Composite drive mandrel anchoring casing head

A casing head and anchoring technology, used in wellbore/well components, earthwork drilling, sealing/packing, etc., can solve the problem of mandrel hanger and casing head body movement, seal failure, accidents, etc. The problem is to avoid the string movement, improve the sealing performance, and improve the sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be explained and described in detail below in conjunction with the accompanying drawings.

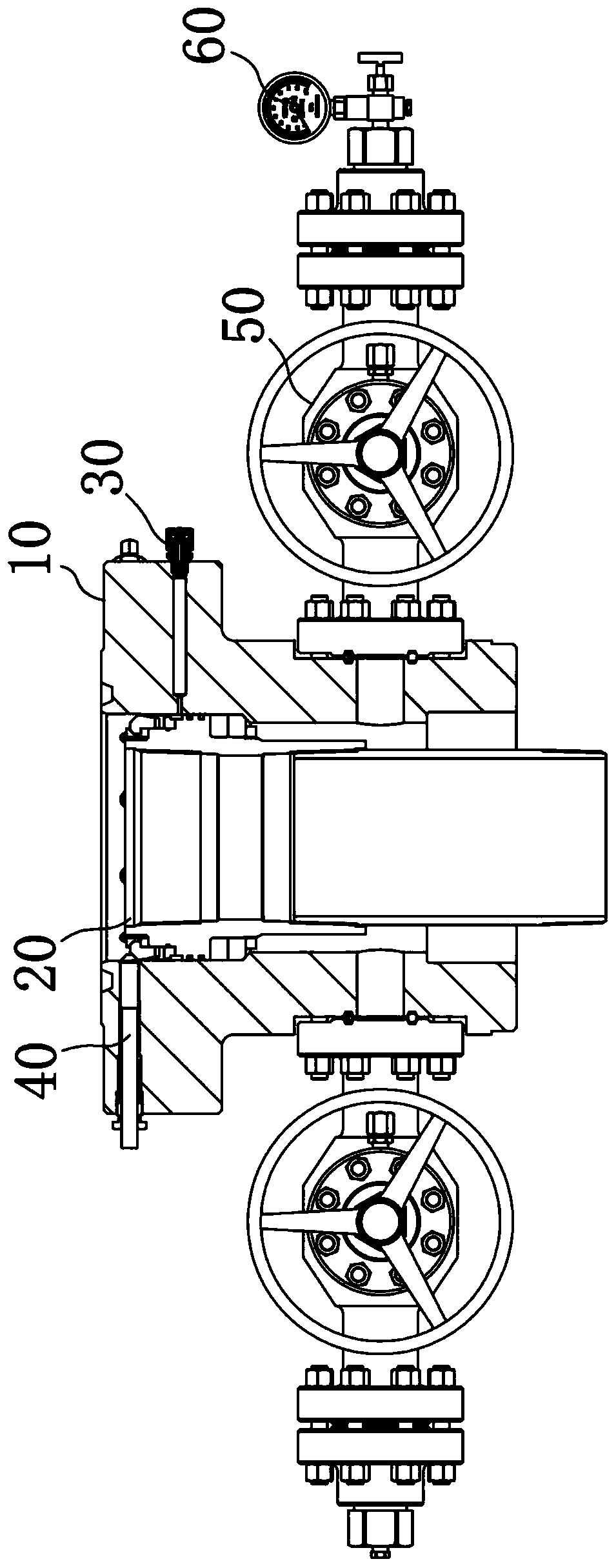

[0047] refer to figure 1 As shown, a composite driving mandrel anchoring casing head includes a casing head housing 10 and an anchoring mandrel unit 20, and the anchoring mandrel unit 20 is set and sealed in the casing head housing 10 and is connected with the casing head housing 10. The casing 10 of the casing head is anchored, which can satisfy the suspension of the mandrel hanger, avoid the movement of the pipe string, and increase the stability and reliability of the casing head.

[0048] Generally speaking, a plurality of wellhead valves 50 and pressure measuring components 60 can be installed on the outside of the casing head housing 10 . The wellhead valve 50 may be, for example, a flat valve; the pressure measuring member 60 may be, for example, a pressure gauge.

