Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about How to "Improve cloth efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

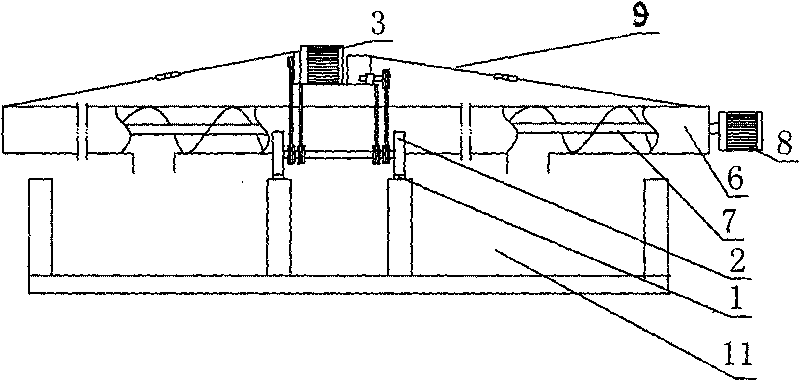

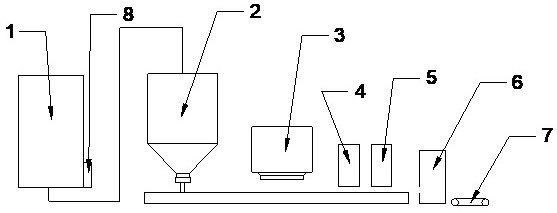

Concrete spreader

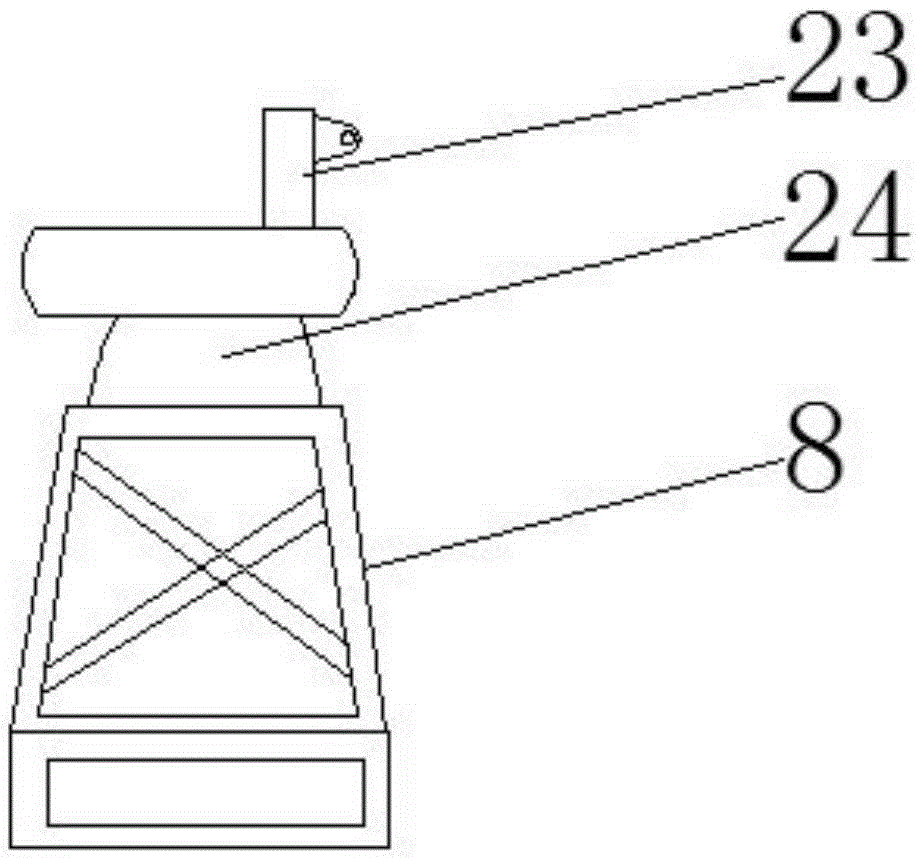

The invention discloses a concrete spreader, mainly comprising a rack (1), a conical tower (2), a counterweight frame (3), a counterweight box (4), a hydraulic station (5), an electric cabinet (6), areducer (7), a big-arm support (8), a big arm (9), a small arm (10), a big-arm oil cylinder (11), a small-arm oil cylinder (12), a connecting rod pair (13), an antifriction bearing (14) and a spreading tube (15). The concrete spreader is characterized in that the conical tower (2) is movably fixed on the rack (1) by a bearing, the counterweight frame (3) is fixed on the conical tower (2), the counterweight box (4) is fixed at the lower part of the tail end of the counterweight frame (3), the hydraulic station (5) is fixed on the upper part of the tail end of the counterweight frame (3), the reducer (7) is arranged on the counterweight frame (3), the big-arm support (8) is fixed on the counterweight frame (3), one end of the big arm (9) is movably connected with the conical tower (2) and the other end thereof is connected with the small arm (10) by the antifriction bearing (14), a fixed support of the connecting rod pair (13) is arranged on the big arm (9) and the other fixed support thereof is arranged on the small arm (10), thereby achieving the design purpose.

Owner:夏成新

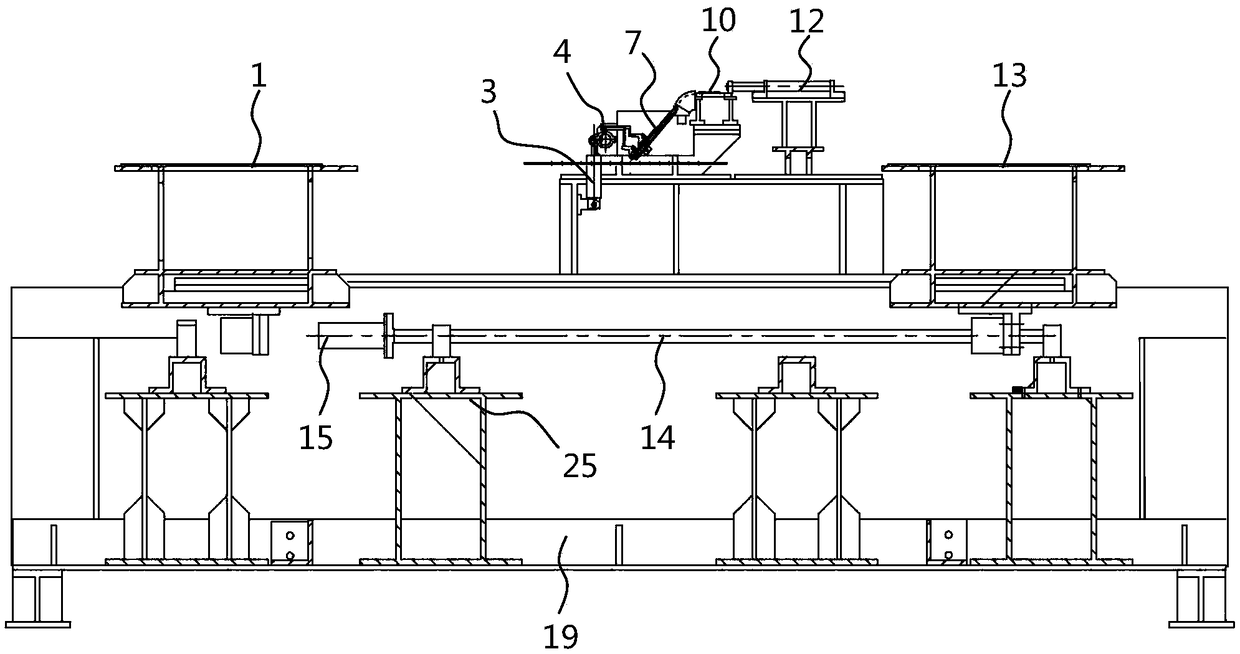

Concrete spreader

InactiveCN103470052ASimple structureGuaranteed uptimeBuilding material handlingMotor speedLight rail

The invention discloses a concrete spreader, which consists of a distributing hopper assembly, a feeding hopper assembly, a large vehicle beam assembly, a distributing frame and a feeding frame, wherein the distributing hopper assembly is arranged on two parallel straight light rail tracks of the large vehicle beam assembly; the large vehicle beam assembly is arranged on two parallel straight light rail tracks of the distributing frame; the feeding hopper assembly is arranged on two parallel straight light rail tracks of the feeding frame; two distributing hopper walking beams are connected with a distributing hopper shell steel structure by welding; a stirring shaft and a spreading shaft are arranged in the distributing hopper shell steel structure, and are connected and driven by using a small motor speed reducer and a large motor speed reducer respectively; a plurality of discharging hole doors are arranged at the bottom of the distributing hopper steel structure, and are connected and driven by using a plurality of air cylinders for opening and closing; a feeding hopper walking beam walks on the two parallel straight light rail tracks on the feeding frame; an arc-shaped door is arranged at the bottom of the feeding hopper shell steel structure; the arc-shaped door is connected and driven by using an oil cylinder. The concrete spreader has the advantages of spreading flexibility, running reliability, automation, high efficiency and high practicability.

Owner:CHANGSHA BROAD HOMES IND GRP CO LED

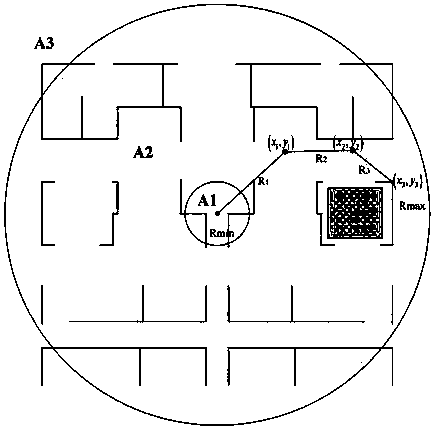

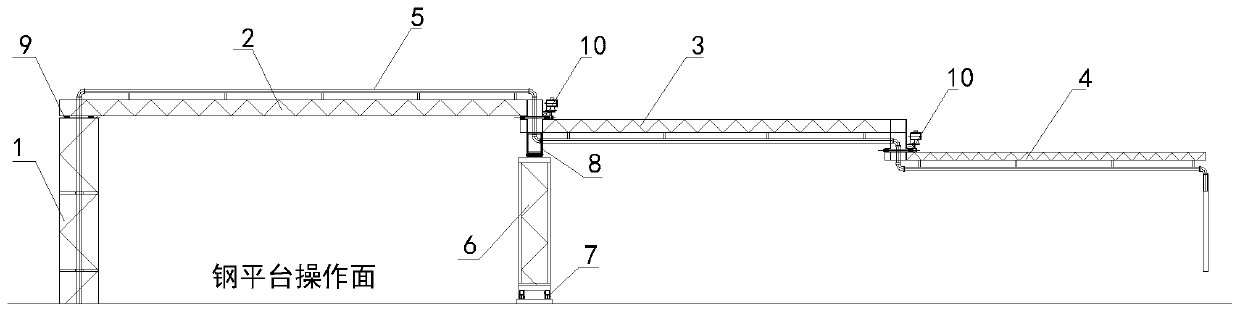

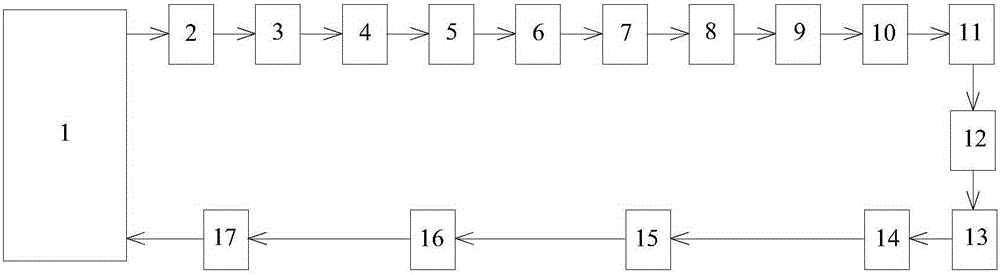

Intelligent concrete distribution control system and method for transverse folding arm concrete spreader

ActiveCN111058637AImprove cloth efficiencyImprove pouring qualityBuilding material handlingDistribution controlControl system

The invention discloses an intelligent concrete distribution control system and method for a transverse folding arm concrete spreader, and belongs to the field of construction engineering machinery. The intelligent concrete distribution system comprises an intelligent terminal, a PLC, a first driver, a second driver, a flow valve, an angle sensor and a flow sensor. According to the system and method, control parameters are sent to the PLC through the intelligent terminal, the first driver and the second driver are controlled by the PLC, and angle control over a rotary mechanism and opening degree control over the flow valve are realized, so that automatic intelligent concrete distribution can be realized through the horizontal folding arm concrete spreader, the concrete distribution position and flow can be precisely controlled, the labor cost is reduced, the concrete distribution efficiency is improved, and the industrialization level of the construction concrete spreader is improved.Meanwhile, the rotation angle of an arm frame, the concrete pouring flow, the position of a discharging port of a pump pipe and the concrete pouring progress can be monitored, precise concrete pouring is achieved, and the concrete pouring quality is improved.

Owner:SHANGHAI CONSTRUCTION GROUP

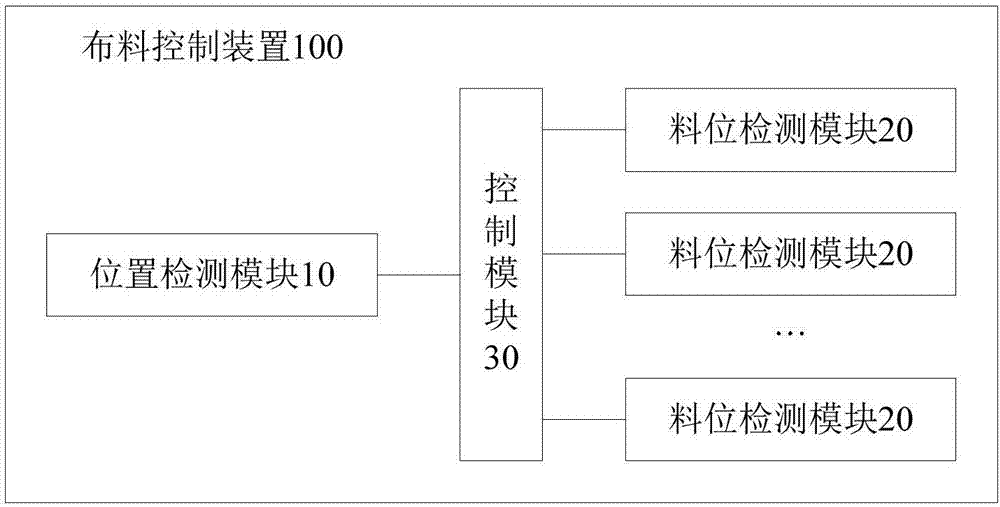

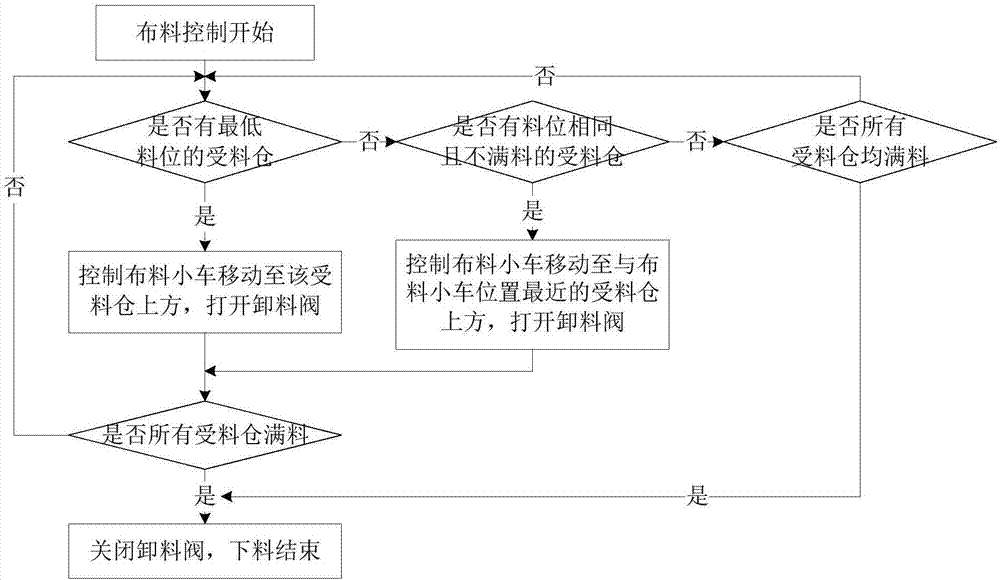

Material distributing controlling device, system and method

The present invention proposes a material distribution control device, system and method, wherein the material distribution control device includes: a position detection module, the position detection module is used to detect the current position of the distribution trolley to obtain the position information of the distribution trolley; corresponding to each receiving bin The set material level detection module, each material level detection module is used to detect the material level of the corresponding receiving bin, so as to obtain the material level information of all receiving bins; the control module, the control module and the position detection module, each material level The detection modules are connected, and the control module is used to control the distributing trolley to carry out the distributing work according to the material level of each receiving bin and the position information of the distributing trolley until all the receiving bins are in a full state. When the material distribution control device controls the material distribution of the material distribution trolley, it has fast response and calculation speed, strong expansion capability, flexible and stable control mode, less detection components, convenient installation, and high material distribution efficiency, which helps to reduce the maintenance workload and cost in the later period. Low.

Owner:SHENWU TECH GRP CO LTD

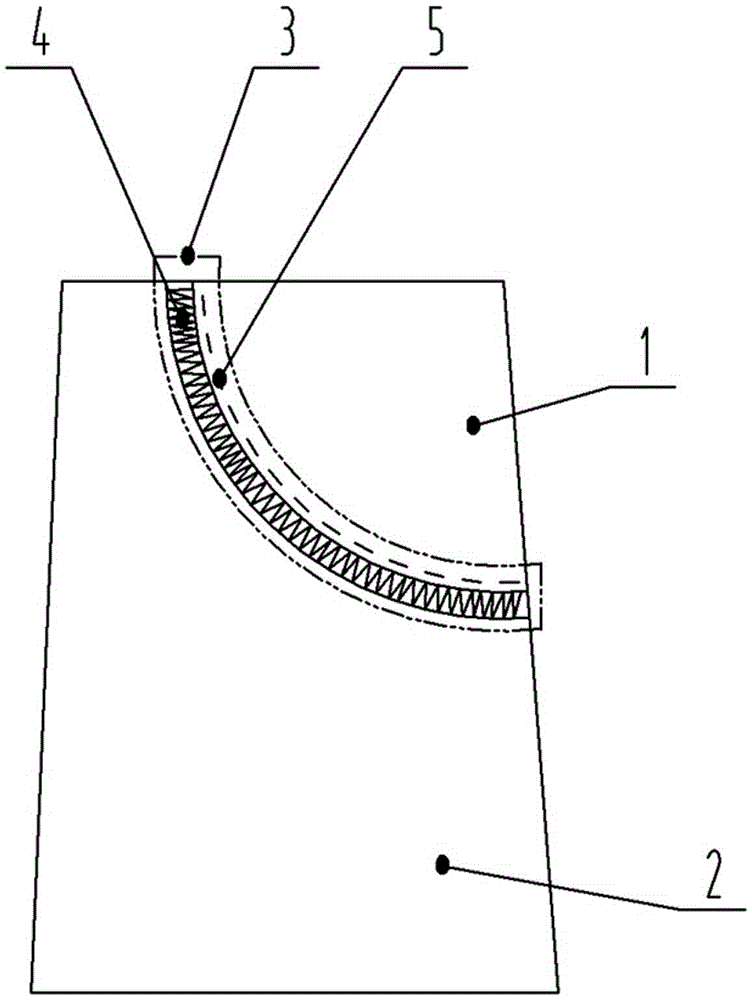

Clothing hanging conveying system

PendingCN111252460AMaintain stabilityImprove clothing efficiencyConveyorsClothes making applicancesClothes hangerStructural engineering

The invention relates to a clothing hanging conveying system, and belongs to the technical field of clothing product conveying equipment. The clothing hanging conveying system comprises a conveying assembly suspended and fixed to the top of a working environment, steering assemblies are arranged at the two ends of the conveying assembly, and an auxiliary conveying assembly is arranged at a rail ofthe conveying assembly; the conveying assembly comprises a fixed frame suspended and fixed to the top of the working environment, mounting strips fixed to the bottom of the fixed frame and overall inan L shape, main conveying rails parallelly arranged on the multiple mounting strips in a two-phase symmetry mode and located at the bottom of the fixed frame, and a driving piece mounted on the inner wall of the fixed frame; and a support is vertically fixed to the side walls of the main conveying rails, the position, close to the main conveying rails, of the support is provided with a station output assembly and a station input assembly, hanger wheels are slidably connected to top face rails of the main conveying rails, and the sides, away from the main conveying rails, of the hanger wheelsare provided with hangers.

