Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

182results about How to "Less likely to cause damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

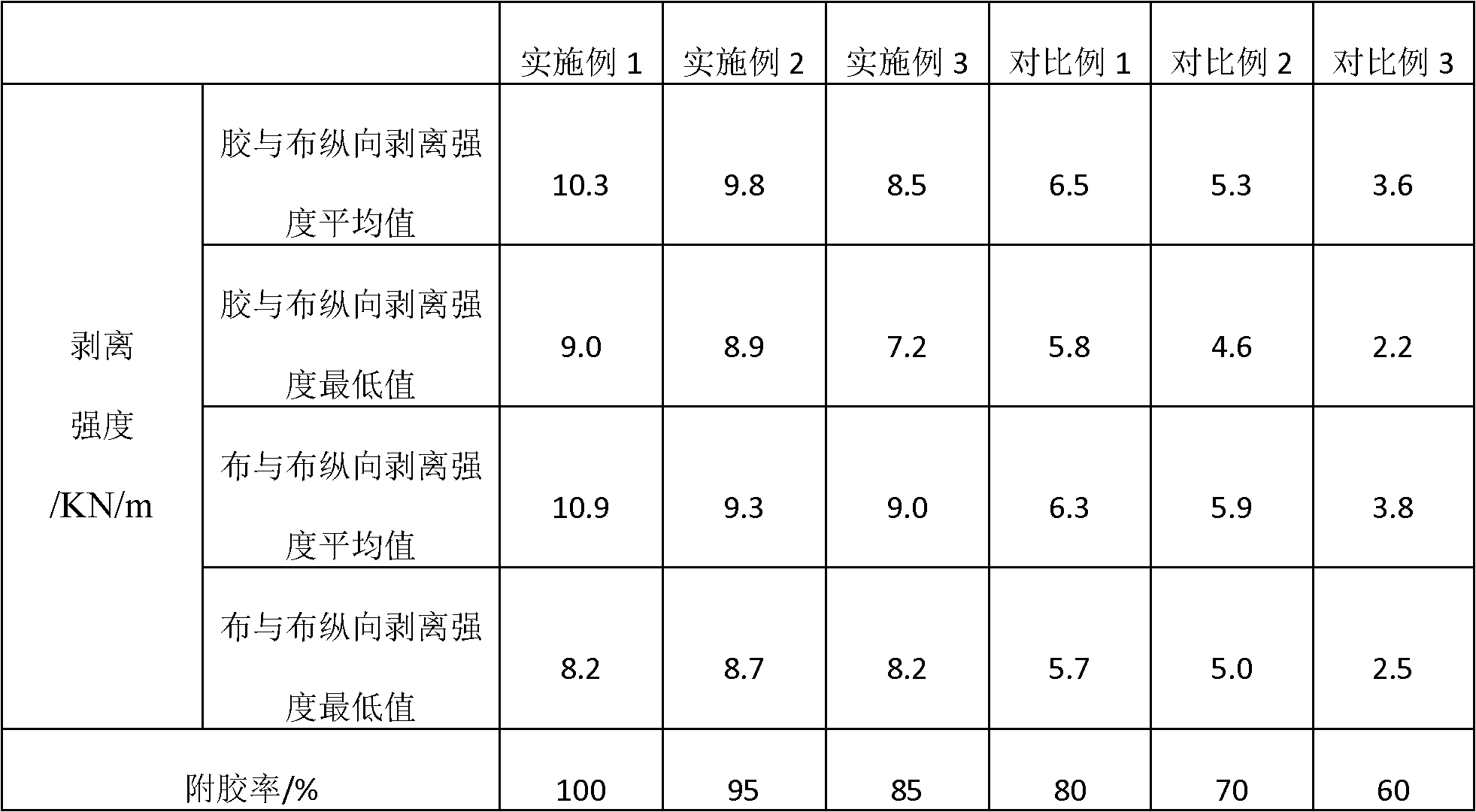

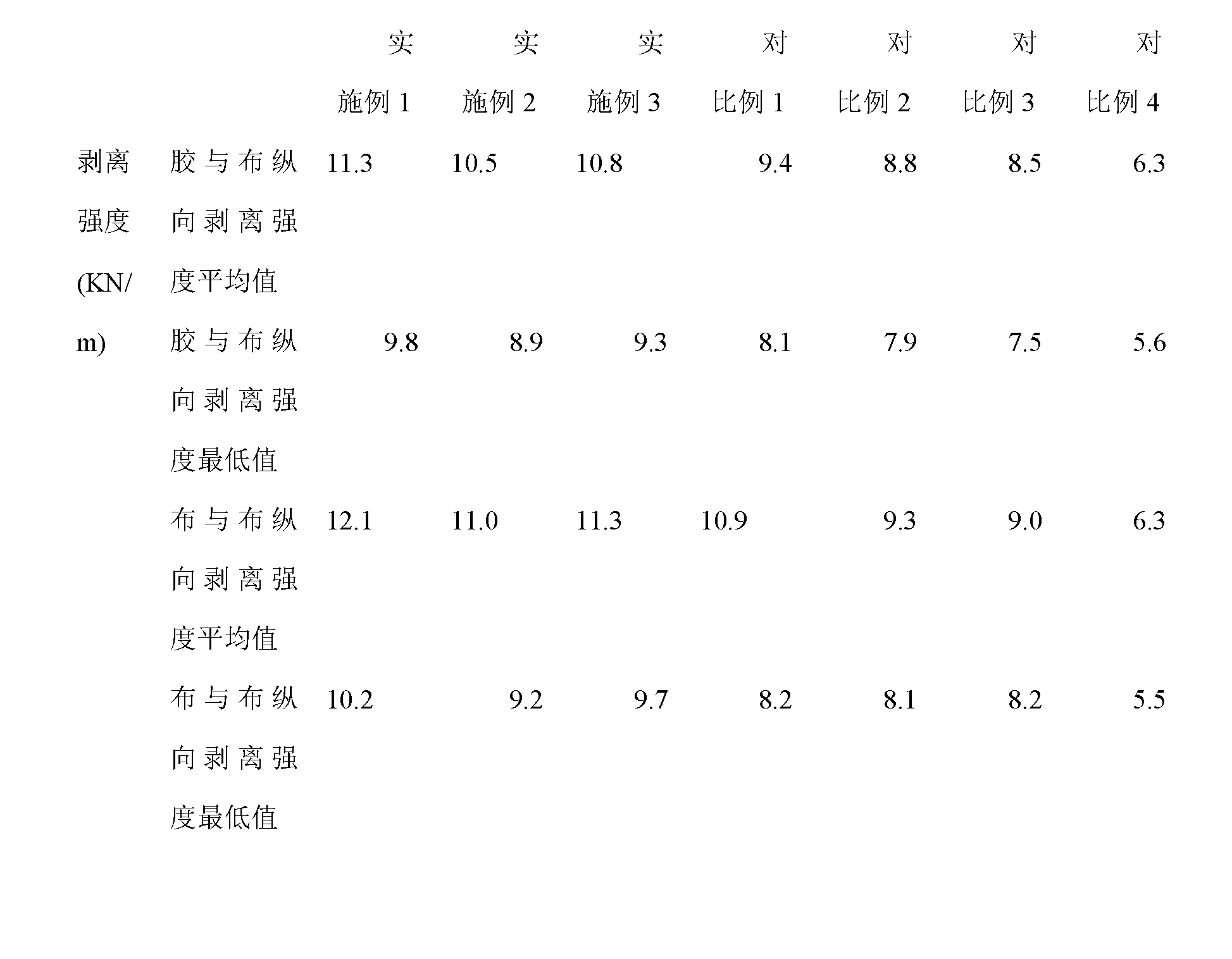

Method for pretreating fibers

The invention relates to a method for pretreating fibers, comprising the following steps of: performing surface activation on fibers by a dopamine hydrochloride biomimetic modification method, and then performing impregnation treatment on the fibers by using impregnation solution composed of rubber latex and phenolic resin, aiming to improve the interface adhesion property of the fibers with rubber so that the fibers are more suitable for tyres, conveyor belts, high-pressure rubber tubes and transmission belts. The method solves the experimental problem caused by high toxicity of isocyanate and avoids damage on the fibers caused by high-temperature treatment; and the process flow is simplified and the production cost is reduced.

