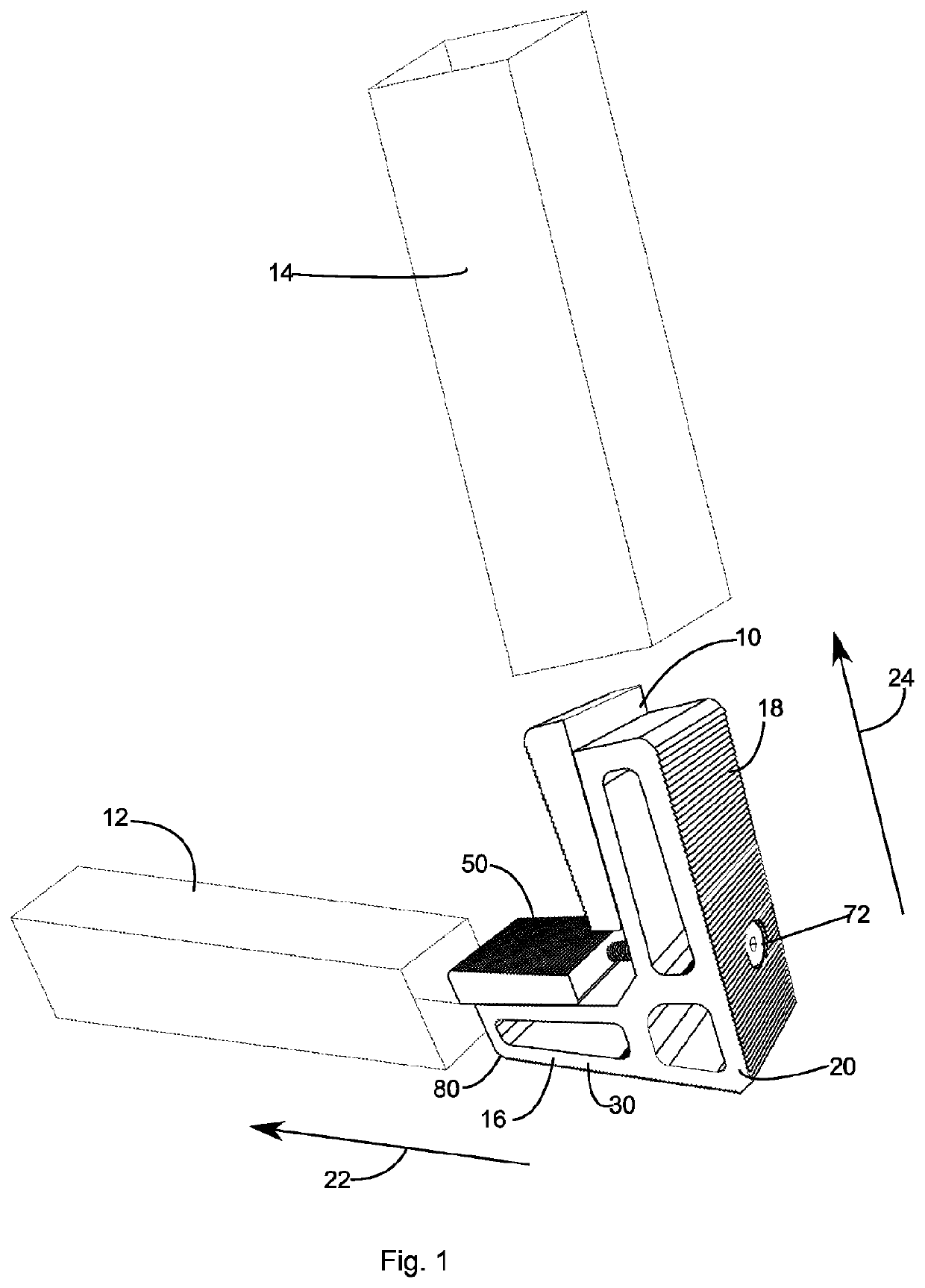

Module for the modular frame of a heavy load transport vehicle

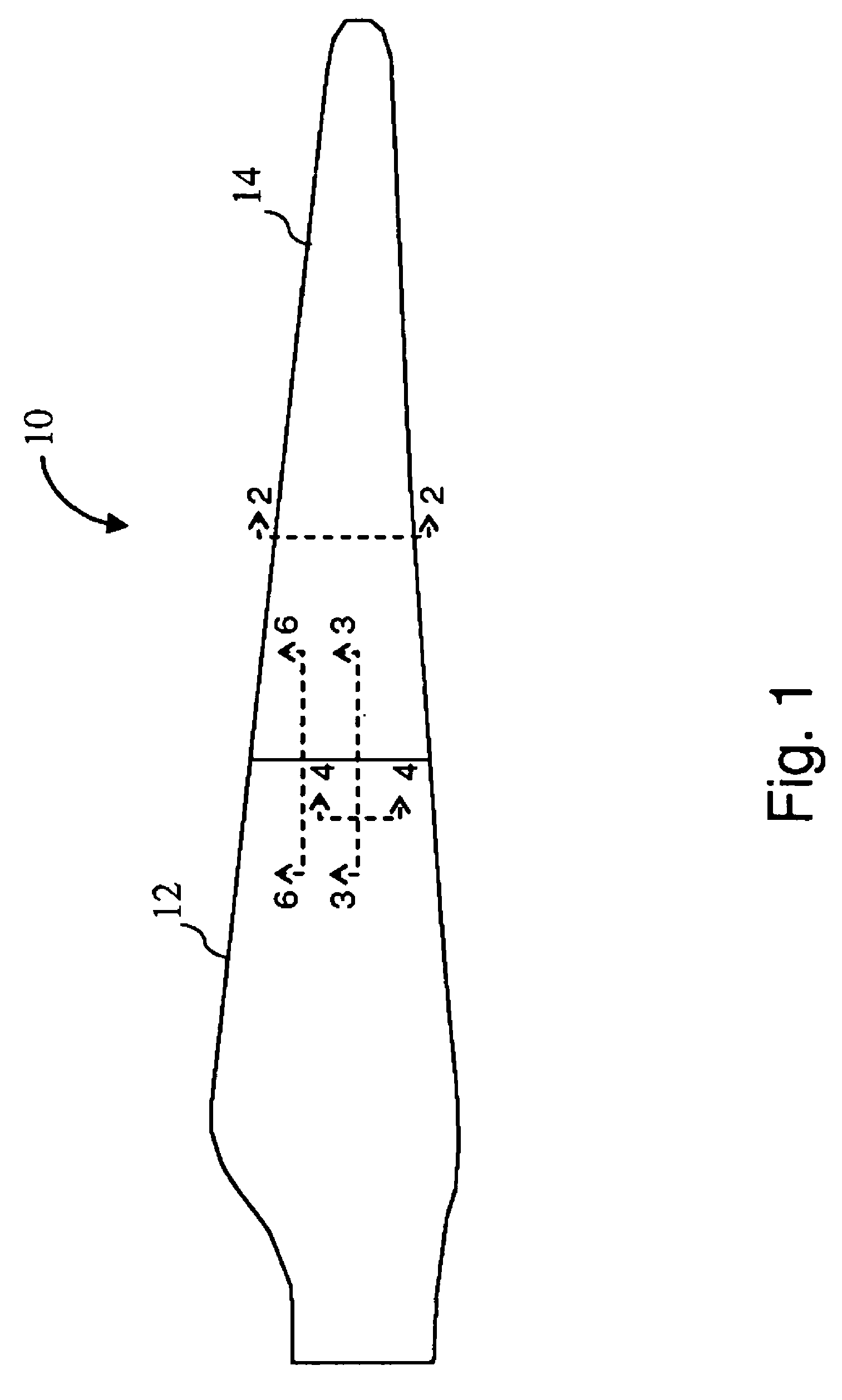

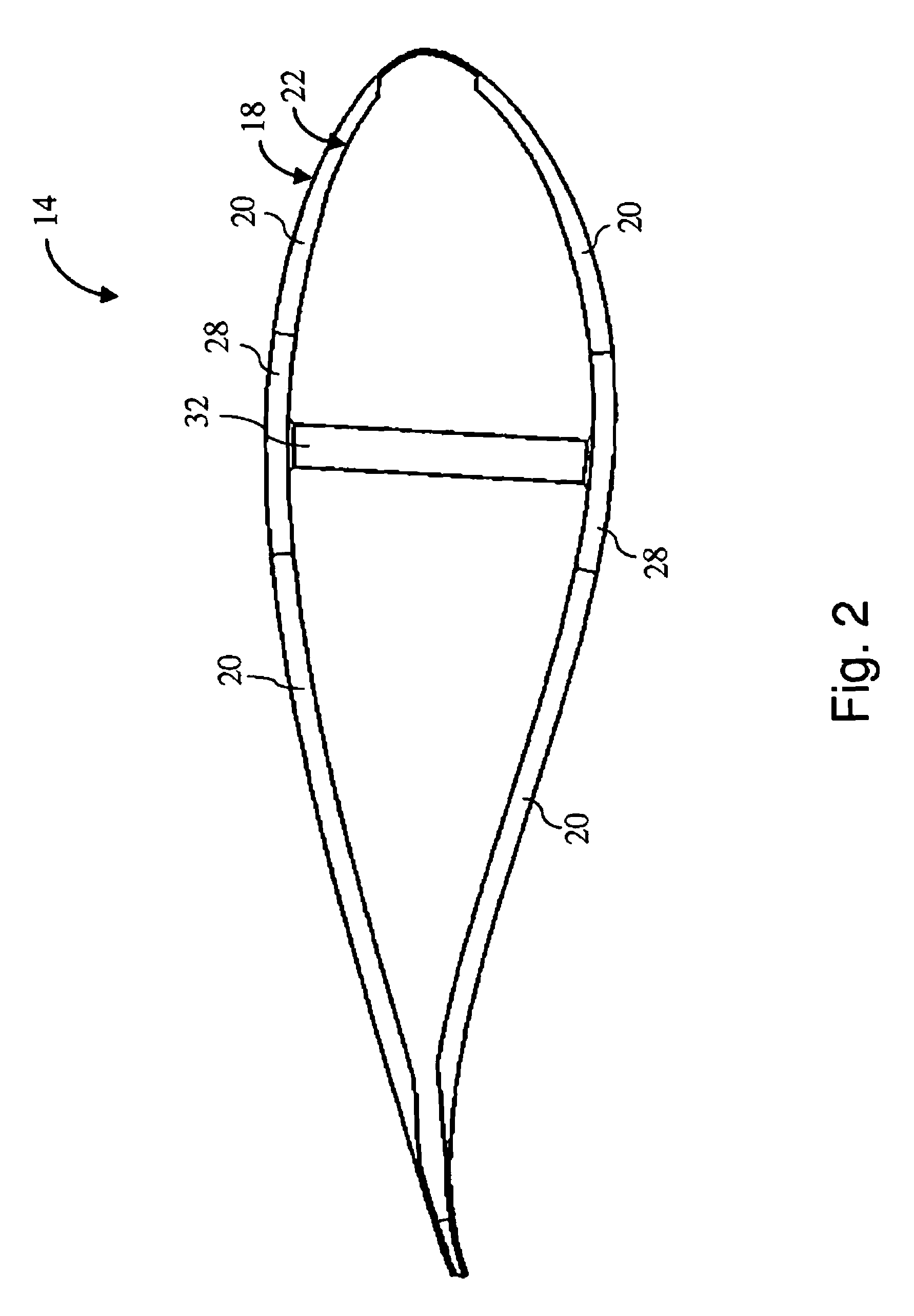

The invention relates to a module (10) for the modular frame (1) of a heavy load transport vehicle (100), characterised in that it comprises, at one end thereof, a junction surface (12) having an oblique bearing surface (13) extending between two parallel planar surfaces (14, 15) inclined relative to the previous one. The invention also relates to a method for mounting such modules. The invention relates to a frame (1) that comprises at least two such modules (10) in which the junction surfaces (12) together define an assembly with an oblique scarf joint, an unabutting scarf joint or key joint (11). The invention also relates to a harbour vehicle (100) comprising at least one such frame (1) and at least one such module (10).

Owner:想象汽车工程诺沃西欧技术事件公司

Enhanced transformer substation dispatching system

InactiveCN106364860AAchieve clearingAchieve stabilityCooling/ventilation/heating modificationsMechanical conveyorsTransformerScarf joint

The invention discloses an enhanced transformer substation dispatching system. The enhanced transformer substation dispatching system comprises an inspection robot transportation platform, a lifting platform, a lifting control device, a fixing device, a communication module and a dispatching server; the dispatching server is arranged in a cuboid-shaped shell; a second groove is formed in the position, which is deviated from a bending and stretching part, on a steel base; a second nut is embedded into the second groove; a scarf joint on a base is scarfed with a scarf hole of the steel base; in addition, when one end of a hydraulic device is placed on a top wall of the steel base, the end of the hydraulic device does not cover the second groove; a second screw rod is in threaded connection with the base downwards through the second groove in the steel base; the defects that an adverse effect generated on the operating of the dispatching server caused by the interference on the operating of the dispatching server in the cuboid-shaped shell produced by the accumulation of particular impurities, the combination firmness of one end of the hydraulic device and the base is poor, and particularly the connection between the steel base and the base is unstable in the prior art are effectively avoided.