Owner:佛山市顺德区宏盈制衣有限公司

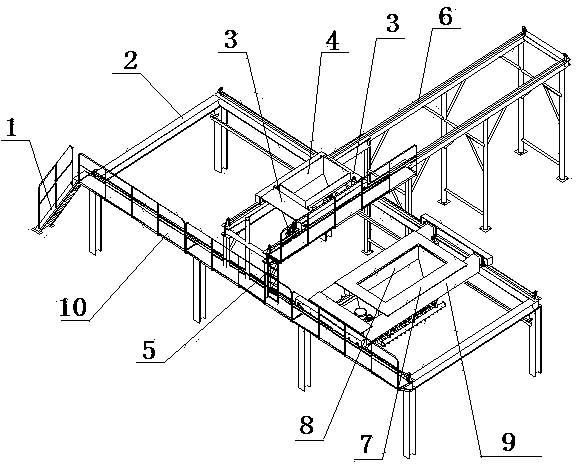

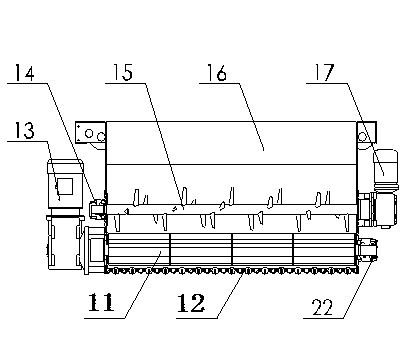

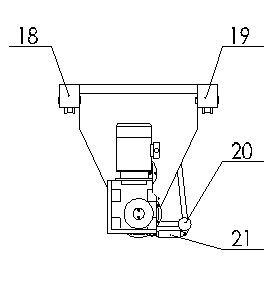

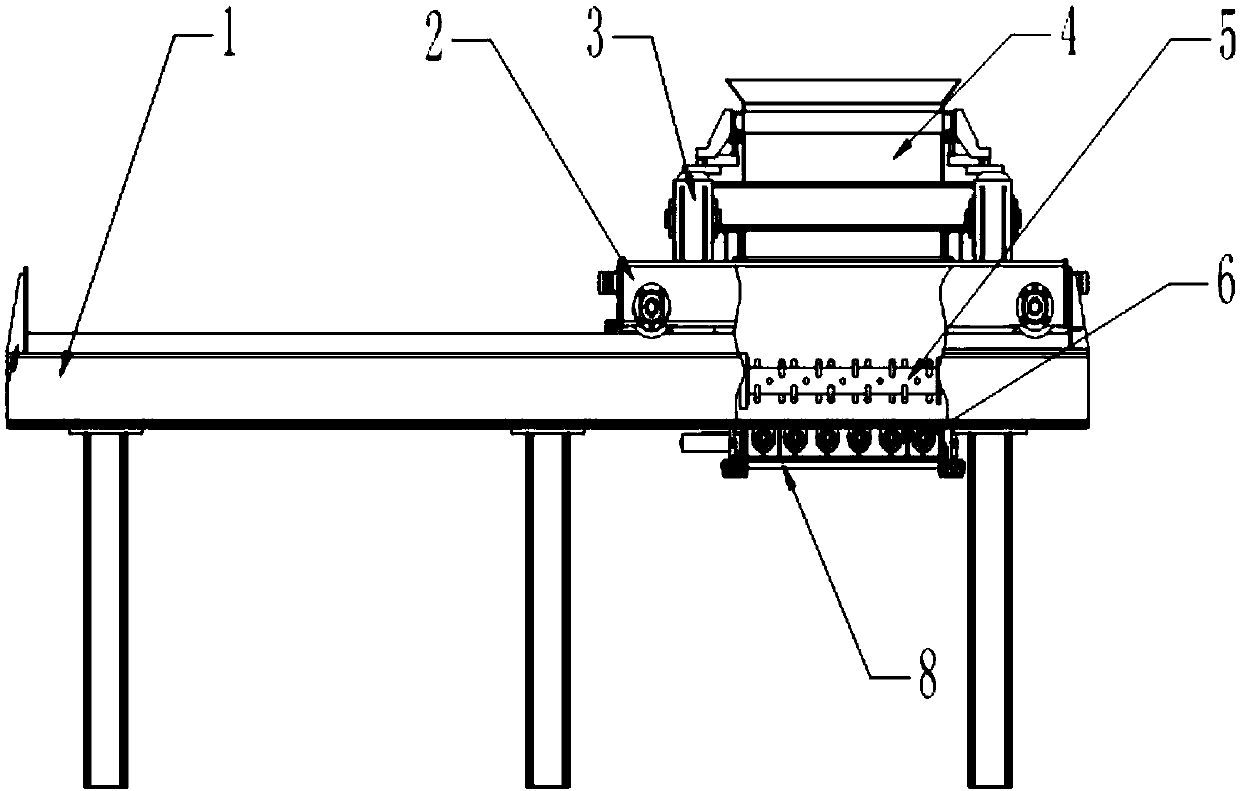

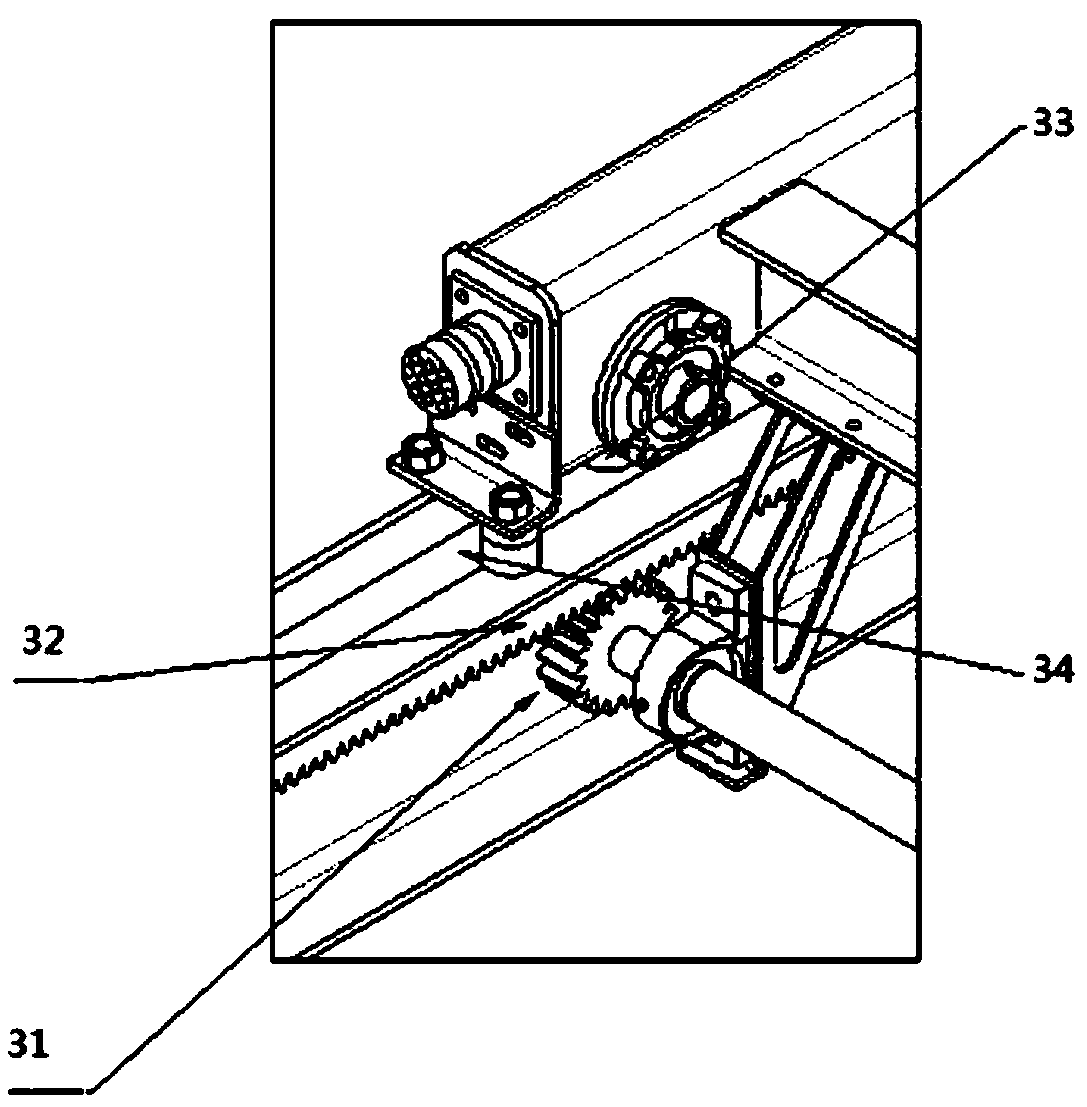

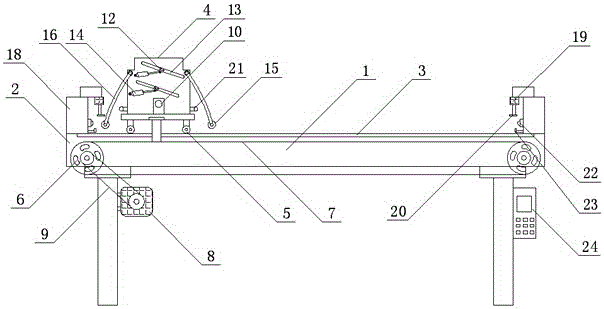

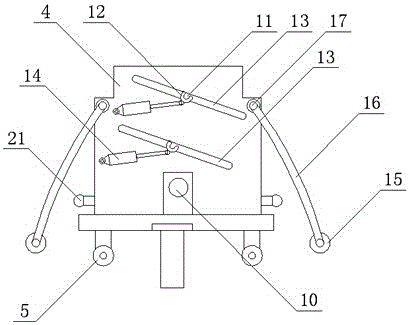

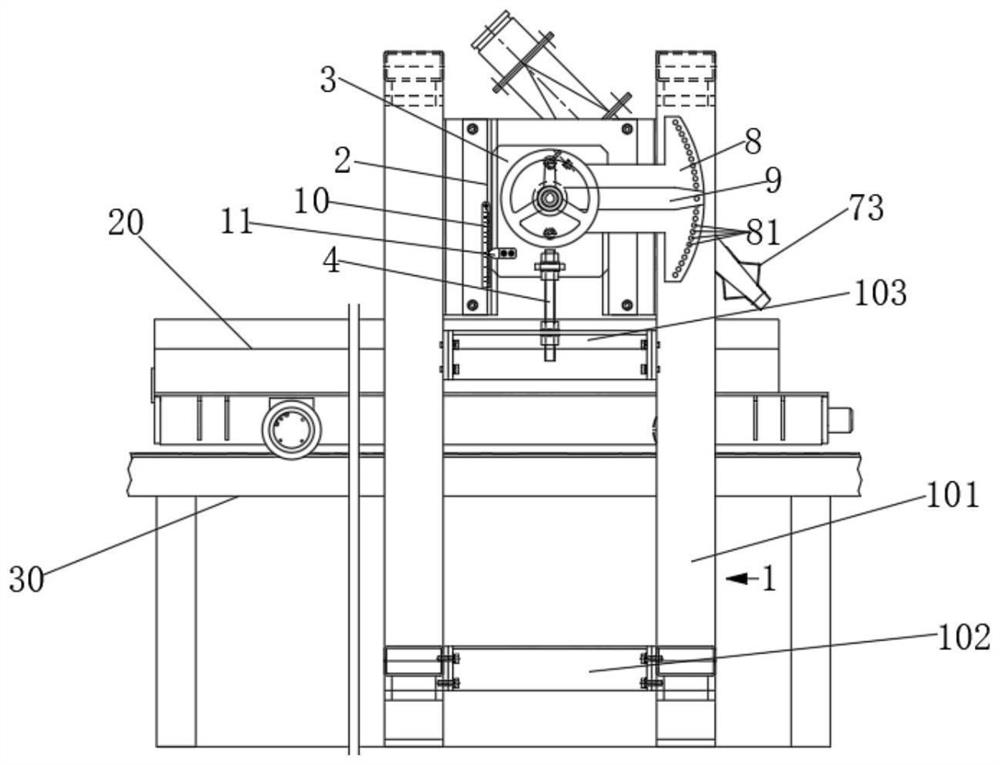

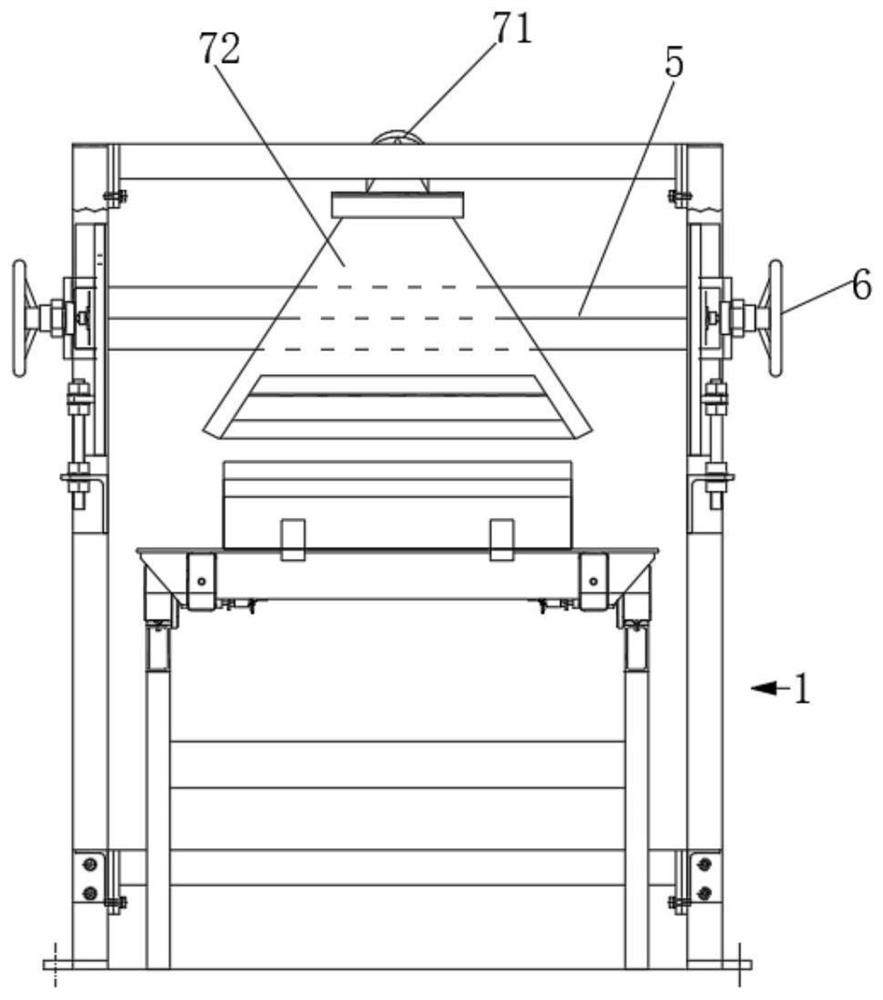

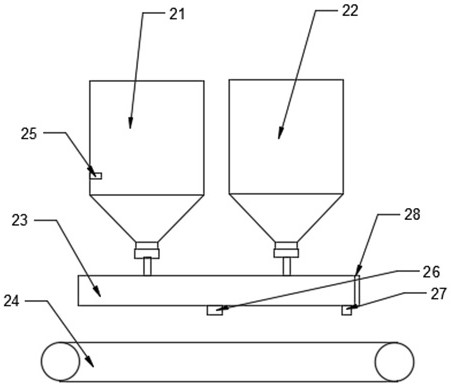

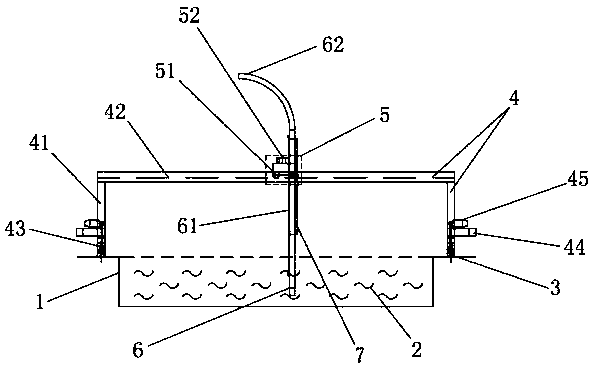

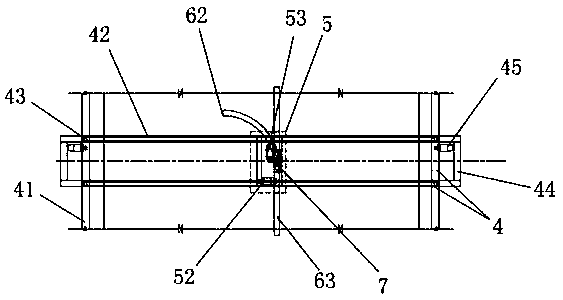

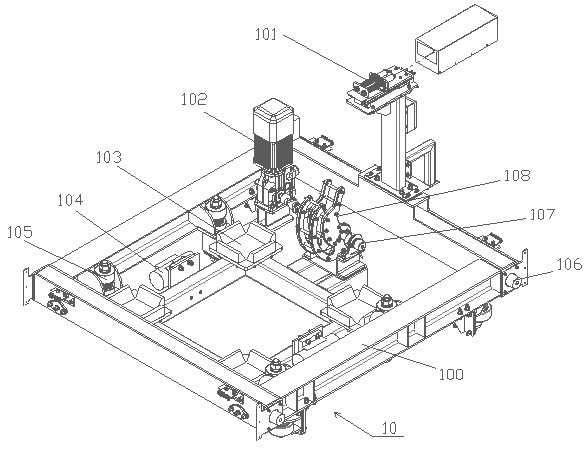

Concrete spreading experimental platform with functions of precise positioning and fine spreading

InactiveCN108678379AAccurate amount of fabricEasy to controlBuilding material handlingMicro motionEngineering

The invention belongs to the field of research and development of concrete member production equipment, and particularly relates to a concrete spreading experimental platform with functions of precisepositioning and fine spreading. According to the technical scheme, the concrete spreading experimental platform with the functions of precise positioning and fine spreading comprises a spreading system and a traveling system, wherein the spreading system comprises a hopper, a scattering device, a screw conveying device, gate assemblies and a bottom plate assembly; the traveling system comprises asteel-structure bracket, a large-vehicle micro-motion traveling device and a small-vehicle micro-motion traveling device, the large-vehicle micro-motion traveling device is mounted on the steel-structure bracket, the small-vehicle micro-motion traveling device is mounted on the large-vehicle micro-motion traveling device, and the spreading system is mounted on the small-vehicle micro-motion traveling device. Quantity and shape of the scattering device and the screw conveying device can be adjusted as required, the scattering device and the screw conveying device can be replaced as required, experimental study for factors affecting spreading precision and wear of core parts can be performed, and spreading compensation technique can be studied in real time according to change of spreading quantity.