Owner:BEIJING UNIV OF CHEM TECH

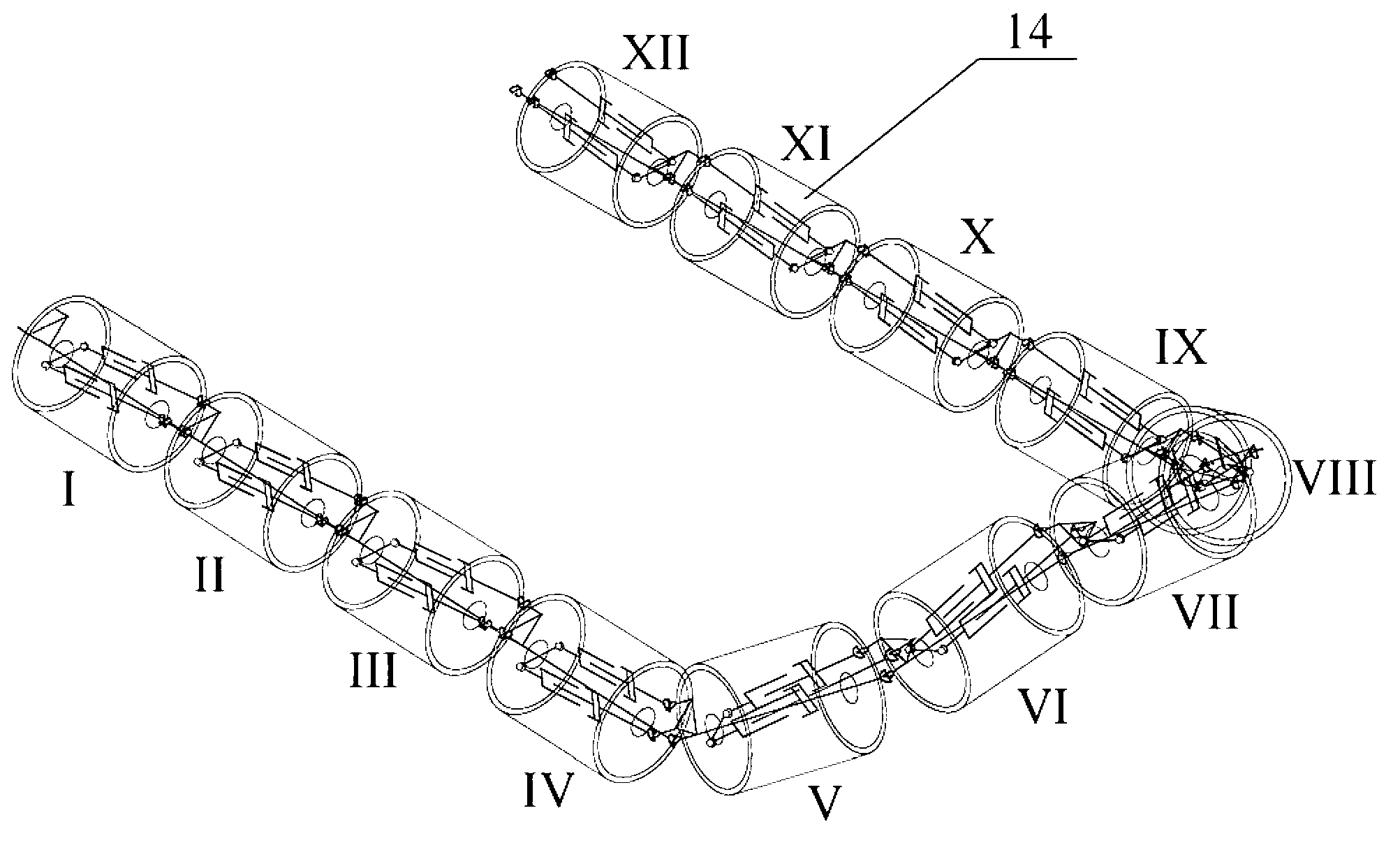

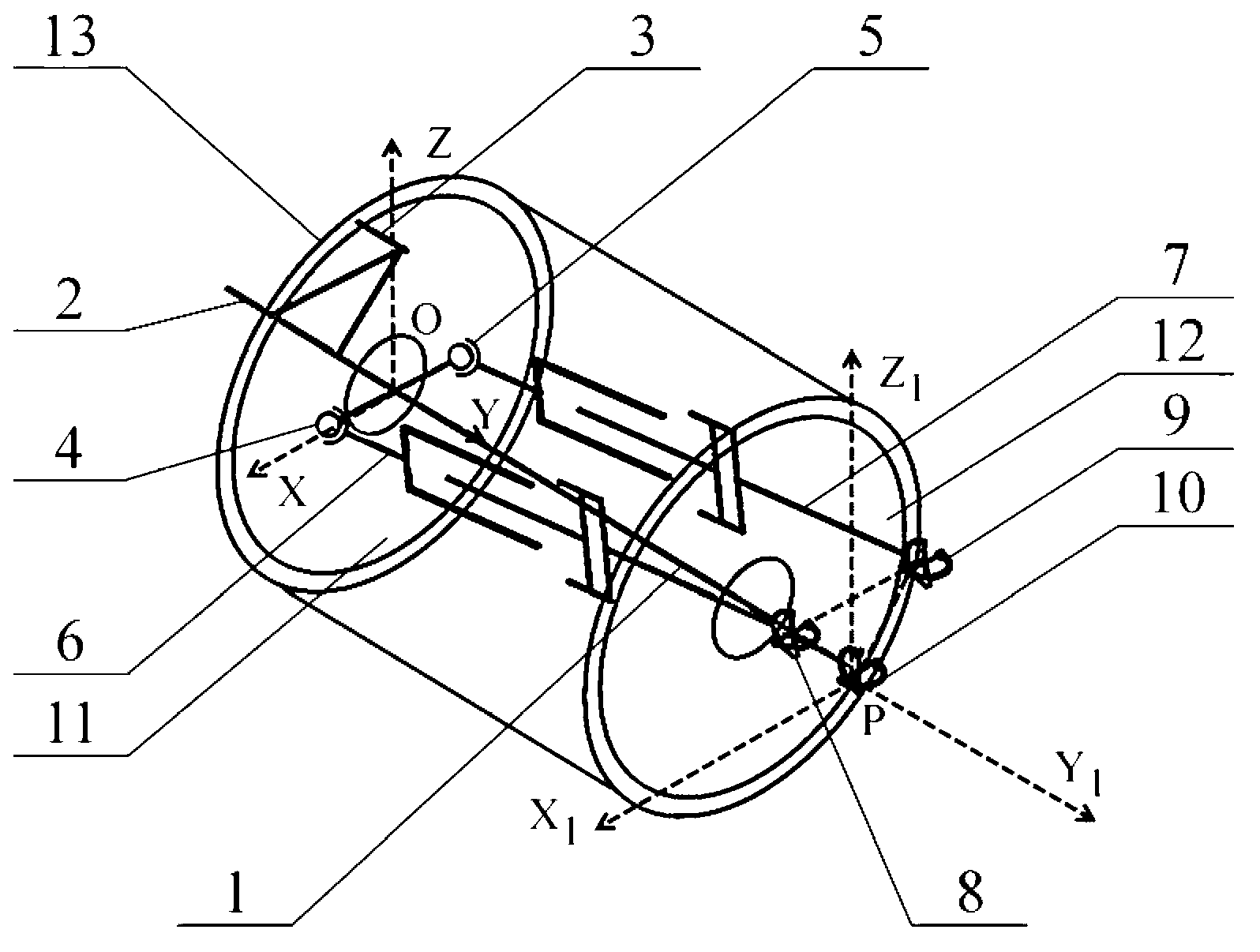

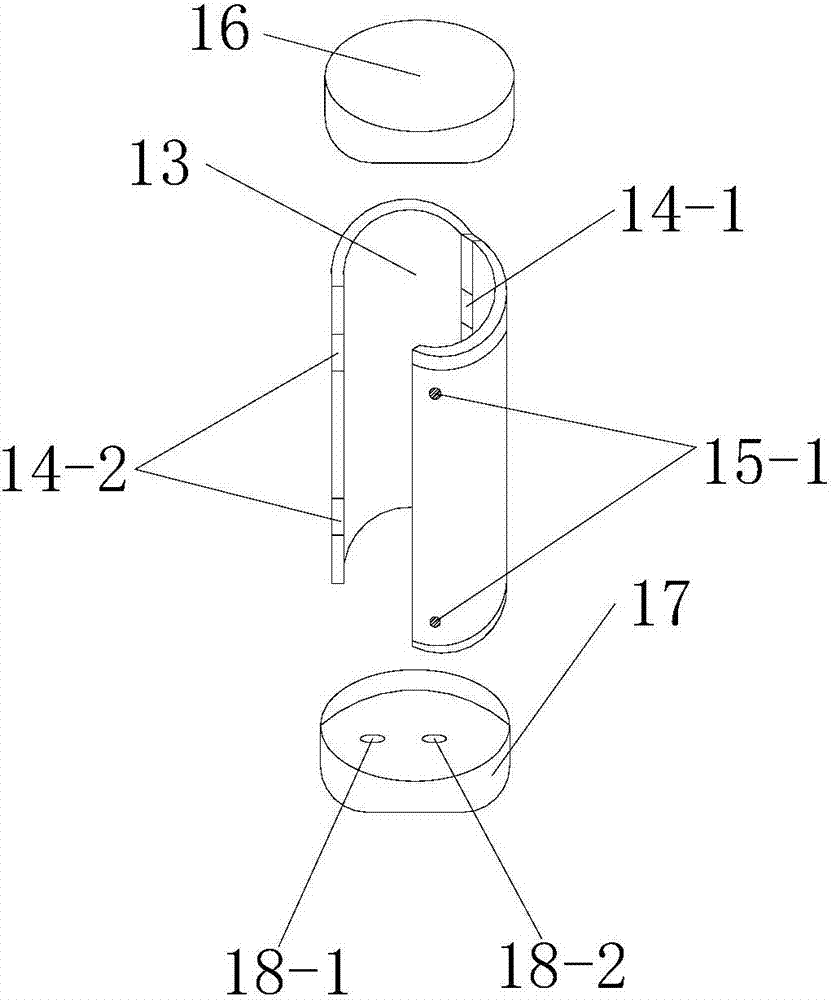

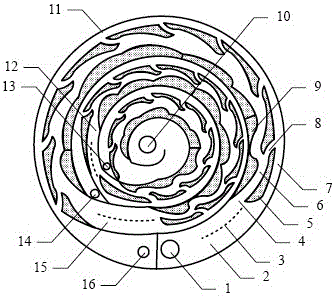

Variable rigidity parallel joint snake-shaped robot mechanism

InactiveCN103056876AHigh body flexibilityImprove flexibilityProgramme-controlled manipulatorTerrainRotational axis

The invention relates to a variable rigidity parallel joint snake-shaped robot mechanism and belongs to the field of robots. A robot is formed by a plurality of action units in serial connection. Each action unit comprises a two freedom degree spatial parallel joint. The joint comprises a fixed U branch chain and two SPDU drive branch chains. Each drive branch chain comprises a variable rigidity linear driver. A rotary shaft and a drive gear parallel with the fixed U branch chain form contour of each action unit. The rotary shaft is connected with the fixed U branch chain through a vibration isolating device which can balance off reverse moment. Rigidity and damp of the drive branch chain is controllable and variable, so that terrain adaptability of the snake robot can be improved by increasing joint flexibility, posture accuracy and stability of the snake robot can be improved by increasing joint rigidity, and applicability of the snake robot is improved. Vibration generated during action of the robot is absorbed by the vibration isolating device and the drive branch chain, impact moment tolerance of the snake robot joint is improved, and accordingly motion speed and efficiency of the robot are increased.

Owner:BEIJING UNIV OF CHEM TECH

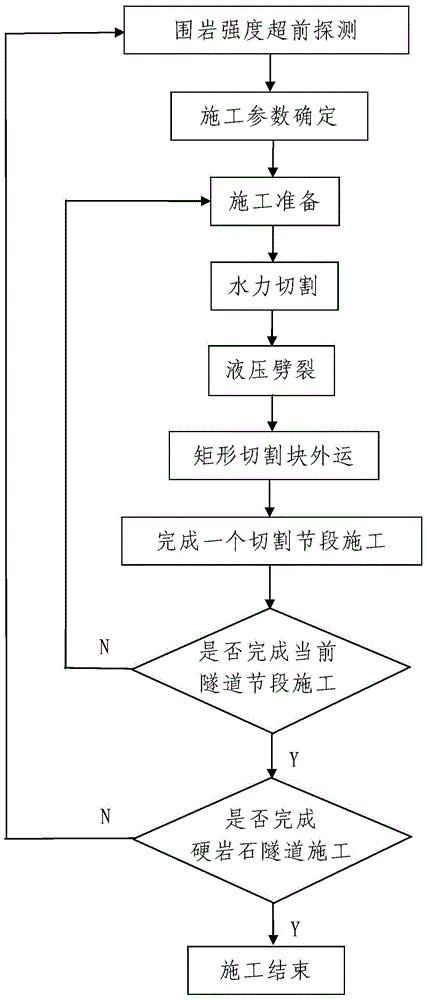

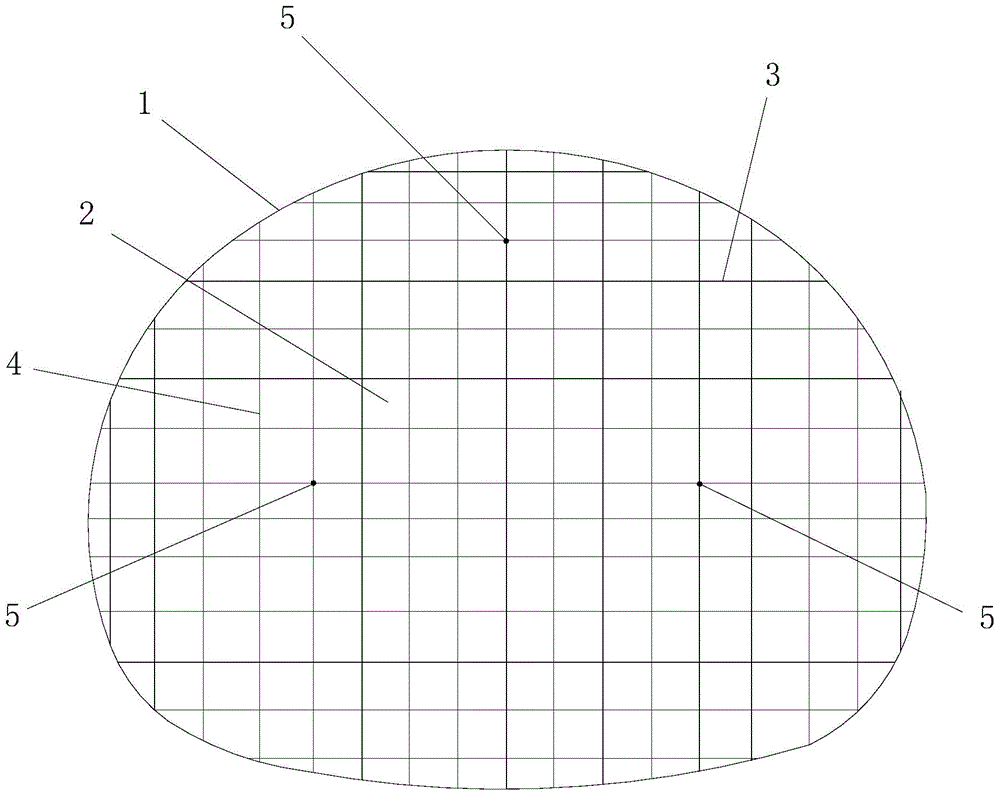

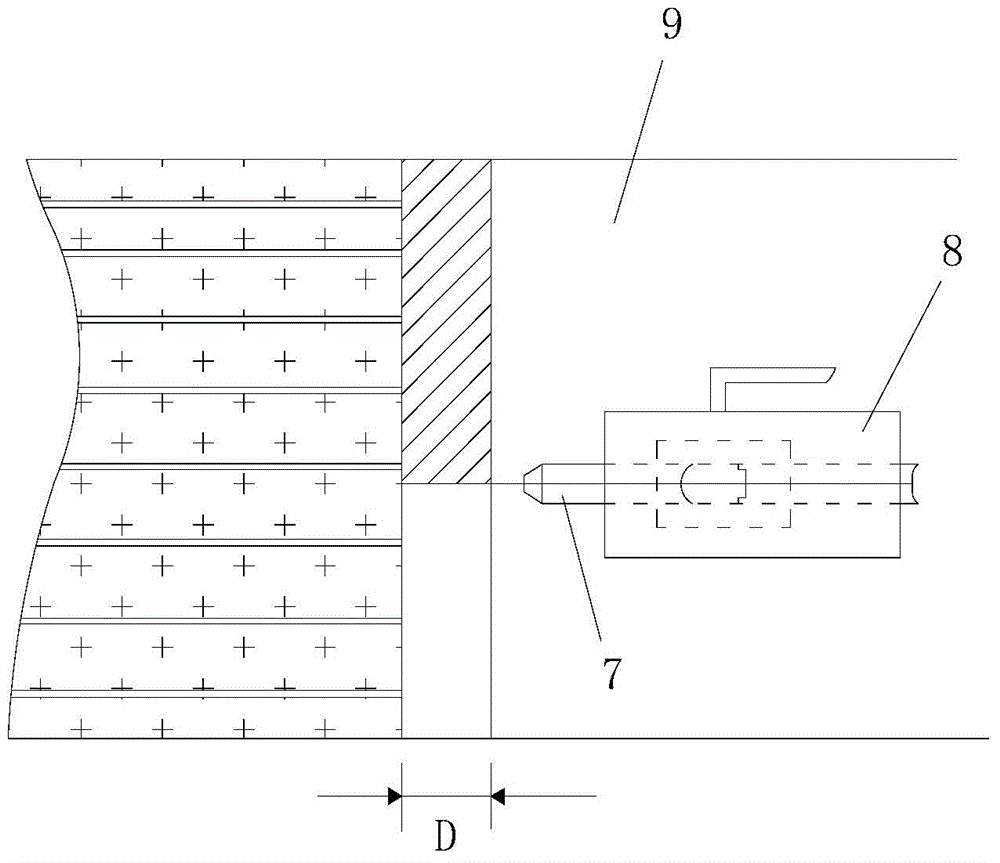

Hard rock tunnel construction method based on water power cutting

The invention discloses a hard rock tunnel construction method based on water power cutting. The hard rock tunnel construction method based on the water power cutting is characterized by constructing multiple tunnel sections from back to front along the longitudinal extending direction of a tunnel. When any one tunnel section is constructed, the process is as follows: 1, surrounding rock classification advanced detection; 2, construction parameter confirmation, wherein the confirmed construction parameters comprise cutting parameters of a water power cutting machine and split force of a hydraulic splitter; 3, current constructed tunnel section construction: constructing multiple cutting sections of the current constructed tunnel sections from back to front along the longitudinal extending direction of the tunnel, wherein when any one cutting section is constructed, the process is as follows: construction preparation, water power cutting, hydraulic splitting and rectangular cutting block outward transporting; 4, repeating steps one, two and three for many times until the construction process of the constructed hard rock tunnel is finished. The method provided by the invention is simple in steps, convenient to implement, lower in input cost, high in construction efficiency, good in construction effect, and can simply, conveniently and quickly finish the construction process of the hard rock tunnel.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

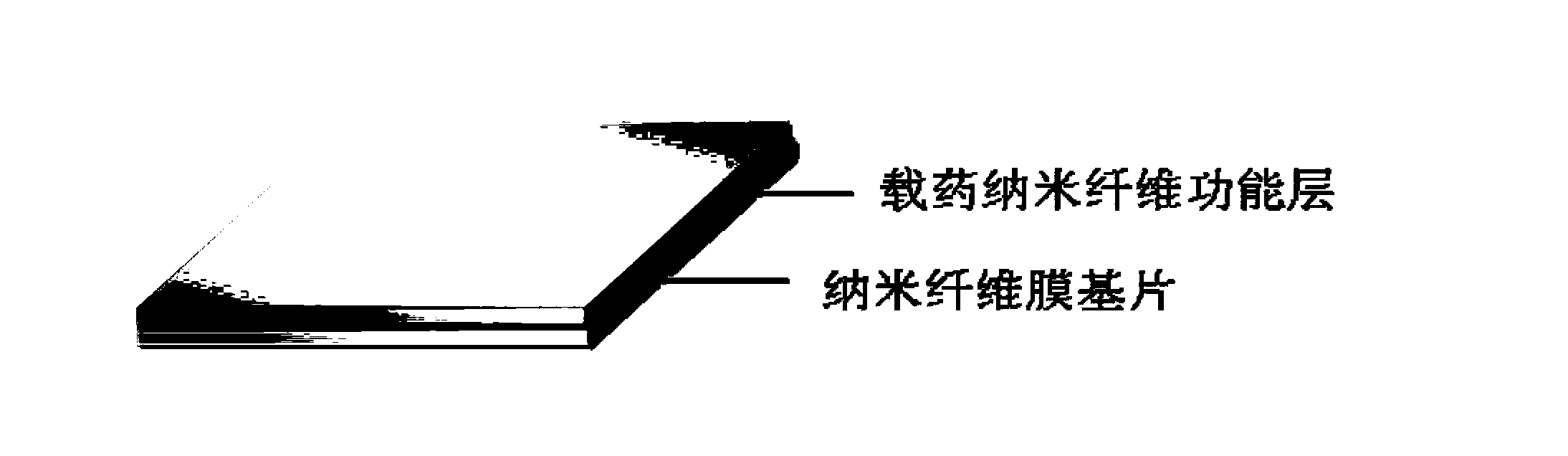

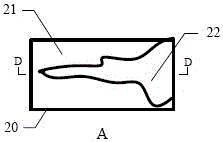

Postoperation anti-infectious composite electrostatic-spinning nanometer fiber-film sheet for repairing hernia and preparation method thereof

InactiveCN104096272ALess likely to cause damageImprove mechanical propertiesSurgeryFiberRecovery position

The invention relates to a postoperation anti-infectious composite electrostatic-spinning nanometer fiber-film sheet for repairing hernia and a preparation method thereof. The hernia-repairing sheet comprises a polymer nanometer fiber-membrane base sheet prepared through an electrostatic spinning method, and a biodegradable high-molecular nanometer fiber functional membrane which is connected with the polymer nanometer fiber-membrane base sheet, is loaded with an anti-infectious medicine and is obtained through an electrostatic spinning method. The polymer nanometer fiber-membrane base sheet is soft and good in mechanical properties, does not cause damage of internal organs and enables an internal organ to be fixedly disposed at a postoperation recovery position. The electrostatic-spinning nanometer fiber functional membrane loaded with the anti-infectious medicine has appropriate degradation speed, and the anti-infectious medicine is gradually released along with degradation of the material, so that postoperation infection and inflammation caused by wound pollution are effectively prevented. The hernia-repairing sheet is capable of effectively reducing inflammation reaction caused by postoperation infection and reducing patient pain after being implanted into a human body for repairing hernia.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Pretreatment method of polyester fiber surface

The invention relates to a pretreatment method of a polyester fiber surface. The method comprises the following steps of: carrying out pretreatment on the surface of a polyester fiber through two steps, firstly activating the surface of the fiber by means of dopamine hydrochloride biomemetic modification, and then carrying out impregnation treatment by using an impregnation solution comprising rubber latex and phenolic resin. The interfacial bonding performance of the fiber with the rubber is improved so that the fiber is more conductive to a tyre, a conveyer belt, a high pressure rubber tube and a transmission belt. The environment problem caused by high toxicity of closed isocyanate is solved, the fiber injury caused by high-temperature treatment is prevented, the process flow is simplified, and the production cost is reduced.

