Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Contoured plate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

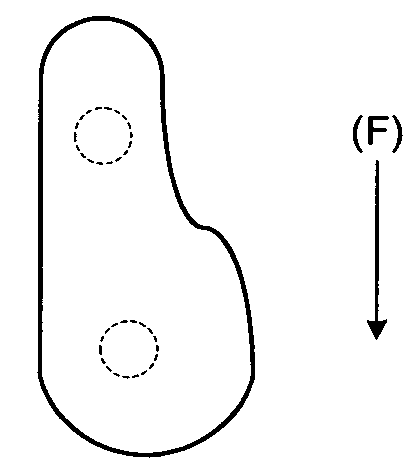

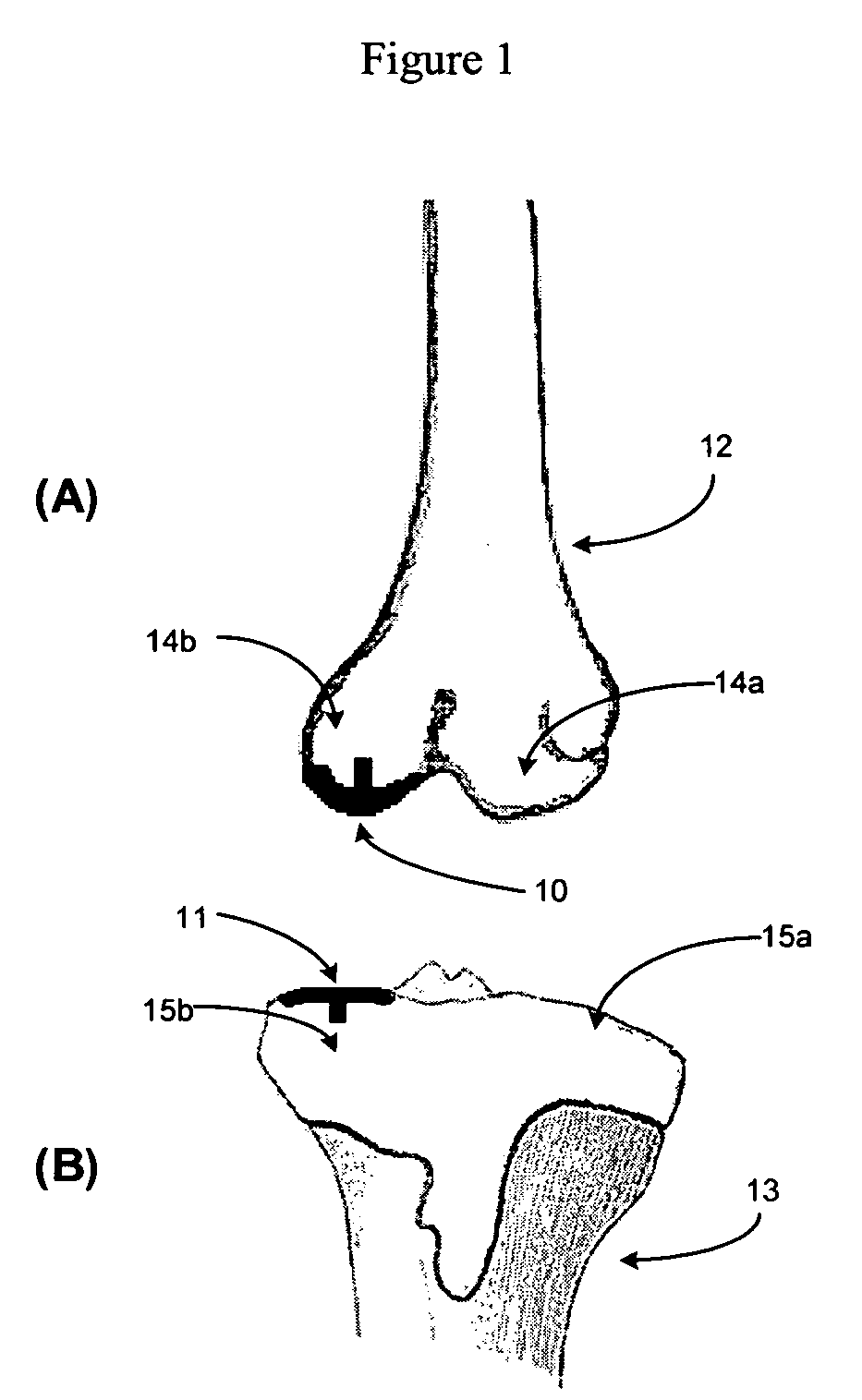

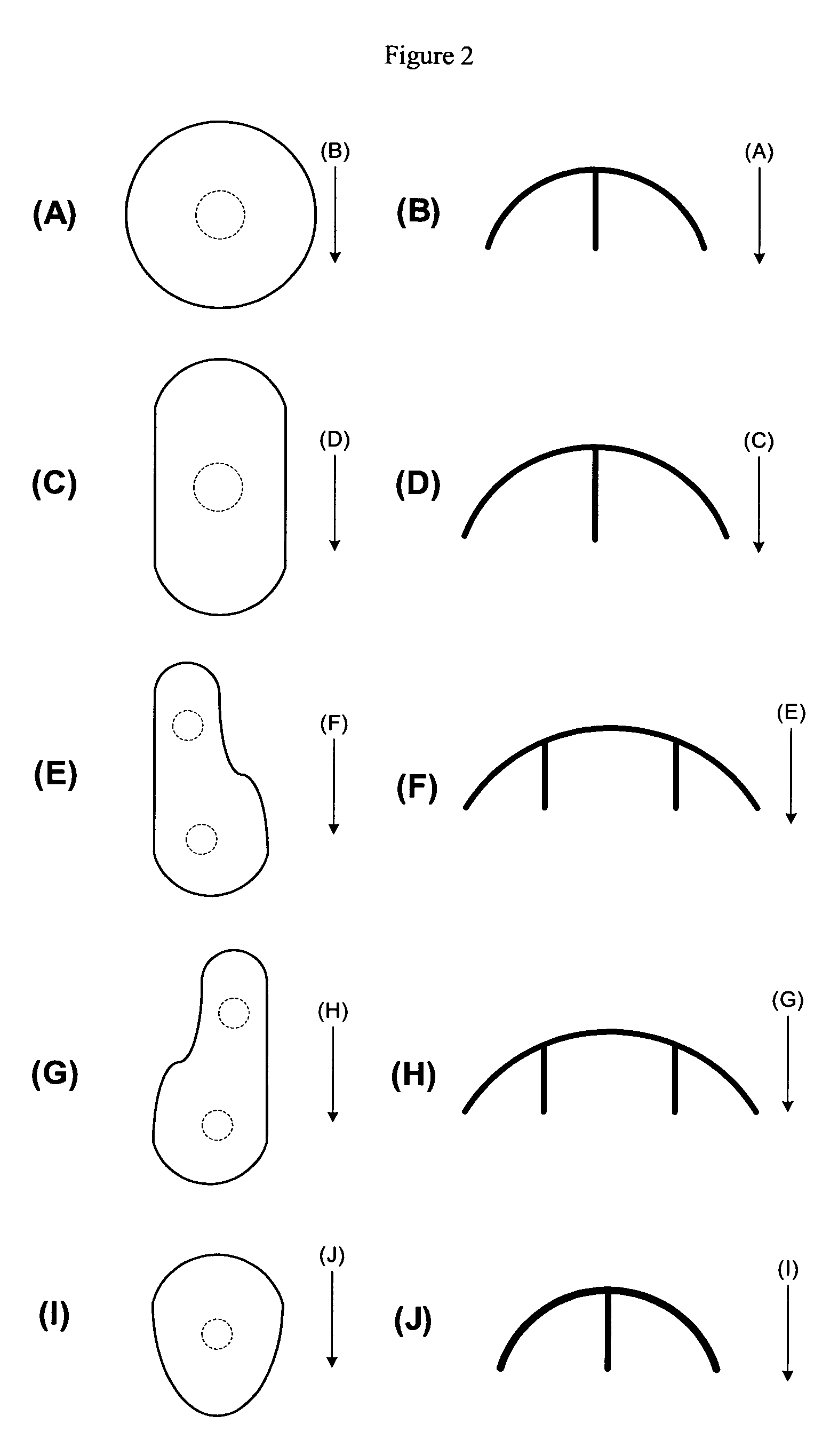

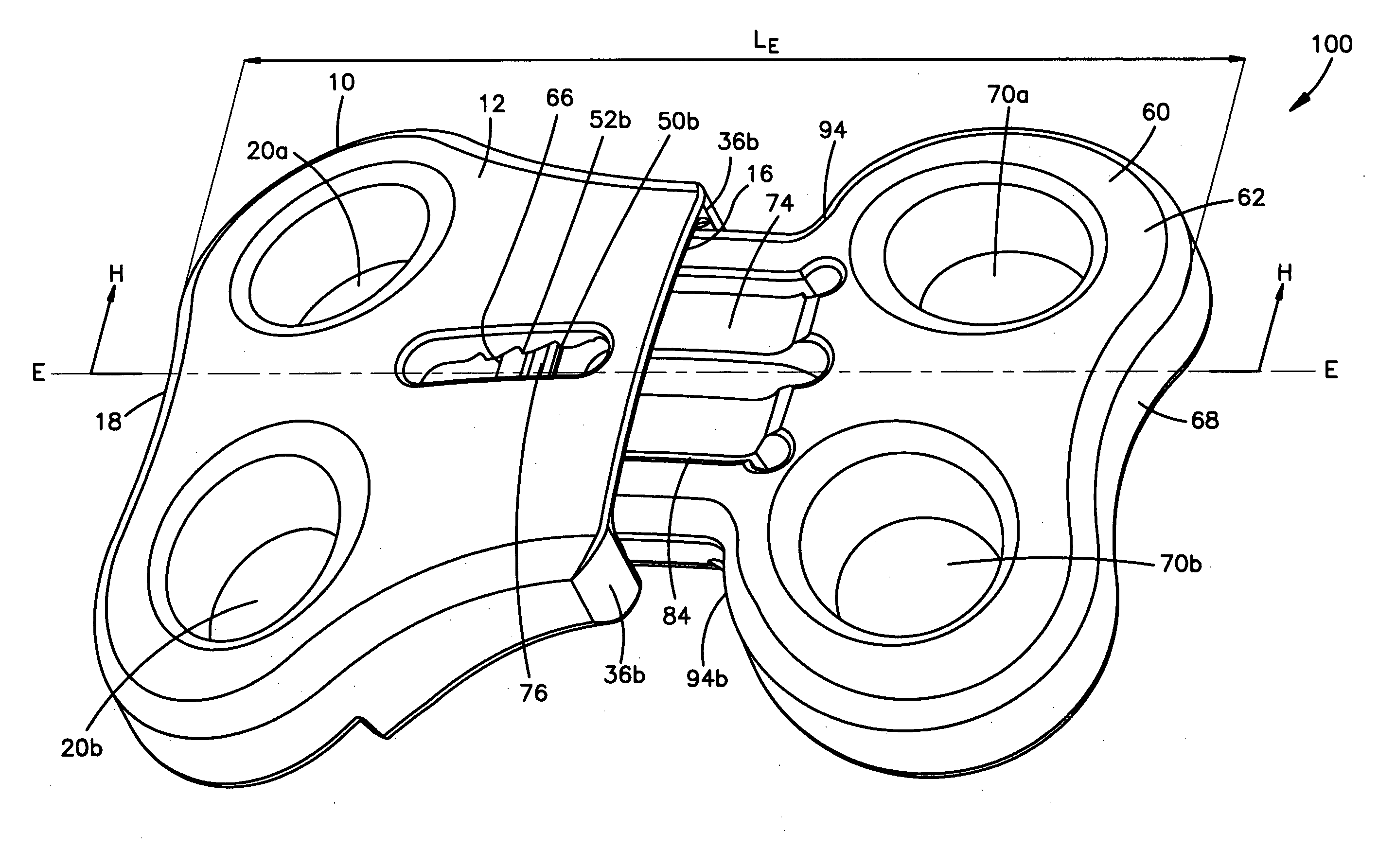

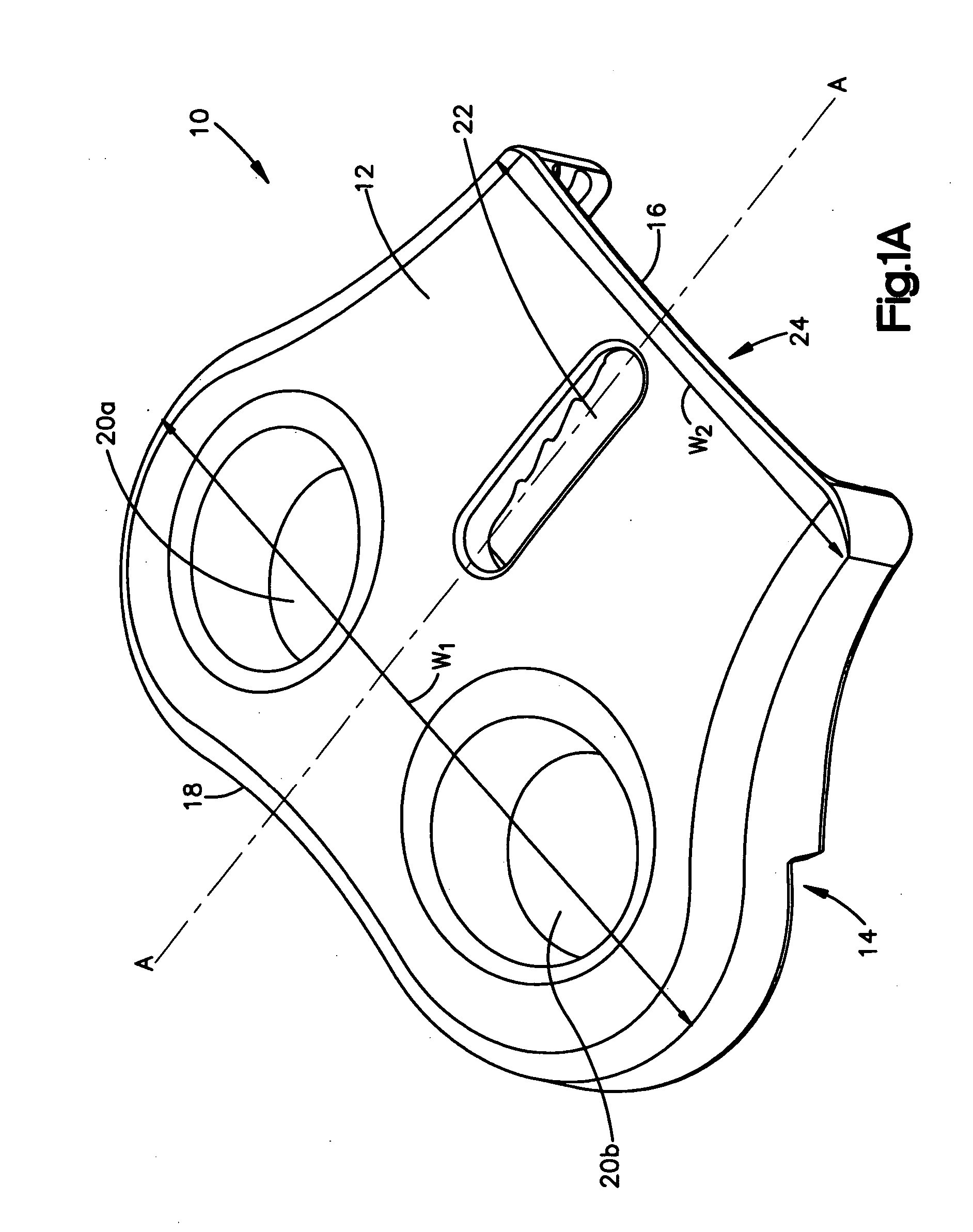

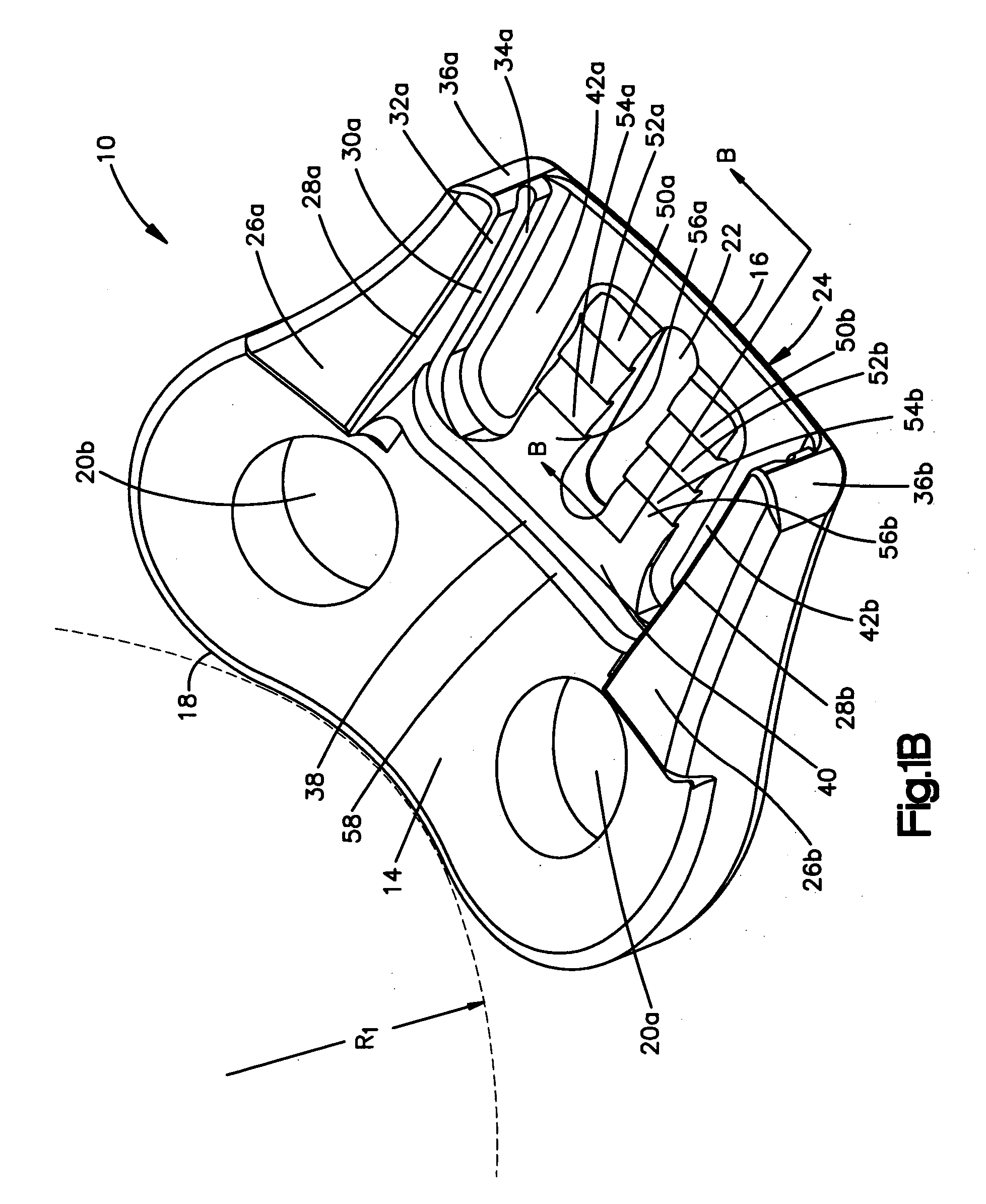

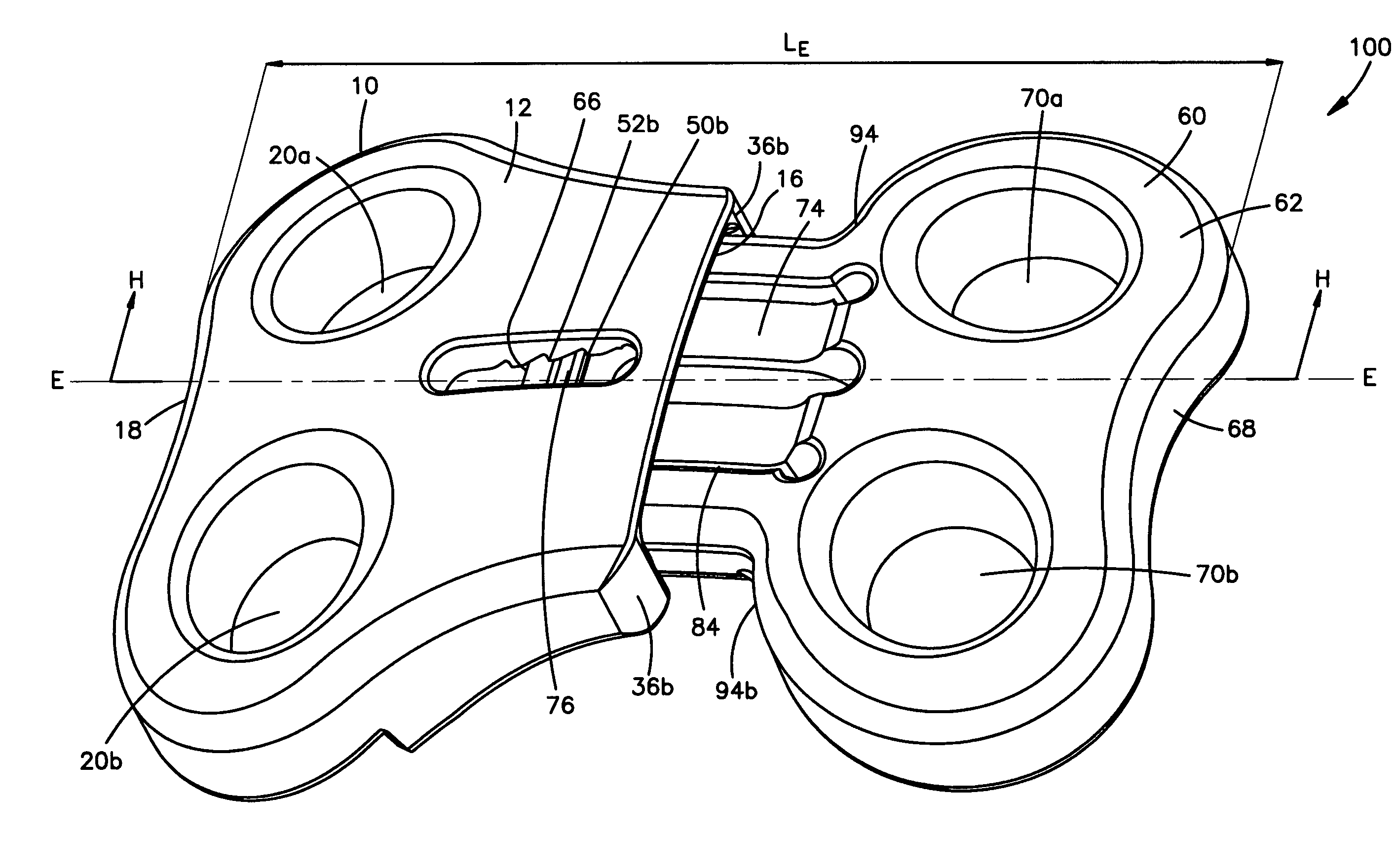

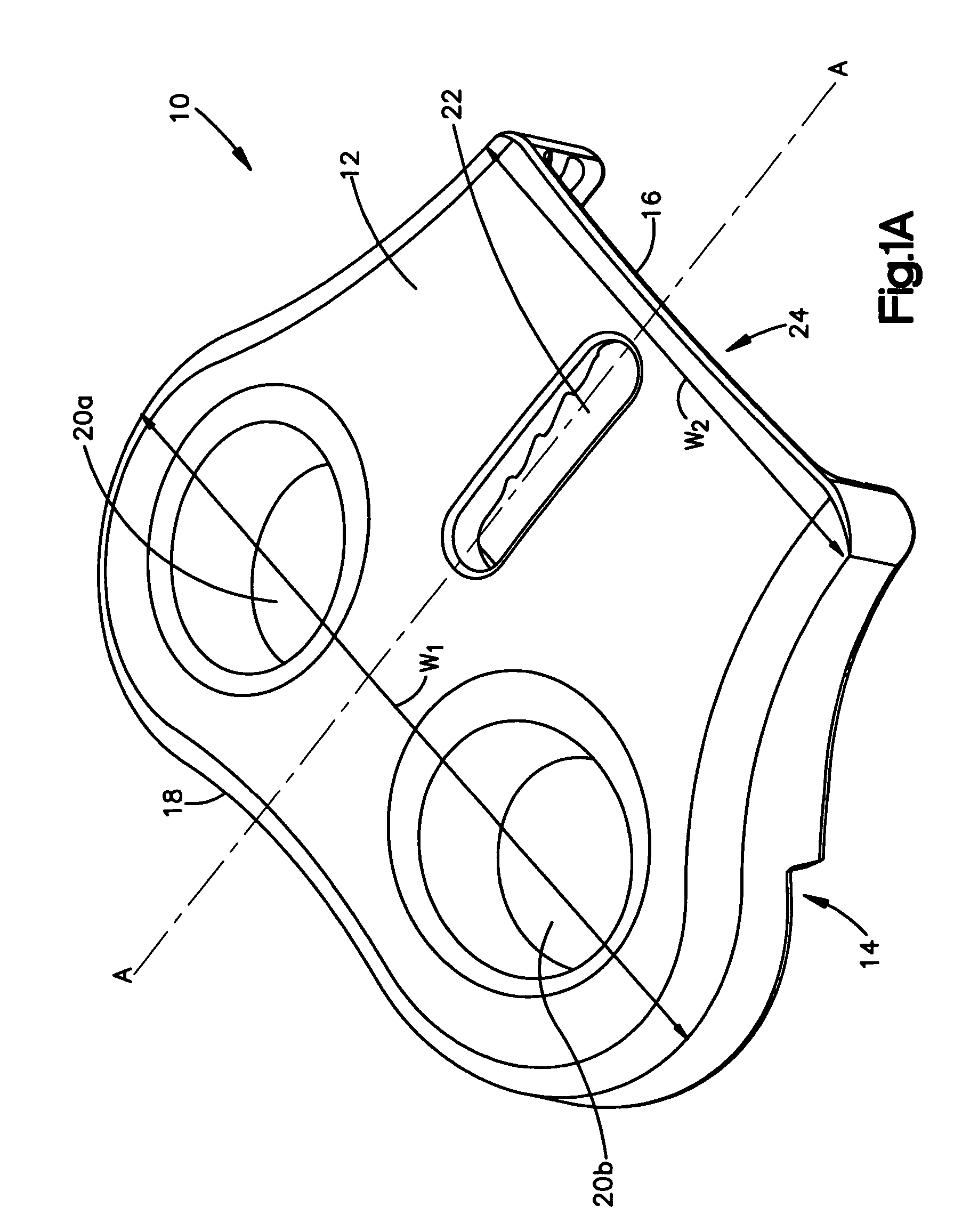

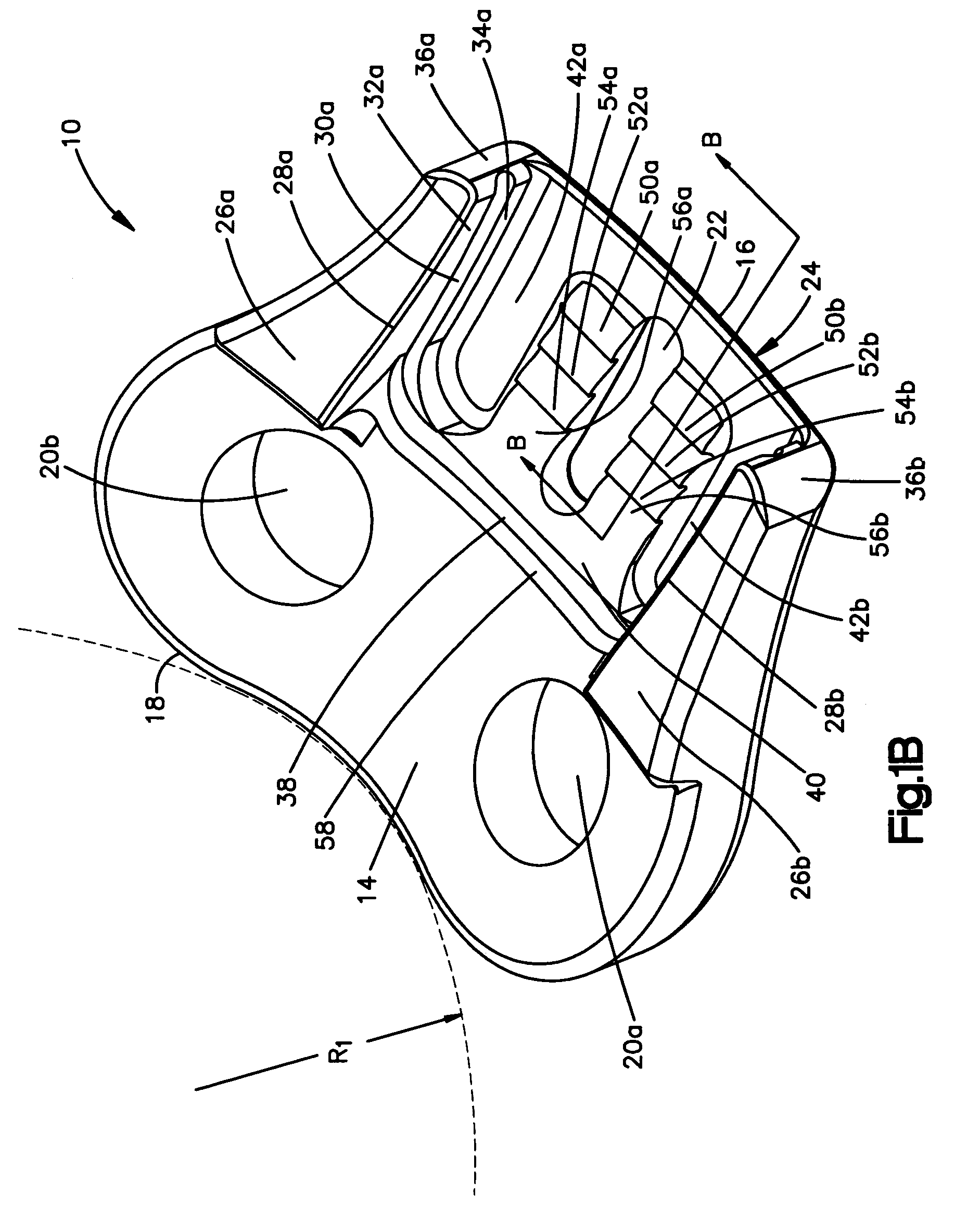

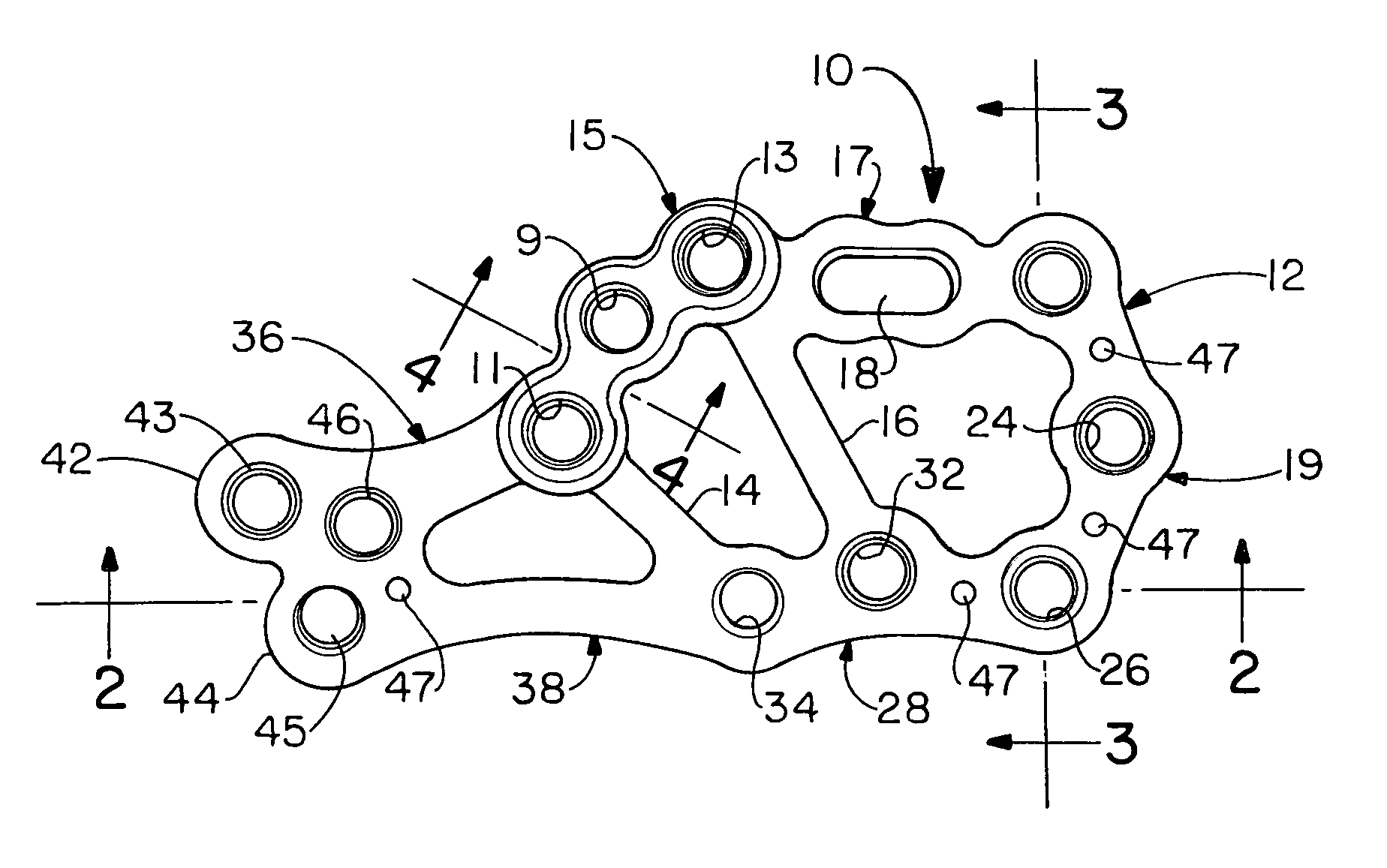

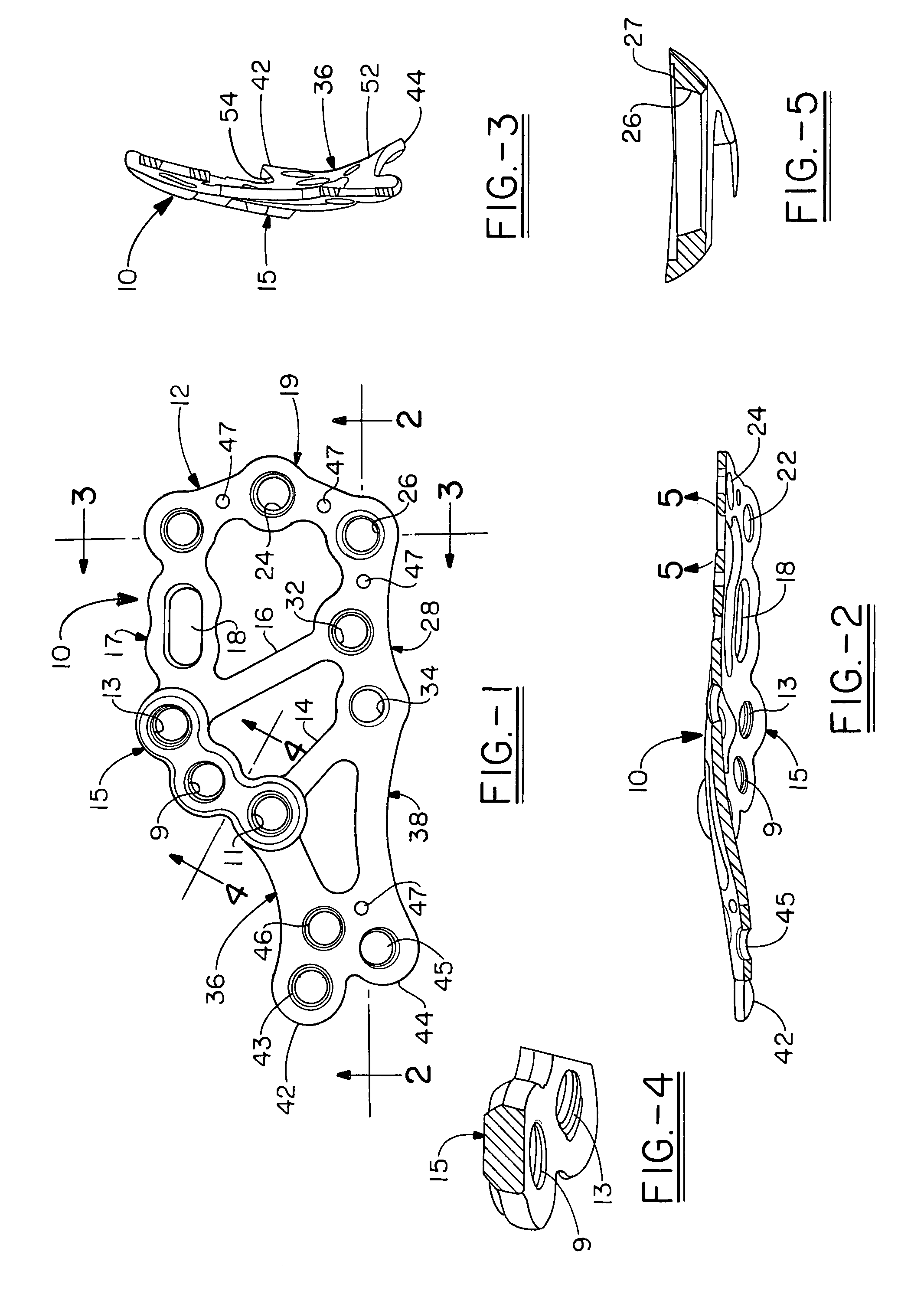

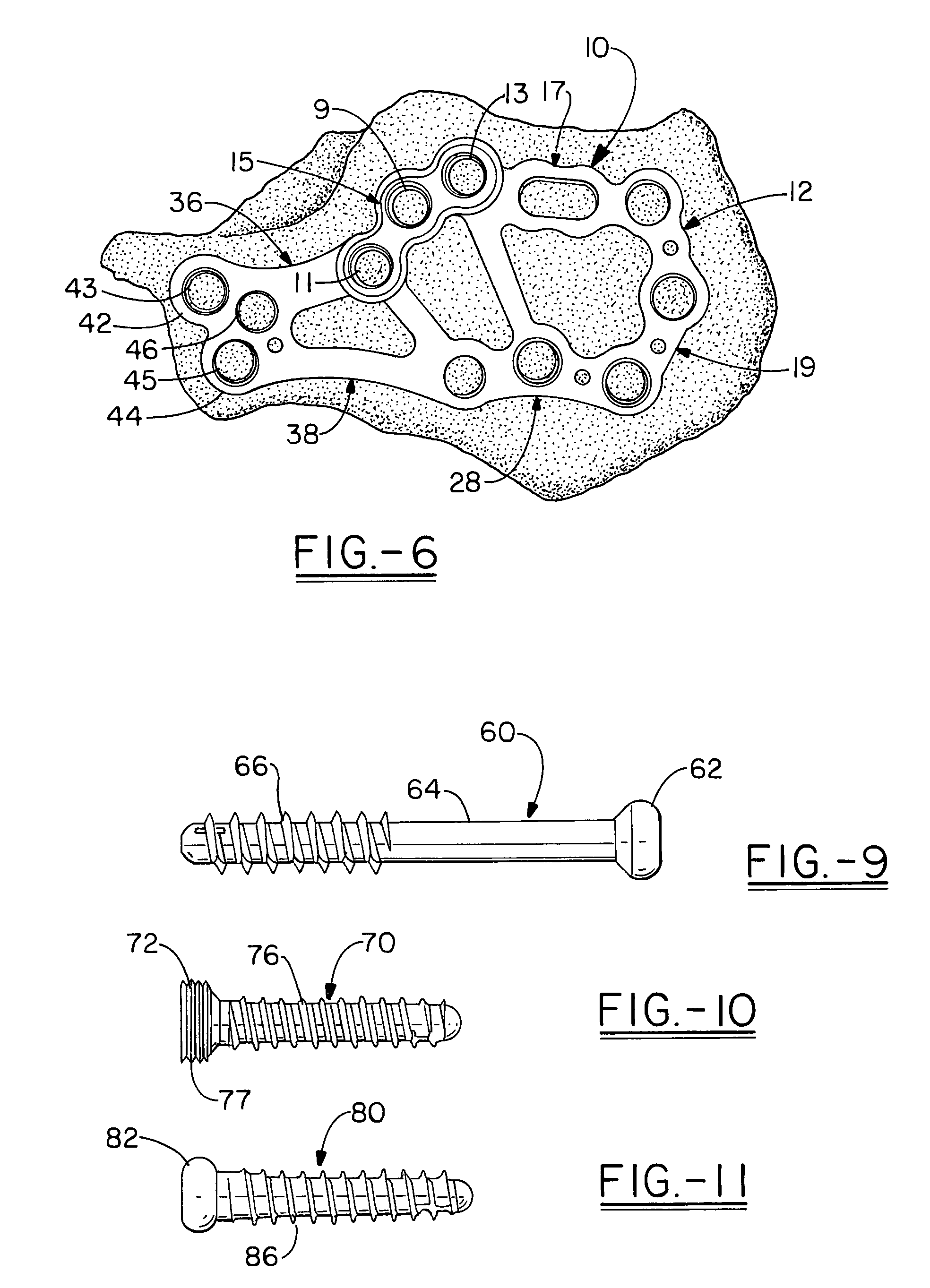

Site specific minimally invasive joint implants

InactiveUS20070021838A1Rapid and successful implantationEasy to disassembleSuture equipmentsBone implantArticular surfacesArticular surface

A prosthetic articular surface for implantation in a joint such as the knee is provided. The prosthetic articular surface comprises a contoured plate having two sides, one side of which is a bone-contacting side and the other side of which is an articular side, and at least one post extending from the bone contacting side. A method of placing the prosthesis at an implant site, a guide tool for facilitating implantation, and a surgical kit containing the prosthesis also are provided. The prosthetic articular surface, method of implanting the prosthesis, guide tool for facilitating implantation, and surgical kit containing the prosthesis may be used to replace or augment a damaged joint in the knee.

Owner:ORTHO VENTIONS

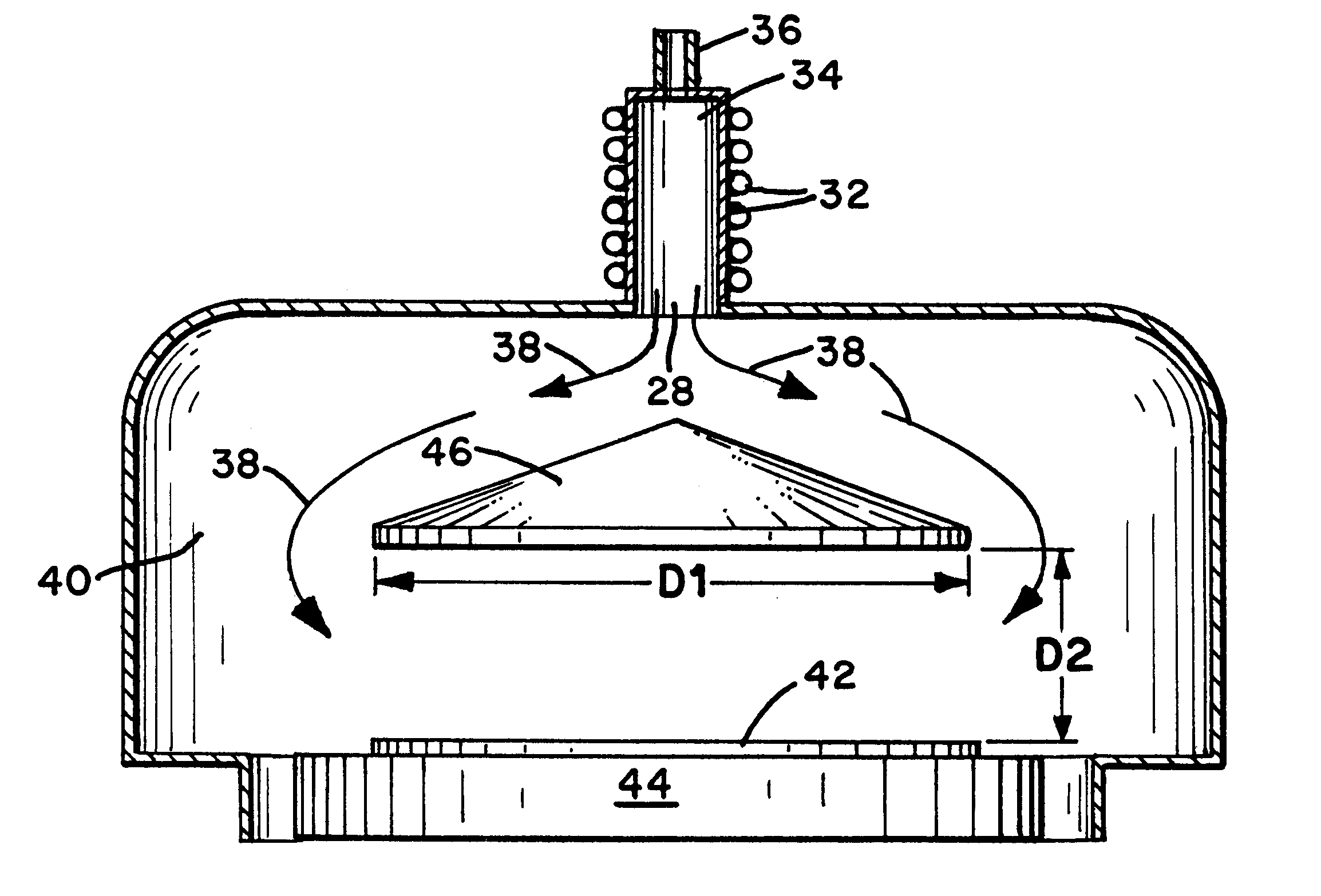

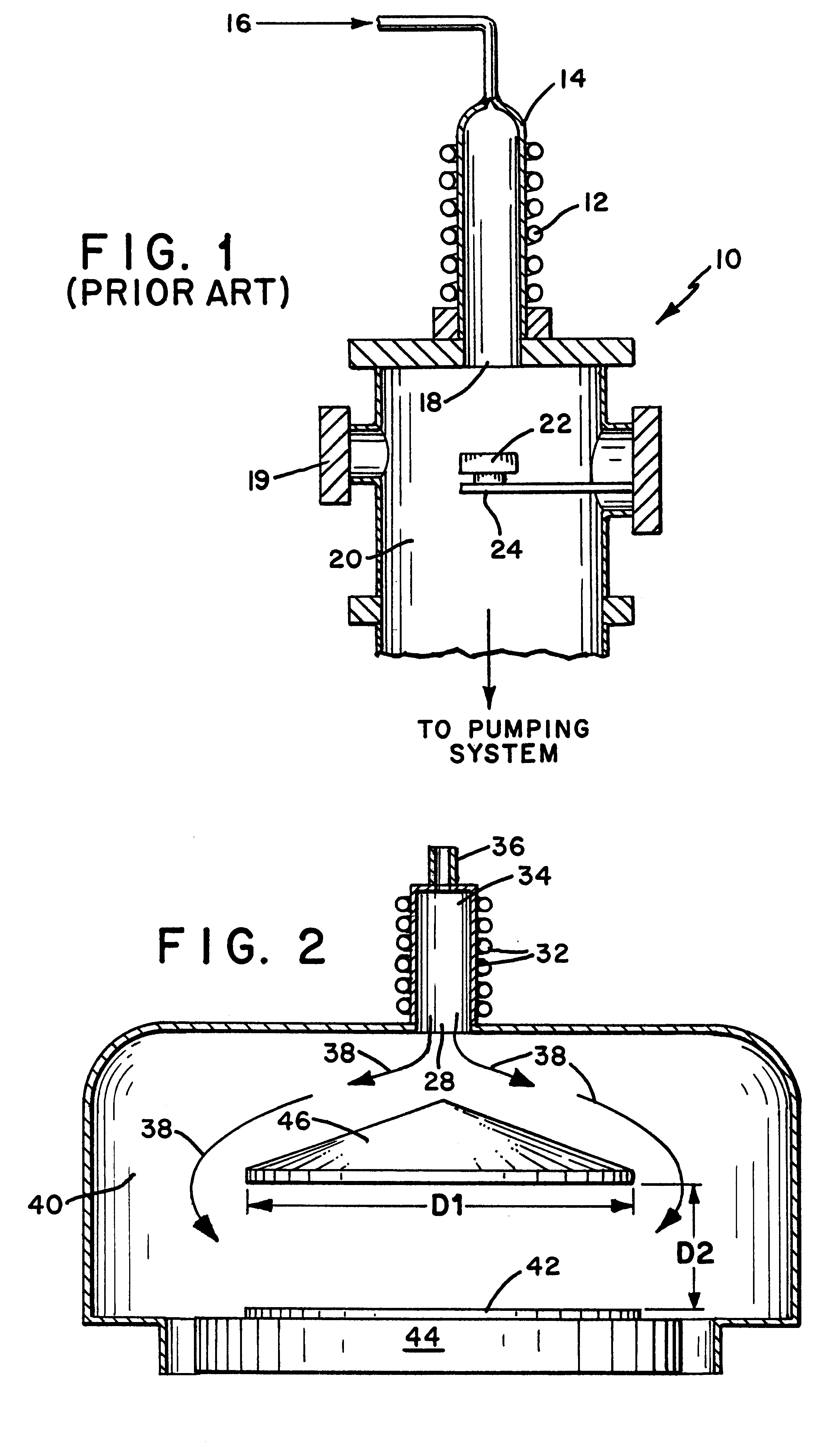

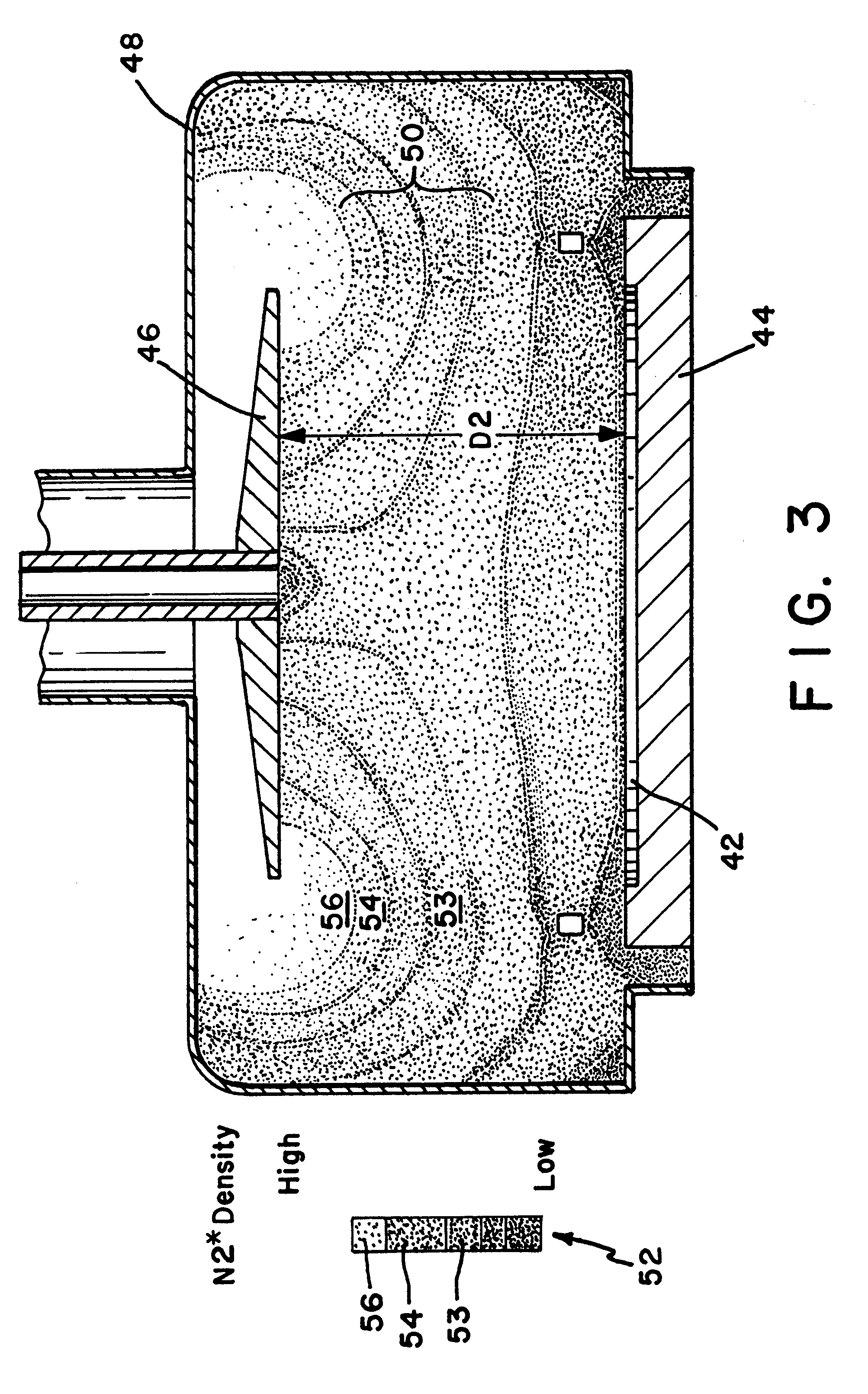

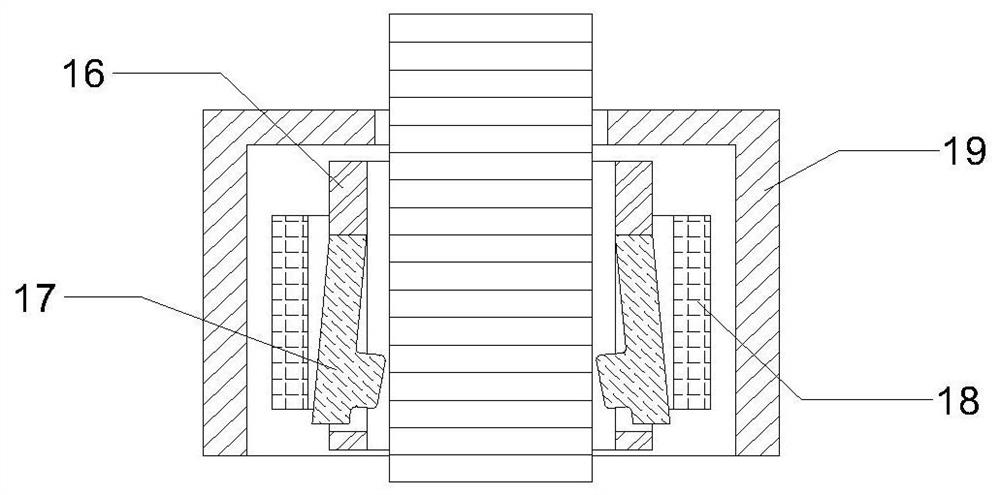

Apparatus and method for injecting and modifying gas concentration of a meta-stable or atomic species in a downstream plasma reactor

InactiveUS6287643B1Reduce lossesElectric discharge tubesPretreated surfacesRemote plasmaHigh density

An apparatus and method for injecting gas within a plasma reactor and tailoring the distribution of an active species generated by the remote plasma source over the substrate or wafer. The distribution may be uniform, wafer-edge concentrated, or wafer-center concentrated. A contoured plate or profiler modifies the distribution. The profiler is an axially symmetric plate, having a narrow top end and a wider bottom end, shaped to redistribute the gas flow