Owner:SHENYANG JIANZHU UNIVERSITY

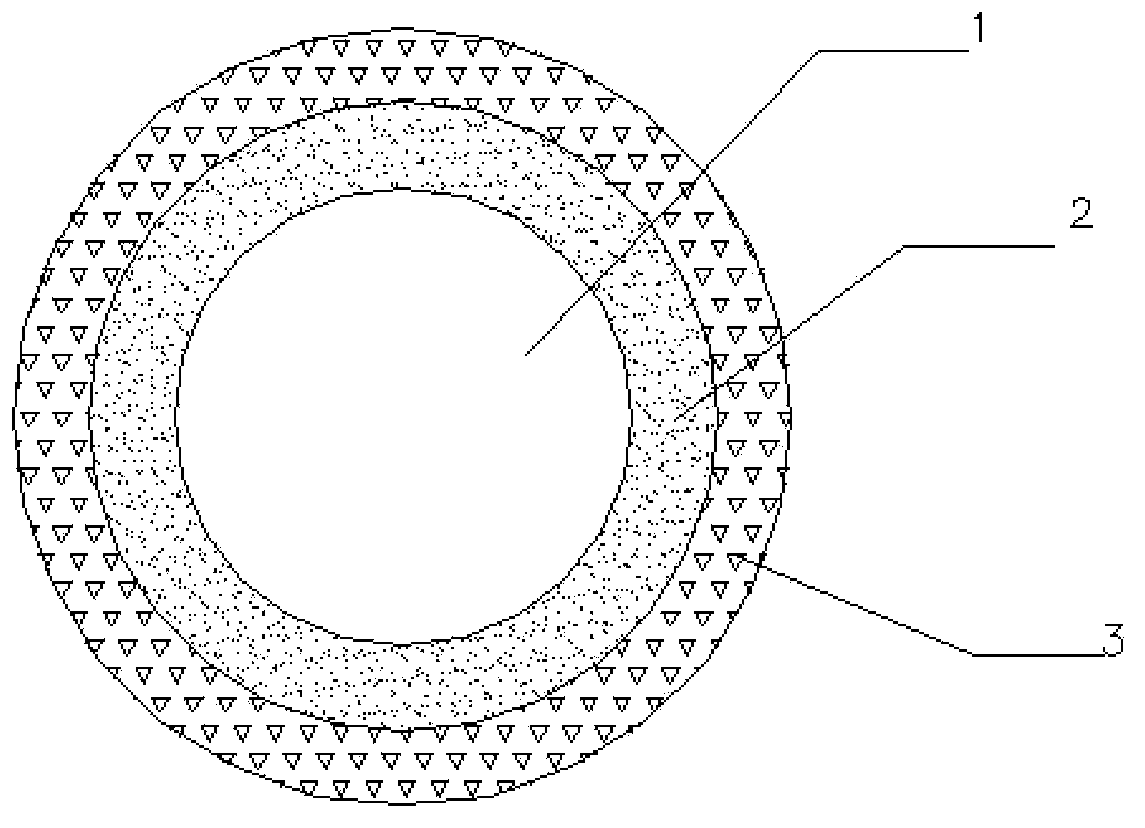

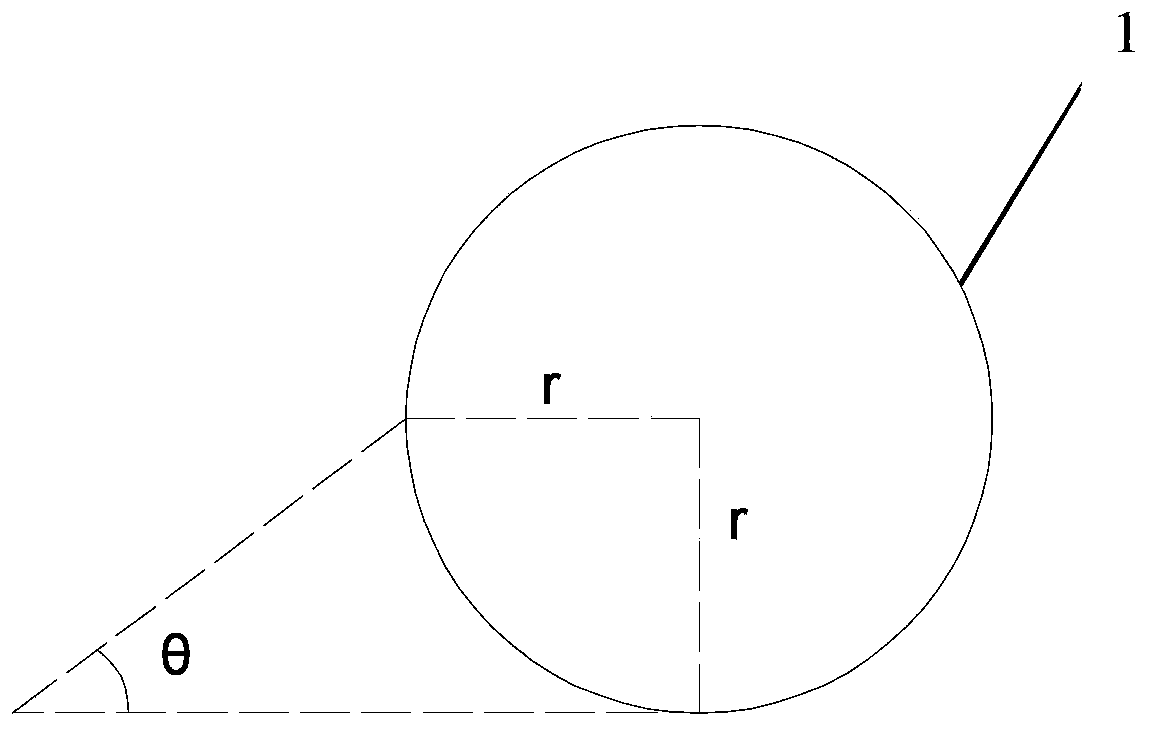

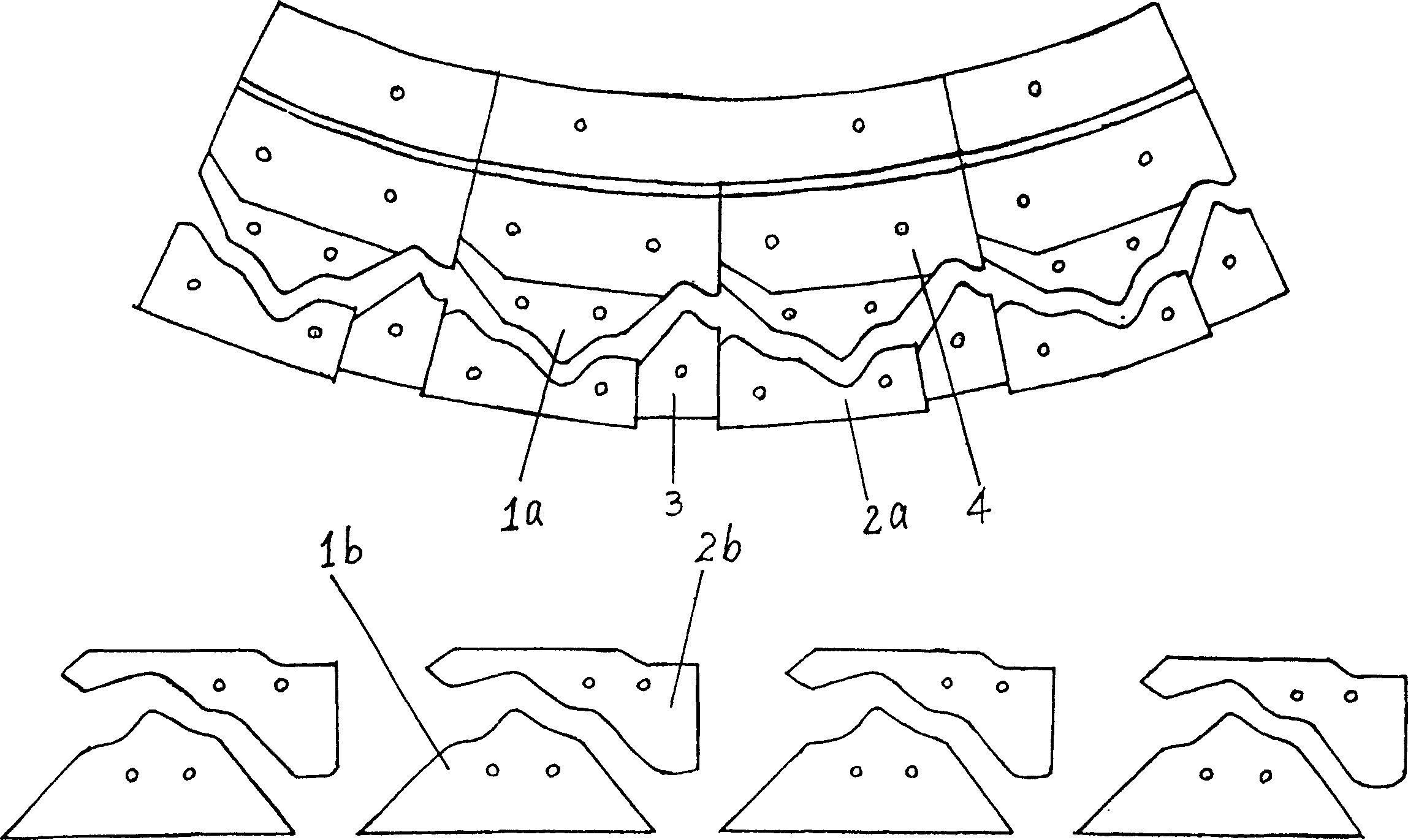

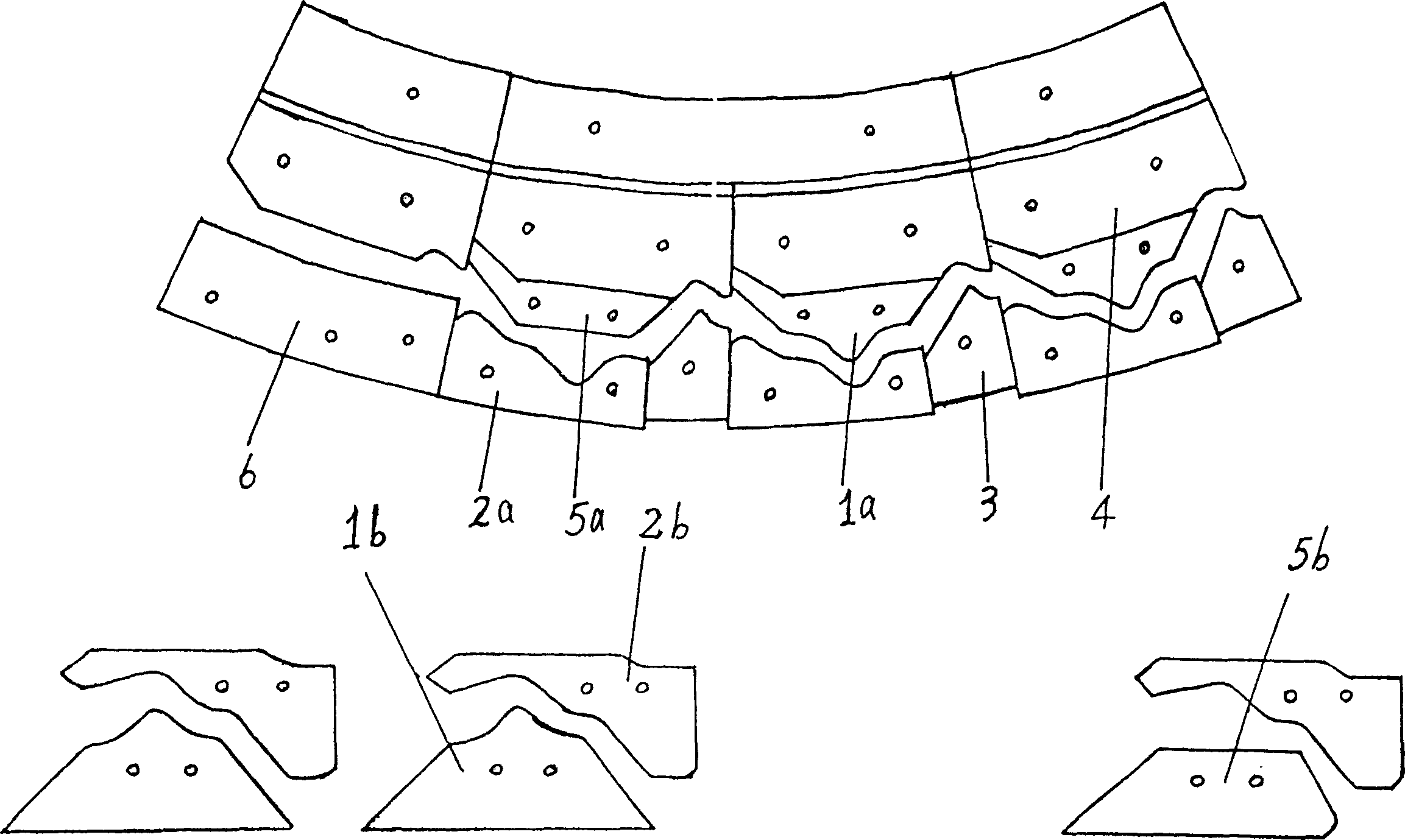

Material distribution technology of one-time forming brazing super-hard material grinding tool

ActiveCN103522206AGood effectSimple and fast operationBonded abrasive wheelsGrinding devicesWear particleMetallurgy

The invention discloses a material distribution technology of a one-time forming brazing super-hard material grinding tool. The material distribution technology includes the following steps that firstly, composite pellets are prepared for standby application, the peripheries of abrasive particles are coated with solder layers to form a composite body, and the periphery of the composite body is coated with a paraffin layer to form composite pellets; secondly, the surface of a base body is cleaned; thirdly, a material distribution area of the surface of the base body is brushed and coated with binding agents; fourthly, the composite pellets are spread in the material distribution area, obtained in the third step, of the surface of the base body, the composite pellets are tightly distributed and stuck to the material distribution area of the surface of the base body so that semi-finished products can be obtained; fifthly, the surfaces of the semi-finished products are cleaned, and the semi-finished products are prepared to be welded. According to the material distribution technology of the one-time forming brazing super-hard material grinding tool, due to the fact that the abrasive particles and solder are matched according to a certain relation and made into the composite body according to a particle preparing technology, a layer of paraffin coats the outer face of the composite body to form the composite pellets, and therefore the material distribution technology is greatly simplified; use of material distribution equipment is combined, stability of the quality of brazing is ensured, and industrial production operation is facilitated. According to the designed scheme, adaptability to workpieces is good, the brazing quality is stable, and the material distribution technology is suitable for industrial production.