Owner:BEIJING UNIV OF CHEM TECH

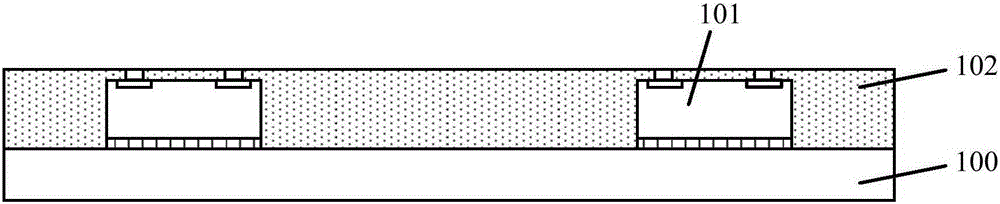

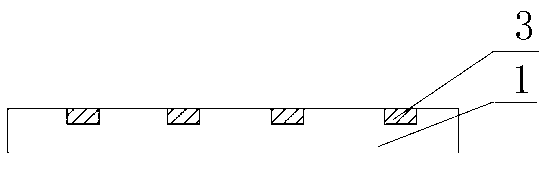

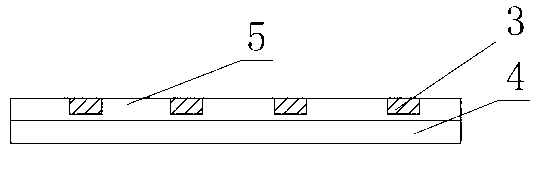

Packaging method

InactiveCN105355569AEliminate driftDrift suppressionSolid-state devicesSemiconductor/solid-state device manufacturingPlastic packagingNon functional

A packaging method comprises the steps of: providing a carrier plate, wherein the carrier plate comprises a plurality of chip regions and cutting regions arranged between the adjacent chip regions, the carrier plate further comprises a first surface, and a plurality of grooves are formed in the cutting regions in the first surface of the carrier plate; providing chips, wherein each chip comprises a functional surface and a non-functional side surface which are opposite to each other, the surface of each functional surface is provided with bumps, and the bumps protrude out of the functional surfaces; fixing the non-functional side surfaces of the chips with the first surface of the carrier plate in the chip regions; forming a plastic packaging layer on the first surface of the carrier plate and the surfaces of the chips, wherein the plastic packaging layer exposes top part surfaces of the bumps; removing the carrier plate after forming the plastic packaging layer; forming a rewiring structure on the surface of the plastic packaging layer and the functional surfaces of the chips; and cutting the plastic packaging layer and the rewiring structure, so that the plurality of chips are separated from one another, thereby forming an independent packaging structure. The yield and reliability of the formed packaging products are improved.

Owner:NANTONG FUJITSU MICROELECTRONICS

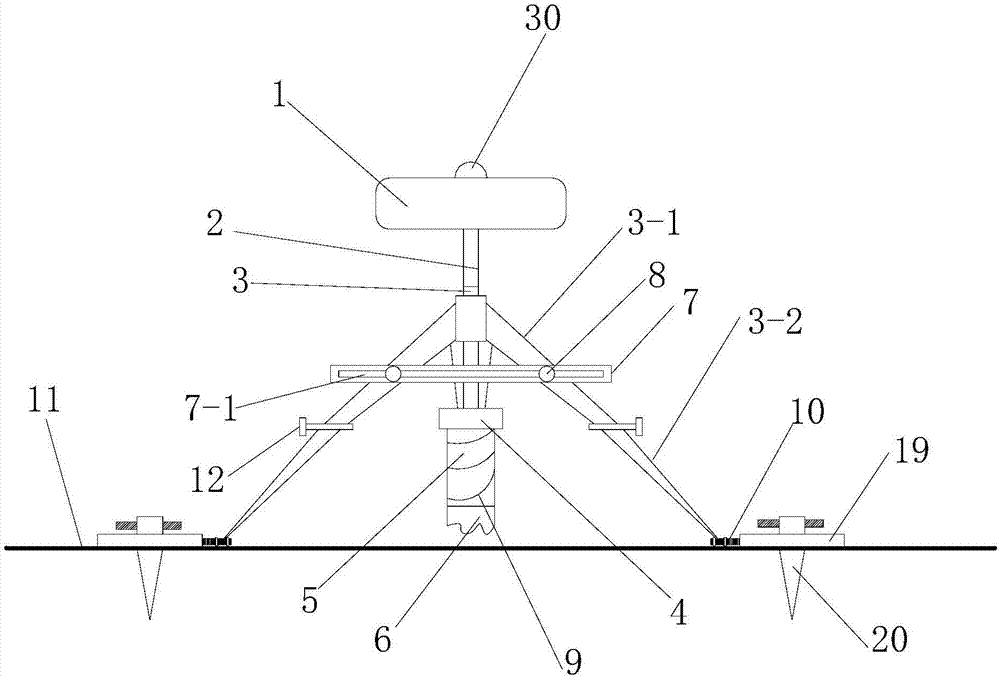

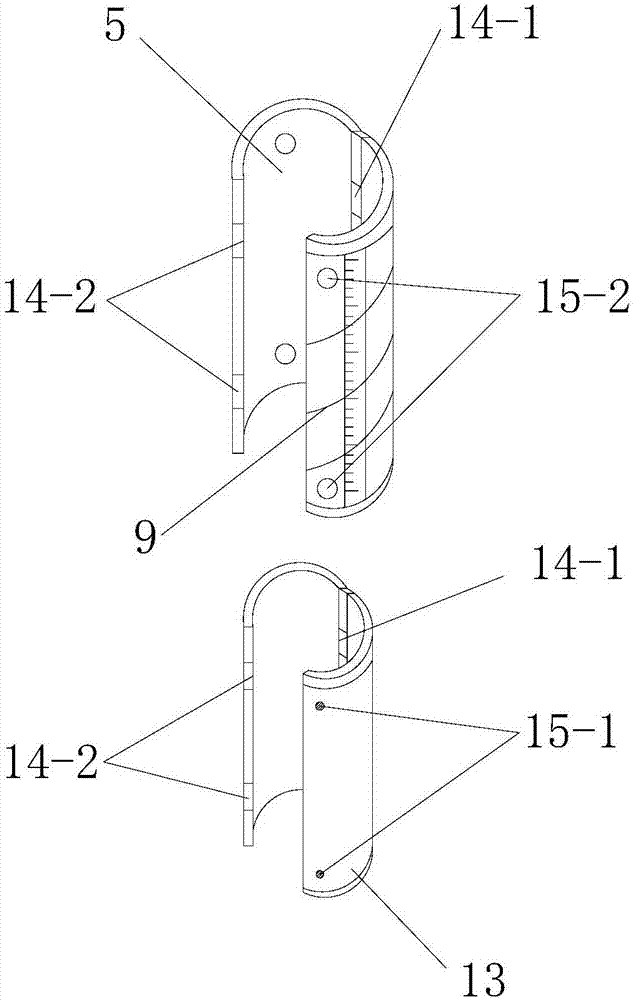

Soil sample collecting device

Owner:BAOJI UNIV OF ARTS & SCI

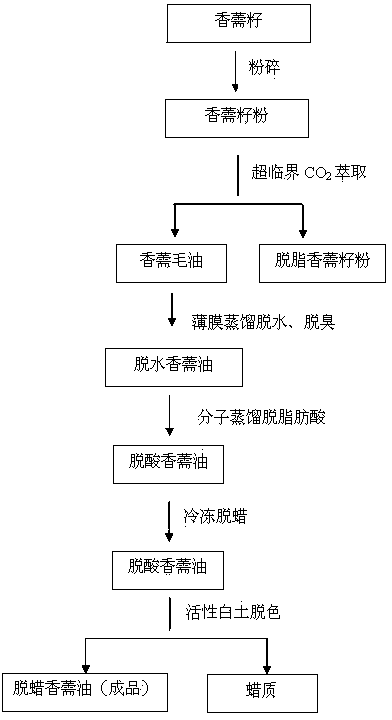

Preparation method of herbal elsholtzia essential oil

ActiveCN103409241AControl freezing temperatureImprove oil yieldEssential-oils/perfumesEngineeringFatty acid

The invention provides a preparation method of herbal elsholtzia essential oil, which is characterized by comprising the following steps: (1) extraction of supercritical CO2: smashed herbal elsholtzia seed power is added to a supercritical feed cylinder and placed in an extraction kettle for extraction of supercritical CO2, so that herbal elsholtzia crude oil can be obtained; (2) dehydration and degassing through thin-film distillation: dehydration and deodorization are performed on the herbal elsholtzia crude oil through the thin-film distillation; (3) fatty acid removal through molecular distillation: the herbal elsholtzia crude oil after dehydration and deodorization is continuously moved to a molecular still, so that deacidification herbal elsholtzia oil and a secondary product free fatty acid can be obtained; (4) activated clay decoloration: the herbal elsholtzia oil after deacidification is decolored via an activated clay decoloration column; (5) freezing and dewaxing: the freezing temperature is controlled, and the herbal elsholtzia oil stands still, or is stirred at intervals, crystallized, settled, filtered or centrifuged and dewaxed, so that faint yellow liquid namely the herbal elsholtzia essential oil can be obtained. According to the preparation method, the herbal elsholtzia essential oil has high oil production and excellent linolenic acid maintenance, the production is safe, the technology is simple, the operation is convenient, and the continuous large-scale production is facilitated.

Owner:丽江先锋食品开发有限公司

Injection of flurbiprofen and its preparing method

InactiveCN1621035AEasy to prepareQuick resultsOrganic active ingredientsAntipyreticSolventLong lasting

The present invention is flurbiprofen ester injection as antiphlogistic and analgetic medicine and its preparation process. Main medicine and supplementary material including solvent, emulsifier, isotonic agent, buffering agent and pH regulator are mixed to compound the injection. Compared with available oral flurbiprofen preparation, the flurbiprofen ester injection has even high curative effect, even fast action, long lasting effect and less stomach mucous membrane damage and other negative effect. The present invention is used in treating chronic rheumarthritis, etc and is especially suitable for relieve post-operational pain and pain caused by cancer, and it has high effect and no addiction.

Owner:梁建华

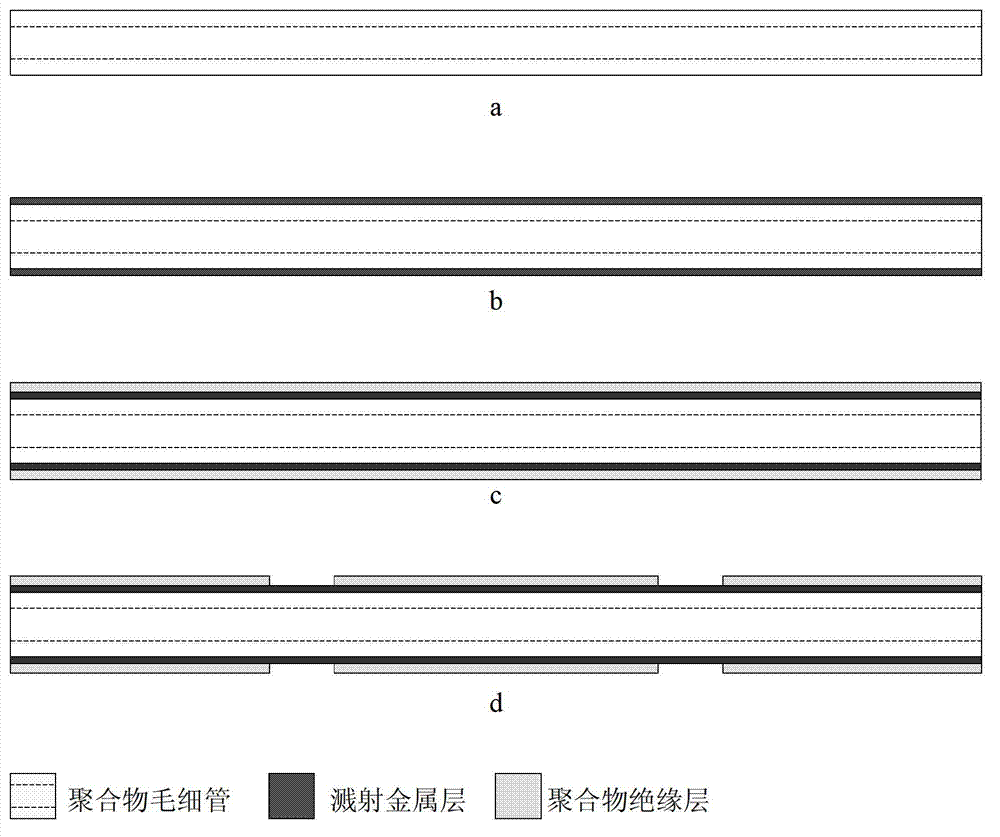

Flexible tubular microelectrode and preparation method thereof

InactiveCN102815664ASimple processLow costFixed microstructural devicesVolume/mass flow by thermal effectsInsulation layerPolymer insulation

The invention discloses a flexible tubular microelectrode and a preparation method thereof. The preparation method comprises the following steps of: firstly, cutting a section of a polymer capillary; secondly, sputtering a metal layer on the surface of the polymer capillary; thirdly, deposing a polymer on the surface of the capillary as an electrode insulation layer; and at last, etching the polymer insulation layer on the surface of the capillary by utilizing laser, and exposing a metal electrode point to obtain the tubular microelectrode. According to the flexible tubular microelectrode prepared by the invention, when electric simulation and electrographic recording are carried out on a physiological tissue by the electrode, a fluid medicine is transported to a tissue organ by a microtubule channel, and a flexible micro-size is beneficial for test or experiment operation and production of an embedded medical device.

Owner:SHANGHAI JIAO TONG UNIV

Air freshener with disinfection function

The invention provides an air freshener with a disinfection function. Raw materials of the air freshener comprise a flower component, a traditional Chinese medicine additive component, sodium stearate, fatty alcohol-polyoxyethy, ethyl alcohol and deionized water. Compared with the traditional air freshener prepared by chemical materials, the air freshener with the disinfection function has the advantages of small toxic and side effects, small irritation, low probability of injury to a human body, low cost and remarkable effect, and is a new generation of air freshener.

Owner:QINGDAO HUAREN TECH INCUBATOR

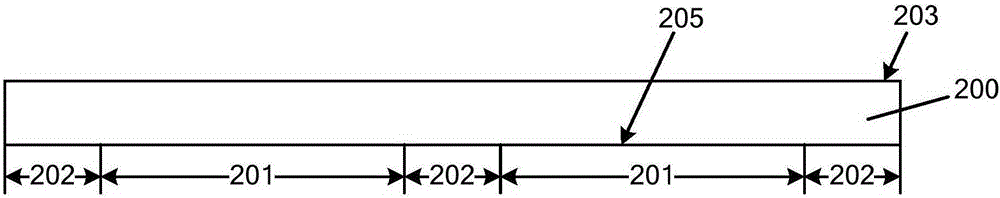

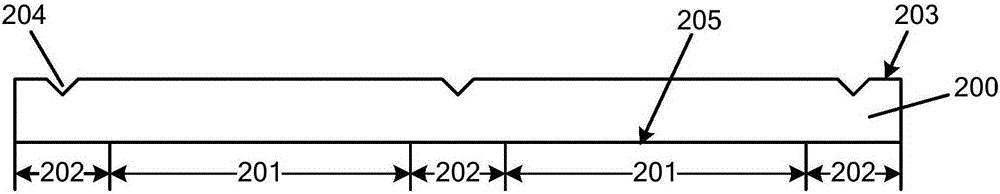

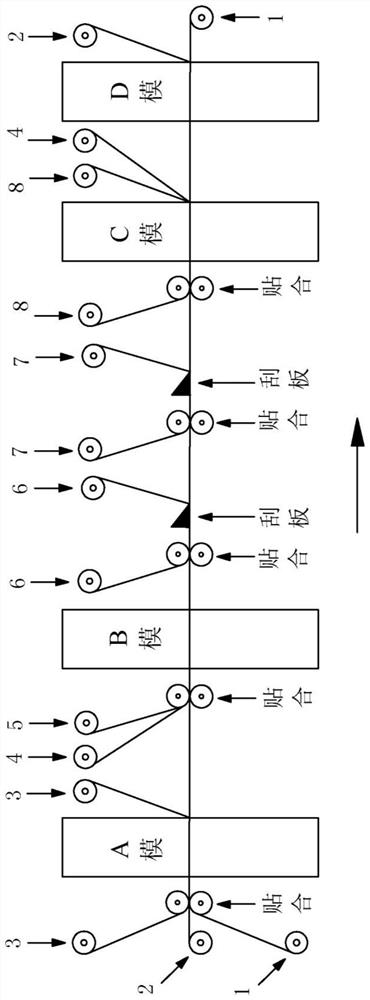

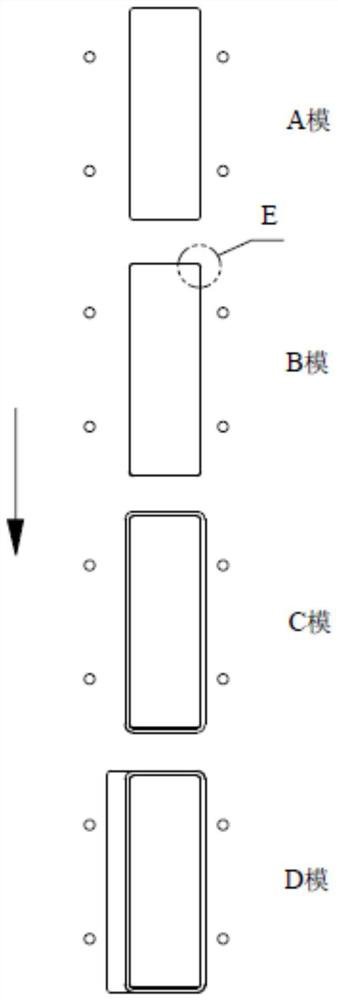

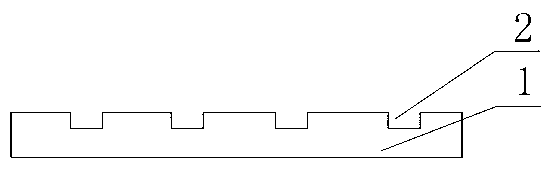

Double-faced adhesive tape product anti-sticking waste discharge production process