incident upon it. The method for tailoring the distribution of the active species over the substrate includes predetermining the profiler diameter and adjusting the profiler height over the substrate. A coaxial injector tube, for the concurrent injection of activated and non-activated gas species, allows gases to be delivered in an axially symmetric manner whereby one gas can be excited in a high density RF plasma, while the other gas can be prevented from excitation and / or dissociation caused by exposure to the plasma or heated surfaces in the source apparatus. The profiler is used in conjunction with the coaxial injector tube for redistributing the excited gases emerging from the injector tube, while allowing the non-excited gases to pass through its center.

Owner:NOVELLUS SYSTEMS

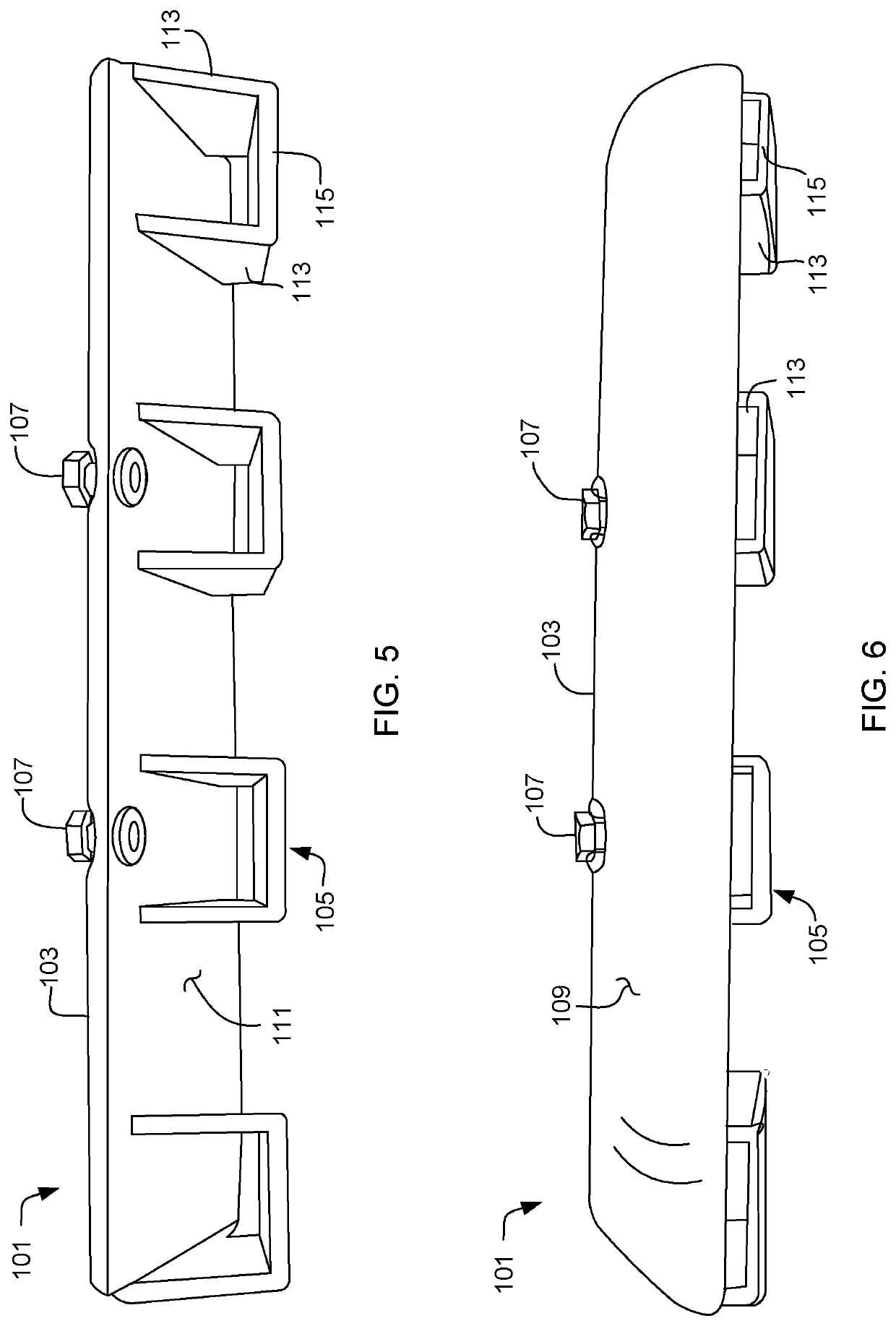

Unidirectional translation system for bone fixation

A fixation assembly is described comprising at least two plates, one of which may be a contoured plate and one of which may be a securing plate. The contoured plate may have a plurality of teeth, and the securing plate may have a resilient securing element. The teeth may be arranged so that the resilient securing element encounters progressive resistance as the plates are compressed.

Owner:SYNTHES USA

Unidirectional translation system for bone fixation

A fixation assembly is described comprising at least two plates, one of which may be a contoured plate and one of which may be a securing plate. The contoured plate may have a plurality of teeth, and the securing plate may have a resilient securing element. The teeth may be arranged so that the resilient securing element encounters progressive resistance as the plates are compressed.

Owner:SYNTHES USA

Calcaneal plate

The present invention is a fully contoured calcaneal plate having substantially no planar surfaces except at the origin. The contoured plate includes radiused sections, one extending inferior to superior is curved inferior to superior in a shape which is close to cylindrical and which approximates the shape of the cuboid bone. The second radiused section is curved in the vicinity of the anterior strut, and in particular at the inferior portion of the plate, to accommodate the peroneal tubercle. The plate has a rectangular or modified ovoid body section and a dog boned shaped tail with triangular placed holes for fixation.