Owner:广东省电力线路器材厂有限公司

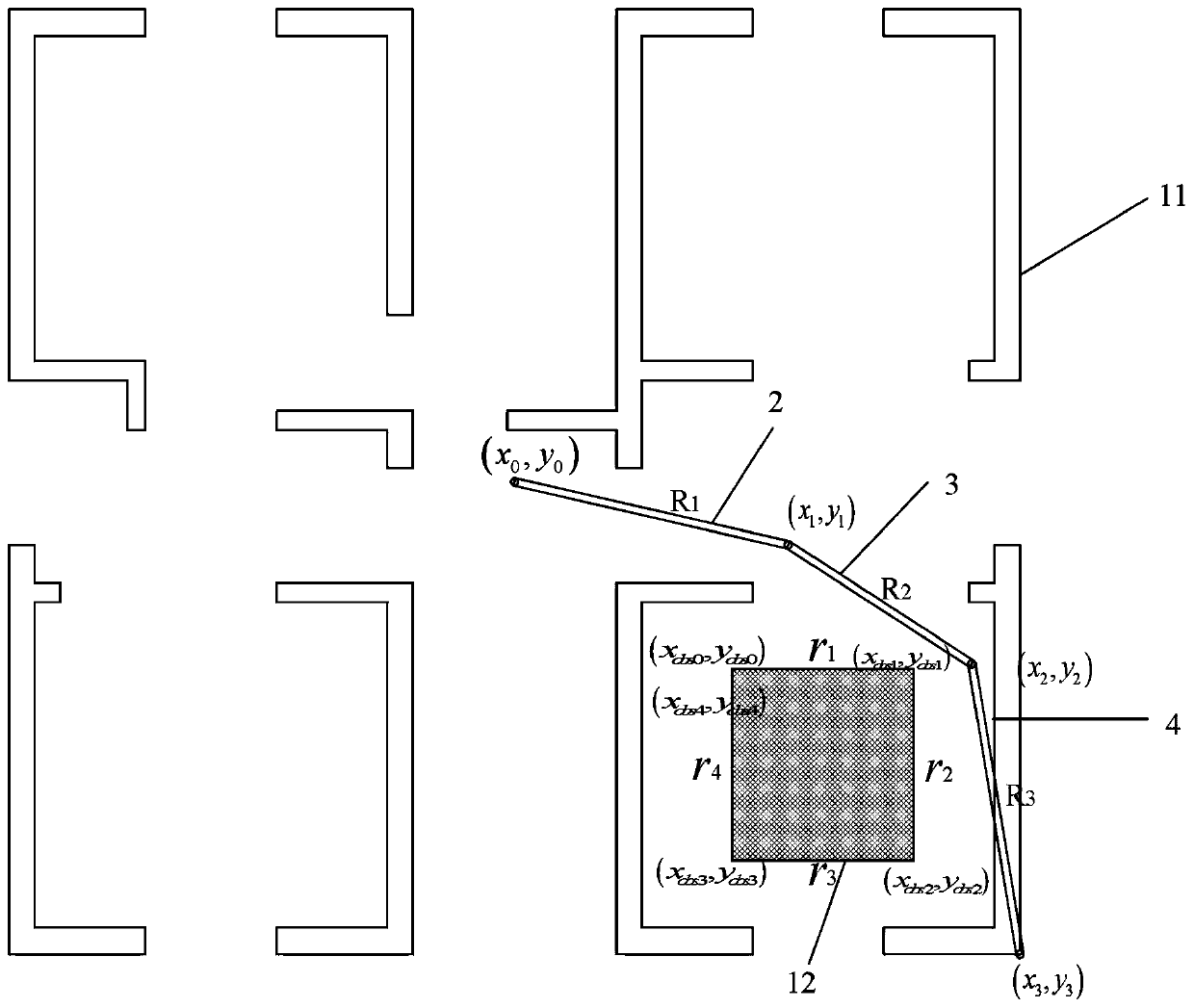

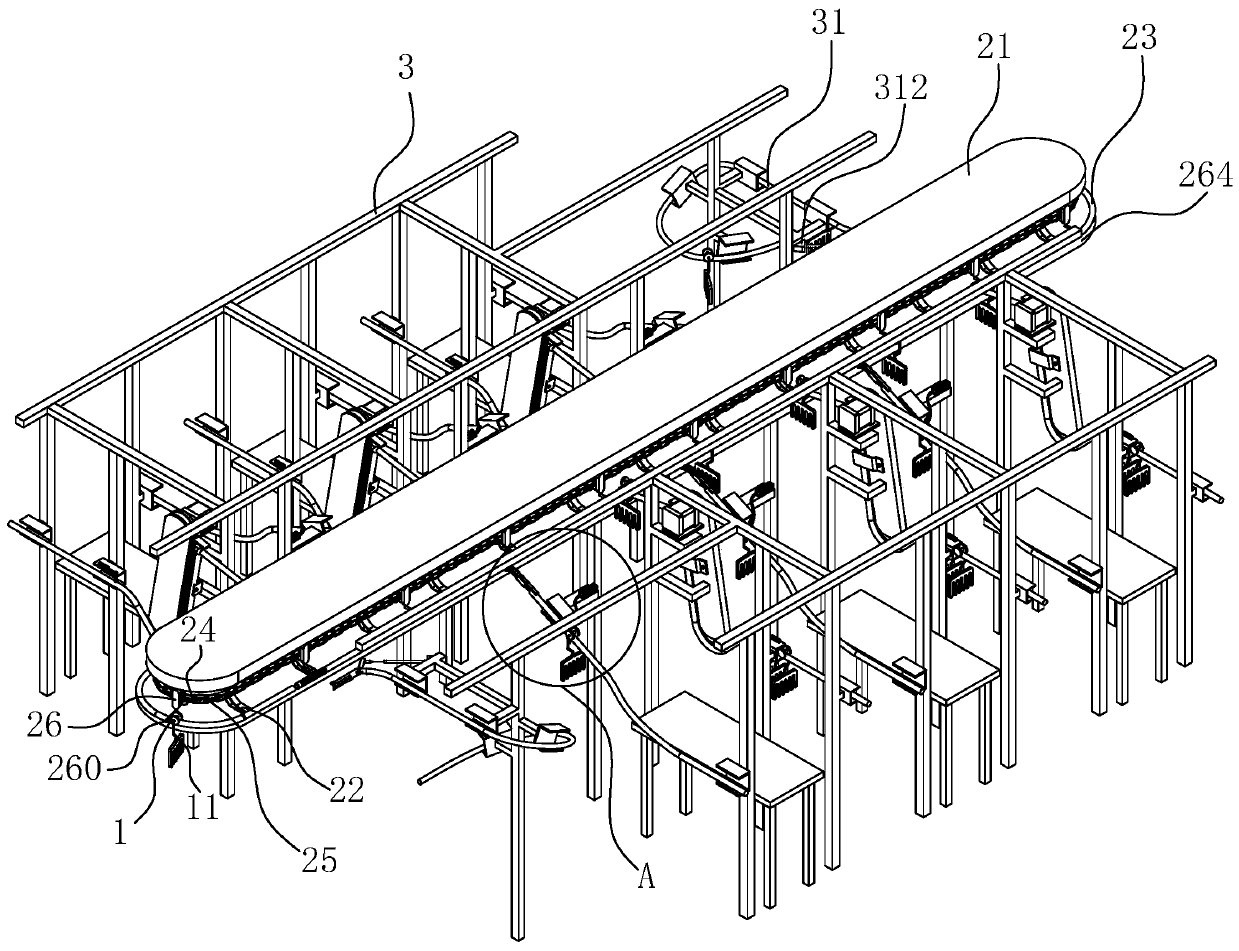

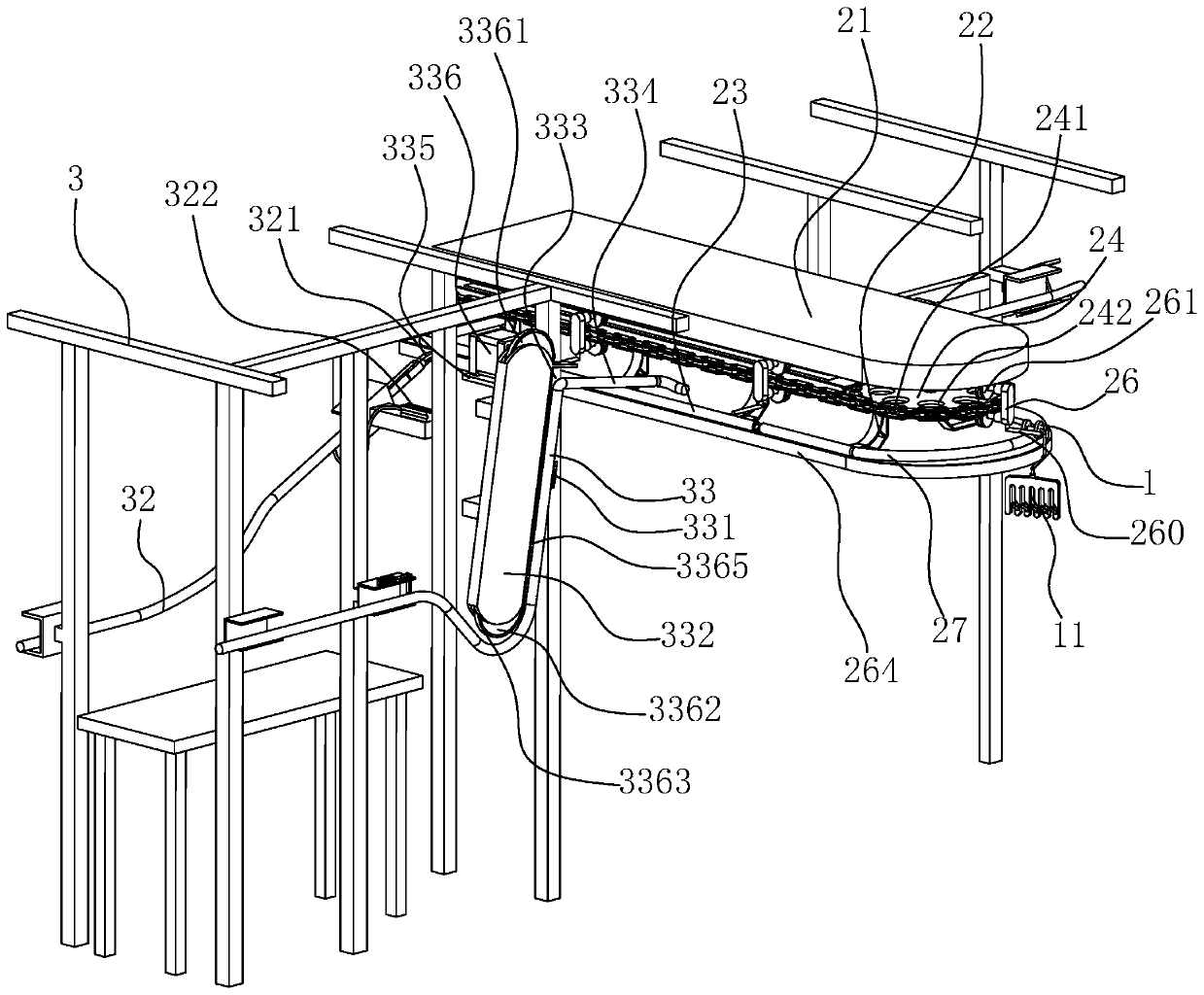

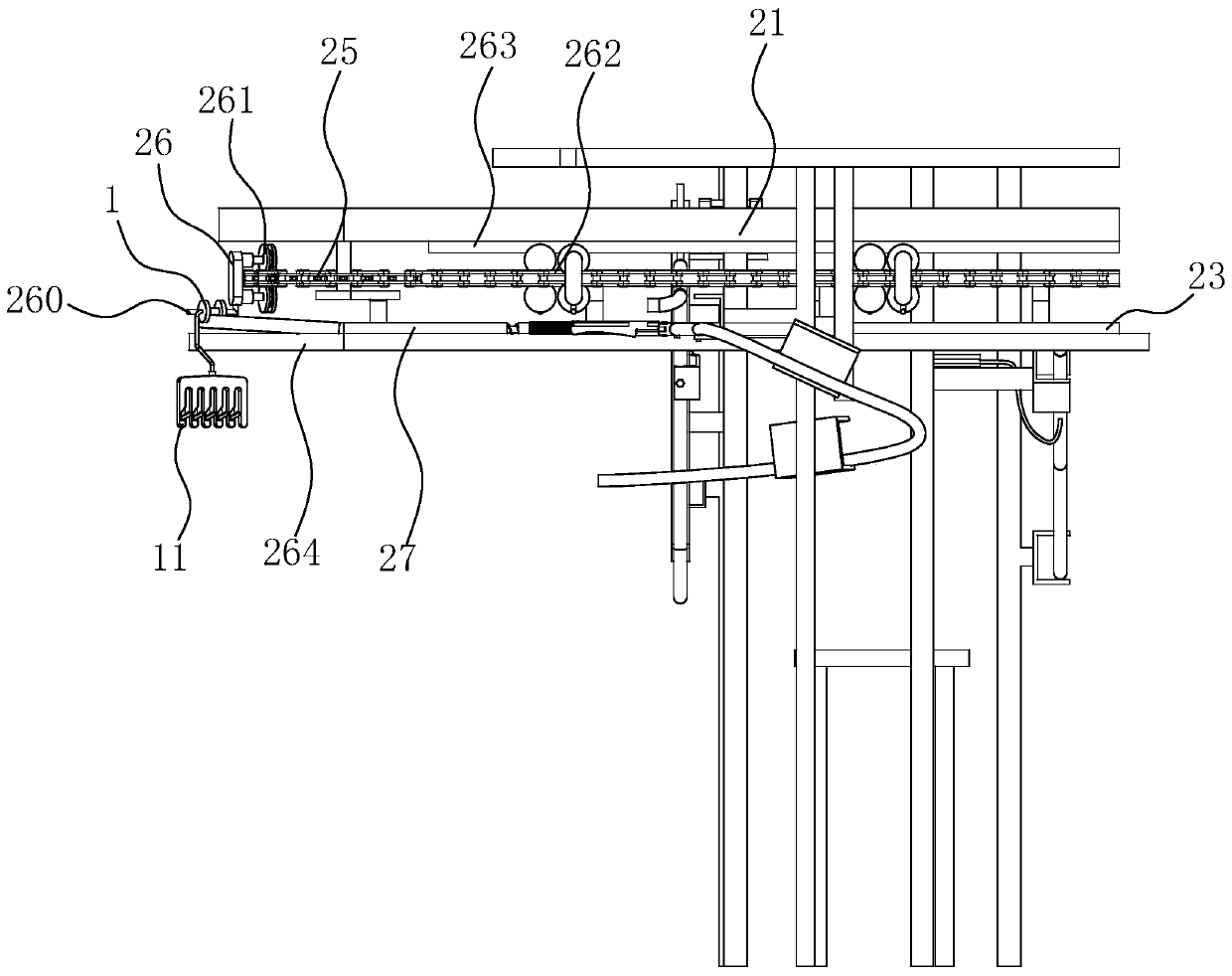

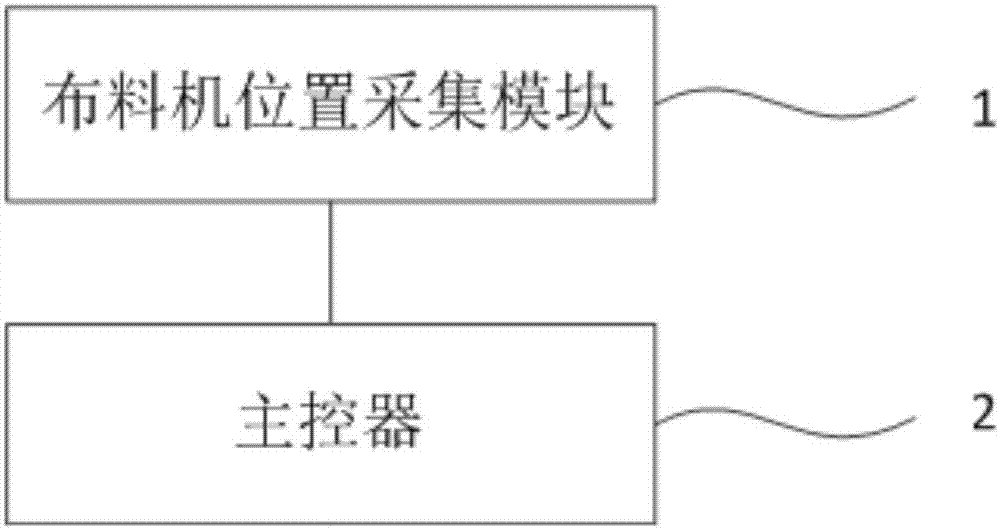

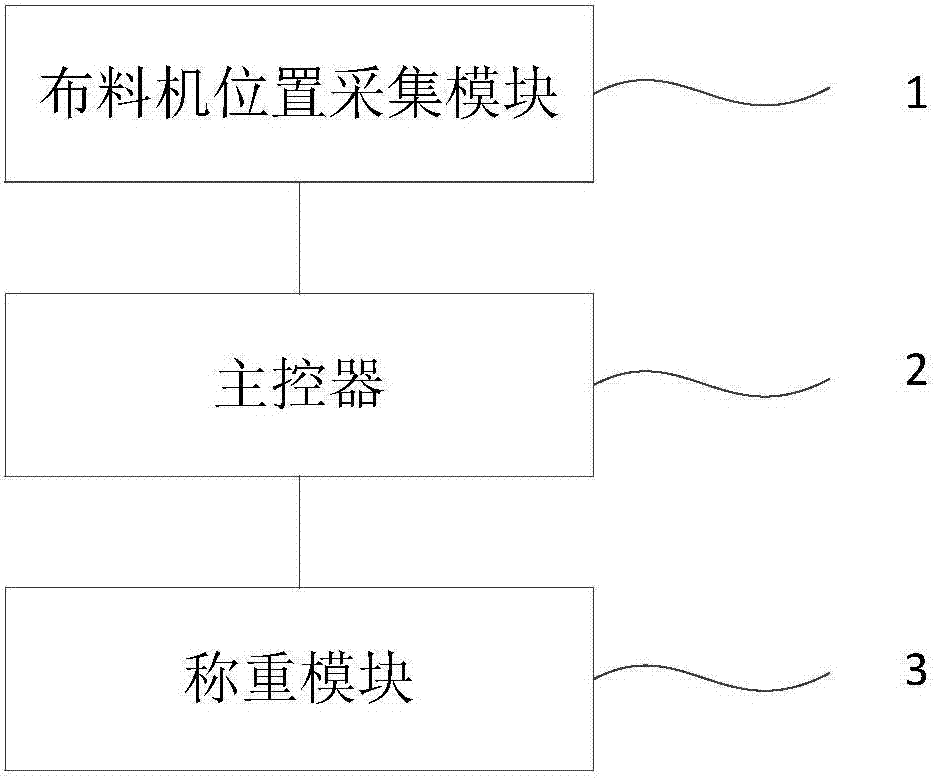

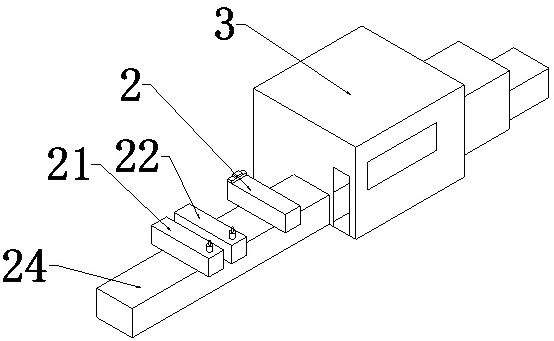

Material distribution control system and method of material distributor

ActiveCN107214834APrecise positioningImprove cloth efficiencyFeeding arrangmentsAuxillary shaping apparatusDistribution controlData processing

The invention discloses a material distribution control system and method of a material distributor. The material distribution control system comprises a material distributor position collection module for collecting position information of the material distributor and sending a position signal to a main controller; the main controller for receiving the position signal sent by the material distributor position collection module and processing data, wherein when the material distributor moves to a preset monitoring position, the main controller controls the material distributor to perform corresponding operation. By application of the material distribution control system of the material distributor, the material distributor position collection module locates the position of the material distributor, so as to realize precise locating of the material distributor during bench formwork material distribution and realize precise material distribution.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

Multipurpose spreading machine with flattening and cloth-pressing functions

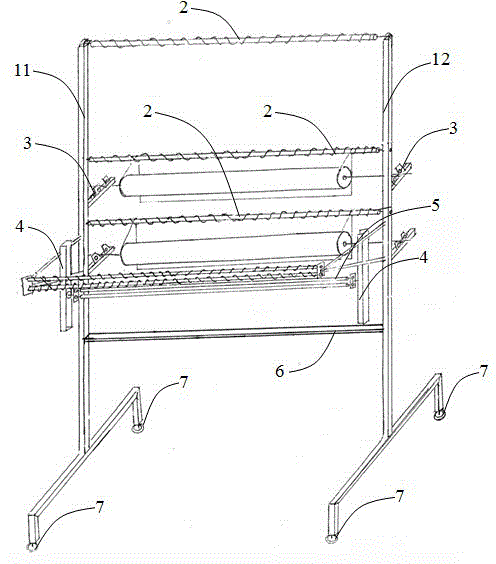

The invention relates to a multipurpose spreading machine with flattening and cloth-pressing functions. The multipurpose spreading machine includes a rack (1). The multipurpose spreading machine is characterized in that two sides of a spreading platform (2) are respectively provided with a side slide rail (3), a door type structure movable spreading frame (4) is arranged on the side slide rail (3), a bottom side of the rack (1) is provided with a reciprocating driving device along the side slide rail (3), one side middle part of the movable spreading frame (4) is provided with a first-stage scroll laying position (10), the upper part of the movable spreading frame (4) is provided with more than one upper scroll laying positions (11), electromagnetic pressurizing devices (19) are mounted on the inner sides of initial fixed mounts (18), and the lifting ends of the electromagnetic pressurizing devices (19) are equipped with cloth-pressing rods (20). The multipurpose spreading machine provided by the invention has a high degree of automation, can pull open a coiled cloth material and spread it on the spreading platform, the uncoiled cloth material does not deviate or wrinkle, also a plurality of cloth rolls can be operated simultaneously each time to release layers of cloth, and the spreading efficiency is greatly improved.

Owner:JIHUA 3506 TEXTILE & APPL

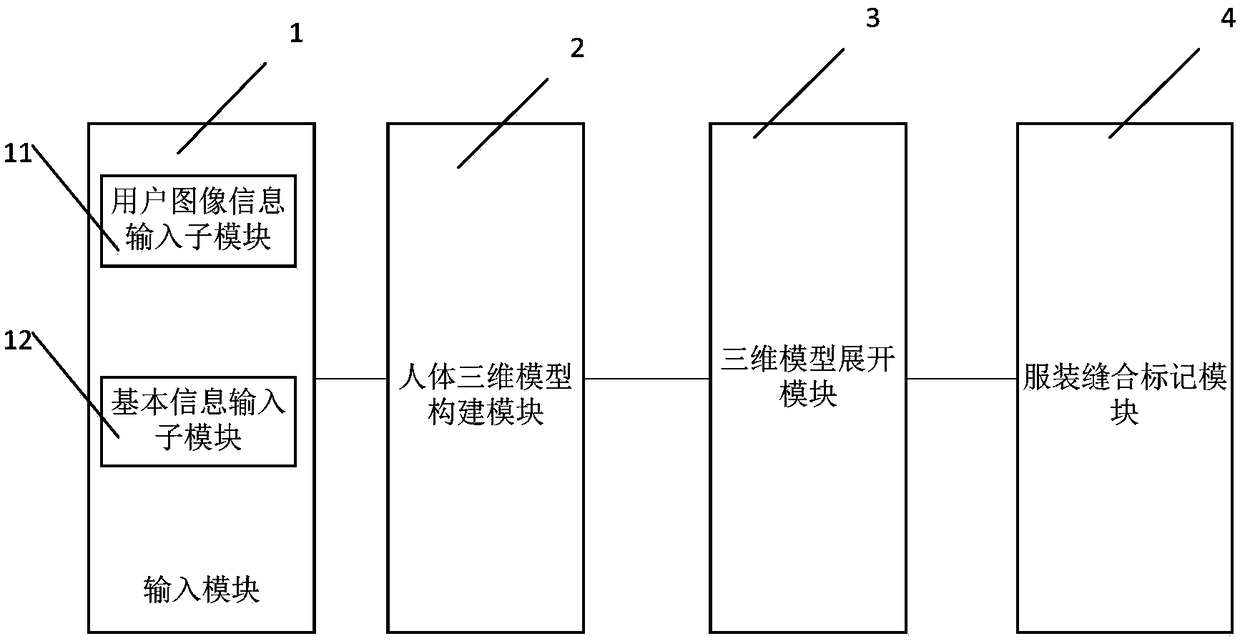

Intelligent cloth cutting system and method

InactiveCN108876913AFor precise cuttingFast croppingImage analysisGeometric image transformationHuman bodyComputer module

The invention discloses an intelligent cloth cutting system comprising an input module, a human body three-dimensional model building module, a three-dimensional model unfolding module and a cloth sewing marking module, wherein the human body three-dimensional model building module is used for building a human body three-dimensional model of a user according to body size information of the user; the three-dimensional model unfolding module is used for cutting and unfolding the human body three-dimensional model according to cutting design of a cloth sample selected by the user, and generatinga two-dimensional cloth cutting and unfolding image which is the same as the design of the cloth sample and matches the body size of the user; the cloth sewing marking module is used for marking cutting lines, cutting and sewing lines, accessories and splicing positions of accessories on the two-dimensional cloth cutting and unfolding image. According to the intelligent cloth cutting system and the method, the two-dimensional cloth cutting and unfolding image can be accurately obtained according to human body three-dimensional model data of the user, clothing factory can cut a cloth sheet according to the two-dimensional cutting and unfolding image, sew cloth according to the sewing lines, thereby clothing efficiency can be improved, sewn cloth is matched with the body size of the user, and effect of cutting cloth to fit the body size can be achieved.

