Silicon micromechanical vibrating gyroscope of I-shaped structure

A technology of silicon micromachines and vibrating gyroscopes, applied in the direction of gyroscope effect for speed measurement, gyroscope/steering sensing equipment, instruments, etc., to reduce temperature errors, suppress interference signals, and increase support stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

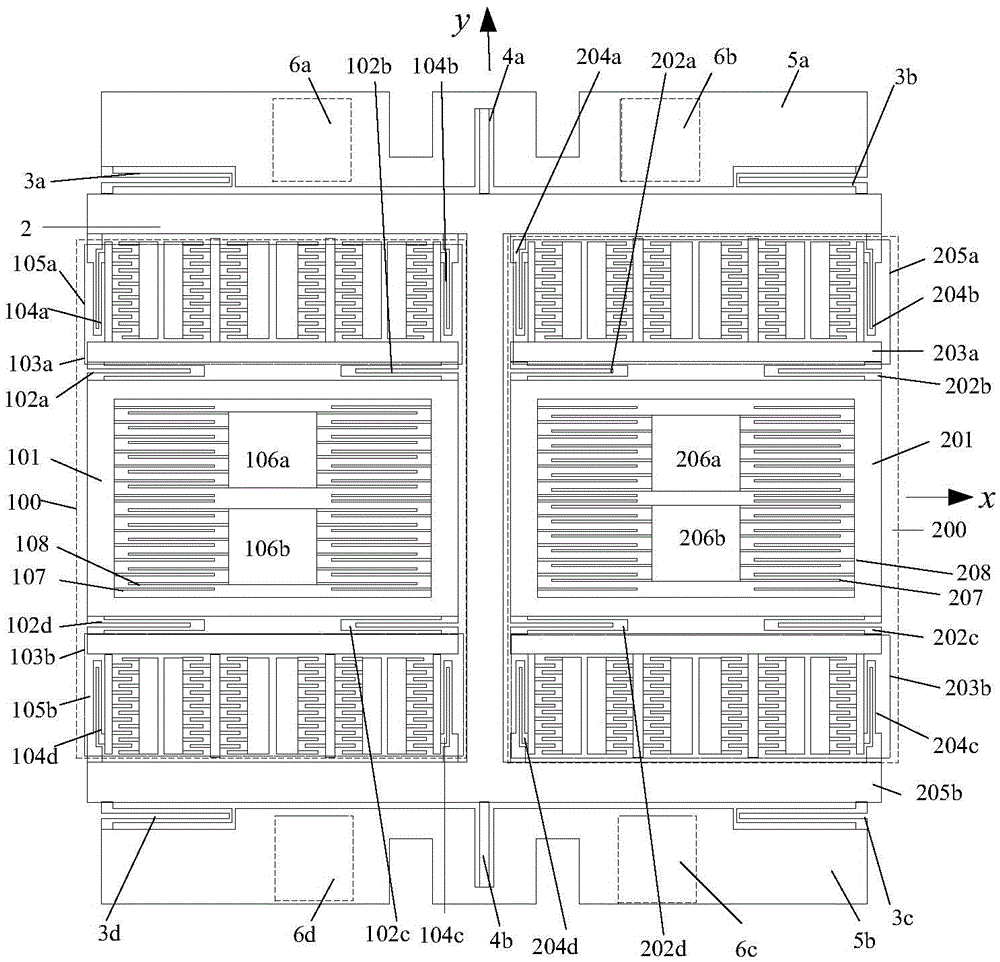

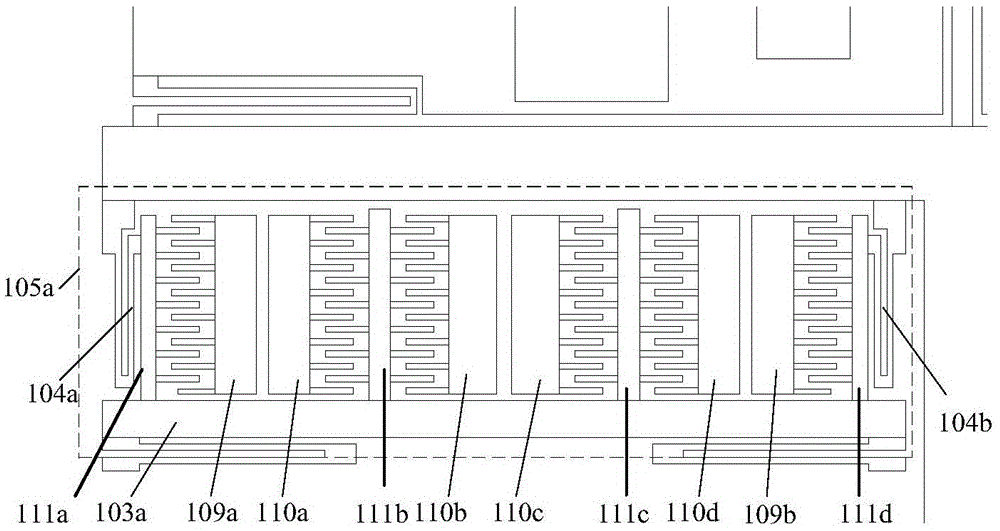

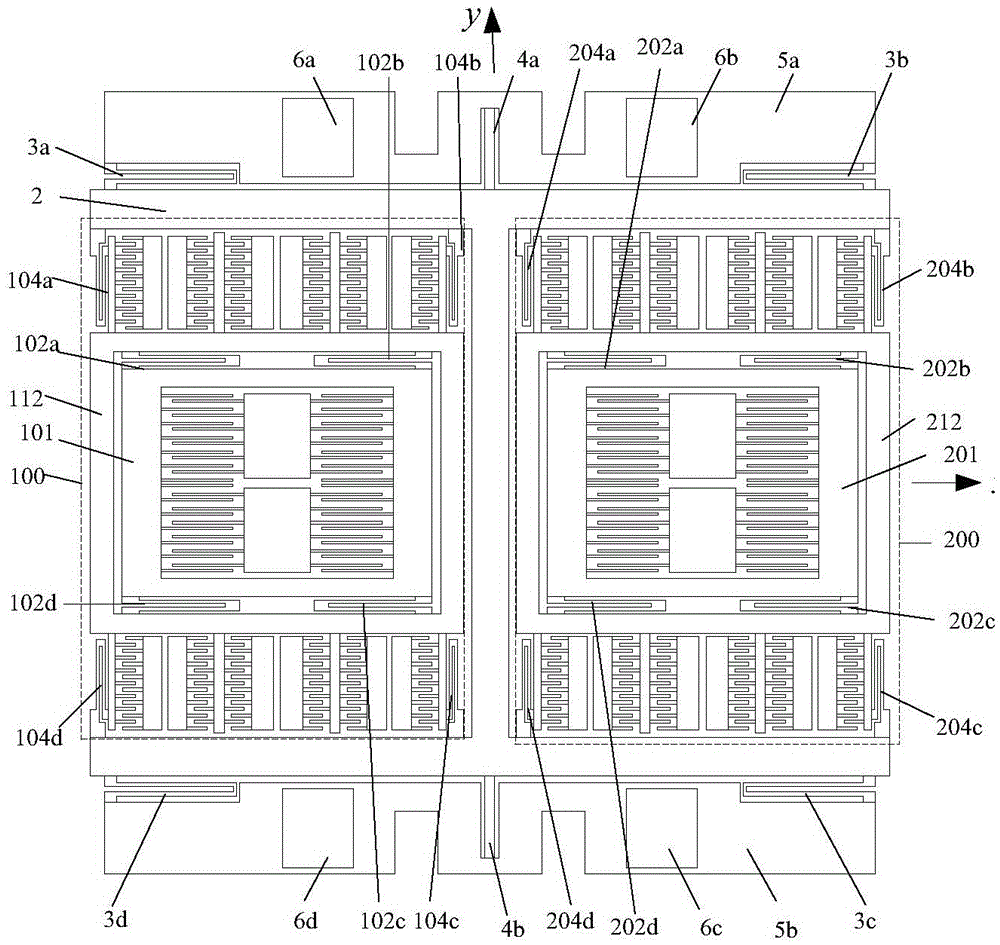

[0015] The silicon micromechanical vibrating gyro with I-shaped structure of the present invention is used to measure the measuring instrument perpendicular to the base level, and is composed of an upper layer of single crystal silicon, a middle layer of single crystal silicon, and a lower layer of single crystal silicon. The upper layer of single crystal silicon is arranged with The silicon micro-gyroscope packaging cover plate for signal input and output lines, the gyroscope mechanical structure is made on the middle layer of single crystal silicon wafer, the lower layer of single crystal silicon is the gyroscope substrate with a fixed base, and the upper layer of single crystal silicon package The cover plate and the lower single crystal substrate form a closed cavity; the mechanical structure of the middle single crystal silicon includes substructures, I-shaped frames, torsion bars, multi-fold beams and isolation structures, and the two substructures are arranged symmetrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com