Experimental method for studying the reaction of fine ore in motion

A test method and powder ore technology, applied in the field of metallurgy, can solve the problems of small temperature difference constant temperature zone, large influence, large temperature difference, etc., to ensure the accuracy and prevent the effect of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

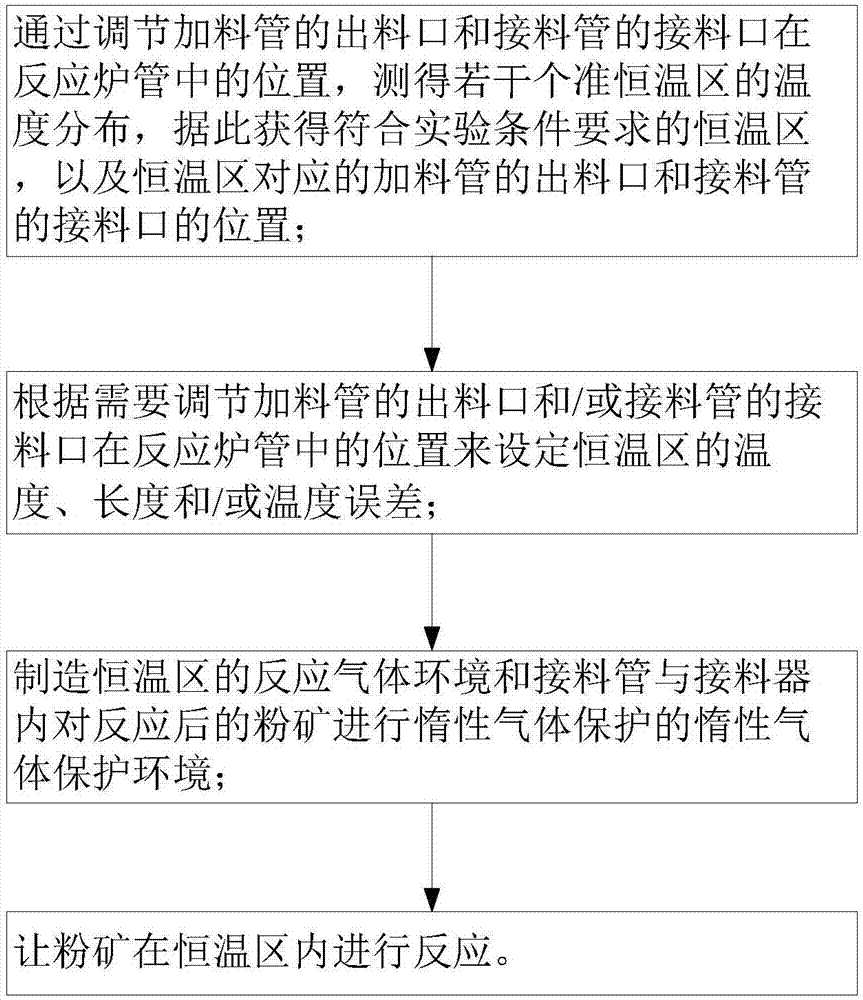

Method used

Image

Examples

Embodiment 1

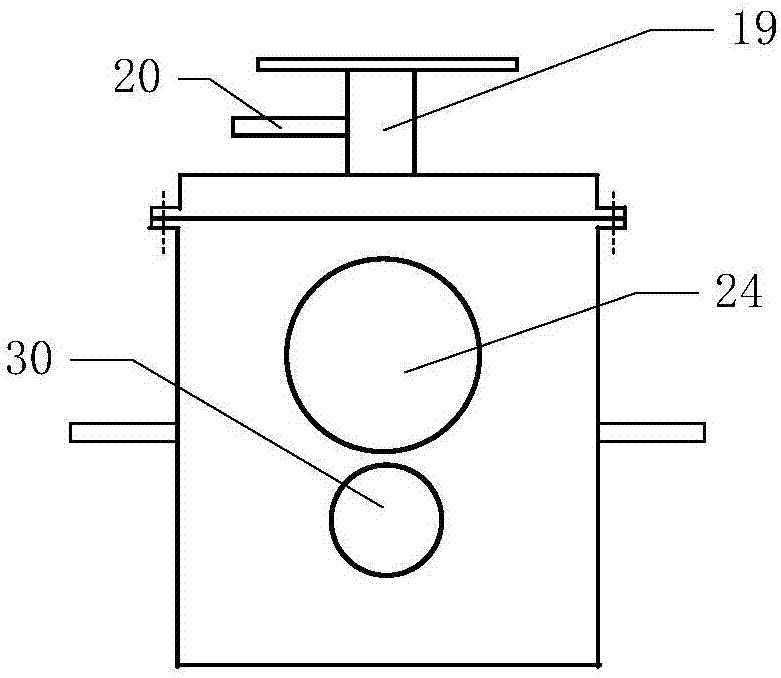

[0141] Taking the 130cm long tubular shaft furnace as an example, the operating temperature of the tubular shaft furnace is 1400°C. The present invention adopts a water-cooled feeding pipe and a feeding pipe protected by an inert gas. The length of the constant temperature zone is set at 50cm. The highest temperature in the zone is 1388°C, the lowest temperature in the constant temperature zone is 1350°C, the temperature in this constant temperature zone is 1369°C, and the error of the temperature in the constant temperature zone is ±19°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com