Owner:天门市志远信息科技有限公司

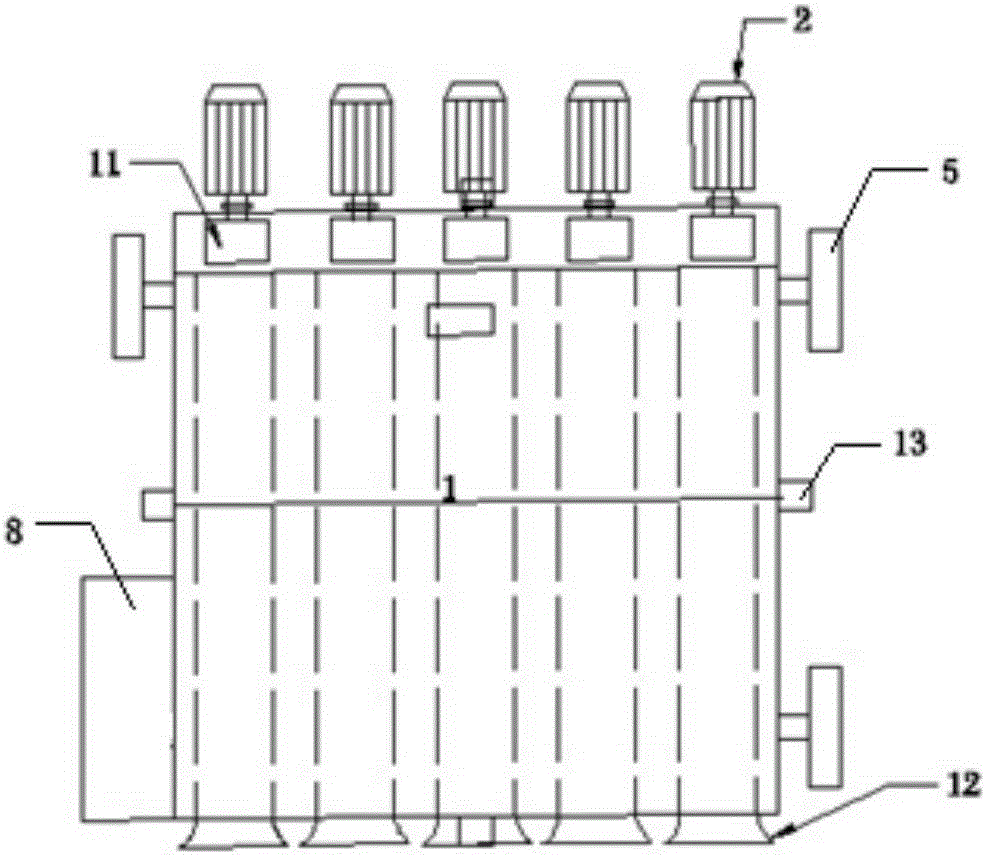

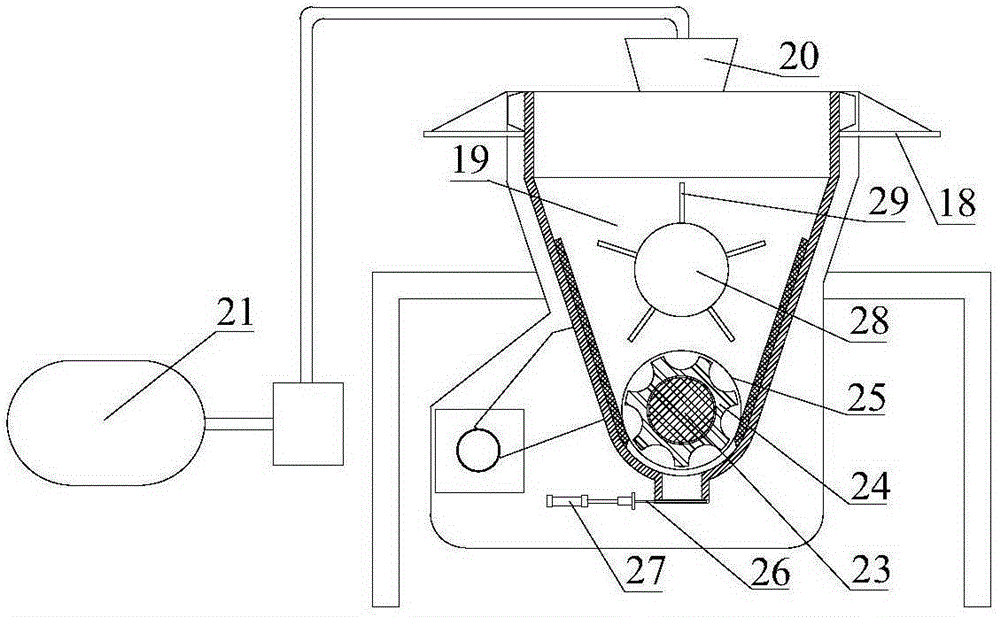

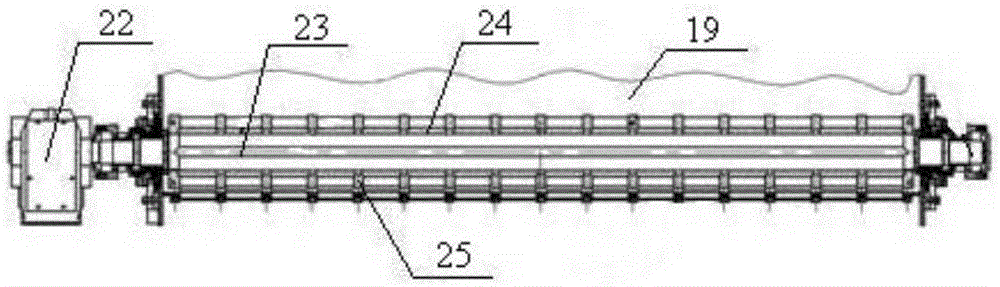

Automatic organic material feeding equipment suitable for worm bioreactor

The invention discloses an automatic organic material feeding equipment suitable for a worm bioreactor. The equipment mainly comprises a support, an organic material storage bin, a plurality of spiral conveyors, a sensor used for detecting margin of organic materials, a PLC, a touch screen, a distance detector, a walking motor, rolling wheels and the like. According to the equipment, the organic materials which are in the state of solid particles or semifluid can be quickly and quantitatively fed into a biological reaction tank according to the different material distributing technology requirements of various worm bioreactors, the mechanization and automation level of the feeding link of the worm bioreactor is greatly improved, and the labor requirements of the feeding link of the worm bioreactor are significantly reduced; meanwhile, the worm living environment is significantly optimized through accurate and quantitative material distributing and diverse material distributing modes, and the good guarantee is supplied for improving the conversion efficiency of the worm bioreactor.

Owner:ZHEJIANG UNIV

Concrete spreader

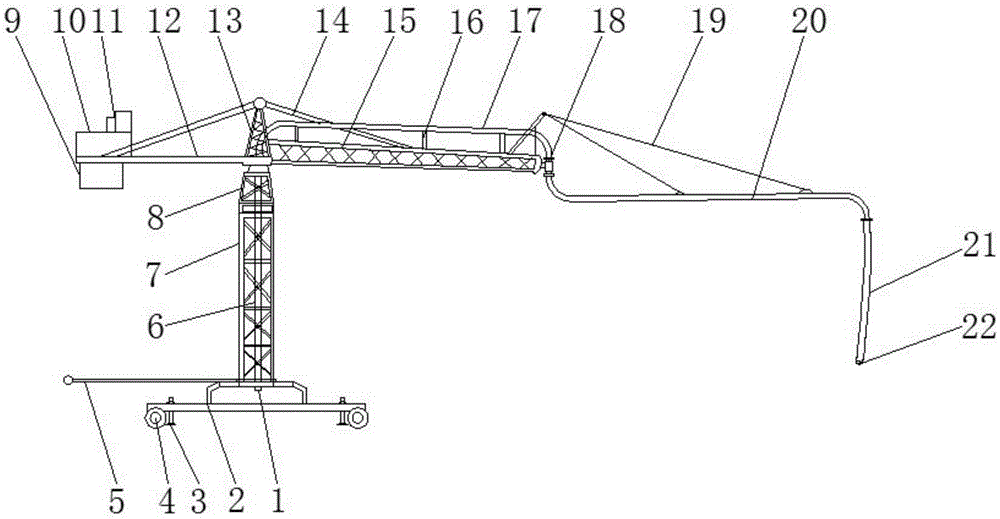

The invention discloses a concrete spreader. The concrete spreader comprises a feed port, a base, a vertical pipe, a vertical column, an electronic control cabinet, a counter weight frame, a beam, a transverse pipe, a front pipe and a material guide pipe. The base is fixed to the bottom of the vertical column. A drawing frame is fixed to the joint of the vertical column and the base. Walking wheels are arranged at the bottom of the base. Supporting legs are arranged inside the walking wheels. The vertical pipe is fixed in the vertical column. A transition supporting column is fixed to the top of the vertical column. A rotation bearing is arranged above the transition supporting column. The beam is arranged on the other side of the upper portion of the rotation bearing through cooperation of a beam head and a beam tail. The transverse pipe is fixed above the beam through a supporting rod. The front pipe is arranged at the end, away from the rotation bearing, of the beam through a rotation support. The front pipe is connected with the front end of the beam through an inclined stay cable. The front end of the front pipe is connected with the material guide pipe. The concrete spreader is high in flexibility and stability, convenient to move and capable of improving spreading efficiency and safety.

Owner:CHONGQING PENGZHOU CONCRETE CO LTD

Multifunctional cloth spreading frame

ActiveCN102942080BSolve efficiency problemsAddress insecurityUnfolding thin materialsVertical barEngineering