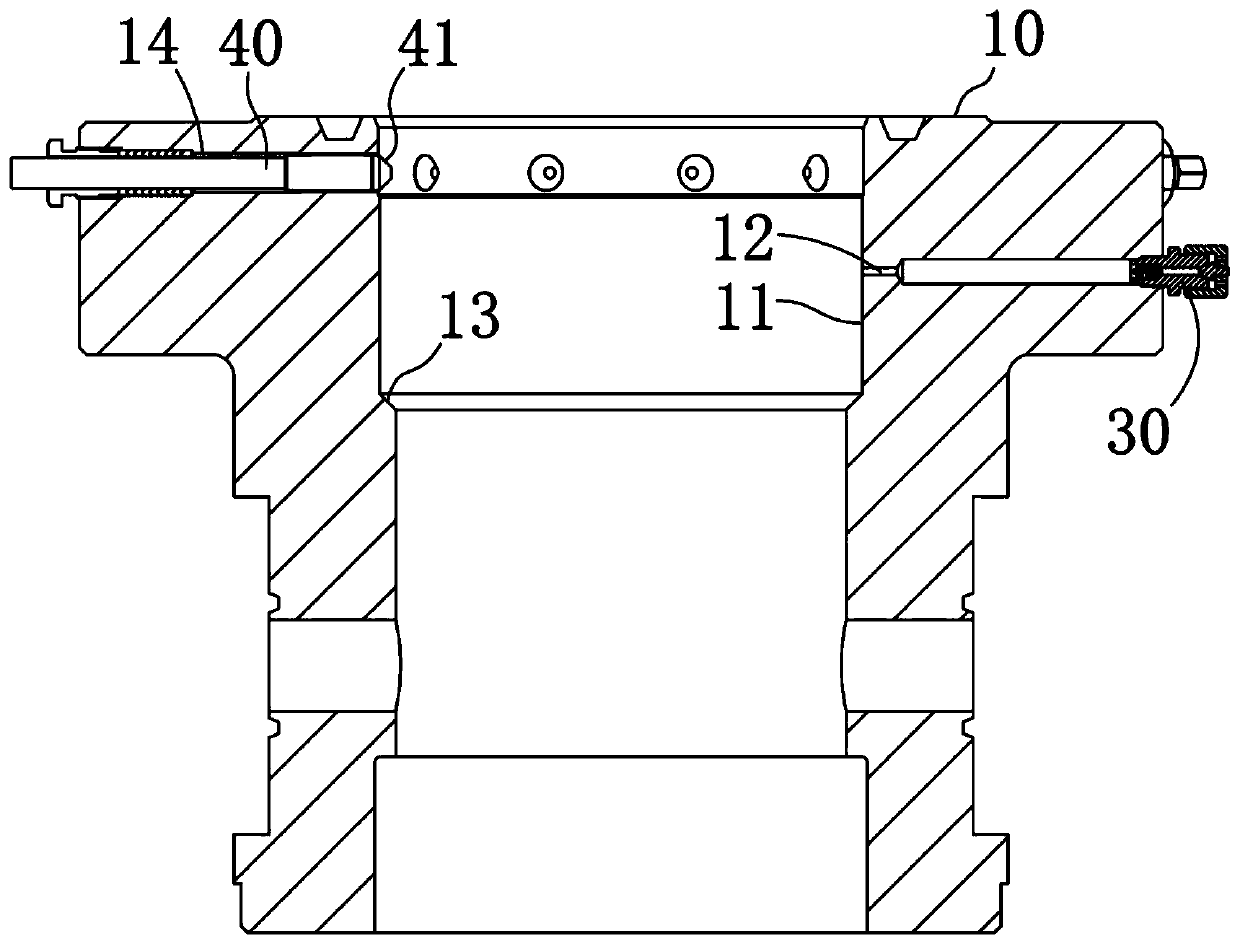

[0049] refer to figure 2 , the casing head housing 10 has a vertically arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com