Owner:ORTHOHELIX SURGICAL DESIGNS

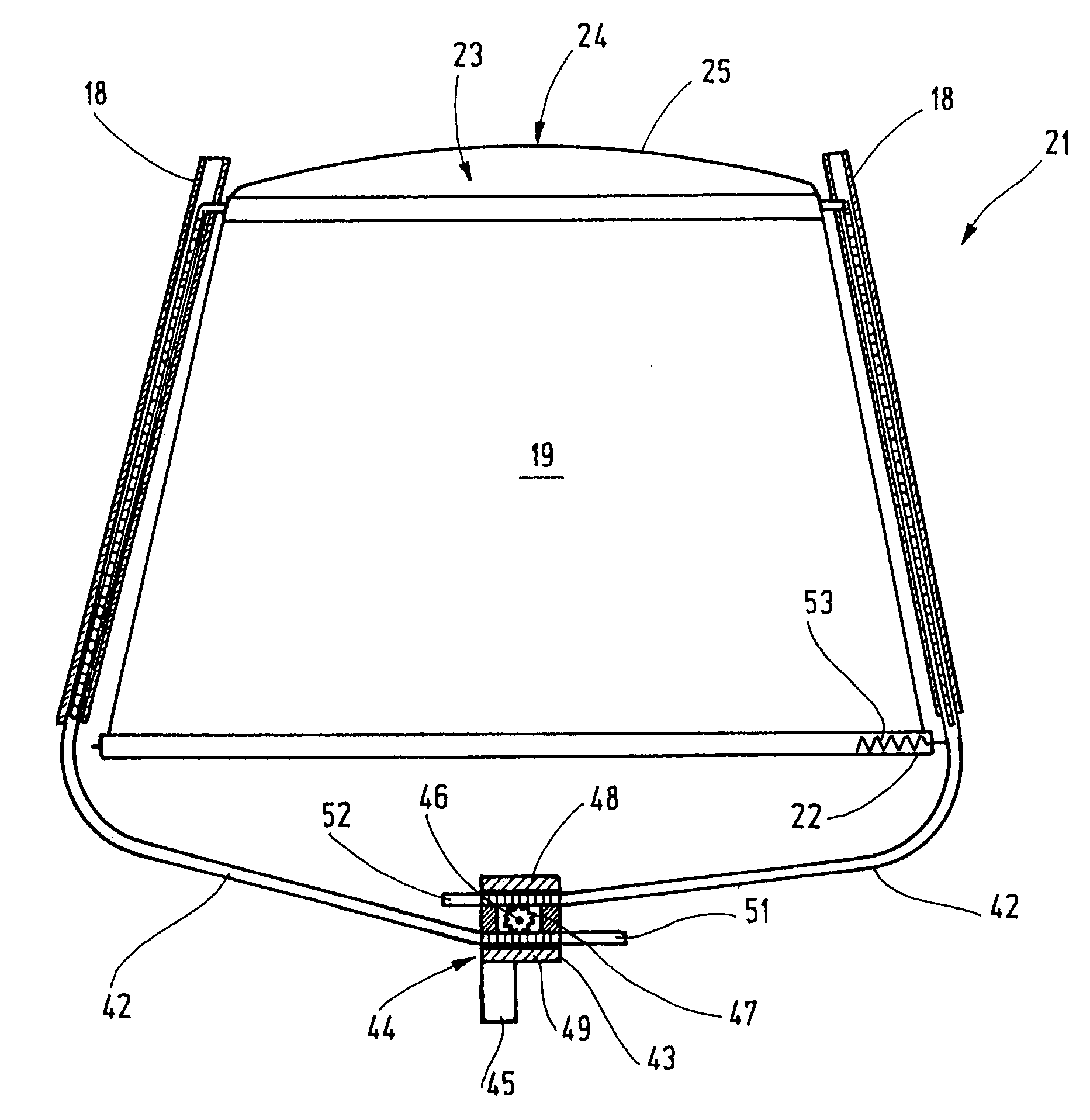

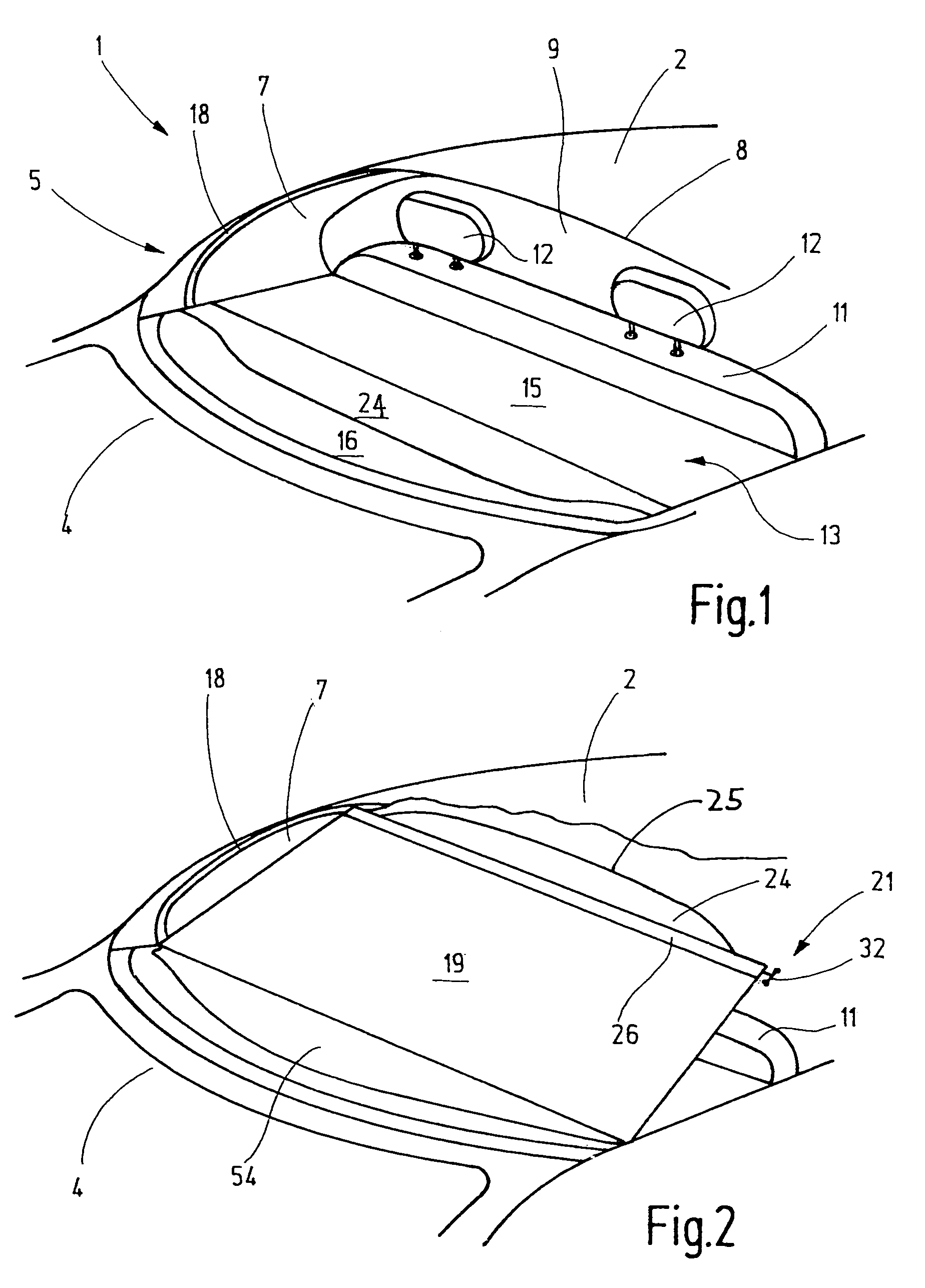

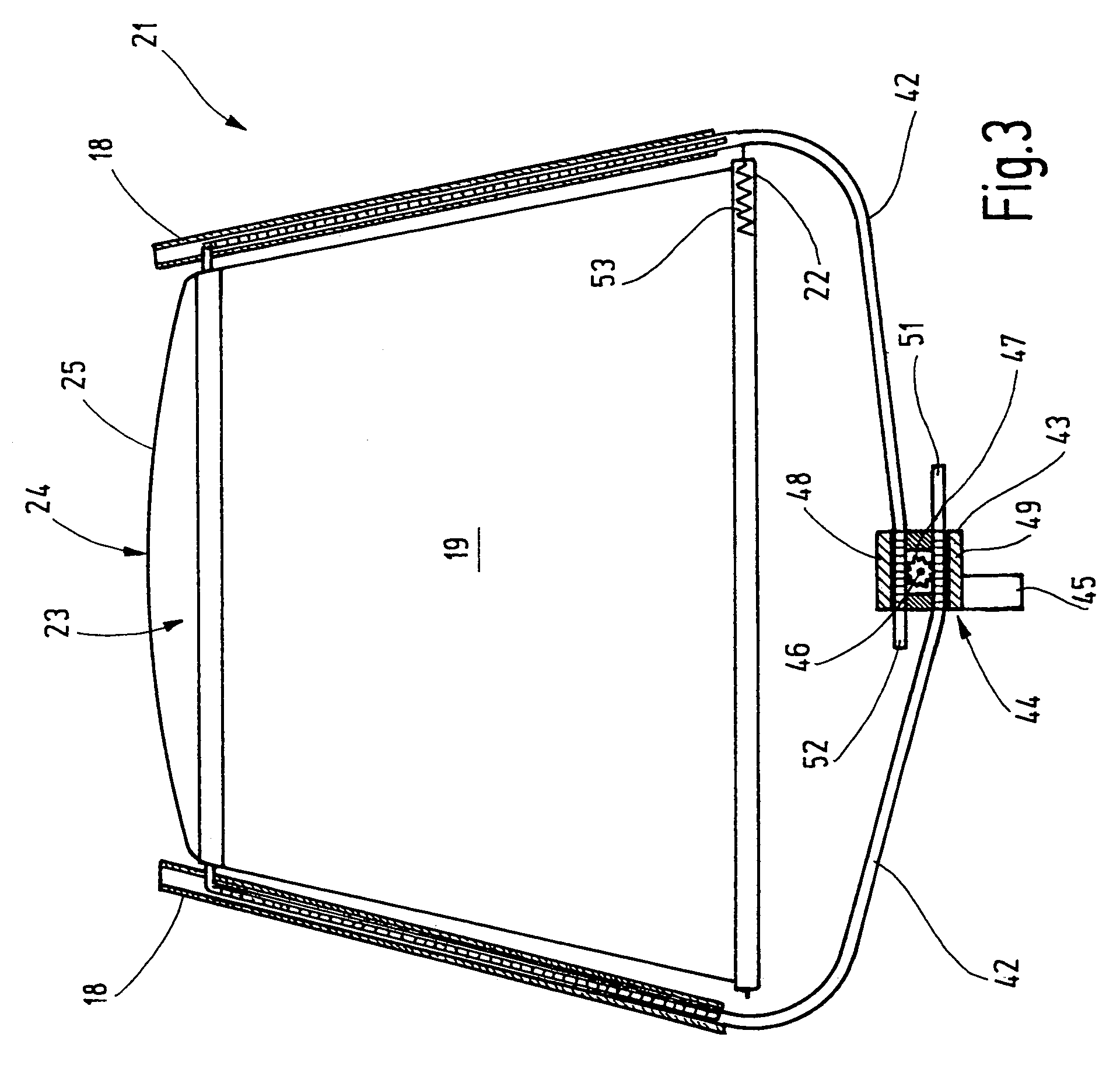

Rear-window roller blind without residual open gap

A rear window roller blind for motor vehicles which has a pull rod assembly with a contoured plate. The contoured plate is used to close the segmented residual gap between the straight pull rod assembly and the curved top edge of the rear window. In order for the contoured plate to lie flush with a rear shelf below the rear window when the roller blind is in a retracted position, it is pivotable about a longitudinal axis of the pull rod assembly during movement of the pull rod between its retracted and extended positions. Such rotational movement is controlled by the contour of guide rails within which the pull rod is guided during such pull out movement.

Owner:BOS

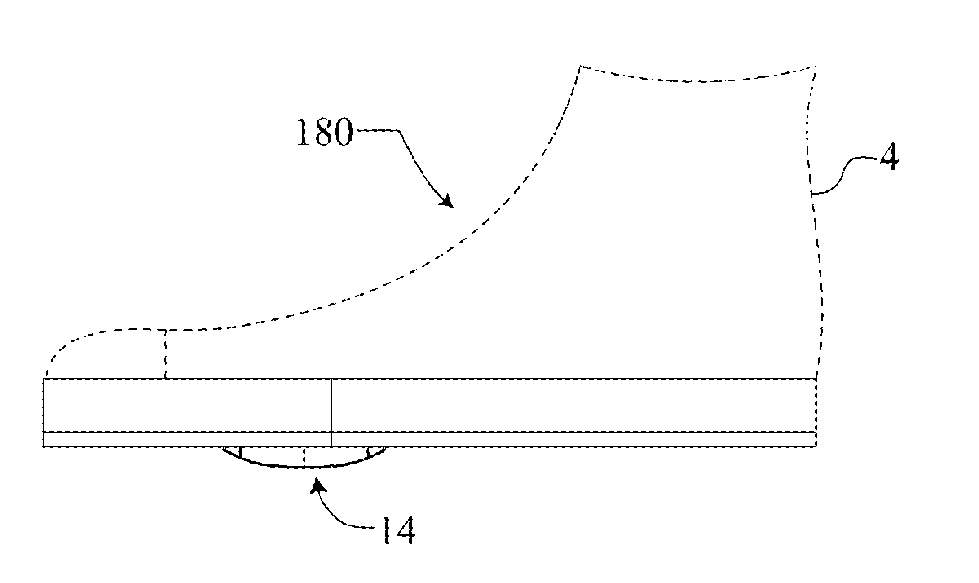

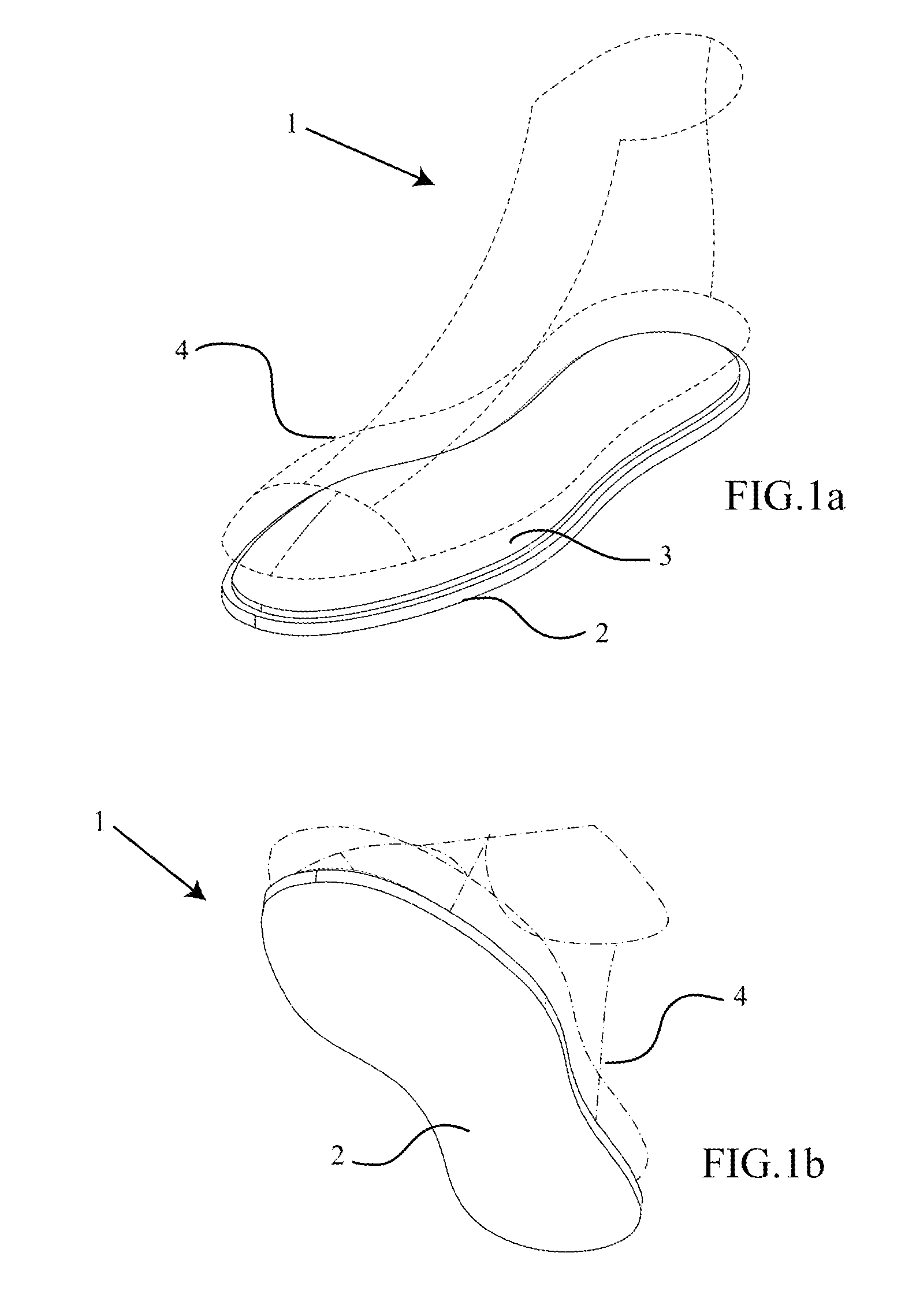

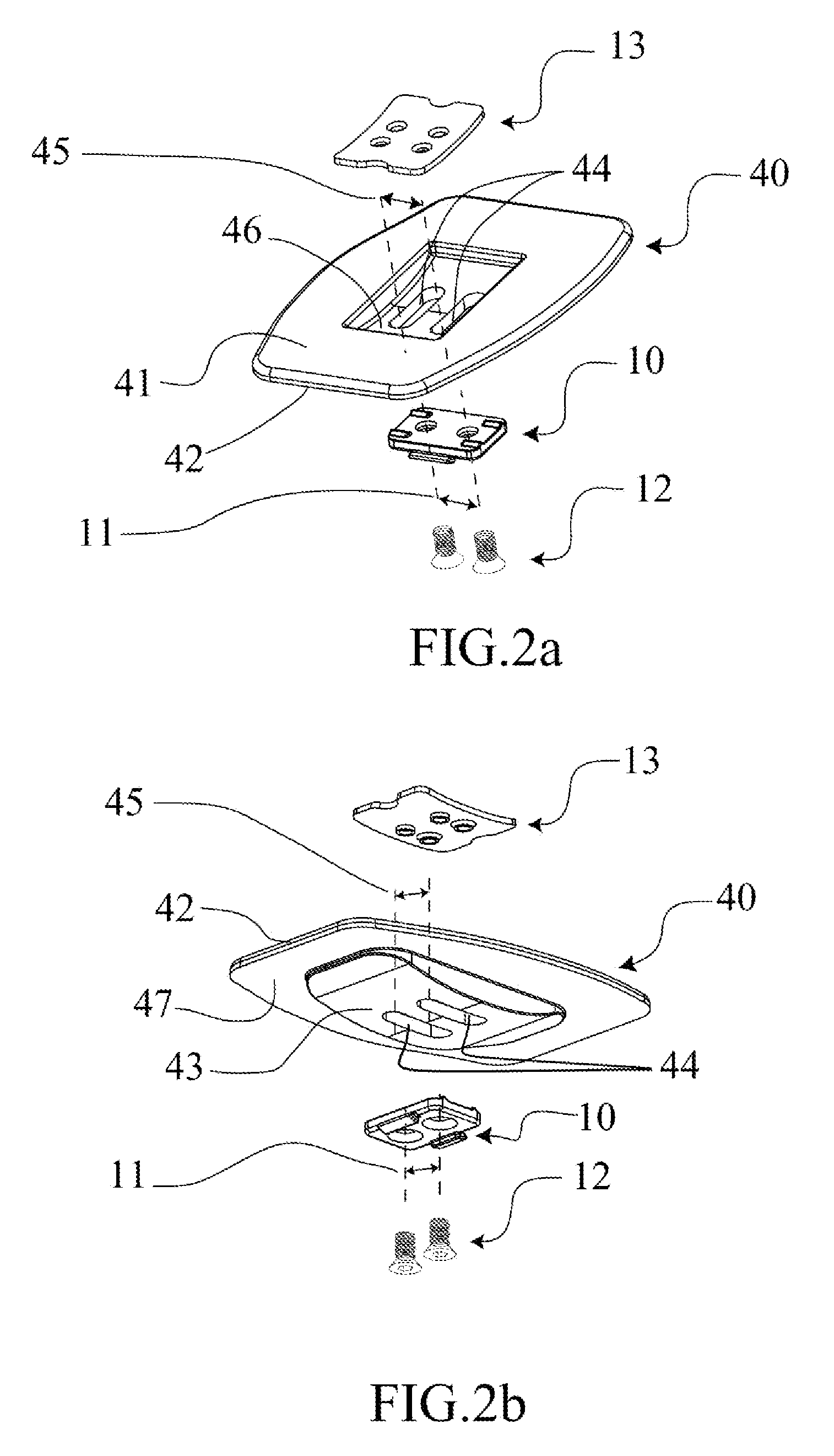

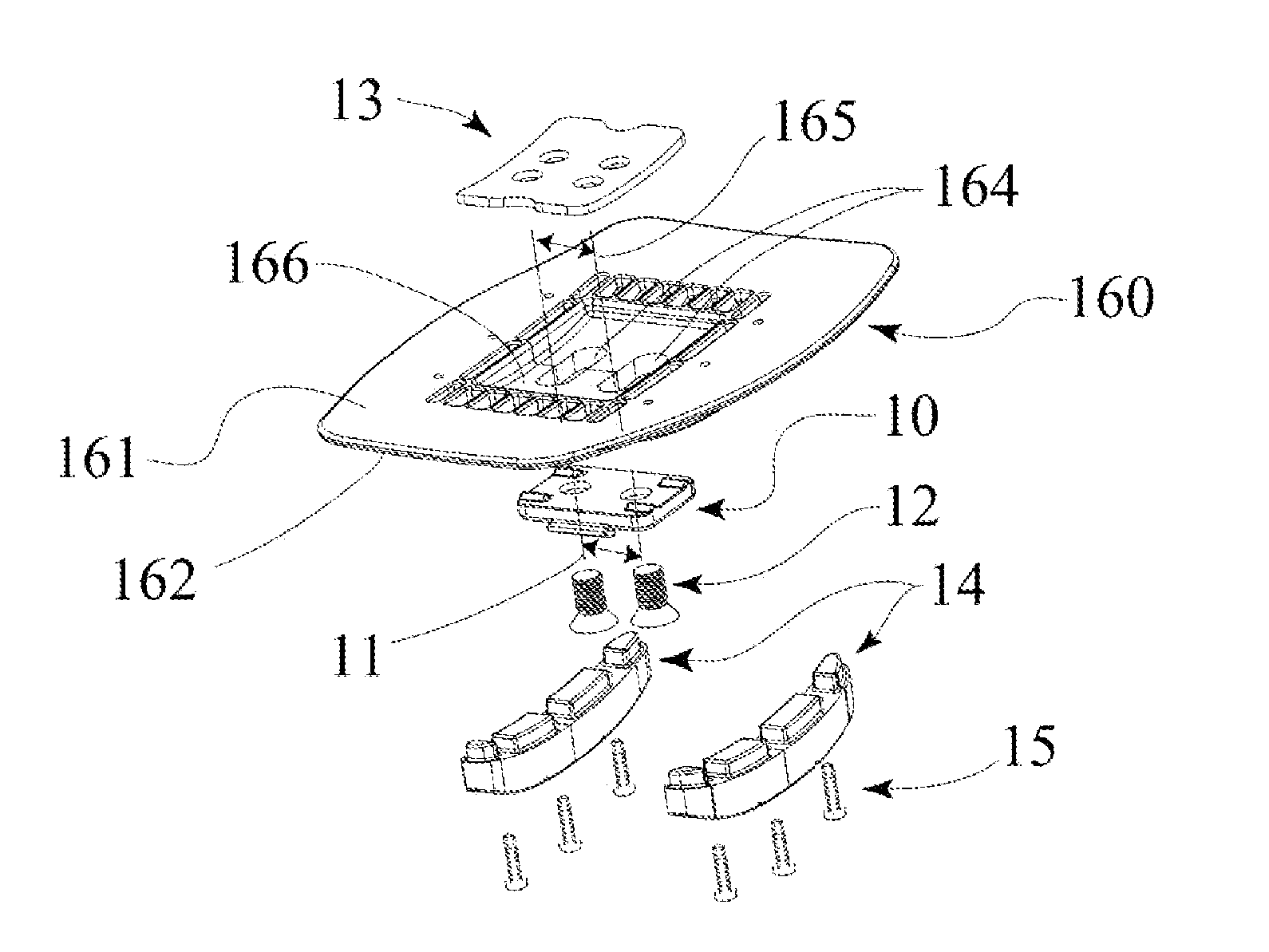

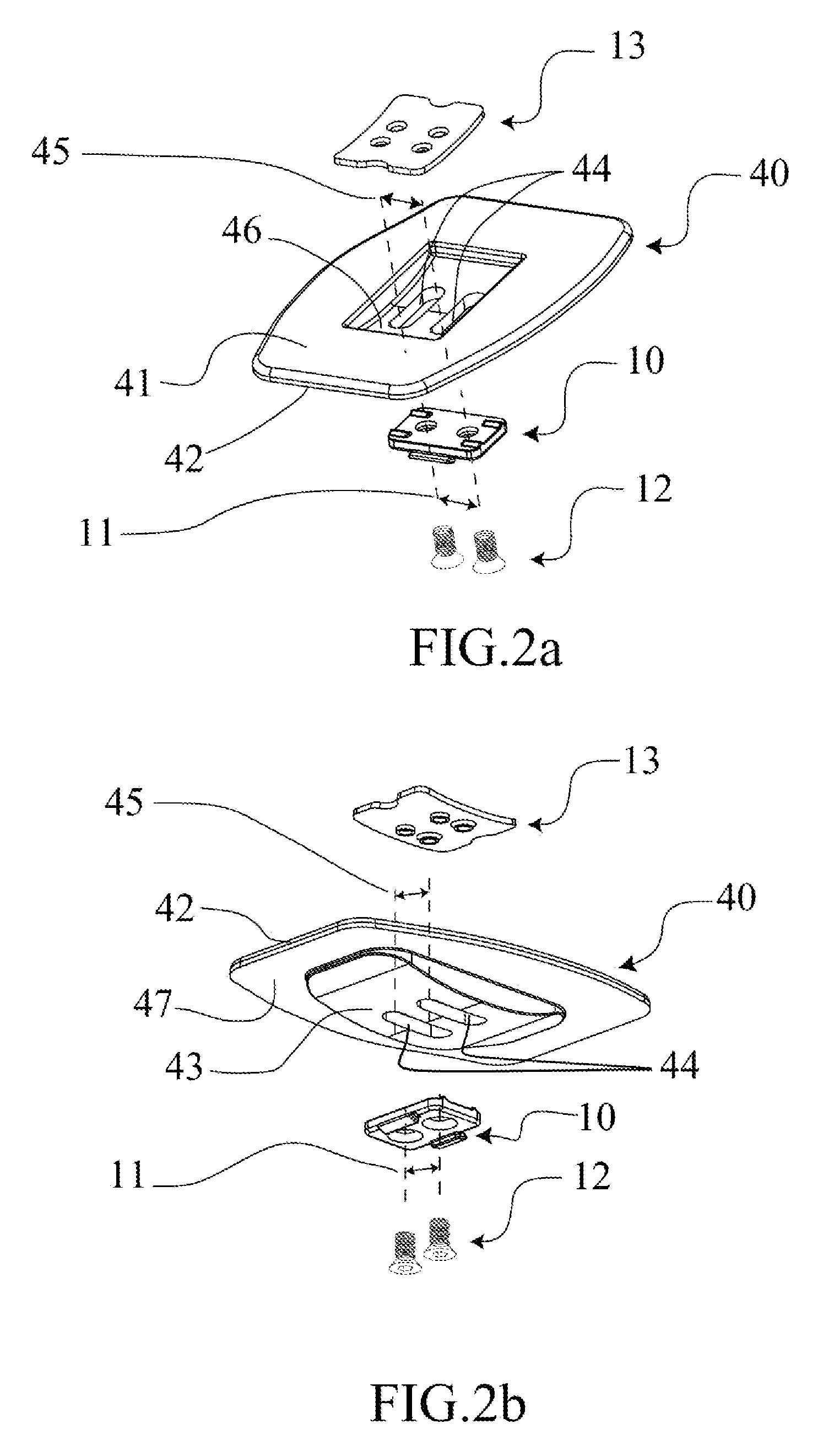

Device for adapting a shoe to attach a cycling cleat

A kit and a method which is used to convert a non-cycling shoe into a cycling shoe which is capable of attaching a cycling cleat. The kit includes a device, fasteners, a template and instructions. The device is a contoured plate which has the appropriate geometry and holes to attach an SPD type cycling cleat. The device may possess ground contact preventing members on the bottom surface to prevent the cycling cleat from contacting the ground while the shoe is used for walking. The template is used to confirm and mark the ideal location for the holes that must be cut thru the shoe sole to accommodate the cleat attachment area and fasteners for the device.