ActiveCN111675007AEasy to operateReduce labor intensityArticle deliveryFilm materialManufacturing engineering

The invention provides a double-faced adhesive tape product anti-sticking waste discharge production process. The double-faced adhesive tape product anti-sticking waste discharge production process comprises the following steps of conducting die cutting on a weak adhesive film material belt to form a weak adhesive film inner hole material in the same shape as an inner hole of a product, discharging the weak adhesive film material belt, sequentially laminating a main material double-faced adhesive tape material belt and a first surface paper material belt, performing die cutting to obtain innerhole wastes of first surface paper, a main material double-sided adhesive tape and a weak adhesive film in sequence from top to bottom, laminating a waste discharge adhesive tape, discharging the waste discharge adhesive tape, the first surface paper material belt and inner hole waste, laminating a second surface paper material belt, performing die cutting to obtain the appearance of the product,discharging the second surface paper material belt and the main material double-sided adhesive tape, then performing die cutting to form the shape of a release film corresponding to the product, discharging the release film material belt, and obtaining a finished product on a bottom supporting film material belt. A weak adhesion die has an anti-adhesion effect, automatic production of product inner hole waste removal can be achieved, the production efficiency and the product quality and yield are improved, and the production cost is reduced.

Owner:郑州领胜科技有限公司

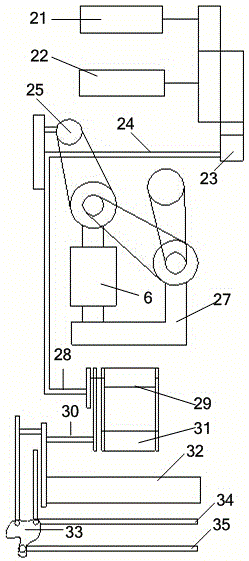

Vertical threshing and rotary tillage combined harvester

InactiveCN104429319AImprove efficiencyImprove stabilityMowersThreshersAgricultural engineeringGravity center

The invention provides a vertical threshing and rotary tillage combined harvester which comprises a stalk cutter, a stalk scrabbling wheel, a threshing vertical shaft, a threshing cylinder, a grain receiver, a straw outlet, a girder frame, a gear case and an engine. The grain receiver, an impurity discharge fan and a straw discharge fan are sequentially arranged at the lower portion of the threshing vertical shaft from bottom to top, the middle of the threshing vertical shaft penetrates through the threshing cylinder, the straw outlet is formed in the top end of the threshing vertical shaft, the stalk cutter and the stalk scrabbling wheel are arranged at the front end of the threshing cylinder, the engine and the gear case are arranged on the girder frame, a rotary cultivator is connected in the gear case, and a walking caterpillar track is arranged at the lower end of the girder frame. The whole vertical threshing and rotary tillage combined harvester is provided with a power transmission route, has a function of simultaneously achieving rice-wheat harvesting and field soil rotary tillage, is compact in structural arrangement, small in size, moderate in gravity center and stable and reliable to operate and is also suitable for operation in southern districts.

Owner:周金保

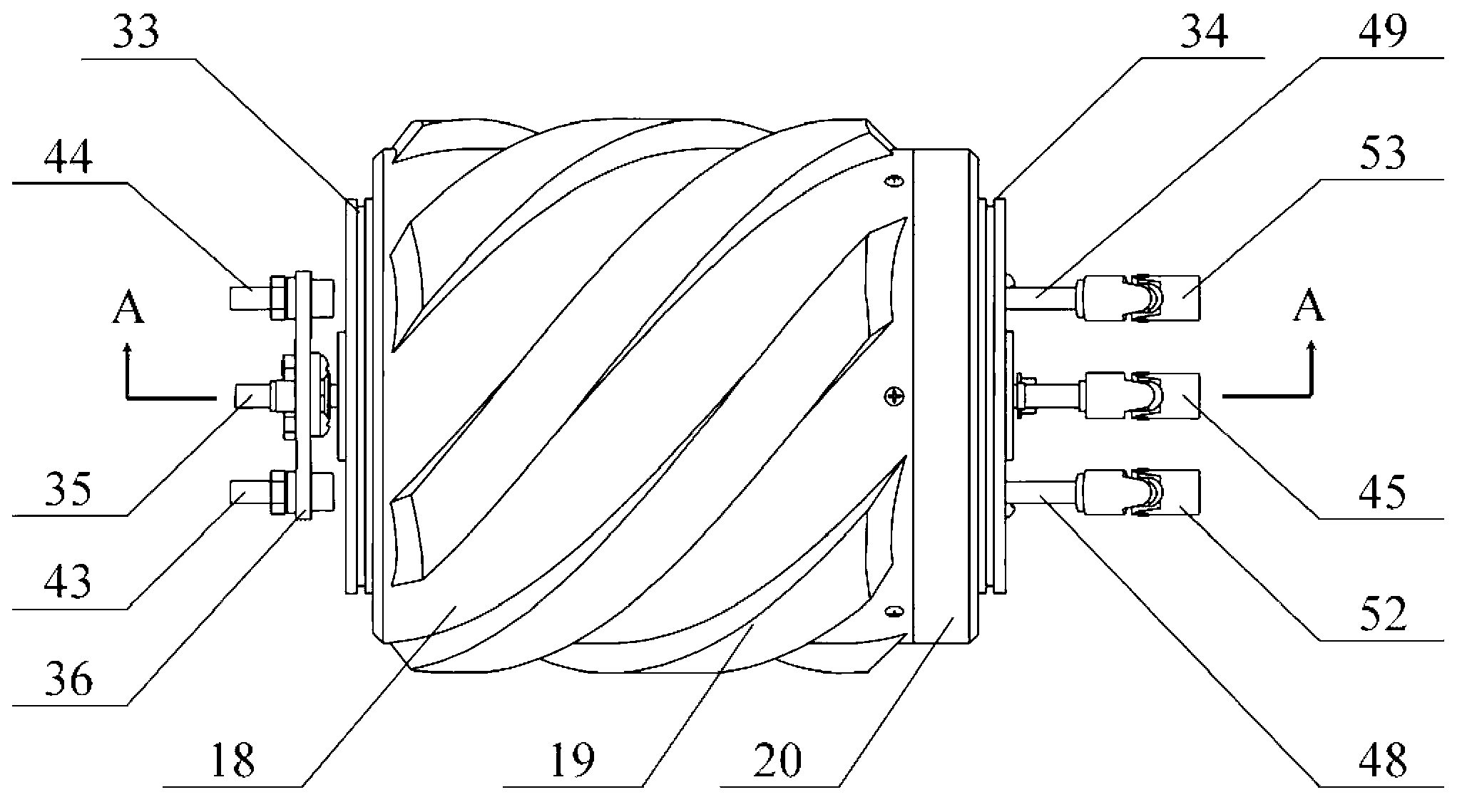

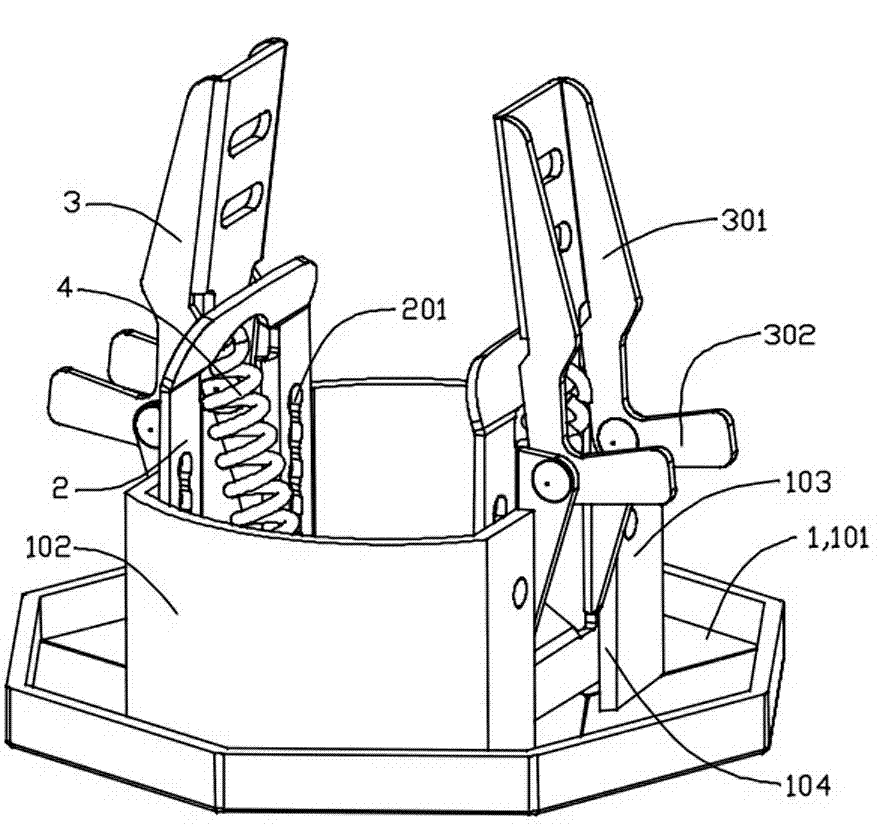

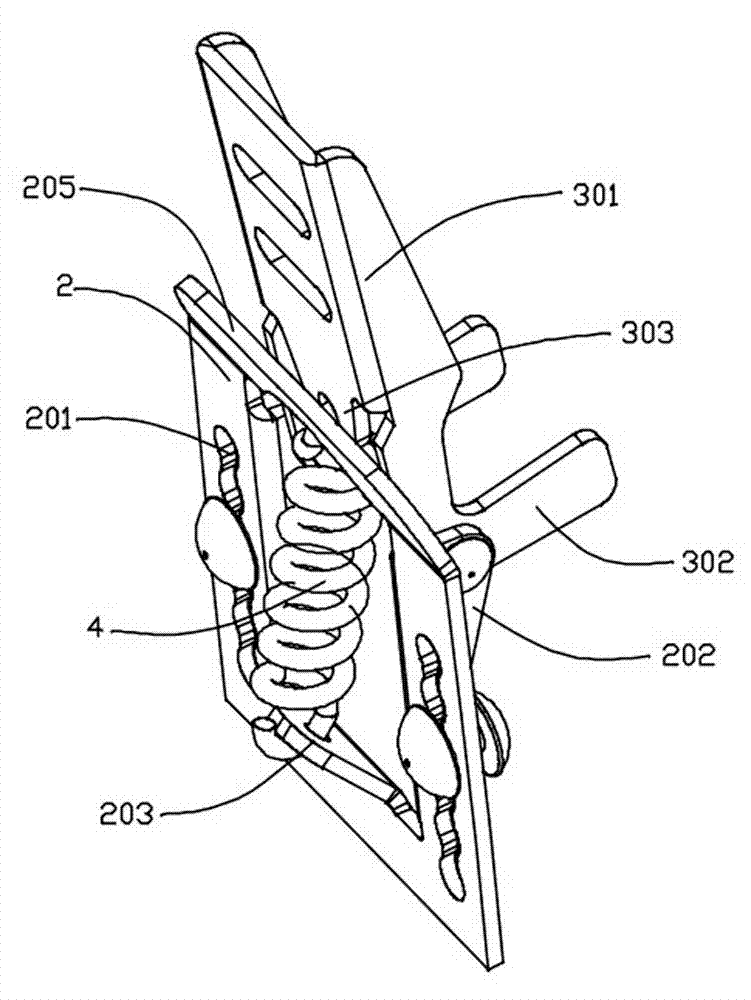

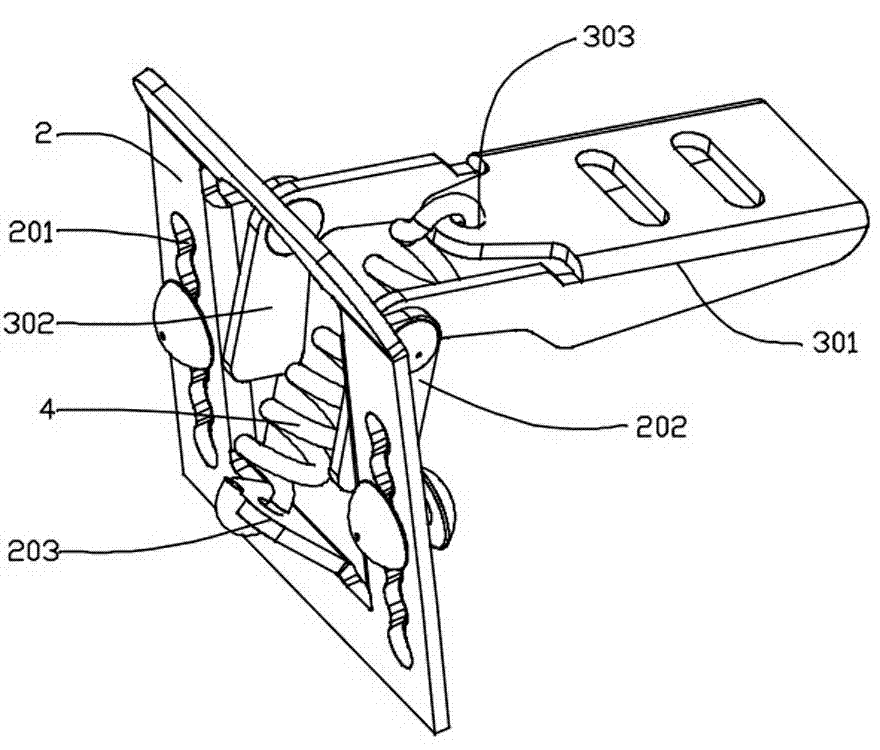

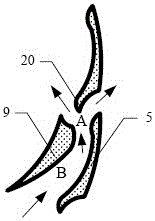

Metamorphic knuckle mechanism of snake-imitation rescuing robot

A metamorphic knuckle mechanism of a snake-imitation rescuing robot comprises a knuckle left end cover, a knuckle right end cover, two RRPRR branches and one RRPRR metamorphic branch. Metamorphic knuckles have two mechanism forms, and the work space and mobility can be changed. In the mechanism form I, a movable pair P in the RRPRR metamorphic branch is in an active moving state, a rotation pair R is in a following state, and then the knuckles have one moving freedom degree and two rotating freedom degrees. In the mechanism form II, the movable pair P in the RRPRR metamorphic branch is in a minimum displacement and locking state, the rotation pair R is in an active state, the knuckles are changed into parallel spherical knuckles in a metamorphic manner, and three rotation freedom degrees are achieved. The metamorphic knuckle mechanism has the beneficial effects of being good in flexibility, high in bearing capability and good in structural robustness and is suitable for the snake-imitation rescuing robot. By means of mutual cooperation of the two mechanism forms of the multiple metamorphic knuckles, the flexibility and adaptability of the snake-imitation rescuing robot under different environments can be effectively improved.

