Semiconductor component test station with detachable electric property detecting system

A detection system and semiconductor technology, which is applied to the testing of single semiconductor devices, components of electrical measuring instruments, and electrical measurement, etc., can solve the problems of surface scratches, defect rate, cost, and contamination of the components to be tested, and achieve operational flexibility. Increase, reduce the damage probability, improve the effect of detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The foregoing and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of preferred embodiments with reference to the accompanying drawings.

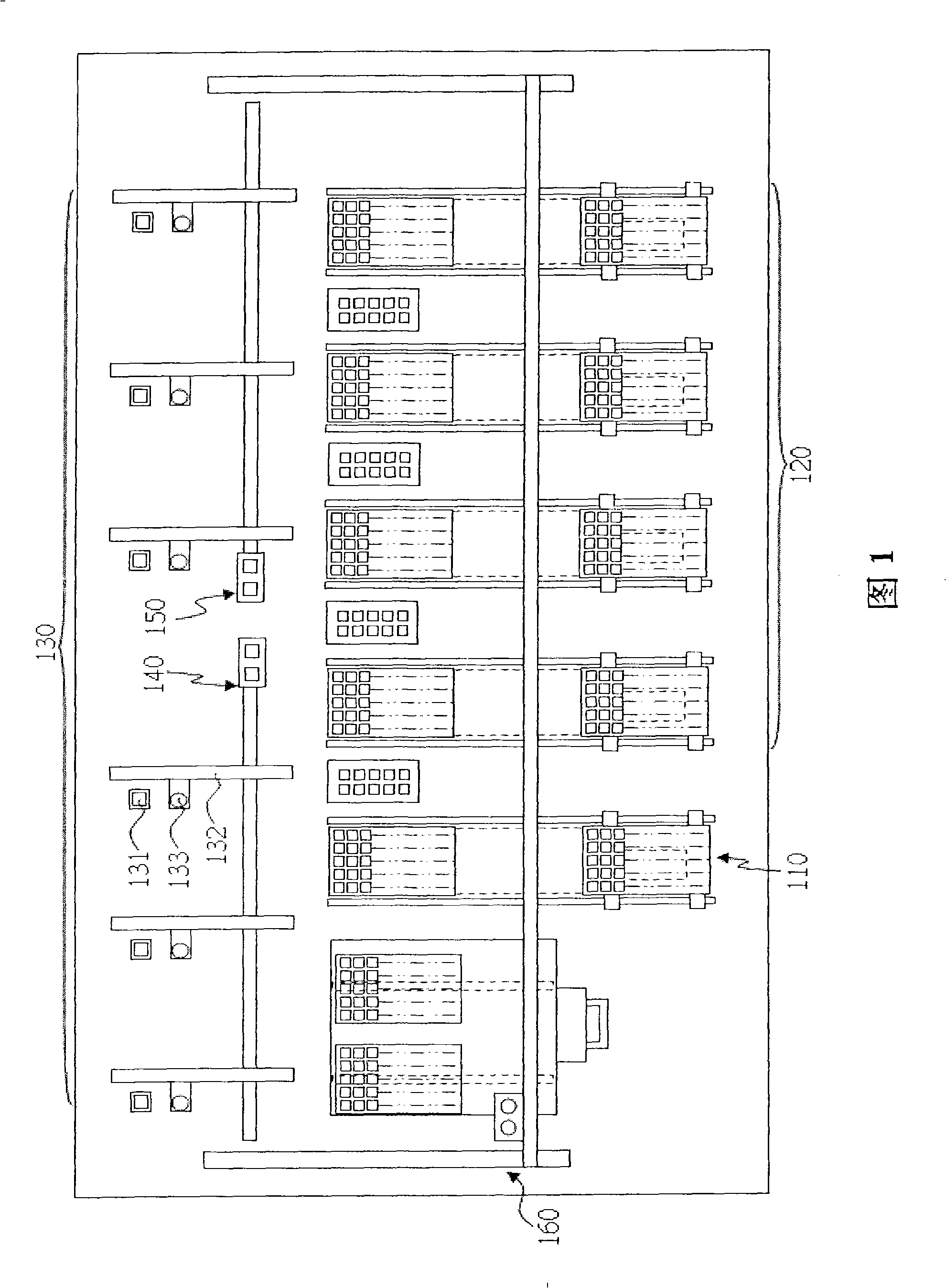

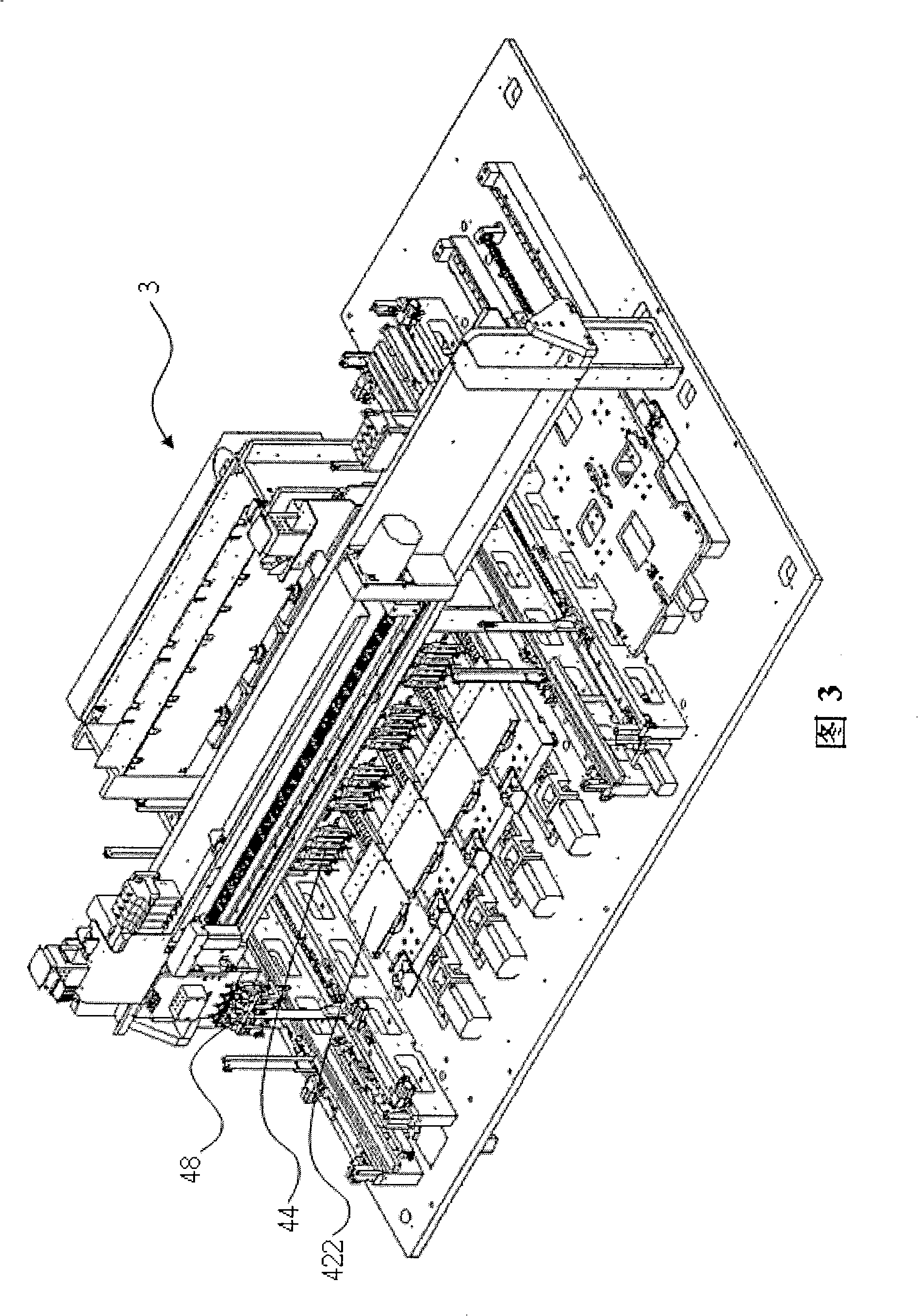

[0046] A preferred embodiment of a semiconductor component testing machine with a separable electrical testing system according to the present invention. FIG. 3 is a three-dimensional schematic view of the appearance of the machine 3; FIG. In this embodiment, a test machine with four sets of test areas is taken as an example, and each test area can test 4 semiconductor components to be tested at a time, so each batch can be 4×4=16 semiconductor components to be tested are tested, thus having a high test efficiency.

[0047] The machine 3 includes: an actual testing system 4 , an electrical testing system 40 , and a control device 47 . In this example, the real-world testing system 4 includes: a plurality of sets of correspondingly configured test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com