Owner:TEWS ERIK HENRY

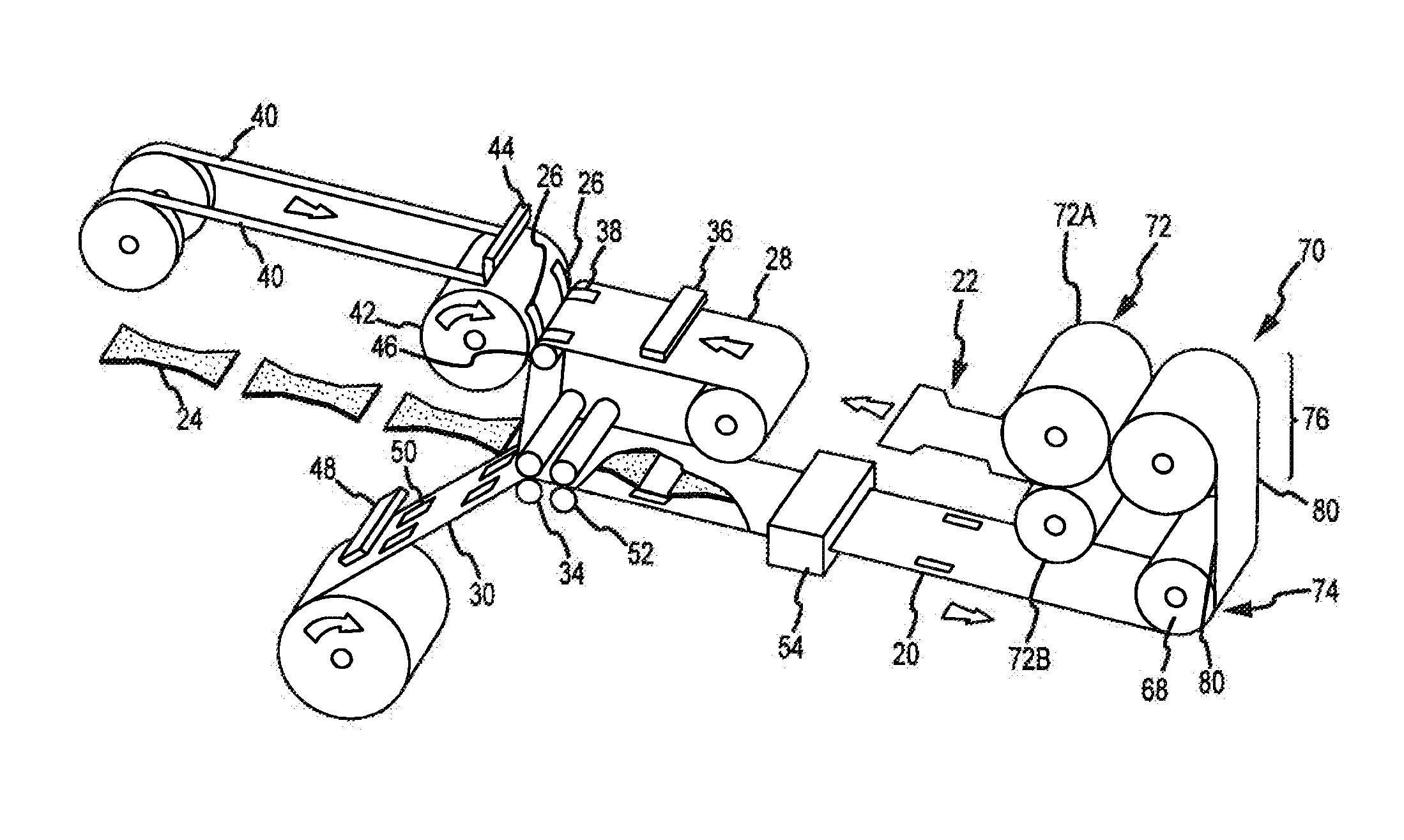

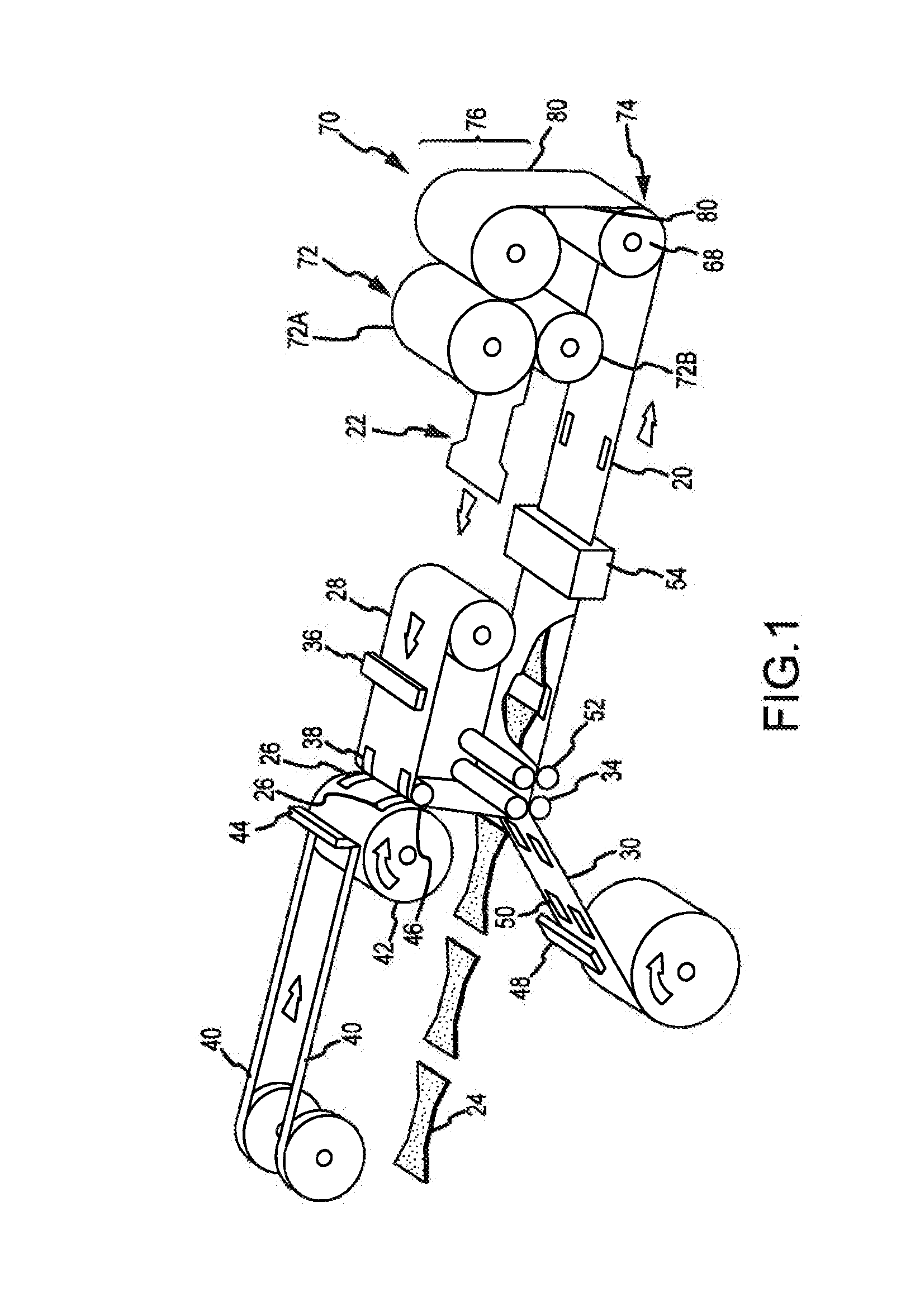

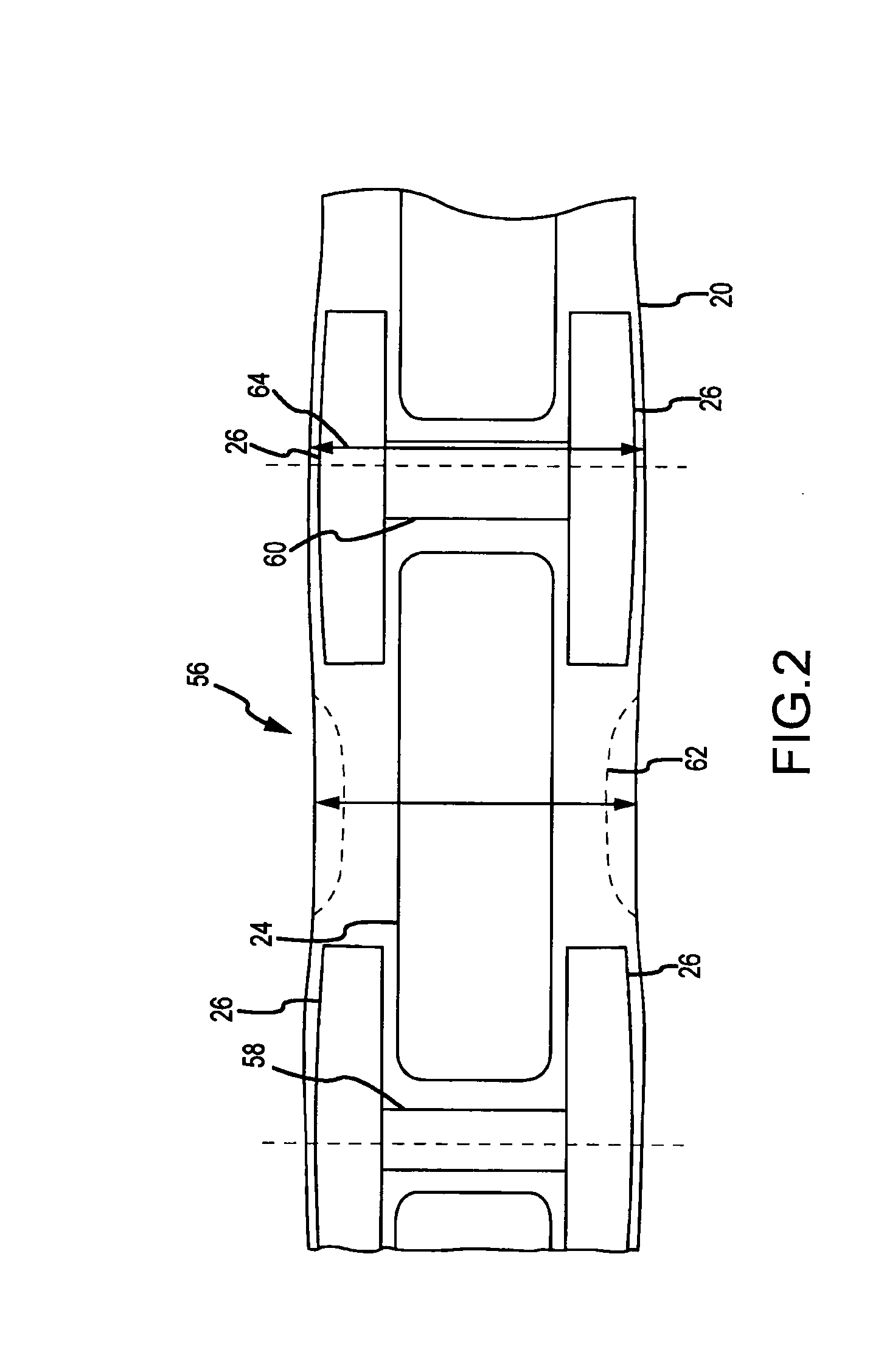

Apparatus And Method For Centering And Spreading A Web

A web centering and spreading processing system and related method are used to center a moving web and then spread the web in order to remove wrinkles from the web. The centering mechanism, in one example, has a centering roller that receives the wrinkles web. The outer edges of the web, which tend to be uneven and not centered, are detected and a signal is sent to the centering roller to move the web laterally and thereby center the web. The centered web, which is substantially centered but not necessarily precisely centered, moves to a spreader station that receives the web and spreads it thereby removing any wrinkles in the web. The spreader station may include a roller with a recessed center area and that has at least one set of contoured plates that move across the roller from an inner position to an outer position. The plates have gripping surfaces that grip the edges of the web and spread the web to remove the wrinkles. The plates also have an inner smooth area that, in conjunction with the recessed area, allow the inner area of the web to essentially float and thereby be spread to remove the wrinkles without binding.

Owner:THE PROCTER & GAMBLE COMPANY

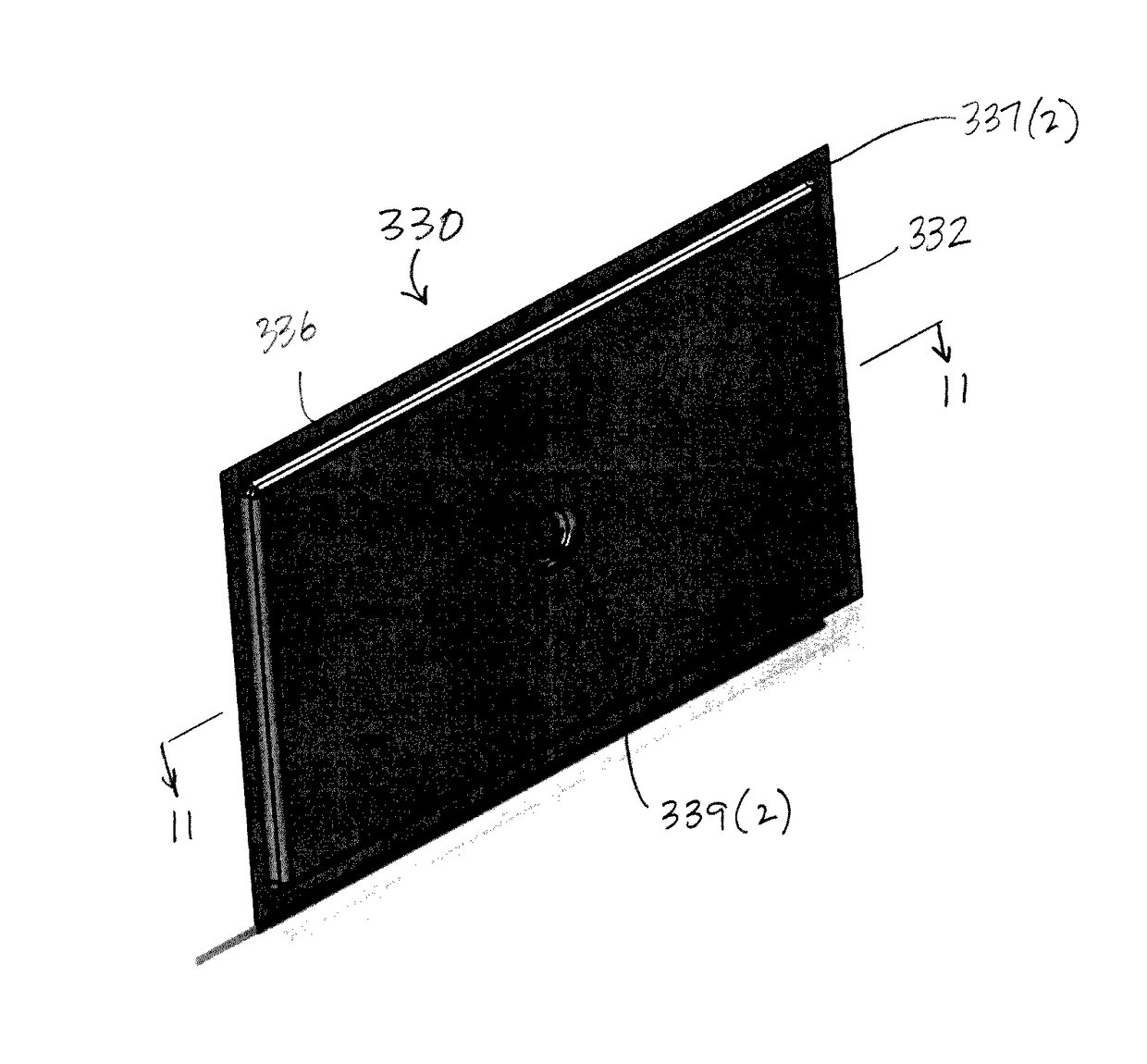

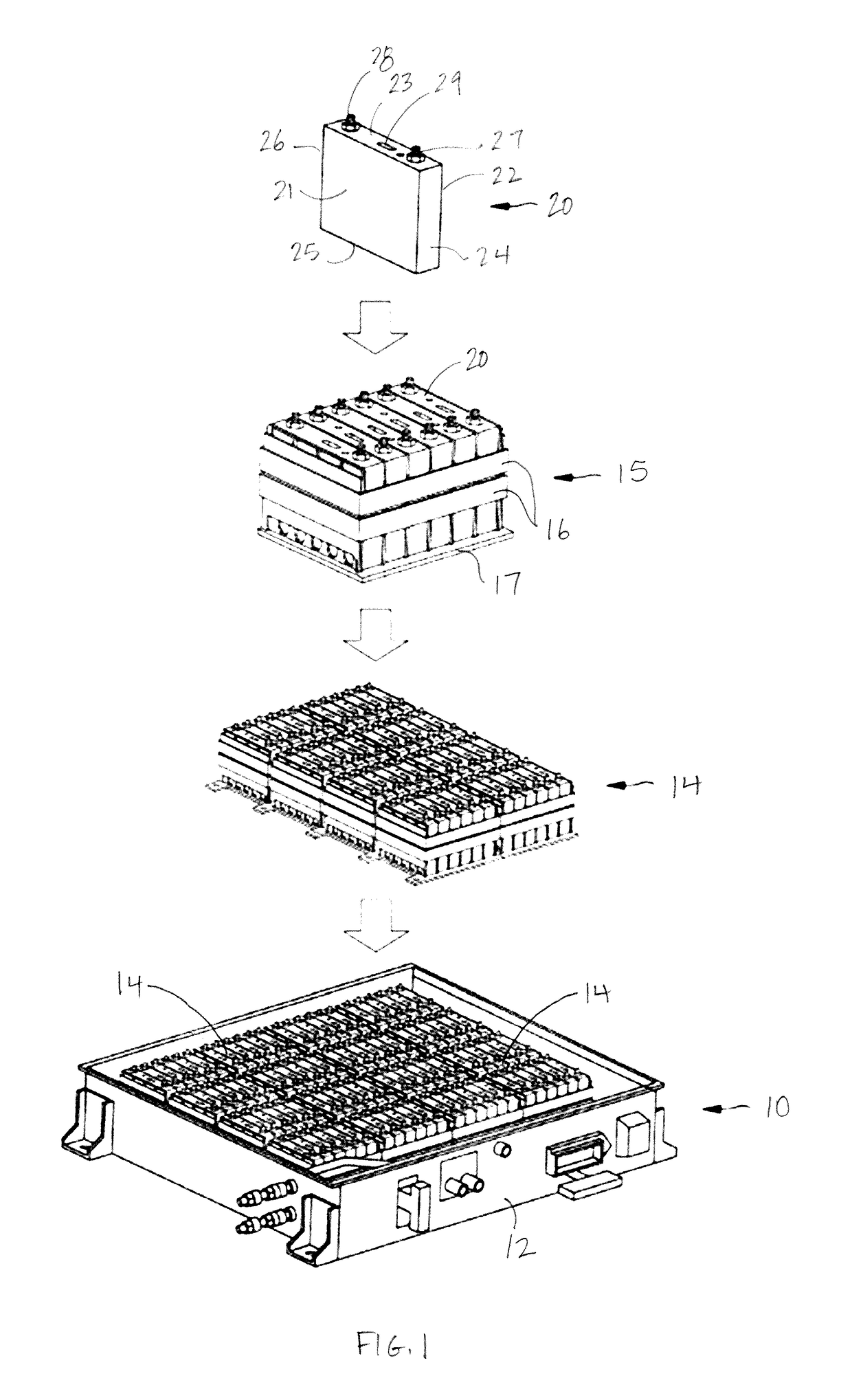

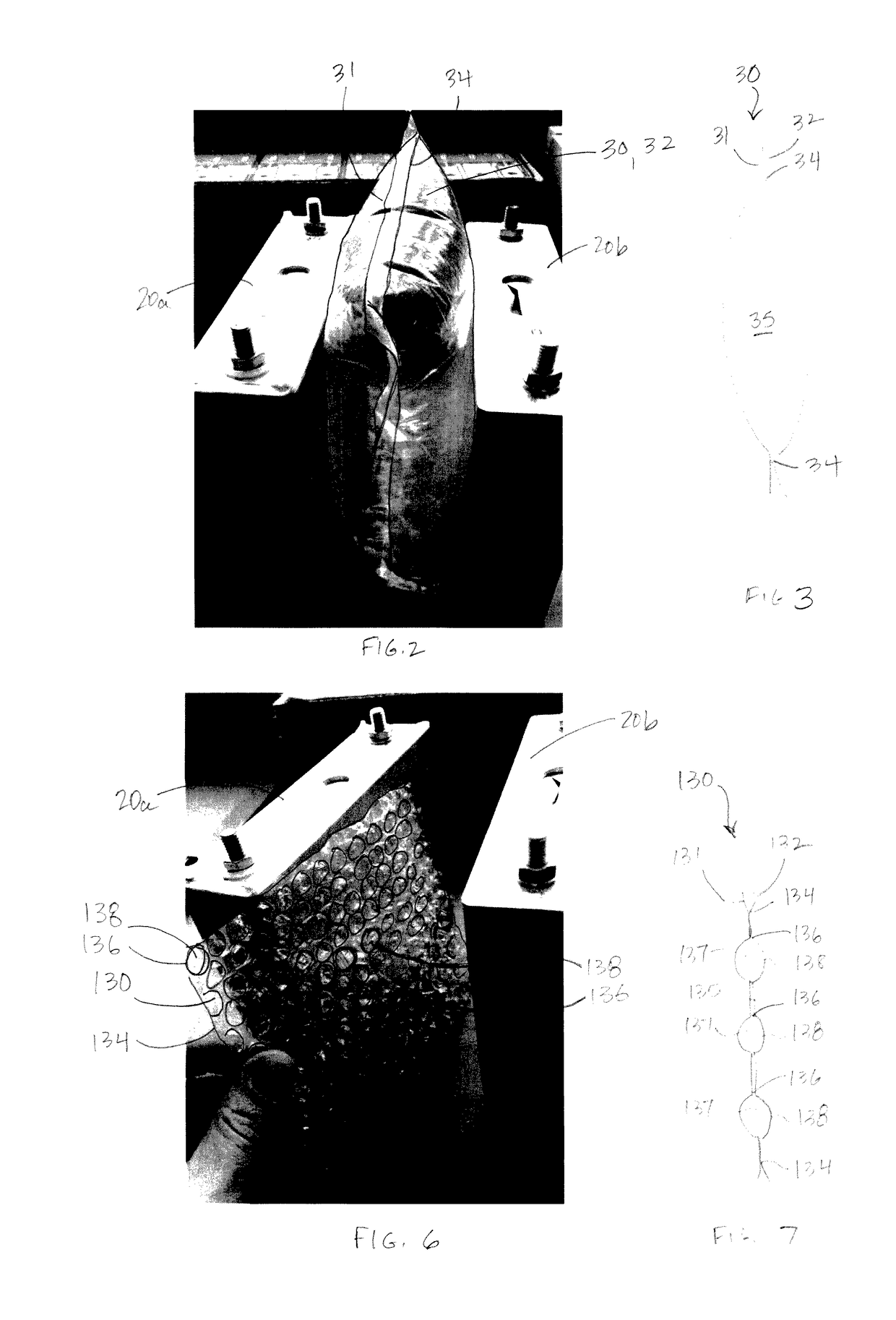

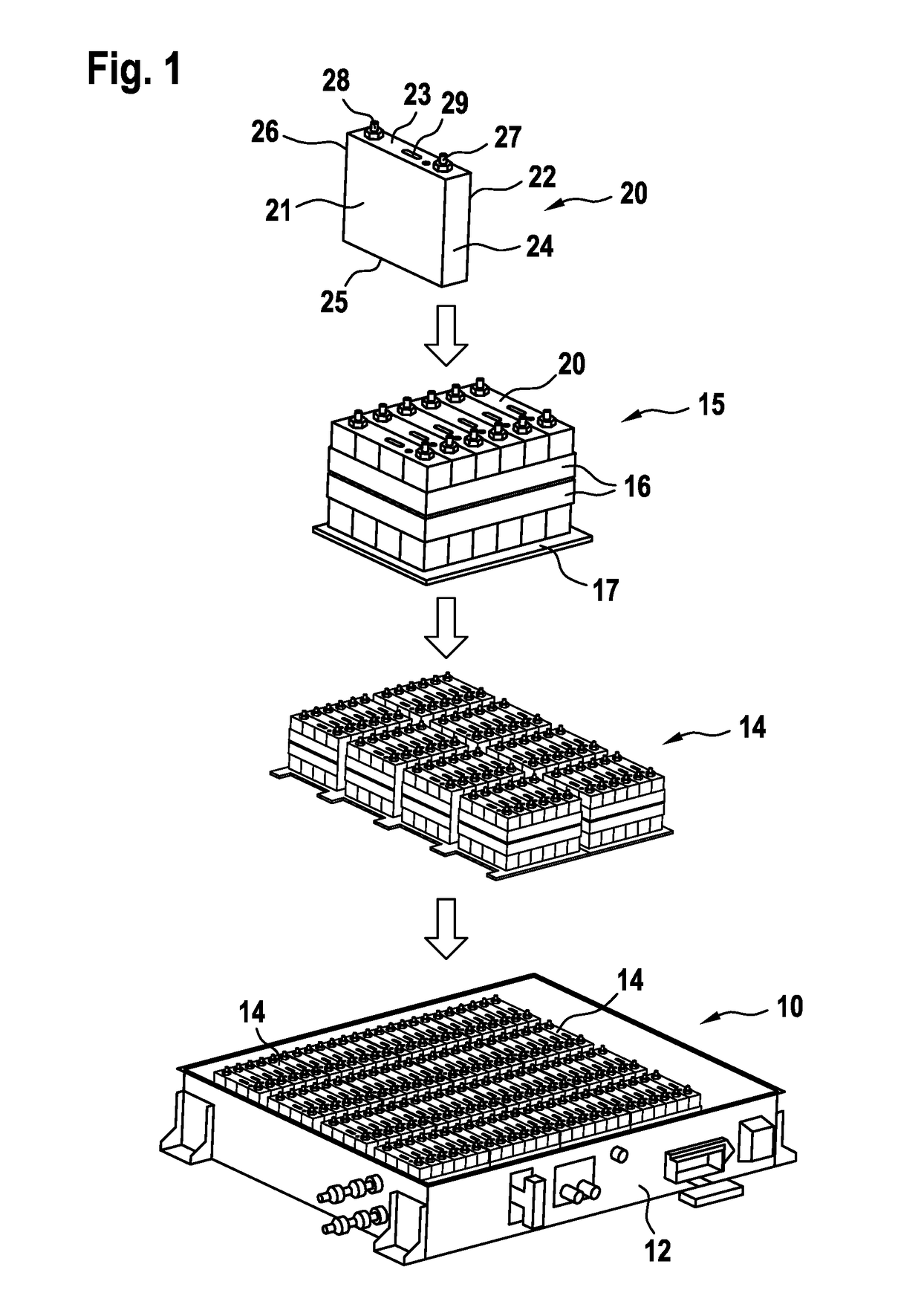

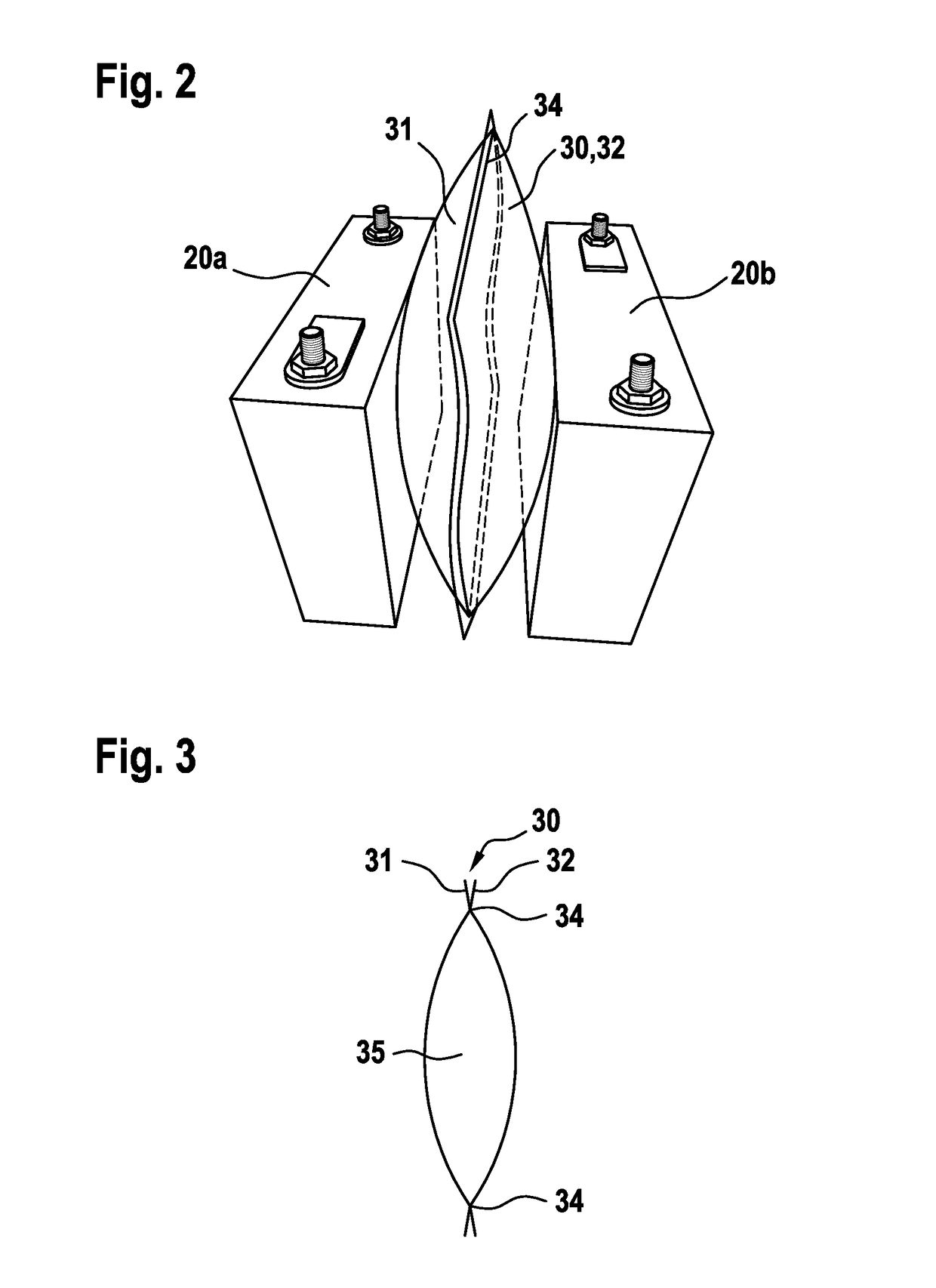

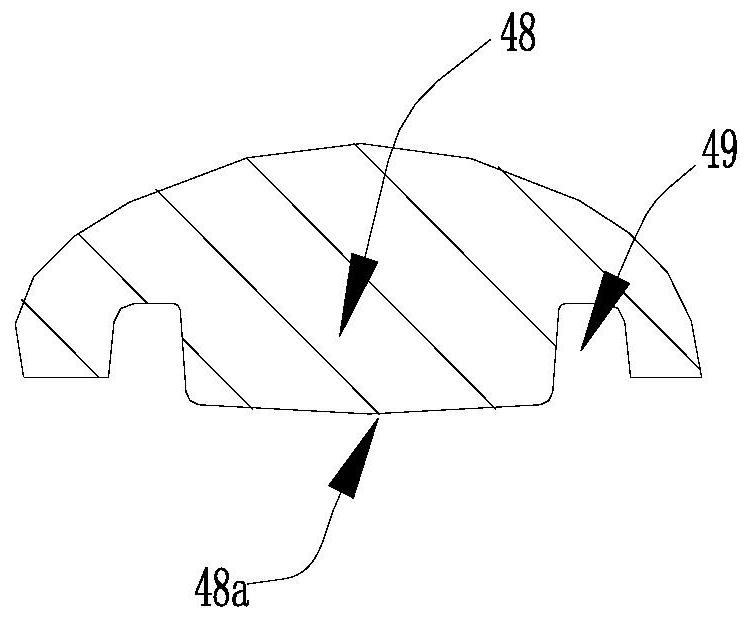

Elastic bellows and battery cell assemblies including same

ActiveUS20170098868A1Low costMaximizing lifetime of battery cellFinal product manufactureSynthetic resin layered productsElectrochemical cellContoured plate

A battery pack includes a battery housing and electrochemical cells disposed in the battery housing in a stacked configuration. Elastic members are disposed between adjacent cells of a cell stack. Each elastic member is a bladder that is formed of a pair of contoured plate portions stacked in a mirrored arrangement, whereby the plate portions cooperate to form a bellows-type compression spring. The elastic members provide a predetermined compression force to each cell while accommodating cell growth during use. The elastic members may include surface features such as strategically shaped and / or located protrusions that are configured to permit compliance and can be tuned to address the requirements of a specific application and permit application of varying stiffness characteristics across a surface of a cell.

Owner:BOSCH BATTERY SYST +1

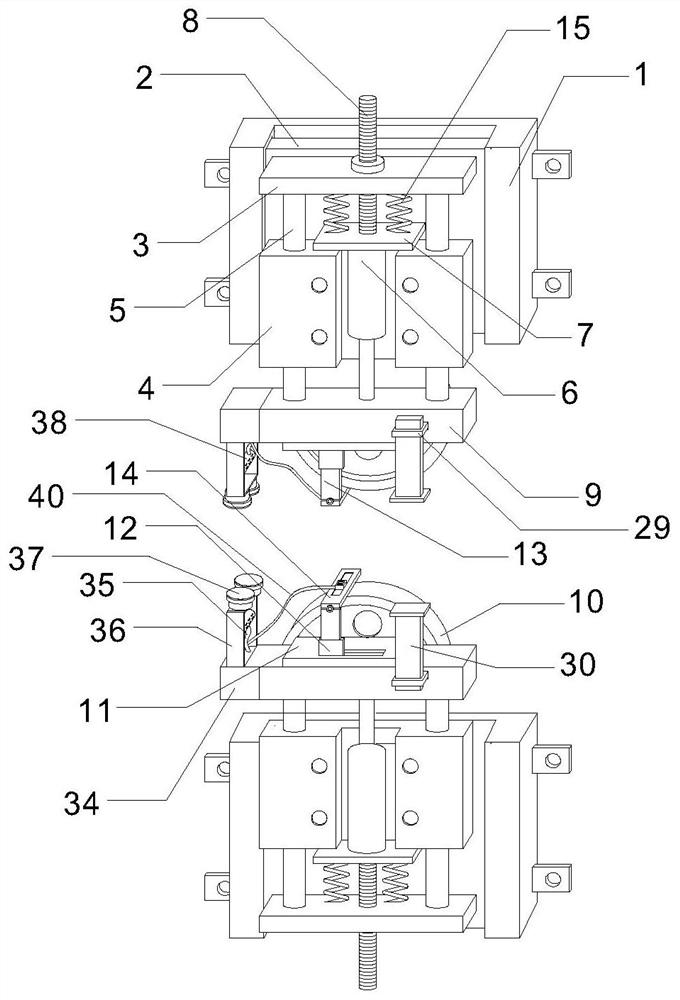

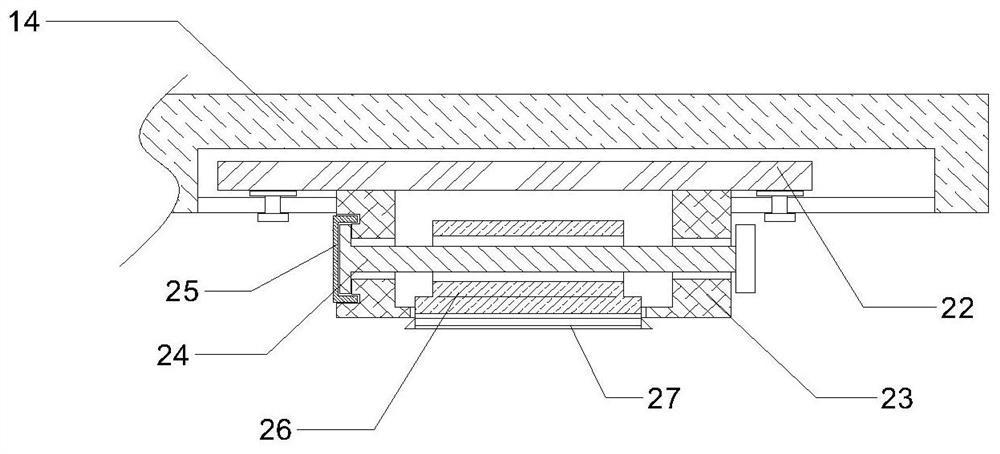

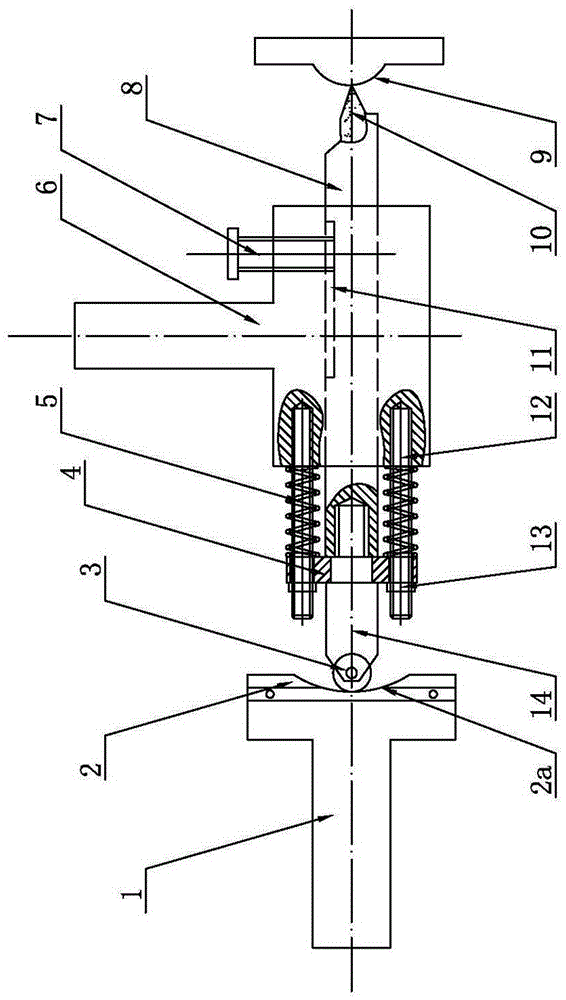

Flat edge scraping mechanism for edge bonding machine and using method of flat edge scraping mechanism

InactiveCN113043396AAvoid offsetGuaranteed contactCleaning using toolsGrinding machinesCircular discEngineering

The invention discloses a flat edge scraping mechanism for an edge bonding machine and a using method of the flat edge scraping mechanism. The flat edge scraping mechanism comprises an upper edge scraping unit and a lower edge scraping unit, wherein the upper edge scraping unit and the lower edge scraping unit are the same in structure and are symmetrically arranged; the upper edge scraping unit comprises a mounting sleeve plate, mounting pieces are fixedly connected to the two sides of the mounting sleeve plate, a mounting groove is formed in the middle of the mounting sleeve plate, clamping grooves are formed in the two sides of the inner wall of the mounting groove, a mounting seat plate is connected to the middle of the inner wall of the mounting groove in a sliding mode, and clamping blocks are fixedly connected to the two ends of the mounting seat plate. According to the flat edge scraping mechanism for the edge bonding machine and the using method of the flat edge scraping mechanism, a buffer attaching spring is arranged, thus, when a special-shaped plate with radian is conveyed and moved, the buffer attaching spring can drive an abutting disc and the like to do up-and-down fluctuation motion along with the radian of the special-shaped plate, the contact between the abutting disc as well as an edge scraping blade and the plate is guaranteed, and the device has the flat edge scraping capability on the special-shaped bent plate.