Owner:BEIJING UNIV OF CHEM TECH

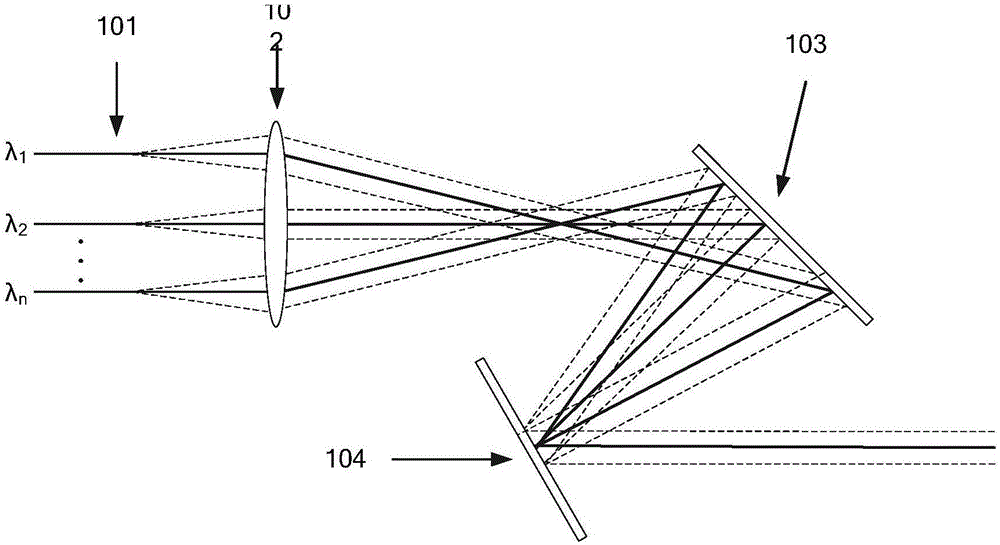

Fiber laser asymmetric compensation spectral synthesizing device

The invention provides a fiber laser asymmetric compensation spectral synthesizing device, which comprises a fiber laser array, a converging lens and two diffraction gratings. The fiber laser array, arranged in parallel, uses the converging lens to collimate the outgoing laser beams and relies on the two diffraction gratings with different linear densities to compensate the angular deflection of the converging lens to different wavelength laser beams. The invention has the advantages of low requirement for the laser line width and the diffraction grating damage threshold, of a strong ability to expand the number of channels and of producing high quality beams. With the device, it is possible to greatly enhance the brightness of the outputted laser from a spectral synthesizing system.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

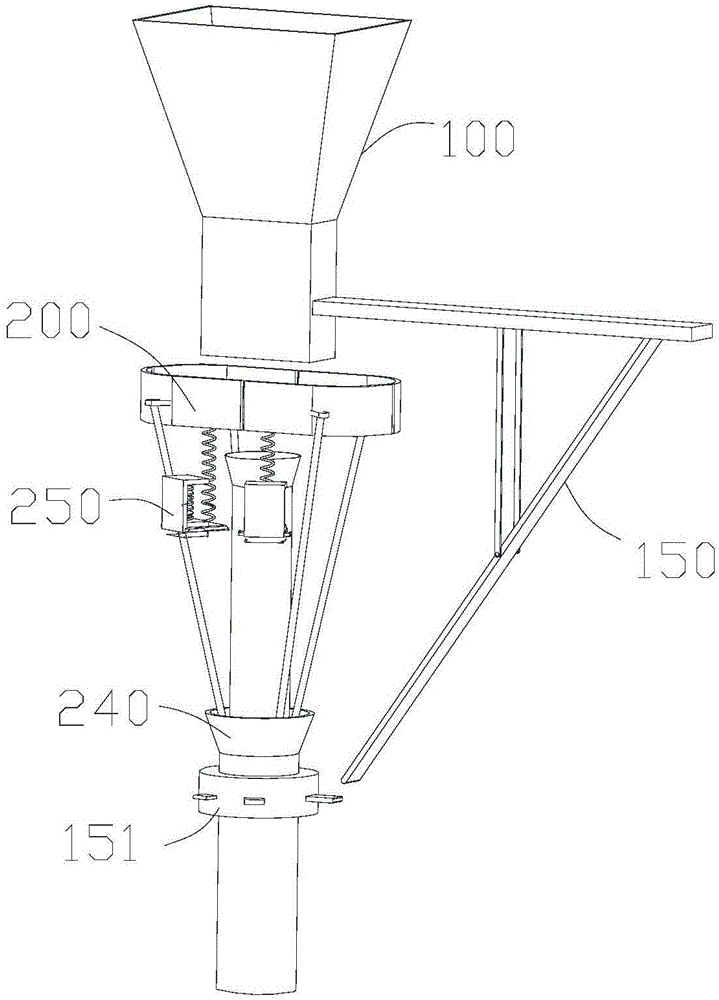

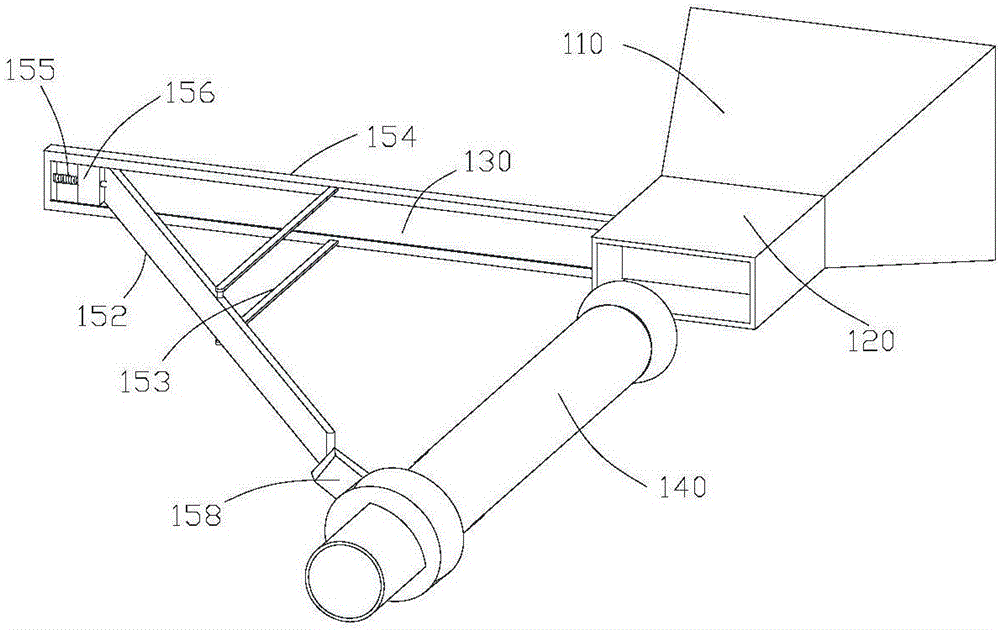

Portable automatic bunching device for crabs

ActiveCN106043777AQuick fixImprove bundling efficiencyBinding material applicationEngineeringAssistive equipment

The invention provides a portable automatic bunching device for crabs, and belongs to the field of crab processing devices. The portable automatic bunching device comprises a feeding mechanism, a bunching mechanism and a positioning mechanism. The positioning mechanism is used for fixing crab legs. The feeding mechanism comprises a hopper, a channel and a baffle. The hopper is mounted at the top of the channel. The channel is vertically arranged. The baffle is mounted in the channel, and is used for controlling the channel to be opened or closed. The positioning mechanism is positioned at the lower part of a discharge opening of the channel, and is used for bearing crabs falling from the discharge opening and fixing the crab legs. The bunching mechanism is located between the positioning mechanism and the feeding mechanism, and is used for bunching crabs. An auxiliary device, that is, the portable automatic bunching device, is simple and reasonable in structure, convenient to process and manufacture, low in manufacturing cost, and convenient to mount and use; and besides, crabs can be quickly fixed through the auxiliary device, workers are not easily injured during the fixing process, and crab claws are not prone to be damaged, so that the crab bunching efficiency is improved, and the auxiliary device is safe, reliable, and convenient to use.

Owner:YANCHENG INST OF TECH

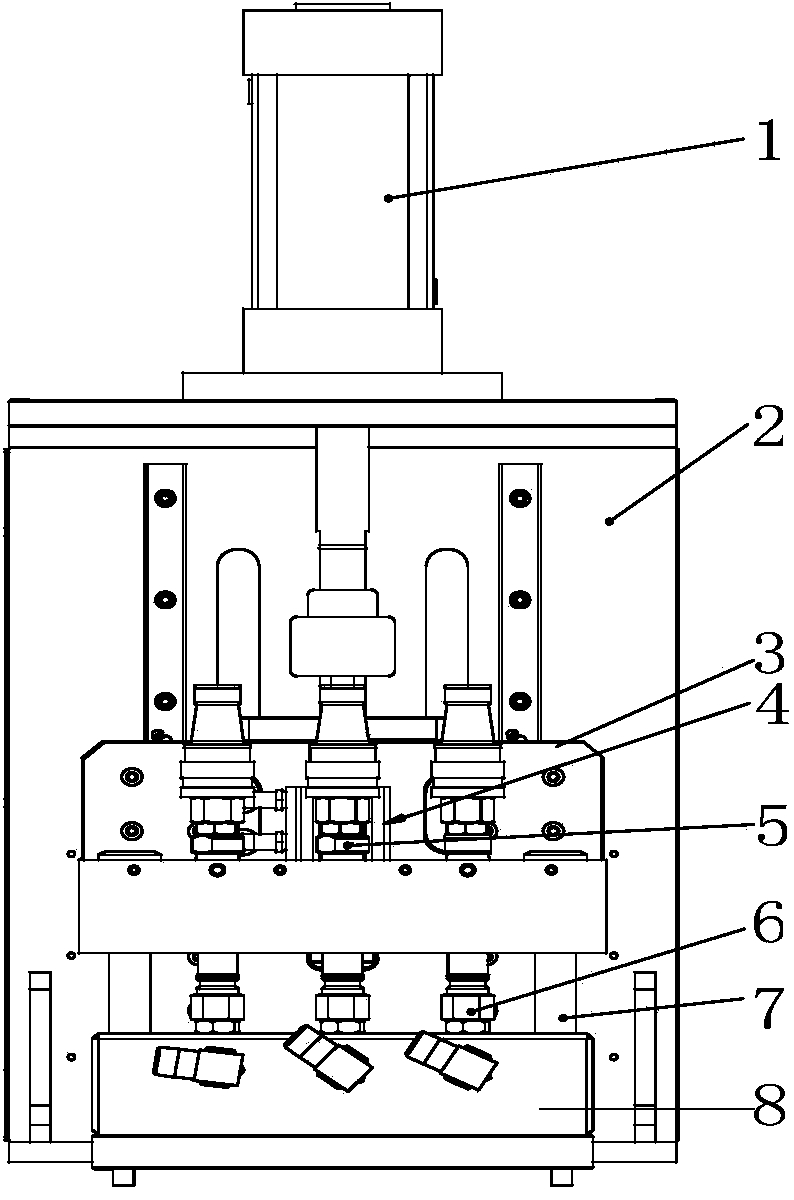

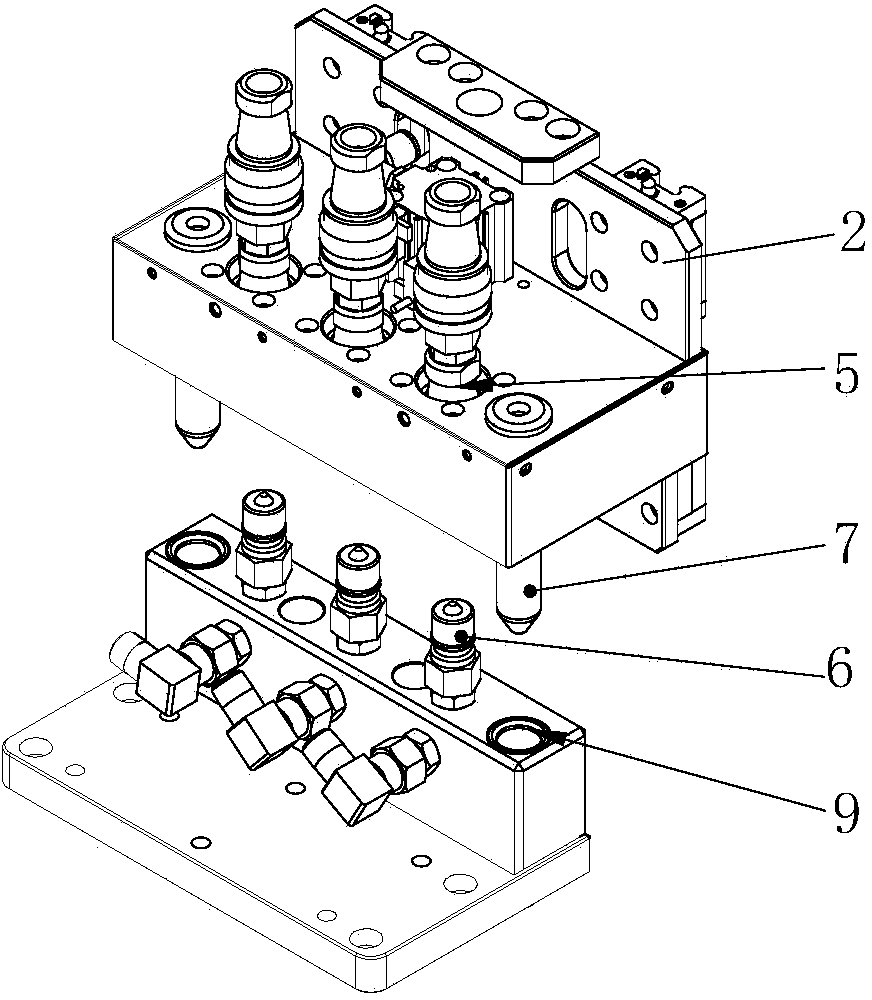

Automatic inserting and pulling mechanism of male and female connectors

InactiveCN104242016AAccurateEven by forceCoupling device engaging/disengagingEngineeringDriving mode

The invention relates to an automatic inserting and pulling mechanism of male and female connectors. A sliding rail is arranged on a fixing seat, an upper support is arranged in the sliding rail and can slide along the sliding rail, and an air cylinder is installed on the fixing seat. A piston rod of the air cylinder is connected with the upper support in a driving mode, a female connector support is installed on the upper support, an unlocking mechanism is arranged beside the female connector support, and a lower support is arranged below the upper support and fixed to the fixing seat. A male connector support is installed on the lower support, and the male connector support is opposite to the female connector support. An alignment pin shaft is arranged on the lower bottom face of the upper support, and correspondingly, a positioning hole matched with the alignment pin shaft is formed in the upper surface of the lower support. A pin shaft positioning manner is adopted so that a male connector and a female connector on the upper support and the lower support can be connected in an alignment mode, it is ensured that the female connector and the male connector are smoothly inserted, alignment is accurate in the inserting and pulling processes, a sealing ring in the female connector is stressed evenly, the male connector and the female connector are not prone to damage, the service life is prolonged, the labor fatigue is relieved, the alignment precision of the two connectors is improved, and leakage of liquid and gas is prevented.