Owner:安康爱多宝动漫文化产业有限公司

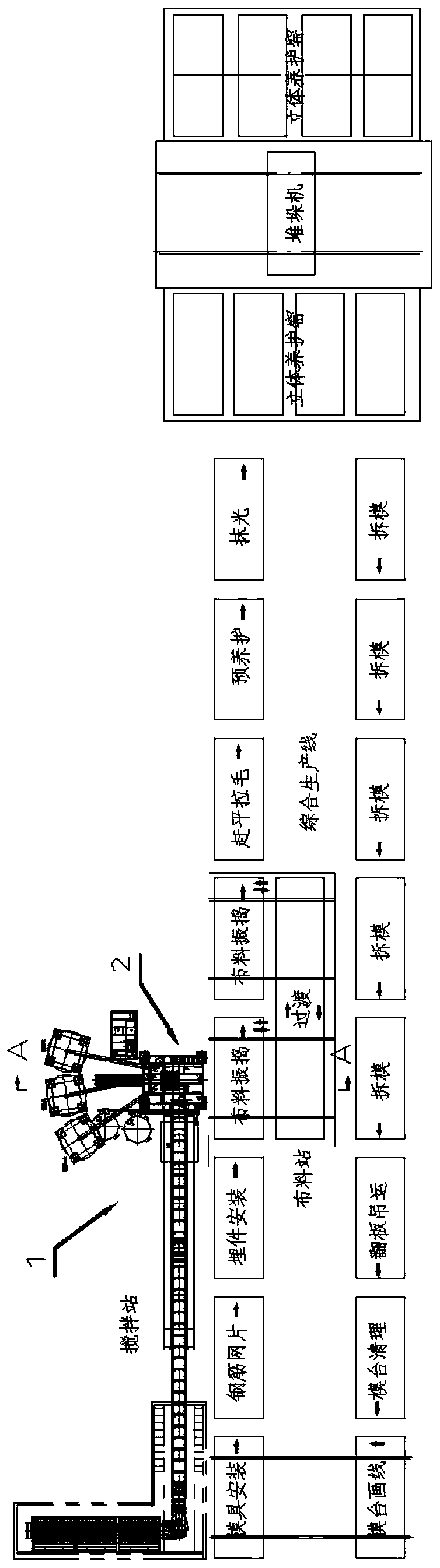

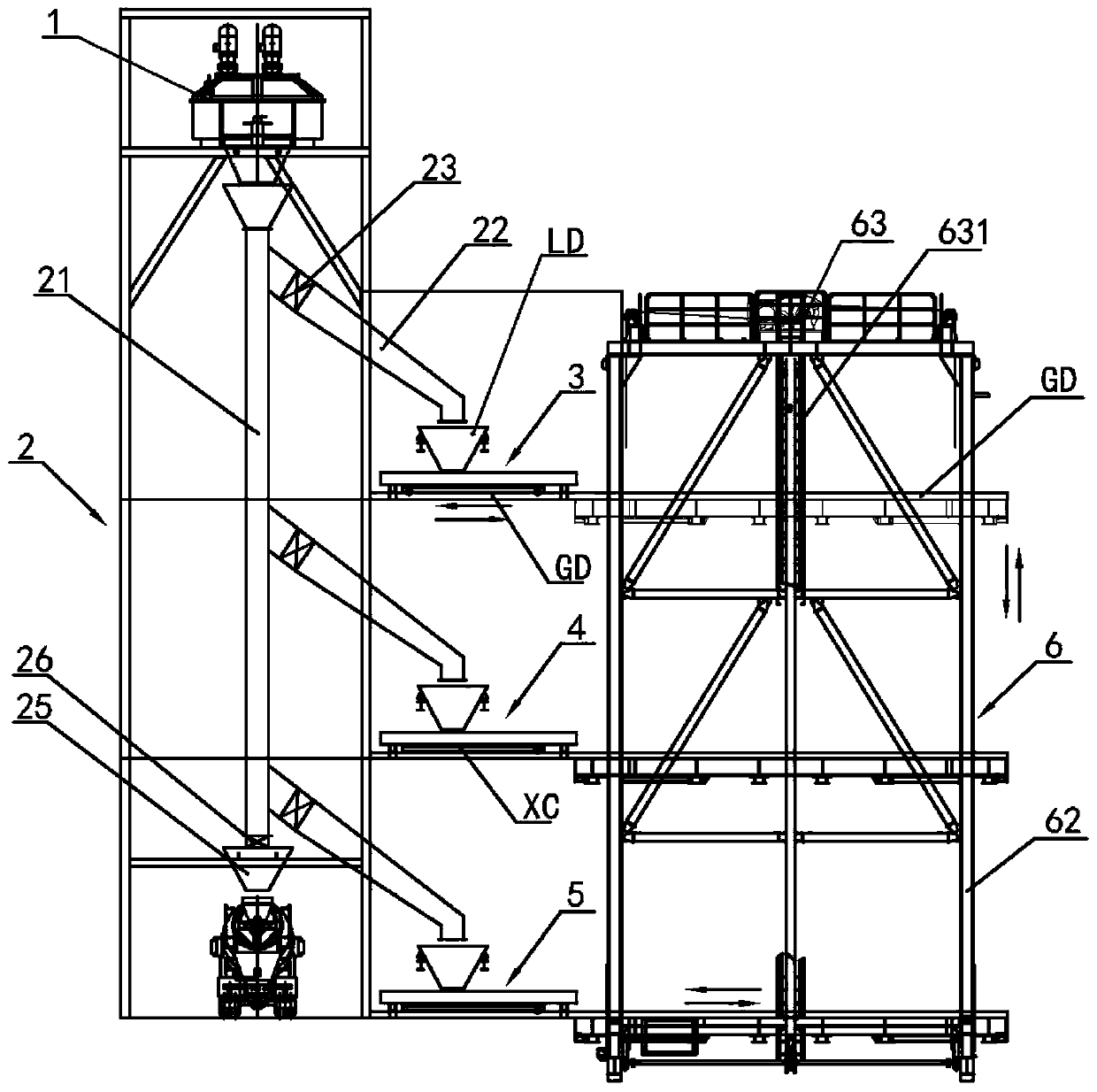

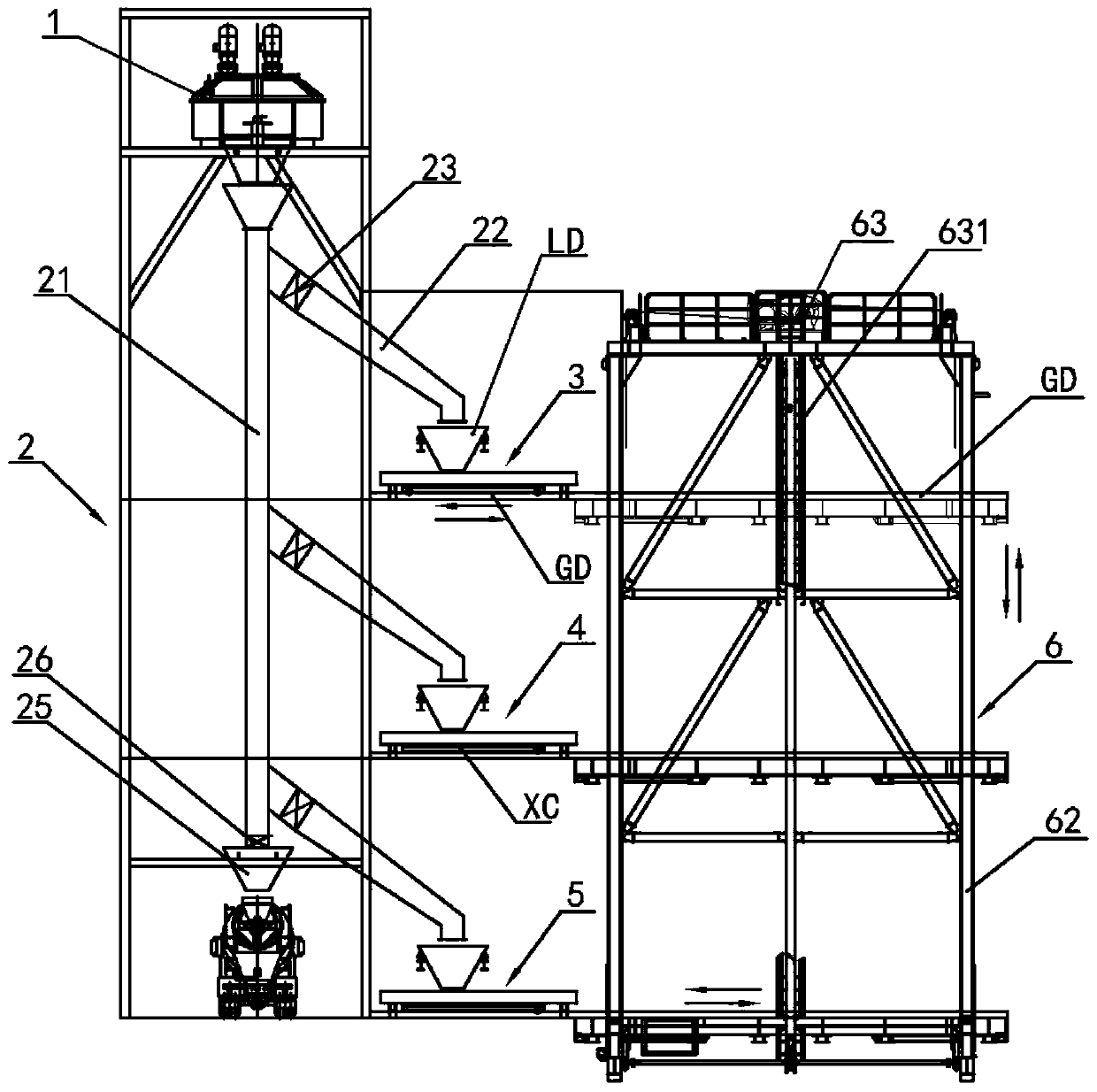

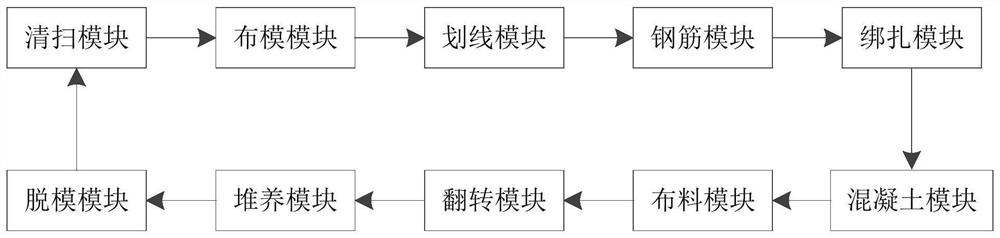

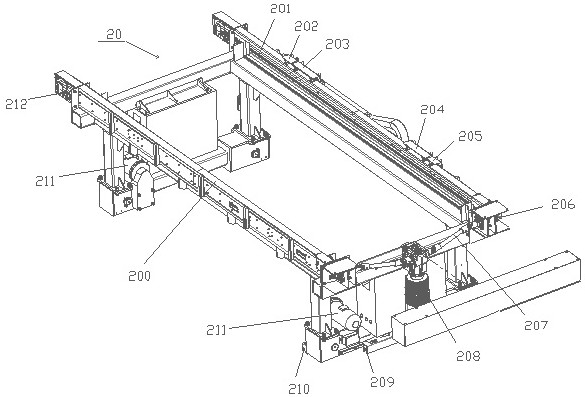

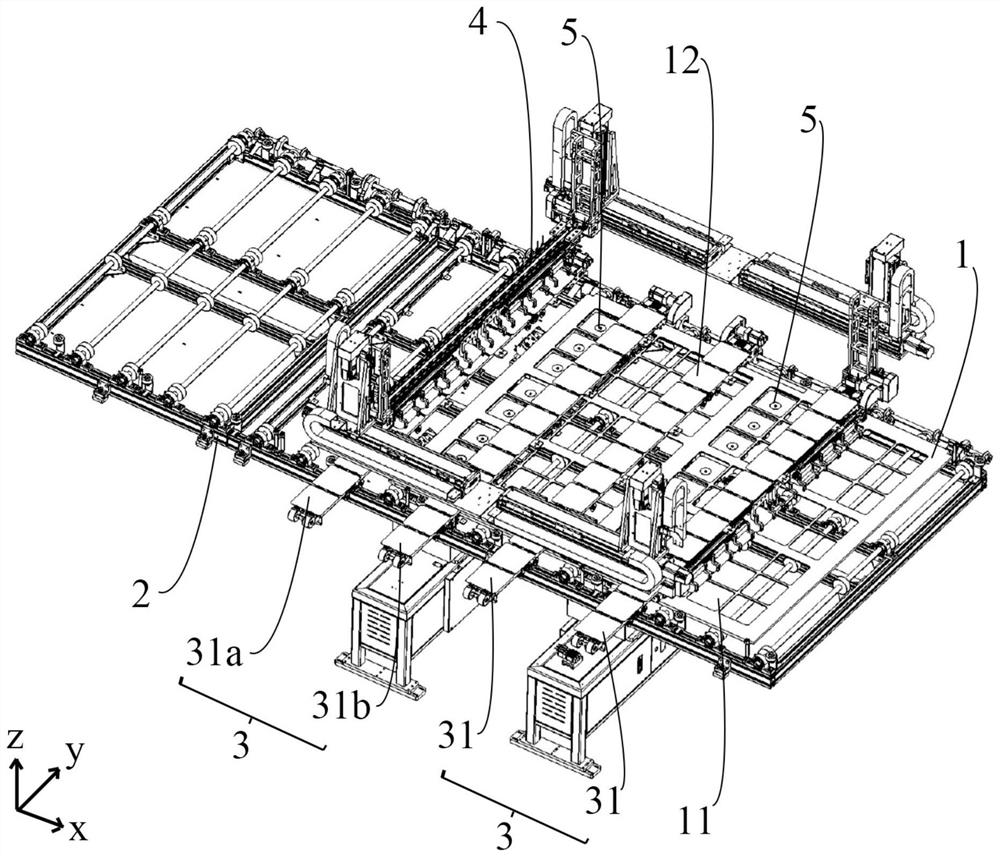

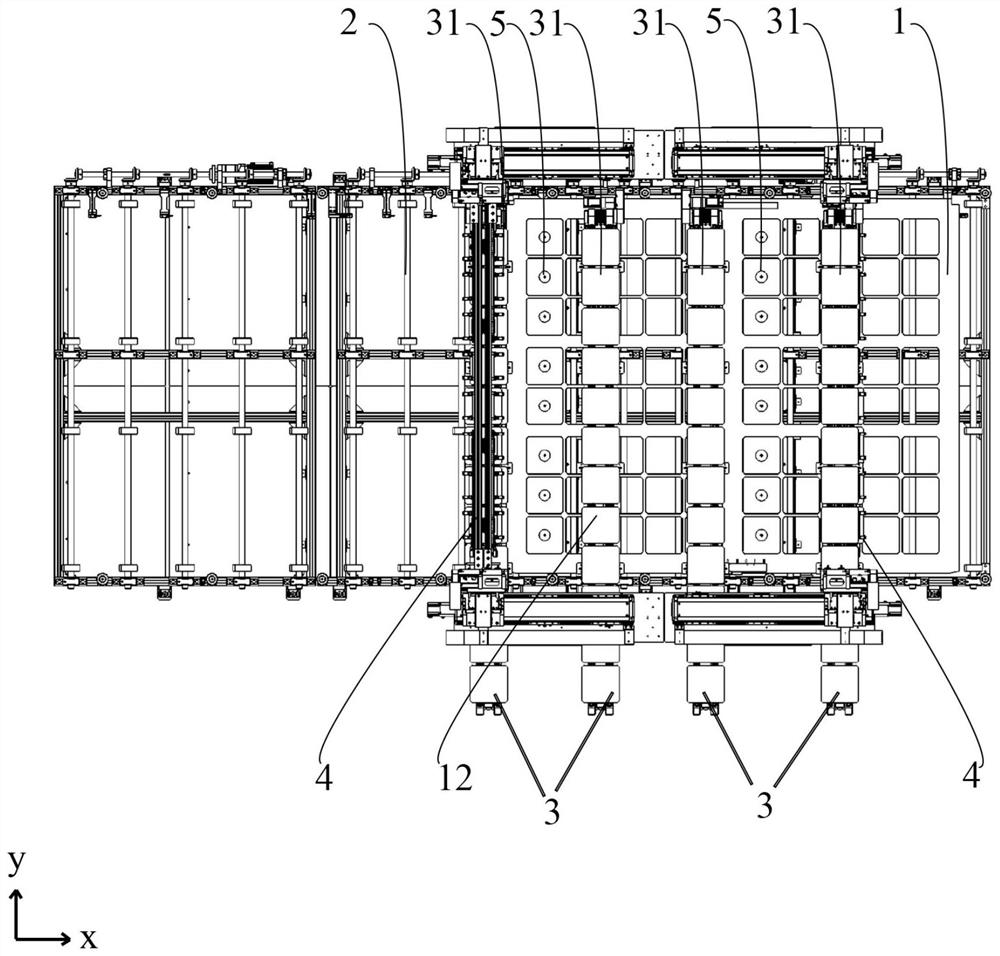

Precast concrete (PC) component comprehensive production system and production method thereof

PendingCN109968516ASolve the time interval problemImprove cloth efficiencyCeramic shaping plantsProduction linePrecast concrete

The invention discloses a precast concrete (PC) component comprehensive production system and a production method thereof. The production system includes a mixing station and moving distributing hoppers, a vertical sliding device, a production line for producing wall boards, a production line for producing composite boards, and a vertical ferry car, the vertical sliding device is located at the tail end of a mixing station conveying device, the production lines are arranged on the same side of the vertical sliding device in an up-down parallel mode, the vertical sliding device is provided withdischarge ports corresponding to the production lines, and can feed the moving distributing hoppers of the production lines at the same time, the vertical ferry car is provided with horizontal railscapable of ascending and descending up and down, and horizontally moving trolleys with jacking devices are installed on distributing vibrating stations corresponding to the production lines through the horizontal rails. The multiple production lines are arranged vertically, through the height space of a plant, the floor area is small. The vertical sliding device can distribute the multiple production lines at the same time, thus the wall boards and the composite boards can be produced simultaneously, and the production efficiency is high. The problems that the processes of production of the wall boards are insulation material laying and secondary distributing pouring and pounding processes more than the processes of production of the composite floor boards are solved by the vertical ferrycar.

Owner:湖南东方红新型建材有限公司

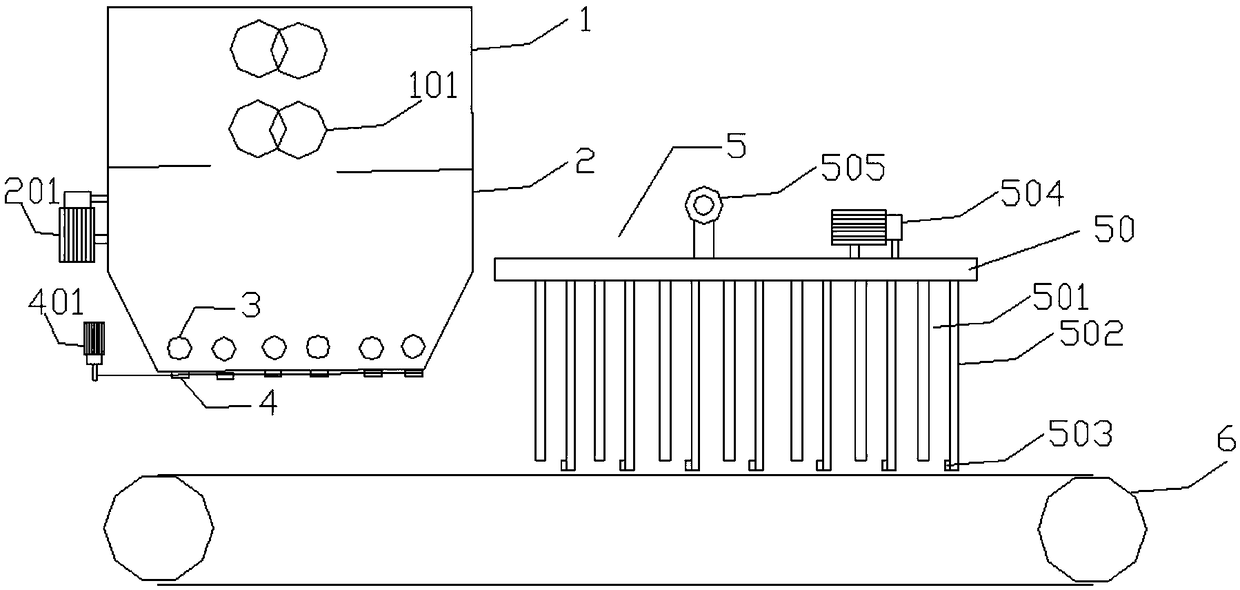

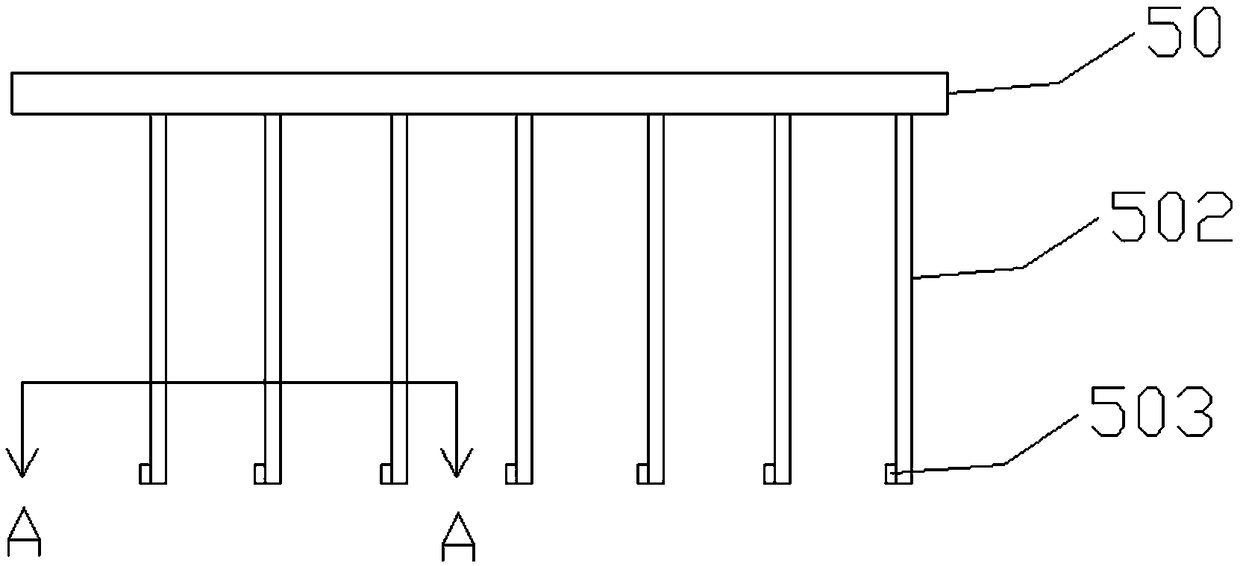

Sludge low-temperature drying distributing system and distributing method

The invention discloses a sludge low-temperature drying distributing system and a distributing method. The distributing system comprises a sludge cake crusher, a sludge bin, a sludge grain blanking screw and a sludge spreader. The sludge cake crusher is connected with the sludge bin of a filter press. Sludge cake crushing tooth rollers are arranged on the sludge cake crusher. The sludge bin is arranged below the sludge cake crushing tooth rollers of the sludge crusher. A sludge bin vibration motor is arranged on the sludge bin. The sludge grain blanking screw is arranged at the bottom of the sludge bin. A plurality of blanking openings formed discontinuously are formed in a sludge outlet in the bottom of the sludge bin. Weighing equipment is arranged at the bottom of the sludge bin. The sludge outlet of the sludge bin is formed above a drying crawler belt of a sludge low-temperature drying system. The sludge spreader is arranged above the drying crawler belt and behind the sludge bin.A sludge guide row plate is arranged at the lower end of the sludge spreader. A sludge spreader vibration motor and a sludge spreader lifting motor are arranged on the sludge spreader. The distributing system and the distributing method can lead the sludge cake from a sludge deep water removal system to directly enter the sludge low-temperature drying system for drying treatment.

Owner:SHANGHAI TECHASE ENVIRONMENT PROTECTION

Process for weaving wool knitted linings

Disclosed is a process for weaving wool knitted linings which comprises, (1) changing the original pattern of one complete braiding for each one path of upper and lower triangle into, every fourth complete braiding for each one path of upper and lower triangle, grinding off the back right side of the needle raising cam by 1.5-2.5mm, appending an active knitting feed and yarn break automatic stop system, (2) raw material selection, (3) weaving.

Owner:天津飞天纺饰针棉有限公司

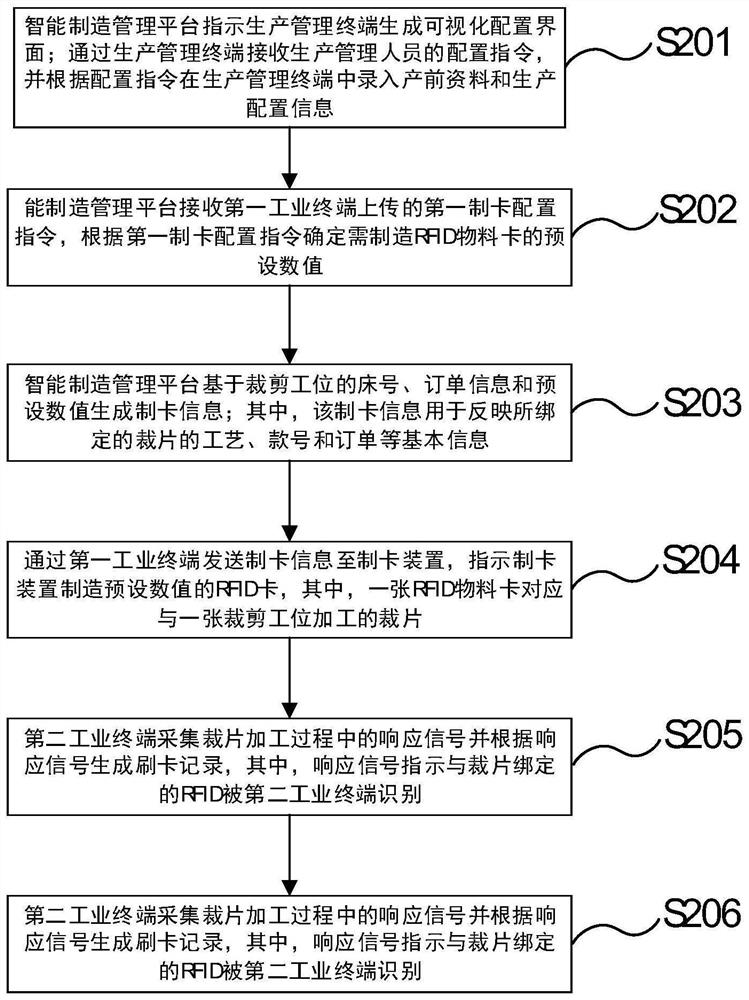

Garment processing and manufacturing method and system

PendingCN114418307ASolve the problem of low interconnectionAchieve standardizationCo-operative working arrangementsOffice automationManufacturing managementSmart manufacturing

The invention relates to a garment processing and manufacturing method and system.The garment processing and manufacturing method comprises the steps that an intelligent manufacturing management platform receives a first card making configuration instruction uploaded by a first industrial terminal, and a preset value of an RFID material card needing to be manufactured is determined according to the first card making configuration instruction, generating card making information based on the bed number of the cutting station, the order information and a preset value; the second industrial terminals collect response signals in the cutting piece processing process and generate card swiping records according to the response signals, the card swiping records in the multiple second industrial terminals are obtained, and production monitoring data are generated in real time based on the card swiping records and order information. And sending the production monitoring data to the first industrial terminal, the second industrial terminal and the production management terminal. According to the invention, the problem that the information interconnection degree is low in the garment processing and manufacturing process is solved, the standardization of production management is realized, the garment manufacturing efficiency is improved, and the garment manufacturing cost is reduced.

Owner:依之帛实业发展(上海)有限责任公司

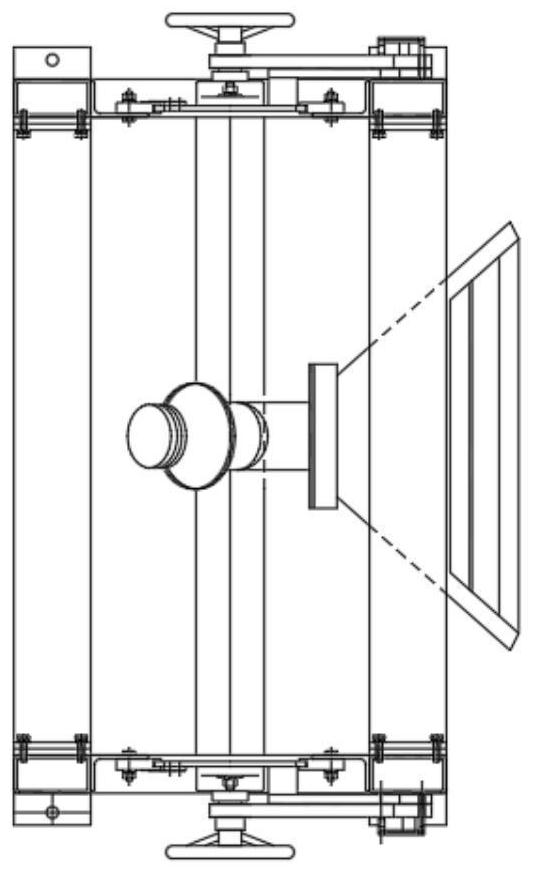

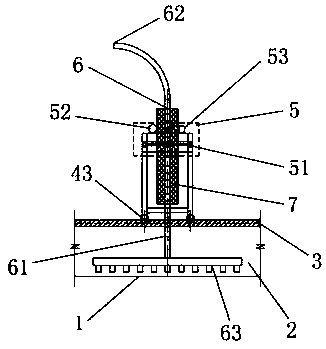

Material distributing device

PendingCN112428406AScientific and reasonable structure designEasy to implementFeeding arrangmentsEngineeringStructural engineering

The invention discloses a material distributing device, and aims to provide a material distributing device which is uniform and efficient in material distribution. The material distributing device comprises a bracket, two sliding seats, an adjusting screw rod, a rotating shaft, two handle wheels, a material distributing nozzle, a positioning plate and a positioning strip, wherein the two sliding seats are symmetrically arranged, the two sides of the sliding seats are mounted at the upper part of the bracket through sliding rails, and the sliding seats can be adjusted to ascend and descend along the bracket; the adjusting screw rod is arranged on the bracket in a penetrating manner and used for adjusting the sliding seats to ascend and descend; the two ends of the rotating shaft are rotationally mounted on the two sliding seats; the two handle wheels are fixedly connected to the two ends of the rotating shaft respectively; the middle of the material distributing nozzle is fixedly connected to the rotating shaft; the positioning plate is fixedly connected to the sliding seats, and through hole groups which are arranged in an arc shape are formed in the positioning plate with the rotating shaft as the center; the positioning strip is fixedly connected to the bracket, is close to the positioning plate and is matched with the positioning plate for use; positioning holes matched withthe through hole groups are formed in the positioning strip; the material distributing nozzle comprises a feeding pipe section connected with a material conveying pipe during use and a material distributing section fixedly connected with the feeding pipe section; and the material distributing section is of a structural form with the thickness gradually decreased and the width gradually increasedin the material direction.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE +1

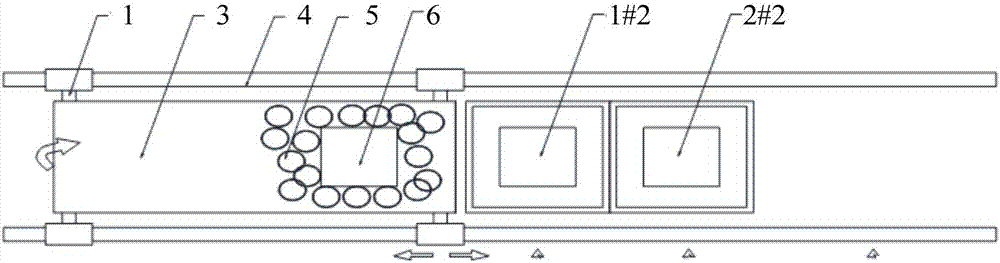

Production systems for concrete elements

ActiveCN104057537BReduce labor intensitySimple structureDischarging arrangementCeramic shaping plantsPre treatmentWaste management

A concrete member production system comprises a formwork table conveying device, formwork table pre-treatment equipment, a first spreader, a second spreader, post-spreading treatment equipment, a maintenance storehouse and an edge-on bottom formwork removal device, wherein a formwork removal station, a formwork pre-treatment station, a first spreading station and a vibro-compacting station are sequentially arranged on the formwork table conveying device and at the exit of the maintenance storehouse; a post-spreading treatment station, a second spreading station and an insulation board placing station are sequentially arranged on the formwork table conveying device and at the entrance of the maintenance storehouse; the edge-on bottom formwork removal device, the formwork table pre-treatment equipment, the first spreader, a formwork vibrating device, the second spreader and the post-spreading treatment equipment are correspondingly arranged on the formwork removal station, the formwork pre-treatment station, the first spreading station, the vibro-compacting station, the second spreading station and the post-spreading treatment station respectively to form a circulating production system. The concrete member production system is operated mechanically, achieves continuous production, saves time and labor and improves the working efficiency.