Owner:淮北市米之悦门业有限公司

Device for adapting a shoe to attach a cycling cleat

A kit and a method which is used to convert a non-cycling shoe into a cycling shoe which is capable of attaching a cycling cleat. The kit includes a device, fasteners, a template and instructions. The device is a contoured plate which has the appropriate geometry and holes to attach an SPD type cycling cleat. The device may possess ground contact preventing members on the bottom surface to prevent the cycling cleat from contacting the ground while the shoe is used for walking. The template is used to confirm and mark the ideal location for the holes that must be cut thru the shoe sole to accommodate the cleat attachment area and fasteners for the device.

Owner:TEWS ERIK HENRY

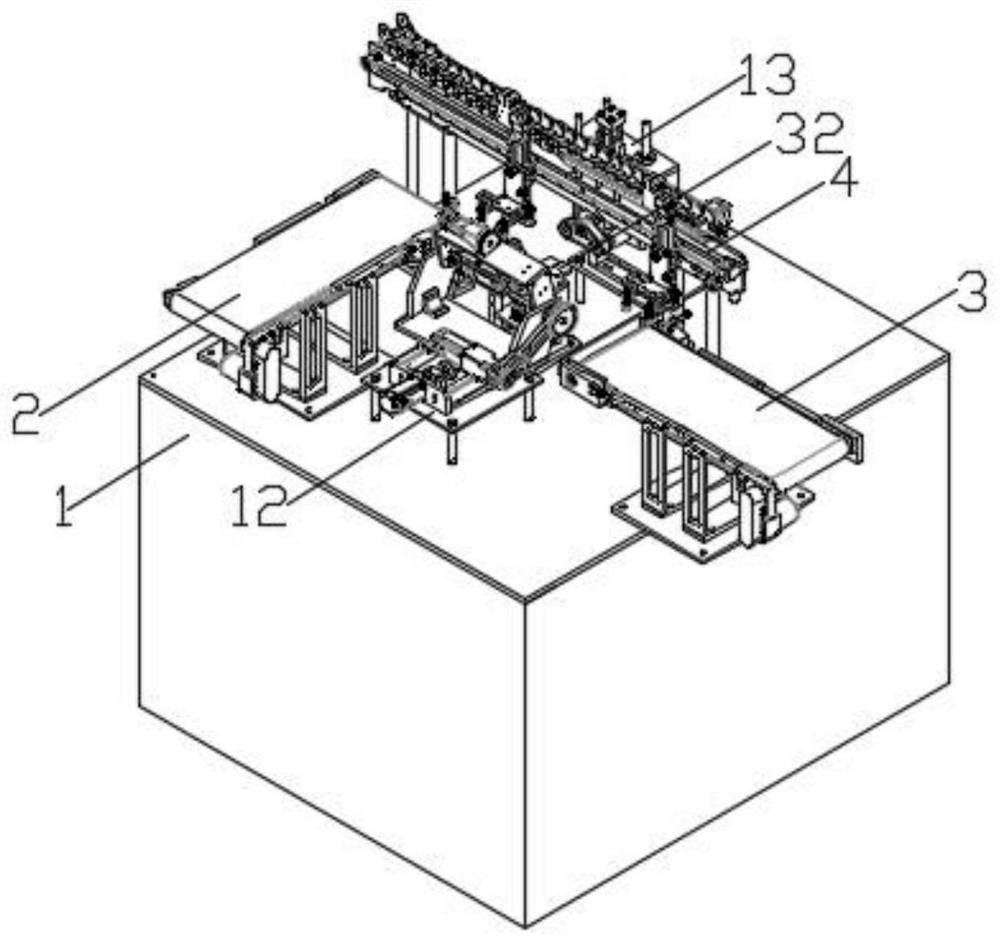

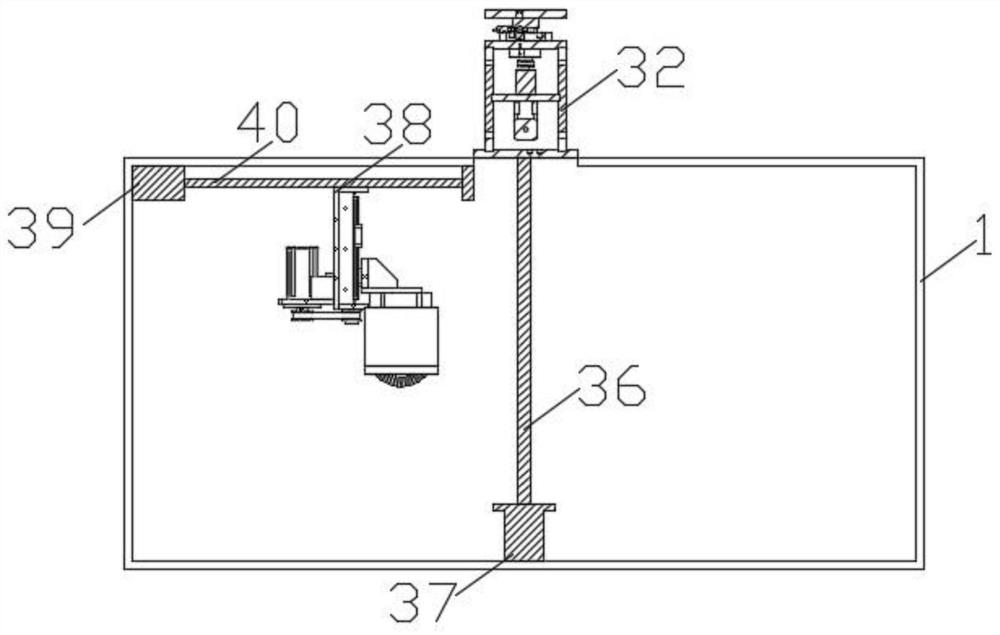

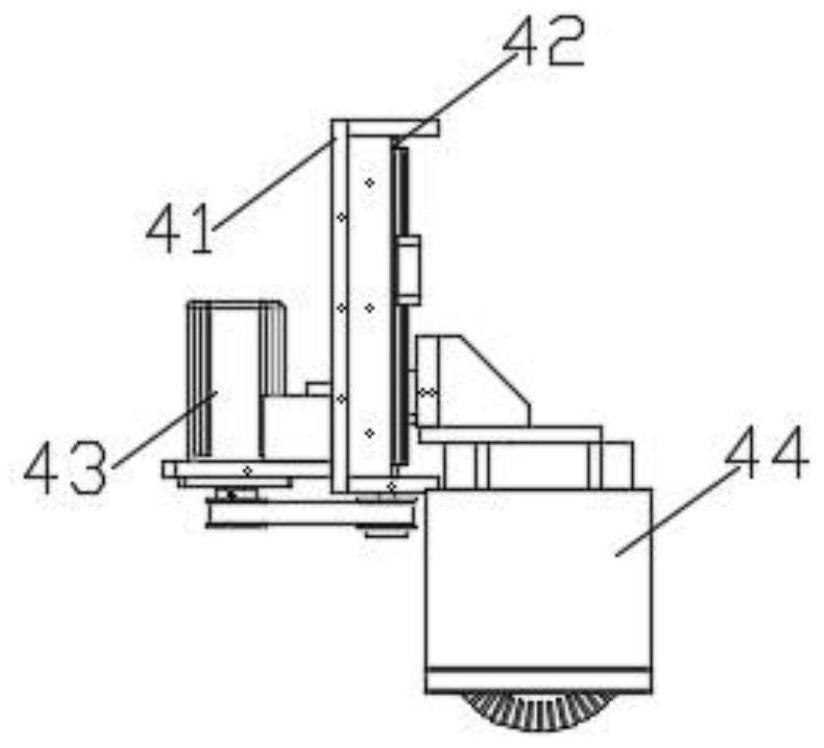

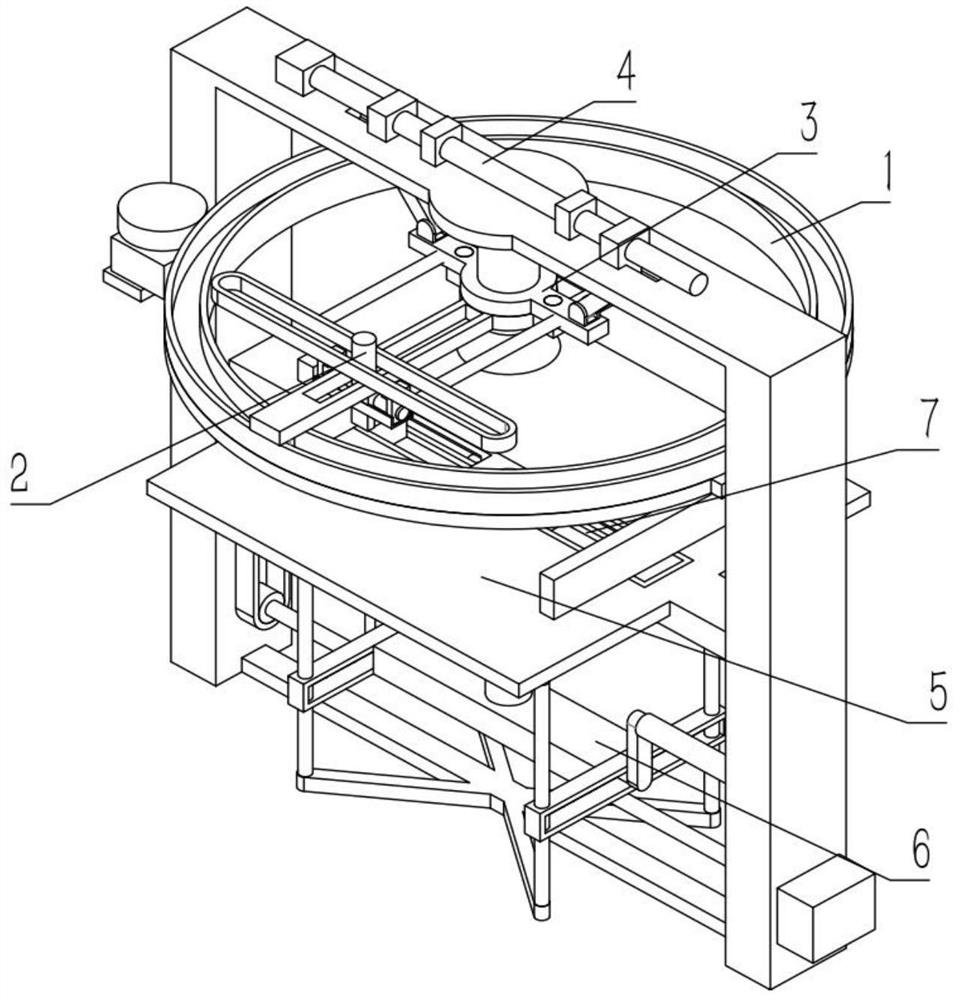

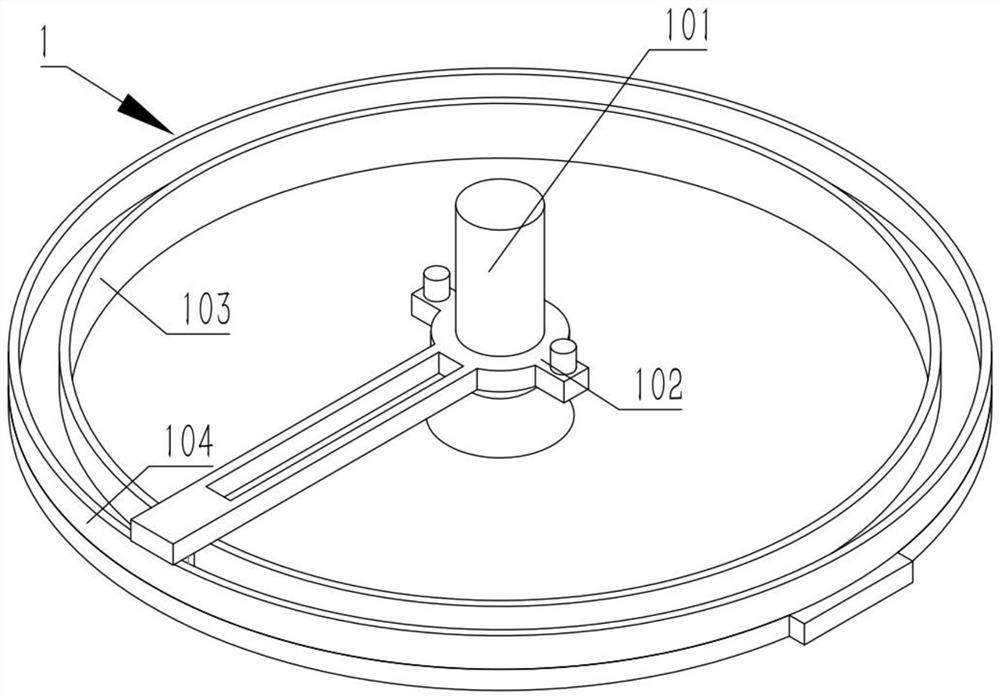

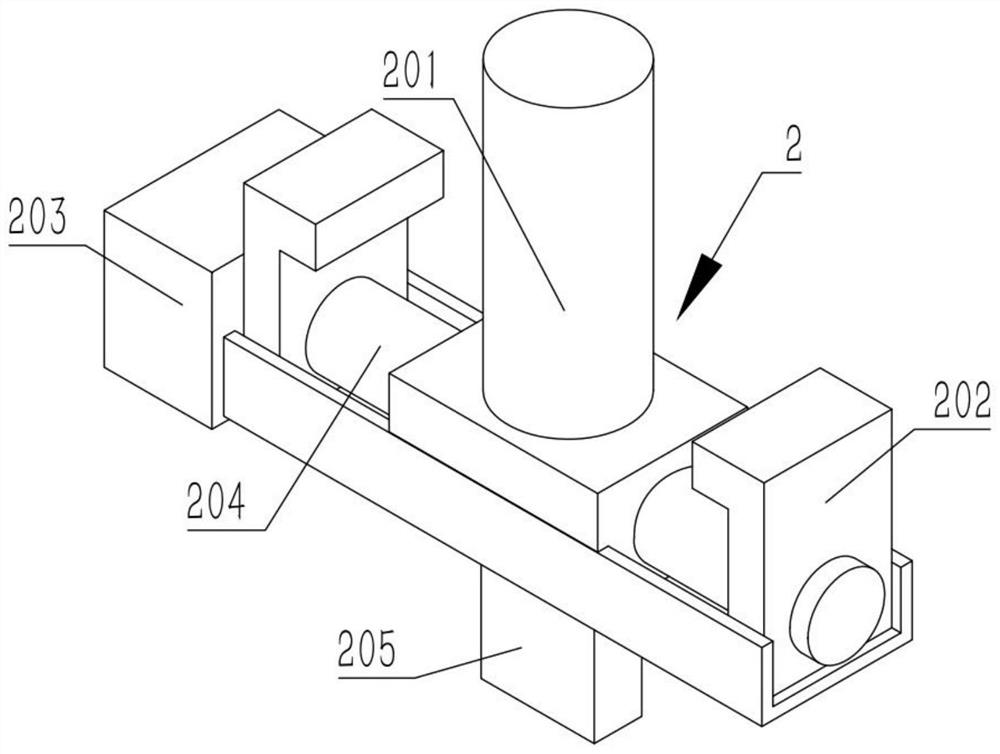

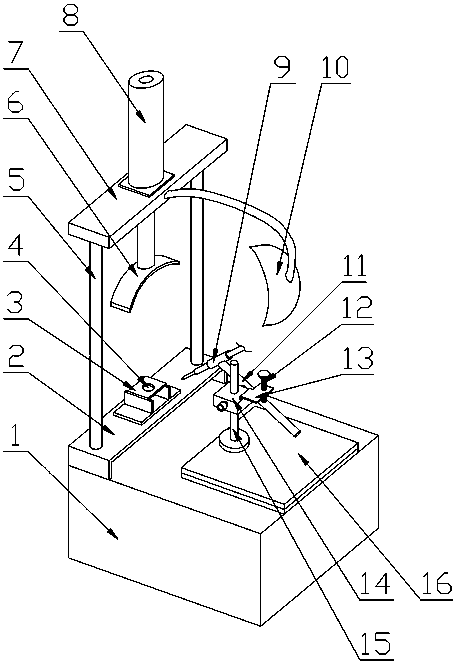

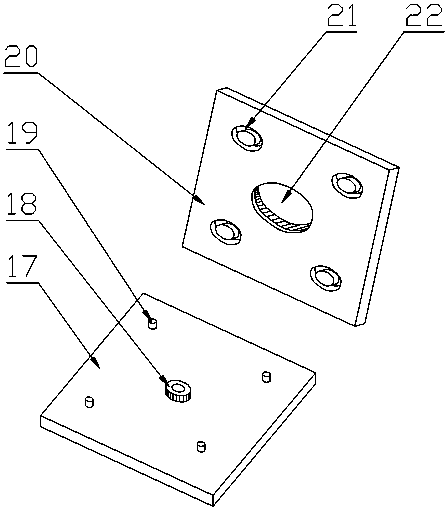

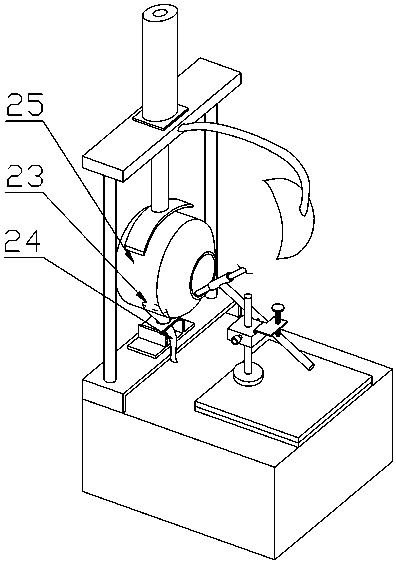

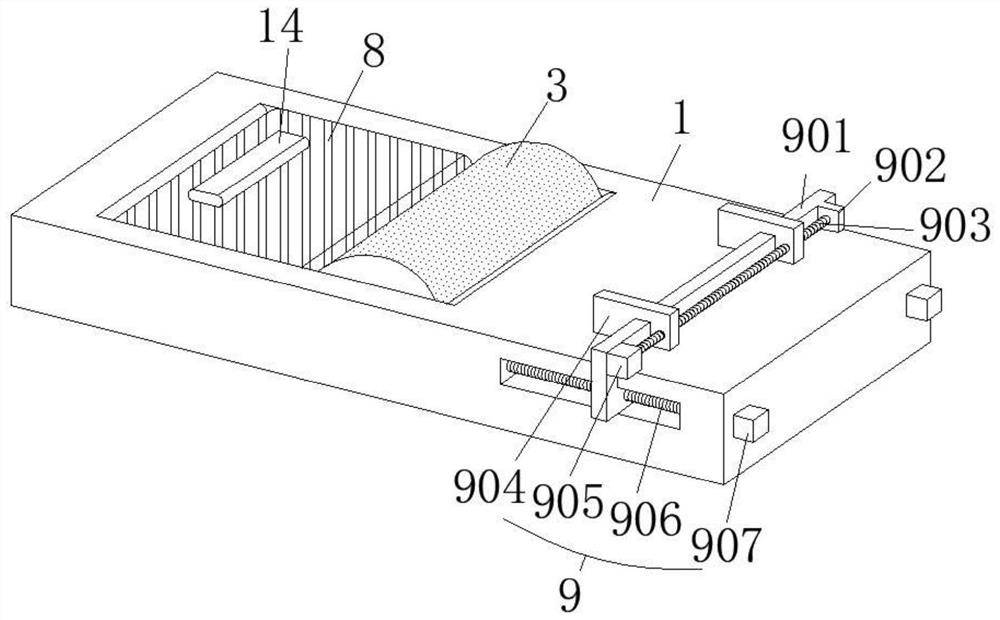

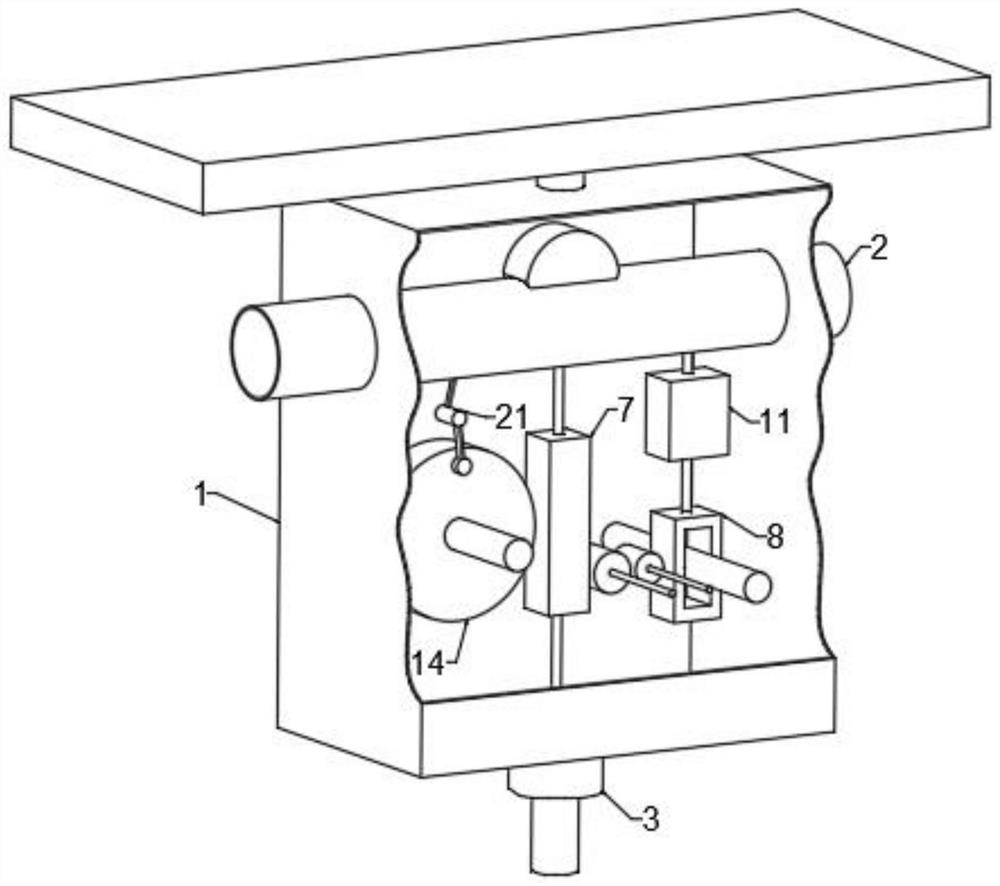

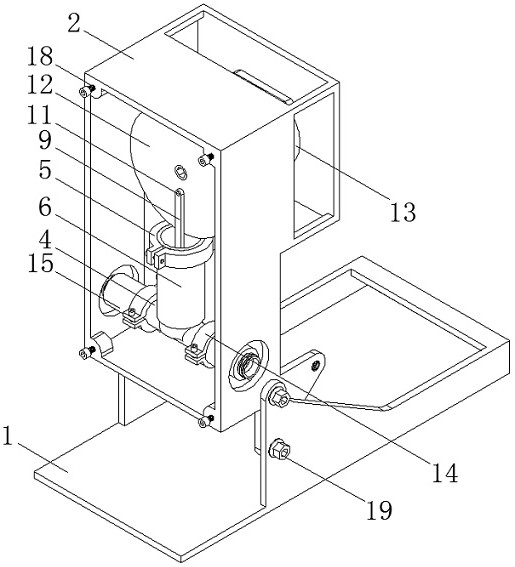

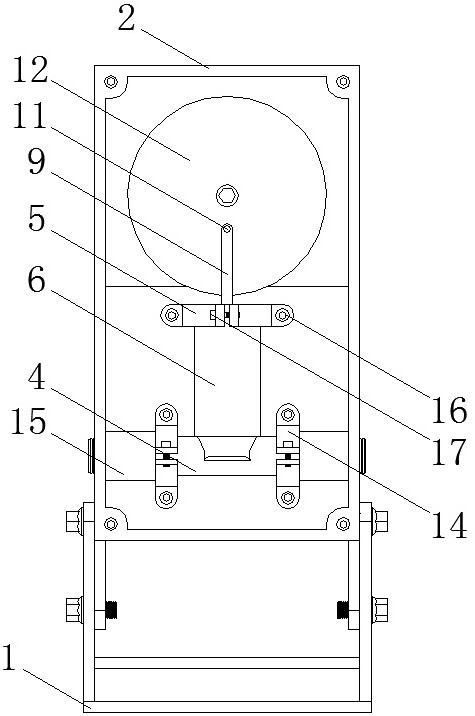

Automatic polishing facility for abnormally-shaped plate machining and working method of automatic polishing facility

InactiveCN112008558AImprove polishing efficiencyReduce wasteGrinding carriagesBelt grinding machinesPolishingEngineering

The invention discloses an automatic polishing facility for abnormally-shaped plate machining and a working method of the automatic polishing facility. According to the polishing facility, a surface polishing mechanism and a side face polishing mechanism are arranged on the two sides of a rotating mechanism, and therefore the polishing efficiency of an abnormally-shaped plate is higher; the abnormally-shaped plate does not need to be moved in the process of polishing the surface and the side face, and therefore the time wasted by movement of the abnormally-shaped plate is greatly shortened; and the requirement for polishing of the upper surface and the side face of the abnormally-shaped plate can be met. Due to the design of a negative pressure suction disc on a rotary supporting plate, side edge fixing does not need to be conducted when the upper surface of the abnormally-shaped plate is polished, the technical problem that when the side face of a plate is fixed, polishing of the upper surface of the plate can be resisted and affected is solved. Meanwhile, when the side face of the abnormally-shaped plate is polished, the situation that the abnormally-shaped plate cannot be misplaced when the side face of the abnormally-shaped plate is polished is guaranteed through fixing absorption of the top and the bottom of the abnormally-shaped plate, and the facility meets the requirement for polishing of the various abnormally-shaped plates and is high in applicability.

