Non-consumable electrode arc hot wire additive manufacturing wire temperature detection control device and method

A non-melting electrode, detection and control technology, applied in the direction of manufacturing tools, arc welding equipment, welding equipment, etc., can solve the problems of poor contact stability between thermocouples and wire materials, unsuitable plasma arc additive manufacturing, and large welding wire temperature errors. Achieve the effect of large temperature detection range, improve stability, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

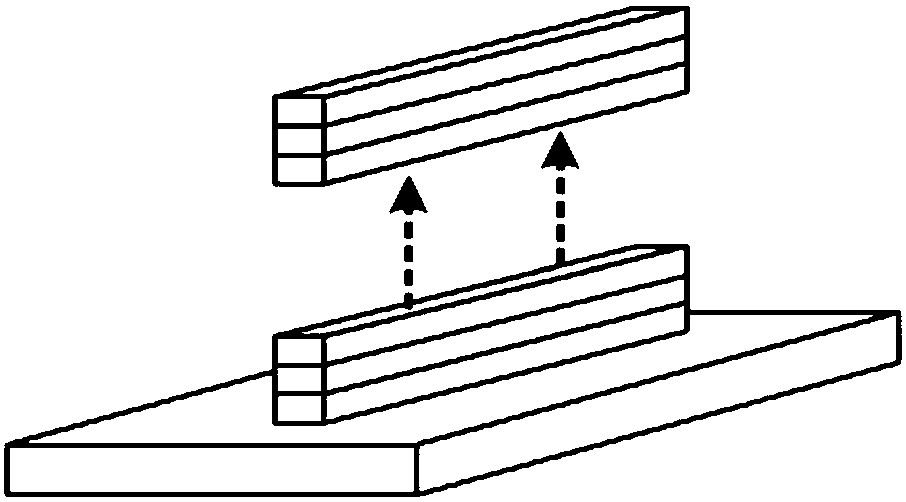

[0032] The invention provides a wire material temperature detection and control method for non-melting electrode arc hot wire additive manufacturing, capable of performing TIG arc hot wire single-channel multi-layer component additive manufacturing of ER5356 aluminum alloy wire with a diameter of 1.0mm The wire temperature detection in the process, and the schematic diagram of the stacking path of the components are shown in the attached image 3 , the specific steps are:

[0033] 1 Before the stacking test starts, set the preset temperature T of the wire 0 The temperature is 240°C, the temperature range ΔT is 10°C, adjust the fixture I4 so that the laser beam emitted by the infrared temperature sensor 3 avoids the arc of the non-melting electrode, and the collection point is positioned on the wire;

[0034] 2. When the welding torch reaches the designated position and strikes the arc, the welding power supply 13 sends a signal to the wire feeder 12, and the wire feeder 12 st...

Embodiment 2

[0042] The invention provides a wire material temperature detection and control method for non-melting electrode arc hot wire additive manufacturing, which can perform the plasma arc hot wire single-channel multi-layer component additive manufacturing process of H08Mn2Si stainless steel wire with a diameter of 1.2mm The temperature detection of the wire material, and the schematic diagram of the stacking path of the components are shown in the attached image 3 , the specific steps are:

[0043] 1 Before the stacking test starts, set the preset temperature T of the wire 0 The temperature is 400°C, the temperature range ΔT is 15°C, adjust the fixture I4 so that the laser beam emitted by the infrared temperature sensor 3 avoids the arc of the non-melting electrode, and the collection point is positioned on the wire;

[0044] 2. When the welding torch reaches the designated position and strikes the arc, the welding power supply 13 sends a signal to the wire feeder 12, and the wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com