Owner:HEBEI XUELONG MACHINERY MFG

Automatic distributing device for O-shaped sealing ring vulcanized formed blank, and distributing method thereof

PendingCN109095159AFast clothImprove cloth efficiencyControl devices for conveyorsVulcanizationDrive motor

The invention discloses an automatic distributing device for an O-shaped sealing ring vulcanized formed blank, and a distributing method thereof, and belongs to the technical field of rubber chemicalmechanical equipment. The automatic distributing device comprises a base, a conveying mechanism, a distributing mechanism, a loading mechanism and a PLC. Two guiding rails and a plurality of fixing seats are arranged parallelly on the base. The conveying mechanism is used for driving movable material discs to conduct comprehensive distributing. The distributing mechanism is provided with a belt machine, a pushing machine, a dividing hopper and a feeding and discharging part; the pushing machine and the dividing hopper are arranged on the two corresponding sides of the belt machine correspondingly; and the feeding and discharging part is mounted on the front side of the dividing hopper to control falling of the blank through a rotating air cylinder. The loading mechanism conveys the O-shaped sealing ring vulcanized formed blank from a hopper onto the belt machine, and stepping distributing is conducted in a pushing mode. The PLC is used for control a driving motor, the belt machine, thepushing machine, a loading machine and the rotating air cylinder to act. The loading process of one-machine and two-position of a vulcanization die-pressing forming machine is met, row-up and multi-hole quick distributing is achieved, the distributing efficiency and automation are improved, manual operation is reduced, and the labor intensity is lowered.

Owner:宣城市安工大工业技术研究院有限公司

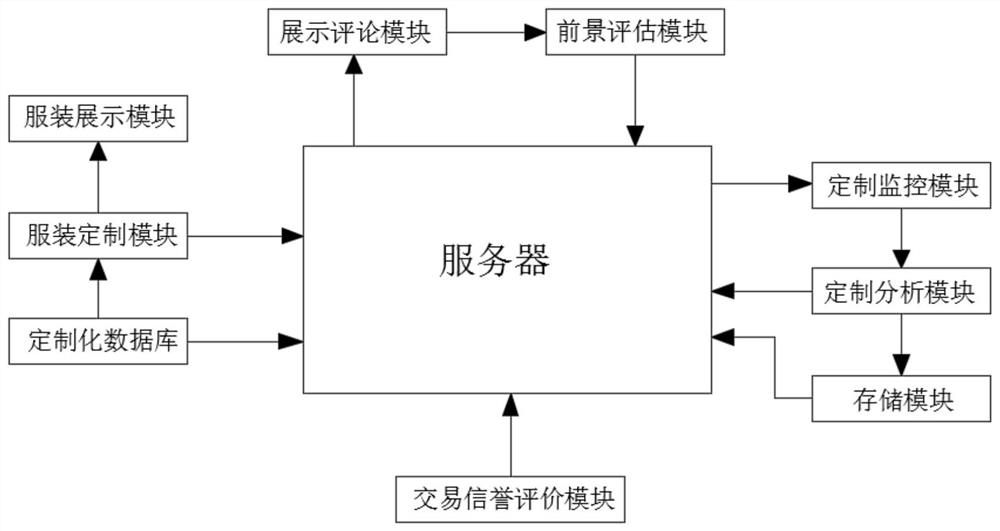

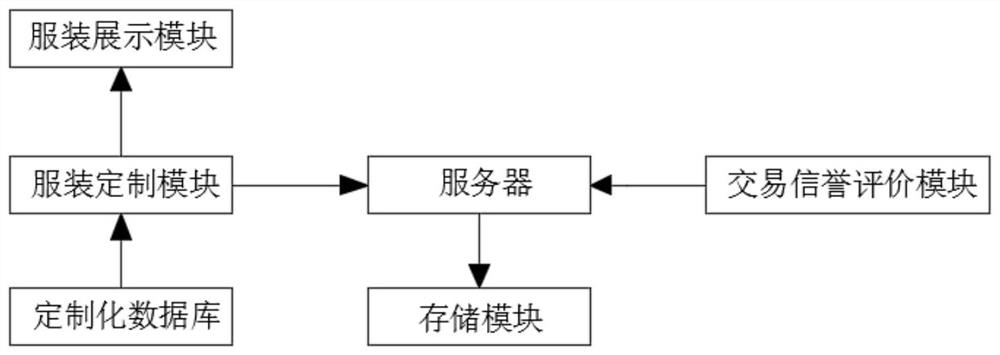

Customized garment ordering management system

InactiveCN113421149AQuality improvementImprove efficiencyBuying/selling/leasing transactionsPersonalizationOrder management system

The invention discloses a customized garment ordering management system, and relates to the technical field of garment design. The system comprises a garment customization module, a customization database, a customization monitoring module, a customization analysis module, a display comment module and a foreground evaluation module, The garment customization module is used for designing and customizing garments by the user through a mobile phone terminal, the style requirements of personalized customers are met, meanwhile, a proper garment maker is selected according to the garment making value of a primary selection person to carry out production and manufacturing on a garment customization order, and the ready-made garment quality and efficiency of the customized garments are improved; the customized monitoring module is used for monitoring production and processing of garment by a user; the display and comment module is used for displaying ready-made garment of customized garment by the user, and other clients browse and comment the ready-made garment; and the foreground evaluation module is used for carrying out foreground evaluation on customized garment of the user according to browsing and comments of other clients, so that a merchant can carry out feedback according to styles designed by the clients, the style requirements of more clients are met, and the garment design level is improved.

Owner:合肥英帝莱克服装科技有限公司

Pocket underlayer and sewing method thereof

The invention belongs to the clothing technical field, and especially relates to a pocket underlayer and a sewing method thereof; the sewing method comprises the following steps: 1, selecting cloth material; 2, shearing and moulding; 3, ironing a splicing portion; 4, splicing a doily with a big lining, and using a flatseam machine to sew the two. The pocket underlayer comprises the doily and the big lining; the doily and the big lining splicing portion relatively connecting line style is a flatseam machine sewing thread type. The pocket underlayer sewing method is relatively simple, can save processing time, can improve making efficiency, and the prepared pocket underlayer is more beautiful in whole profile; the pocket underlayer and the sewing method are suitable for popularization enforcement.

Owner:郑州领秀梦舒雅服饰有限公司

Manufacturing method of fur garment

InactiveCN105639756AGood wearing experienceEasy to cut and sewProtective garmentSpecial outerwear garmentsChemistryFur garment

The invention provides a manufacturing method of a fur garment. The manufacturing method comprises the following steps that multiple pieces of tanned animal fur are sewn and connected, large animal fur can be obtained, the reverse side of the animal fur is painted with adhesive and bonded with a knitted lining, the fur is heated for 3-8 minutes at the temperature of 50 DEG C-60 DEG C, tailored and sewn into a garment, knitted tapes are sewn to edge junctions of the joints of the garment, the garment is washed for 5-10 minutes in organic solvent at the constant temperature, the garment is dried for 3-8 minutes at the temperature of 30 DEG C-50 DEG C to obtain the fur garment, and the obtained solvent for drying can be recycled and reused. According to the fur garment manufactured through the method, knitted fabric is adopted to replace real silk fabric to serve as the lining, and the situations of wrinkling and silk hooking of the real silk lining are avoided; the fur garment is stiff, and wearing experience is better; the method of bonding the knitted lining and then carrying out tailoring and sewing is adopted, the fur garment is convenient to tailor and sew, and garment manufacturing efficiency is improved.