Owner:程晋芹

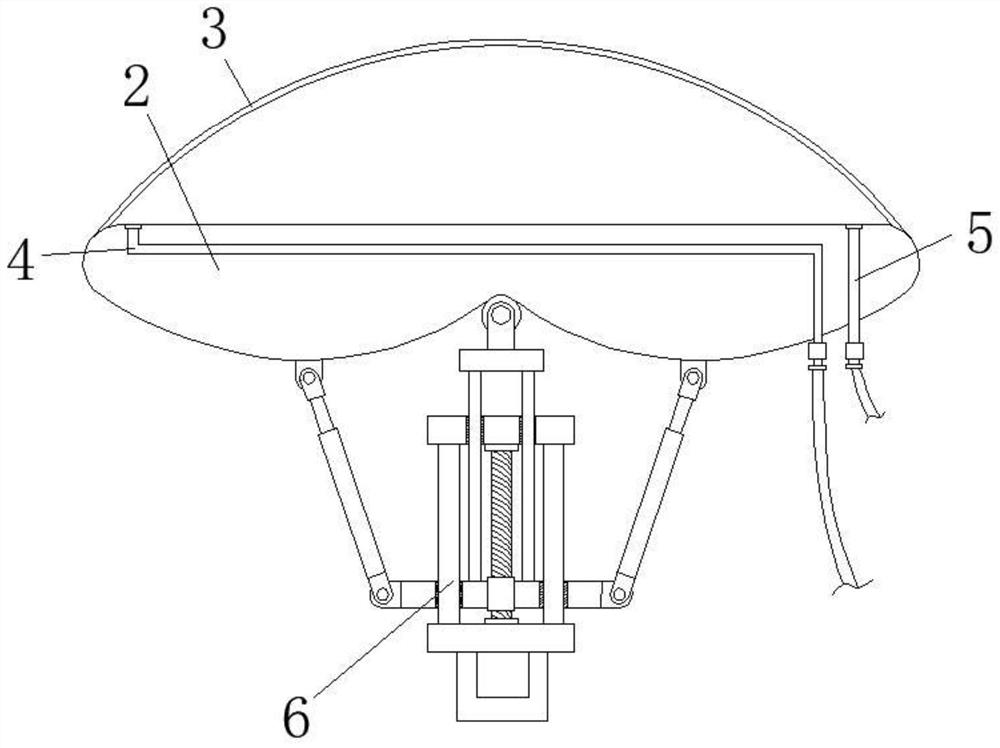

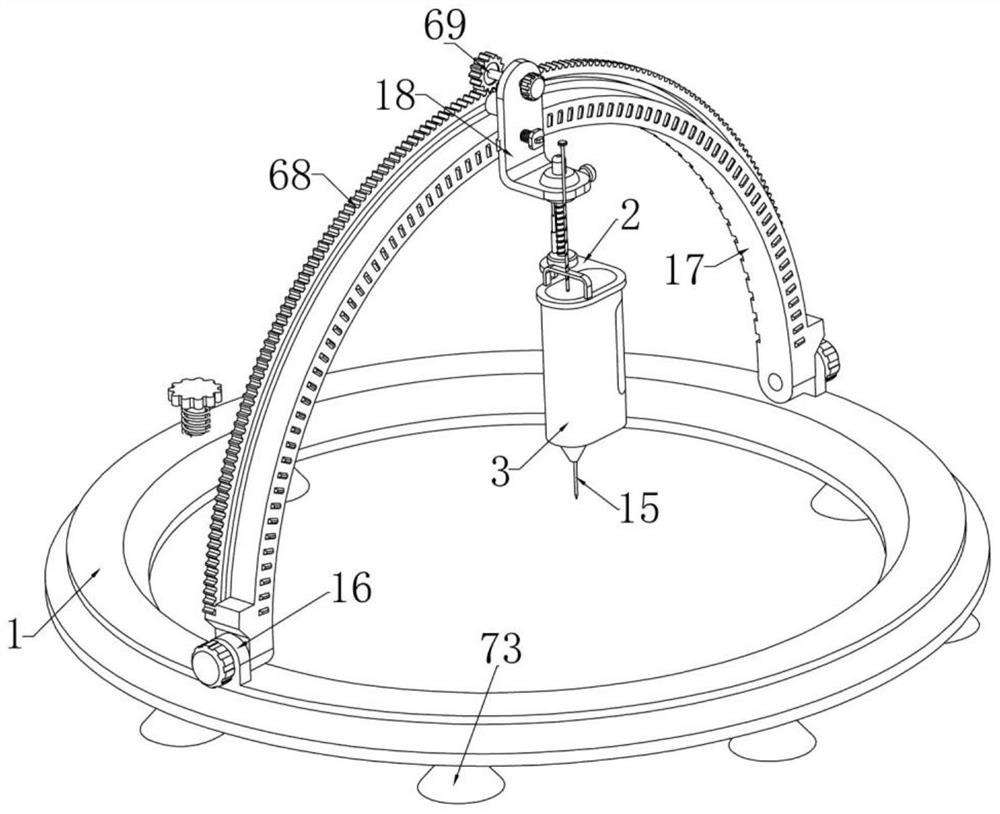

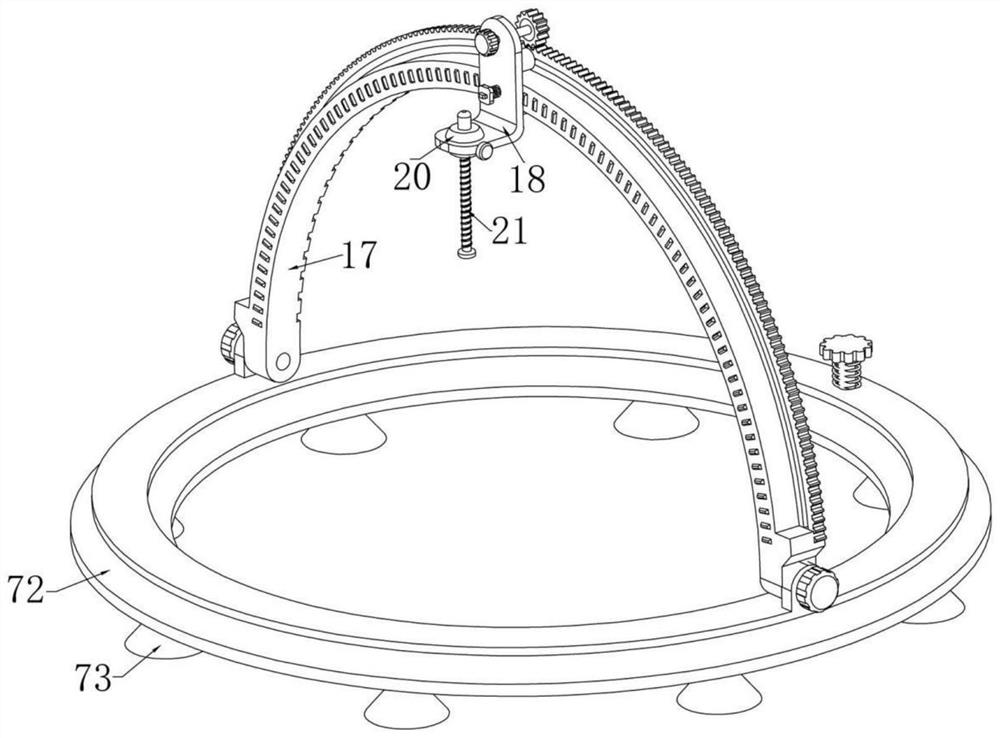

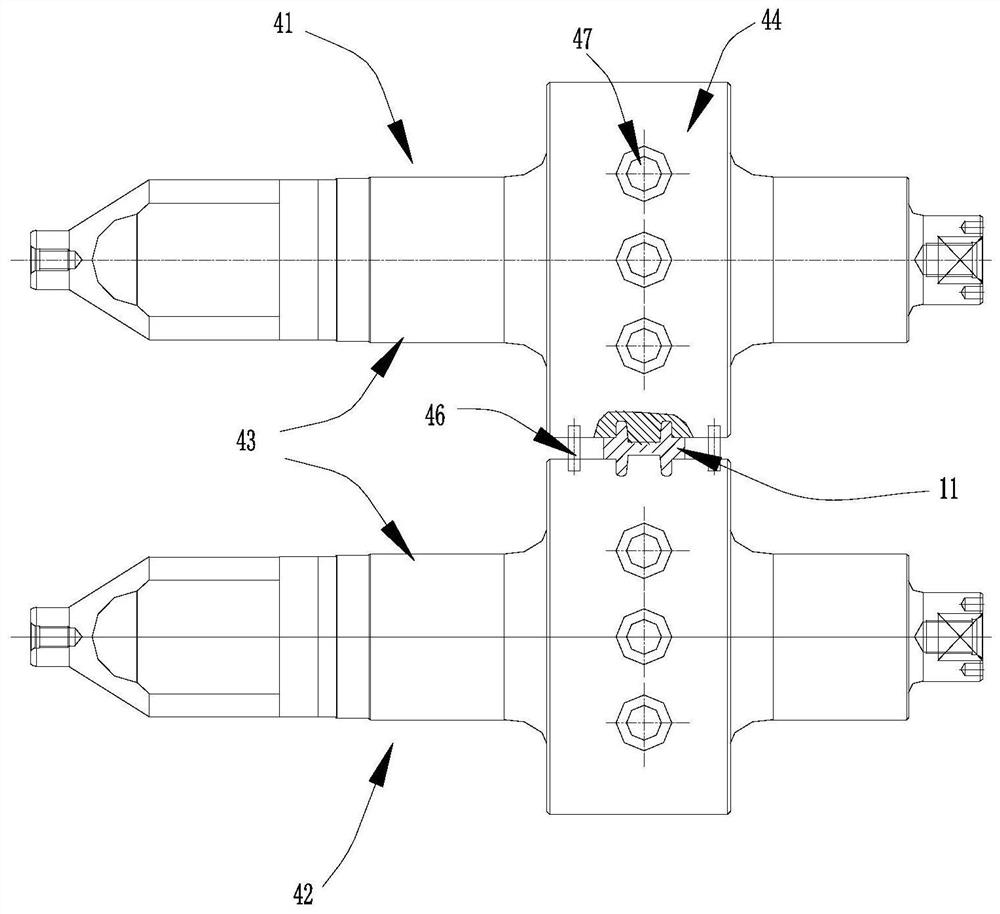

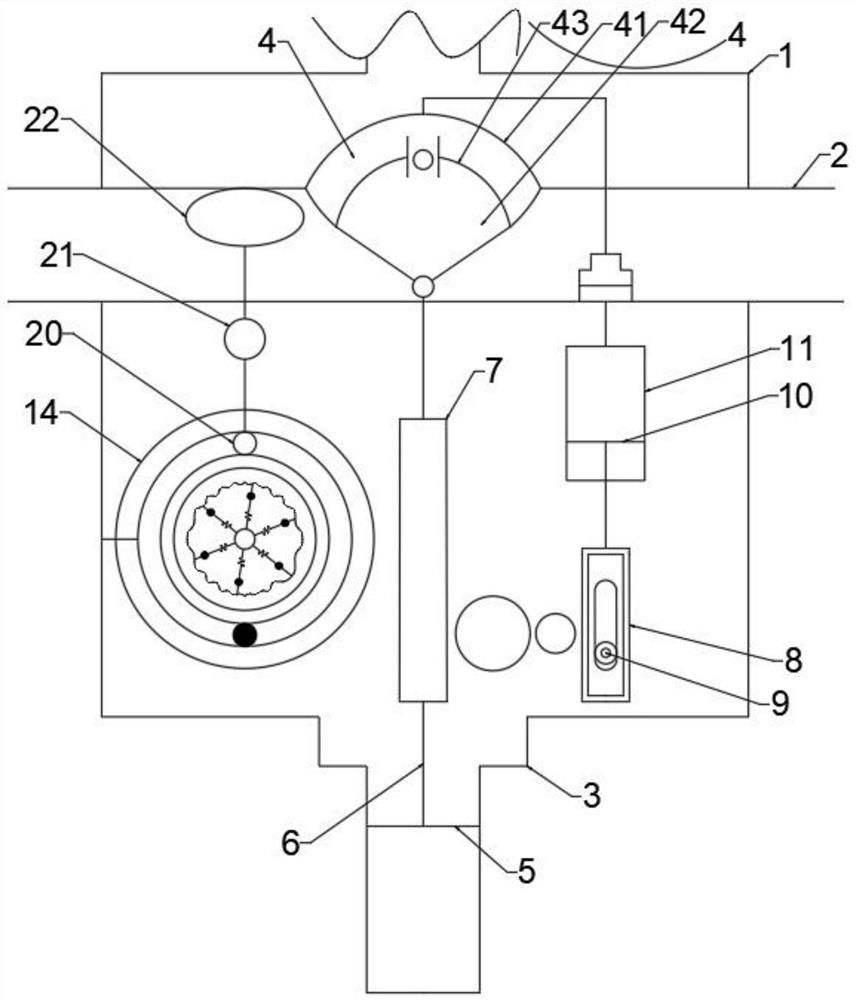

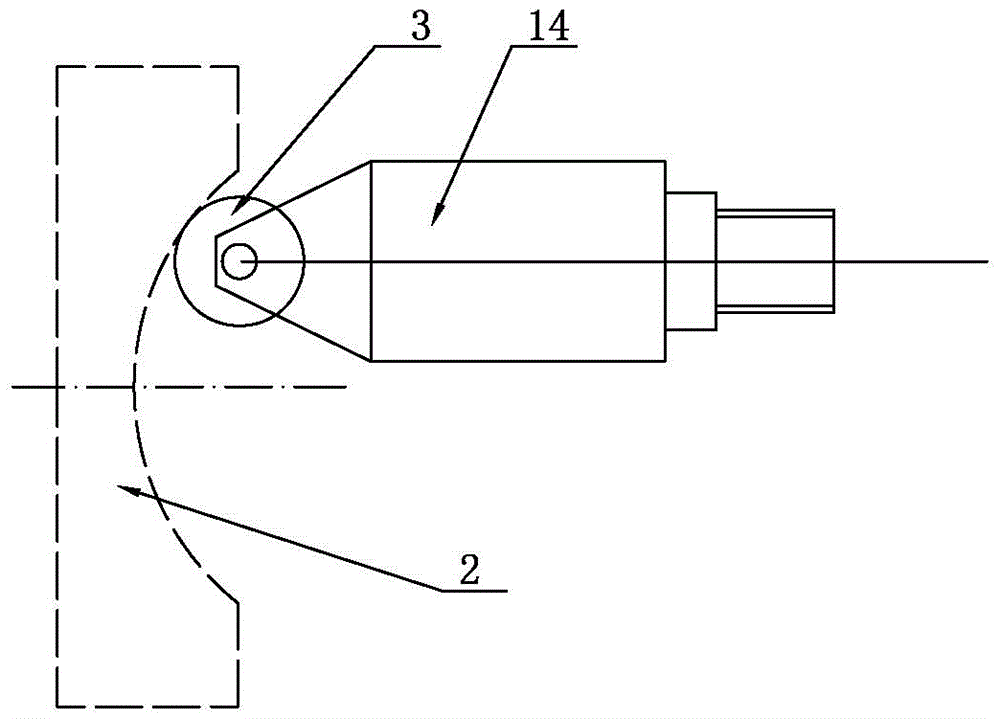

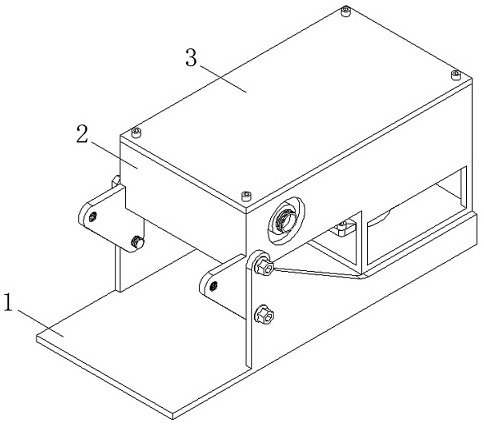

Special-shaped plate cutting device and method

ActiveCN113001634AEasy to operateVarious cutting effectsMetal working apparatusContoured platePhysics

The invention relates to the technical field of special-shaped plate cutting, in particular to a special-shaped plate cutting device and method. The method comprises the following steps that firstly, a plate is placed between two positioning sliding blocks, and the two positioning sliding blocks move towards the middle to position the plate; secondly, at the moment, a clamping suction cup moves upwards to suck the plate to drive the plate to move upwards, and the clamping suction cup and a fixing rod clamp the plate; thirdly, after the arc radius needing to be cut is adjusted, a cutting tool is locked, a rotating frame rotates to drive the cutting tool to rotate, and arc cutting is completed; and fourthly, through cooperation of a rotating mechanism and an auxiliary mechanism, cutting under more conditions is completed. By means of the device, arc cutting can be conducted on the plate, the needed arc radius can be rapidly adjusted, the application range is wider, adjustment is rapid, and operation is easy.

Owner:江西辉泰电子有限公司

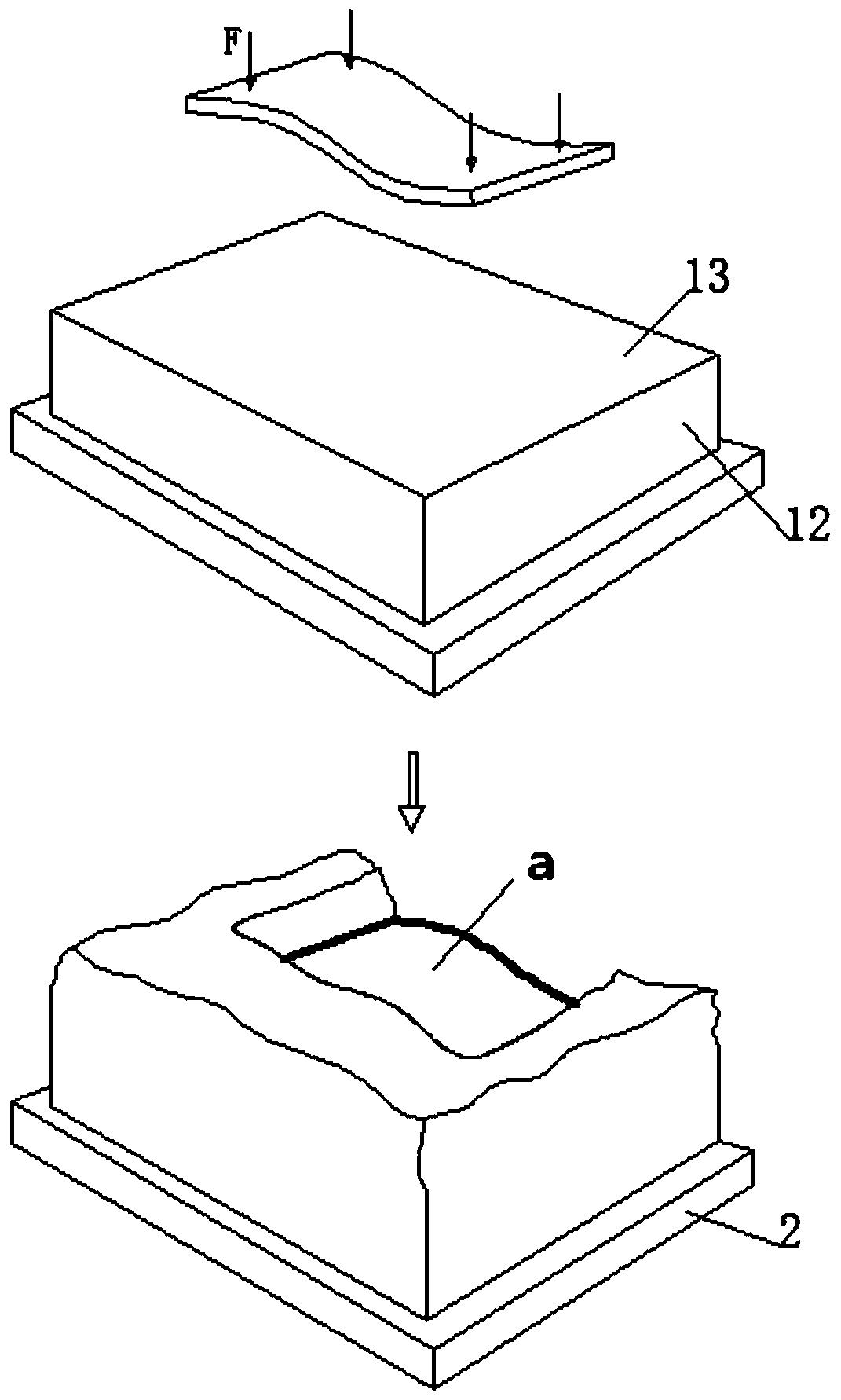

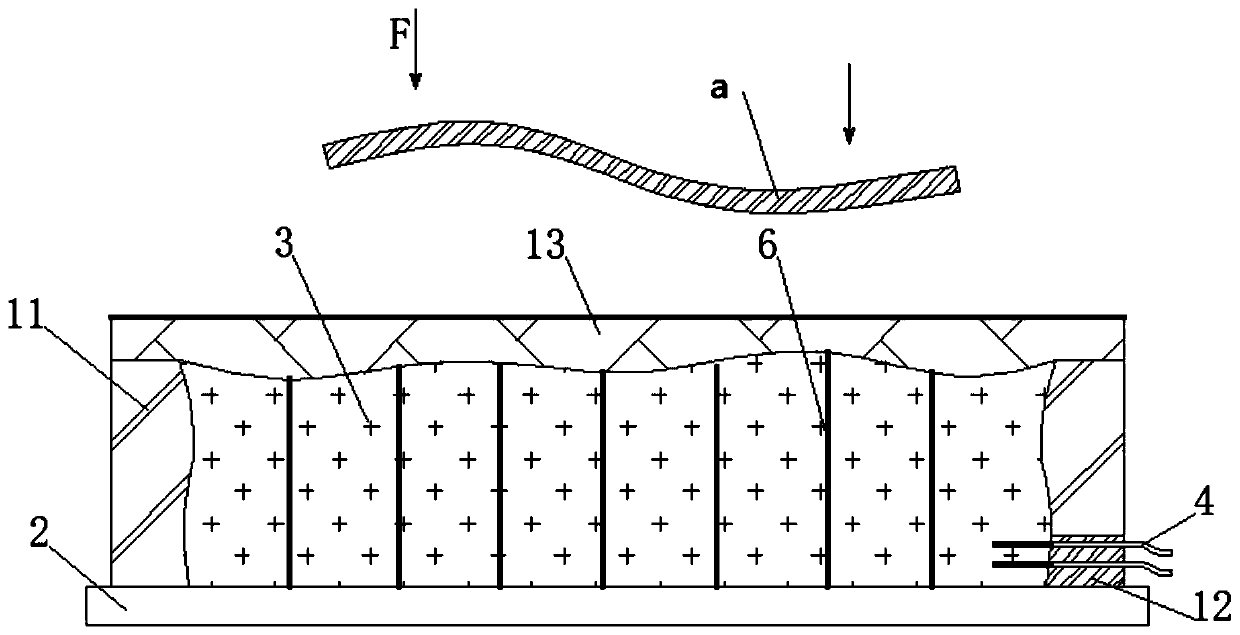

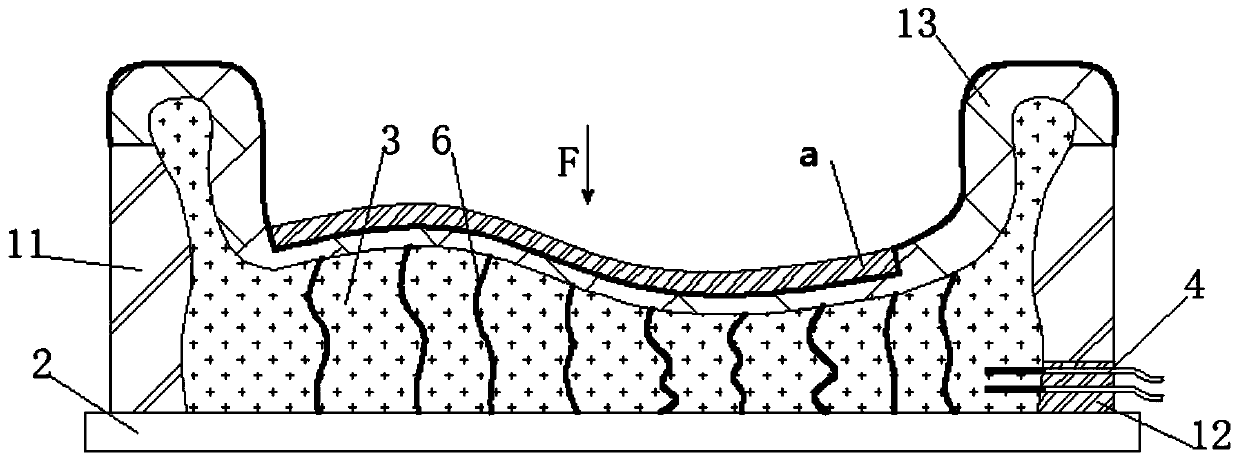

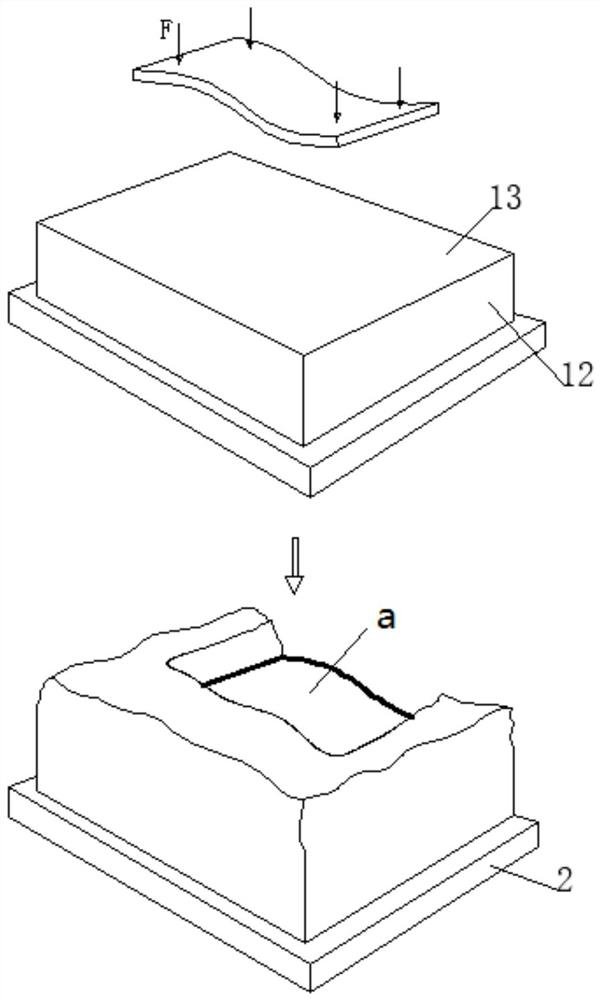

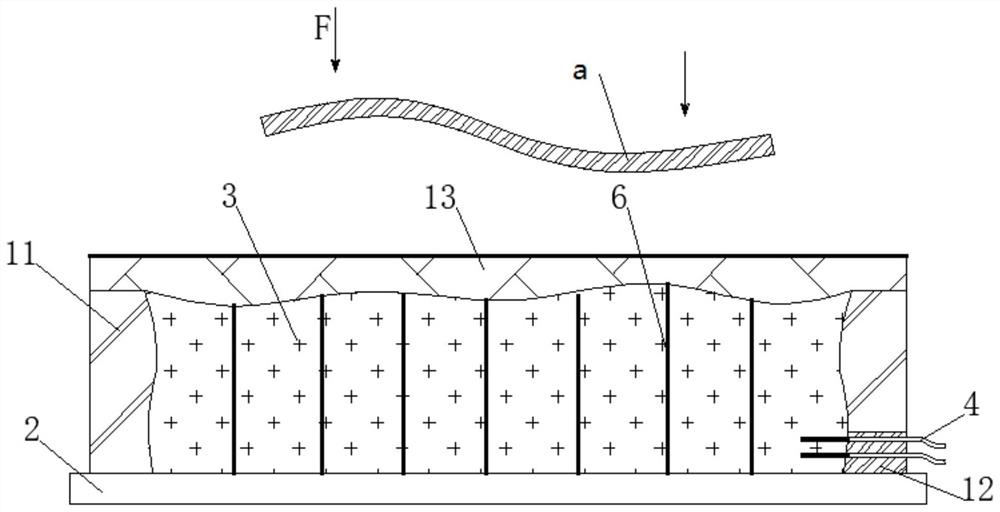

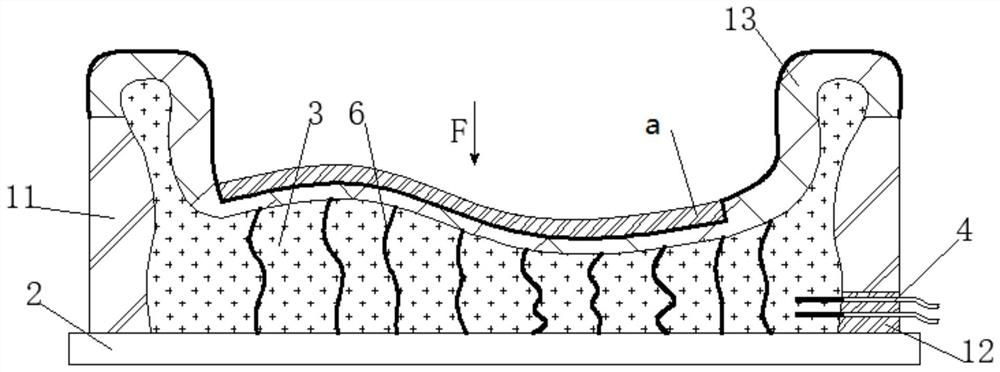

Rigid-flexible conversion positioning type special-shaped plate surface treatment process

The invention discloses a rigid-flexible conversion positioning type special-shaped plate surface treatment process, and belongs to the field of plate treatment. The rigid-flexible conversion positioning type special-shaped plate surface treatment process is characterized in that a rigid-flexible deformation plate is arranged, so that before the surface treatment of a special-shaped plate, force is applied to a special-shaped plate body to enable the special-shaped plate body to act on the flexible rigid-flexible deformation plate, then the special-shaped plate makes complete contact with therigid-flexible deformation plate, at the moment, the rigid-flexible deformation plate is powered on, the rigid-flexible deformation plate is changed into a rigid state and forms a positioning groove,and the shape of the back face of the special-shaped plate is completely engraved in the positioning groove; and at the moment when the special-shaped plate is ground, the rigid rigid-flexible deformation plate has a supporting effect on the special-shaped plate without a gap between the rigid rigid-flexible deformation plate and the special-shaped plate, so that the special-shaped plate is stressed more uniformly during surface treatment, the situation that the special-shaped plate is damaged during grinding is effectively avoided, meanwhile, the stability during treatment can be effectivelyimproved, and the surface treatment efficiency and effect are improved.

Owner:庞海峰

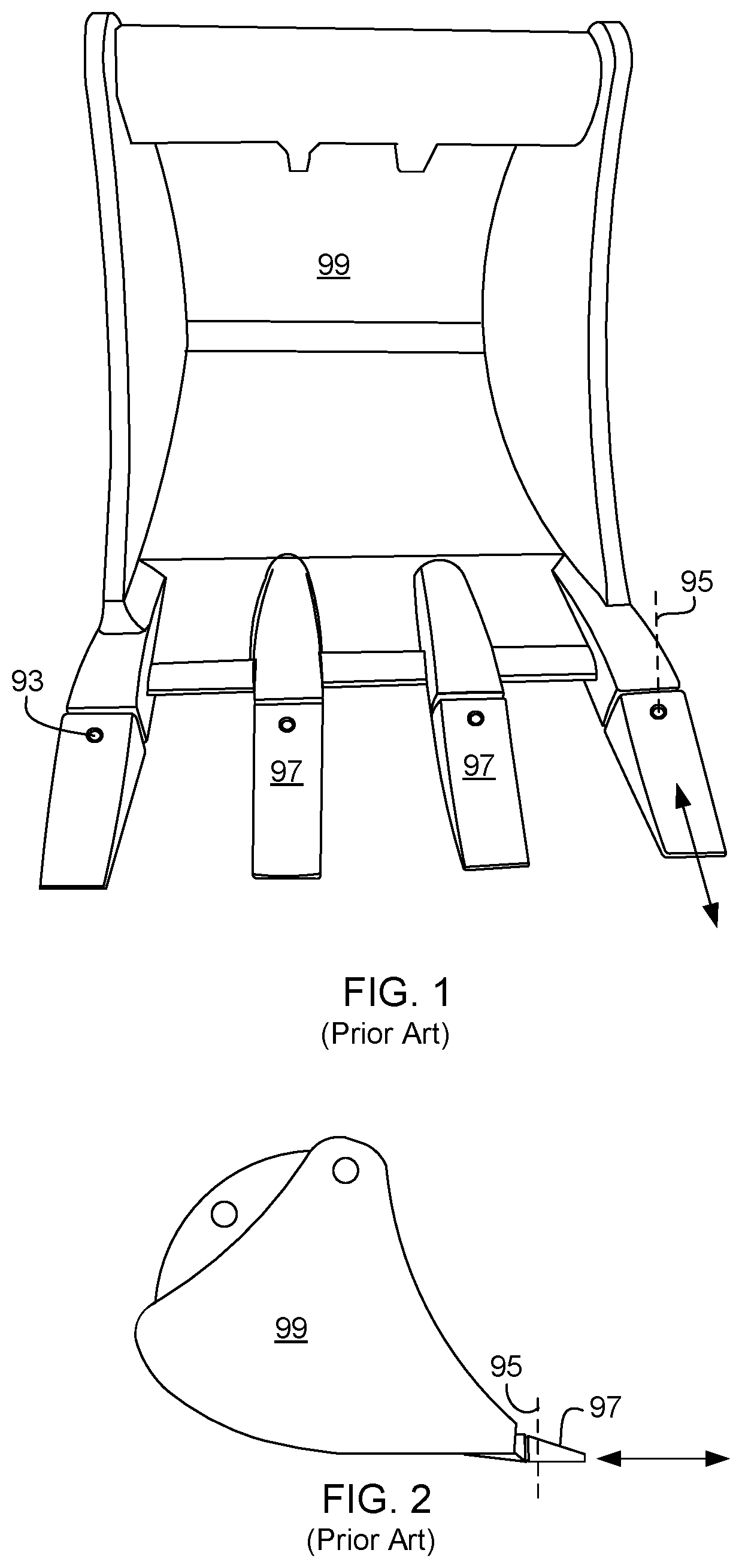

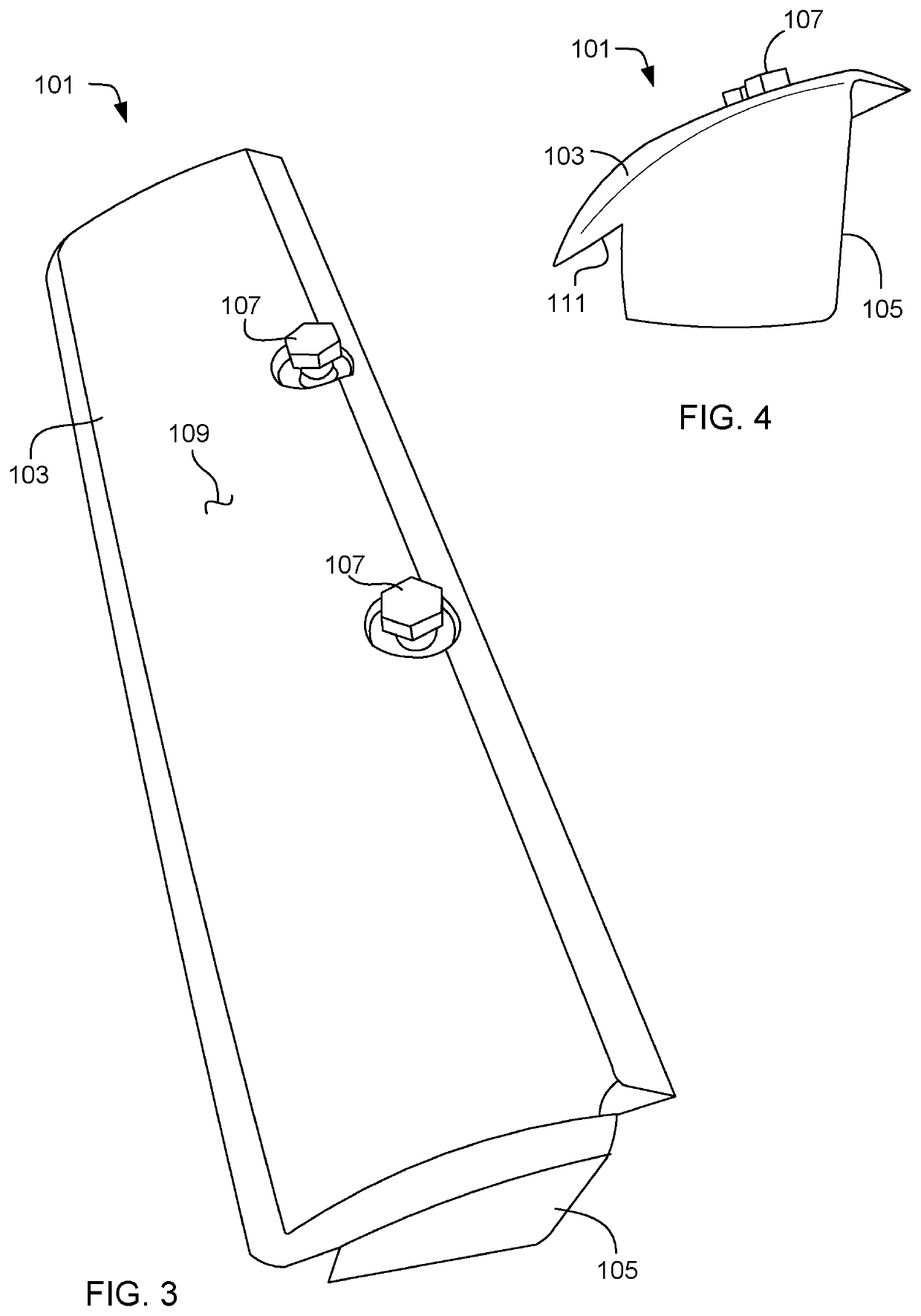

Digging bar attachment for toothed bucket

ActiveUS10689826B1Easy to useOvercome disadvantagesMechanical machines/dredgersClassical mechanicsContoured plate

A digging attachment device for use with a toothed earth working bucket includes a contoured plate configured to be at least the width of the combined teeth of the bucket and extends over the ends of the teeth when seated. The device further includes a plurality of slots coupled to a lower surface of the plate. The slots are configured to accept the teeth of the bucket. The slots are tapered such that its internal distance within the slots relative to the lower surface of the plate progressively decreases to match the contour of the bucket teeth. The device further includes a fastener hole and fastener in communication with at least one of the plate and slots. The fastener is configured to be set within the countersink of the teeth fasteners. The device is secured without manipulation, adjustment, and removal of any portion of any earth working bucket.

