Heat convection testing method and system for composite insulator including artificial defect

A technology of composite insulators and test methods, applied in the detection field of composite insulators, to reduce the probability of damage, avoid internal short circuits, and avoid disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

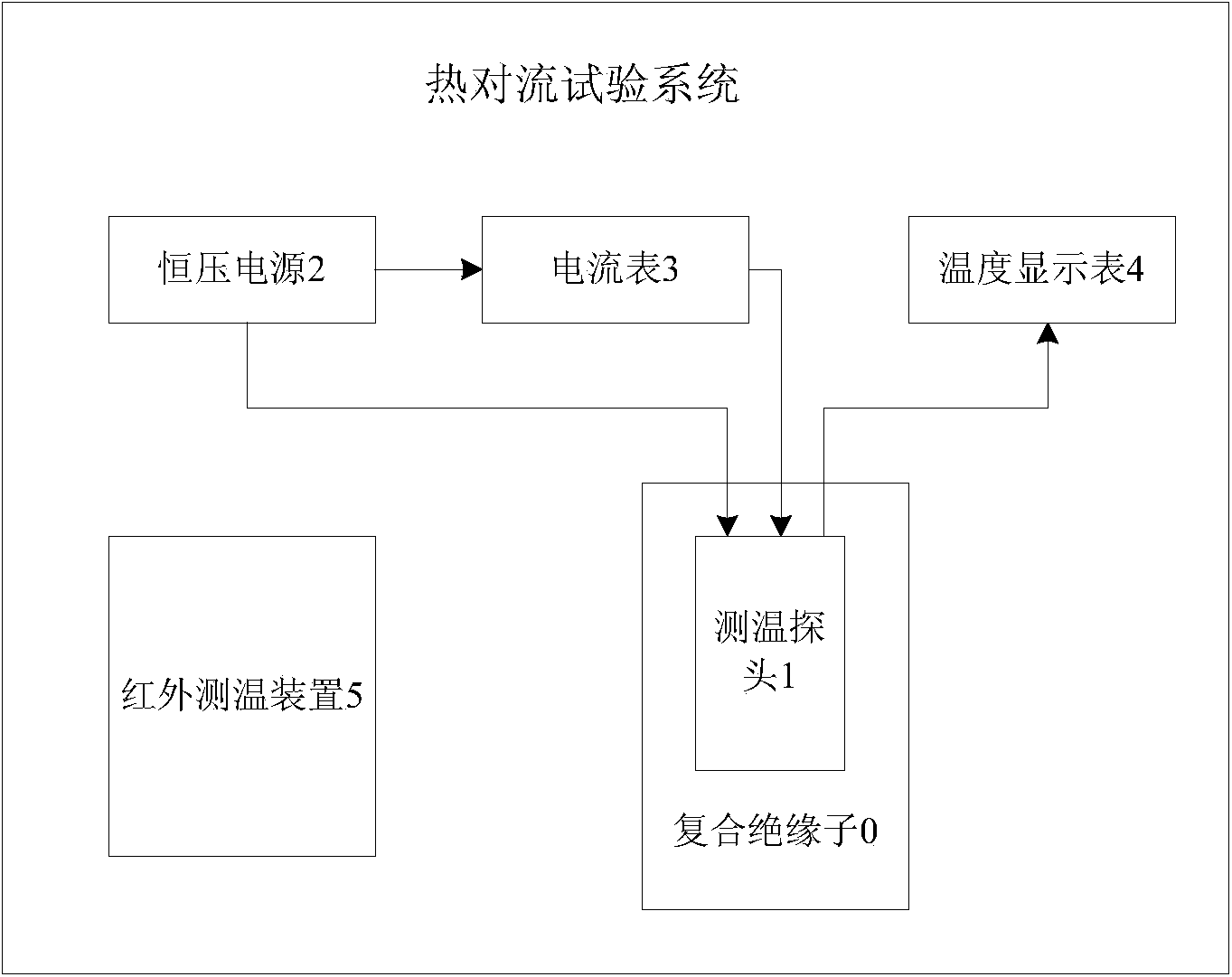

[0054] The core idea of the present invention is: put a temperature-raising temperature probe into the interface between the silicone rubber sheath of the composite insulator and the epoxy resin mandrel, and use an infrared temperature measuring device to measure the temperature outside, thereby obtaining a composite The relationship between the temperature rise of the outer surface and the actual temperature rise inside the insulator when the temperature rise occurs inside the insulator.