Owner:SUZHOU YOUBEI PRECISION INTELLIGENT EQUIP CO LTD

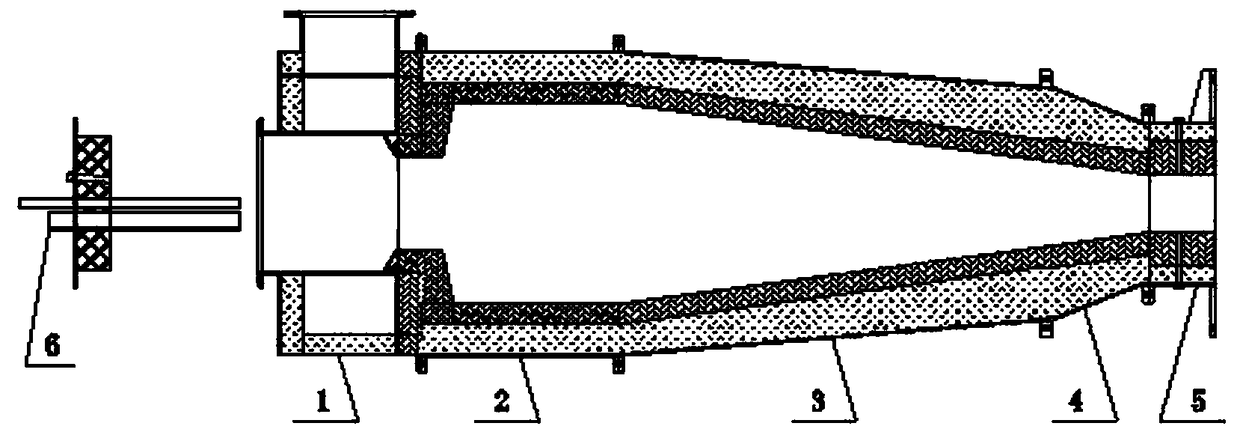

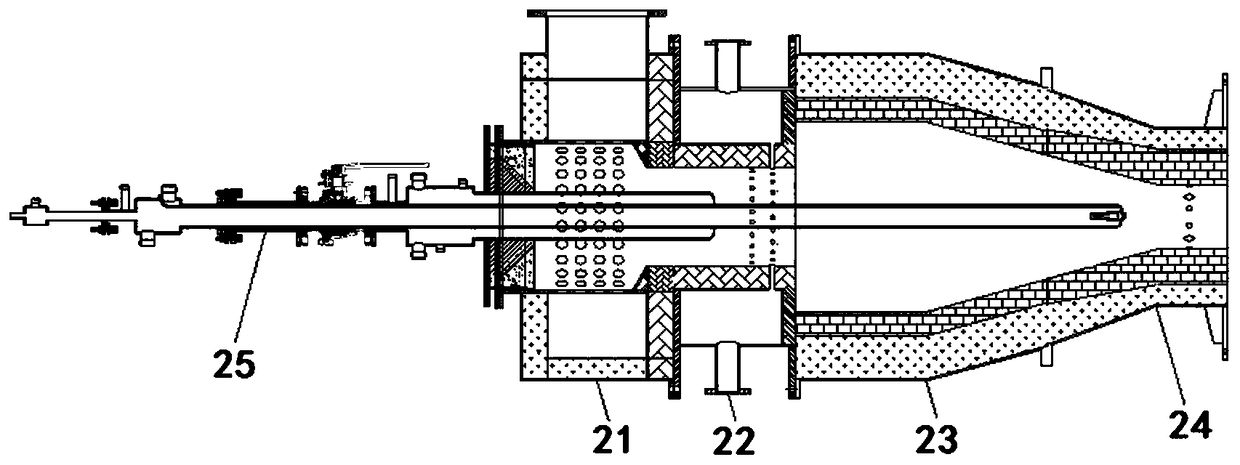

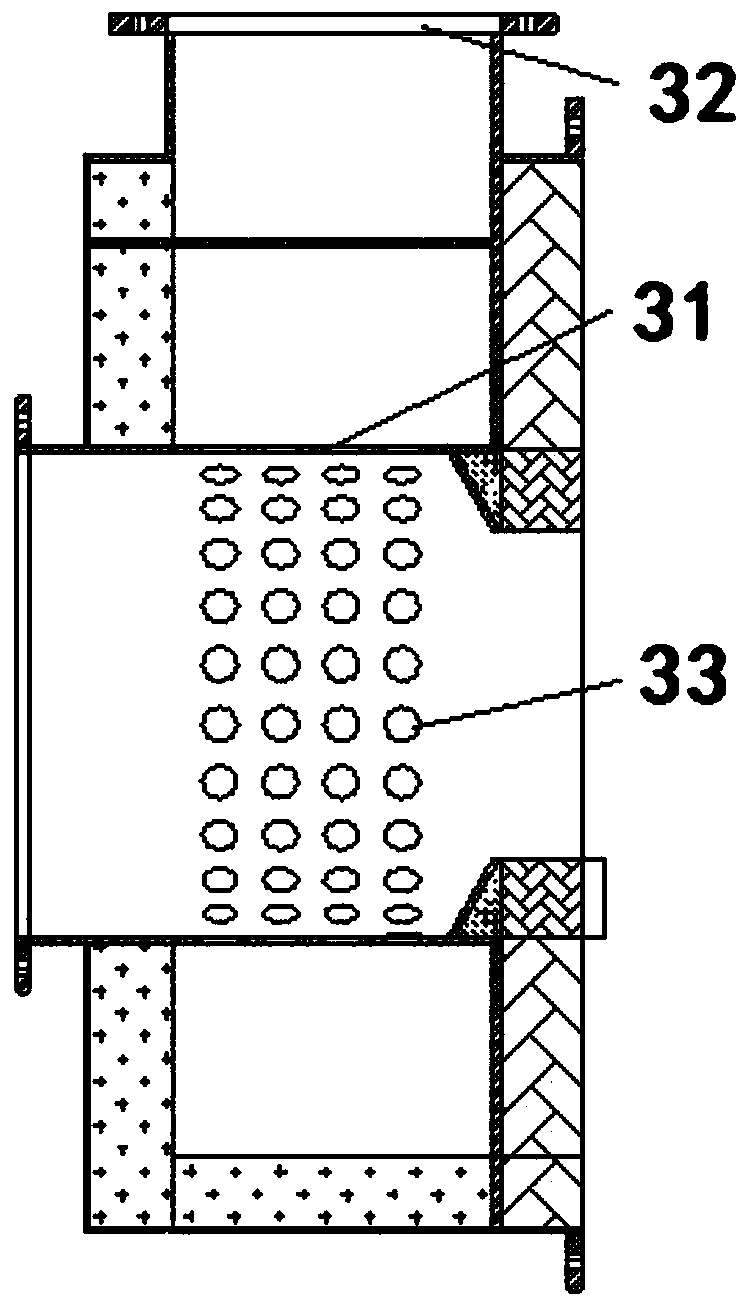

Novel hard carbon black reaction furnace

PendingCN109054460ALess likely to cause damageExtended service lifePigmenting treatmentCombustionProcess engineering

The invention discloses a novel hard carbon black reaction furnace. The carbon black reaction furnace is formed by an air distributor, a gas distributor, a combustion section and a throat pipe straight section through axial coaxial sealing connection. A raw oil gun is axially and horizontally arranged in the central position of a panel of the carbon black reaction furnace; a muzzle of the raw oilgun extends into the front 200 to 300 mm part of the throat pipe straight section. The novel hard carbon black reaction furnace disclosed by the invention has the following technical effects: different types of carbon black can be produced without changing a reaction furnace body; by using the reaction furnace to produce carbon black, the requirements on the quality on raw oil can be reduced and the production cost of enterprises is reduced; a product of the carbon black has the advantages of high color strength, high compression oil absorption value and capability of meeting the quality requirements of all-steel radial tires; in addition, preheated air, gas and raw oil has no damages on the reaction furnace body in the combustion reaction process, so that the service life of the reactionfurnace is prolonged.

