Crab automatic bundling auxiliary device

An auxiliary device and automatic strapping technology, which is applied to the parts of strapping machinery, packaging, and packaged food. It can solve the problems of easy breakage, high cost of quick-packing boxes, and damage to crab claws, etc., and achieves convenient installation and use. Convenient, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

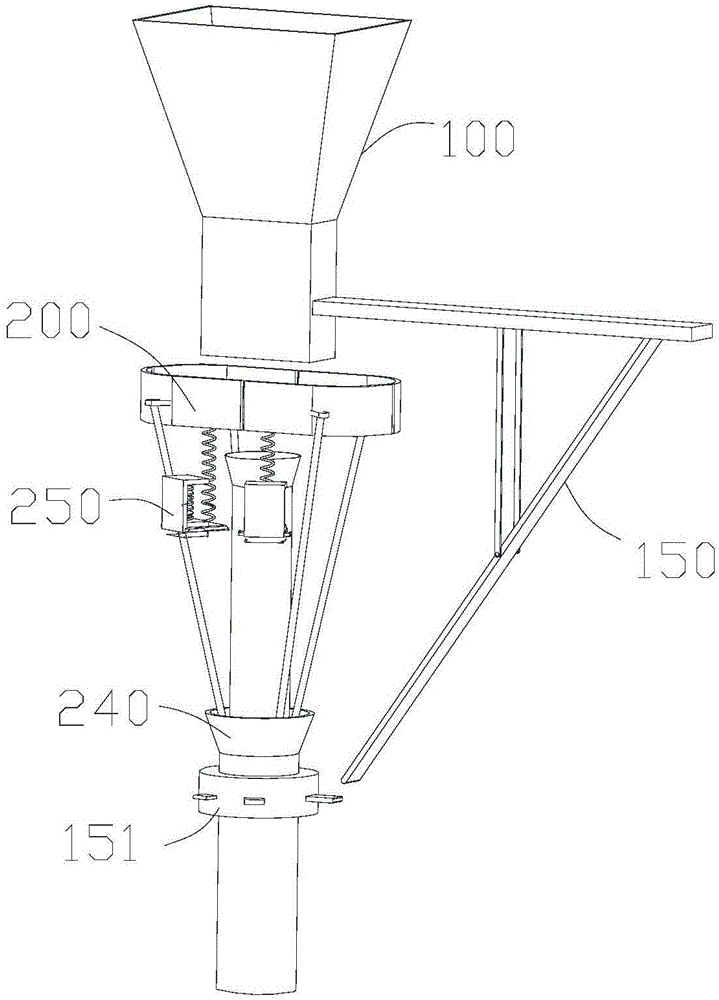

[0041] see figure 1 , this embodiment provides an automatic crab bundling auxiliary device, including a blanking mechanism 100 and a positioning mechanism 200 .

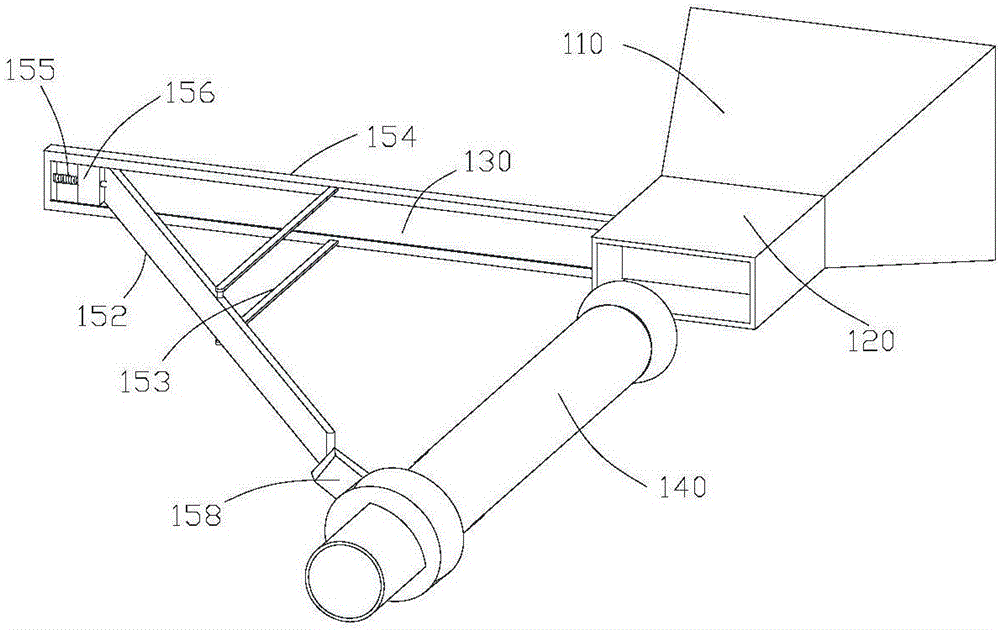

[0042] see figure 1 and figure 2 , The dropping mechanism 100 includes a hopper 110 , a material channel 120 , a baffle 130 , a drive assembly 150 and a crab drop tube 140 .

[0043] The hopper 110 is the inlet of the crab. It is preferably arranged as follows: the hopper 110 is set to a funnel shape, and the necking end of the hopper 110 is connected to the material channel 120, and the open end of the hopper 110 is positioned above, and the crab is removed from the open end of the hopper 110. Putting in is easy to operate, and when the crab is put in, it is convenient to adjust the put-in form of the crab. The open end has a larger space and is convenient to operate. After the position of the crab is adjusted, it falls into the feed channel 120 from the narrowed end, and the position of the crab is fixed and no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com