[0055] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

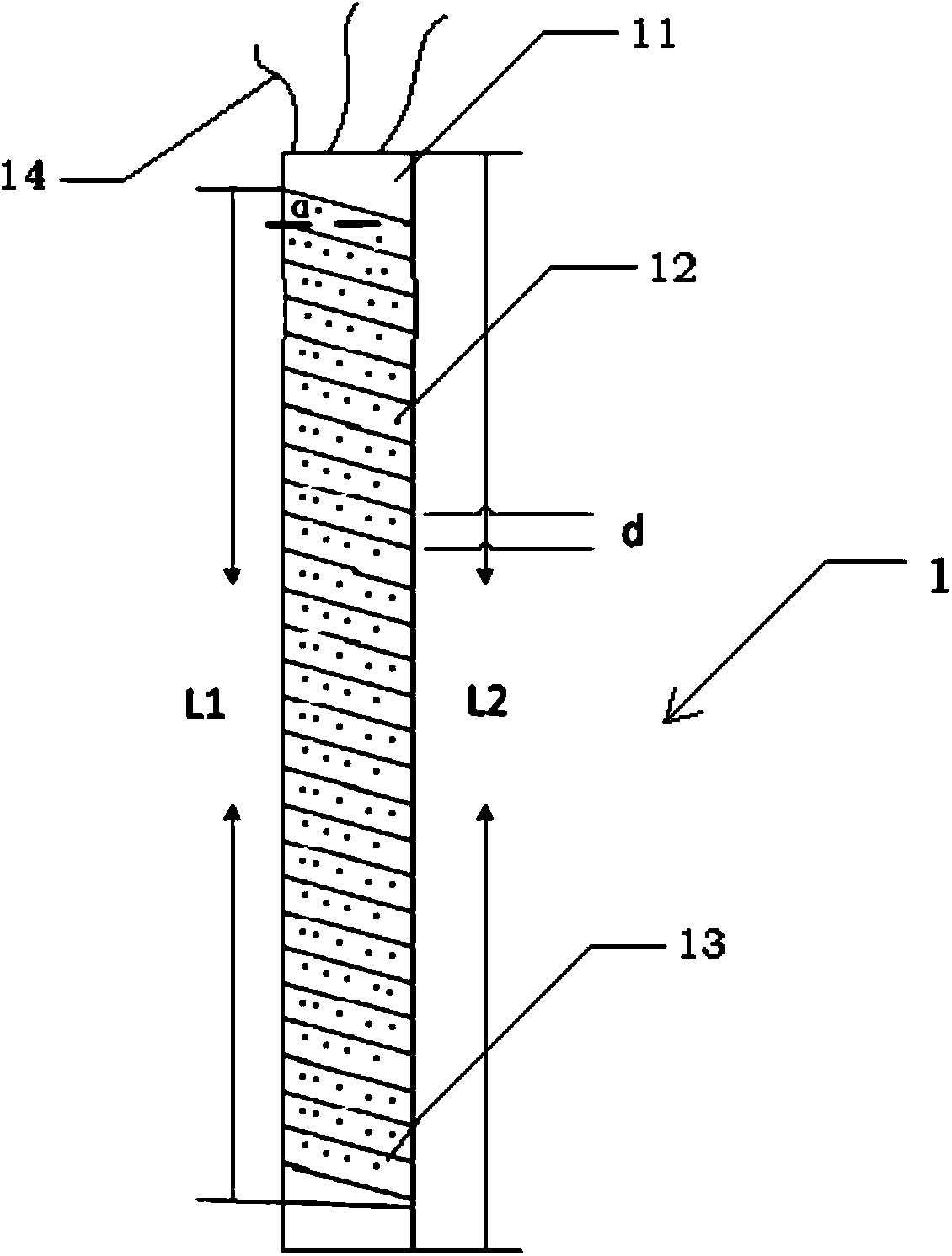

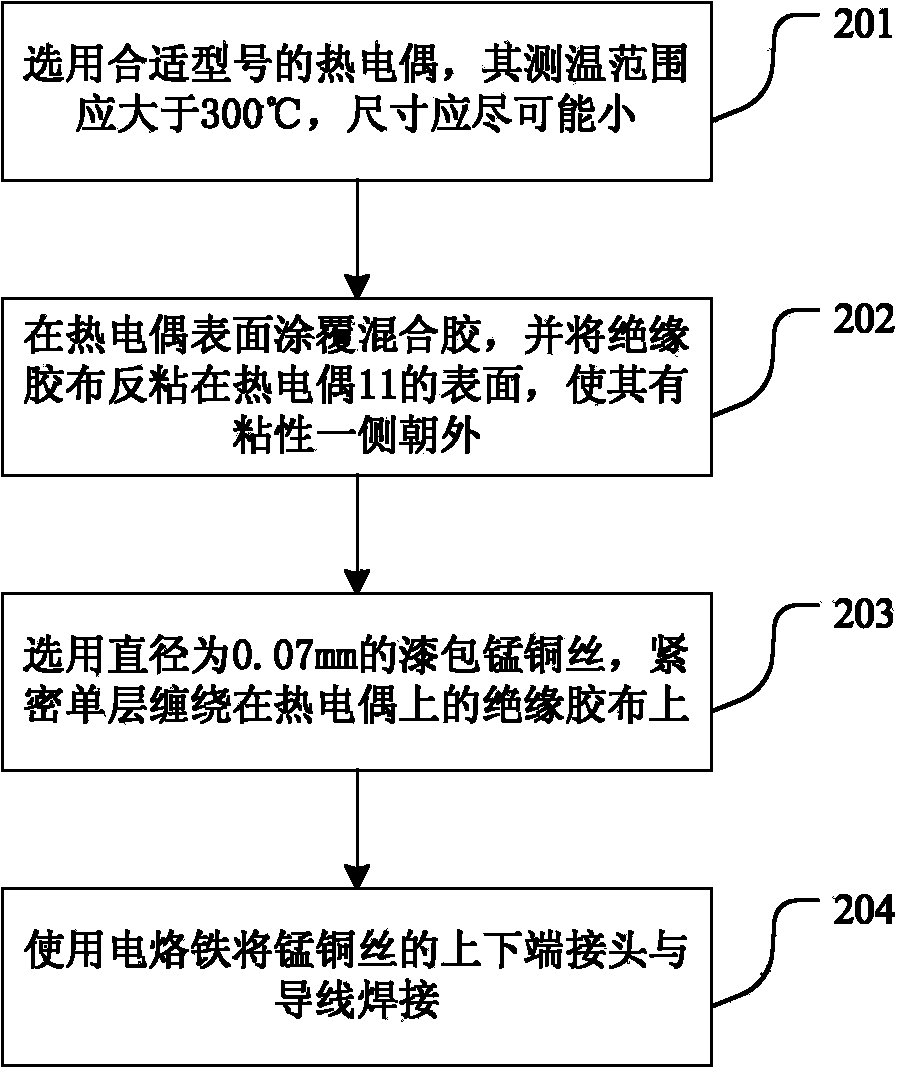

[0056] see figure 1 As shown, the temperature-measuring probe 1 that can be heated in this embodiment main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com