Owner:WUHAI BLACK CAT CARBON BLACK

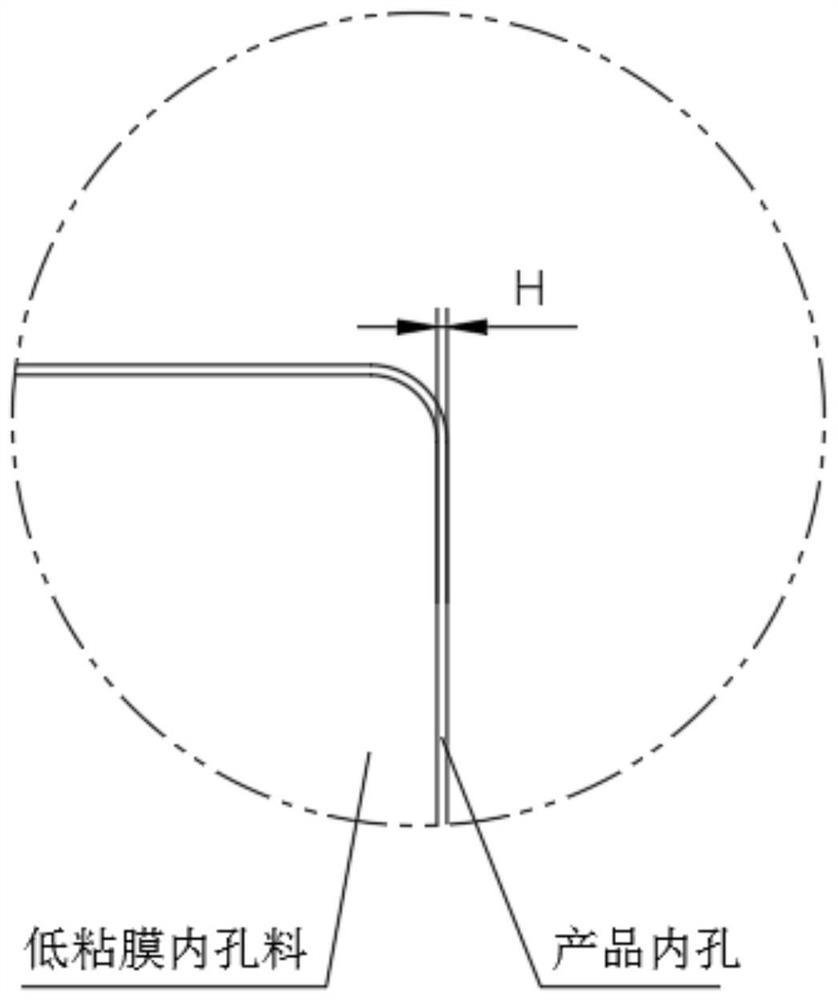

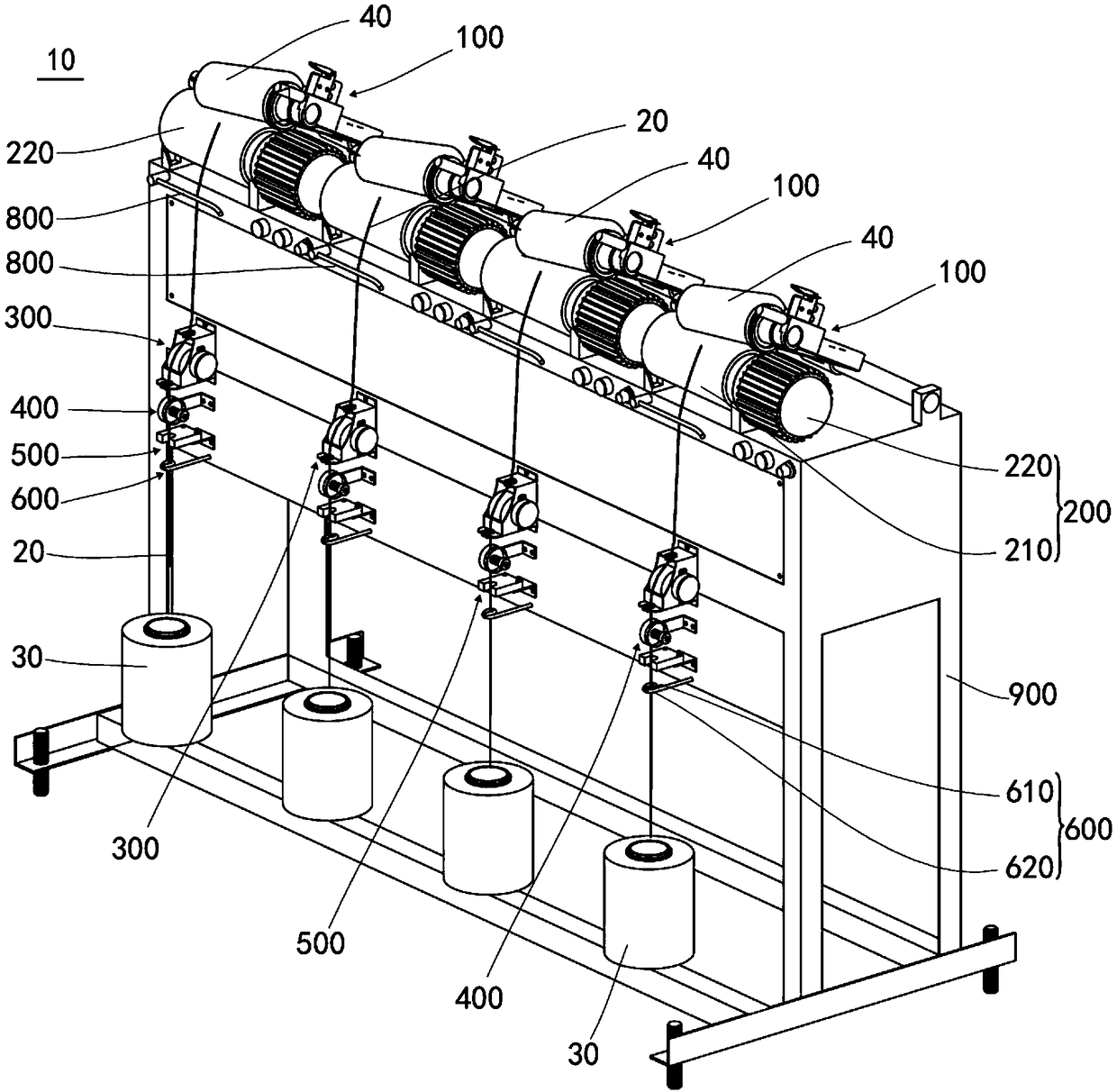

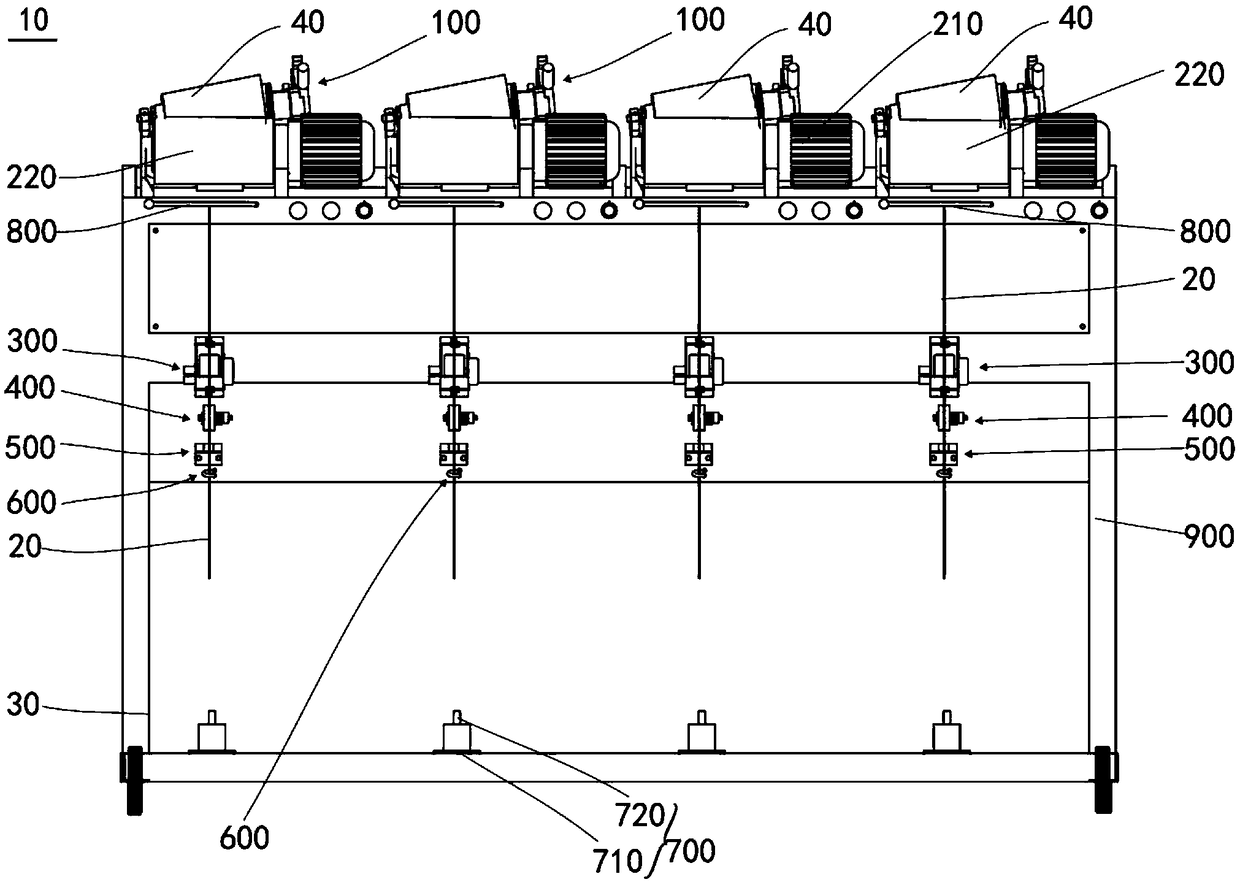

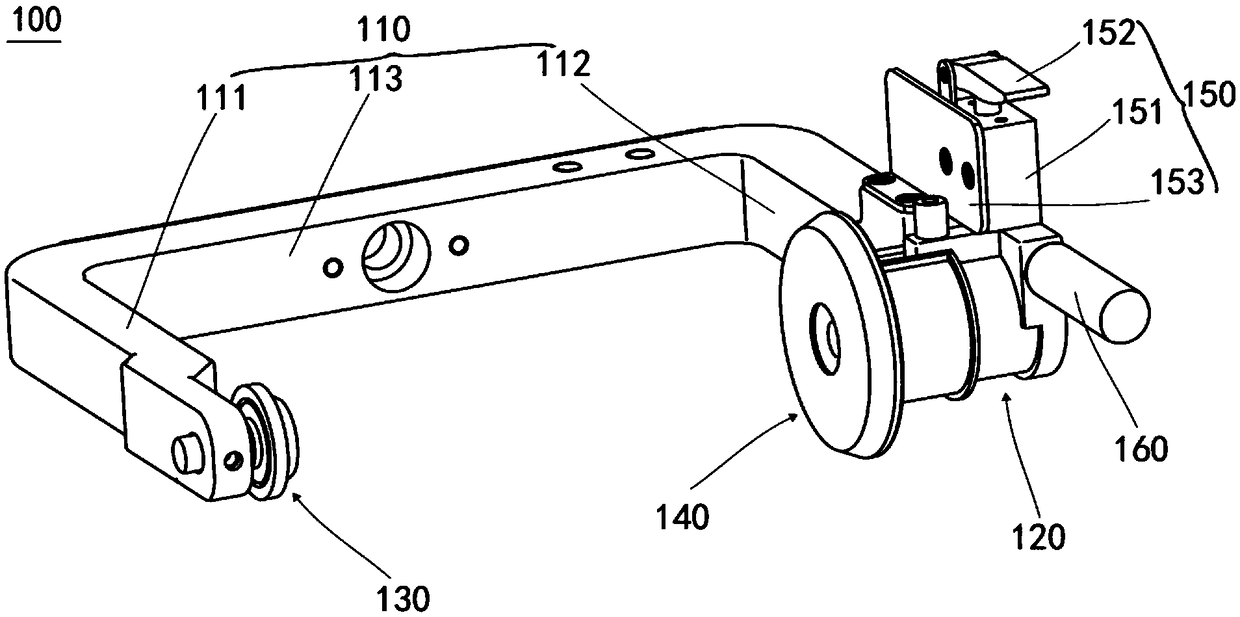

Chemical fiber yarn oiling groove drum type winding machine

PendingCN109502425AWinding effect is goodLess likely to cause damageFilament handlingWind drivenWinding machine

The invention discloses a chemical fiber yarn oiling groove drum type winding machine. The chemical fiber yarn oiling groove drum type winding machine comprises a machine frame, an oiling device, a swing frame device and a winding device, wherein the oiling device comprises an oil passing box used for containing oil materials, an oil passing wheel arranged in the oil passing box and an oil wheel driving part connected with the oil passing wheel, the oil passing box is provided with an oil passing window, the oil passing wheel part protrudes out of the oil passing window, and the oil wheel driving part is used for driving the oil passing wheel to rotate; the swing frame device is arranged on the machine frame and is used for allowing a conical bobbin to be installed; the winding device comprises a groove drum and a winding driving part, the groove drum is rotatably connected with the machine frame, the groove drum is close to the swing frame device, and is used for being in contact withand rotationally matched with the conical bobbin on the swing frame device, the winding driving part is connected with the groove drum and used for driving the groove drum to rotate, and the rotationof the groove drum drives the conical bobbin to rotate so as to realize winding of yarns passing through the oiling device and being oiled. The chemical fiber yarn oiling groove drum type winding machine is good in winding effect.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

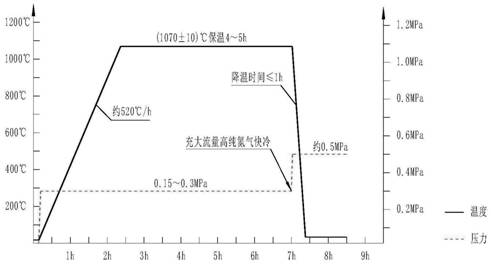

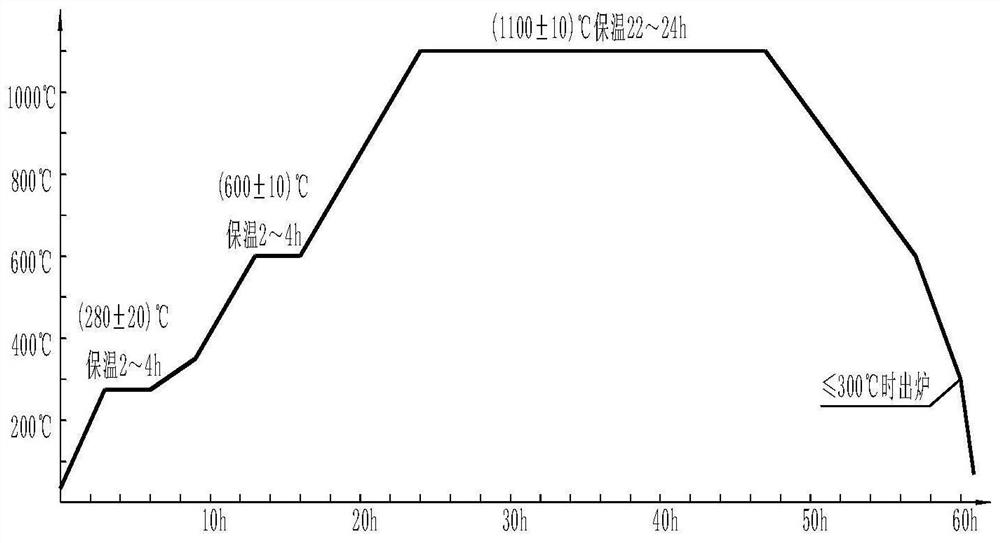

Chromizing nitriding surface treatment technology for austenitic stainless steel

PendingCN113005395ALess likely to cause damagePrevent hardeningSolid state diffusion coatingPtru catalystSS - Stainless steel

The invention belongs to the field of nuclear fuel manufacturing, and particularly relates to a chromizing nitriding surface treatment technology for austenitic stainless steel, which comprises the following steps: burying a workpiece into a chromizing agent, filling the workpiece and the chromizing agent into a chromizing tank, putting the chromizing tank into a chromizing furnace for chromizing heat treatment, putting the workpiece into a high-pressure vacuum gas quenching furnace, and converting a chromizing layer into a chromizing and nitriding composite layer, wherein the chromizing agent comprises chromium powder, a filling agent and a catalyst, and chromizing heat treatment comprises chromizing powder pretreatment, loading and packaging and then heat treatment; the nitriding treatment comprises cleaning and drying a sample, the workpiece and a nitriding furnace, and then carrying out nitriding heat treatment on the nitriding furnace. By means of the formula of the chromizing agent, the hardening phenomenon is avoided, damage to the workpiece is not likely to be caused, the relation between the chromizing heat preservation time factor and the chromizing layer thickness is designed, the chromizing layer thickness is controlled, workpiece deformation is reduced, the solid solution nitriding technology can meet the nitriding requirement, and the adverse effect on the material performance in the powder chromizing process is eliminated.

Owner:CNNC JIANZHONG NUCLEAR FUEL

Ceiling fixing fastener assembly for LED (Light Emitting Diode) lamp

ActiveCN103017110AEasy to installQuick installationLighting support devicesPoint-like light sourceAcute angleEngineering

The invention discloses a ceiling fixing fastener assembly for an LED (Light Emitting Diode) lamp. The ceiling fixing fastener assembly comprises a decorative cover and a fixing fastener, wherein the decorative cover at least comprises two circumferentially and uniformly distributed mounting parts, and the fixing fastener is hinged on the mounting part and is provided with a fastening part and an elastic element; the installation of the elastic element comprises the following steps that the direction of acting force acting on the fixing fastener reverses after turning a first turnover angle, so that the fixing fastener turns over from a mounting position to a locking position; and the direction of acting force acting on the fixing fastener reverses after turning a second turnover angle, so that the fixing fastener turns over from a locking position to a mounting position; and the first turnover angle and the second turnover angle are acute angles. After the fixing fastener rotates over the turnover angle, the acting force of the elastic element on the fixing fastener reverses to generate turnover, so that the LED lamp can be quickly fixed and dismantled on the ceiling by the fixing fastener without damaging a mounting surface, and the mounting reliability of the LED lamp is improved.

Owner:浙江捷莱光电科技有限公司

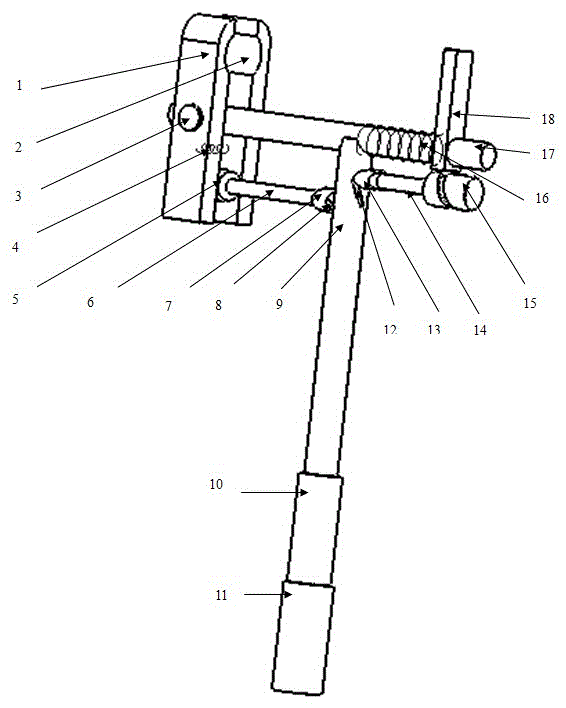

Fluorescent lamp tube replacing device

The invention provides a fluorescent lamp tube replacing device which comprises two lamp claws, two guide rods, two springs, a cam, a left supporting arm, two eccentric wheels, a locking pull wire, a hollow strut, an adjustment screw, an adjustment nut, a pressing plate pull wire, a right supporting arm, a slotted cylindrical cam and an end pressing plate. The pull wire is connected with the lamp claws, and the pressing plate pull wire is connected with the end pressing plate. A lamp tube clamping mechanism is characterized in that the two clamp claws are located on one guide rod, the springs are connected to the lamp claws to enable the two clamp claws to be kept in a semi-enclasping state, the cam is located between the clamp claws, and the left supporting arm is connected with the strut. The problems that people need to dismount or mount a fluorescent lamp by climbing a ladder or stepping on a stool due to the fact that the position of a lamp tube is too high, and people fall off from the high position or have an electric shock hazard easily are solved. Most of all, the fluorescent lamp tube replacing device provides a convenient and reliable tool used for mounting or dismounting the lamp tube for the old, the children, short people and people with acrophobia.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Textile fabric dye

InactiveCN106988132AUniform and firm dyeingReduce manufacturing costDyeing processPyrophosphateEthyl acetate

The invention relates to a textile fabric dye, comprising, by weight, 30-40 parts of attapulgite clay, 2-4 parts of polypropylene glycol, 3-5 parts of tetracarboxydiphthalic ether dianhydride, 1-2 parts of zinc stearate, 10-13 parts of blocked isocyanate, 8-9 parts of calcium sulfate, 9-10 parts of magnesium sulfate, 2-3 parts of aluminum oxide powder, 20-30 parts of waterborne nano color paste, 7-9 parts of a surfactant, 6-8 parts of ethyl acetate, 10-12 parts of an initiator, 15-25 parts of plant extract, 12-15 parts of chitosan, 2-3 parts of mica powder, 1-1.6 pars of tetramethyl ammonium bromide, 1-3 parts of a water softener, 3-4 parts of sodium carbonate, 2-3 parts of sodium pyrophosphate, 5-8 parts of iron blue, and 20-30 parts of water. The textile fabric dye is low in cost, natural and healthy, nontoxic and harmless to human body, and resistant to fading; the preparation method is simple, has low equipment requirements and is easy to popularize.

Owner:合肥云都棉花有限公司

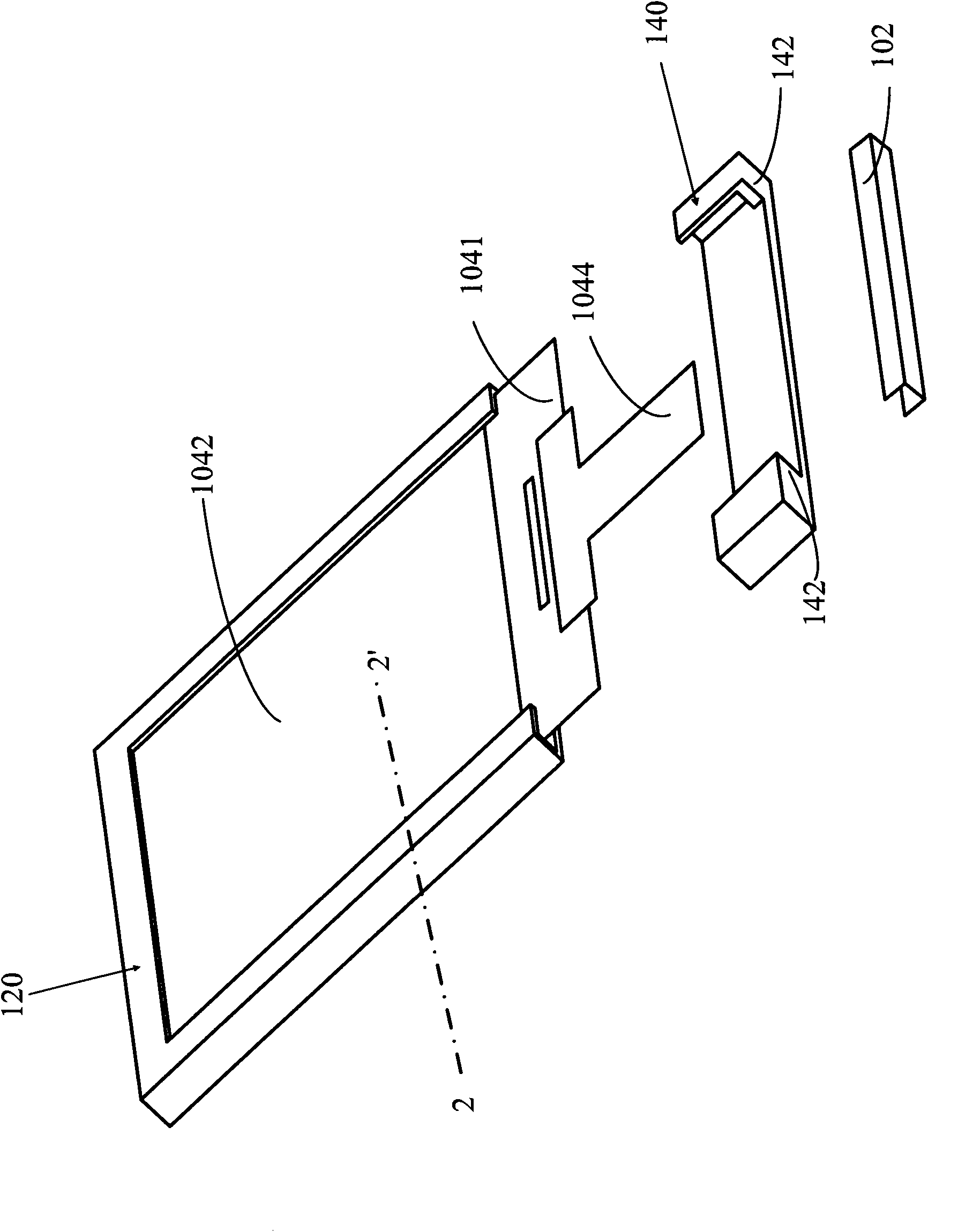

LCD device

ActiveCN101551534AShorten the timeNot easy to damageNon-linear opticsLiquid-crystal displayEngineering

The invention provides an LCD device, comprising a liquid crystal display panel, an optical film set and a plastic frame. The plastic frame comprises a first body and a second body, wherein the first body has a first frame body and a second frame body, and a spacing plate protruding from the side walls is fixed between the two frame bodies. Edges, the spacing plate and the side wall of the first frame body form a first guide groove and a first opening, and the liquid crystal display panel is inserted from the first opening and fixed in the first guide groove. Edges, the spacing plate and the side walls of the second frame body form a second guide groove and a second opening, and the optical film set is inserted from the second opening and fixed in the second guide groove. The first body the second body are connected and covers the first and the second openings, for fixing the liquid crystal display panel and the optical film set in the plastic frame.