Owner:HARDIN BRANDON

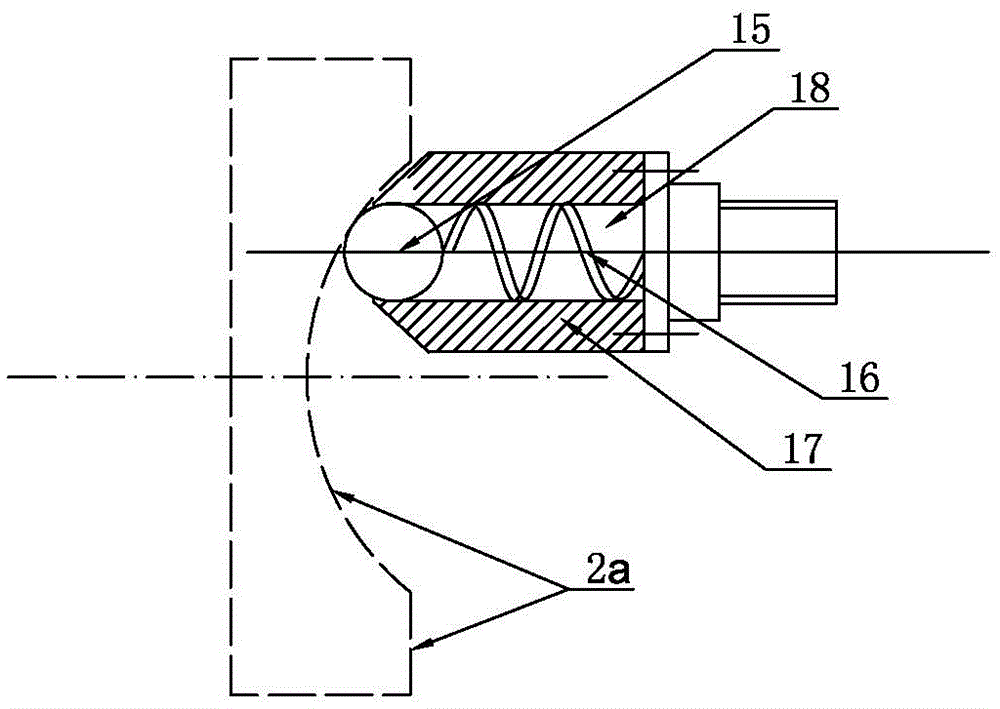

Welding device for kettle spout

InactiveCN107775151AExquisite structureStable and efficient weldingWelding accessoriesArchitectural engineeringWater bottle

The invention relates to a kettle spout welding device, which has a base, a support plate is provided on one side of the base, a spout shelf is erected in the middle of the support plate, a spout hole is provided on the spout shelf, and spout holes are provided on both sides of the support plate. There is a pillar, the upper part of the pillar is set with a cylinder plate, and a pot pressing cylinder is arranged vertically downward on the cylinder plate, and the lower end of the piston rod of the pot pressing cylinder is provided with an arc-shaped pressing plate, which is arranged opposite to the hole of the spout ;The base on the other side opposite to the spout shelf is provided with a spout weld profiling plate, and a column is arranged on the upper surface of the spout weld profiling plate, and a mounting seat for adjusting up and down along the column is provided on the column , the side of the mounting seat is connected with a support rod through a pin shaft, and the front end of the support rod is equipped with an argon arc welding torch, which is used to weld the spout of the kettle, and the rear part of the mounting seat is welded with a pressure rod plate, a pressure rod The plate is threaded to connect the pressure rod bolts; the invention has simple and exquisite structure, stable and efficient welding, and has good practical application and popularization value.

Owner:大冶市荣成不锈钢制品有限公司

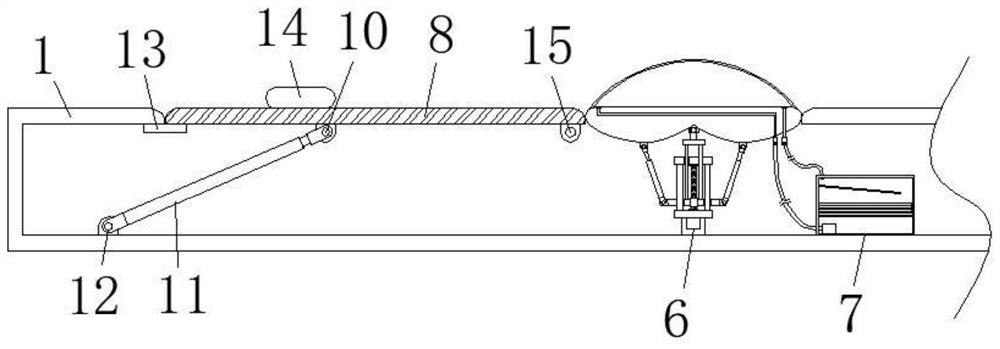

A kind of medical waist rehabilitation training equipment

ActiveCN110897781BGymnastic exercisingChiropractic devicesPhysical medicine and rehabilitationElectric machinery

The invention discloses a medical waist rehabilitation training equipment, which comprises a box body, a special-shaped plate, a support mechanism, an infusion mechanism, and a movable plate. The special-shaped plate is covered with a leather sheath, and a No. No. pre-buried water pipes. By controlling the amount of liquid in and out, the holster loses the liquid sink and the liquid bulge, and reheats the liquid, so that the reciprocating process can make the waist reciprocate up and down and slowly move through the flow of liquid, while Warm fluids are also more comfortable for the patient. Secondly, its No. 1 motor can also be turned on, and the No. 1 motor will force its No. 1 sliding frame to slide vertically in the No. 1 sliding rod by driving the No. 1 threaded rod to rotate, so that its special-shaped plate can be lifted upwards, and then The controller can control the reciprocating contraction and relaxation movements of its two No. 1 electric push rods, which can make the special-shaped plate swing slowly left and right, and can further perform rehabilitation exercises on the patient's waist.

Owner:江涛

Elastic bellows and battery cell assemblies including same

ActiveUS9929441B2Low costMaximizing lifetime of battery cellFinal product manufactureCell electrodesElectrochemical cellContoured plate

A battery pack includes a battery housing and electrochemical cells disposed in the battery housing in a stacked configuration. Elastic members are disposed between adjacent cells of a cell stack. Each elastic member is a bladder that is formed of a pair of contoured plate portions stacked in a mirrored arrangement, whereby the plate portions cooperate to form a bellows-type compression spring. The elastic members provide a predetermined compression force to each cell while accommodating cell growth during use. The elastic members may include surface features such as strategically shaped and / or located protrusions that are configured to permit compliance and can be tuned to address the requirements of a specific application and permit application of varying stiffness characteristics across a surface of a cell.

Owner:BOSCH BATTERY SYST +1

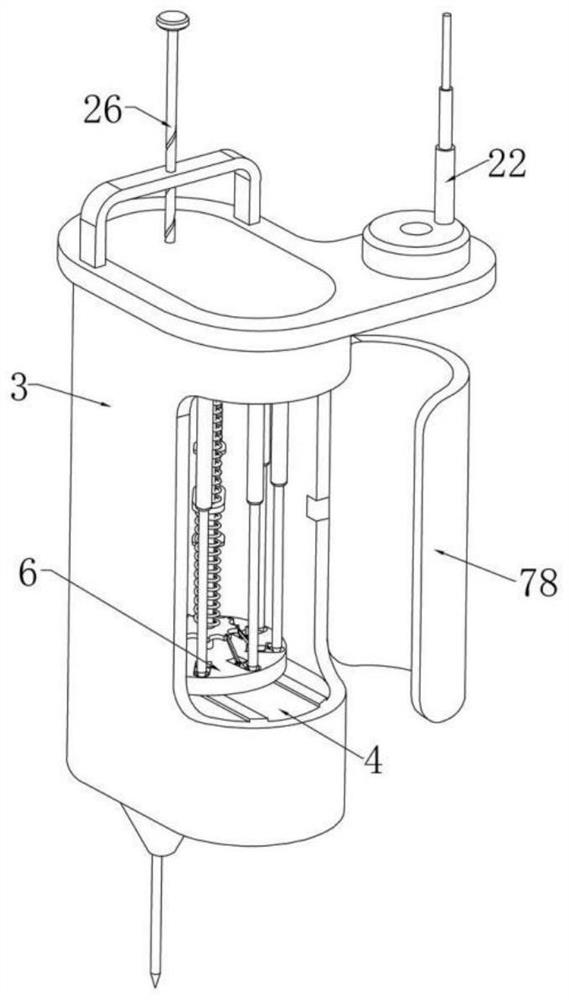

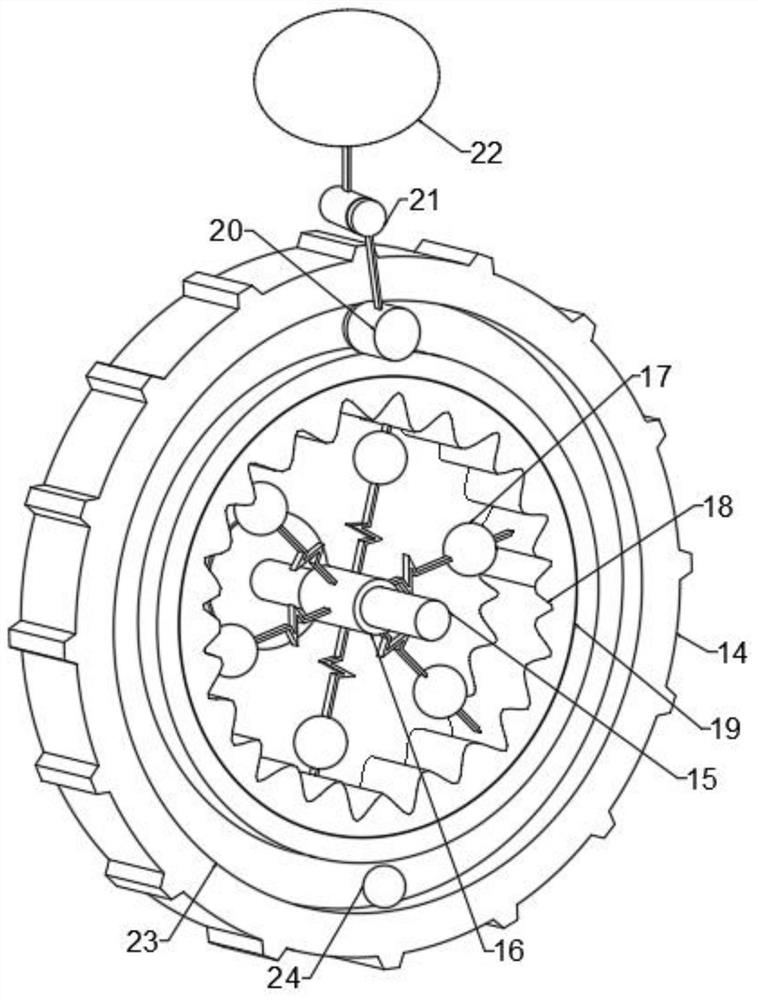

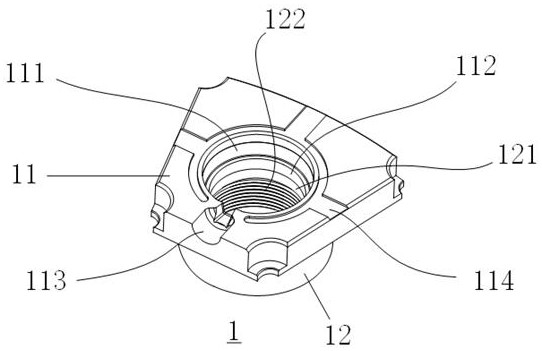

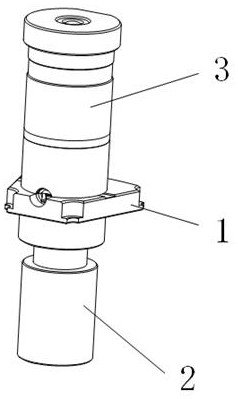

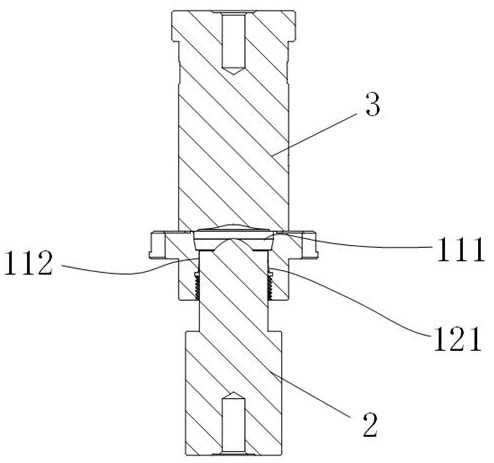

Positioning device for acupuncture and moxibustion

InactiveCN114668657AReduce infectionPrevent deviationAcupunctureDevices for locating reflex pointsAcupuncture needlesPhysical medicine and rehabilitation

The invention provides a positioning device for acupuncture and moxibustion, and effectively solves the problems that during operation of medical staff, acupuncture points are shifted due to errors of puncture angles or shaking of hands, and pain of patients is increased due to repeated needle application. Comprising a positioning ring, an adjusting device is rotatably installed at the upper end of the positioning ring, a special-shaped plate moving up and down is installed on the adjusting device, an acupuncture cylinder is fixedly installed at the lower end of the special-shaped plate, limiting plates are fixedly installed in the upper end and the lower end of the acupuncture cylinder respectively, and a supporting rod is slidably installed between the two limiting plates; through cooperative use of the driving rod, the lower belt wheel, the threaded groove, the boss, the left belt wheel and the rotating gear, the effect of rotatably pushing the acupuncture needle is achieved through the operation, the working pressure of medical staff can be well saved, the acupuncture precision is high, the acupuncture positioning effect is remarkable, acupuncture deviation caused by human factors is avoided, and the acupuncture accuracy is improved. Meanwhile, the needle cavity does not need to be frequently opened for filling the needle, and operation is easy.

Owner:THE THIRD AFFILIATED HOSPITAL OF XINXIANG MEDICAL UNIV

A kind of special-shaped ring blank forming method

ActiveCN108817093BReduce labor intensityImprove working environmentRollsMetal rolling arrangementsStructural engineeringContoured plate

The invention relates to the field of machining and manufacturing of special-shaped rings, in particular to a special-shaped ring workblank forming method. The special-shaped ring workblank forming method comprises the following steps that 1, plate materials are fed into a roller device, the front and back end faces of the plate are rolled through the roller device to form rolled faces, and the rolled faces on the two sides correspond to each other, wherein each rolled face comprises a ring body and a groove located in the ring body; and 2, the special-shaped plate rolled in the step 1 is subjected to annealing operation; and 3, the annealed special-shaped plate is subjected to stamping operation, and a special-shaped ring workblank is obtained. According to the special-shaped ring workblank forming method, the technological steps are simplified, and production efficiency is improved.

Owner:马兴法

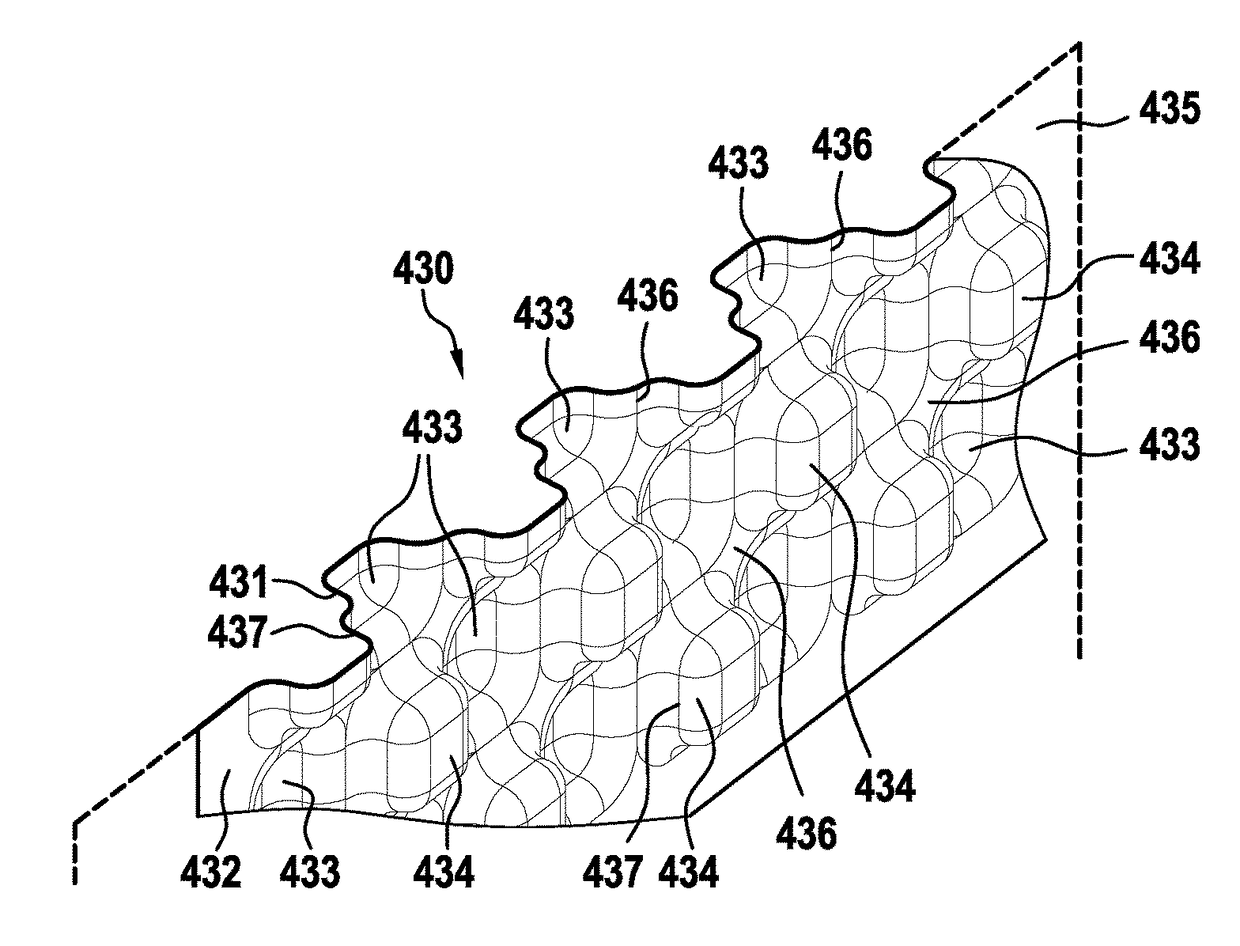

Tank bottom structure of a metal inner tank of a membrane cryogenic storage tank

ActiveCN112145954BNot affectedReduce yield damageVessel manufacturingVessel wallsLongitudinal waveDeep drawing

The invention discloses a tank bottom structure of a metal inner tank of a membrane type cryogenic storage tank. The bottom of the tank is approximately circular in structure. unit or several basic units, the substrate is welded or deep-drawn (deep-drawn), the basic unit is composed of a flat plate, a longitudinal wave and a transverse wave on the plate, and the longitudinal wave and the transverse wave are both recessed on one side In the protruding arched structure, the longitudinal wave and the transverse wave are vertically interlaced and connected together through a smooth transition of a curved surface, and both the longitudinal wave and the transverse wave are in a smooth transition with the surrounding flat plates through a curved surface. The tank bottom structure of the metal inner tank of the membrane cryogenic storage tank can avoid stress concentration during thermal expansion and contraction, and only a small number of molds are required for manufacturing, which can improve on-site assembly efficiency during assembly.

