Automatic organic material feeding equipment suitable for worm bioreactor

A technology of bioreactors and organic materials, applied in animal husbandry, etc., can solve the problems of high labor intensity, harsh working environment, and long time for fabrics, so as to improve conversion efficiency and economic benefits, reduce labor intensity, and improve The effect of cloth efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

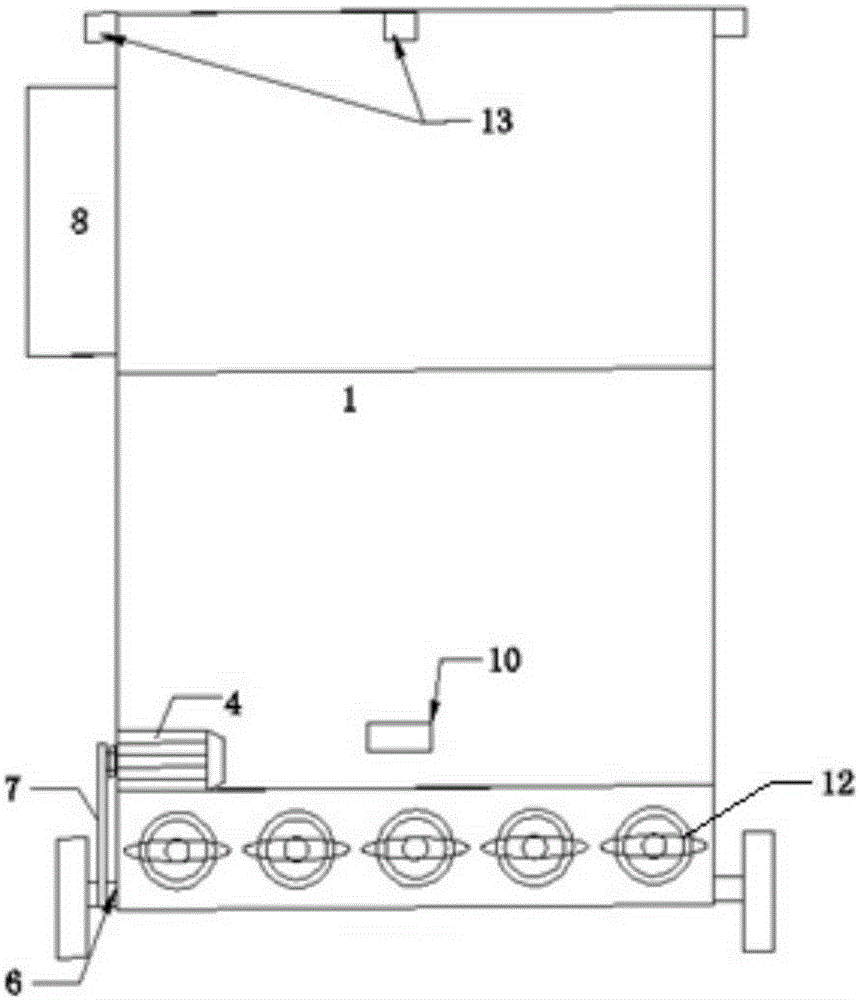

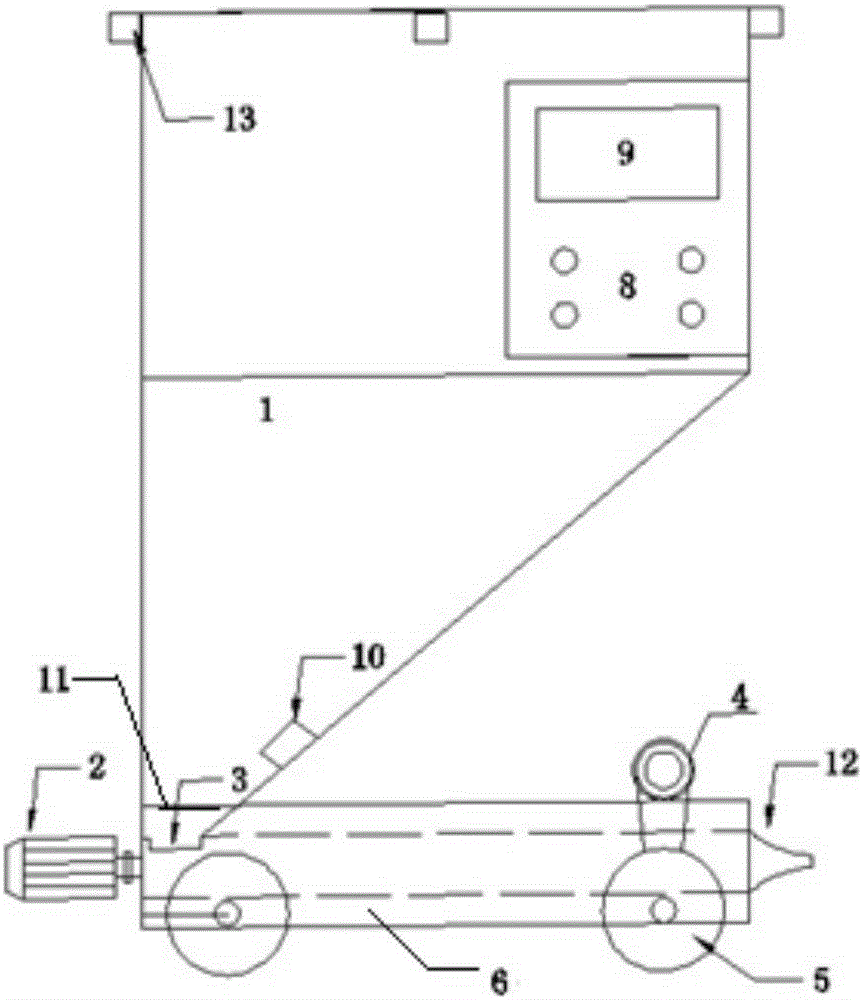

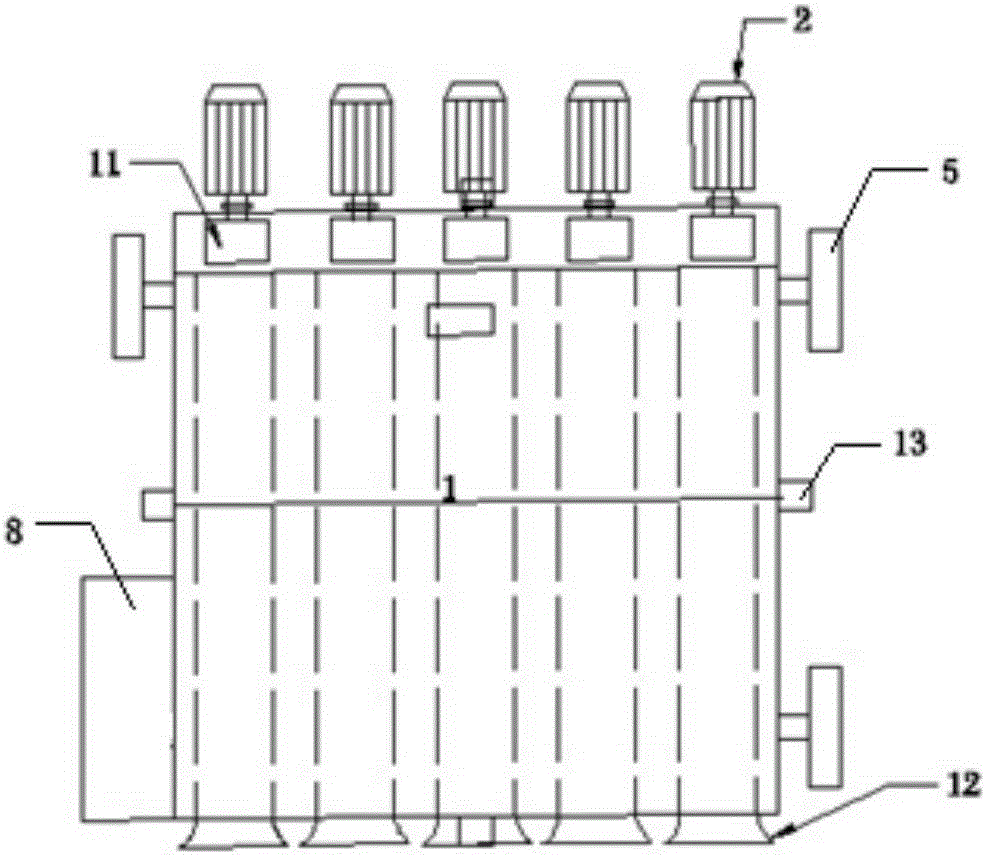

[0020] The present invention will be further described below in conjunction with accompanying drawing.

[0021] refer to Figure 1-4 , the organic material automatic feeding equipment of the present invention comprises a support 6 and an organic material storage bin 1 fixed on the support 6 and several screw conveyors 2, the screw conveyor 2 is arranged below the organic material storage bin 1, and the organic material The lower part of the storage bin 1 can be designed into a wedge shape, and the bottom is provided with a number of feeding holes 11, and each feeding hole 11 is connected with the feeding port 3 of a screw conveyor 2, and the upper part of the outer circumference of the organic material storage bin 1 is evenly equipped with 4 The distance detector 13 used to detect the distance between the equipment and the surrounding obstacles. The bottom of the inner side of the organic material storage bin 1 is provided with a sensor 10 for detecting the material surplus in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com