Owner:AU OPTRONICS (SUZHOU) CORP LTD +2

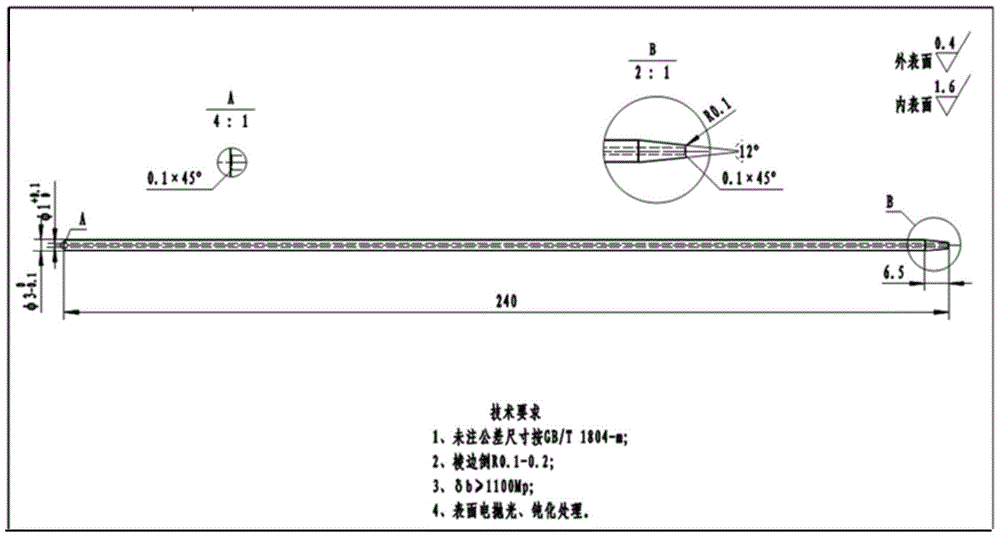

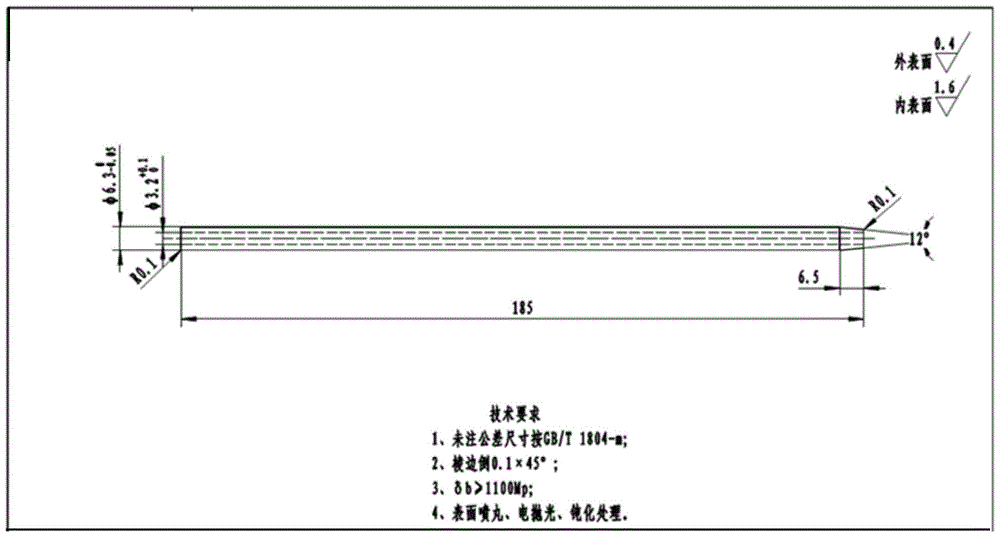

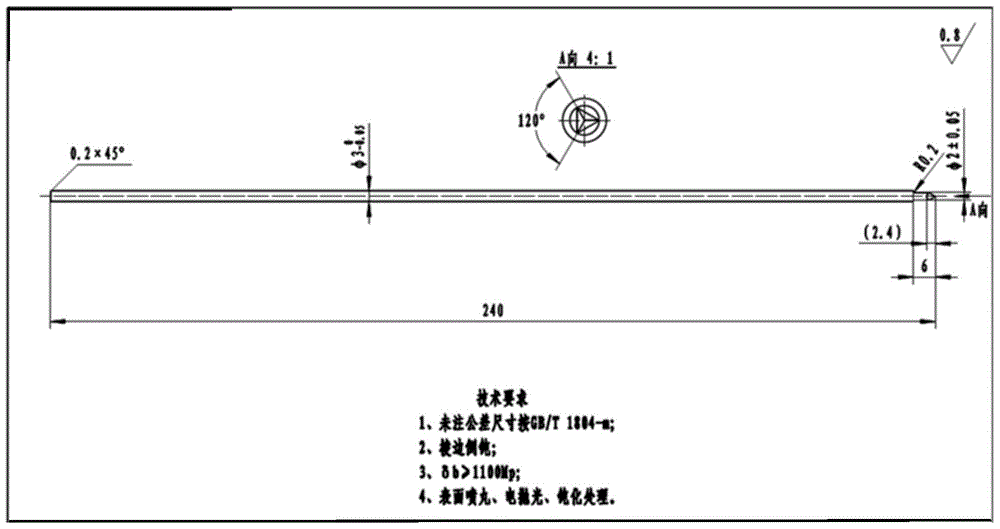

transforaminal puncture system

InactiveCN103976779BSimplified piercing processSimple cutting processCannulasSurgical needlesSacroiliac jointIntervertebral foramen

The invention relates to medical instruments, and discloses an intervertebral foramen mirror puncturing system. The intervertebral foramen mirror puncturing system comprises a one-level cannula, a two-level cannula, an opening awl, an anchor needle and a ring saw. The awl head of the opening awl is provided with a protection shoulder, the head end of the anchor needle is provided with a self-tapping thread and is blunt, the blunt head of the anchor needle is designed not to cause hurt easily when penetrating through the zygopophysis to be close to the nerve, and the bone way can be adjusted more easily and conveniently through the self-tapping thread of the head end of the anchor needle. The ring saw is used for cutting the zygopophysis from the side face by the angle by which the anchor needle enters the canalis vertebralis to expand the bone way until the diameter of the bone way is enough for an endoscope to be placed. By means of the intervertebral foramen mirror puncturing system, the puncturing process of the lumbar vertebra intervertebral foramen mirror operation is obviously simplified, operation is reliable and practical, the operation safety and the operation successful rate are improved, and the parts, exposed to the radiation, of an operator and a patient are greatly reduced.

Owner:SHANGHAI EAST HOSPITAL

Crab automatic bundling auxiliary device

ActiveCN105799967AQuick fixImprove bundling efficiencyPackaging foodstuffsBundling machine detailsProcess equipmentElectrical and Electronics engineering

The invention provides a crab automatic bundling auxiliary device and belongs to the field of crab processing equipment.The crab automatic bundling auxiliary device comprises a discharging mechanism and a positioning mechanism for fixing crab legs.The discharging mechanism comprises a hopper, a material channel and a baffle.The hopper is installed at the top of the material channel, the material channel is vertically arranged, and the baffle is installed in the material channel and used for controlling the material channel to be unblocked or blocked.The positioning mechanism is located below a discharging port of the material channel and used for receiving crabs falling off the position of the discharging port and fixing the crab legs.The auxiliary device is simple and reasonable in structure, convenient to process and manufacture, low in manufacturing cost and convenient to install and use.The crab automatic bundling auxiliary device can fix the crab quickly, does not damage workers in the fixing process, does not damage crab claws, improves crab bundling efficiency, and is safe, reliable and convenient to use.

Owner:YANCHENG INST OF TECH

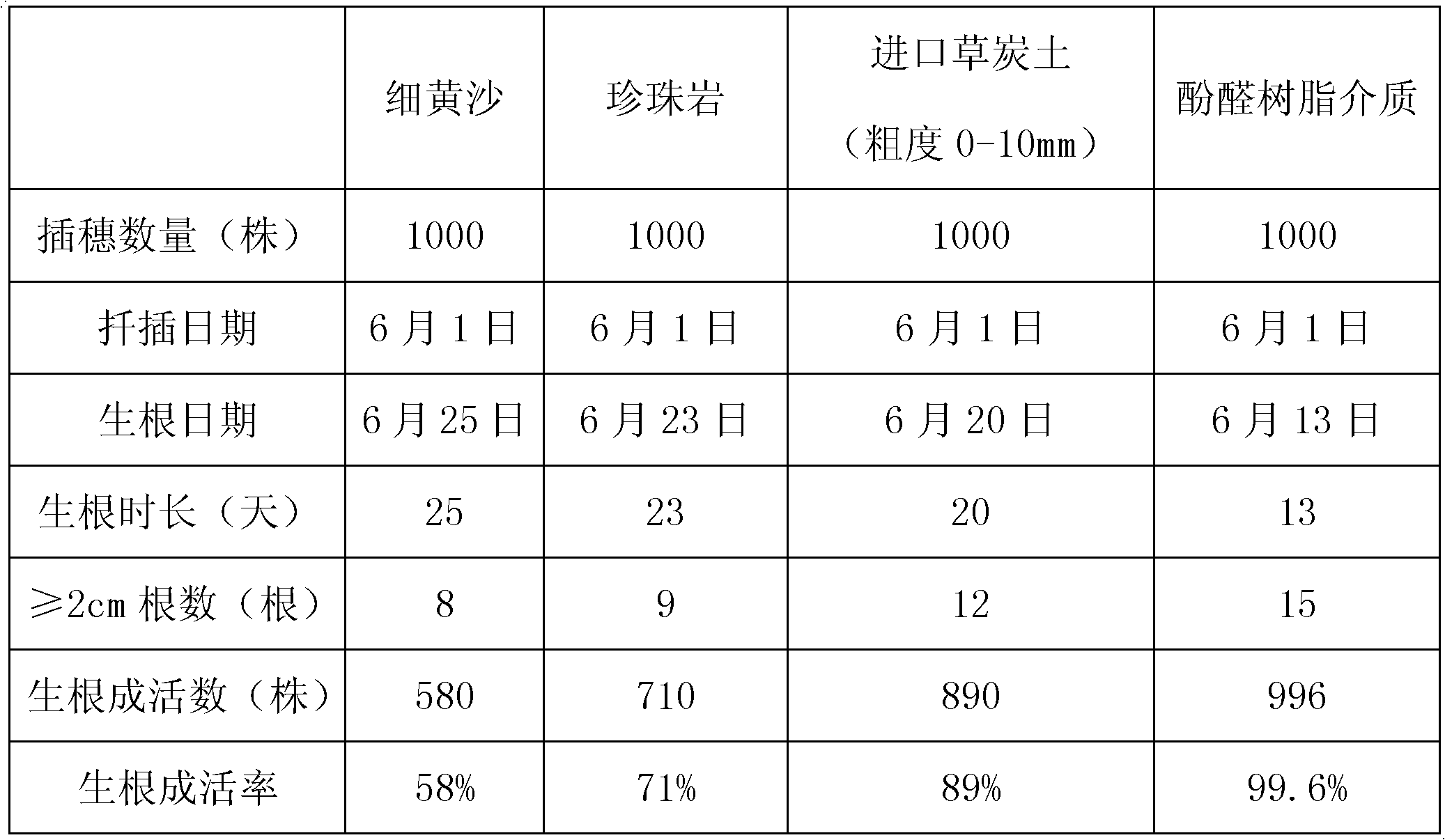

Phenolic resin foam medium block for cuttage

InactiveCN102675820AImprove seedling rateImprove Greenhouse UtilizationHorticultureRoot systemChemistry

The invention discloses a phenolic resin foam medium block for cuttage. A specific activating agent is added in a phenolic resin matrix and is physically foamed by a foaming agent to form a loose cross-linking structure; then the loose cross-linking structure is cured to form a microporous foam body with a certain strength under the action of a curing agent; and finally the foam body is cut into a medium block for cuttage. The medium block is provided with microporous holes and is light in weight, low in price and high in planting percentage during cuttage for planting seedlings; due to the blocky characteristic, the phenolic resin is extremely firm, cultured seedlings are especially suitable for long-distance transportation, and thus the possibility that the root system is damaged is reduced; the damage to the root system hardly occurs when the cultured seedlings cut by the medium block are transplanted; the root system is strong in vitality and stress resistance, so that the recovering stage after the plants are transferred into basins is greatly shortened; and the plants are grown to be consistent after the seedlings cut by the medium block are transferred into the basins or transplanted and the rate of the finished products is high.

Owner:CHANGSHU JIASHENG AGRI SCI & TECH DEV

Using method of blood distributor

ActiveCN106823474AEasy to separateLess likely to cause damageLiquid separationProcess engineeringCell isolation

The invention provides a using method of a blood distributor. The using method comprises the following steps: a first step of selecting a main sorting blood distributor with certain size and certain fluid distributing channel layer number according to the experimental and sorting needs; a second step of connecting a sampler to a total sample inlet; a third step of adding samples; a fourth step of detecting and regulating sample flow speed in real time; and a fifth step of cleaning the blood distributor after all samples are added. The using method has the beneficial effect of providing a cell separating device which can be quickly separate cells, is simple and convenient to operate, and is not liable to cause cell damages, and the cell device can separate while introduce liquid, and can perform multi-time circulating separation, so that separating efficiency is improved. Meanwhile, the invention further provides a using method used for the device.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

High light-permeability antenna

InactiveCN102983391AReduce thicknessLess likely to cause damageRadiating elements structural formsProtective material radiating elementsMicro nanoSilver paste

The invention discloses a high light-permeability antenna. The high light-permeability antenna comprises a transparent substrate and conductive materials, wherein micro-nanoscale grooves are formed in the surface of the transparent substrate, and the conductive materials are located inside the micro-nanoscale grooves. The high light-permeability antenna is manufactured by means of micro-nano machining technology, and the influences of the conductive materials on the light transmittance of the antenna are enabled to be reduced to the lowest. Due to the fact the width of each groove is in micro-nanoscale, the conductive materials are enabled not to be limited to transparent conductive materials, and other materials can be used, for example, nanometer silver paste. In addition, by means of the micro-nano machining technology, the high light-permeability antenna with the integrally formed transparent substrate and the conductive materials is achieved, the thickness of the antenna is reduced, and deformation of and damages to the antenna are not caused easily.

Owner:DIGICAN SHANGHAI CORP

Environment-friendly antibacterial air freshener

The invention provides an environment-friendly antibacterial air freshener. The environment-friendly antibacterial air freshener is prepared from a flower component, a traditional Chinese medicine additive component, ethyl alcohol and deionized water. Compared with a traditional air freshener prepared by chemical raw materials, the environment-friendly antibacterial air freshener provided by the invention has the advantages that toxic and side effects are few, the irritation is small, a human body cannot be easily damaged, the cost is low, and the effect is obvious; the environment-friendly antibacterial air freshener is a new-generation air freshener.

Owner:苏赵珍

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com