Owner:NANJING INST OF RAILWAY TECH

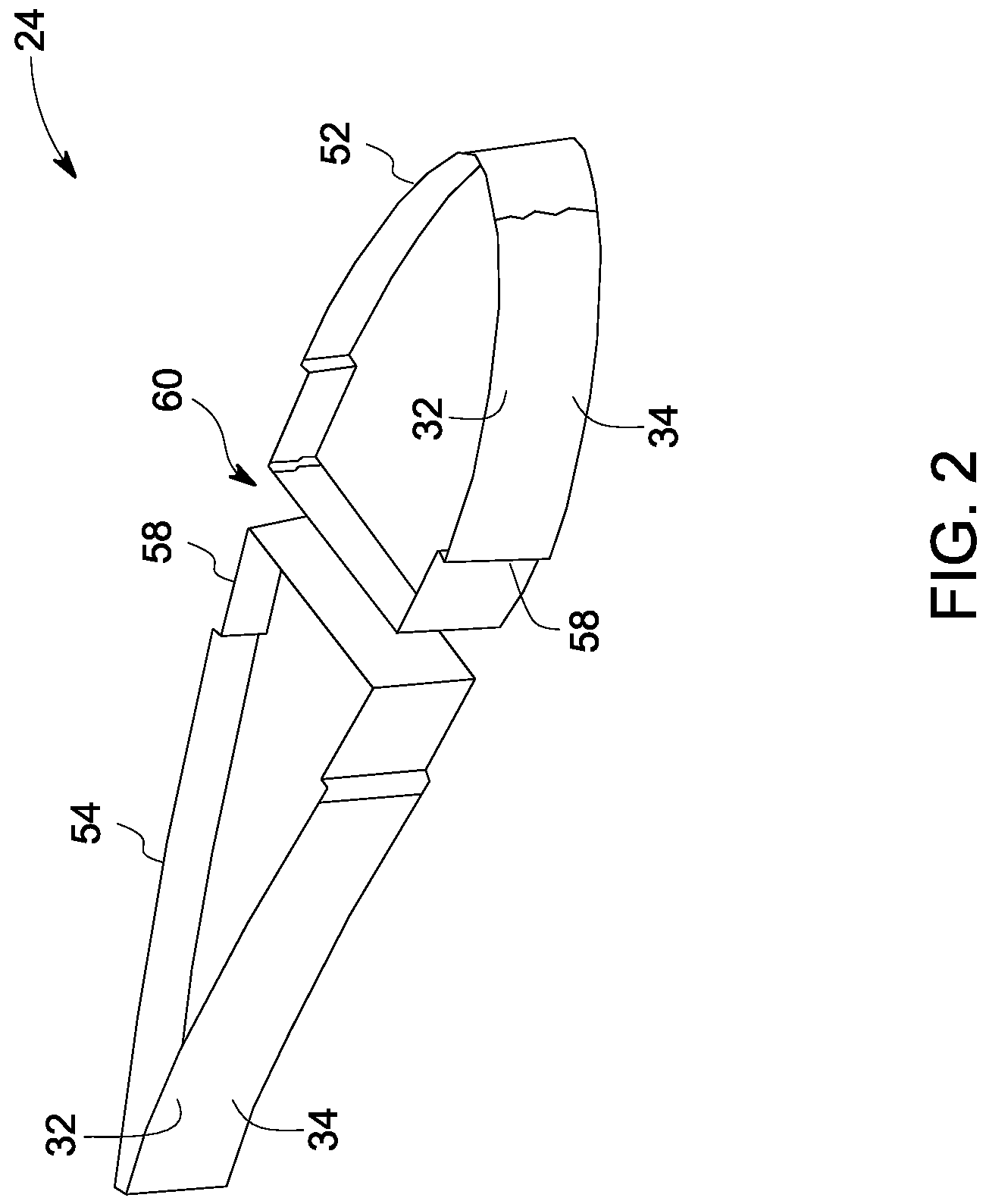

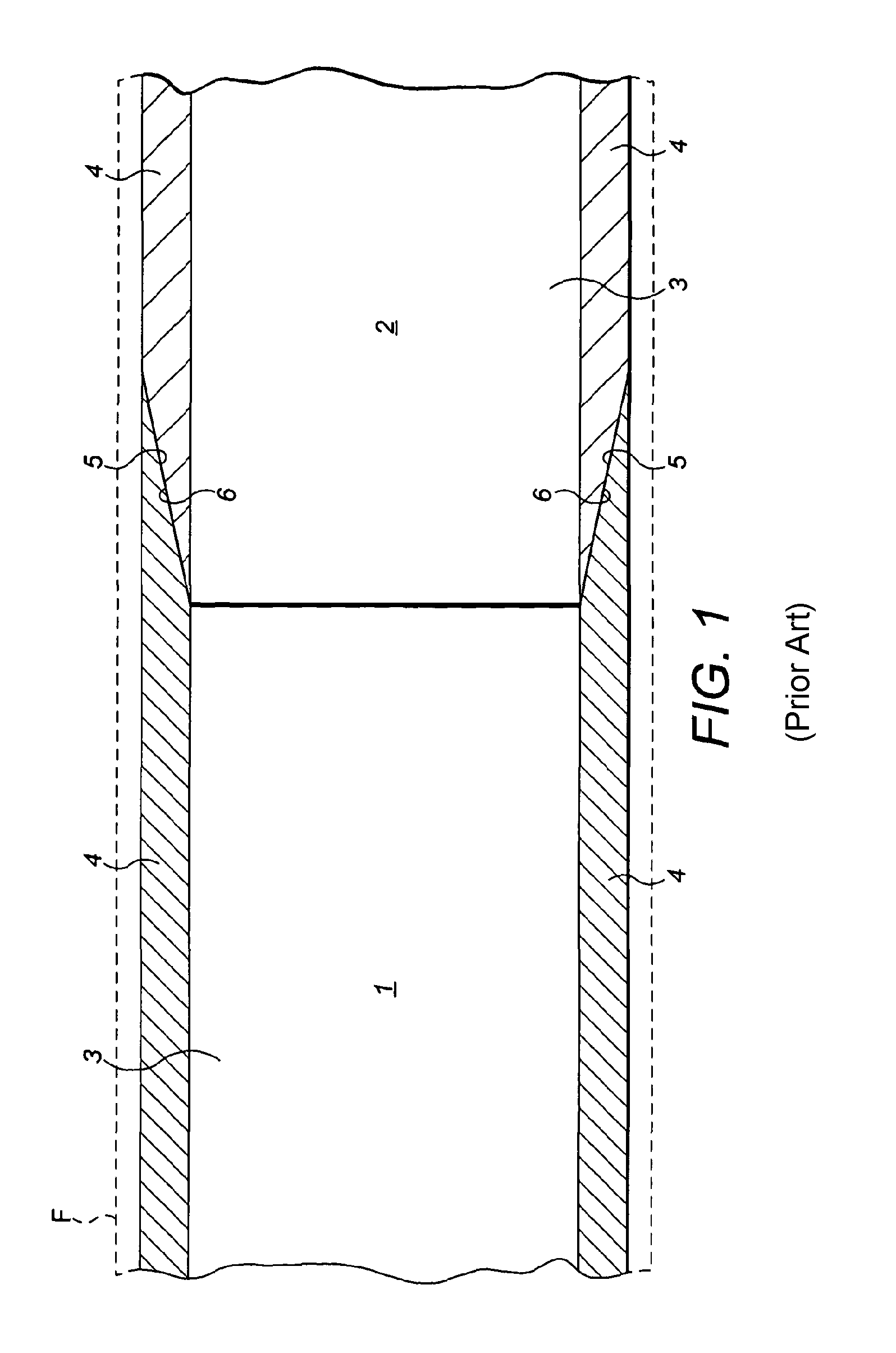

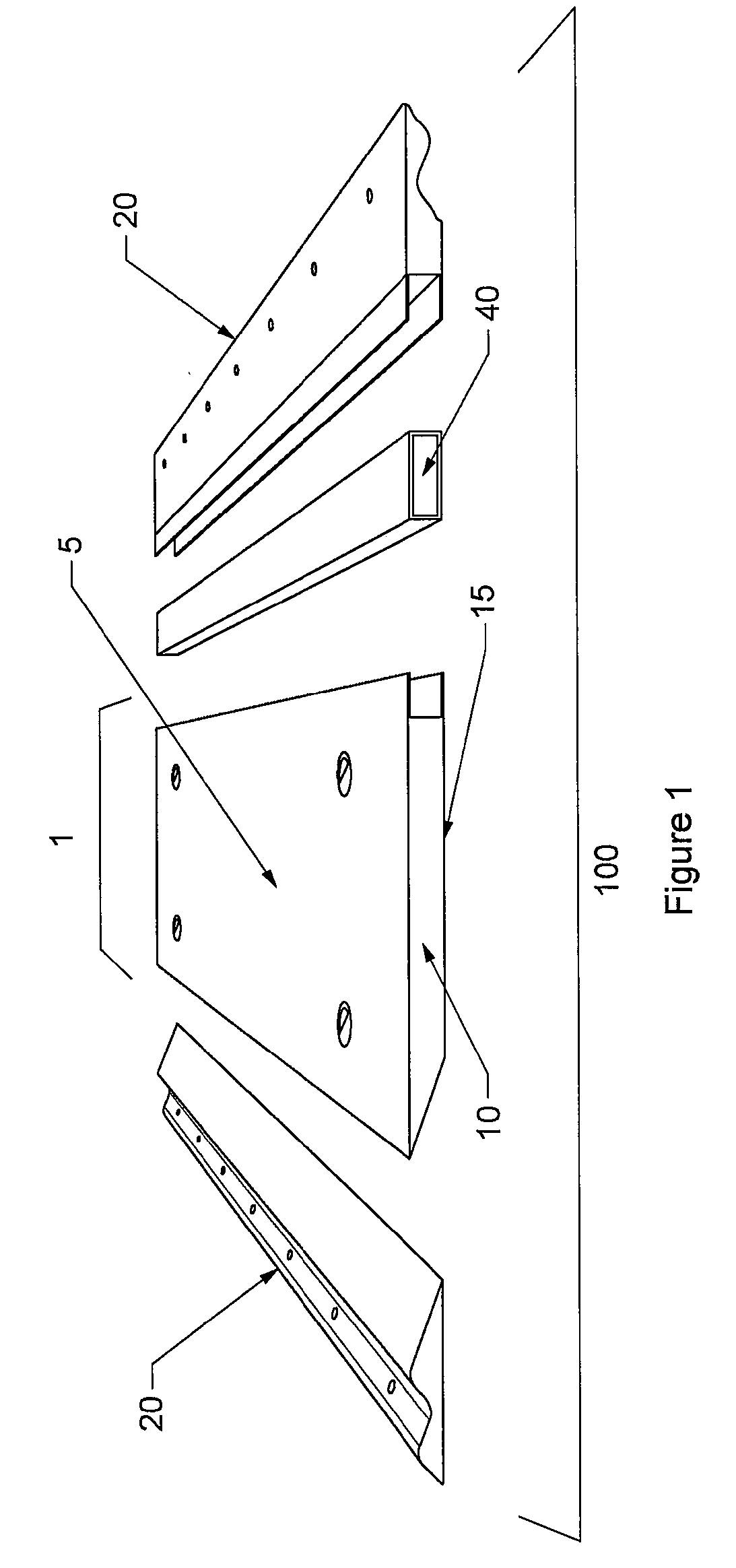

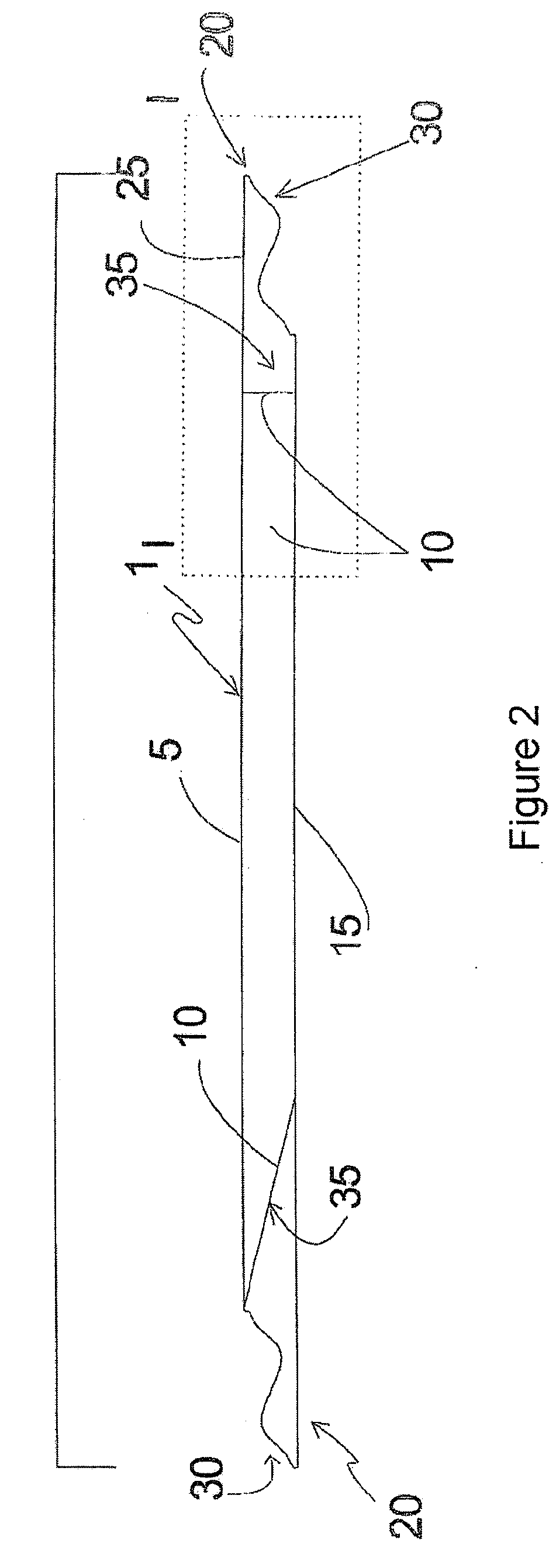

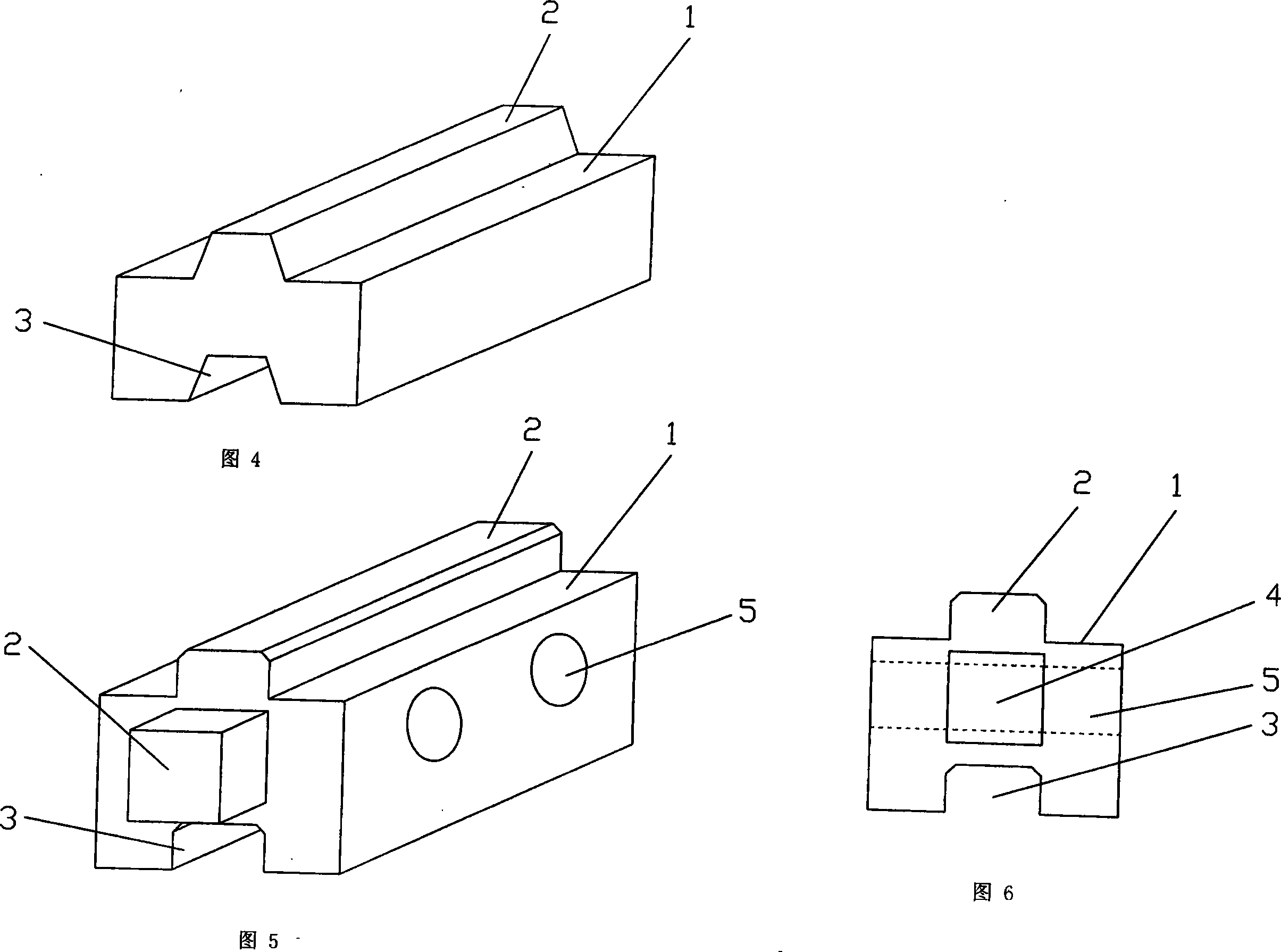

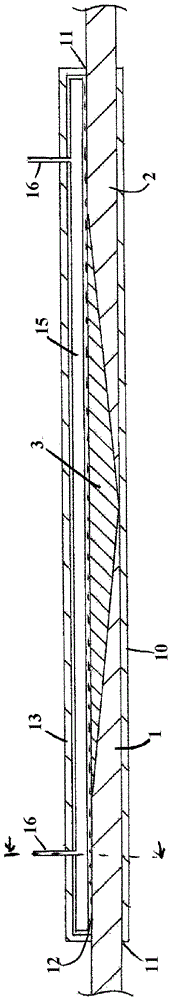

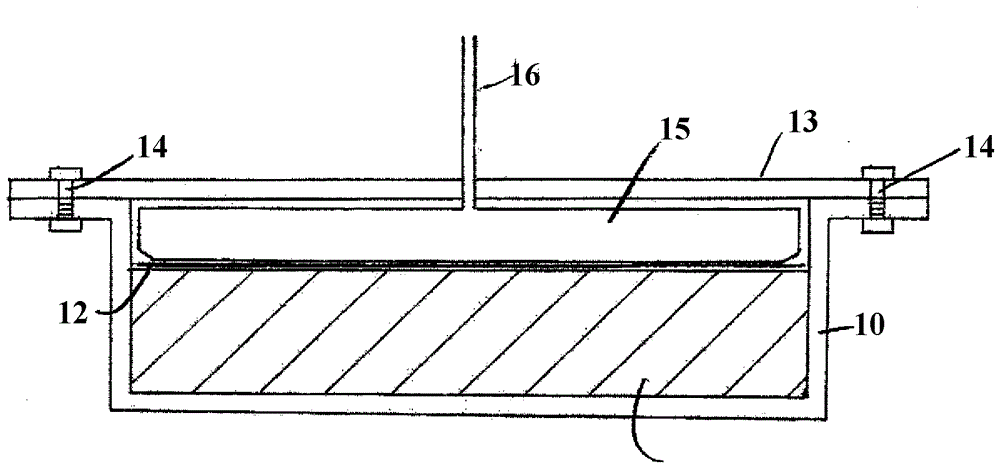

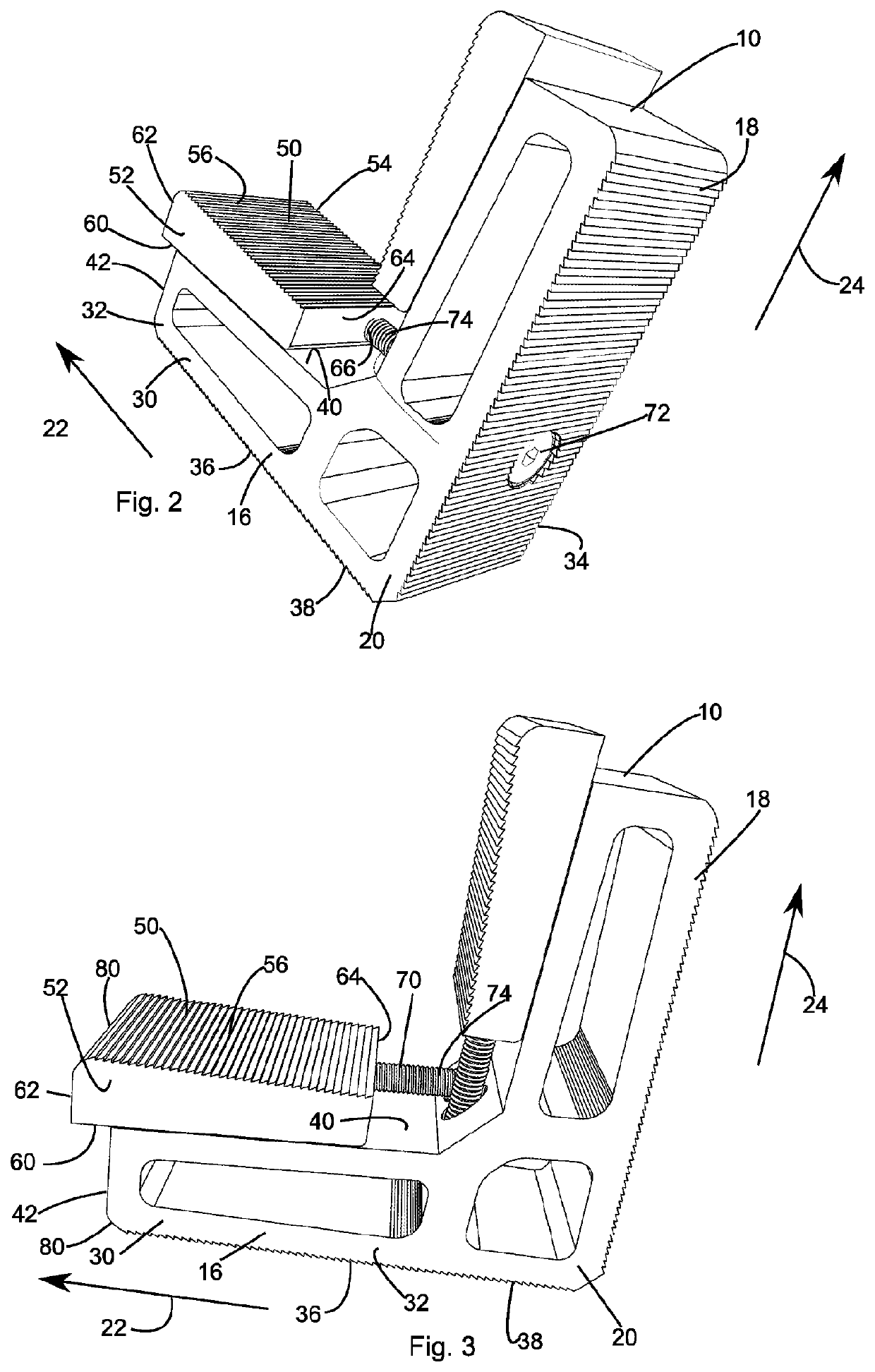

Method and tool for forming a scarf joint

A method of forming a scarf joint between first and second elongate composite components (1,2), each having a complimentary tapered end surface (4,5) is disclosed. At least one of the components is formed of a stack of fibre layers impregnated in resin, with the tapered end surface (4) being formed by each