Owner:宇欧围护技术(上海)有限公司

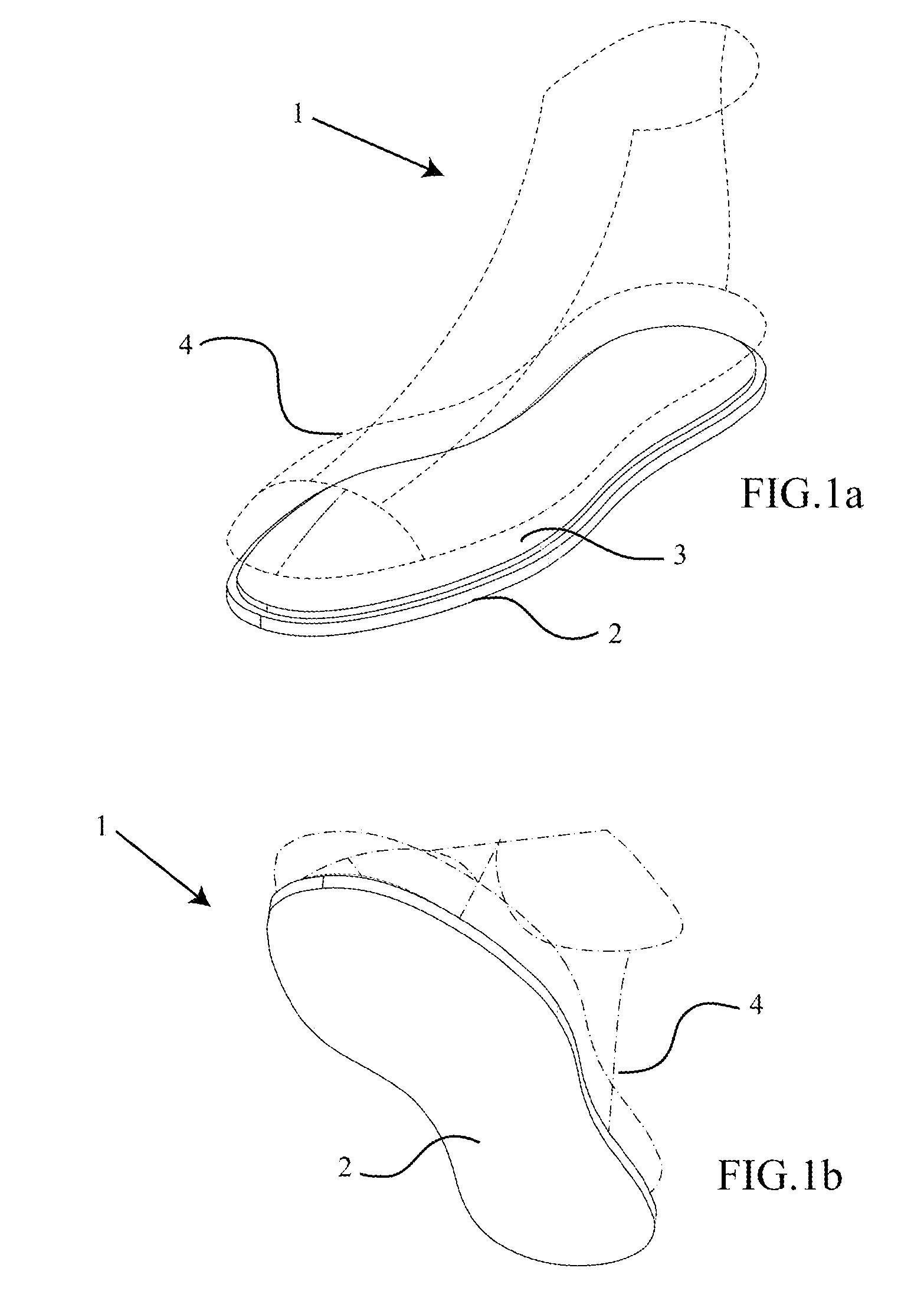

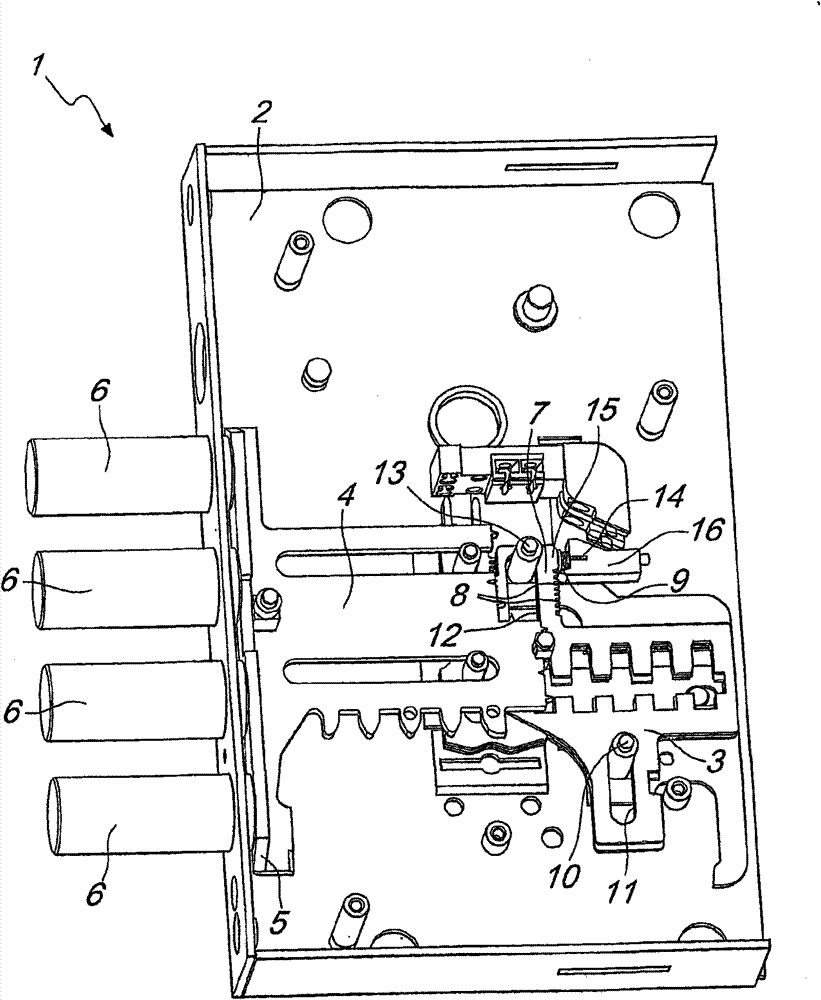

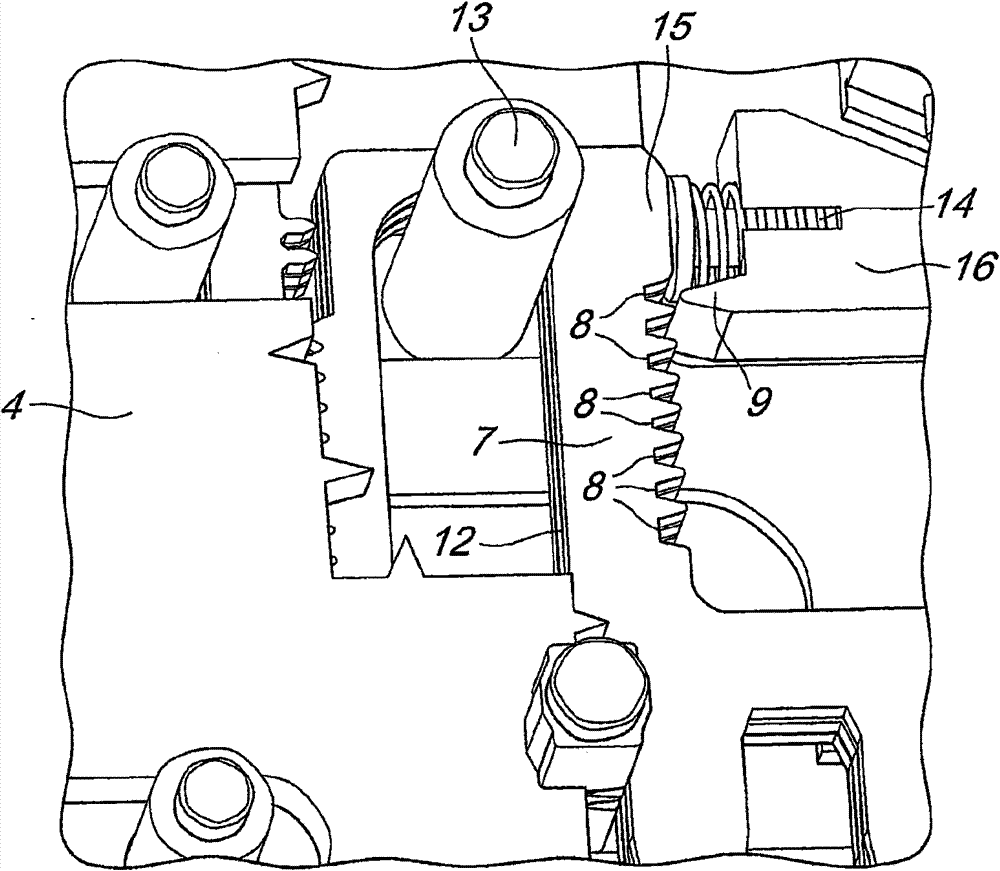

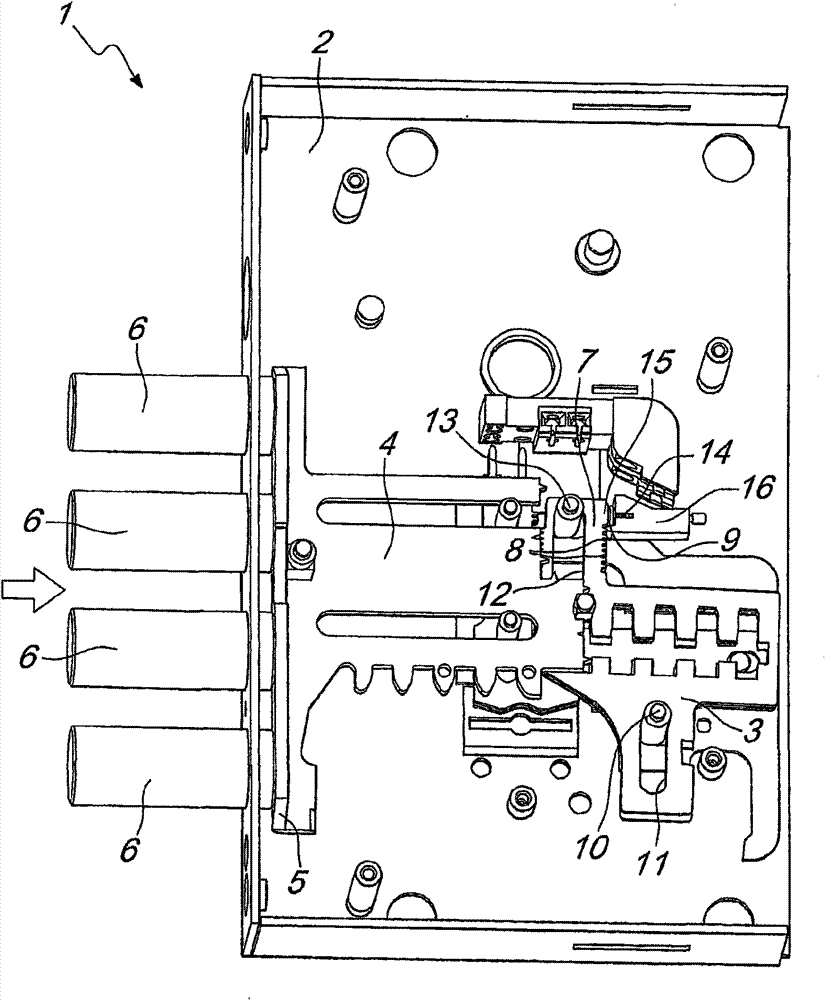

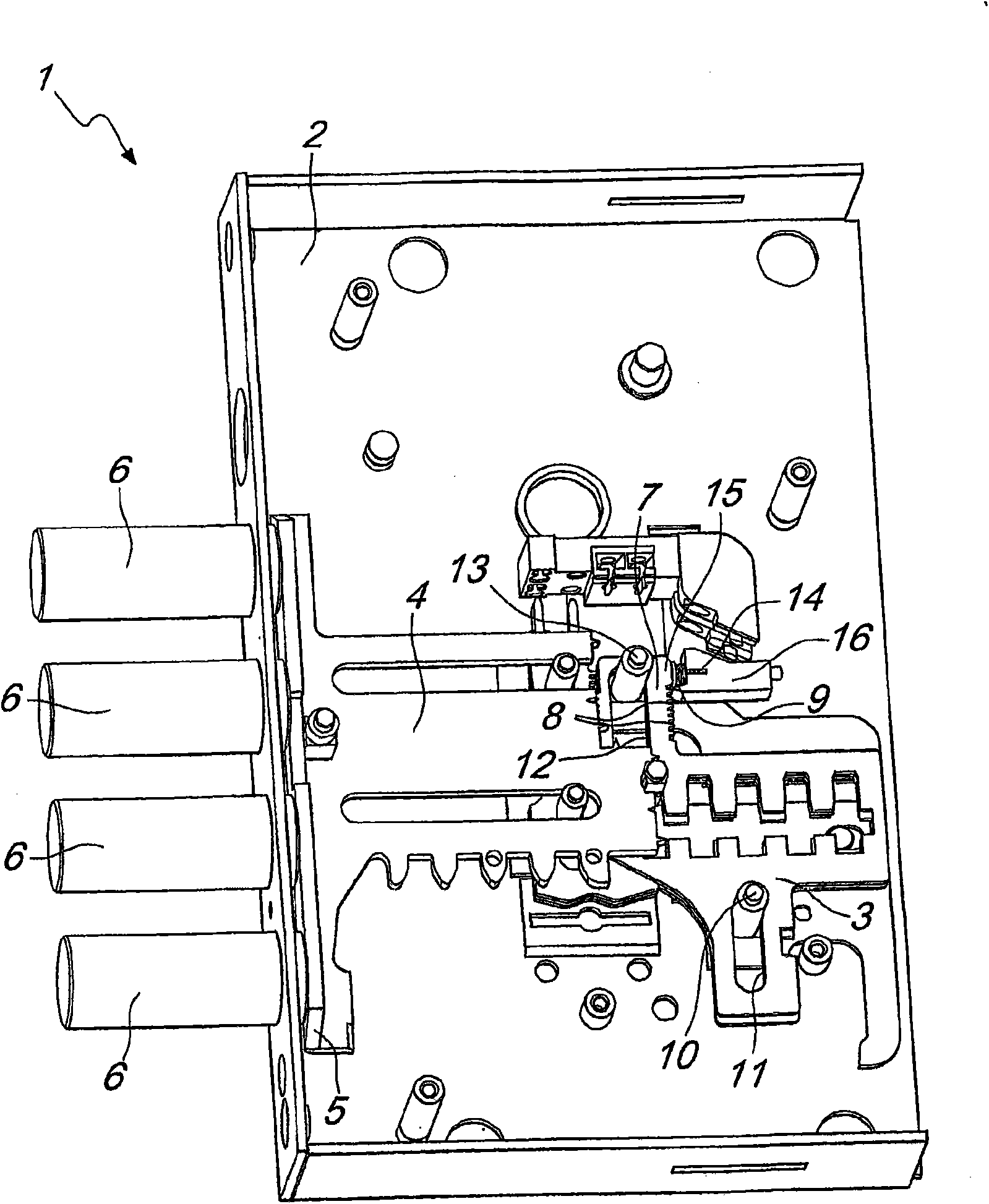

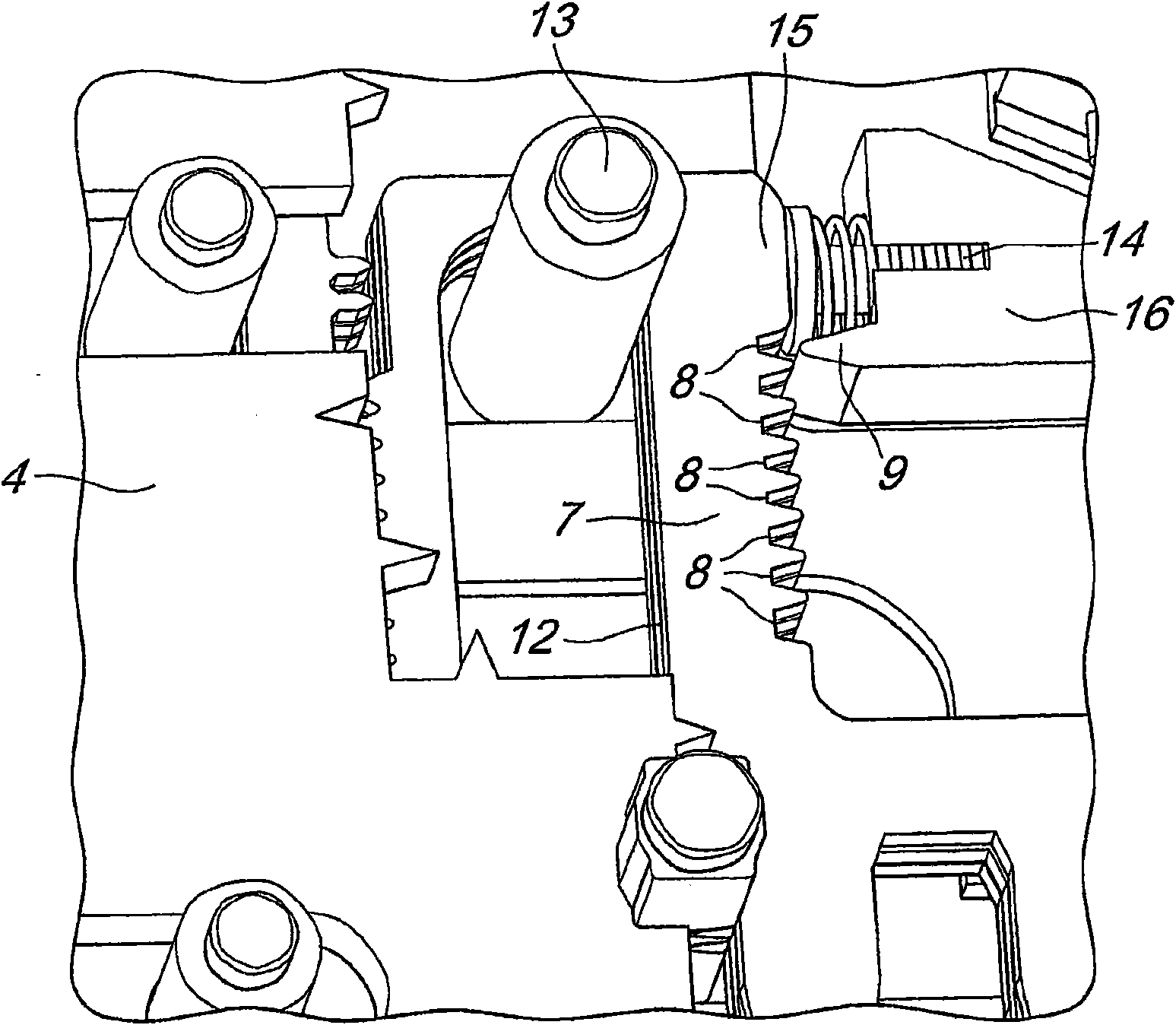

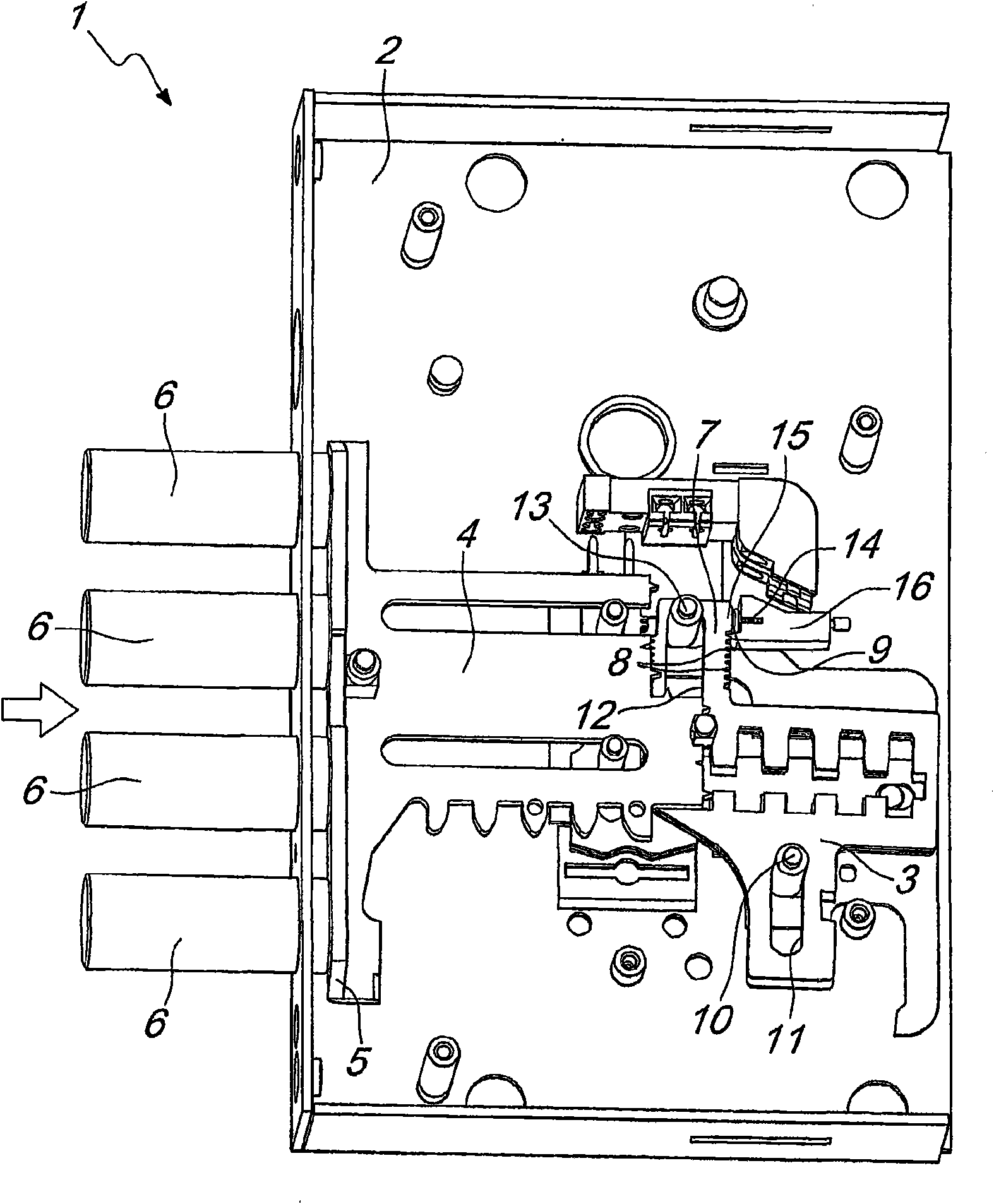

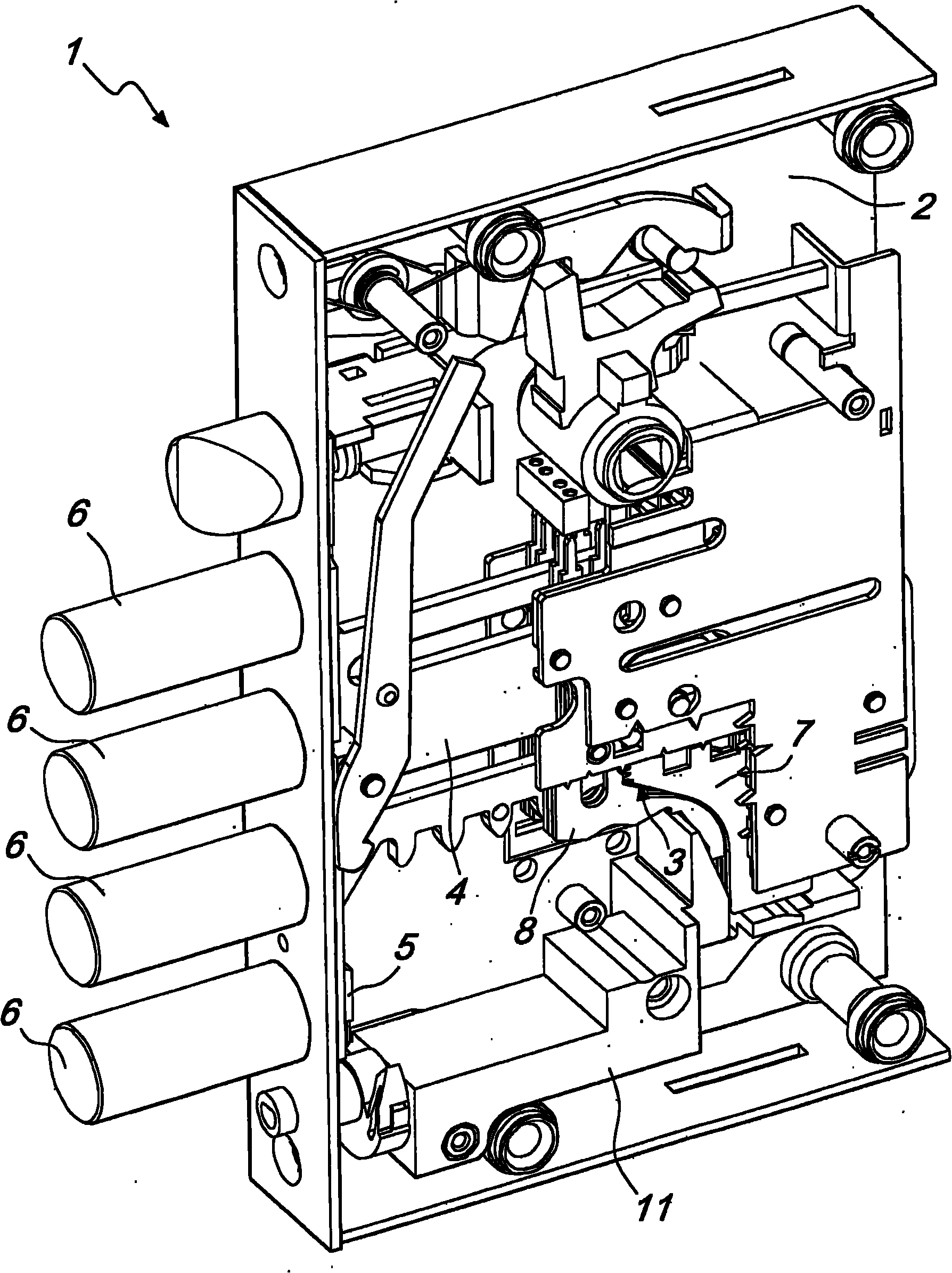

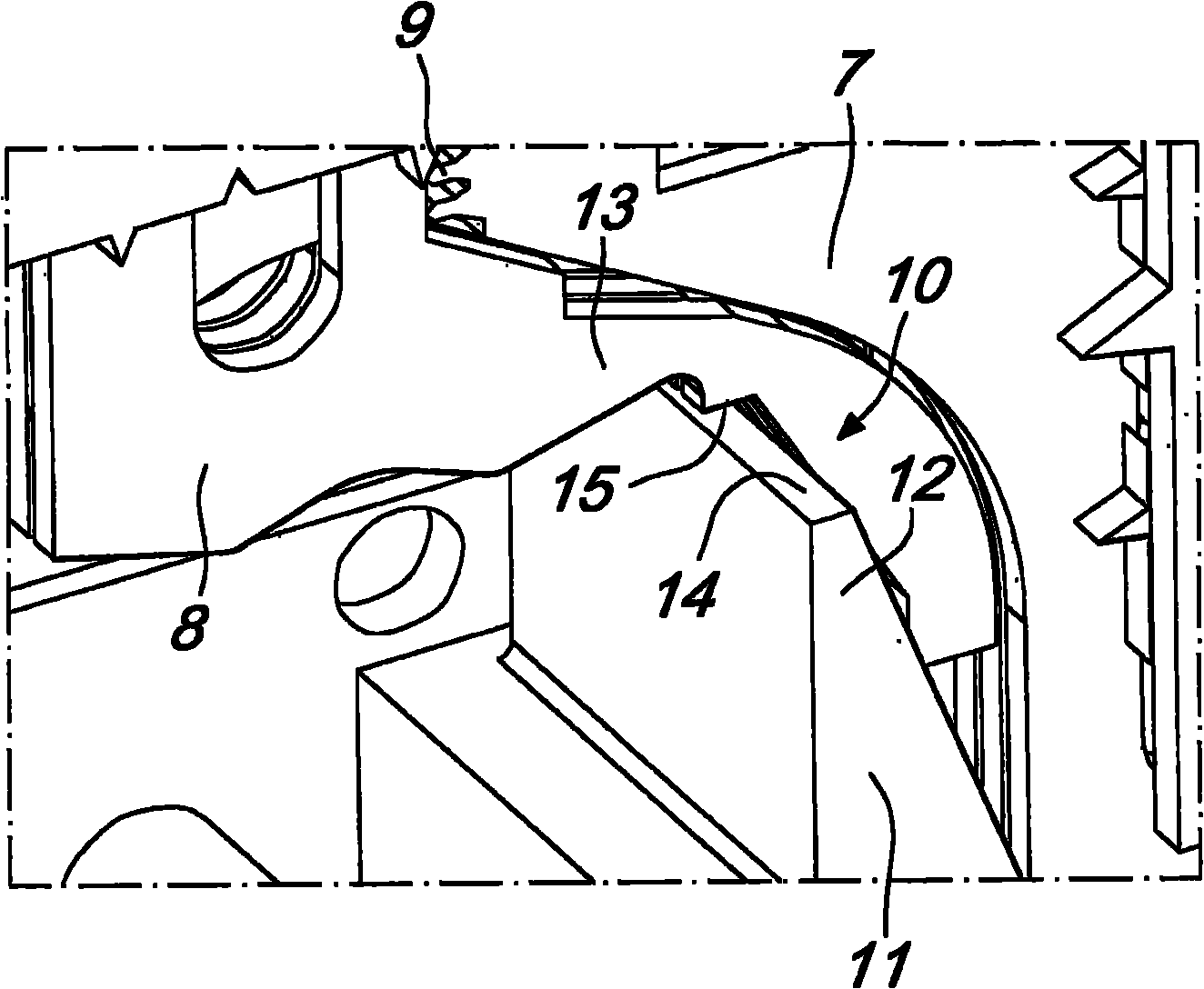

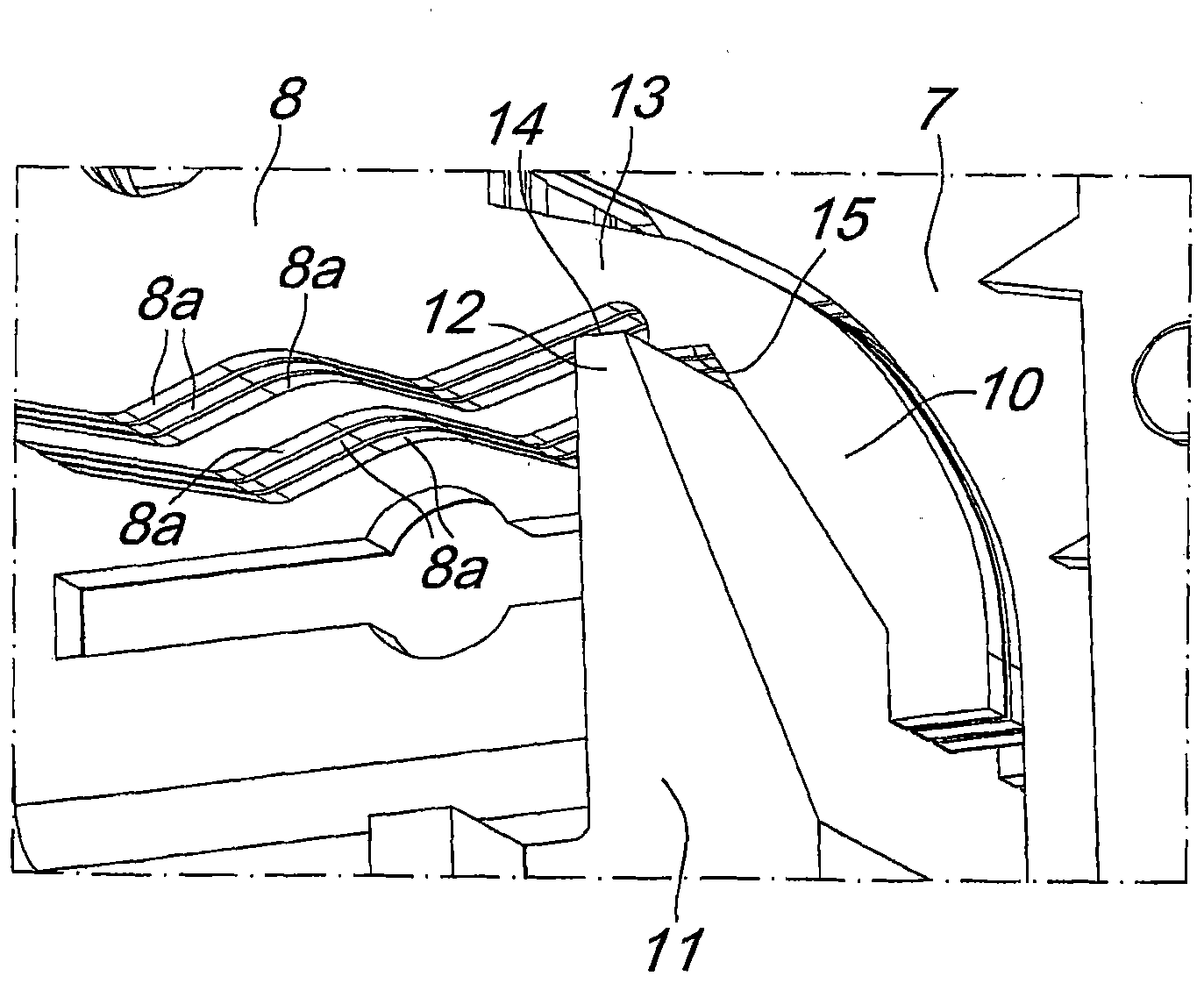

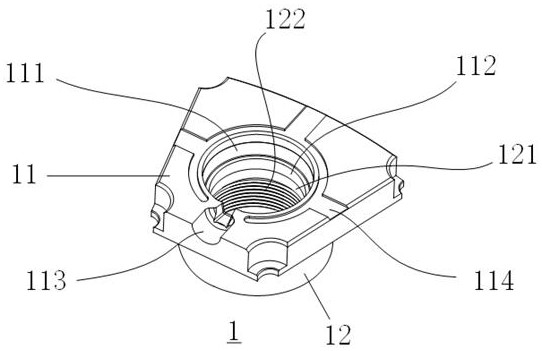

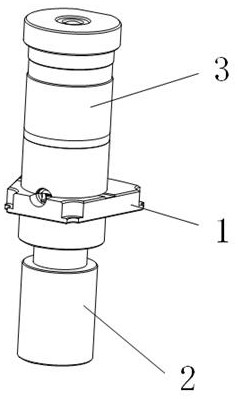

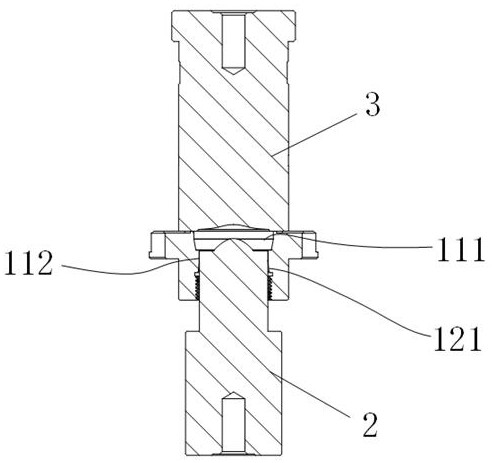

Break-in resistant lock

A break-in resistant lock (1), of the type which comprises a box-like body (2) for accommodating a plurality of contoured plates (3) provided with a respective portion which is suitable for detachable engagement on a corresponding area of a rod (4) which can perform a translational motion and supports, at its free end (5), at least one bolt (6) which can retract monolithically with the rod (4). The plates (3) can perform a vertical translational motion by way of the action of the key and release, when they are raised, the translational motion of the rod (4) and the bolts (6) for their retraction and protrusion. At least one of the plates (3) comprises at least one area (7) provided with at least one seat (8) which is aligned and proximate to at least one protrusion (9) which is shaped substantially complementarily with respect to the shape of the seat (8). The at least one plate (3) provided with the at least one seat (8) is able to oscillate, about a guiding pivot (10) rigidly coupled to the box-like body (2), from a first configuration for mutual engagement of the at least one seat (8) with the respective at least one protrusion (9), as a consequence of external break-in actions aimed at retracting the rod (4) and the bolts (6), in which translational motion of the plates (3) is not allowed and therefore the rod (4) is locked, to a second inactive configuration, in which the seat (8) and the protrusion (9) are spaced and the translational motion of the plates (3) is free and therefore the rod (4) can be extracted and retracted.

Owner:CISA

Break-in resistant lock

A break-in resistant lock (1), of the type which comprises a box-like body (2) for accommodating a plurality of contoured plates (3) provided with a respective portion which is suitable for detachable engagement on a corresponding area of a rod (4) which can perform a translational motion and supports, at its free end (5), at least one bolt (6) which can retract monolithically with the rod (4). The plates (3) can perform a vertical translational motion by way of the action of the key and release, when they are raised, the translational motion of the rod (4) and the bolts (6) for their retraction and protrusion. At least one of the plates (3) comprises at least one area (7) provided with at least one seat (8) which is aligned and proximate to at least one protrusion (9) which is shaped substantially complementarily with respect to the shape of the seat (8). The at least one plate (3) provided with the at least one seat (8) is able to oscillate, about a guiding pivot (10) rigidly coupled to the box-like body (2), from a first configuration for mutual engagement of the at least one seat (8) with the respective at least one protrusion (9), as a consequence of external break-in actionsaimed at retracting the rod (4) and the bolts (6), in which translational motion of the plates (3) is not allowed and therefore the rod (4) is locked, to a second inactive configuration, in which theseat (8) and the protrusion (9) are spaced and the translational motion of the plates (3) is free and therefore the rod (4) can be extracted and retracted.

Owner:CISA

Medical anaesthesia machine flow amplifying device based on loop heating

The invention discloses a medical anaesthesia machine flow amplification device based on loop heating, which comprises a shell, an anaesthesia tube is fixed in the shell, the anaesthesia tube is respectively connected with an input end and an output end through pipelines, a bed body is fixed above the shell, a telescopic rod is fixed below the shell, the lower end of the telescopic rod is in contact with the ground, and the lower end of the telescopic rod is in contact with the ground. A control assembly is fixedly connected to the upper portion of the telescopic rod, a supporting plate is fixed to the interior of the telescopic rod, a fixing rod is fixed to the upper portion of the supporting plate, the control assembly comprises a special-shaped plate, the special-shaped plate is fixed to the interior of the anesthesia tube, and flexible cotton is fixedly connected to the left end and the right end of the lower portion of the special-shaped plate. The lower portion of the flexible cotton is fixedly connected with the upper end of a fixing rod, a movable column is movably connected to the middle of the movable plate, and a toothed plate is fixed to the middle of the fixing rod. The medical anaesthesia machine flow amplification device has characteristics of dosage controlling according to the patient type and adrenaline injection to fat patients.

Owner:南京蒙故奇科技有限公司

Triangular door steel waterproof curved surface processing device

ActiveCN103480902BEasy to processEasy to implementPlaning/slotting machinesCopying process control systemsEngineeringCam

The invention relates to a triangular door steel water-stop curved surface processing device in the field of ship lock water-stop processing equipment, including a guide rail frame. The profiling surface; the device also includes a knife bar seat, a knife bar is slidingly arranged in the knife bar seat, a knife head is installed at one end of the knife bar, and a guide device that interferes with the profiling surface is connected at the other end of the knife bar. The pressing plate is relatively fixed, and through holes are respectively arranged on both sides of the pressing plate. The knife bar seat is connected with one end of the screw rod. The screw rod is set through the through hole. When working, fix the guide rail frame with the side tool holder of the planer, fix the tool bar seat with the vertical tool holder of the planer, and fix the workpiece on the worktable. The arc surface feed movement can easily process the Ω-shaped surface, which is used in the shape and surface processing of arc-shaped components.

Owner:THE JIANGSU GENERAL FACTORY OF WATER CONSERVANCY MACHINERY

Machining method of E-shaped bushing

A machining method of an E-shaped bushing comprises the steps that 1, a rough blank is manufactured, wherein the rough blank is sequentially provided with a special-shaped plate, a positioning cylinder, a connecting cylinder and a positioning block from top to bottom, and a center hole is formed in the middle of the special-shaped plate; 2, the upper surface of the special-shaped plate is cut, and a glue opening is formed; 3, nickel plating treatment is performed; 4, the positioning block is fixed, and rough turning machining is conducted on the outer diameter of the positioning cylinder; 5, the outer diameter of the positioning cylinder serves as the standard, and rough turning machining is conducted on the inner diameter of the center hole of the special-shaped plate; 6, the connecting cylinder and the positioning block of the semi-finished product are cut off, and the special-shaped plate and the positioning cylinder are left; 7, finish turning is conducted on the outer diameter of the positioning cylinder; and 8, finish turning is conducted on the inner diameter of the cavity and the inner diameter of a positioning channel, and a final finished product is formed. By means of the machining method, the concentricity of the cavity, the positioning channel and an upper mold core is ensured, and the situation that a plastic lens is eccentric is avoided.

Owner:DONGGUAN HARMONY COOPERATION PLASTIC & HARDWARE TECH CO LTD

Break-in resistant lock

A break-in resistant lock (1) comprising a box-like body (2) for accommodating a plurality of contoured plates (3) provided with a respective portion which is suitable for detachable engagement on a corresponding area of a rod (4) which can perform a translational motion and supports, at its free end (5), at least one bolt (6) which can retract jointly with the rod (4). The plates (3) can perform a vertical translational motion by way of the action of the key and release the translational motion, when they are lifted, of the rod (4) and of the bolts (6) for their retraction and protrusion. At least one of the plates (3) is constituted by a respective rear plate (7) and by a respective front tumbler (8), which are mutually coupled by means of a complementary contoured portion provided on their mutually facing edges (9). The front tumbler (8) comprises a protruding arm (10), which is interposed between the front of the rear plate (7) and a protective housing (11). The arm (10) has a shape and dimensions which are complementary to the interspace provided between the plate (7) and the housing (11) to prevent the possibility to access the plate (7) with break-in tools.

Owner:CISA

A special-shaped plate surface treatment process with rigid-flexible conversion and positioning

The invention discloses a surface treatment process for a special-shaped plate with rigid-flexible conversion and positioning, which belongs to the field of plate treatment. A surface treatment process for a special-shaped plate with rigid-flexible conversion and positioning. Before, force is applied to the special-shaped plate itself to make it act on the flexible rigid-flexible deformation plate, so that the special-shaped plate is in full contact with the rigid-flexible deformation plate. At this time, the rigid-flexible deformation plate is electrified, and the rigid-flexible deformation plate becomes rigid and forms The positioning groove, the positioning groove completely reproduces the shape of the back of the special-shaped plate. The plate is more evenly stressed during surface treatment, effectively avoiding damage during grinding, and can effectively improve the stability during treatment, thereby improving the efficiency and effect of surface treatment.

Owner:庞海峰

A kind of processing method of E-type bushing

Owner:DONGGUAN HARMONY COOPERATION PLASTIC & HARDWARE TECH CO LTD

Special grouting machine for dam termite nest

ActiveCN111771855BAvoid bringing upReduce workloadFoundation engineeringMarine site engineeringMachineScrew thread

The invention discloses a special grouting machine for termite nests in dikes and dams, which comprises a bottom plate with a rectangular plate-shaped outline, two sets of bottom vertical plates with a plate-shaped outline are arranged on the upper side of the bottom plate, and the upper sides of the bottom vertical plates are welded and fixed There are two sets of outlines, the outline is a strip-shaped supporting beam, the end of the bottom vertical plate facing away from the supporting beam is triangular, and the end of the bottom vertical plate facing away from the supporting beam is provided with holes under the vertical plate and holes on the vertical plate , a top box is arranged between the bottom vertical plates of the two groups, the outline of the top box is a box-like structure, two sets of triangular plates are arranged at the lower end of the top box, and a group of rotating holes and Two groups of angle holes, each of the rotation holes and the angle holes is threadedly connected with a group of angle locking screws, and four sets of fixed tables distributed in a rectangular array are arranged in the opening part of the top box, and the inside of the fixed tables are all opened with Threaded hole. The special grouting machine for termite nests in embankments can be driven by electricity or manually, and is suitable for popularization and use.

Owner:珠海经济特区白蚁防治技术推广站

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com