Owner:ZHEJIANG JUFENG FASHION CO LTD

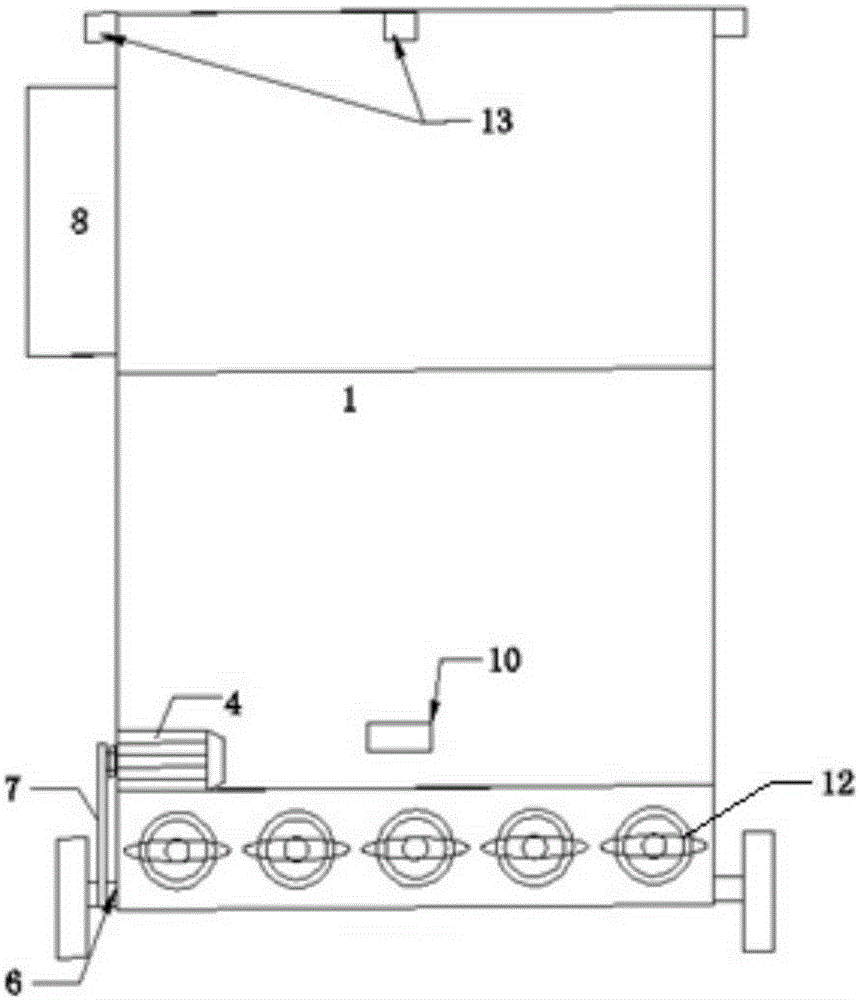

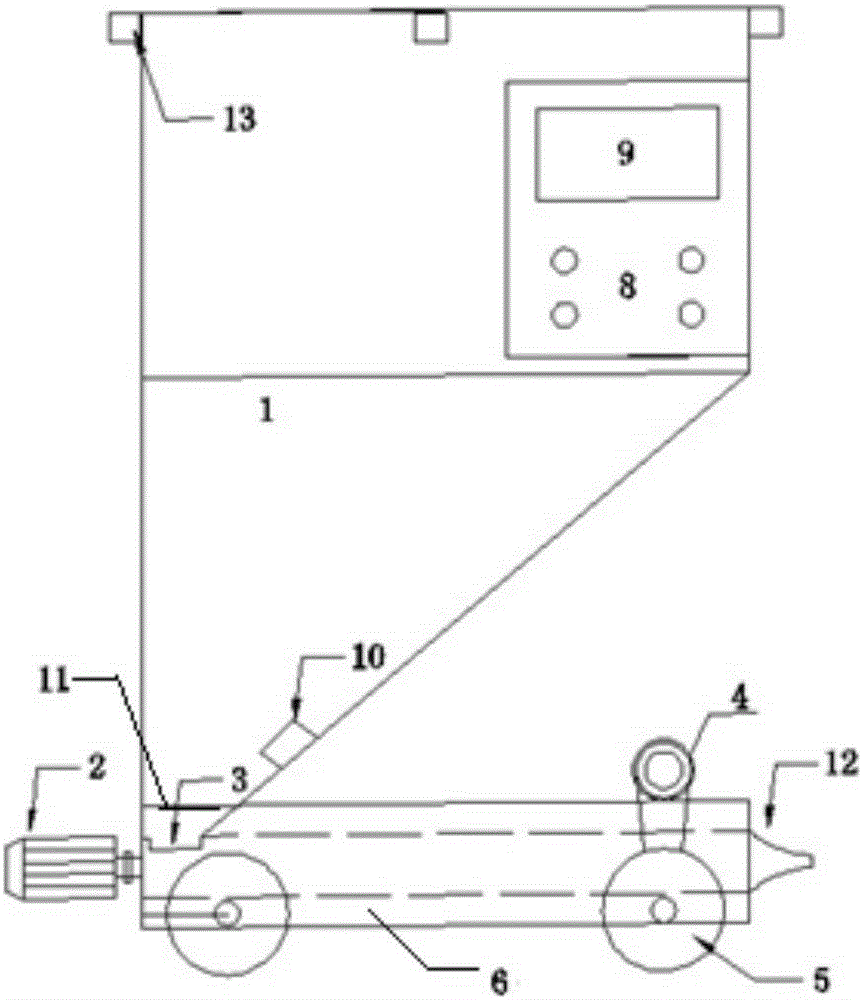

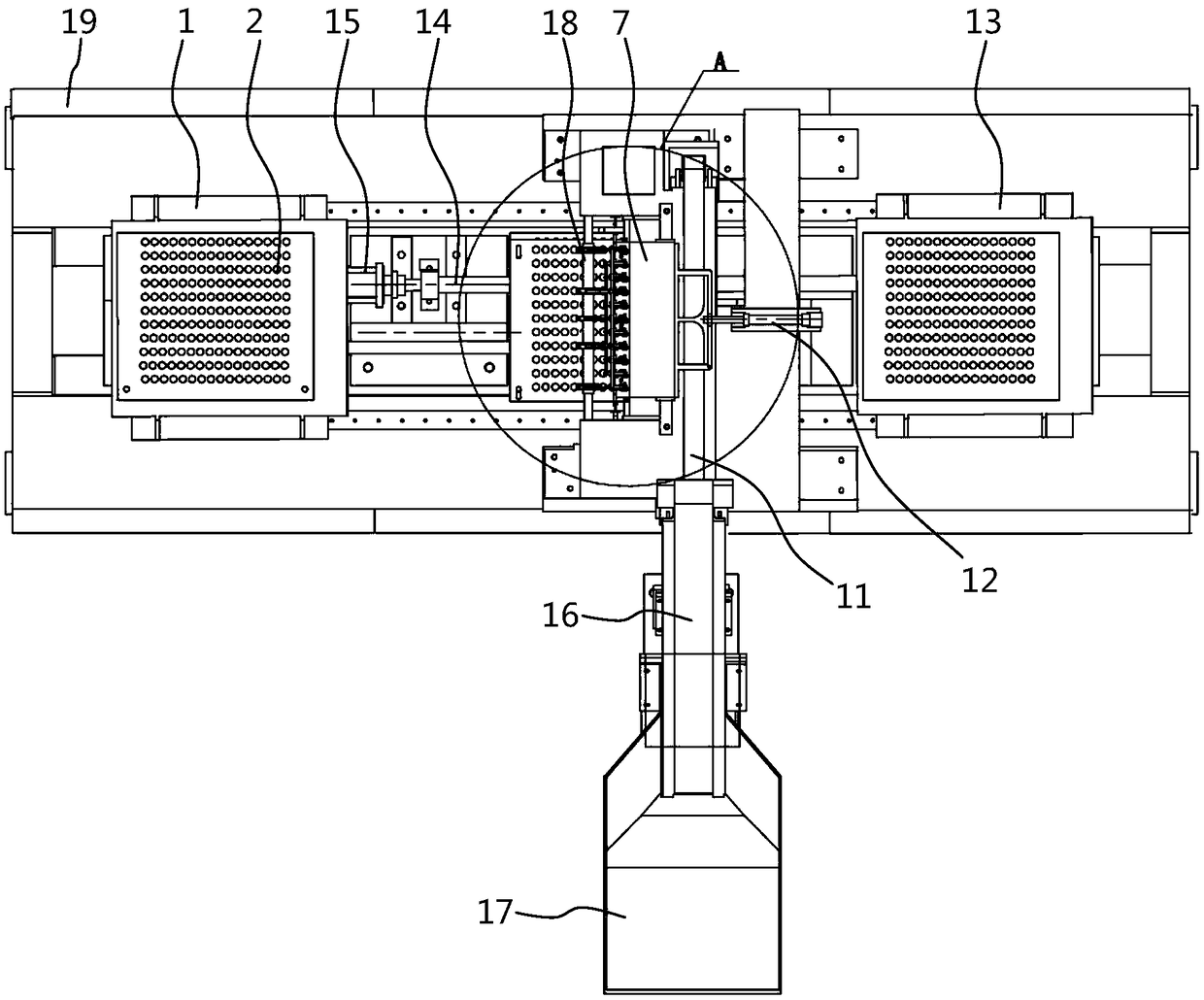

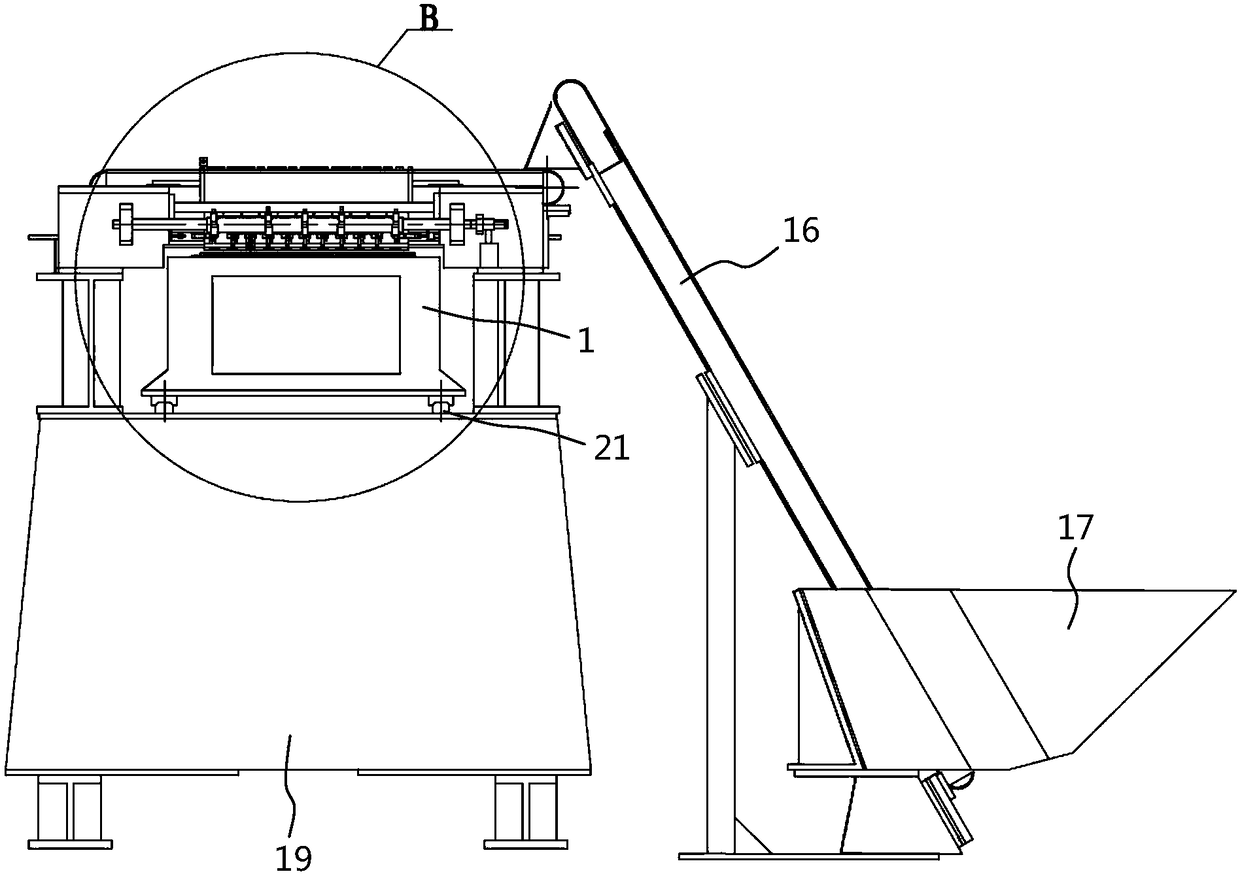

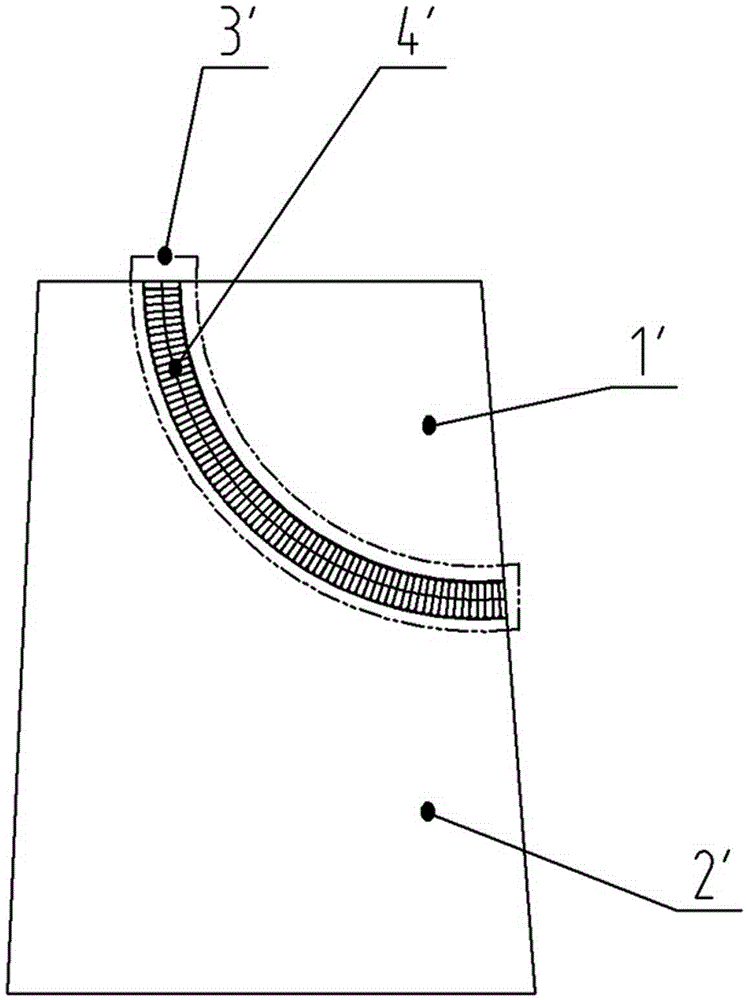

Distribution auger vehicle of fermentation tank

InactiveCN101701178AReasonable structural designImprove cloth efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsAutomatic controlAutomotive engineering

The invention relates to a distribution auger vehicle of a fermentation tank, consisting of a large frame (10), a traveling mechanism, a feeding mechanism and a distribution mechanism. The traveling mechanism consists of a track (1), traveling wheels (2) and a motor (3); the feeding mechanism consists of a cabin body (4), a harrowing wheel (5) and a conveyor belt feeding device; and the distribution mechanism consists of a distribution cylinder (6), an auger (7) and an auger motor (8). The invention has the advantages of reasonable structural design, high distribution efficiency, low energy consumption, time, labor and force saving, capability of realizing automation by being matched with an automatic control device, convenient use and low production cost.

Owner:荆门市万泰机械有限公司

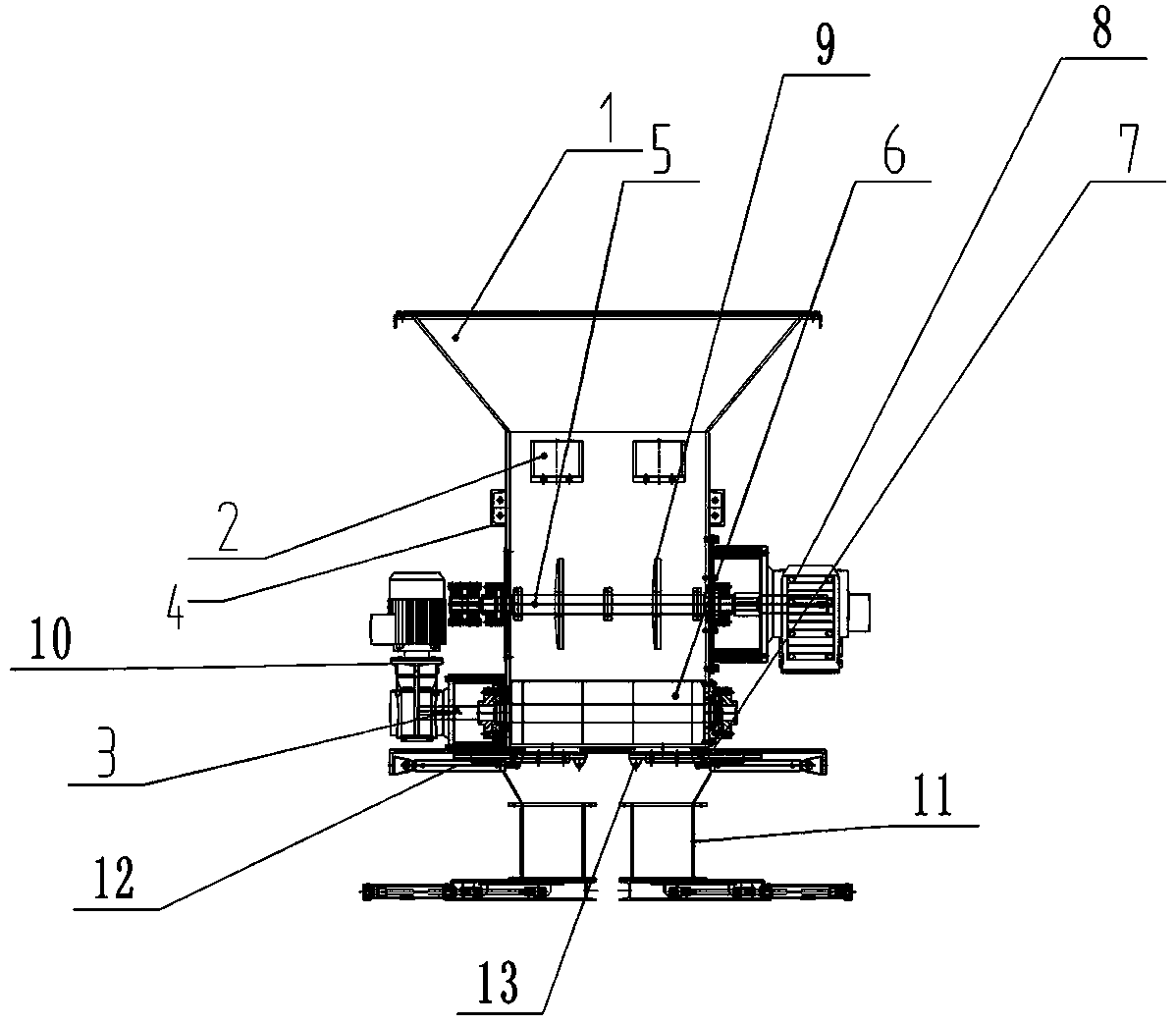

Special distributing machine for chain blocks

The invention discloses a special distributing machine for chain blocks. The special distributing machine comprises a distributing hopper 1, a stirring device and a material distributing device, wherein the stirring device and the distributing device are positioned below the distributing hopper 1. The stirring device comprises a stirring shaft 5, a stirring motor speed reducer assembly 8 and a stirring blade 9. A rotating shaft of the stirring motor speed reducer assembly 8 is in transmission connection with the stirring shaft 5. The stirring blade 9 is fixedly connected with the stirring shaft 5. The special distributing machine has the beneficial effects of being high in distributing efficiency and controllable in distribution quantity.

Owner:NANTONG HENGDA MACHINERY MFG

Ceramic product production system based on digital material distribution

ActiveCN113696321AImprove Cloth Effects and EfficiencyImprove cloth efficiencyFeeding arrangmentsAuxillary shaping apparatusDigital inkGreen body

The invention relates to a ceramic product production system based on digital material distribution, and relates to the technical field of ceramic products. The ceramic product production system based on digital material distribution is characterized in that a toner preparation unit is used for preparing toner and conveying the toner to a digital material distribution unit for digital material distribution; after materials are pressed and moulded through a moulding press unit, a digital ink jet unit is used for carrying out pattern ink jet, and a digital glaze spraying unit is used for carrying out digital glaze spraying; a kiln-entering high-temperature unit is used for carrying out kiln-entering high-temperature firing, and then edge grinding and brushing-polishing are carried out; and qualified products are put in storage, so that preparation is completed. The blanking speed of the backing material is determined by the digital material distribution unit according to the calculated material distribution parameters of the backing material, and the central control unit adjusts the material distribution parameters of the fabric according to the total material distribution amount and flatness of the backing material, so that the blanking of the fabric supplements and perfects the backing material, the flatness of the backing material is improved, meanwhile, the color of a green body and particles are completely matched with the pattern color of the surface and the surface particles, and the distribution effect and efficiency of the digital cloth are improved.

Owner:佛山市高明贝斯特陶瓷有限公司 +1

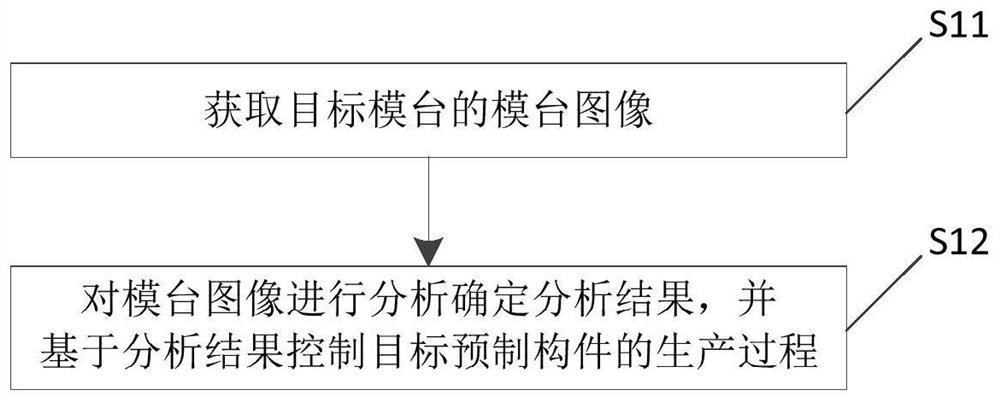

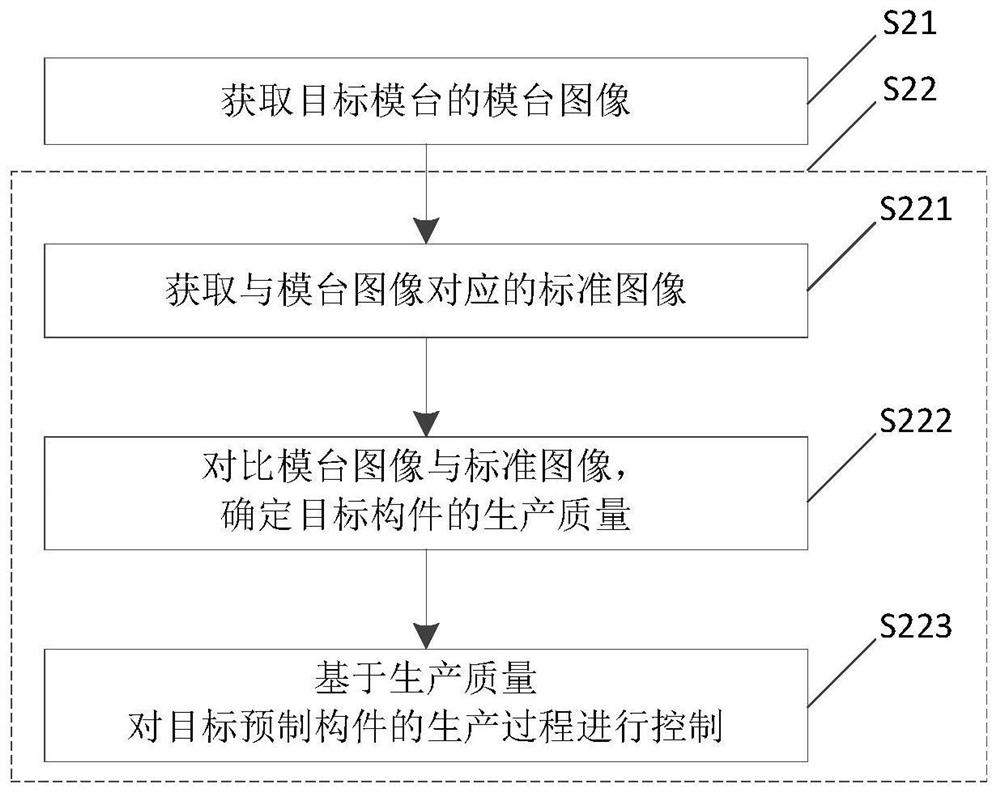

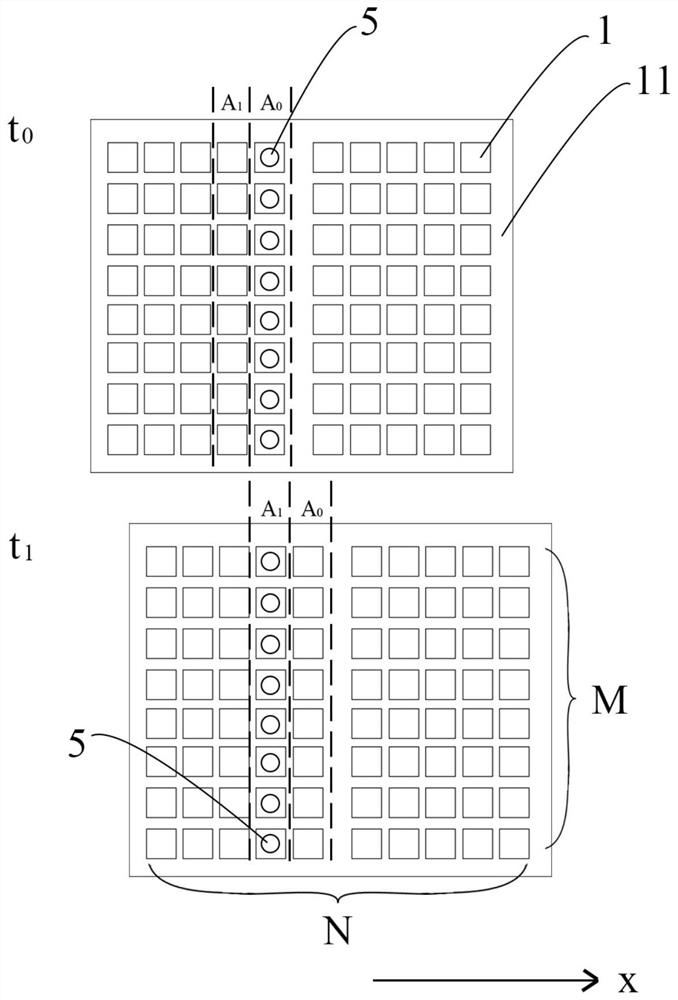

Production control method, control equipment and system for concrete prefabricated part

PendingCN113070996ARealize the intelligent fabric processImprove cloth efficiencyAuxillary shaping apparatusVisual technologyControl engineering

The invention relates to the technical field of buildings, in particular to a production control method, control equipment and system for a concrete prefabricated part. The method comprises the steps of acquiring a mold table image of a target mold table, wherein the target mold table is used for bearing at least one target prefabricated part; and analyzing the mold table image to determine an analysis result, and controlling the production process of the target prefabricated part on the basis of the analysis result. According to the method, the mold table image is collected in real time to control the production process, manual control can be avoided, the problem of conversion of drawing information can also be avoided, and the production efficiency of the prefabricated part is improved; and that is, the visual technology is applied to intelligent operation of the production process, automatic data acquisition is achieved, operation of intelligent equipment is driven, the technical difficulty and the production cost are reduced, and the digital application degree is greatly improved.

Owner:珠海筑享云科技有限公司

Multi-sprayer foam concrete spreading device and operation method

PendingCN108691417AEasy to operateGood fabric effectBuilding material handlingComplex mathematical operationsFoam concreteSprayer

The invention discloses a multi-sprayer foam concrete spreading device and operation method, and belongs to the field of foam concrete construction. The multi-sprayer foam concrete spreading device mainly comprises a moving frame, a mobile station, a spreading rod and the like; and is characterized in that 1, the number and inner diameters of sprayers can be selected from multiple schemes, the universality is high, the device is suitable for various types of foaming machines and delivery pumps, the flow velocity of foam concrete slurry is adjustable, and a best foam concrete spreading effect can be achieved; 2, the sprayers disperse the kinetic energy of the slurry intensively ejected from the tail end of a delivery hose, weaken the impact force, reduce the probability that multiple smallpores are communicated with one other to form big pores, and improve the compressive strength of foam concrete; 3, the mechanical automation degree is high, operators are reduced, the labor intensityis reduced, the sanitary conditions of environmental protection are improved, artificial disturbance is avoided, and the solidification quality of the foam concrete is improved. The multi-sprayer foamconcrete spreading device is combined with the corresponding operation method, so that the spreading efficiency and quality can be improved, energy is saved, emission is reduced, and the economic benefits and social benefits are significant.

Owner:NINGBO COMM ENG CONSTR GRP

Distributing machine and operation method thereof

PendingCN112549278AWill not affect normal useEasy to replaceFeeding arrangmentsControl engineeringMachine

The invention discloses a distributing machine and an operation method thereof. The distributing machine comprises a rail car, a loading hopper device and a control electric box, wherein the loading hopper device is installed on the rail car and can move relative to the rail car; a hopper used for loading concrete is detachably arranged on the loading hopper device; the loading hopper device comprises a limiting block assembly, a discharging vibration ball, a hook opening device and a hopper opening device; and the rail car comprises a transmission device used for driving the loading hopper device to move, and a rail walking device used for running on a rail. The distributing machine provided by the invention has the following advantages that the distributing efficiency is higher, the effect is better, the operation is conducted easily, the convenience in maintenance and repair is achieved, the hopper is easy to replace, and the cleaning of the hopper does not influence electrical components of the distributing machine.

Owner:YAU LEE WAH CONSTRUCTION MATERIALS (HUIZHOU) COMPANY LIMITED

Distributing device of solar cells

ActiveCN113394148AFeeding speed is slowLess likely to cause damageSemiconductor/solid-state device manufacturingConveyor partsElectrical batteryEngineering

The invention provides a distributing device for solar cells, the distributing device comprises a carrier plate transmission device, feeding devices, taking devices and a deviation rectifying device, a plurality of feeding devices are arranged, each feeding device comprises a plurality of rows of feeding rails, and each feeding device corresponds to one taking device and one deviation rectifying device; the taking device can sequentially grab the silicon wafers on the different feeding rails in the same group of feeding devices, that is, the plurality of feeding rails of the same group of feeding devices can share one group of taking device, and the plurality of feeding rails sequentially supply materials, so that the feeding speed of the feeding rails can be much slower than the material taking speed of the taking device; and therefore, when the material taking device is high in speed to meet the requirement for high material distribution efficiency, the feeding track has the low conveying speed, and silicon wafers are not prone to being damaged.

Owner:CFDR SHENZHEN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com