fibre layer extending longitudinally progressively further than the adjacent layer. The method comprises applying adhesive to at least one of the tapered end surfaces (4,5), attaching a moulding tool around the first and second elongate components with their tapered end surfaces being adjacent to one another, applying a positive pressure increase to urge the tapered surfaces (4,5) towards one another without locally reducing the pressure below the vapour pressure of the resin or adhesive throughout the curing process, and curing the resin and adhesive in the moulding tool with the pressure applied.

Owner:BLADE DYNAMICS LTD

Joint construction of wire

InactiveCN101226792AAvoid entanglementInsulated cablesCable/conductor manufactureWire rodScarf joint

A scarf joint structure of wires comprises a wire coating body, wherein a male button unit and a female button unit are respectively arranged on the external surface of the wire coating body, the male button unit and the female button unit can be jointed with each other. The wires are enabled to be in scarf joint by overlapping parallel, winding or other modes, thereby functions of storing and arranging wires, avoiding wire intertwining and winding up and fixing wires which are too long can be achieved.

Owner:张明卿

Mitre joint support

ActiveUS20210046615A1Easy to moveFacilitated releaseDoors/windowsFencingScarf jointClassical mechanics

Owner:TOMM TECH PTY LTD

Half-shaft pre-upsetting cooling system

The invention discloses a half-shaft pre-upsetting cooling system which comprises a pre-mounting mold formed from a fixed disk, a clamping block, a mold protecting sleeve, an inner insert block and an outer insert block, wherein the fixed disk and the mold protecting sleeve are connected through a first screw, and the clamping block is arranged in the mold protecting sleeve and is connected with the mold protecting sleeve through the fixed disk in a scarf joint mode; the inner insert block and the outer insert block tightly clamp pre-upsetting components and parts and are fixed through a second screw; and a circulating cooling device is arranged outside the mold protecting sleeve. The cooling mode of circulating water is adopted, so that he circulating water can take away heat produced during the operation of the mold, and the mold always stays in the temperature state during preheating. Meanwhile, the water flow has low pressure in the mold cooling system so that the self circulation problem can be solved, and a small cooling pump is added so that water can circulate in the mold cooling system; thus, the phenomena of cracking due to heat expansion and difficult demolding are reduced, and the service life of the mold is prolonged.

Owner:QINGTE GRP

Scarf connection for a wind turbine rotor blade

Owner:LM WIND POWER US TECH APS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com