Precast concrete (PC) component comprehensive production system and production method thereof

A production system and component technology, applied in ceramic molding workshops, ceramic molding machines, manufacturing tools, etc., can solve the problems of low efficiency, inability to mix and produce wallboards and laminated panels at the same time, and long cloth intervals to achieve high production efficiency , The plane occupies a small area, and the effect of reducing the occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

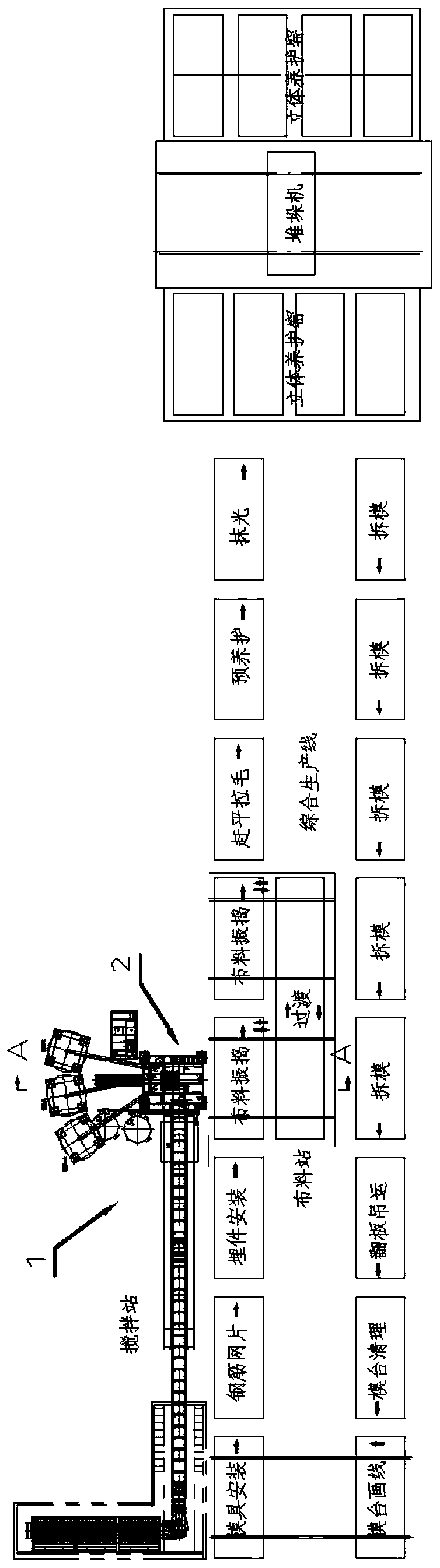

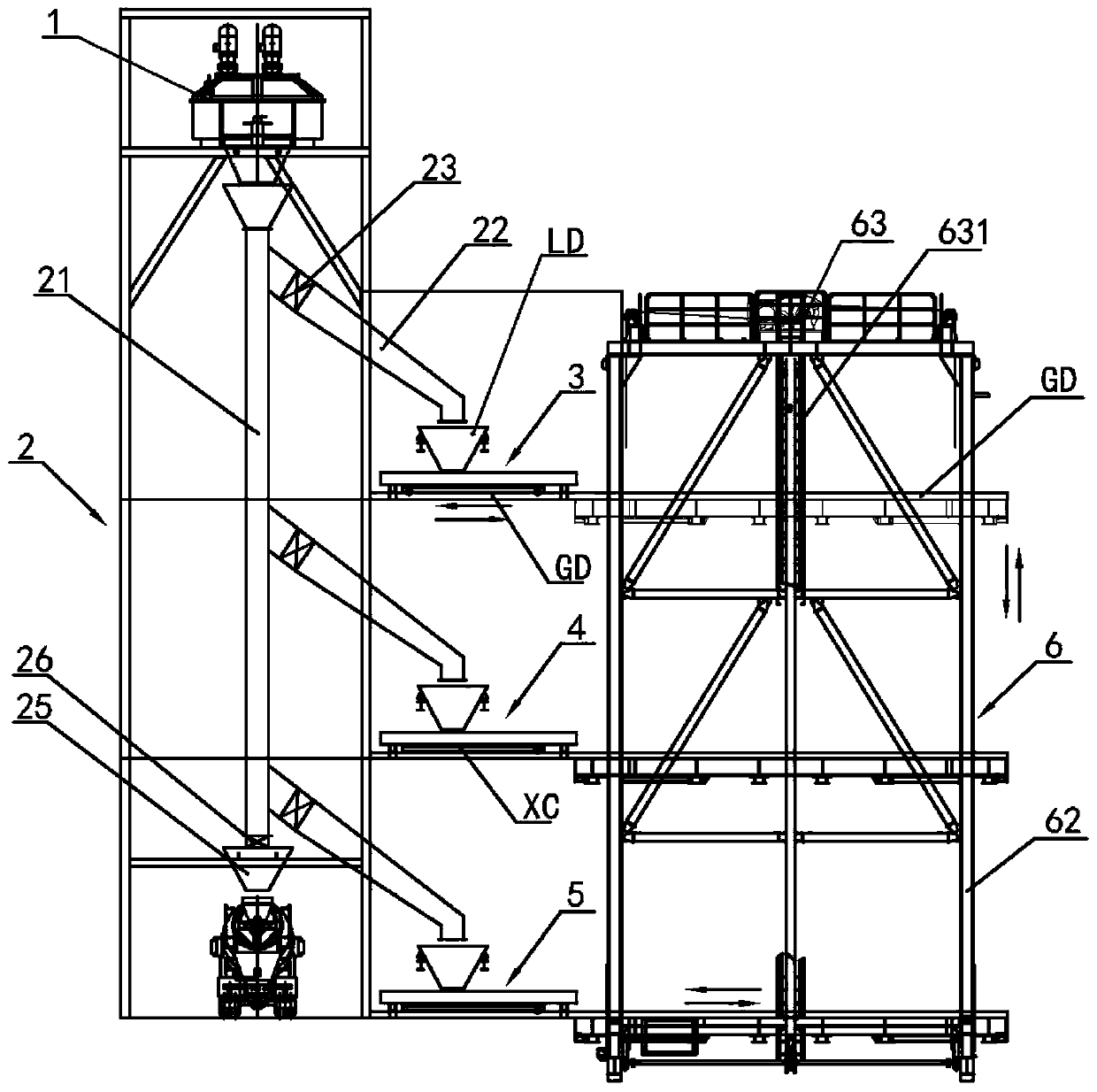

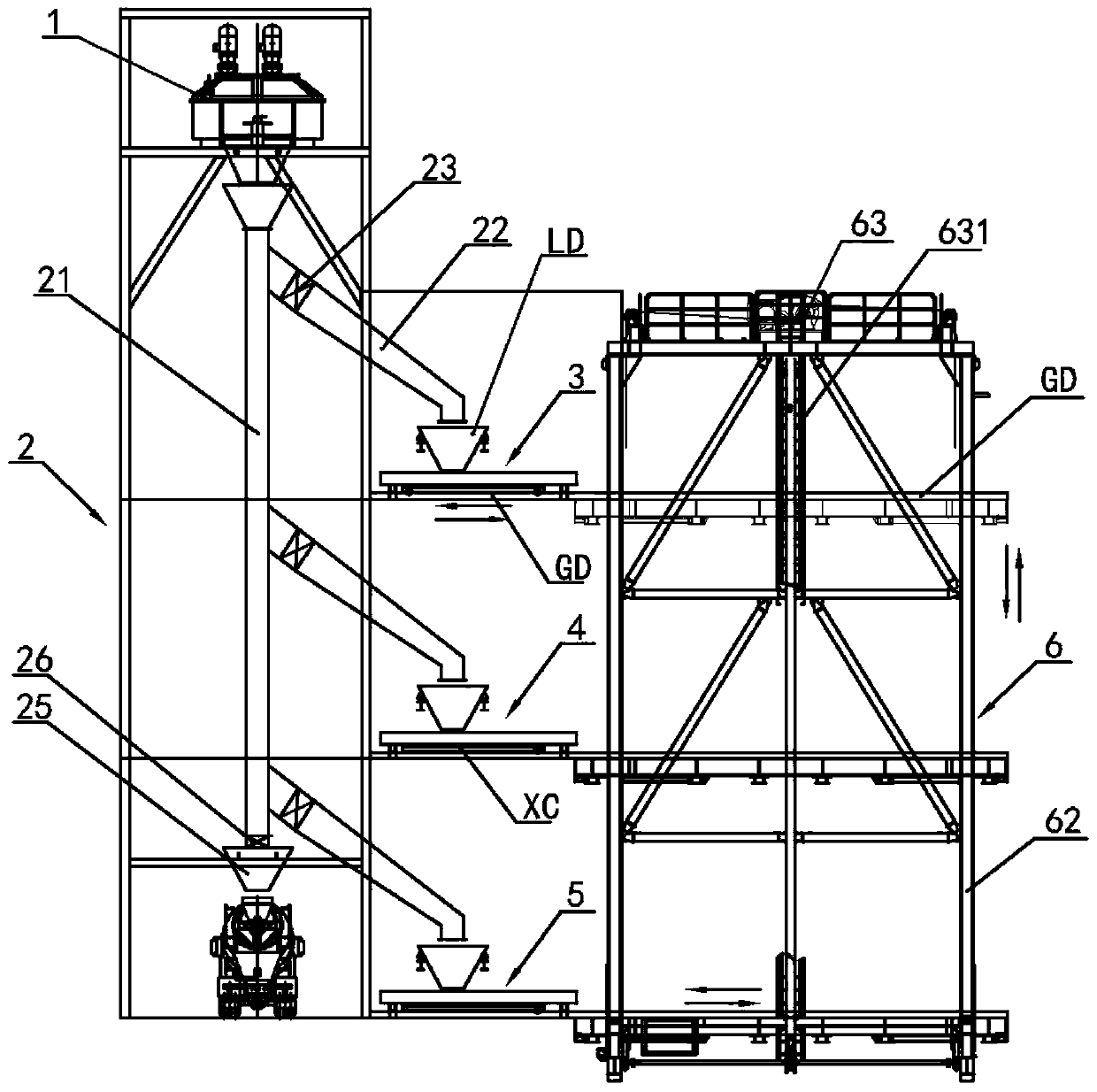

[0024] combine figure 1 , figure 2 It can be seen that the comprehensive production system for PC components disclosed in this embodiment includes a mixing station 1, a vertical material slide device 2, an outer wall panel production line 3, an inner wall panel production line 4, a laminated panel production line 5 and a vertical ferry car 6.

[0025] combine figure 1 , figure 2 It can be seen that the mixing station 1 adopts an existing conventional mixing station, and the vertical material slide device 2 is arranged at the discharge end of the mixing station 1 .

[0026] Such as figure 2 As shown, the vertical material distributing device 2 includes a material slide tube 21, a material slide tube 22 and a solenoid valve 23, and each production line corresponds to a material slide tube. The material slide connecting pipe 22 is connected to the side wall of the material slide cylinder 21 in the downward inclined state, and the electromagnetic valve 23 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com